Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about "Dough mixing/kneading methods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

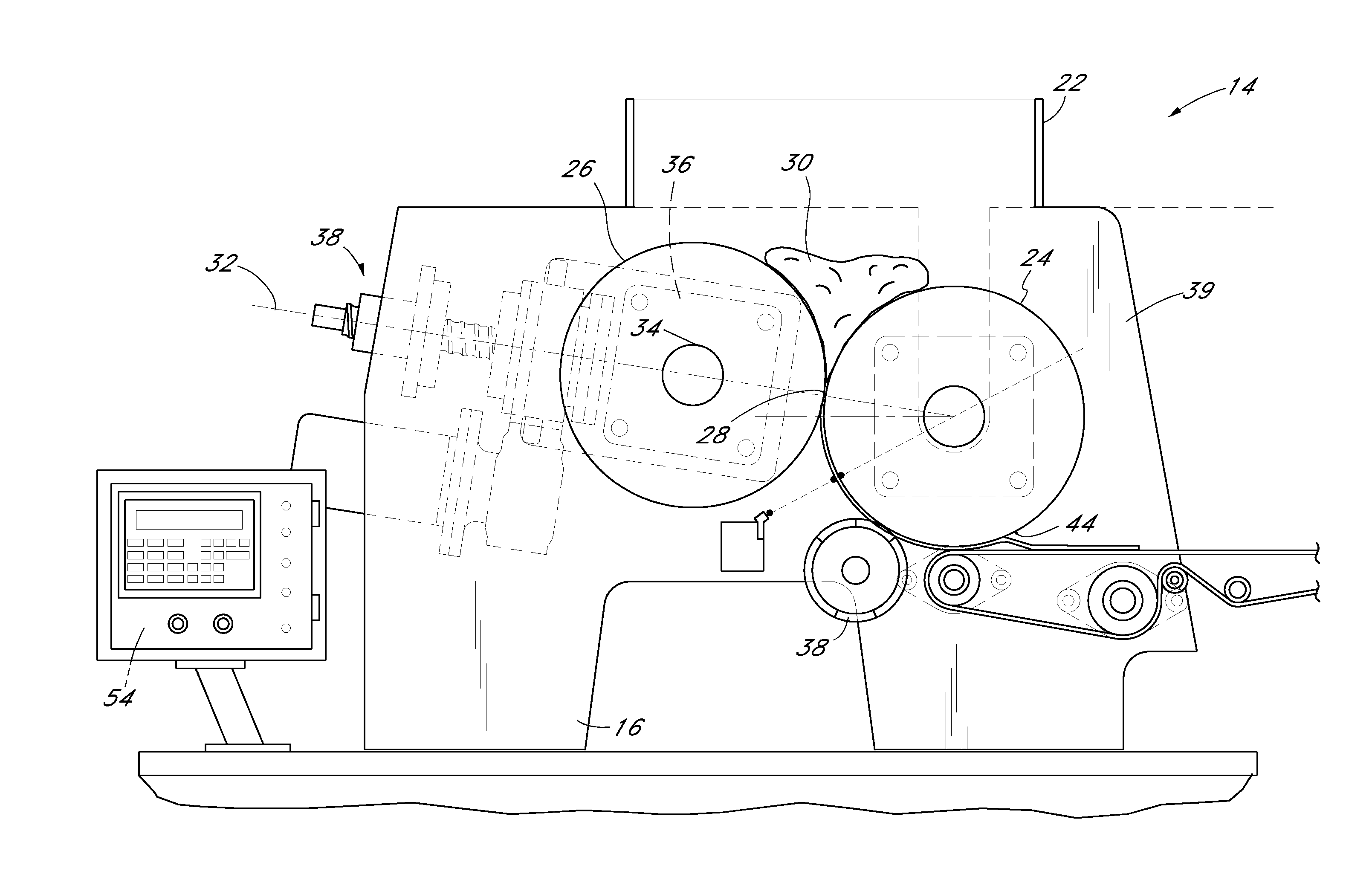

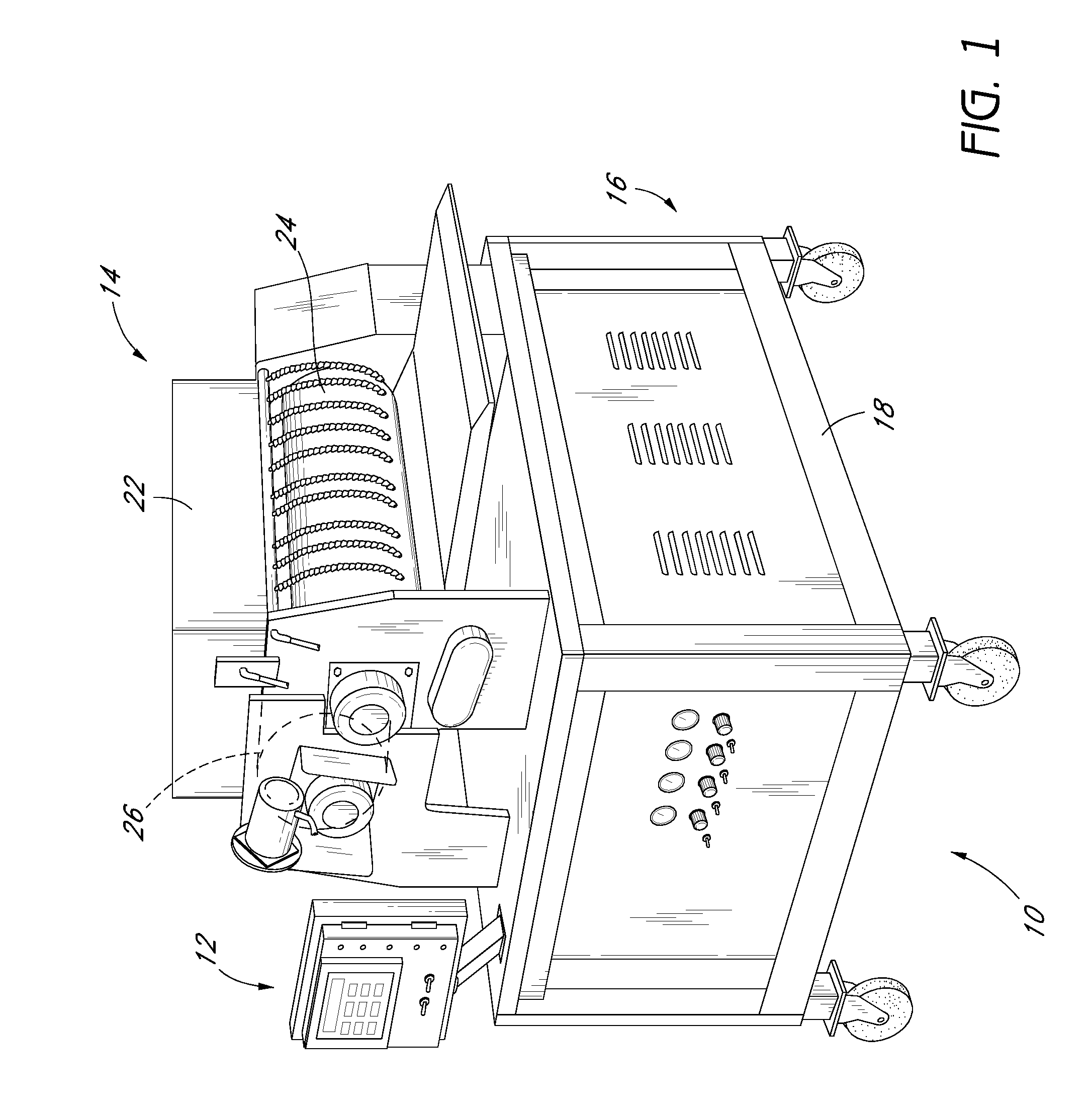

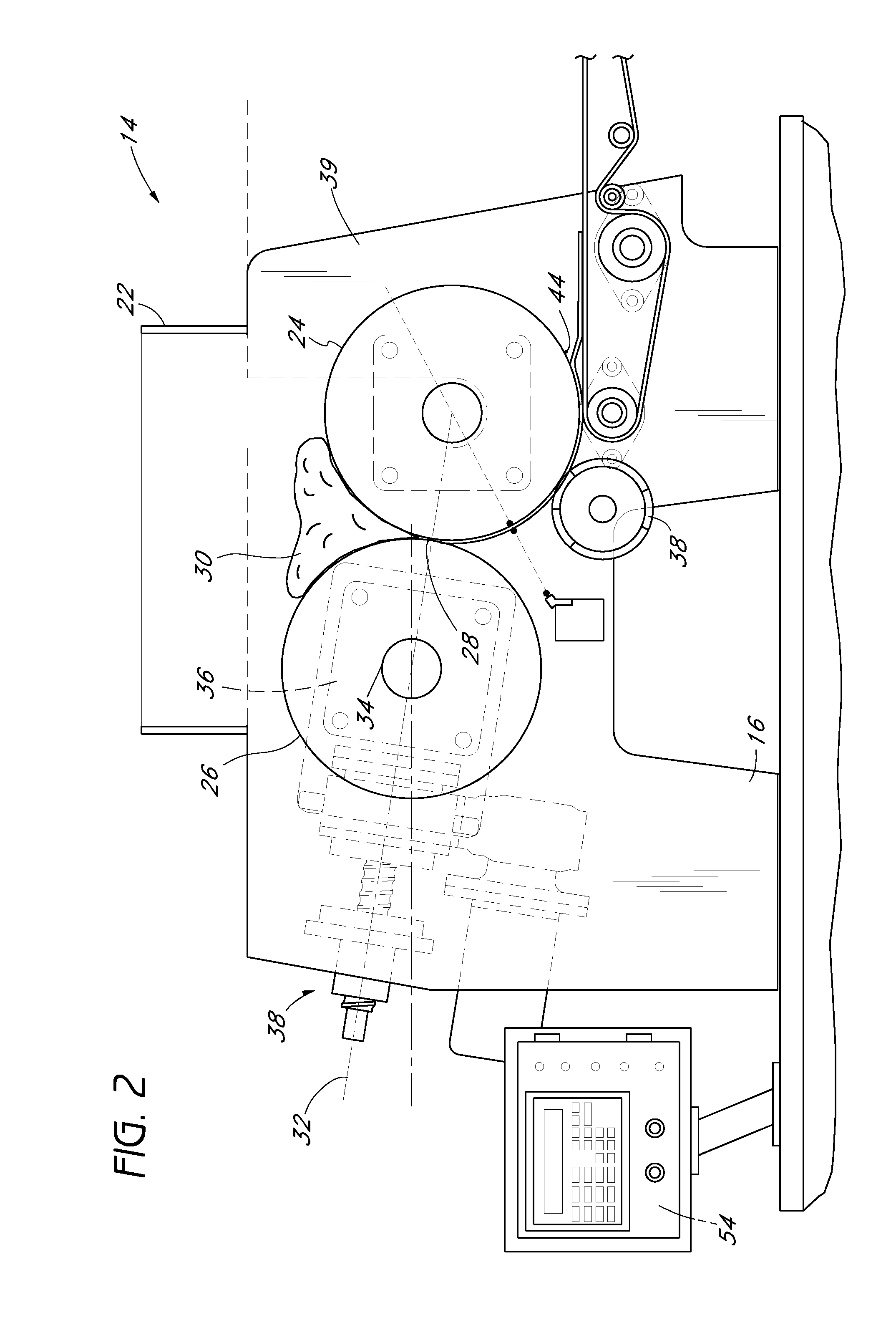

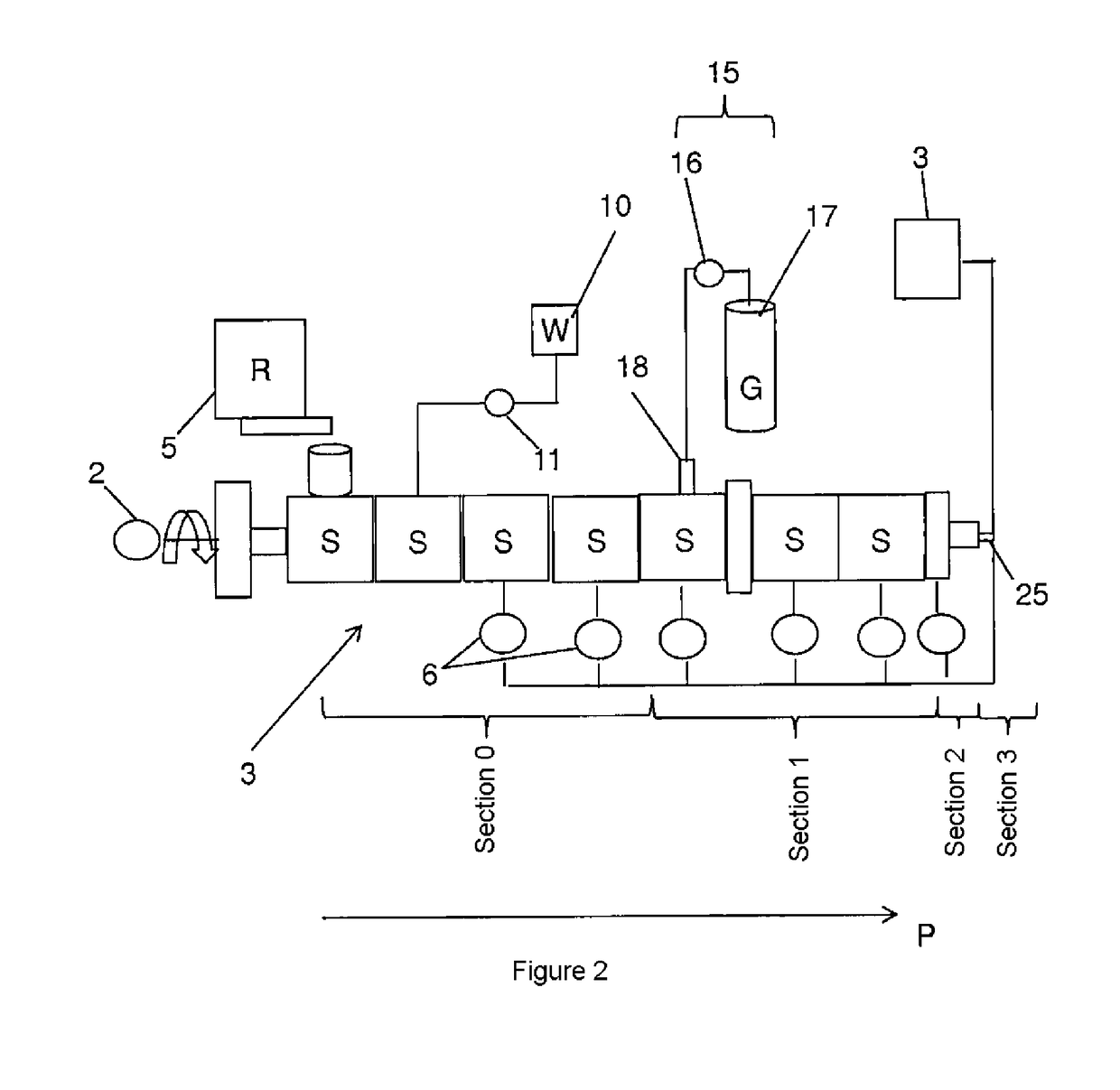

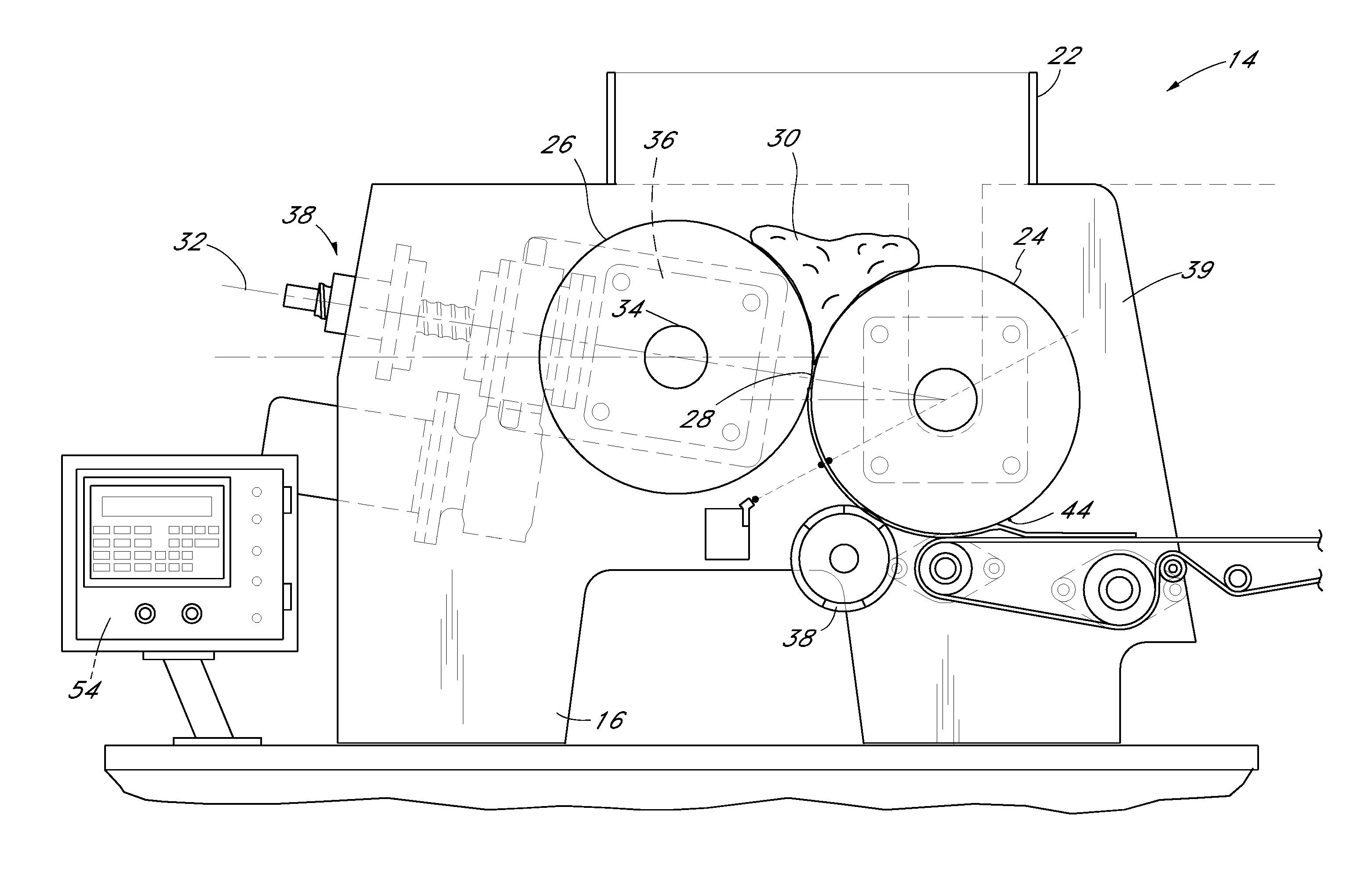

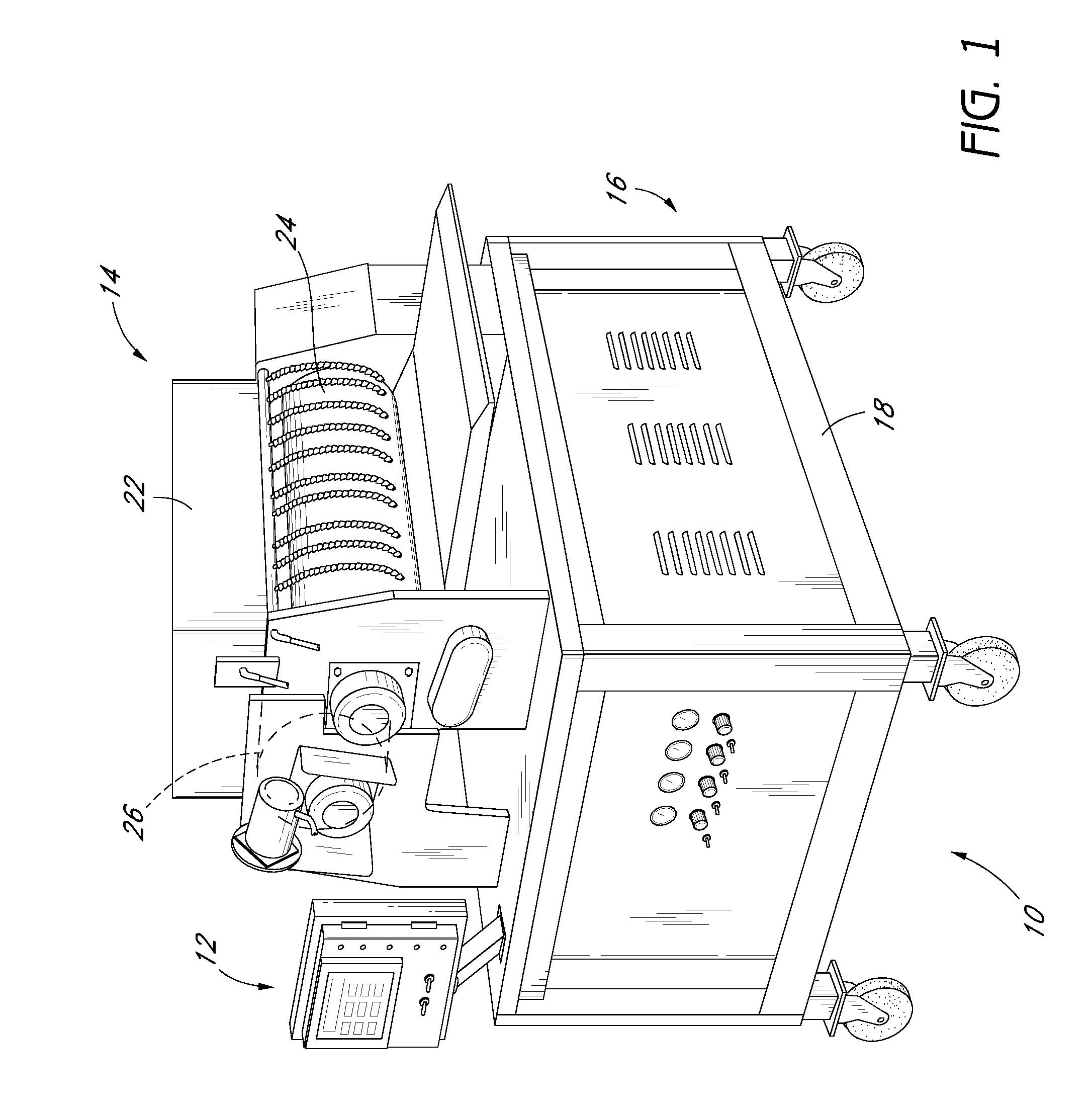

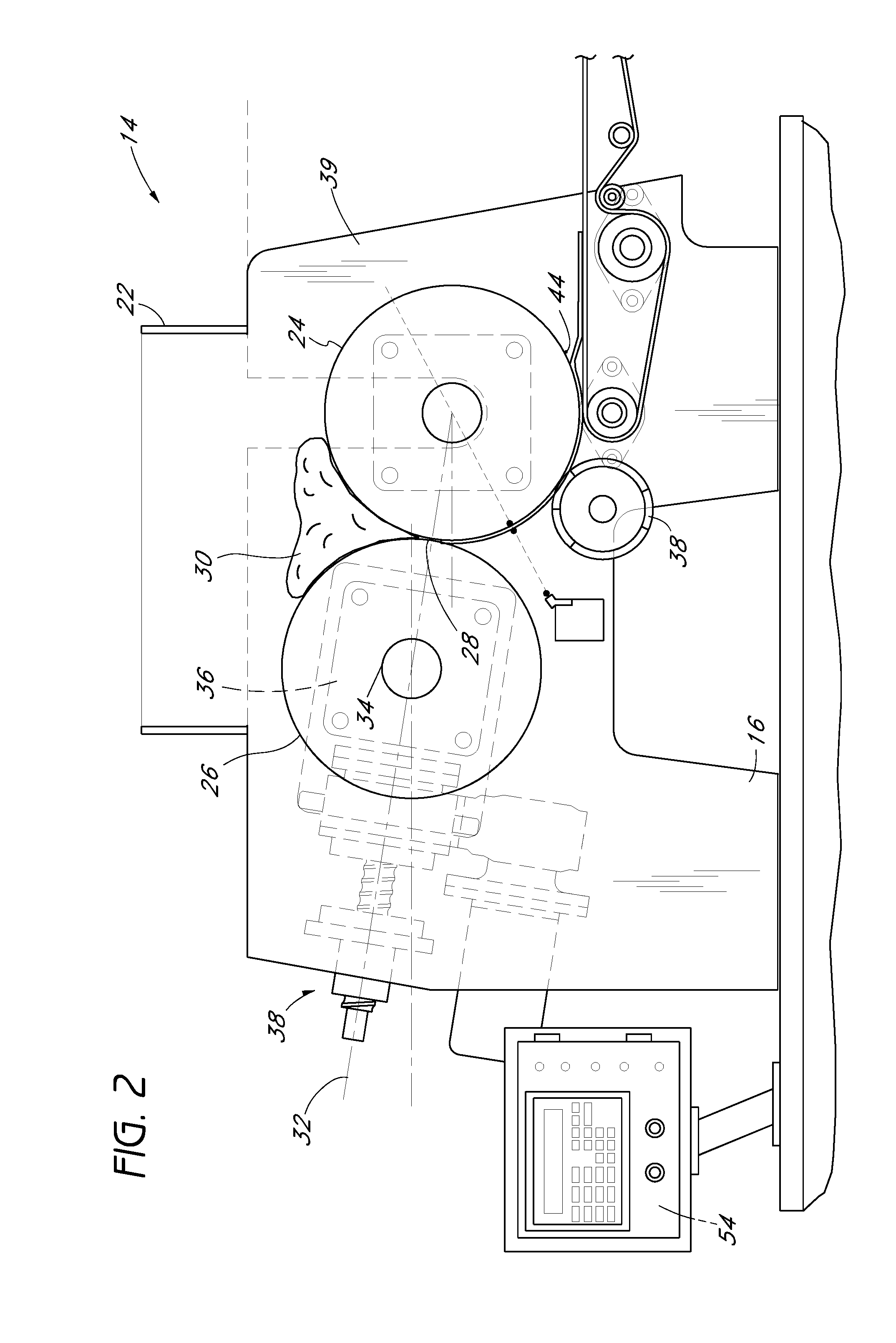

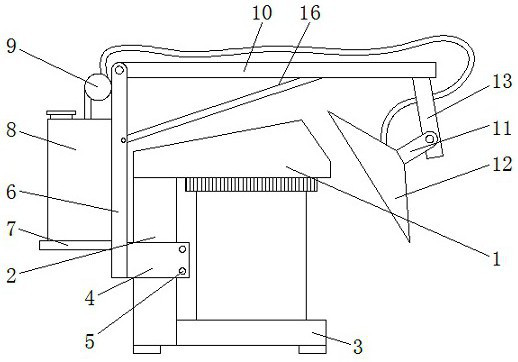

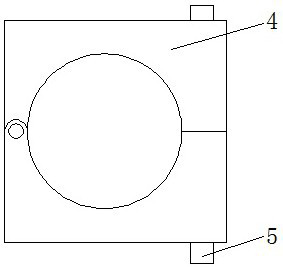

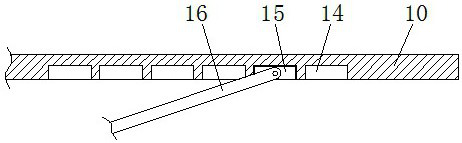

Sheeter with thickness control

ActiveUS20120225151A1Reduce accidental movementChange in magnitudeDough-sheeters/rolling-machines/rolling-pinsConfectioneryControl systemEngineering

A thickness control system for a high speed tortilla sheeting machine can adjust a pinch point gap between a pair of sheeting rollers to maintain a generally uniform thickness of the produced “masa” (i.e., corn dough) sheet. The sheeting machine can include a pinch point gap adjustment device which guides at least one of the rollers through an arcuate path to thereby adjust a magnitude of the pinch point gap. The controller can direct one or more actuators to change the position of the roller along the archive path to thereby change the distance between the two sheeting rollers as desired to produce a masa sheet at the desired preset thickness.

Owner:J C FORD

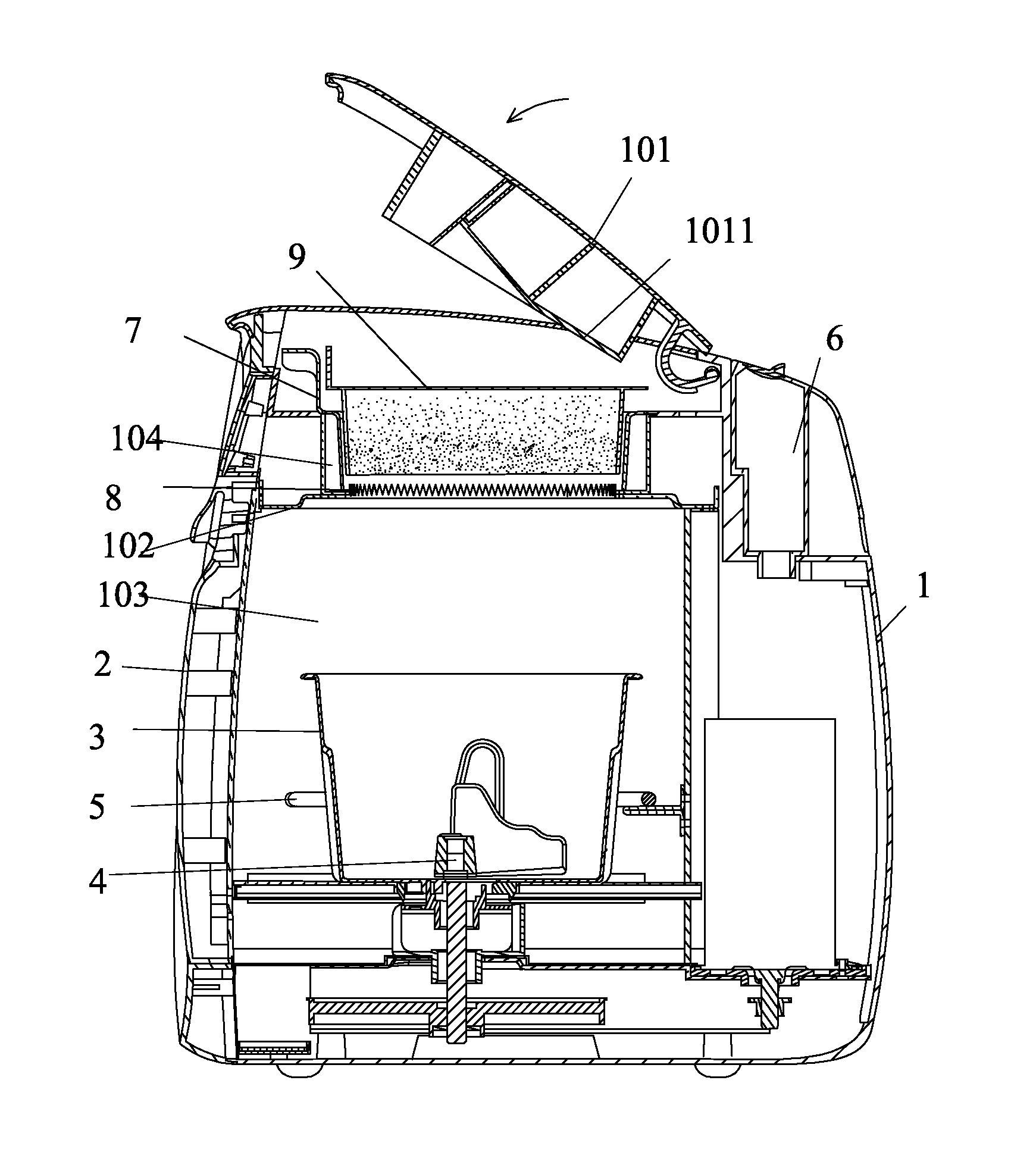

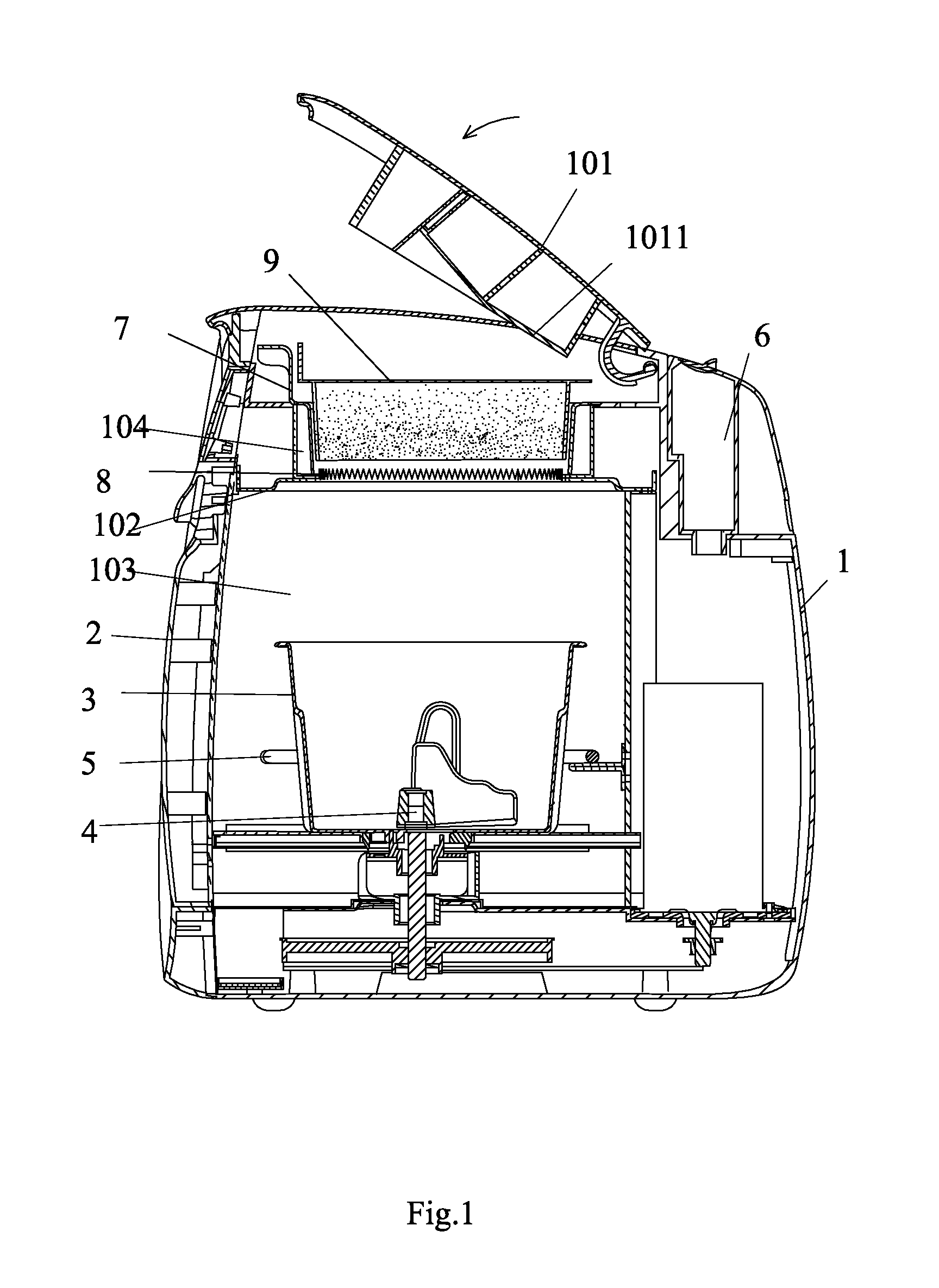

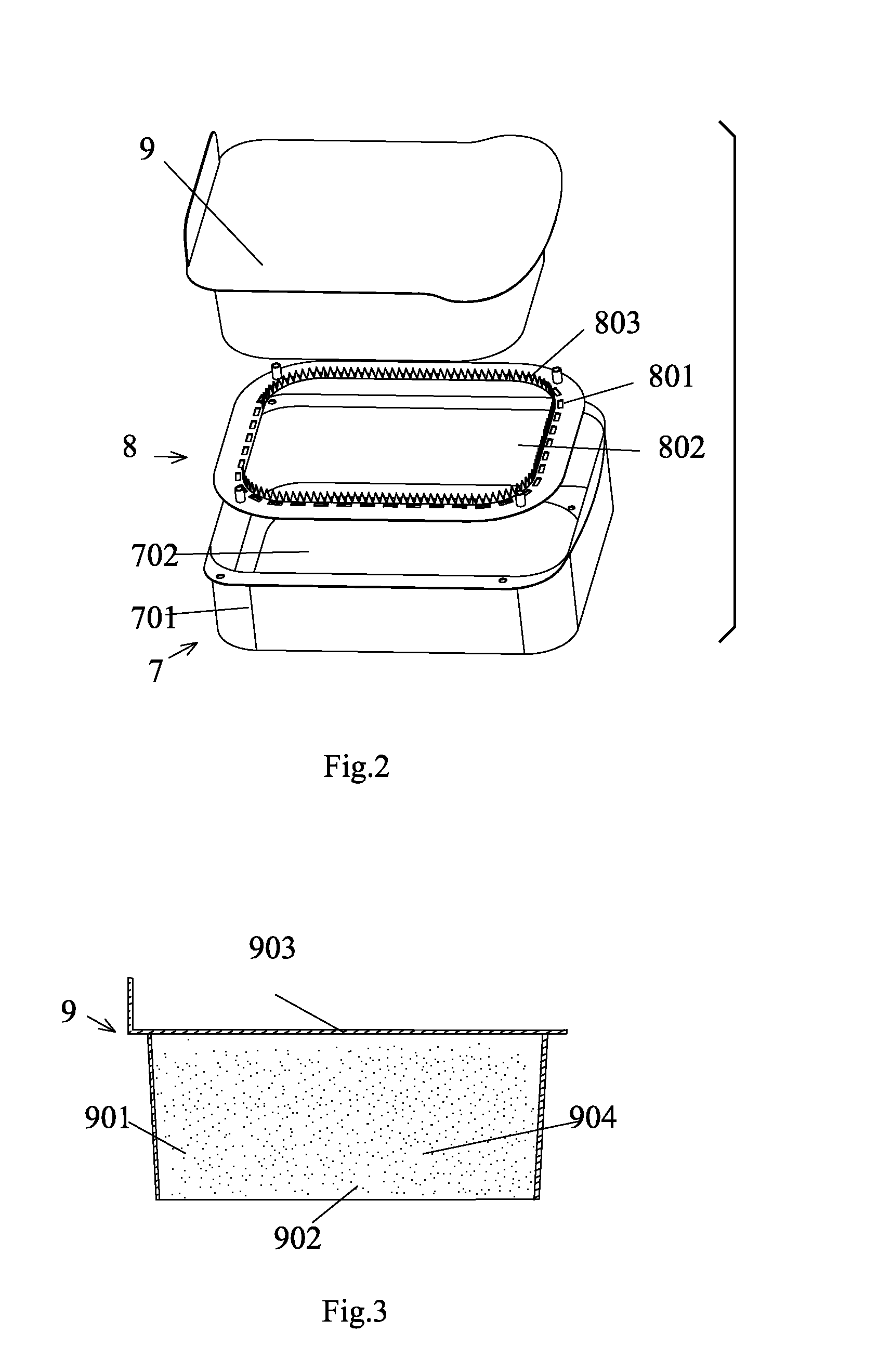

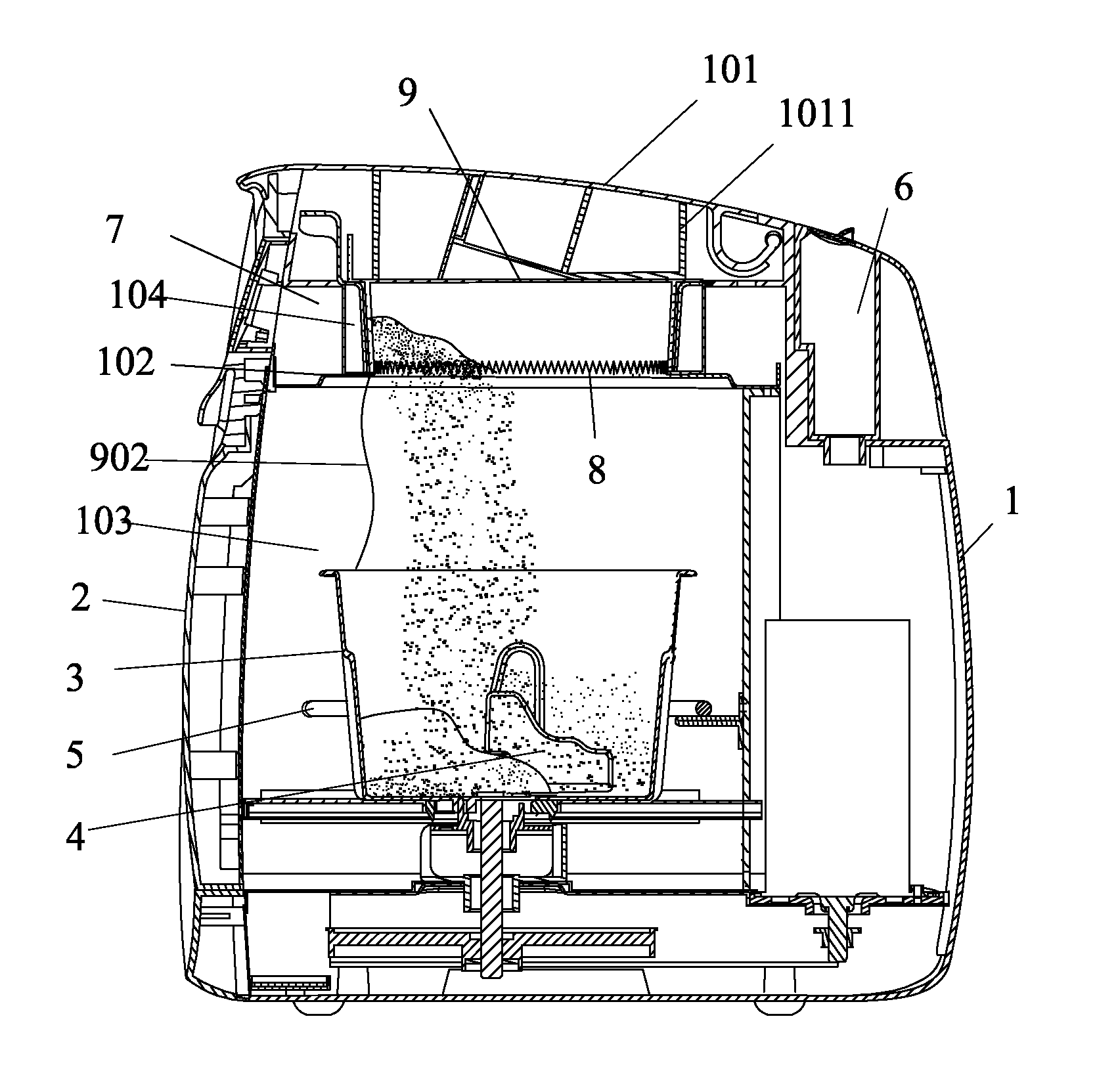

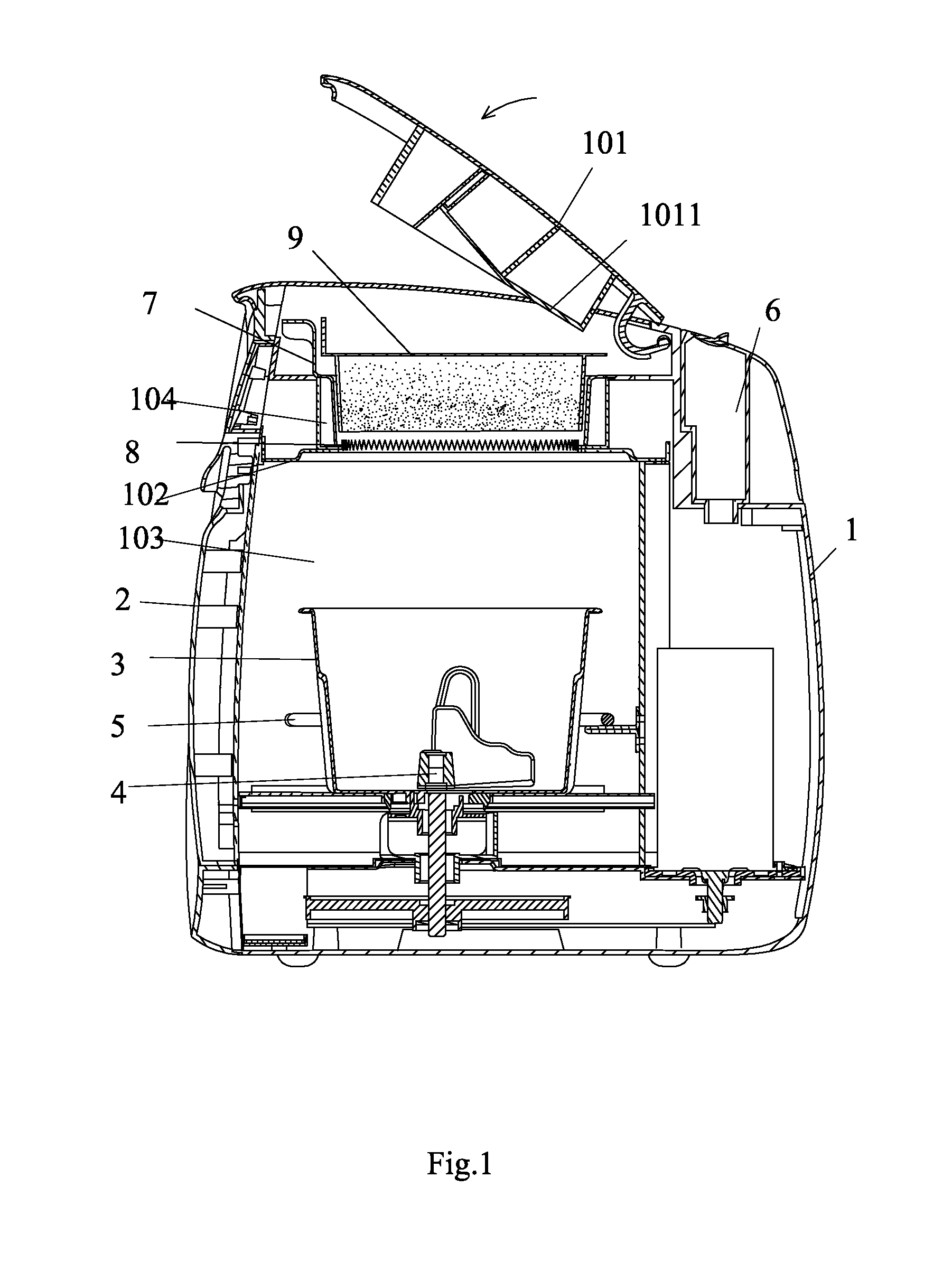

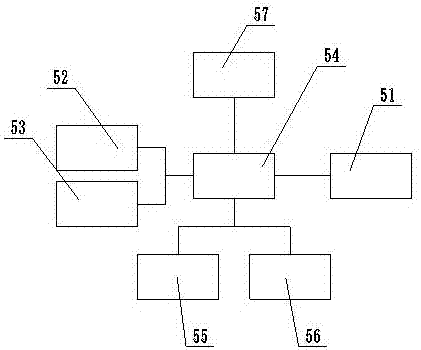

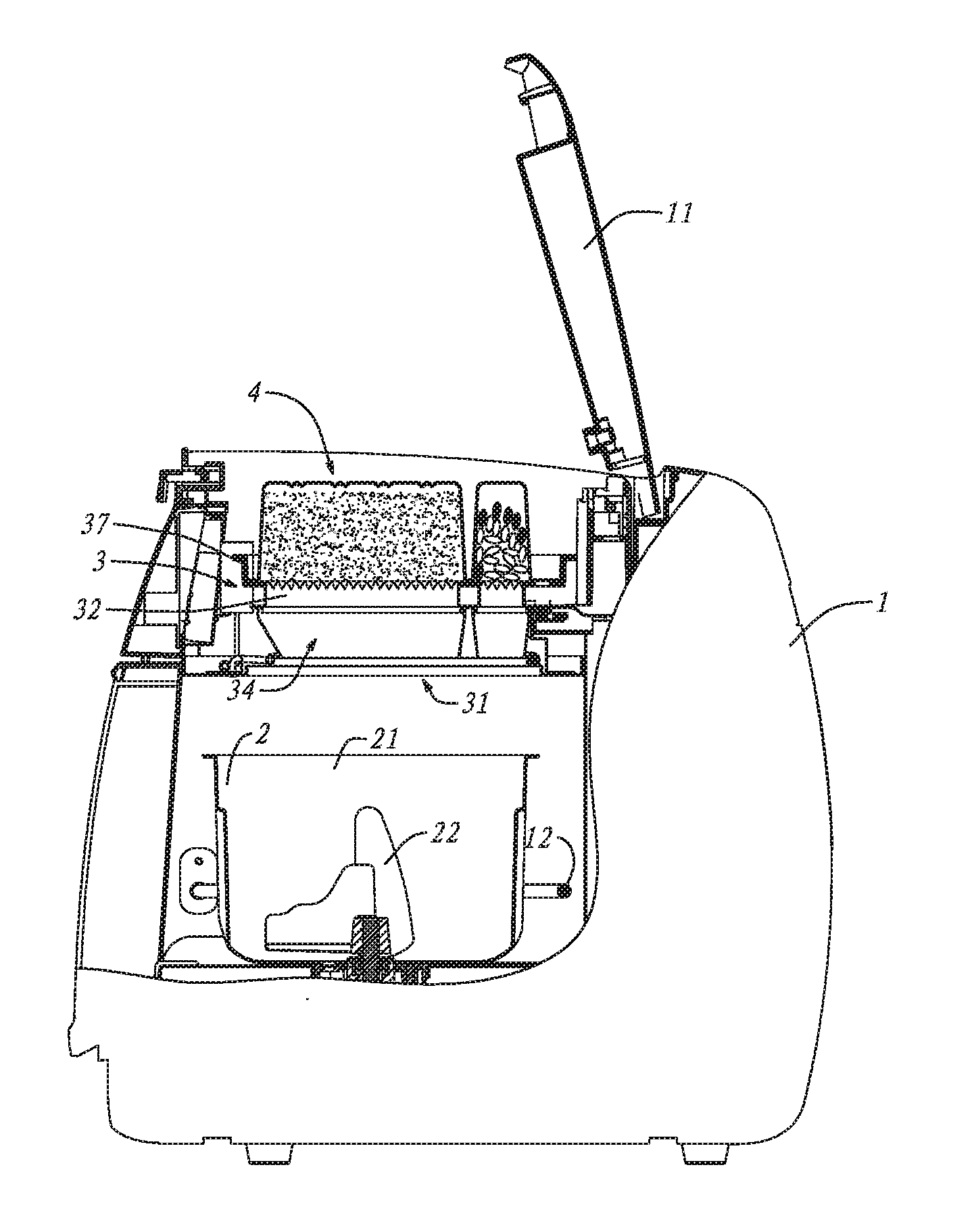

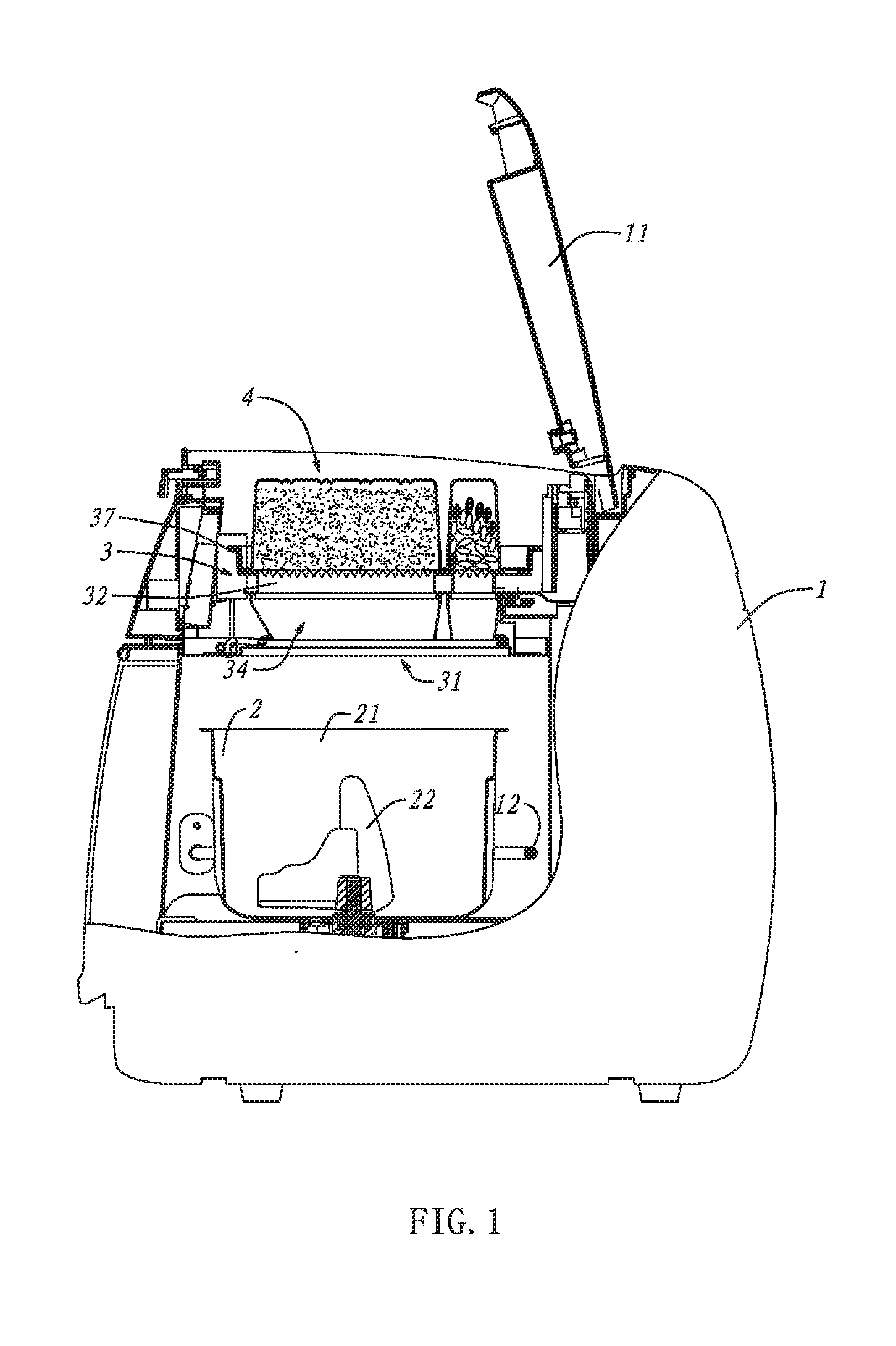

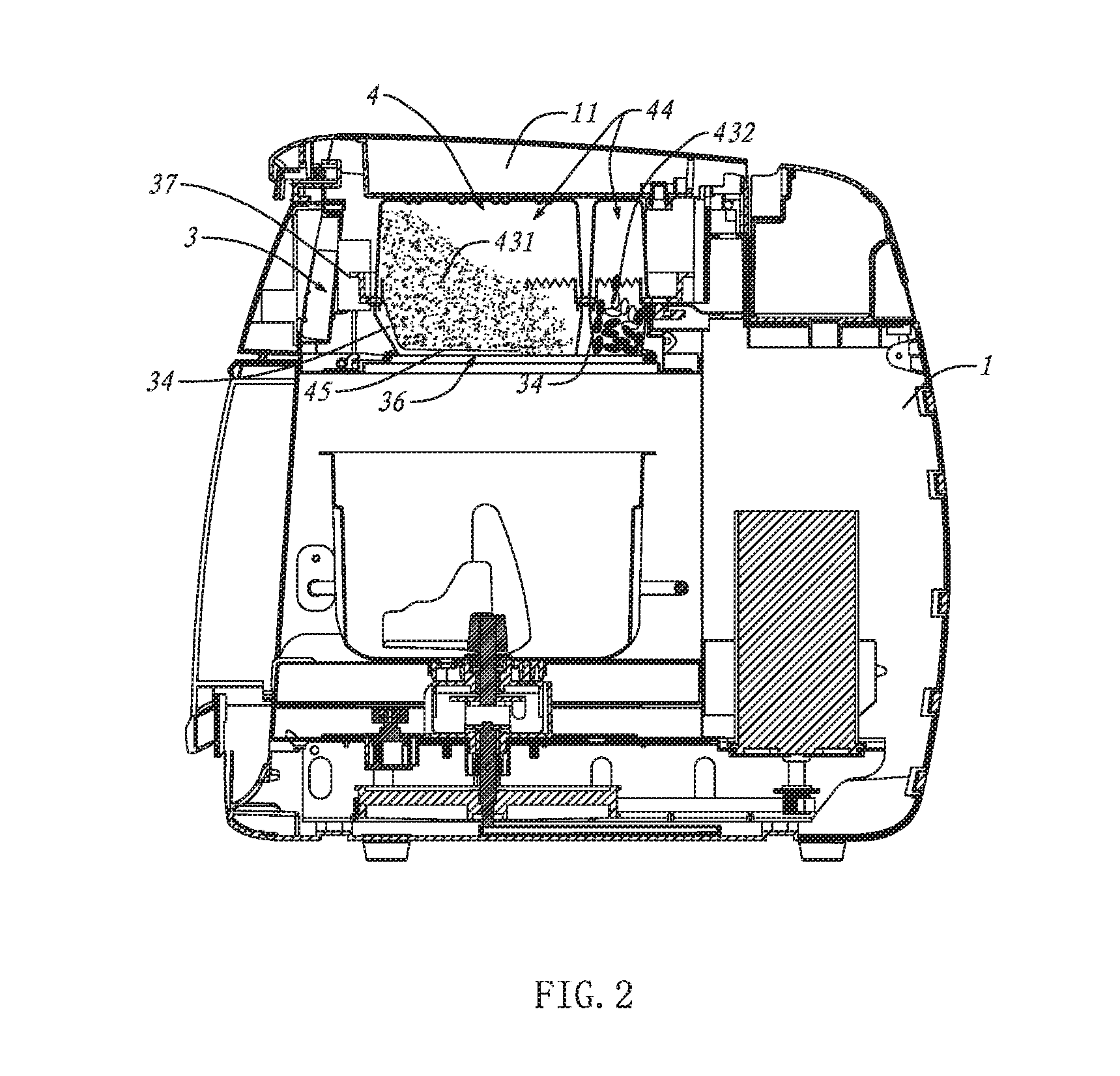

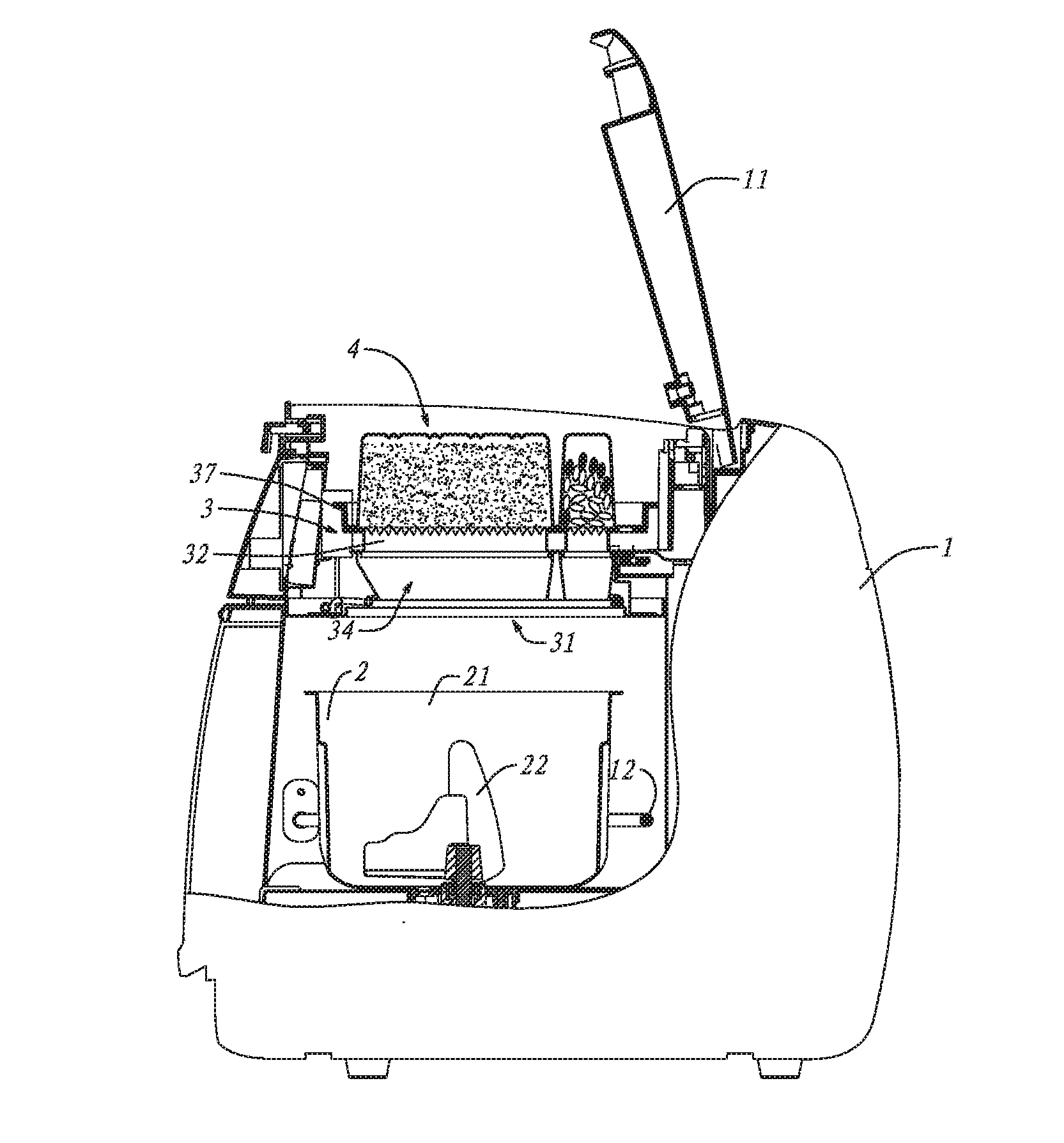

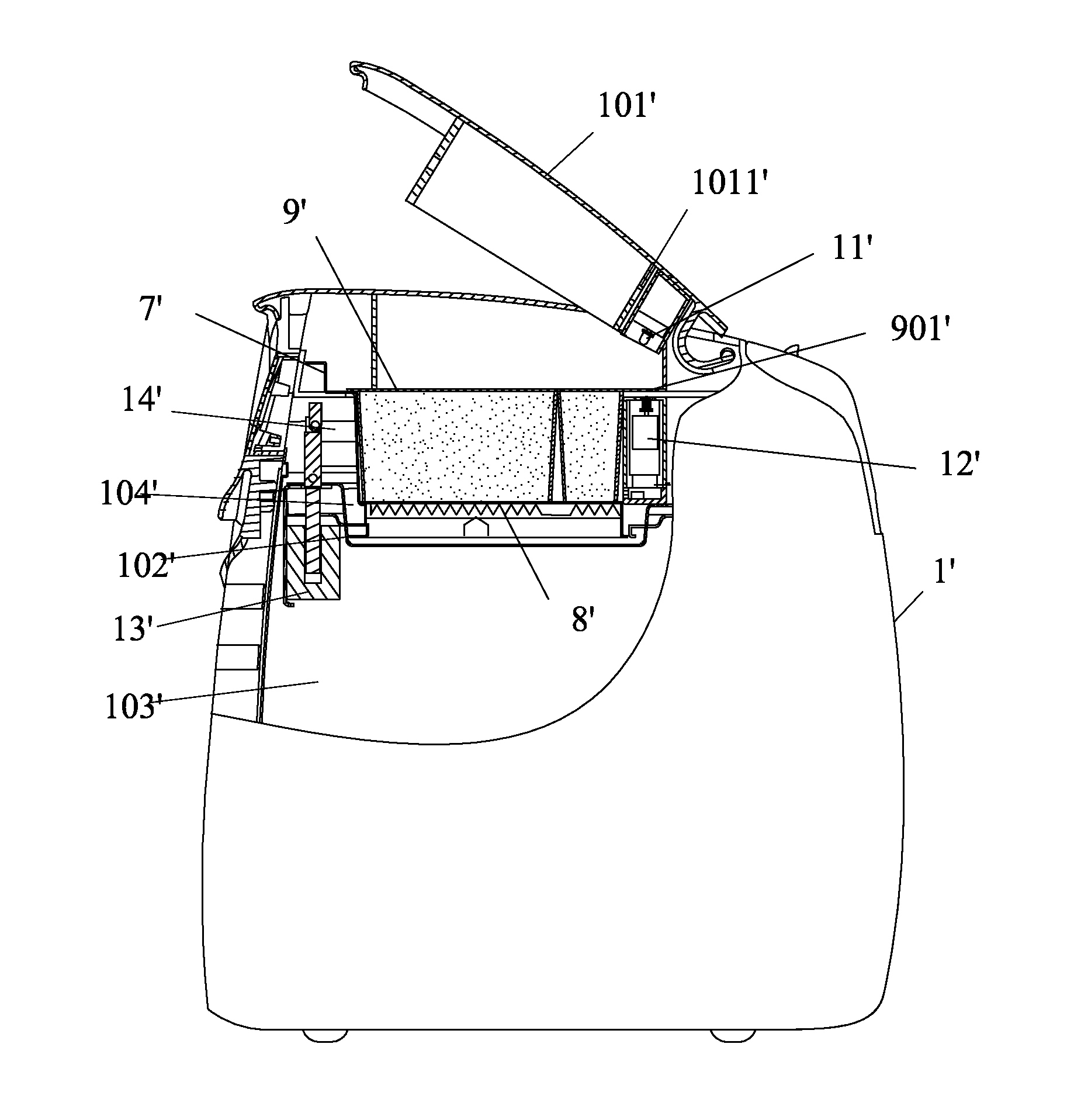

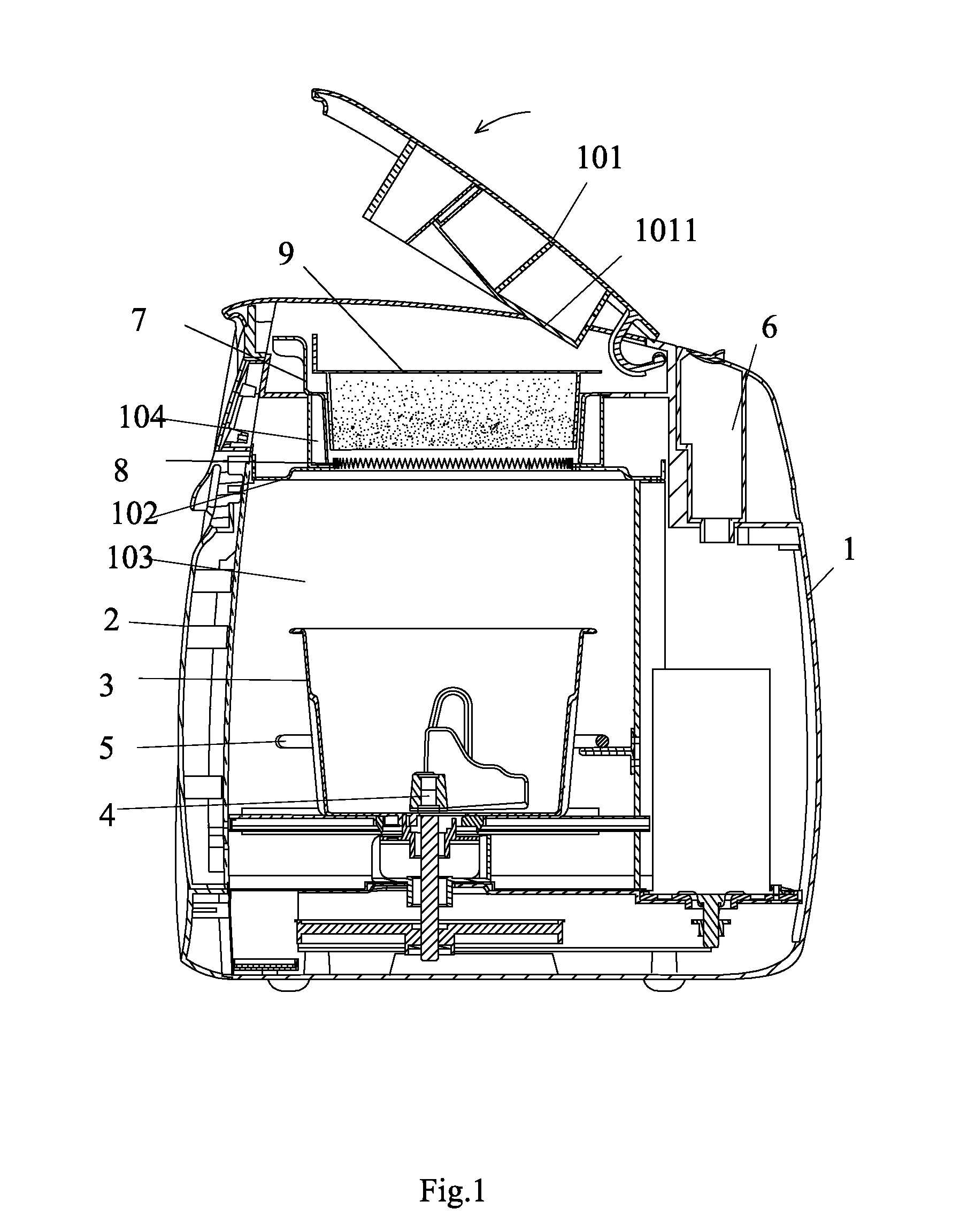

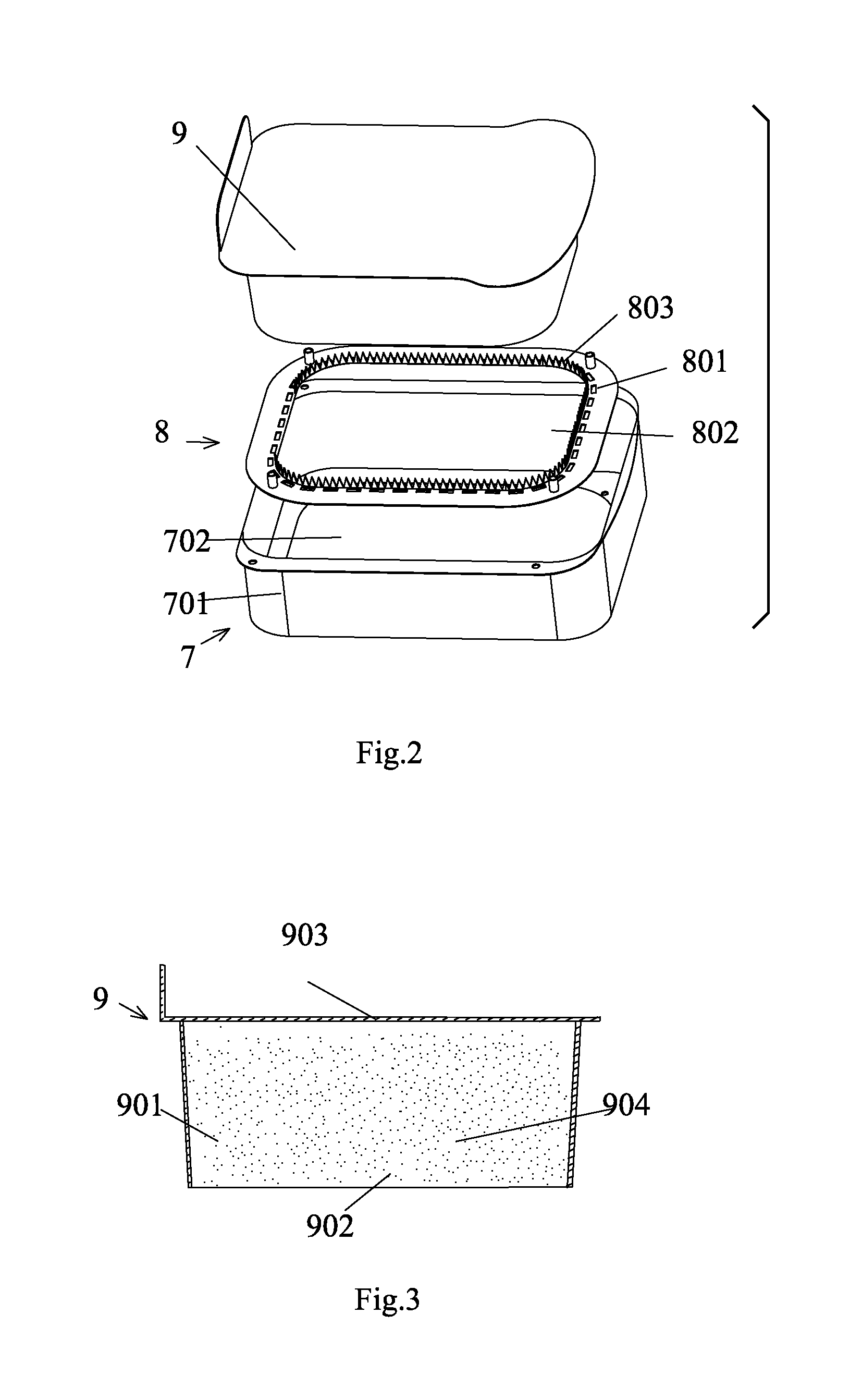

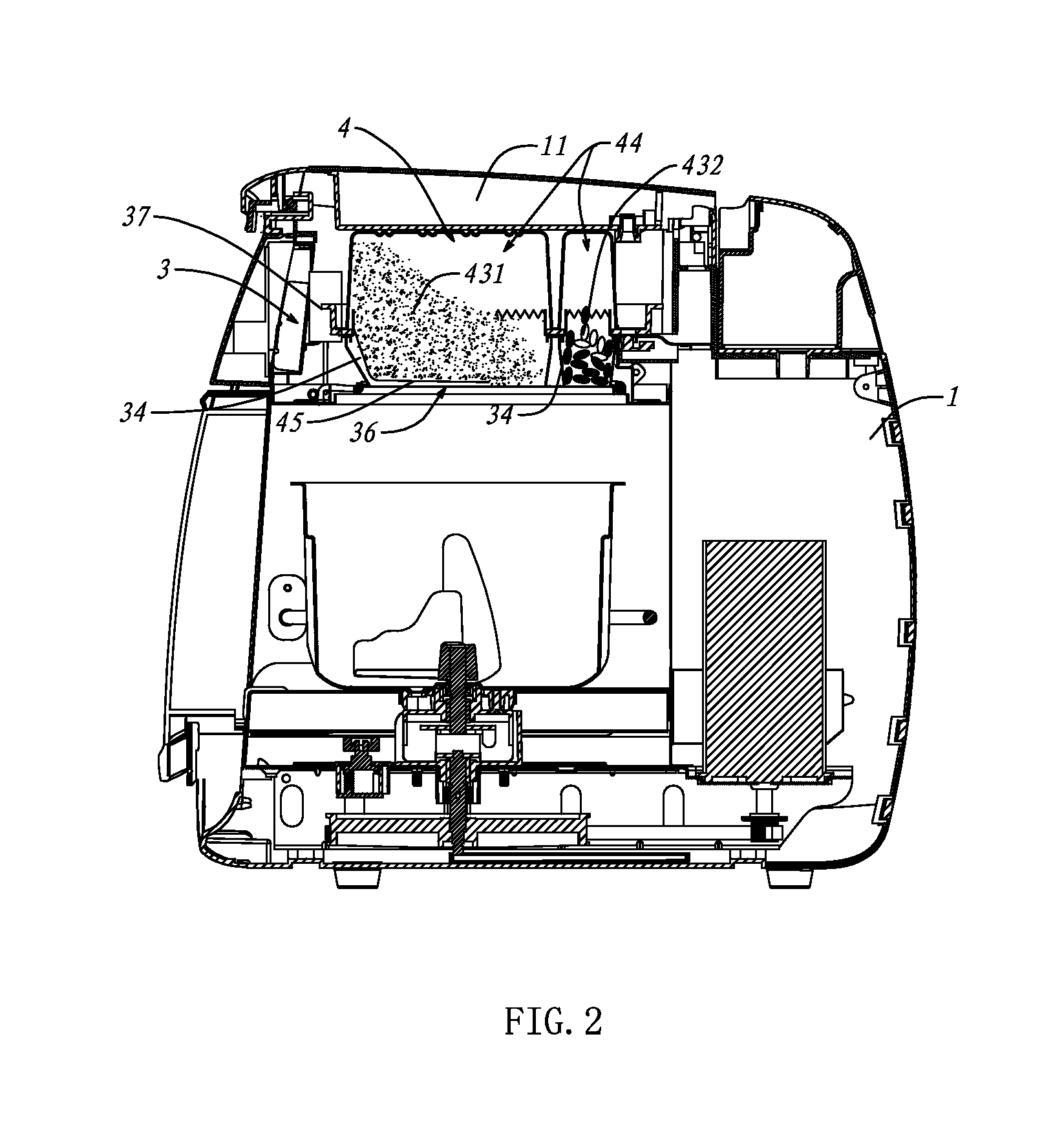

Self-making bread method, bread machine and bread ingredient box thereof

InactiveUS20130186285A1Simplify ingredient preparationAvoid mistakesBaking vesselsDough mixing/kneading methodsAdditive ingredientEngineering

The self-making bread method includes: weighing a certain amount of ingredients according to a bread recipe and placing them in a bread ingredient box; putting the bread ingredient box into the corresponding containing region of the top portion of the bread machine; using the jagged ring of the bottom portion of said containing region to open the thin film of the bottom portion of the bread ingredient box, so the ingredients will fall into the mixing container in the bread machine; controlling the water delivering mechanism inside the bread machine to deliver a certain amount of water into said mixing container; starting the mixing device inside the bread machine, which mixes the ingredients into an appropriate dough; turning off the mixing device; energizing the electric heating tube in the bread machine, to bake the dough inside the mixing container into bread.

Owner:TSANN KUEN ZHANGZHOU ENTERPRISE CO LTD

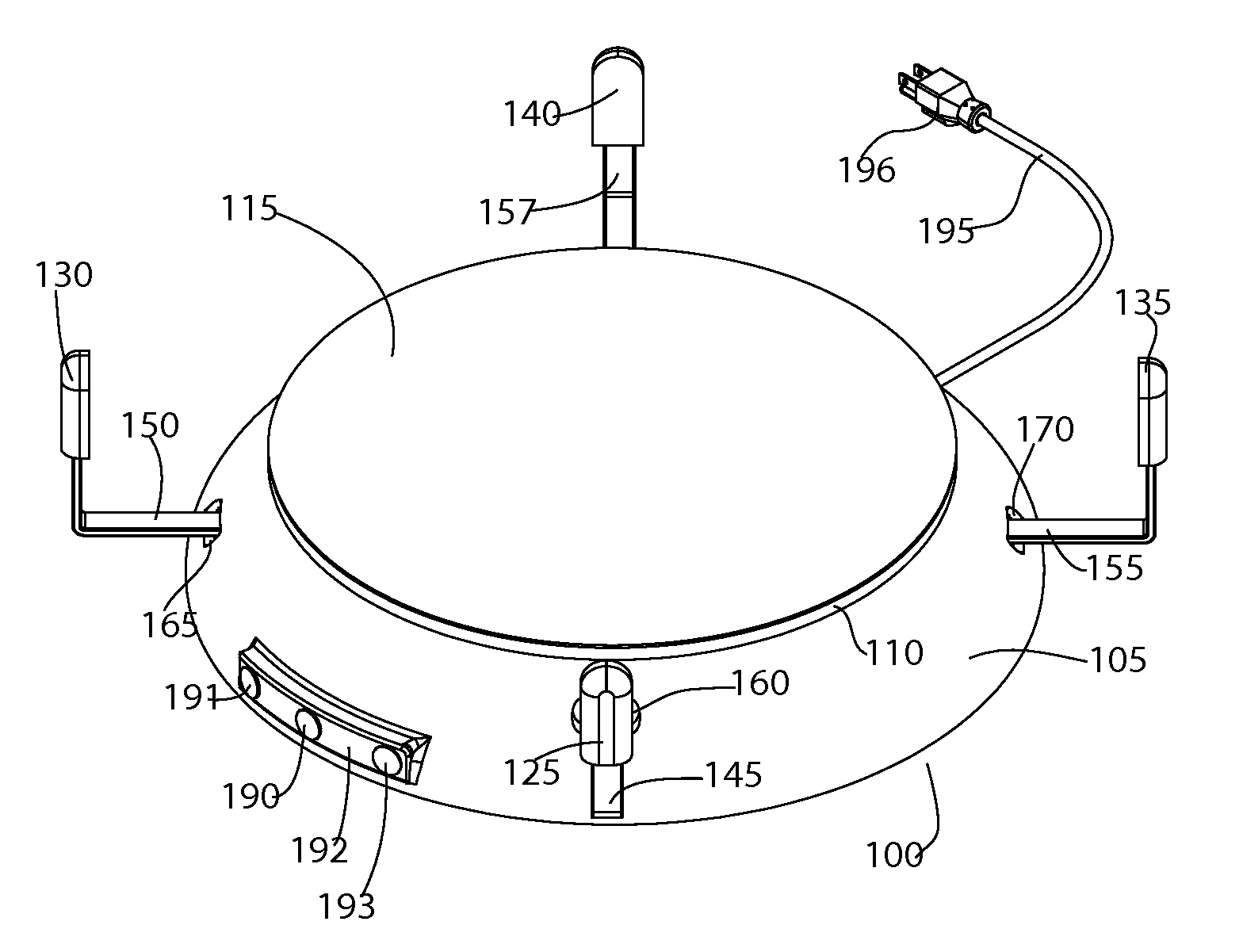

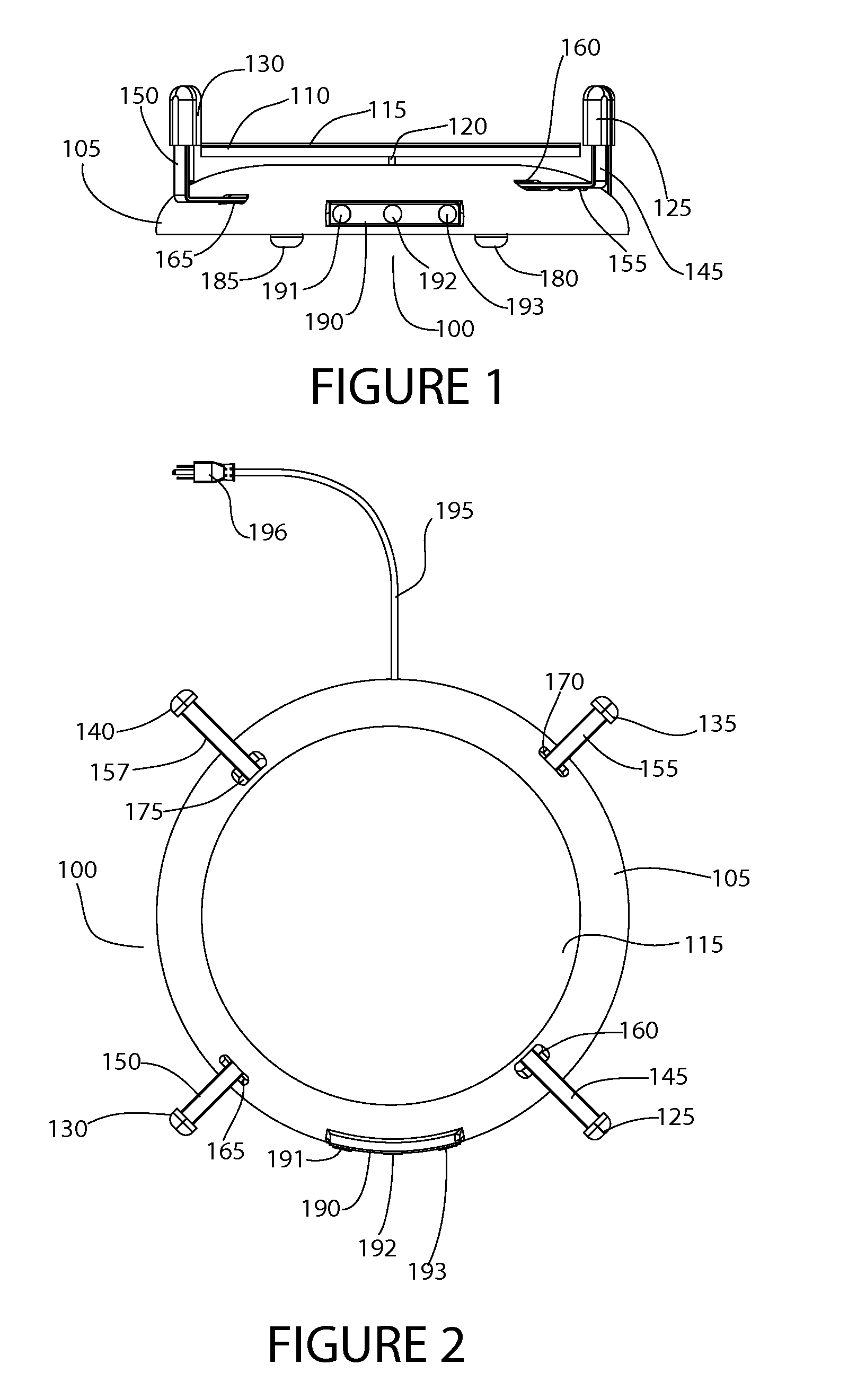

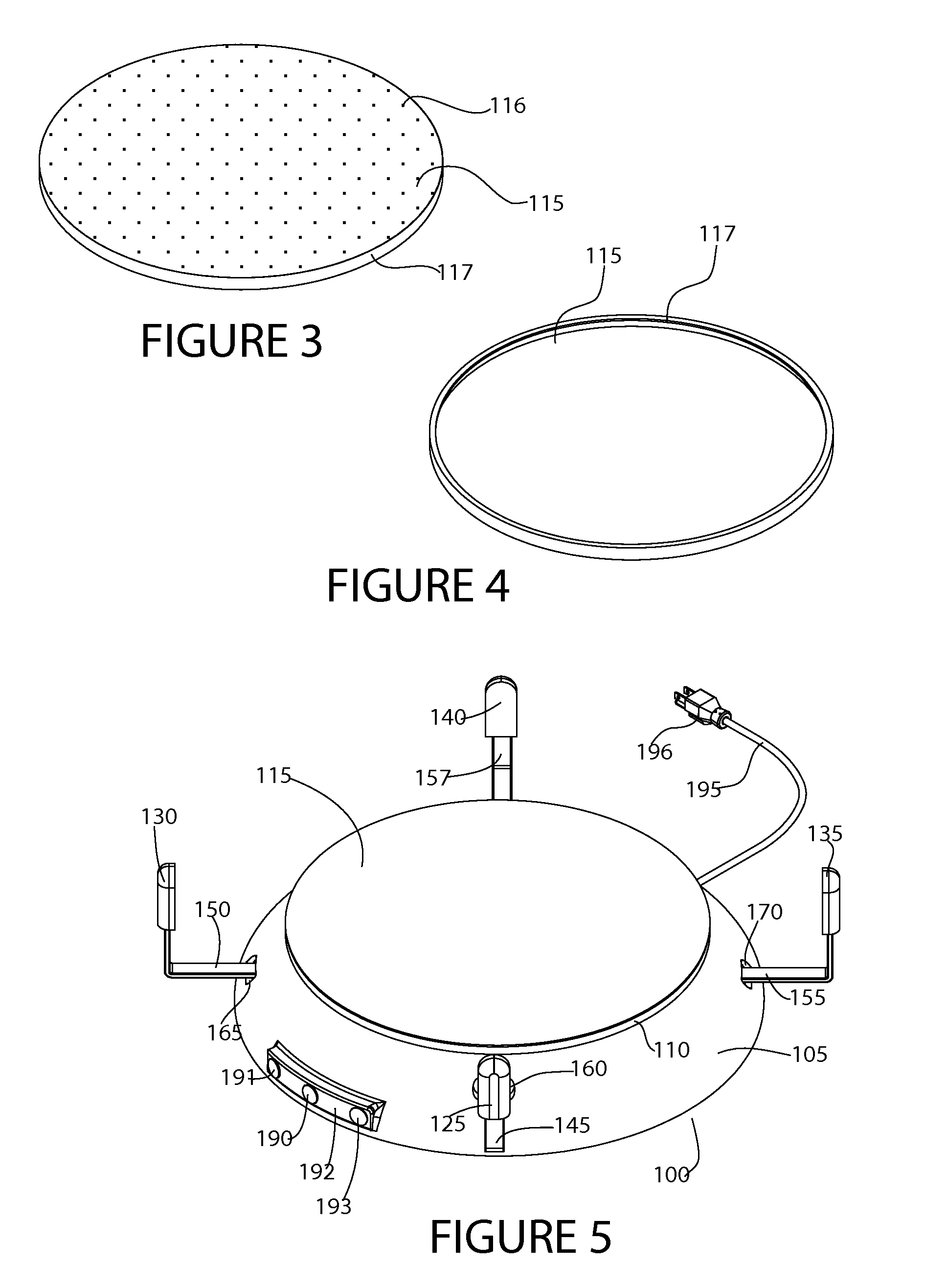

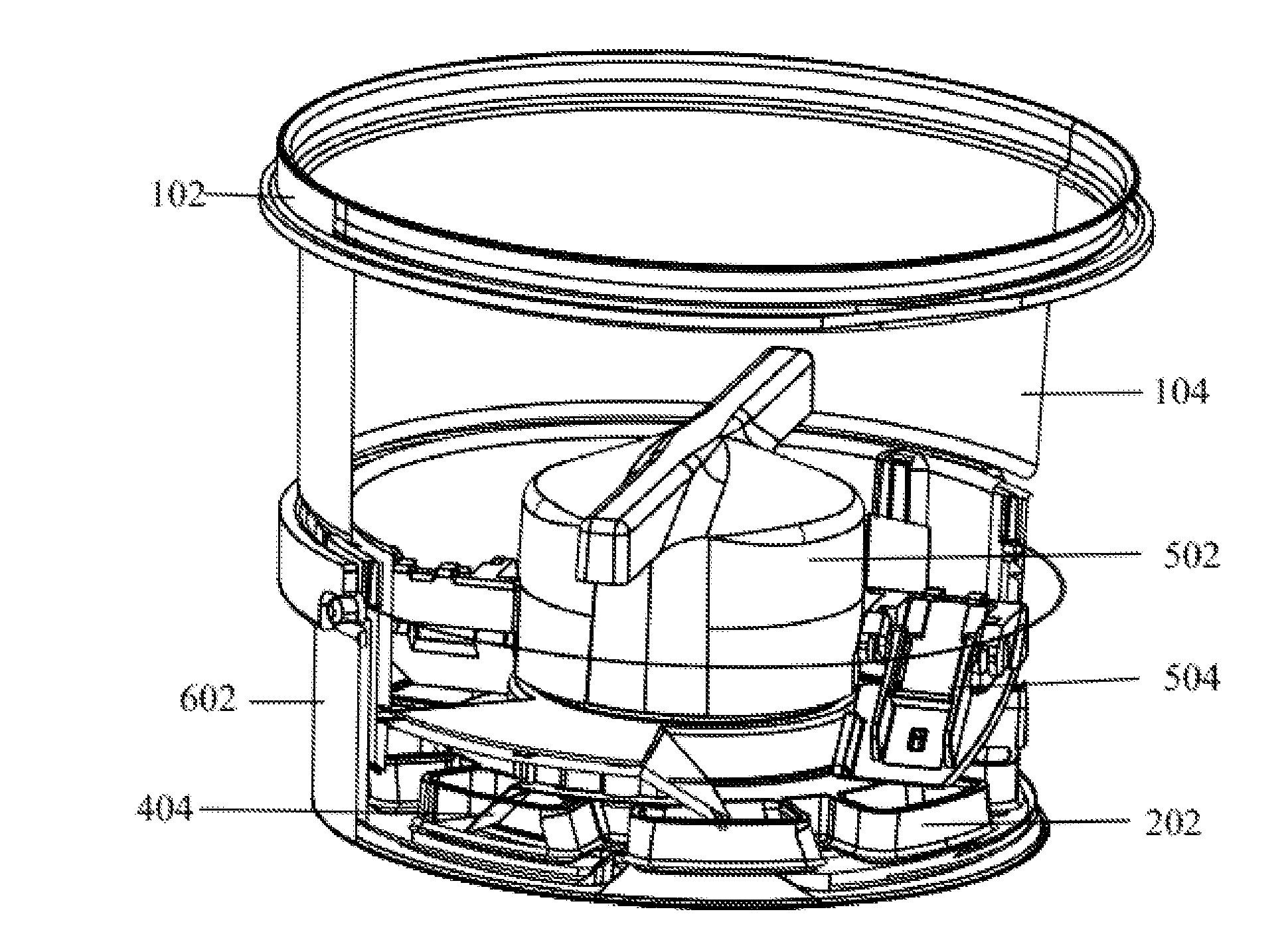

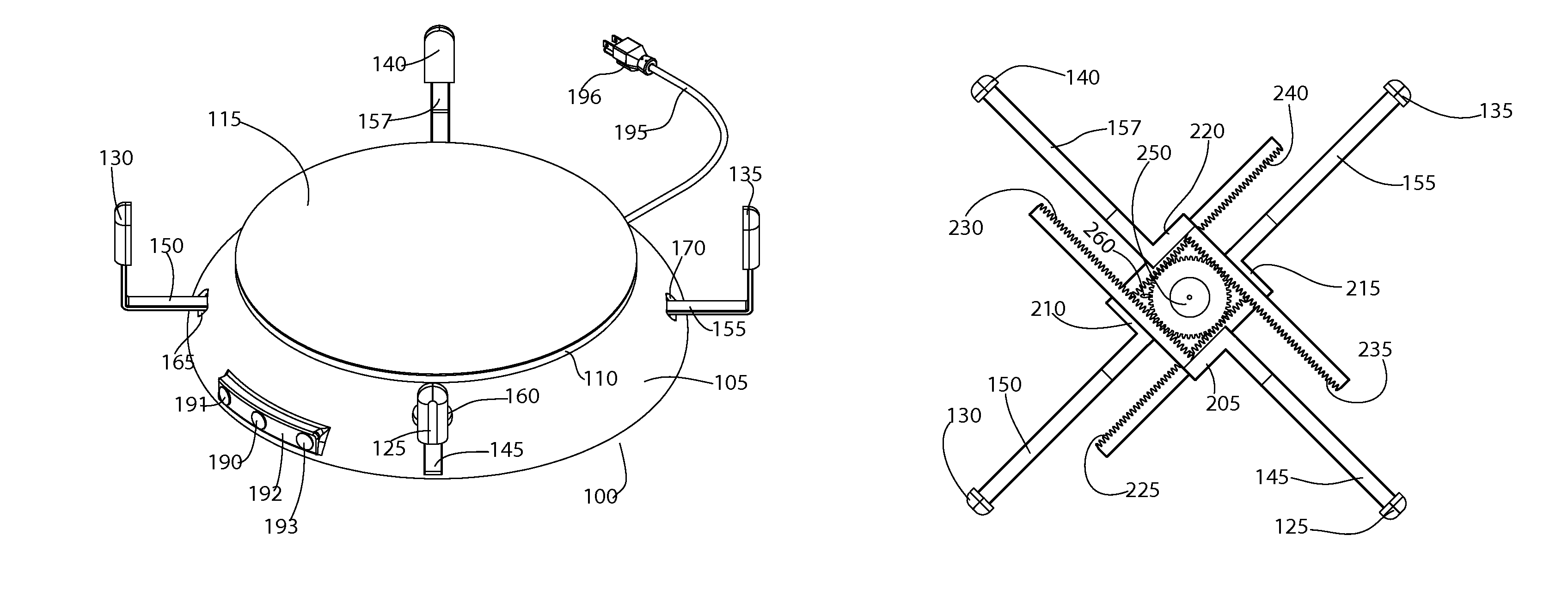

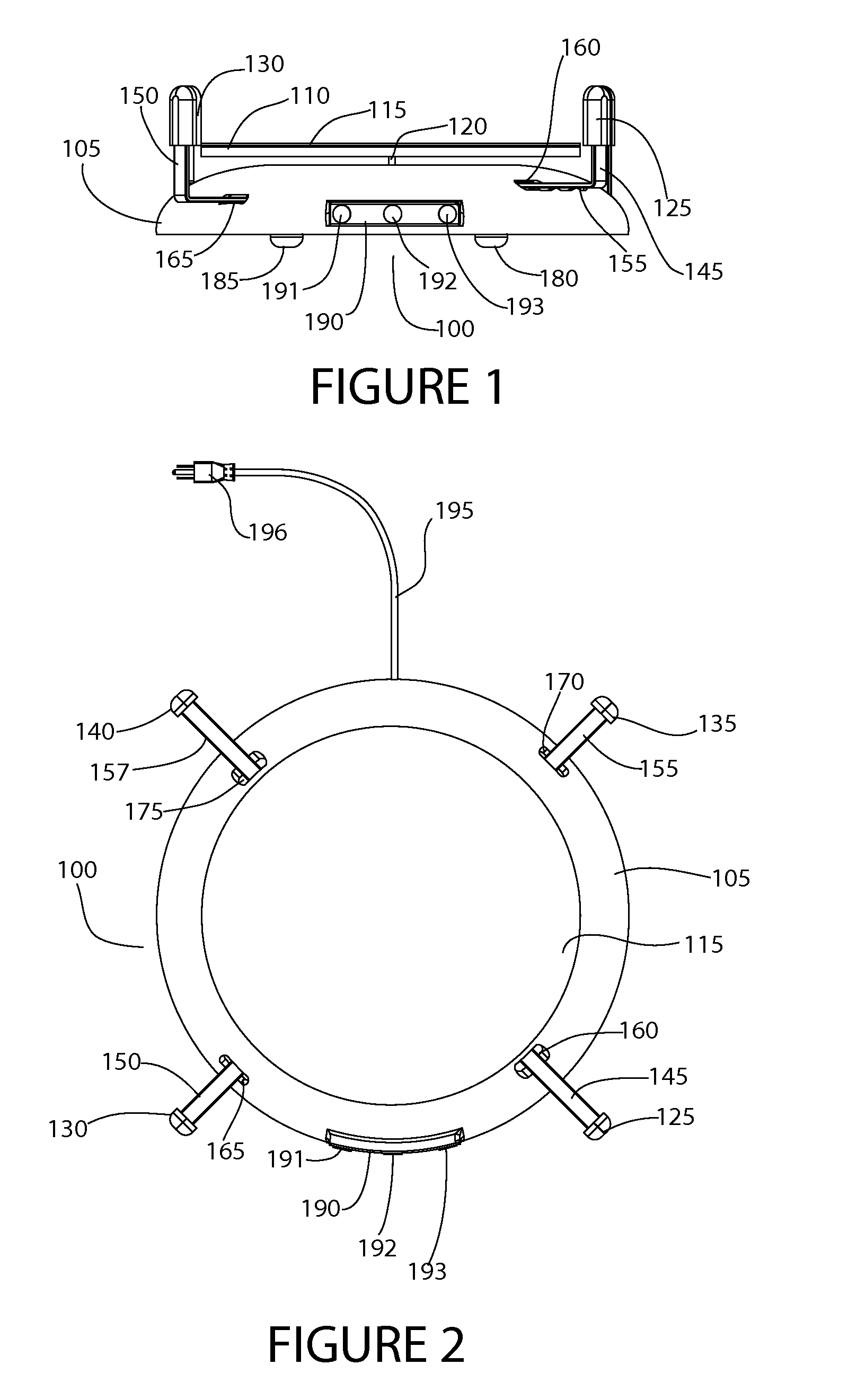

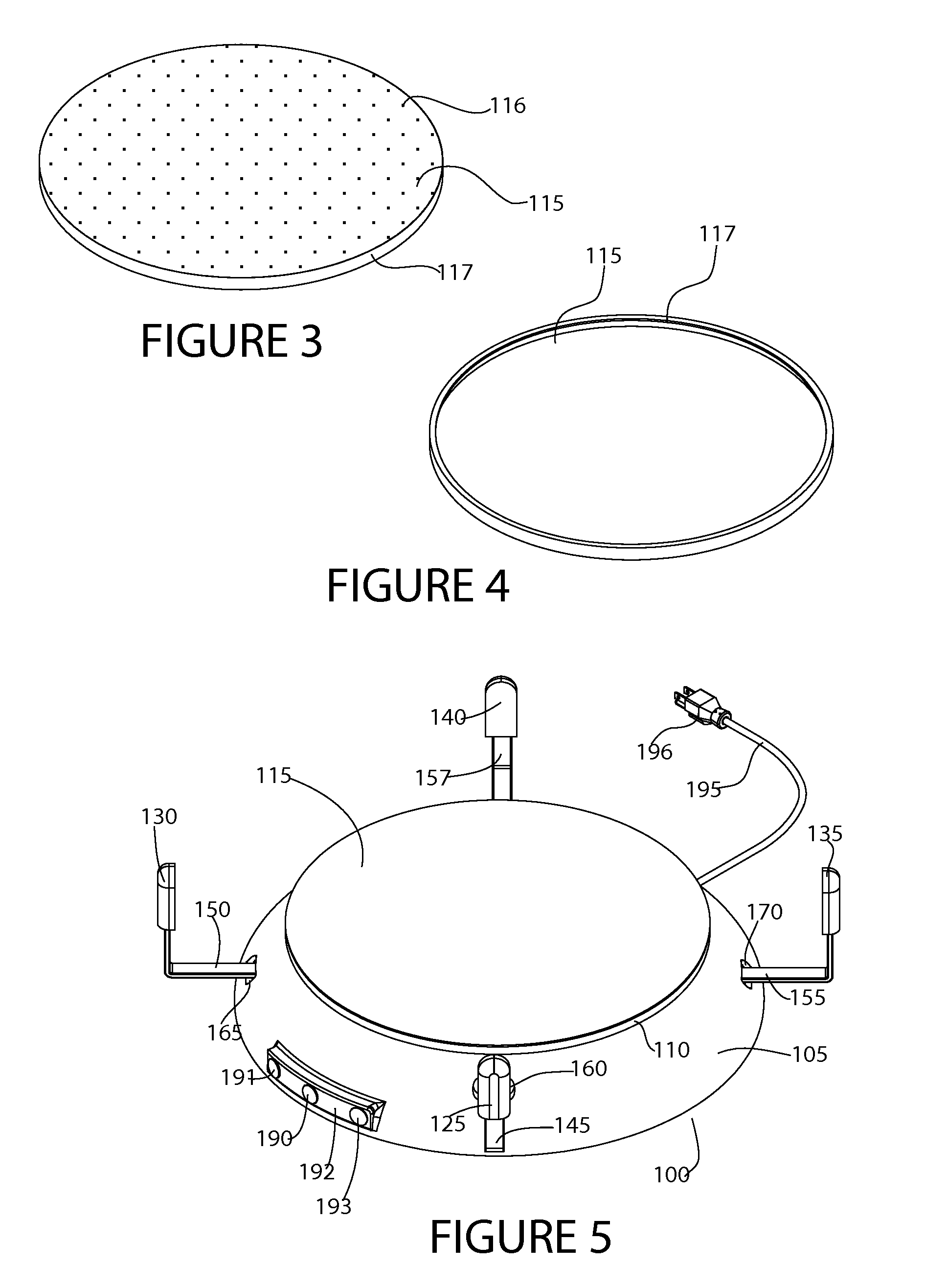

Batter shaking apparatus

ActiveUS20100227038A1Shaking/oscillating/vibrating mixersTransportation and packagingLocking mechanismEngineering

A kitchen shaking apparatus includes a housing, a controllable oscillating actuator contained in the housing, a platform mechanically coupled to the controllable oscillating actuator, and a plurality of adjustable coacting restraining arms operably coupled to the housing. Each of the restraining arms including a vertical segment and a horizontal segment and is positioned and configured to allow the vertical segment to contact an object on the platform. A speed control is configured to control frequency of oscillation of the actuator. A timer control is configured to control duration of operation of the actuator. A locking mechanism releasably locks at least one adjustable restraining arm at a user-selectable position. A removable pad is attached to the top surface of the platform. After shaking mixed ingredients using the apparatus, the ingredients are devoid of substantial air pockets and the consistency is improved for an enhanced processed food product.

Owner:CARROLL STEPHEN

Self-making bread method, bread machine and bread ingredient box thereof

ActiveUS20110195162A1Convenient for ingredientEasy to identifyMeat/fish preservationPre-baking dough treatmentAdditive ingredientEngineering

The self-making bread method includes: weighing a certain amount of ingredients according to a bread recipe and placing them in a bread ingredient box; putting the bread ingredient box into the corresponding containing region of the top portion of the bread machine; using the jagged ring of the bottom portion of said containing region to open the thin film of the bottom portion of the bread ingredient box, so the ingredients will fall into the mixing container in the bread machine; controlling the water delivering mechanism inside the bread machine to deliver a certain amount of water into said mixing container; starting the mixing device inside the bread machine, which mixes the ingredients into an appropriate dough; turning off the mixing device; energizing the electric heating tube in the bread machine, to bake the dough inside the mixing container into bread.

Owner:TSANN KUEN ZHANGZHOU ENTERPRISE CO LTD

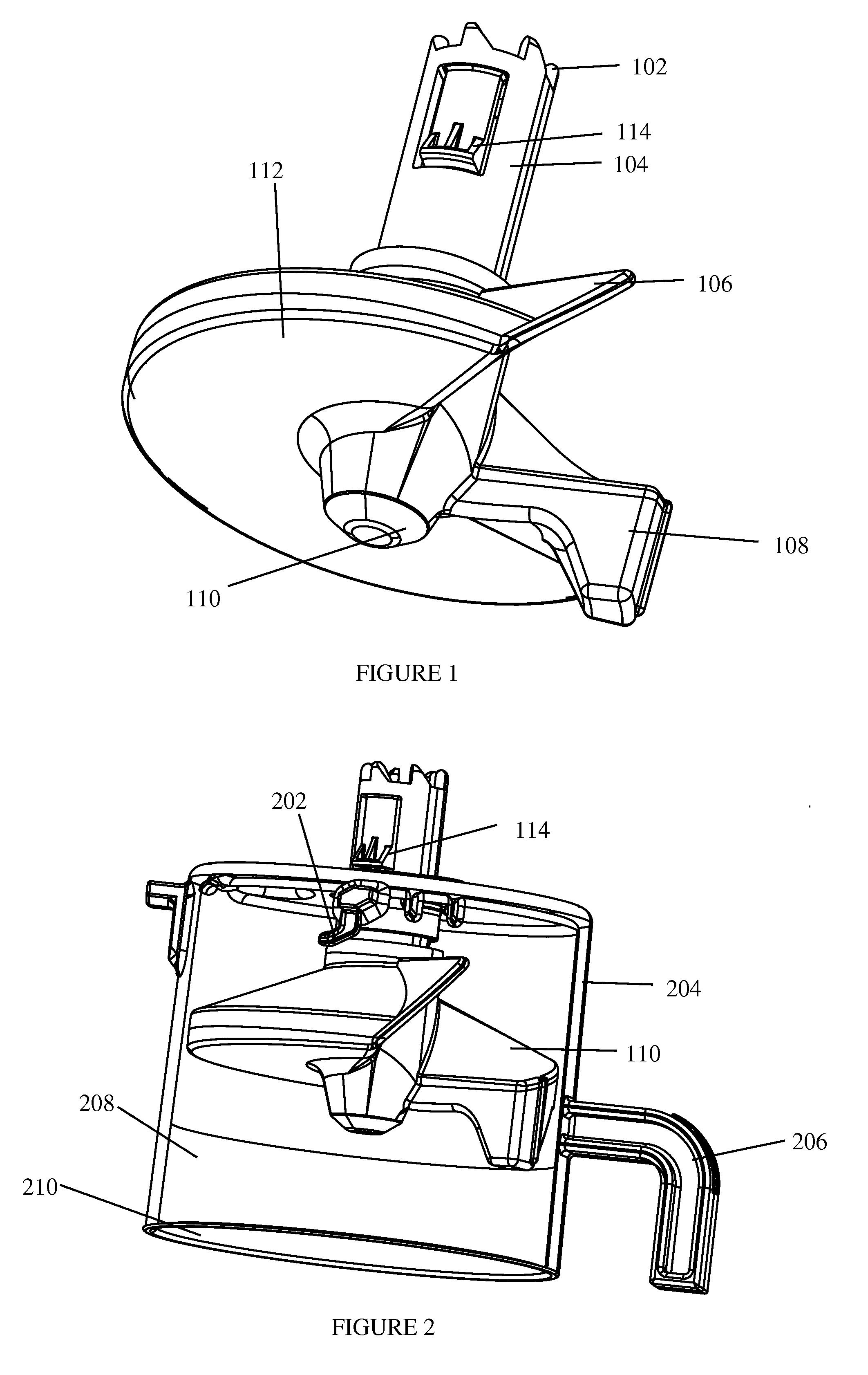

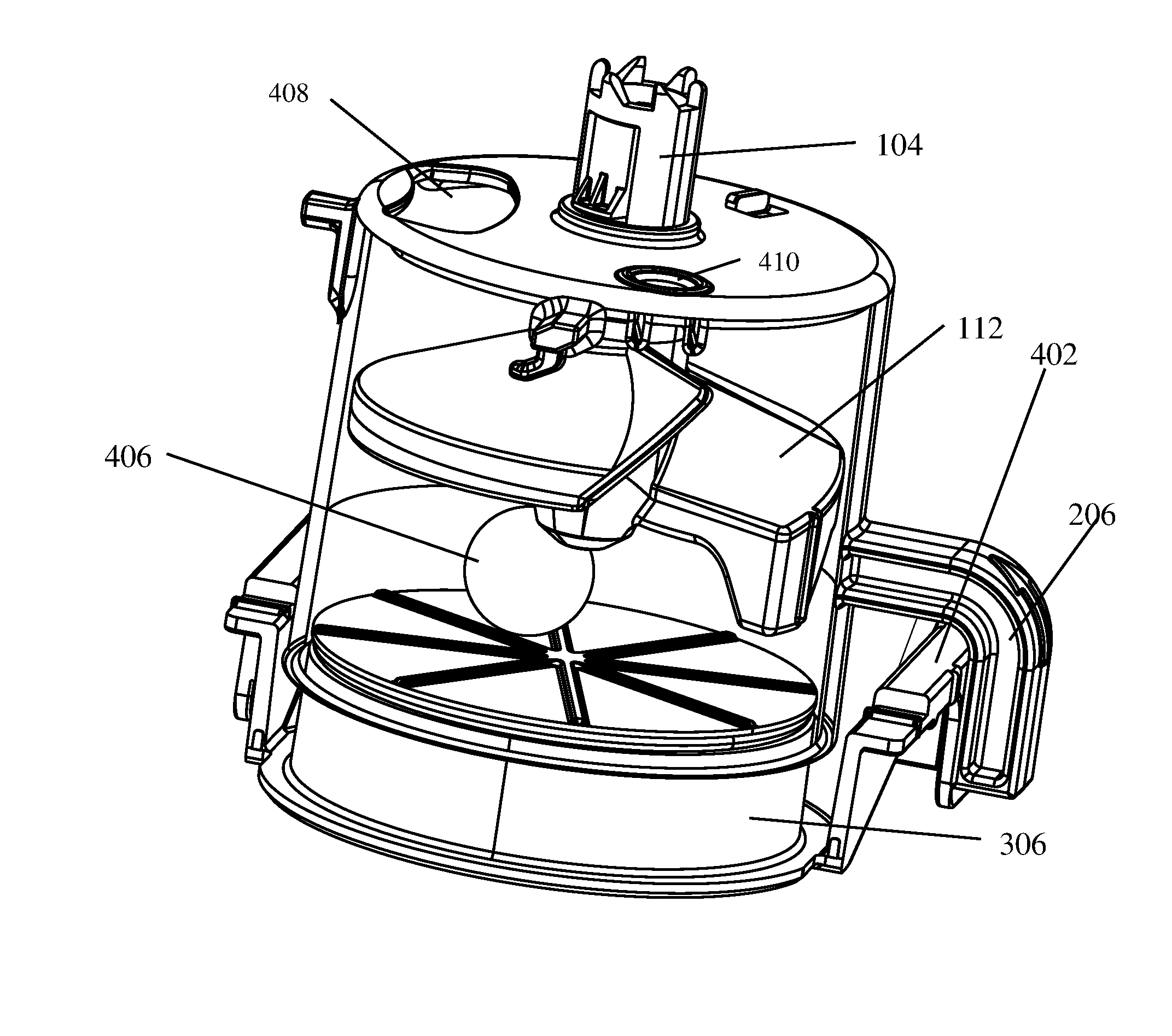

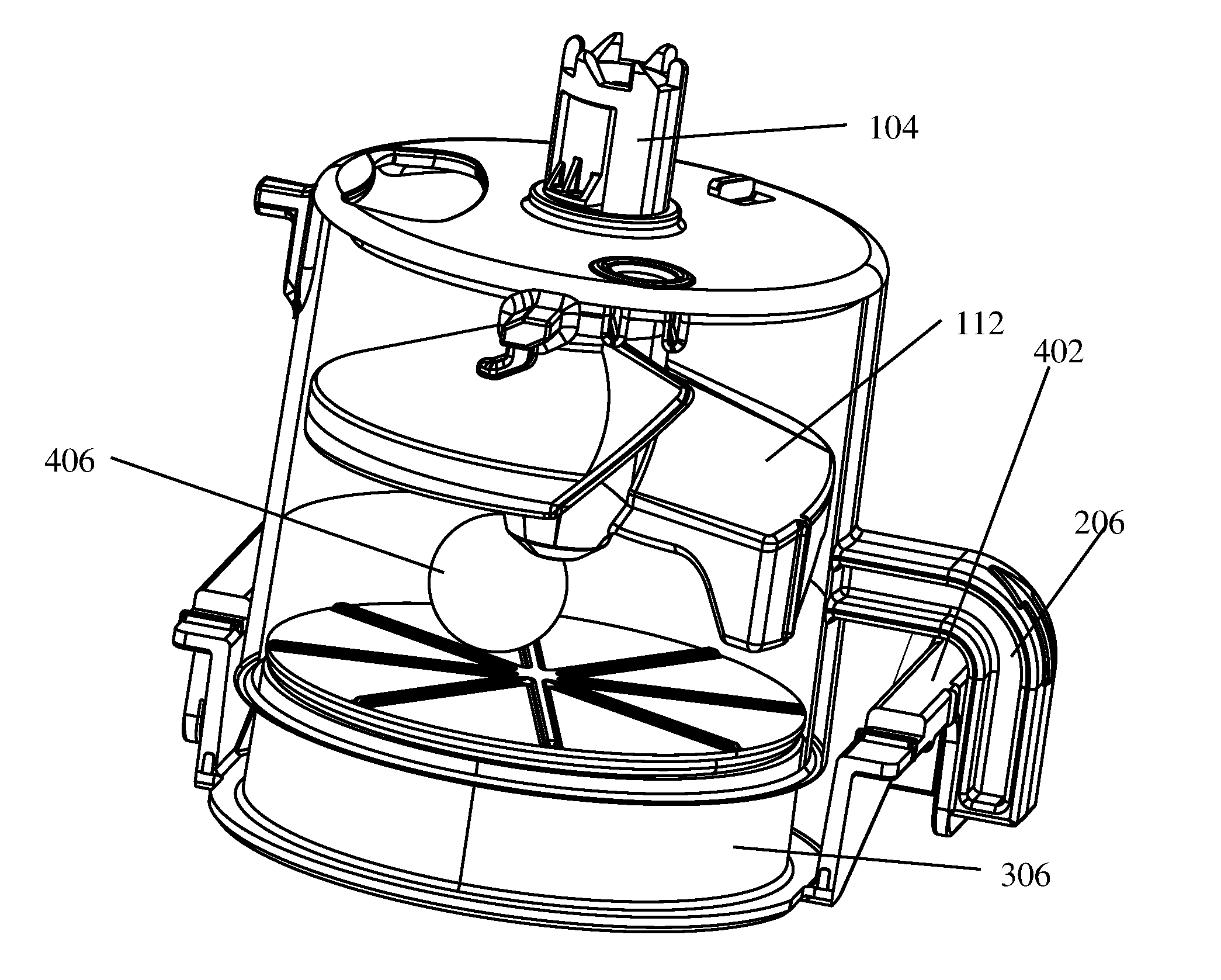

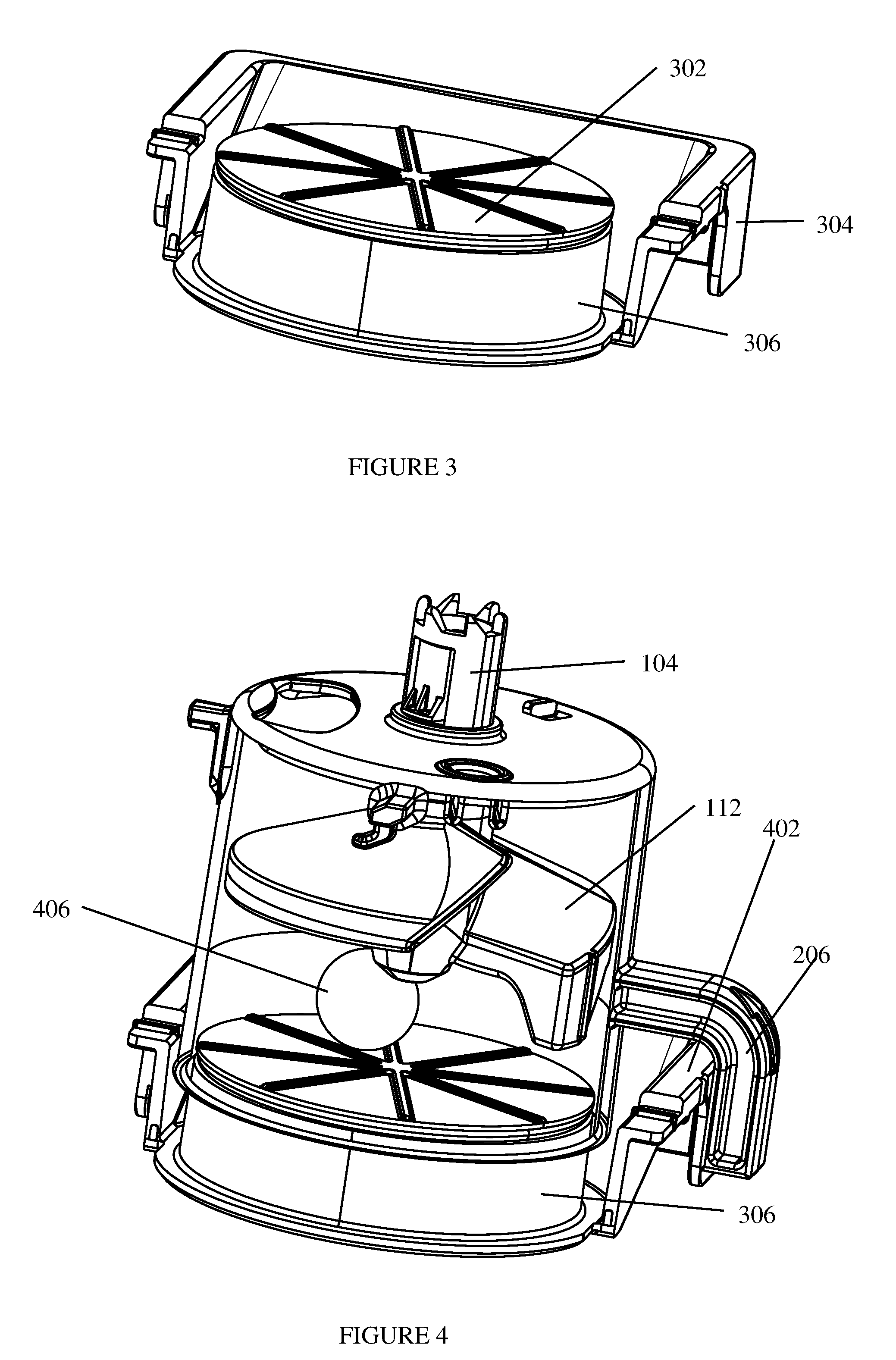

Apparatus, system and method for an adaptive kneading technology for a food preparation appliance

The present invention presents a kneading mechanism for a food preparation appliance. The kneading mechanism has a kneading container, a blade assembly and a kneading base. The kneading container has an open bottom face and the kneading base has a textured surface. An adaptive kneading technology which resides in a processor is used to form an optimal viscoelastic dough ball. Since there is variation in the gluten content and the amount of water used makes the dough ball have a viscoelastic nature this technology due to its self-learning mechanism optimizes the kneading of single dough balls using adaptive kneading technology.

Owner:ZIMPLISTIC

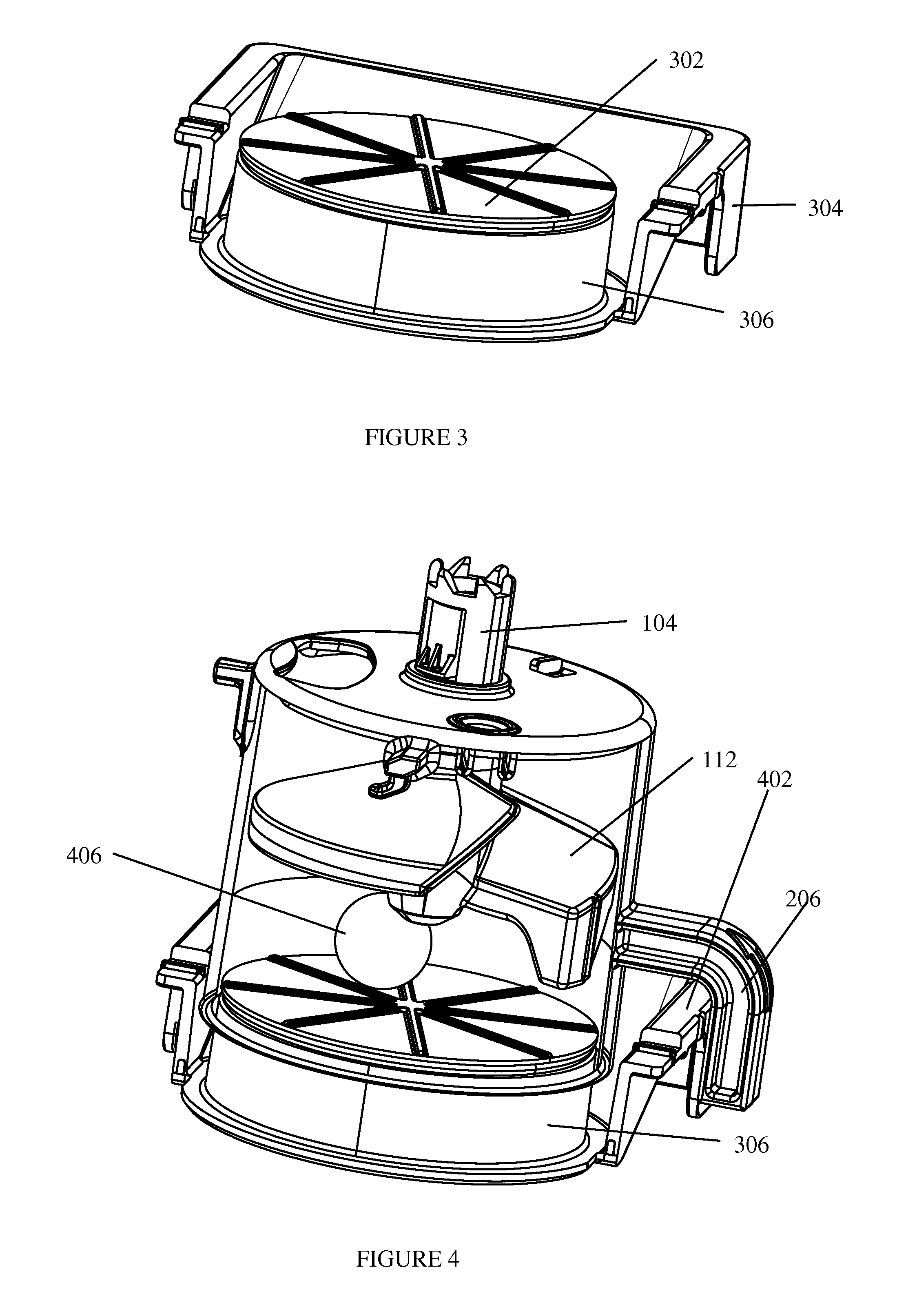

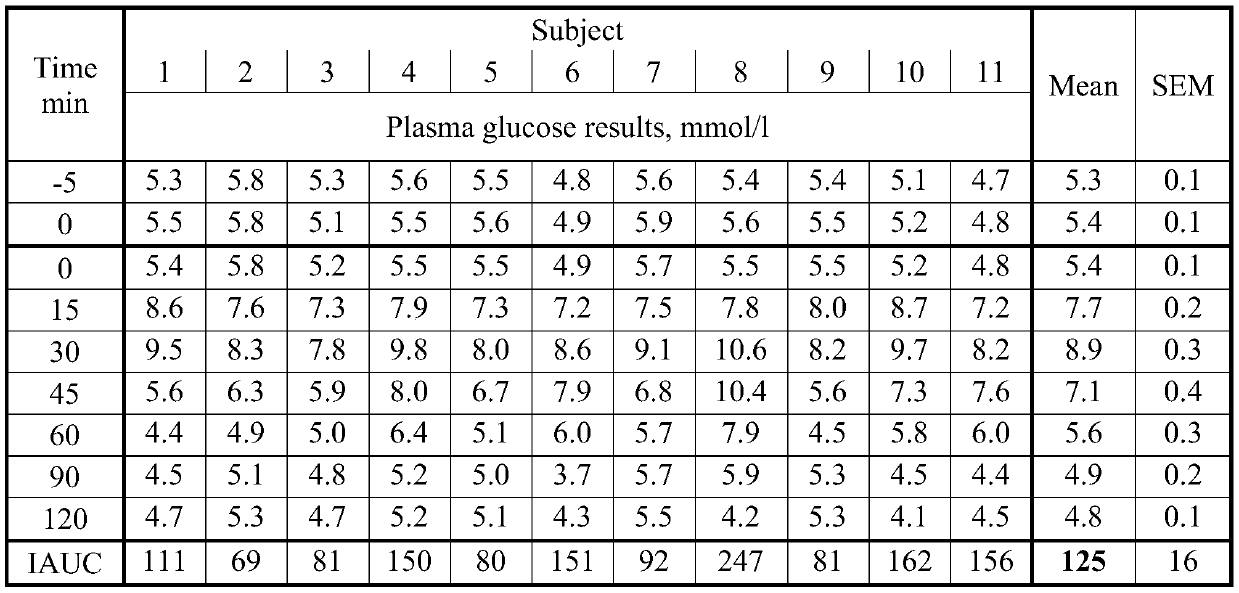

Composition of low GI potato bread and preparation method of composition

InactiveCN110839674AReduce intakeIncrease peristalsisDough irradiationDough heat treatmentBiotechnologyNutritive values

The invention is suitable for the technical field of nutritious food, and provides a composition of low GI potato bread. The composition comprises the following components: wheat flour, potato flour,purple potato flour, maltitol, erythritol, inulin, a polyphenol extract, yeast powder, salt, butter, coconut oil, an egg liquid, a compound modifier and water. Aiming at the defect of high GI value ofcommon wheat flour bread, the low GI potato bread is researched and developed through adjustment of the composition; by adopting potato powder, purple potato powder, sugar alcohol and particularly adding inulin dietary fiber, the low GI potato bread not only has a good supplement effect in the aspects of minerals, vitamins, essential amino acids, dietary fiber and the like, but also a low GI bread product is obtained through reasonable compatibility of raw material components; and the bread does not cause rapid fluctuation of blood sugar after being ate, so that the bread not only can meet the nutritional requirements of common diets of eaters, but also has obvious improvement in the aspects of bread calories, flavor and nutritional value.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD

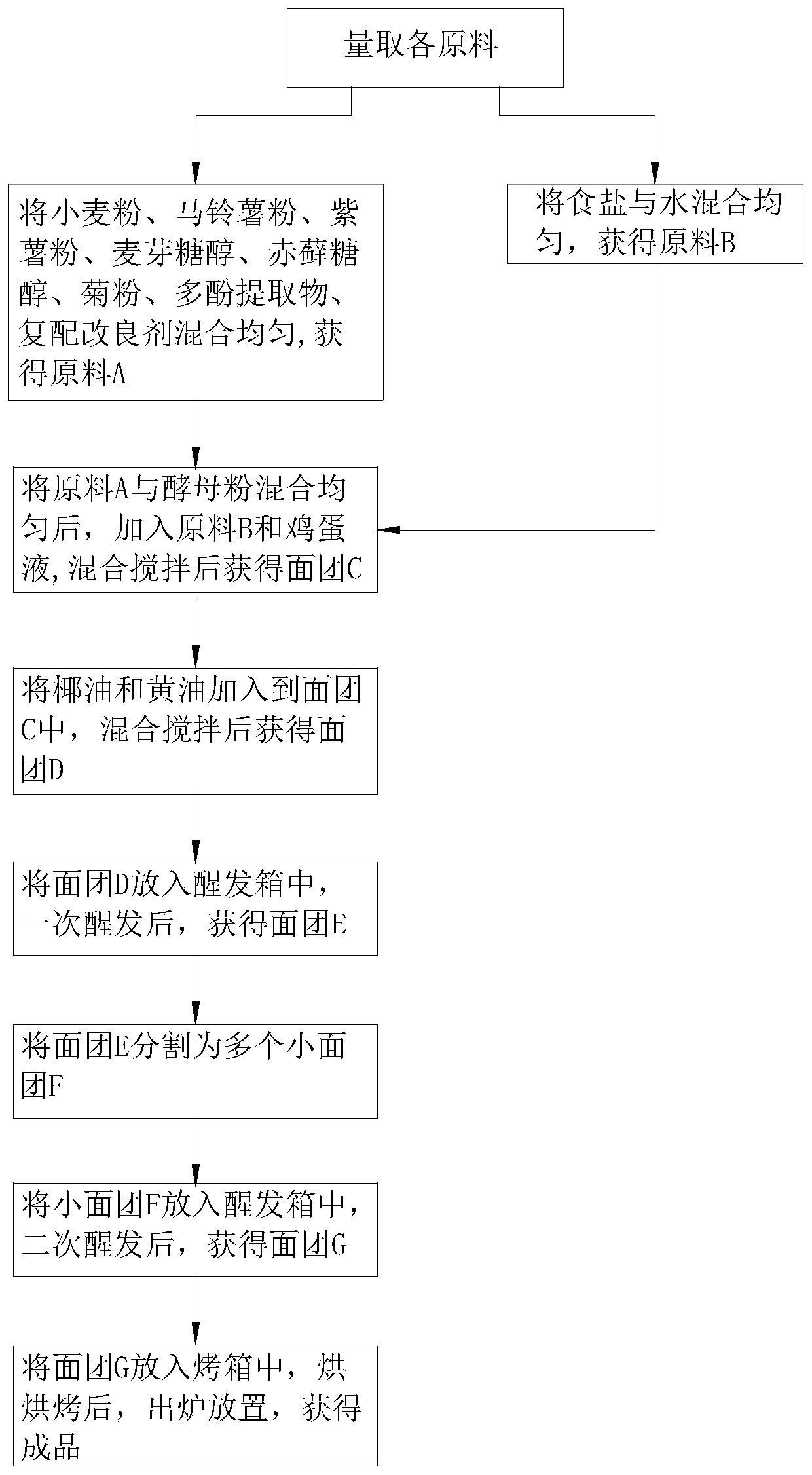

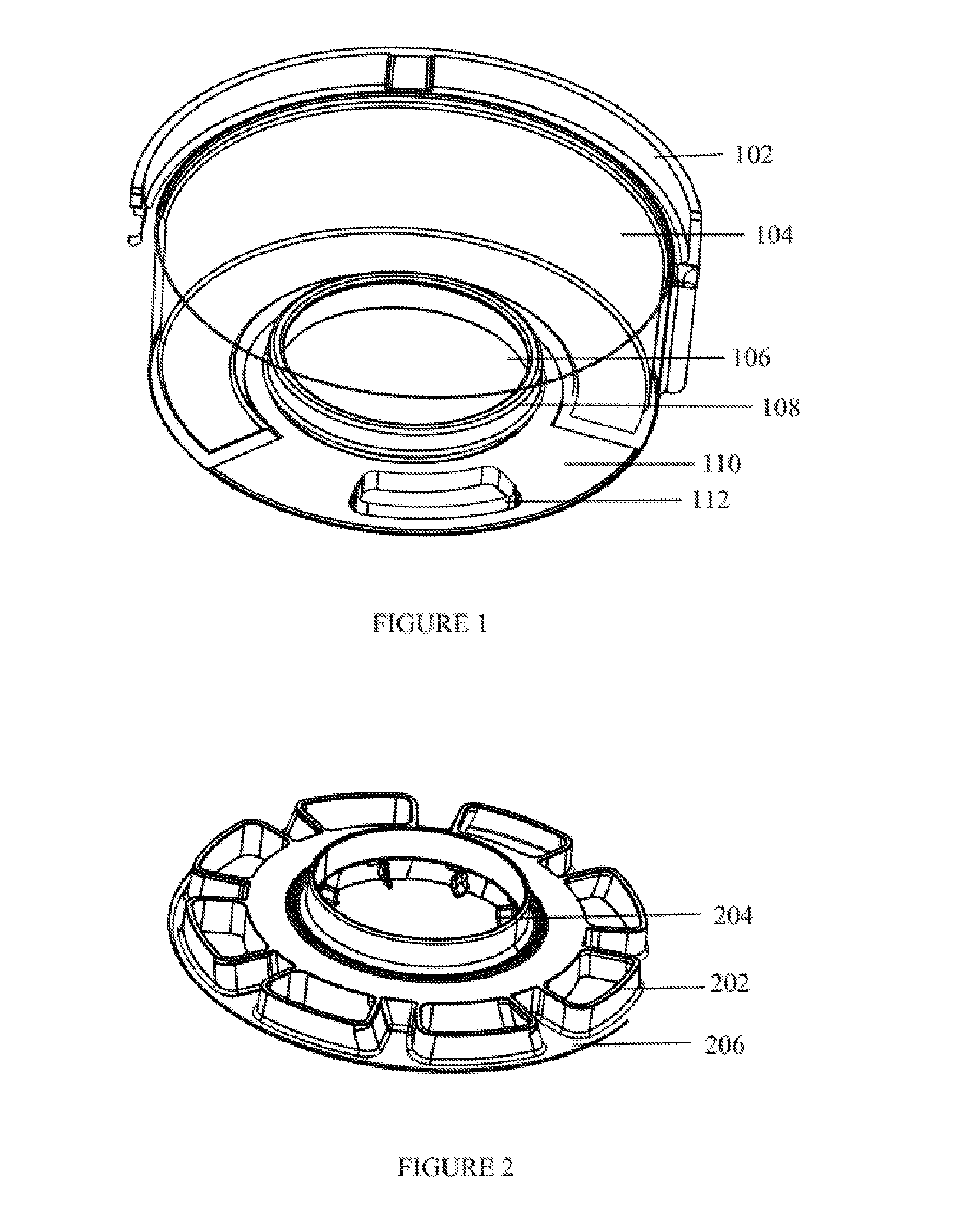

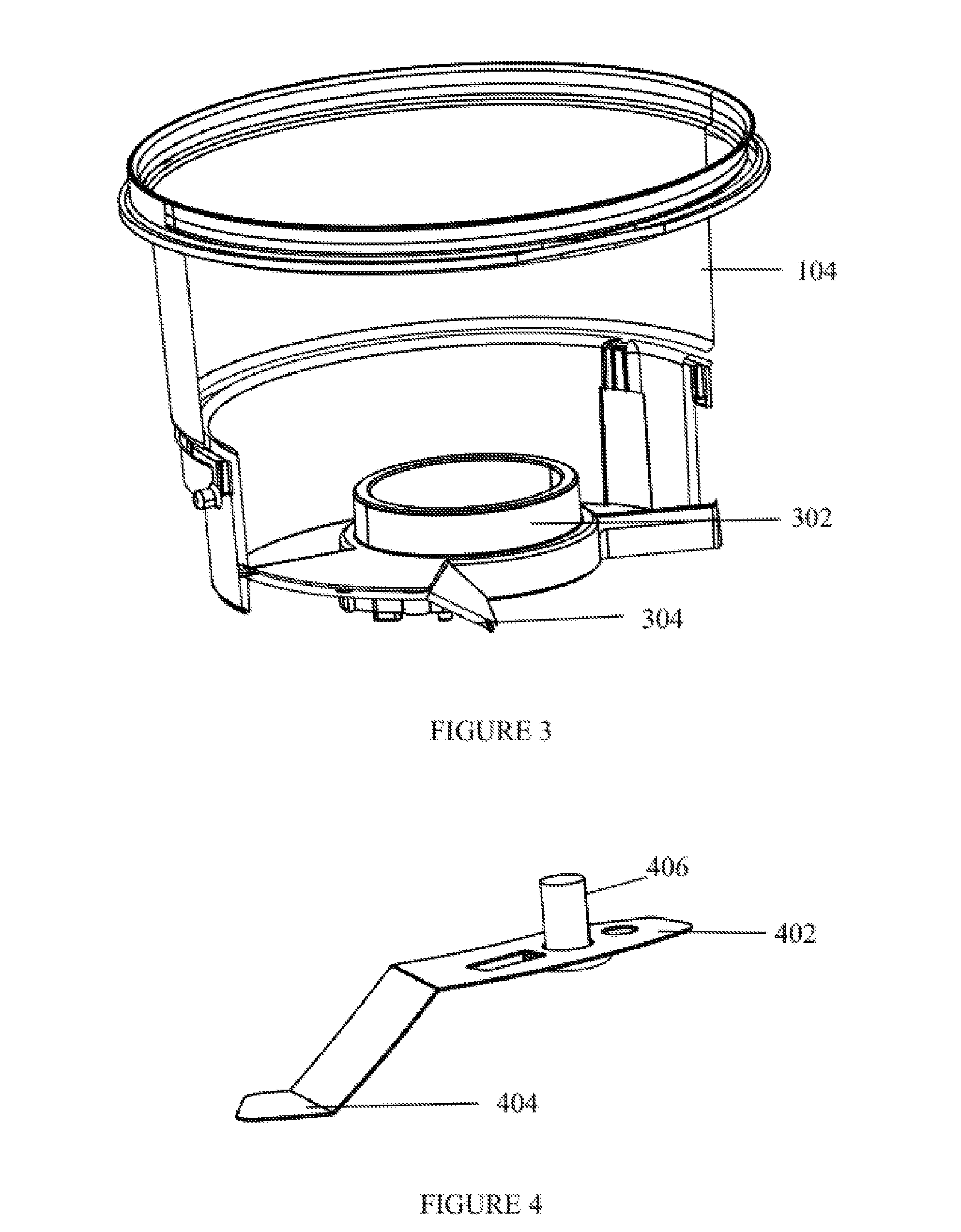

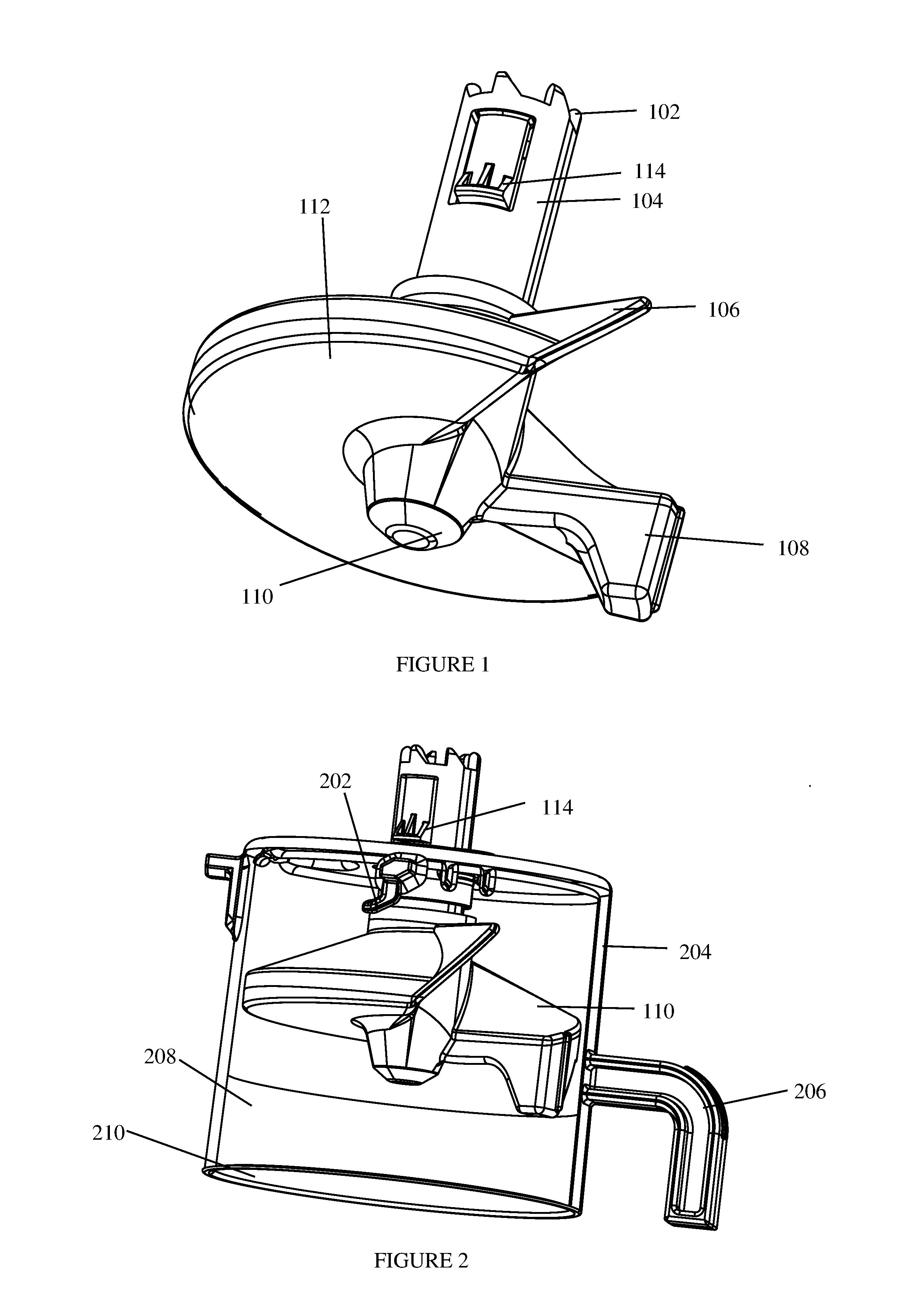

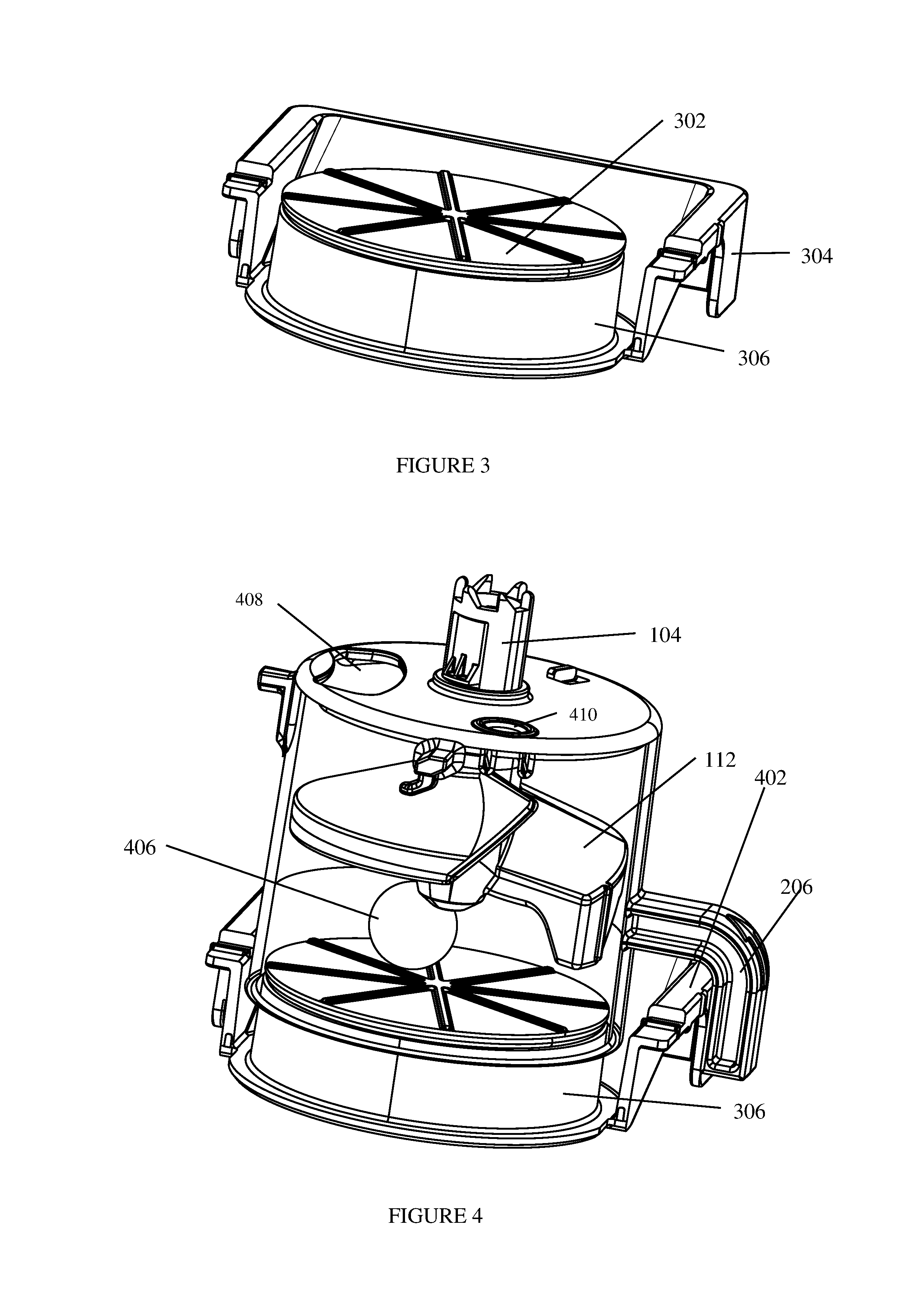

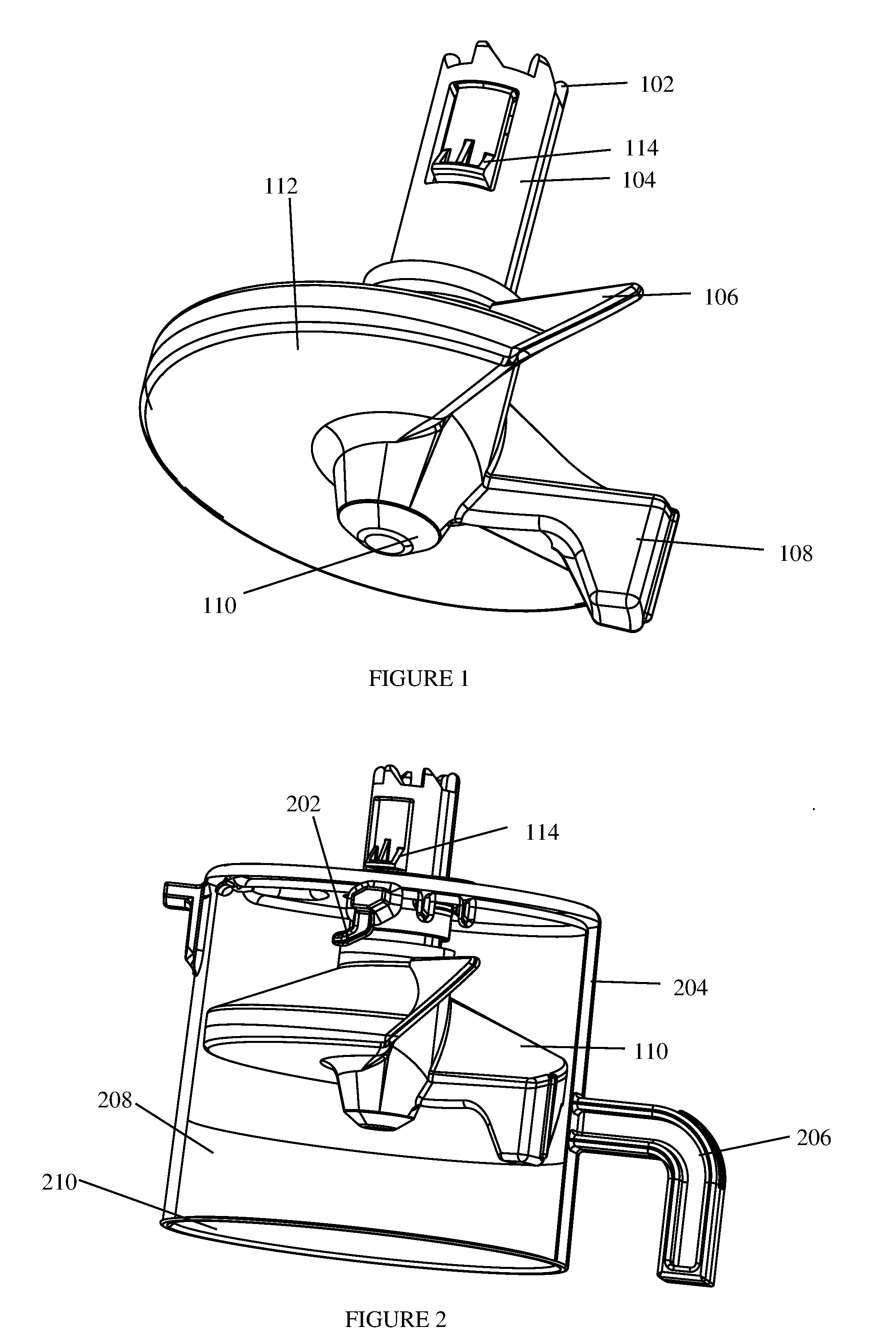

Dry flour dispensing apparatus and using the same for a food preparation appliance

ActiveUS20150181894A1Powdered material dispensingMixing/kneading structural elementsEngineeringFood preparation

The instant disclosure presents a technological advancement of the flour dispensing mechanism for a food preparation appliance. The flour dispensing mechanism comprises a dry flour container, a blade assembly and a compartment wheel. The blade assembly comprises at least one packer and a blade. The dry flour container contains a knocker. The compartment wheel comprises a plurality of compartments as cubes. The gear box and motor estimate the quantity of the flour being dispensed using a software. The software also enables to estimate the level of dry flour in the dry flour container.

Owner:ZIMPLISTIC

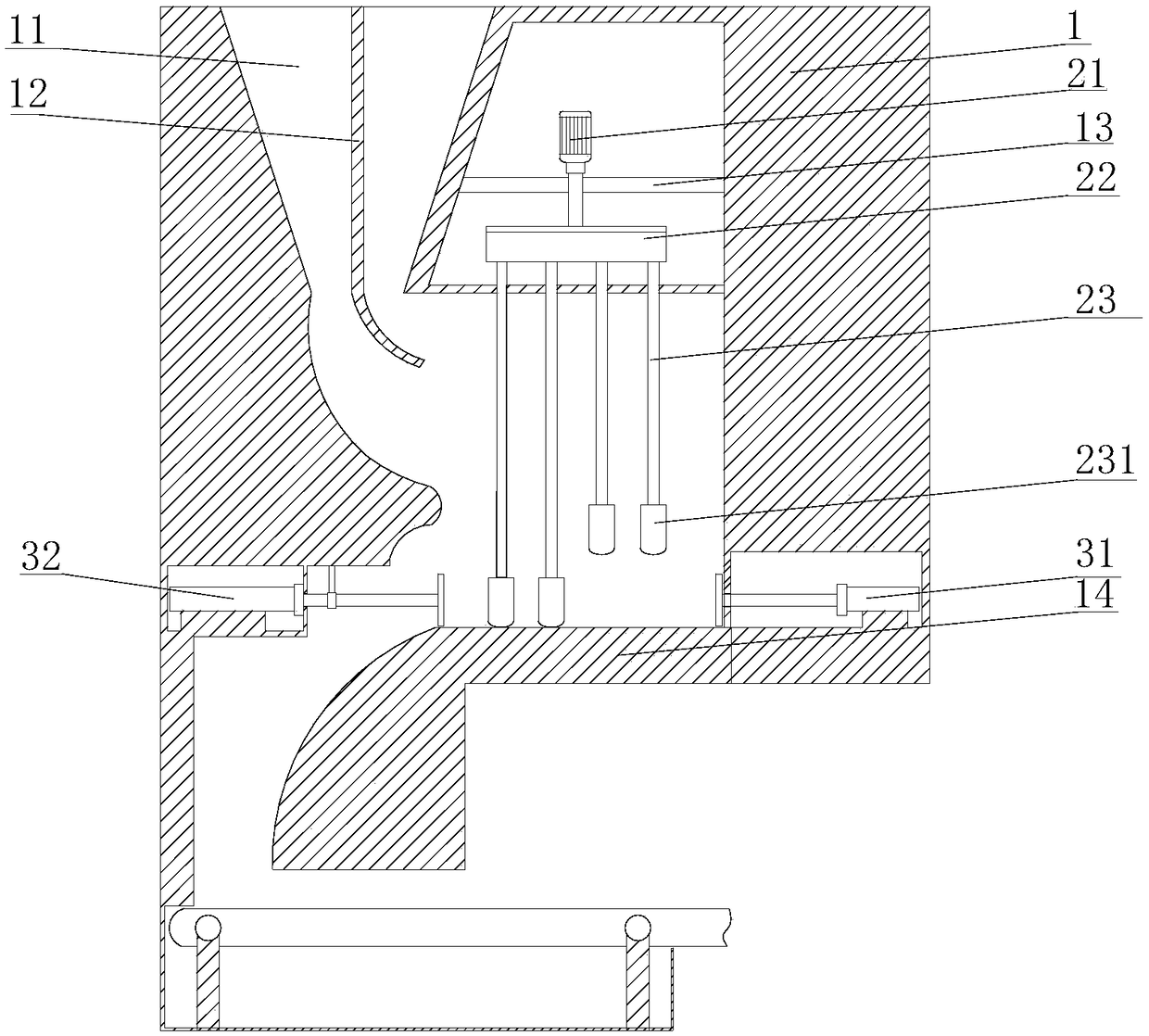

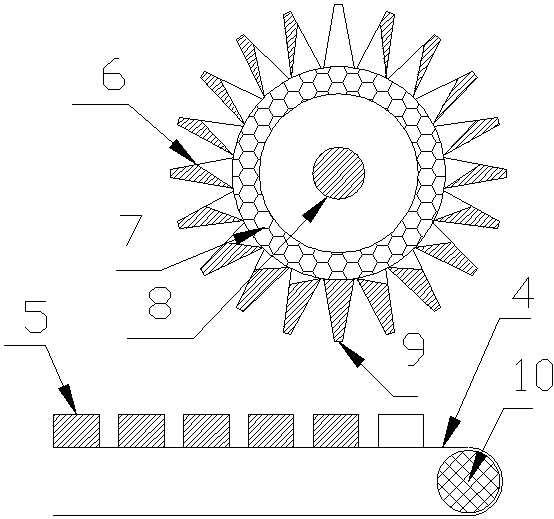

Full-intelligent-control 360-degree bionic rubbing and kneading technique

ActiveCN107509757AKeep healthyPremium tasteMixing/kneading structural elementsDough mixing/kneading methodsEngineeringIntelligent control

The invention discloses a full-intelligent-control 360-degree bionic rubbing and kneading technique, namely an intelligent machine integrated with mechanical automation, process standardization and control digitization. The intelligent machine is utilized for kneading dough, so that the labor and the time are saved, the cost is lowered, and the food health is effectively guaranteed; a traditional dough kneading process is reduced by virtue of bionic mechanical arms, so that the high-quality taste of traditional noodles is guaranteed; the noodles with three tastes of softness, chewiness and glutinousness are successfully produced by virtue of an intelligent control system; and a driving mechanism is connected with a kneading cavity assembly for driving the kneading cavity assembly to rotate, multiple bionic rubbing and kneading mechanisms are distributed around the kneading cavity assembly and are fixedly arranged on a stander, power output ends of the bionic rubbing and kneading mechanisms are in contact with the kneading cavity assembly so as to realize bionic rubbing and kneading actions, a control system is arranged at the stander and can be used for controlling the driving mechanism and the kneading cavity assembly to cooperatively work so as to realize 360-degree bionic rubbing and kneading.

Owner:STATE GRID CORP OF CHINA +1

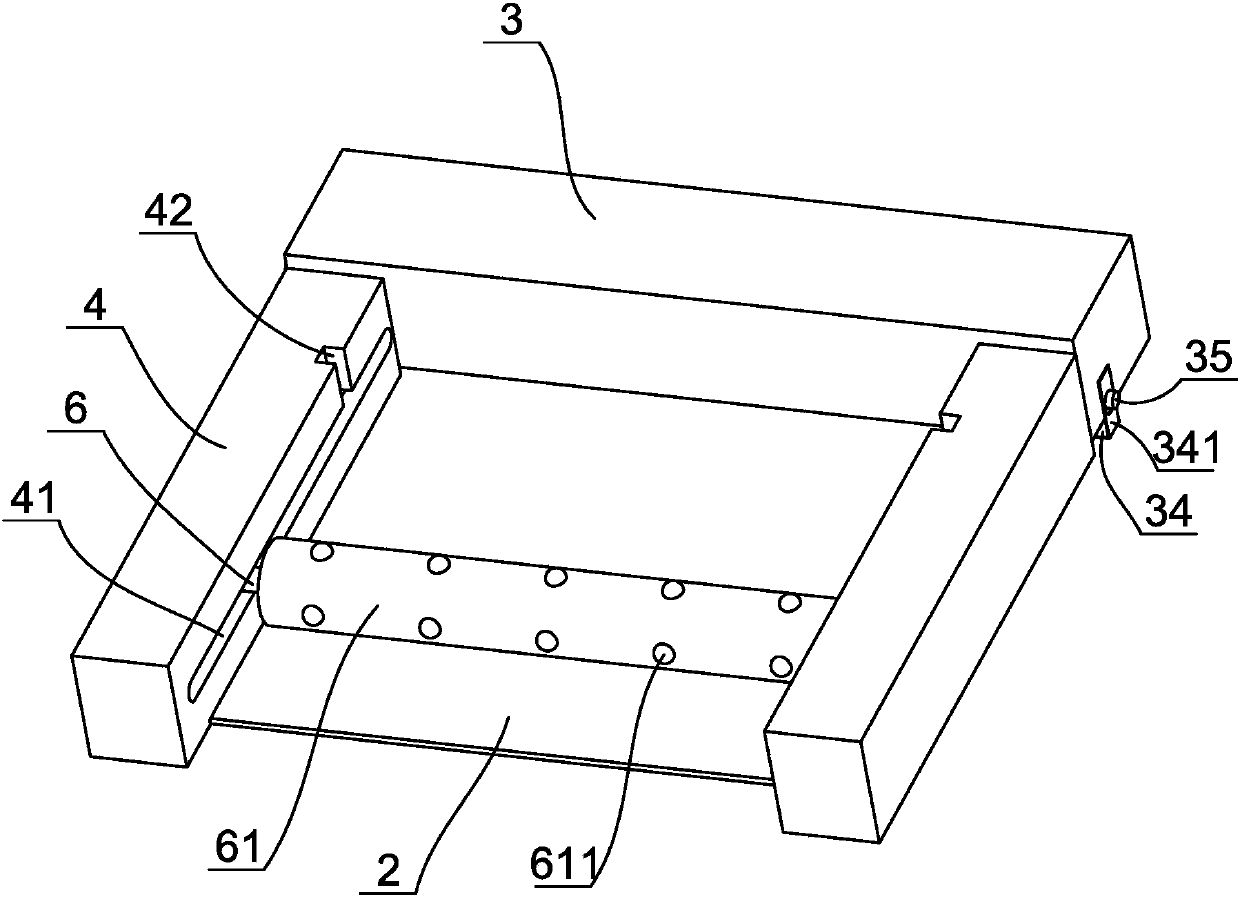

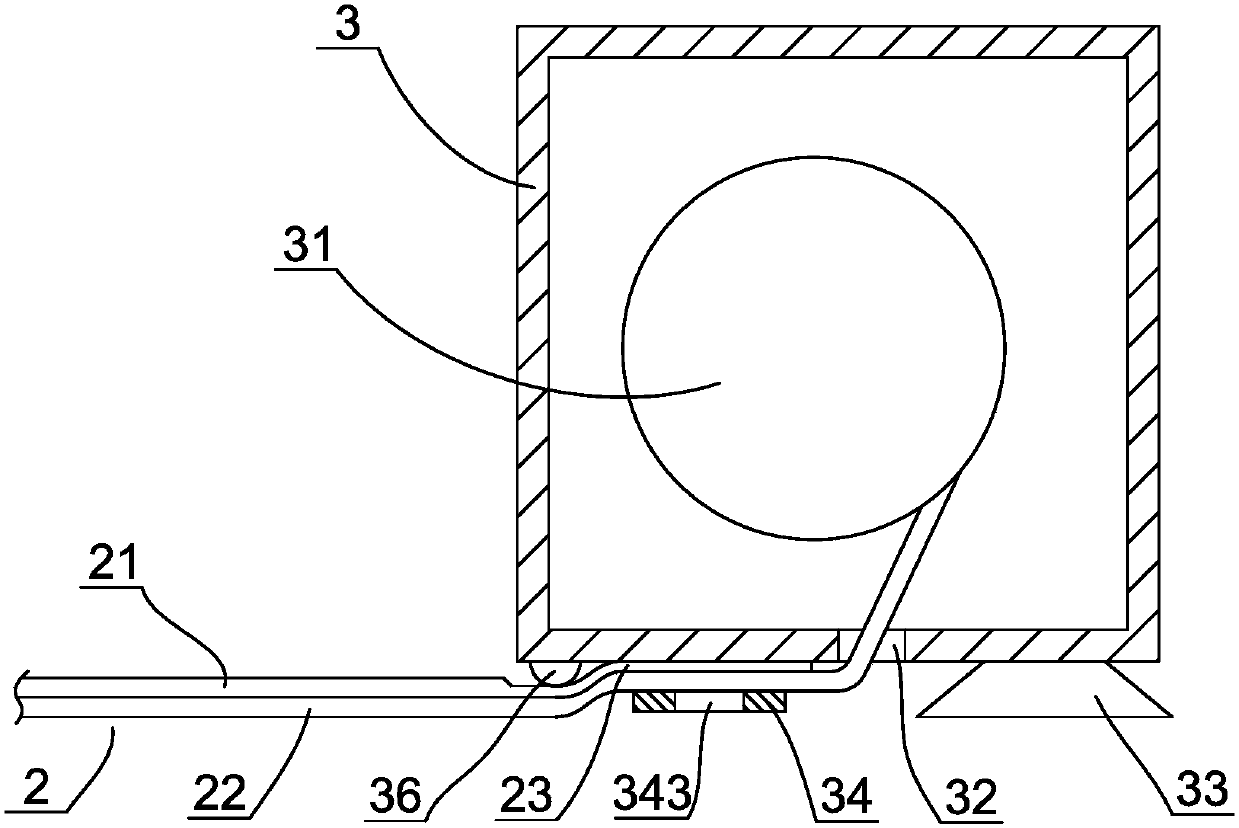

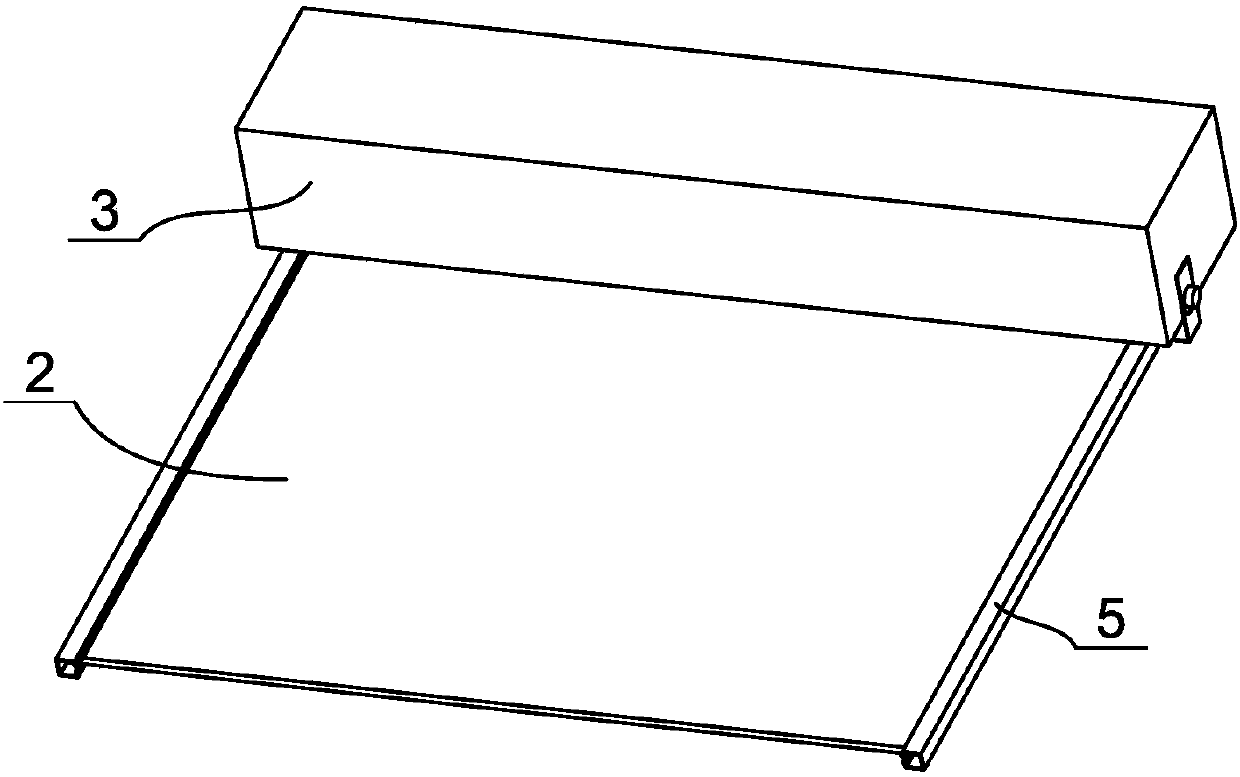

Automatic bread maker, ingredient box and bread making method

ActiveUS20160360760A1Save preparation timeMeet needsDough/pre-mixesBaking vesselsCooking & bakingAdditive ingredient

A method of making bread uses an automatic bread maker and an ingredient box. The method includes: put the bread ingredient with flour and baking powder according to proper formula into the accommodating room of the ingredient box and packaged; then place the ingredient box faced down in the hanging rack above the baking pan inside the automatic bread maker, operate the bread maker to make the sawtooth blade of the hanging rack pierced the film of the ingredient box and the bread ingredient inside fell down into the baking pan, then water the baking pan; close the housing of the automatic bread maker and turn on the baking pan, the bread ingredient is processed with working dough of mixing, stirring and kneading; get the baking pan out, and remove the bread of baked and shaped.

Owner:TSANN KUEN ZHANGZHOU ENTERPRISE CO LTD

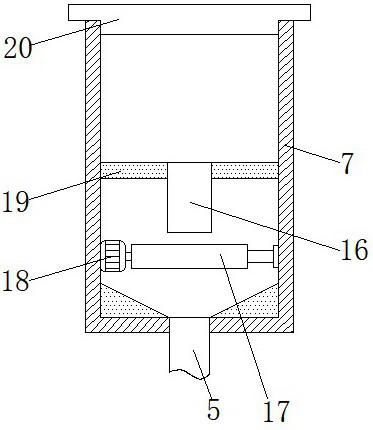

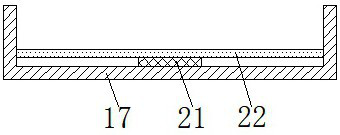

Dough kneading device and dough kneading method

ActiveCN107691546AAvoid bloatingPrevent leakageMixing/kneading structural elementsMixing/kneading with rollersFermentationMechanical engineering

The invention discloses a dough kneading device and a dough kneading method. The dough kneading device comprises a dough pressing roll, a sheet-shaped bag body composed of an upper gasket and a lowergasket, and a U-shaped frame composed of a receiving box body and pressure strips; sealing clamps are arranged on two sides of the sheet-shaped bag body; a winding roll is arranged in the receiving box body; the bottom surface of the receiving box body is provided with a strip opening, an elastic sealing strip and a vacuum sucker; the front side edge of the lower gasket is connected with the winding roll; the dough pressing roll comprises a rolling shaft, a dough kneading roller which can sleeve the rolling shaft and a dough rolling roller; a plurality of hemispherical bulges are arranged on the circumferential surface of the dough kneading roller; and two ends of the rolling shaft are connected with the pressure strips on the left side and the right side respectively in a sliding manner.By adopting the dough kneading device, during dough kneading, the dough kneading roller rolls dry and wet raw materials in the sheet-shaped bag body and enables the rolled dry and wet raw materials toform a dough blank, then the sheet-shaped bag body is flattened, dough kneading is finished on the upper gasket and the lower gasket, and then fermentation and exhaust of a dough are finished in thesealed sheet-shaped bag body to start preparation of wheaten foods. The dough kneading device provided by the invention can effectively improve the preparation efficiency of the wheaten foods and is convenient in storage at the same time.

Owner:宁波北仑思行硅胶制品有限公司

Automatic bread maker, ingredient box and bread making method

ActiveUS20160360761A1Save preparation timeMeet needsDough/pre-mixesBaking vesselsCooking & bakingAdditive ingredient

A method of making bread uses an automatic bread maker and an ingredient box. The method includes: put the bread ingredient with flour and baking powder according to proper formula into the accommodating room of the ingredient box and packaged; then place the ingredient box faced down in the hanging rack above the baking pan inside the automatic bread maker, operate the bread maker to make the sawtooth blade of the hanging rack pierced the film of the ingredient box and the bread ingredient inside fell down into the baking pan, then water the baking pan; close the housing of the automatic bread maker and turn on the baking pan, the bread ingredient is processed with working dough of mixing, stirring and kneading; get the baking pan out, and remove the bread of baked and shaped.

Owner:TSANN KUEN ZHANGZHOU ENTERPRISE CO LTD

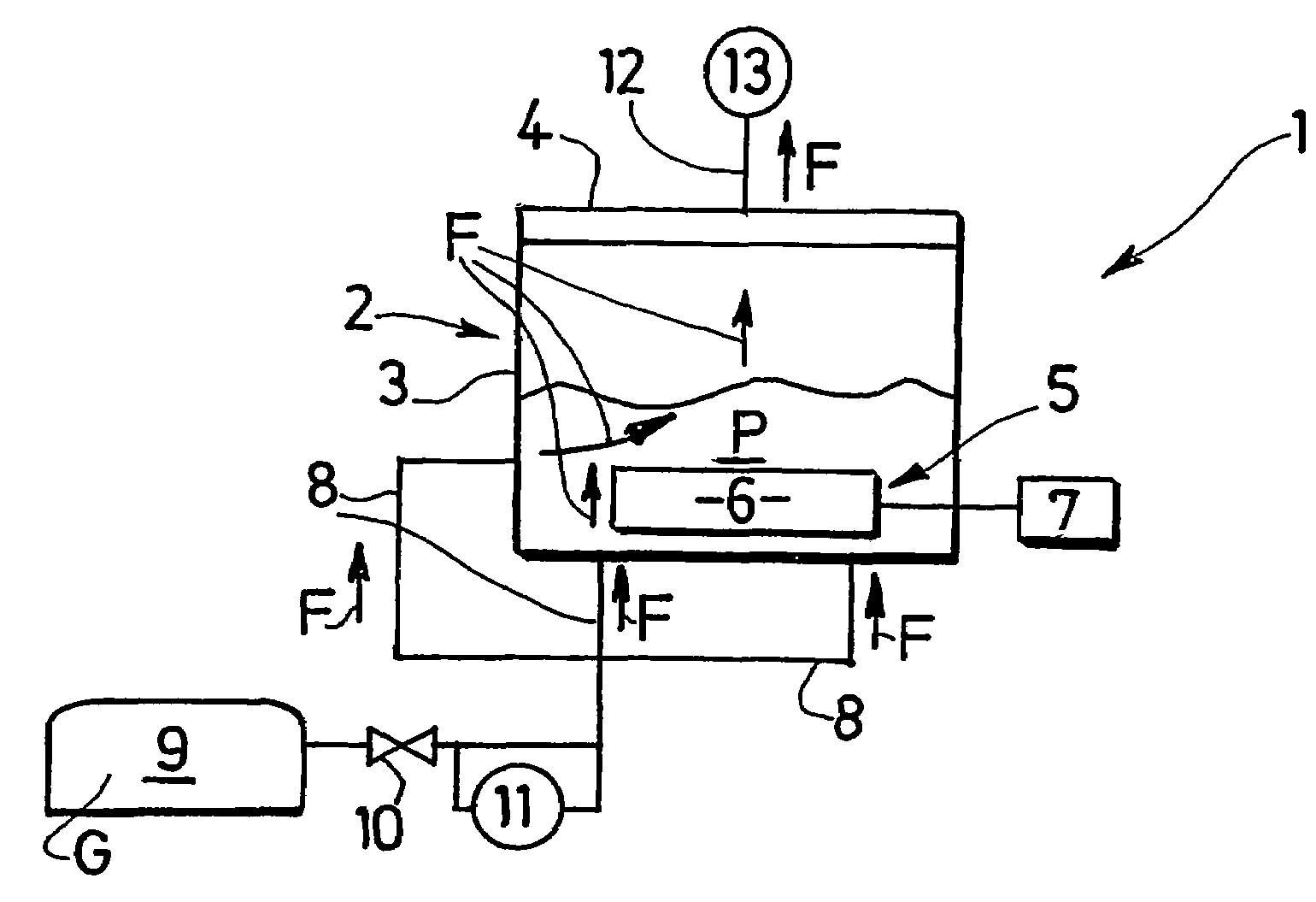

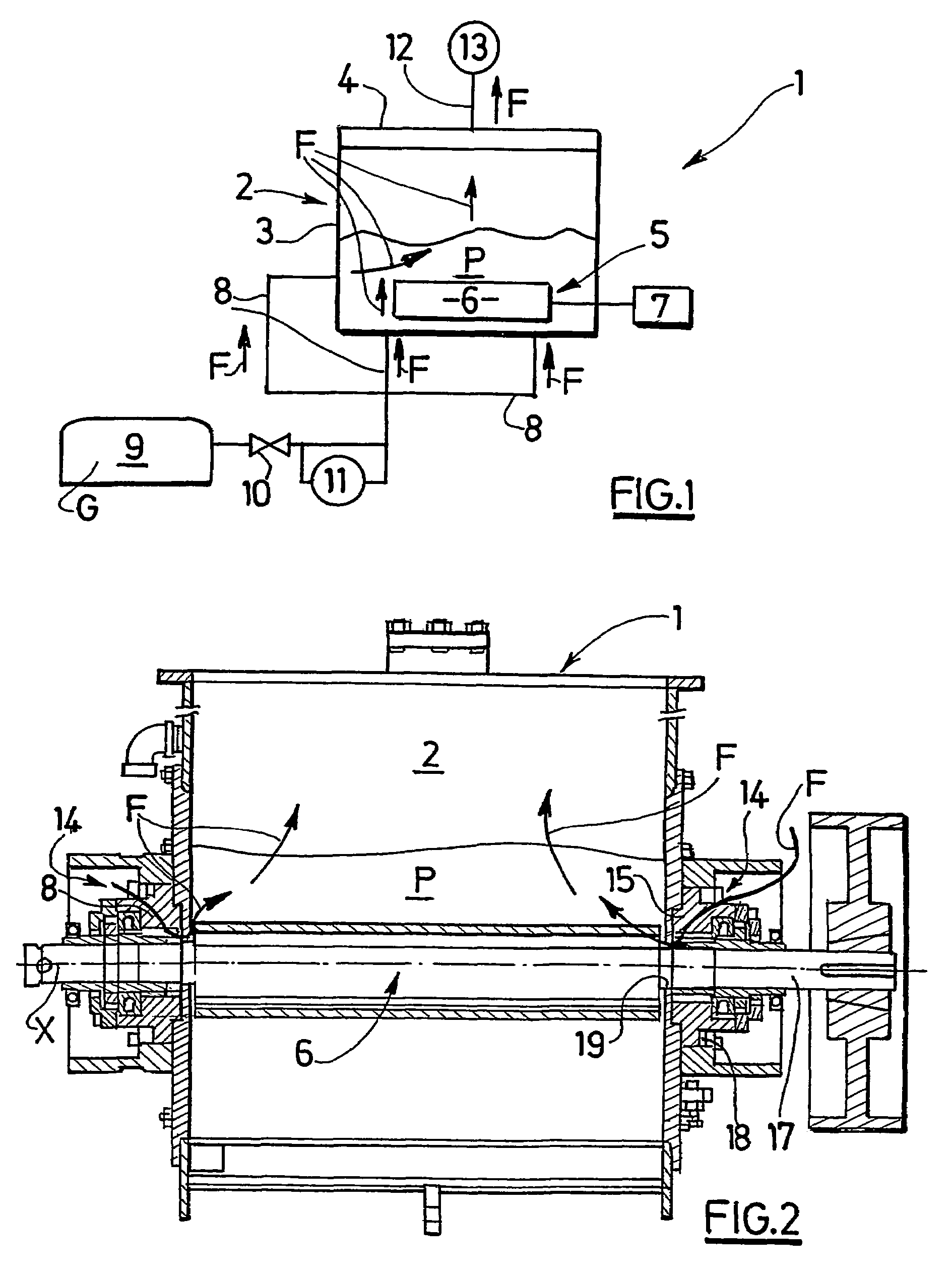

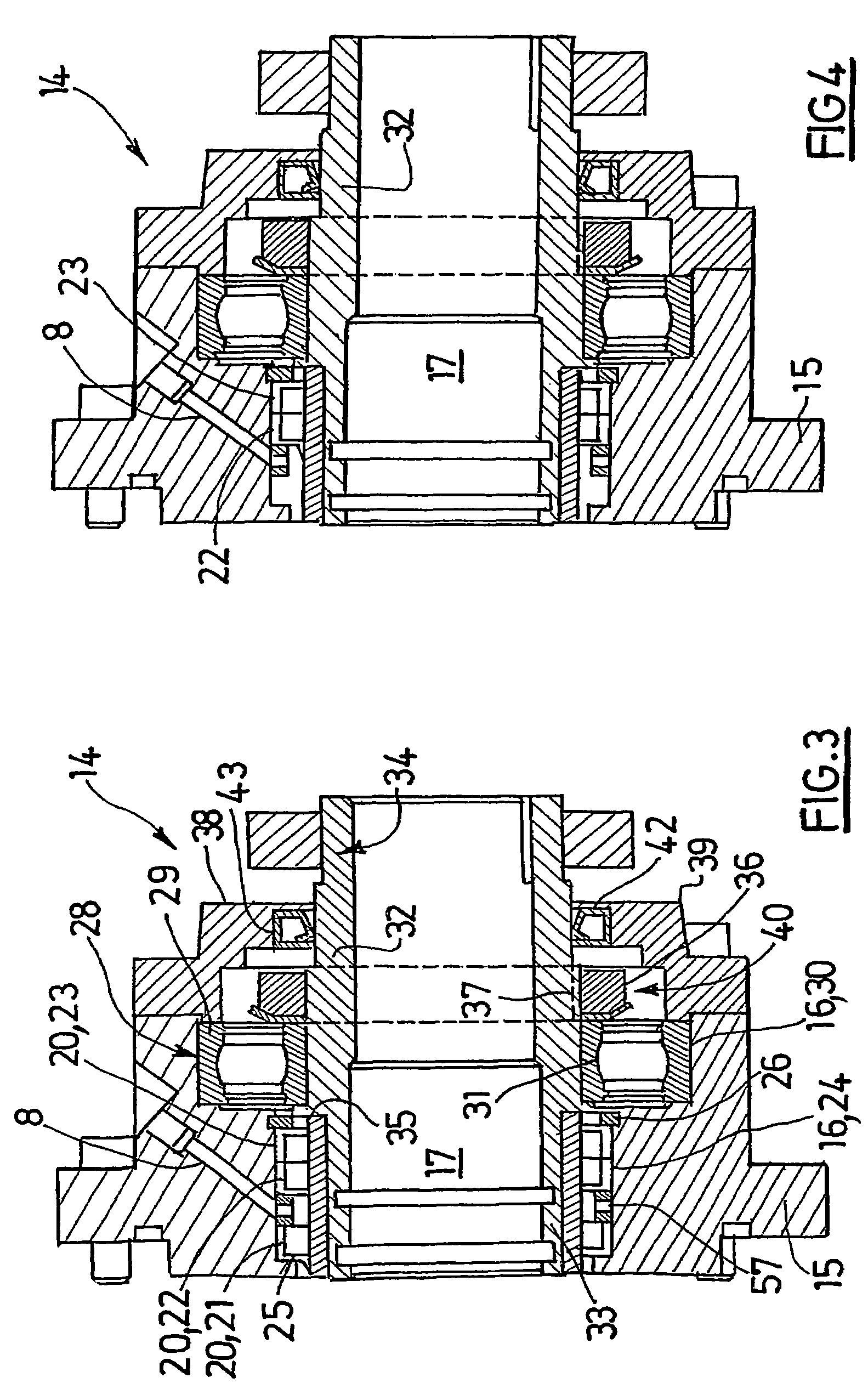

Vacuum kneading method with the introduction of oxygen and the device used to carry out said method

InactiveUS7514112B2Easy accessReduced dimensionDough treatmentTransportation and packagingEngineeringProduct gas

The invention relates to a method of kneading dough in order to produce bread or similar products. According to the invention, the dough ingredients are introduced into a chamber and all of said ingredients are subsequently kneaded. The inventive method is characterised in that it comprises: a vacuum phase during which a vacuum is applied in the chamber; and one or more phases involving the introduction of gas, during which a gas containing oxygen is introduced into the chamber. The aforementioned vacuum phase continues more or less throughout the entire kneading phase, with at least one part of each introduction phase taking place simultaneously with the kneading phase. The invention also relates to a device that is used to carry out said method.

Owner:VMI INC

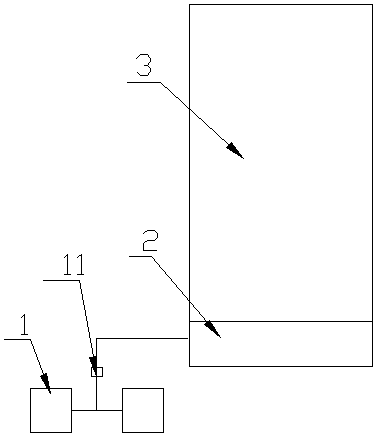

Method and device on consumable material as well as corresponding material

PendingCN110341179AReduce overheadAvoid damageBioreactor/fermenter combinationsAdditive manufacturing apparatusCivil engineering

The invention discloses a method and device on a consumable material as well as a corresponding material. According to the operation conducted on the going or the operation conducted in a plan, the requirement for the consumable material of the operation is obtained, measures are taken before the consumable material is used up, and the consumable material is prevented from being completely used upwithout human or other machine intervention or monitoring. In some cases, the device can reminds when the work in the plan is not started, in other cases, the device can reminds in an ongoing work process. By adopting the scheme of the method and / or the device, the personnel cannot need to monitor all the time, the operation can be carried out within the regular duty time of the personnel, the work can be carried out continuously when the personnel are not in the monitoring time, so that the efficiency is maximized, and the expenditure of manpower resources and damage of other tools or machines are reduced.

Owner:殷向明 +1

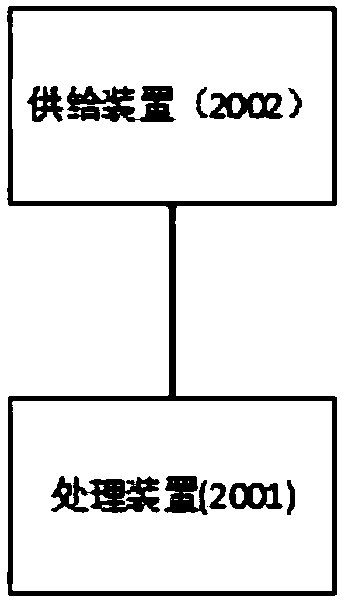

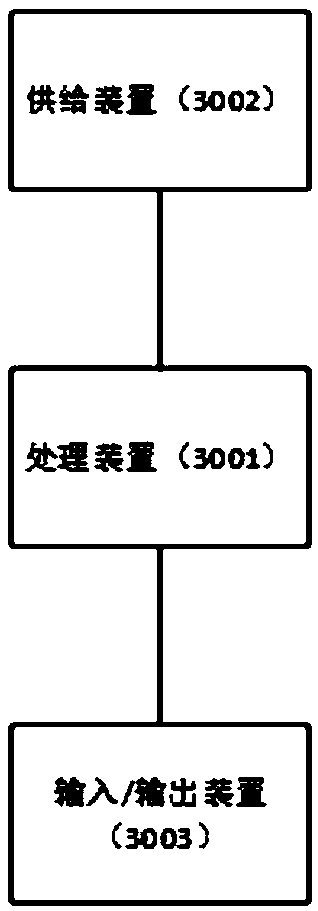

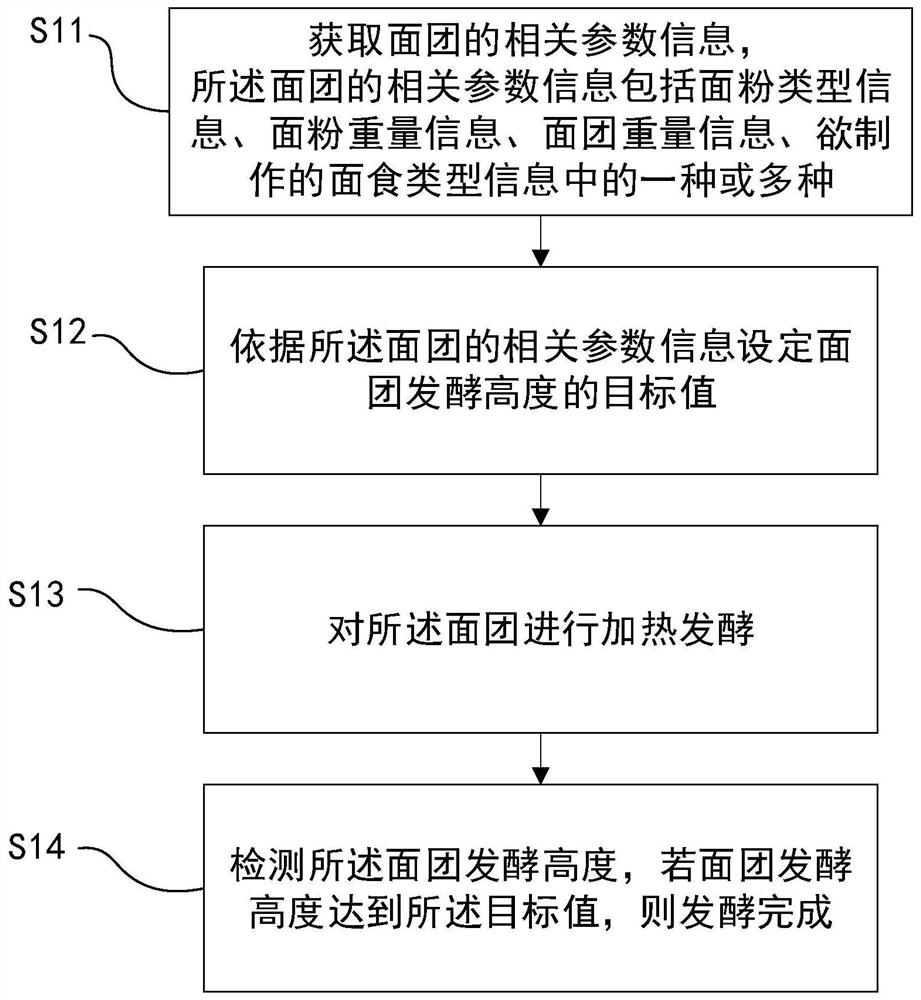

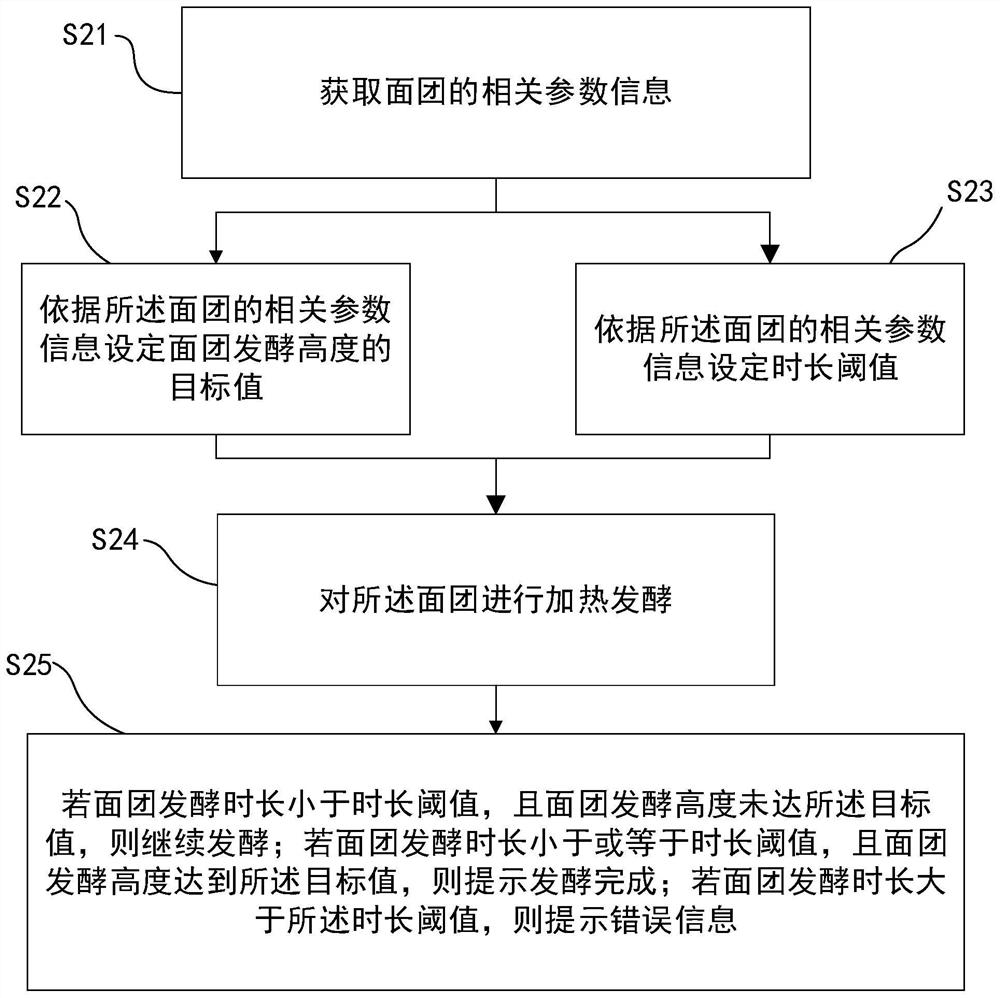

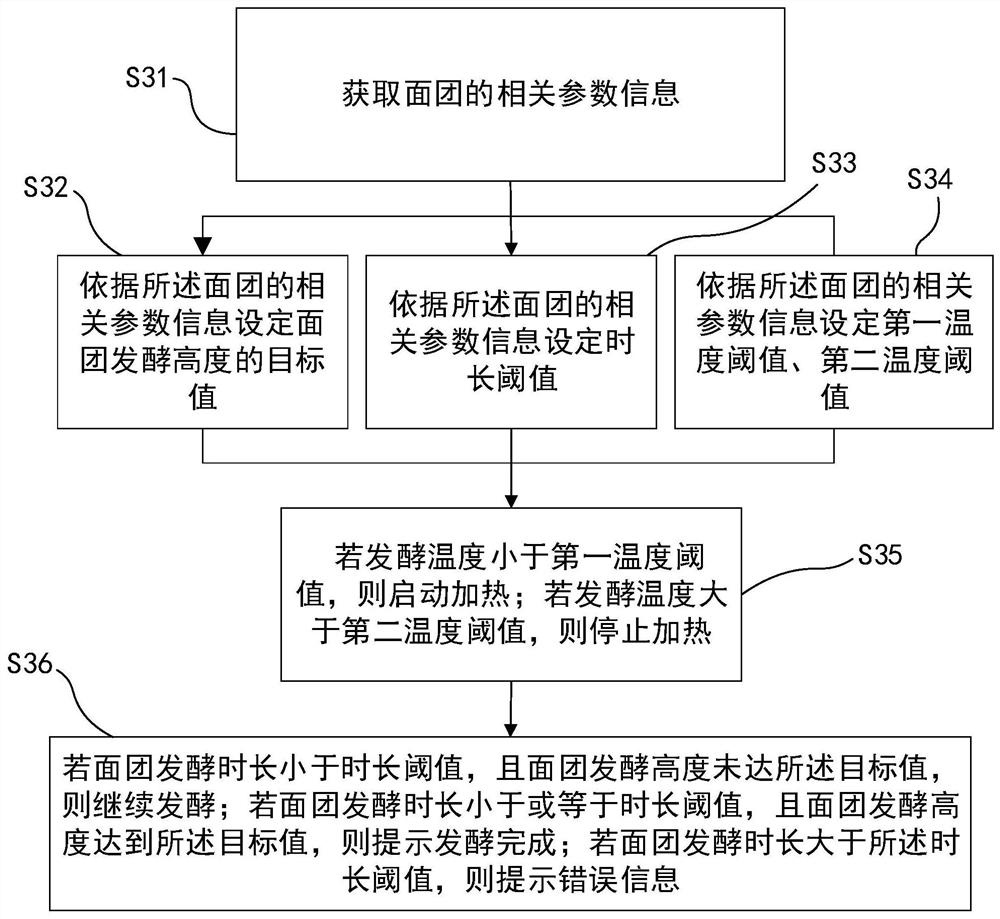

Dough fermentation control method, dough kneading control method and dough kneading machine

ActiveCN111937935AMixing/kneading structural elementsUsing subsonic/sonic/ultrasonic vibration meansBiotechnologyBiochemical engineering

The invention provides a dough fermentation control method, a dough kneading control method and a dough kneading machine, wherein the dough fermentation control method comprises the following steps of: obtaining relevant parameter information of dough, wherein the relevant parameter information of the dough comprises one or more of flour type information, flour weight information, dough weight information and type information of a cooked wheaten food to be made; setting a target value of the fermentation height of the dough according to the relevant parameter information of the dough; heatingand fermenting the dough; and detecting the fermentation height of the dough, and, if the fermentation height of the dough reaches the target value, completing the fermentation. The dough fermentationcontrol method provided by the invention can be suitable for controlling the fermentation process under the conditions of different flour amounts, different flour types, different cooked wheaten foods to be made and the like; the fermentation effect can be improved; and the fermentation failure probability is reduced. The dough kneading control method provided by the invention comprises the doughfermentation control method. The dough kneading machine provided by the invention can execute the dough kneading control method.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

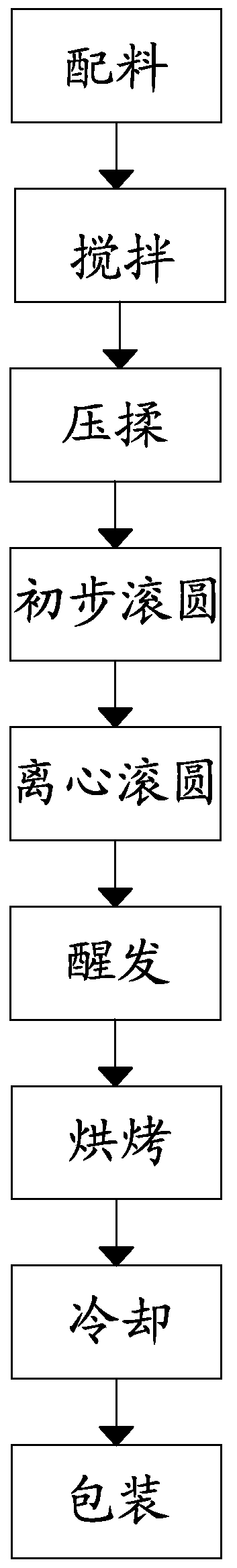

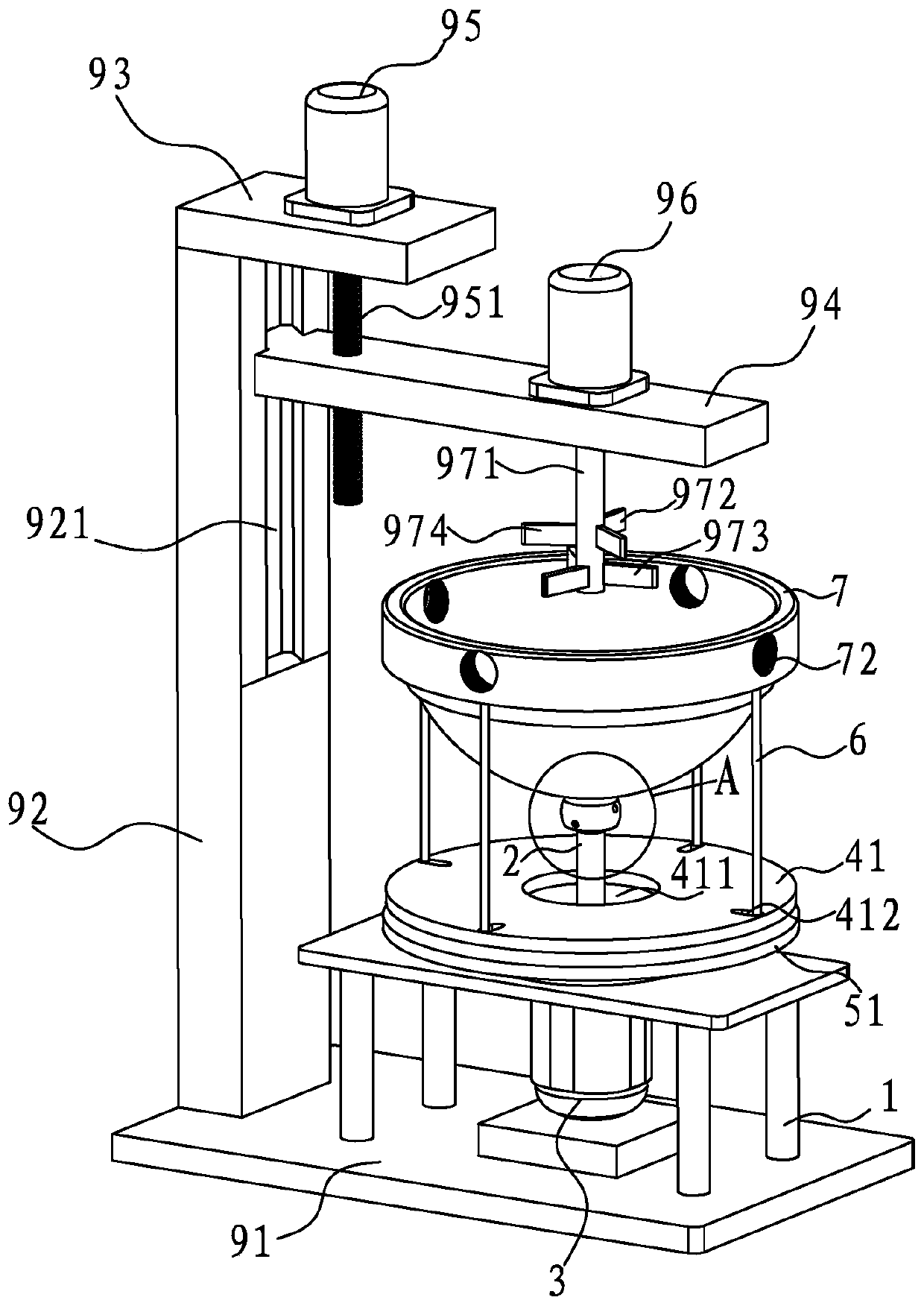

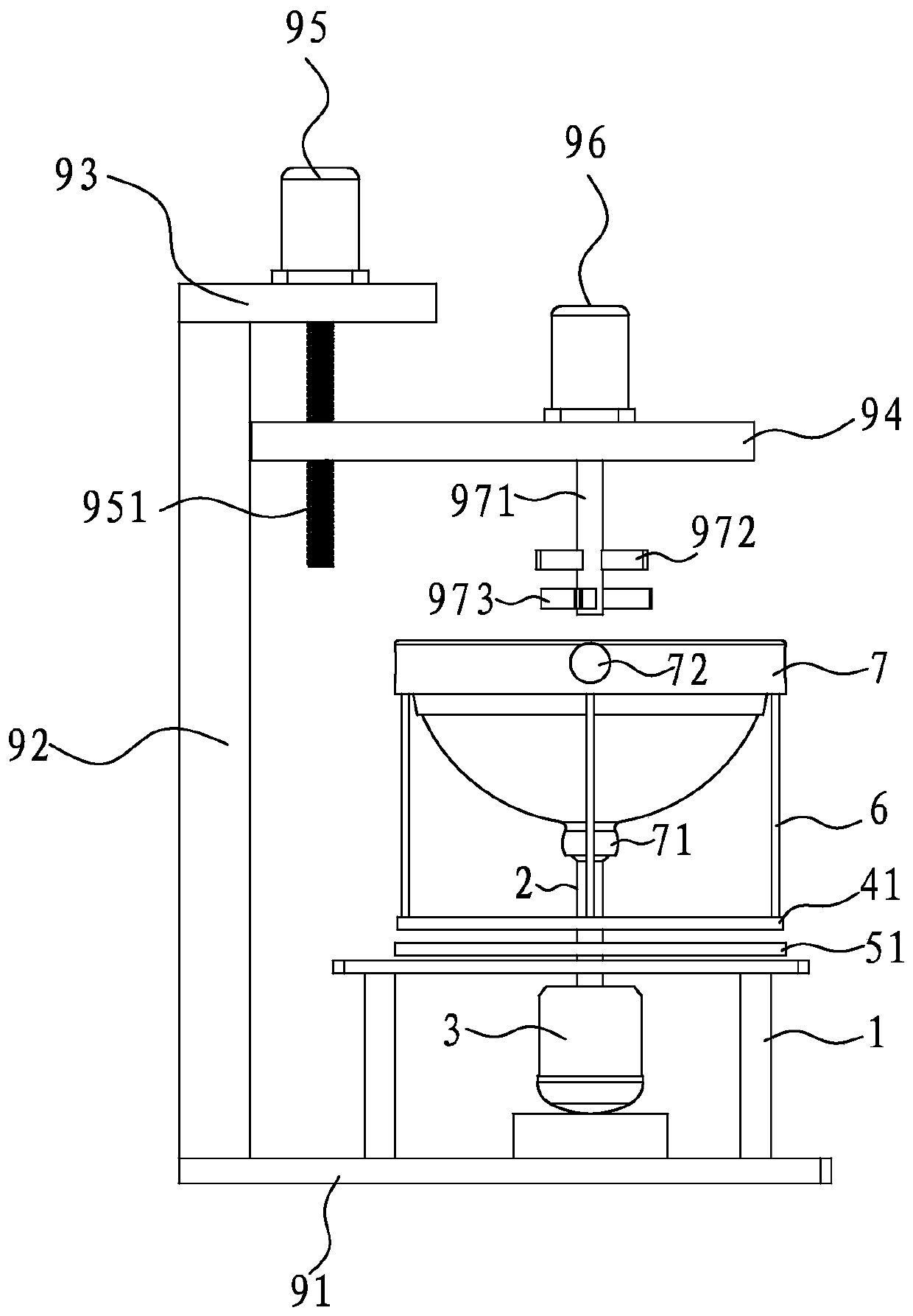

Production method for fermented bread

ActiveCN111226999AReduce pollutionImprove round efficiencyMixing/kneading with vertically-mounted toolsDough mixing/kneading methodsCircular discFood science

The invention discloses a production method for fermented bread. The production method comprises the following steps: material proportioning, stirring, press-kneading, preliminary rounding, centrifugal rounding, dough recovery, baking, cooling and packaging, wherein the steps of stirring, press-kneading, preliminary rounding and centrifugal rounding are completed through a stirring rounding device; and the stirring rounding device comprises a rounding base, a first rotary disk, a supporting shaft, a connecting dough stick and a hemispherical tray, wherein the first rotary disk is arranged on the rounding base, a first through hole, which is used for enabling the supporting shaft to pass through, is formed in the middle of the first rotary disk, a connecting recess is arranged at the bottomof the hemispherical tray, one end of the supporting shaft is a spherical body end, the spherical body end is in matched nested connection with the connecting recess, the other end of the supportingshaft penetrates through the first through hole and is connected with the rounding base, and the two ends of the connecting dough stick are separately connected with the hemispherical tray and the first rotary disk. Dough is rounded through the stirring rounding device, so that pollution to the dough is reduced while the efficiency of rounding of the dough is increased.

Owner:福建麦香园食品有限公司

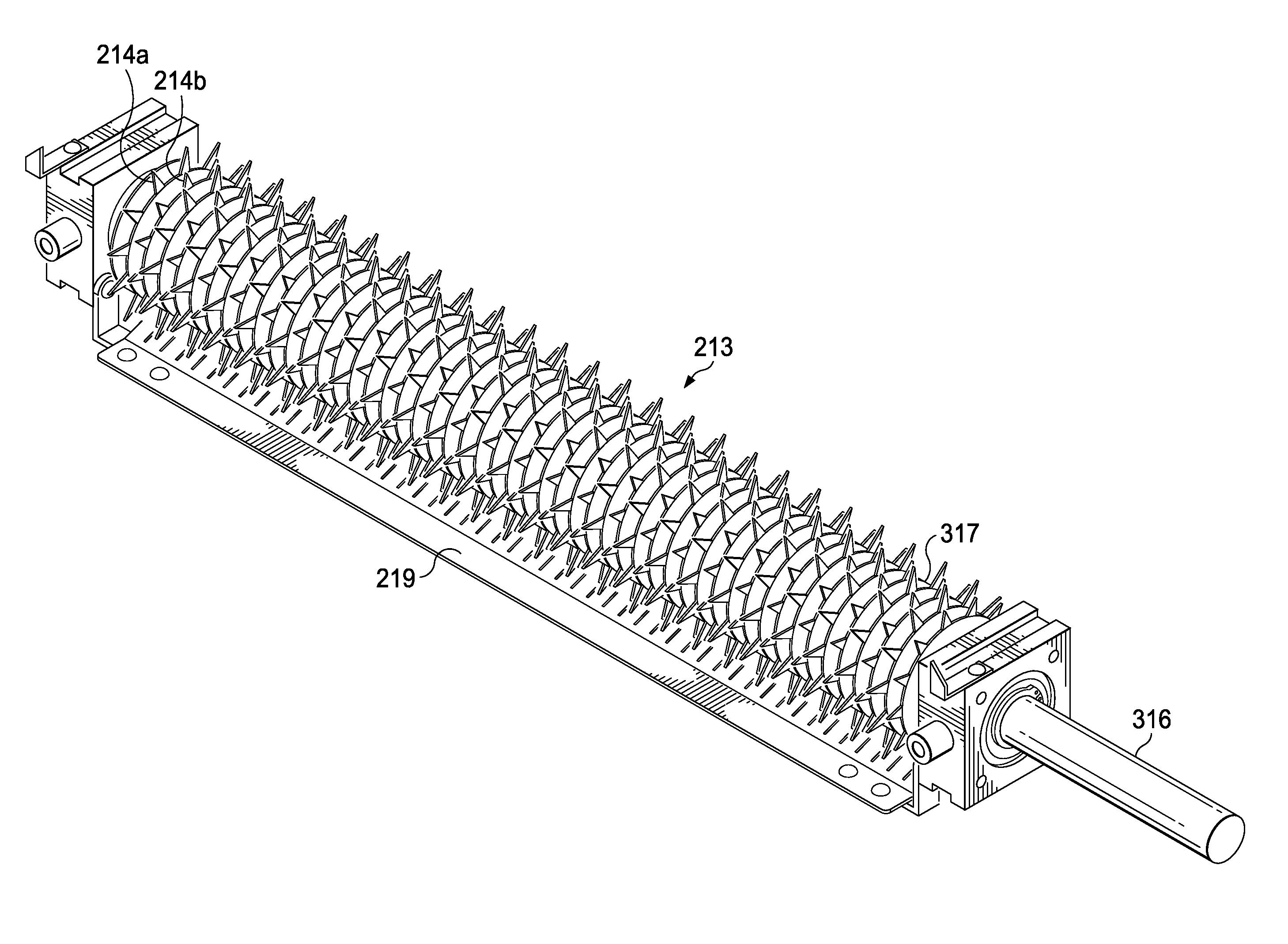

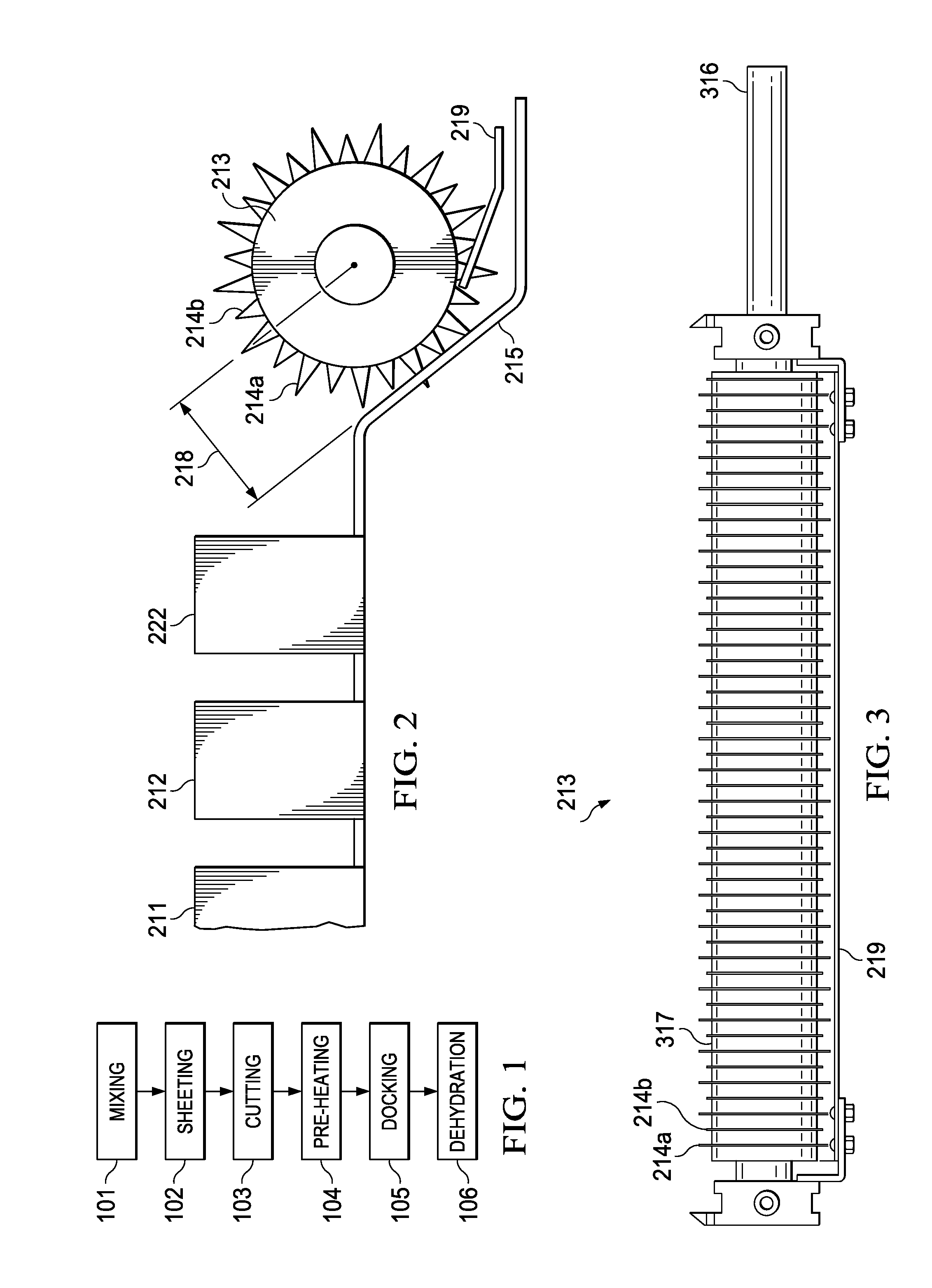

System and apparatus for controlling blistering

ActiveUS9554580B2Capping machinery safety/controlFood mechanical treatmentAdditive ingredientEngineering

A system and method for controlling blisters. The method begins by mixing the ingredients to form a dough with a moisture content between about 35% and 60%. The dough is sheeted and cut. Thereafter, the dough is pre-heated to reduce the moisture content to between about 10% and about 45%. The preforms are then docked and dehydrated. The docking system, in one embodiment, has a backing plate and a docking device with at least two docking pins of varying lengths. The docking device is adjustable relative to the backing plate. The system also has a removing plate which removes preforms from the docking pins.

Owner:FRITO LAY NORTH AMERICA INC

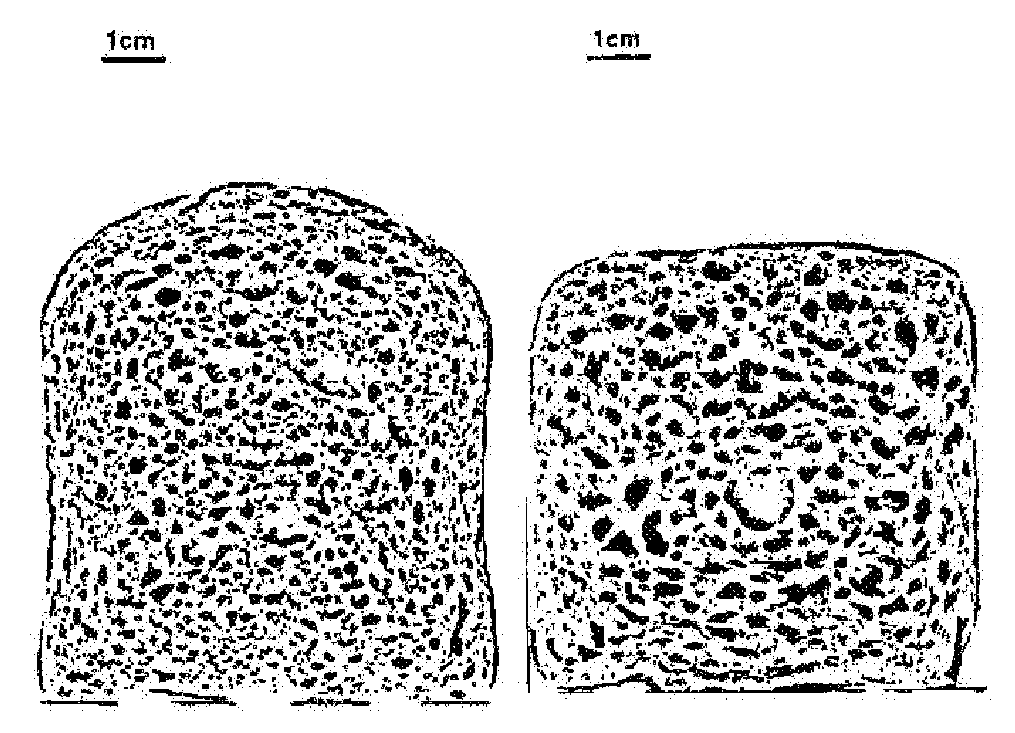

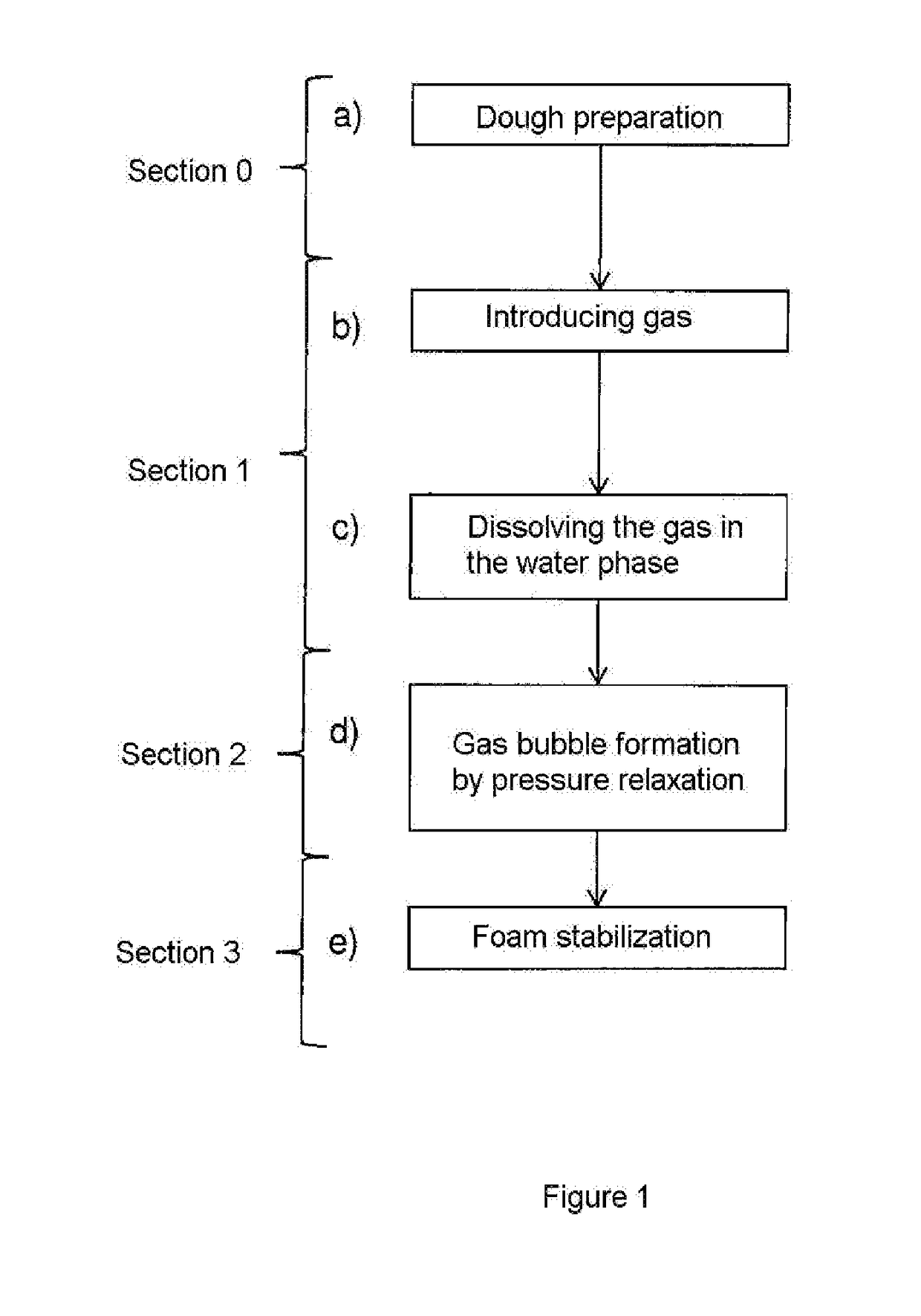

Foamed, dough-based food and apparatus and method for production thereof and use of the apparatus

ActiveUS20180317501A1Degradation for retention propertyLittle wearMixing/kneading with horizontally-mounted toolsPre-baking dough treatmentMethods of productionGas bubble

A dough-based food product, an apparatus and method for production of the dough-based food product. A food product matrix to be foamed includes a proportion by weight of a starch-containing raw material and a proportion by weight of water. Gas that has been dissolved or is to be dissolved is introduced into the food product matrix to be foamed. The gas is dissolved under pressure in the food product matrix to be foamed. Gas bubbles are formed by expansion and increasing the volume with a resulting reduction in density of the dough as a result of bubble growth for formation of a foamed food product matrix of the food product to be produced. The foam is then stabilized. Gas is introduced into and dissolved in the aqueous component of the food product matrix to be foamed in a subcritical state below the critical point and at a pressure of 10 bar≤p<critical pressure of the gas.

Owner:ETH ZZURICH +1

Self-making bread method, bread machine and bread ingredient box thereof

ActiveUS20130189406A1Simplify ingredient preparationAvoid mistakesReady-for-oven doughsDough treatmentAdditive ingredientEngineering

The self-making bread method includes: weighing a certain amount of ingredients according to a bread recipe and placing them in a bread ingredient box; putting the bread ingredient box into the corresponding containing region of the top portion of the bread machine; using the jagged ring of the bottom portion of said containing region to open the thin film of the bottom portion of the bread ingredient box, so the ingredients will fall into the mixing container in the bread machine; controlling the water delivering mechanism inside the bread machine to deliver a certain amount of water into said mixing container; starting the mixing device inside the bread machine, which mixes the ingredients into an appropriate dough; turning off the mixing device; energizing the electric heating tube in the bread machine, to bake the dough inside the mixing container into bread.

Owner:TSANN KUEN ZHANGZHOU ENTERPRISE CO LTD

Batter shaking apparatus

ActiveUS8201987B2Shaking/oscillating/vibrating mixersTransportation and packagingLocking mechanismEngineering

A kitchen shaking apparatus includes a housing, a controllable oscillating actuator contained in the housing, a platform mechanically coupled to the controllable oscillating actuator, and a plurality of adjustable coacting restraining arms operably coupled to the housing. Each of the restraining arms including a vertical segment and a horizontal segment and is positioned and configured to allow the vertical segment to contact an object on the platform. A speed control is configured to control frequency of oscillation of the actuator. A timer control is configured to control duration of operation of the actuator. A locking mechanism releasably locks at least one adjustable restraining arm at a user-selectable position. A removable pad is attached to the top surface of the platform. After shaking mixed ingredients using the apparatus, the ingredients are devoid of substantial air pockets and the consistency is improved for an enhanced processed food product.

Owner:CARROLL STEPHEN

Sheeter with thickness control

ActiveUS8740602B2Reduce accidental movementChange in magnitudeConfectioneryPress rollersControl systemActuator

Owner:J C FORD

Apparatus, system and method for an adaptive kneading technology for a food preparation appliance

ActiveUS9456615B2Mixing/kneading structural elementsTransportation and packagingWater useEngineering

The present invention presents a kneading mechanism for a food preparation appliance. The kneading mechanism has a kneading container, a blade assembly and a kneading base. The kneading container has an open bottom face and the kneading base has a textured surface. An adaptive kneading technology which resides in a processor is used to form an optimal viscoelastic dough ball. Since there is variation in the gluten content and the amount of water used makes the dough ball have a viscoelastic nature this technology due to its self-learning mechanism optimizes the kneading of single dough balls using adaptive kneading technology.

Owner:ZIMPLISTIC

Method for an adaptive kneading technology for a food preparation appliance

ActiveUS20160213009A1Mixing/kneading structural elementsTransportation and packagingEngineeringSelf adaptive

Owner:ZIMPLISTIC

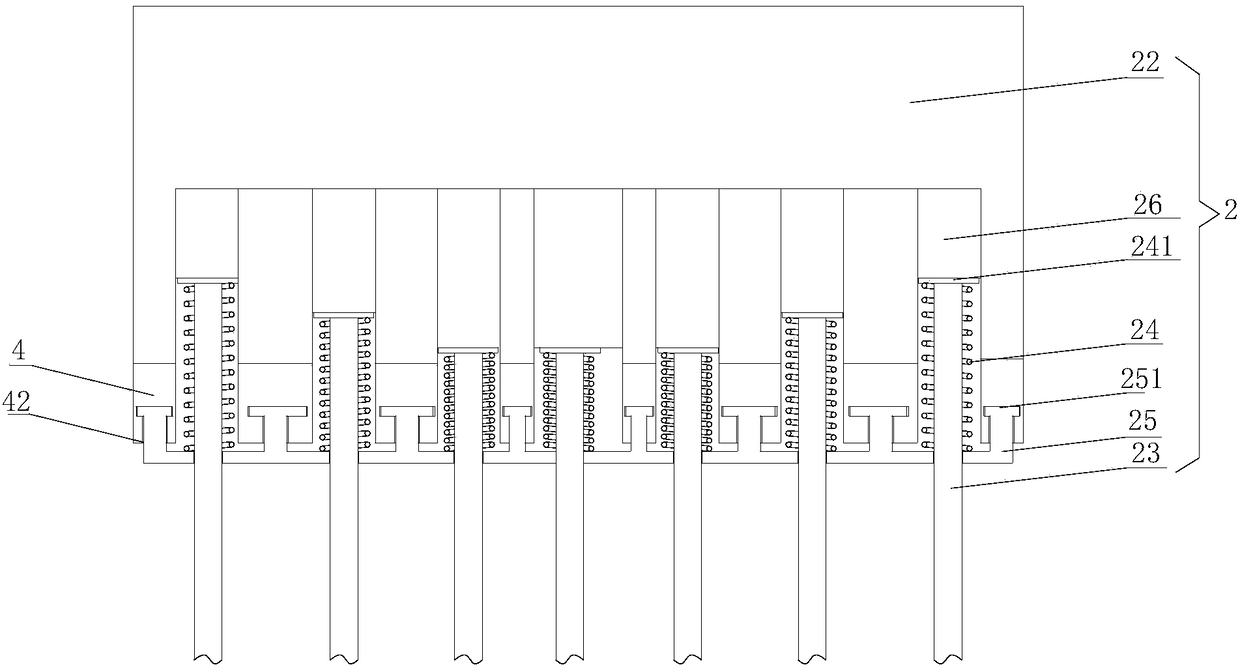

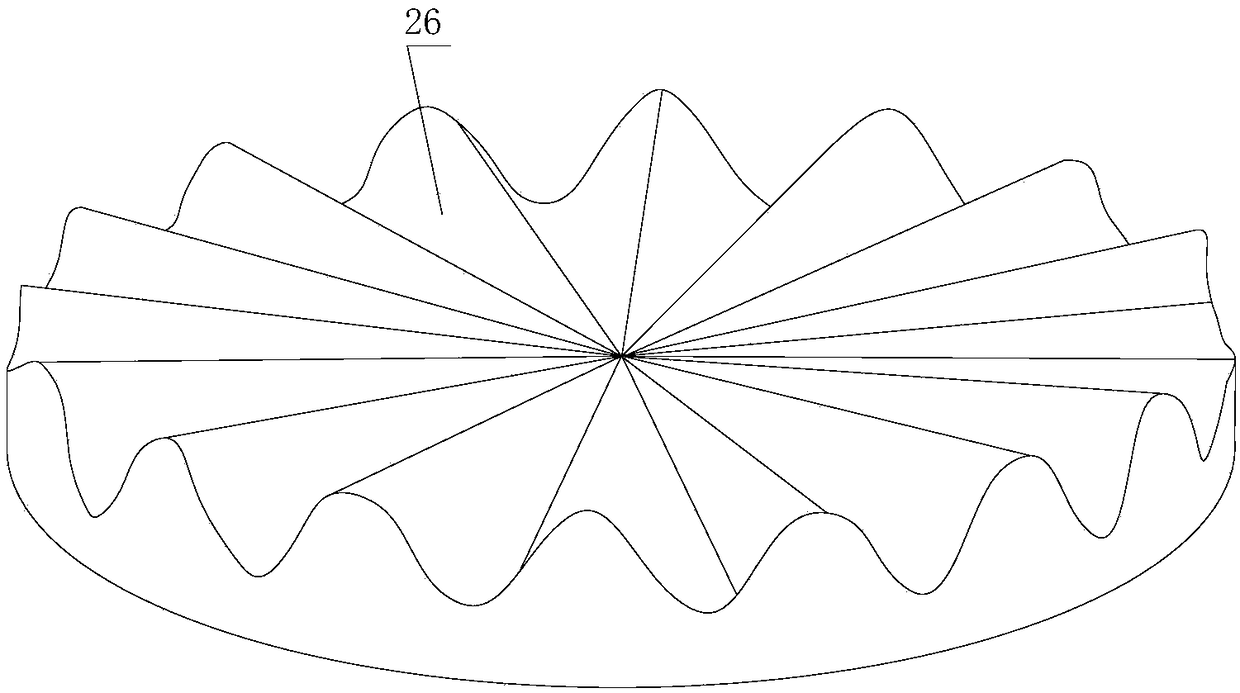

Automatic dough pressing and forming machine and application method thereof

InactiveCN108283196AAvoid spreadingReduce areaMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsWave shapeEngineering

The invention discloses an automatic dough pressing and forming machine and an application method thereof. The automatic dough pressing and forming machine comprises a dough pressing housing, whereina partition board is vertically arranged at a feed opening formed in the top of the dough pressing housing; a dough pressing device and a dough pushing device are separately mounted in an inner cavityof the dough pressing housing; the dough pressing device consists of a motor, a rotating plate, dough pressing rods, springs, limiting plates and wave-shaped circular plates; the motor is fixed to ahorizontal rod at the top of the inner cavity of the dough pressing housing; a circumference surface of the rotating plate is connected with the output end of the motor; after flour and water are poured in the dough pressing plate between a push plate A and a push plate B, the motor is started to drive the rotating plate to rotate; the convex parts of the wave-shaped circular plates continuously press pressure onto the bottom plate, so that the springs are contracted; the dough pressing rods fall to extrude the flour, the bottom plates slowly slide in the concave parts of the wave-shaped circular plates, and each spring gradually restores elasticity to lift the corresponding flour pressing rod upwards. The automatic dough pressing and forming machine disclosed by the invention has the effects of being high in degree of automation, quick in dough pressing and uniform in dough kneading.

Owner:南京启沅自动化技术有限责任公司

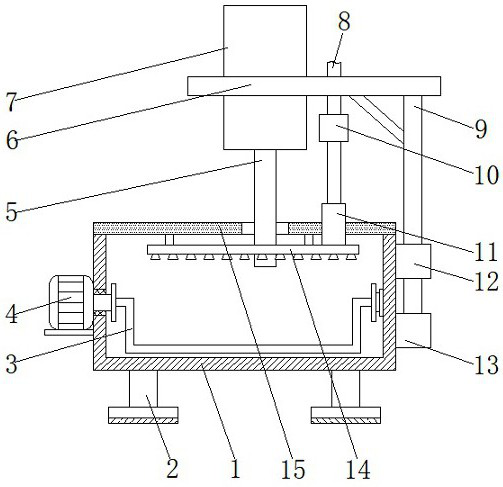

Automatic dough kneading machine and using method thereof

InactiveCN112450236ATo achieve the convenient functionEasy to useMixing/kneading structural elementsMixing/kneading with horizontally-mounted toolsEngineeringMachine

The invention discloses an automatic dough kneading machine and a using method thereof. The automatic dough kneading machine comprises a dough kneading bin, wherein a cover plate is arranged at the top of the dough kneading bin; a mounting sleeve is fixedly connected to the right side of the dough kneading bin; a vertical rod is placed in an inner cavity of the mounting sleeve; a mounting plate isfixedly connected to the top of the vertical rod; a storage bin is fixedly connected to the surface of the mounting plate; a baffle is fixedly connected to an inner cavity of the storage bin; and a screw feeder is fixedly connected to the surface of the baffle. According to the automatic dough kneading machine disclosed by the invention, through the dough kneading bin, a discharging hose, the storage bin, a water inlet pipe, the vertical rod, an electromagnetic valve, a connecting steel pipe, an annular pipe, the cover plate, the screw feeder, a placing frame, a servo motor, a gravity sensorand a movable plate, the device is convenient to use, and the problems that a dough kneading machine in the existing market is not convenient to use, the working procedures of using, loading and the like of the equipment still need manual participation, workers still need real-time participation on site during operation, the automation degree of the equipment is insufficient, and operation and useof a user are not facilitated are solved.

Owner:滕丽阳

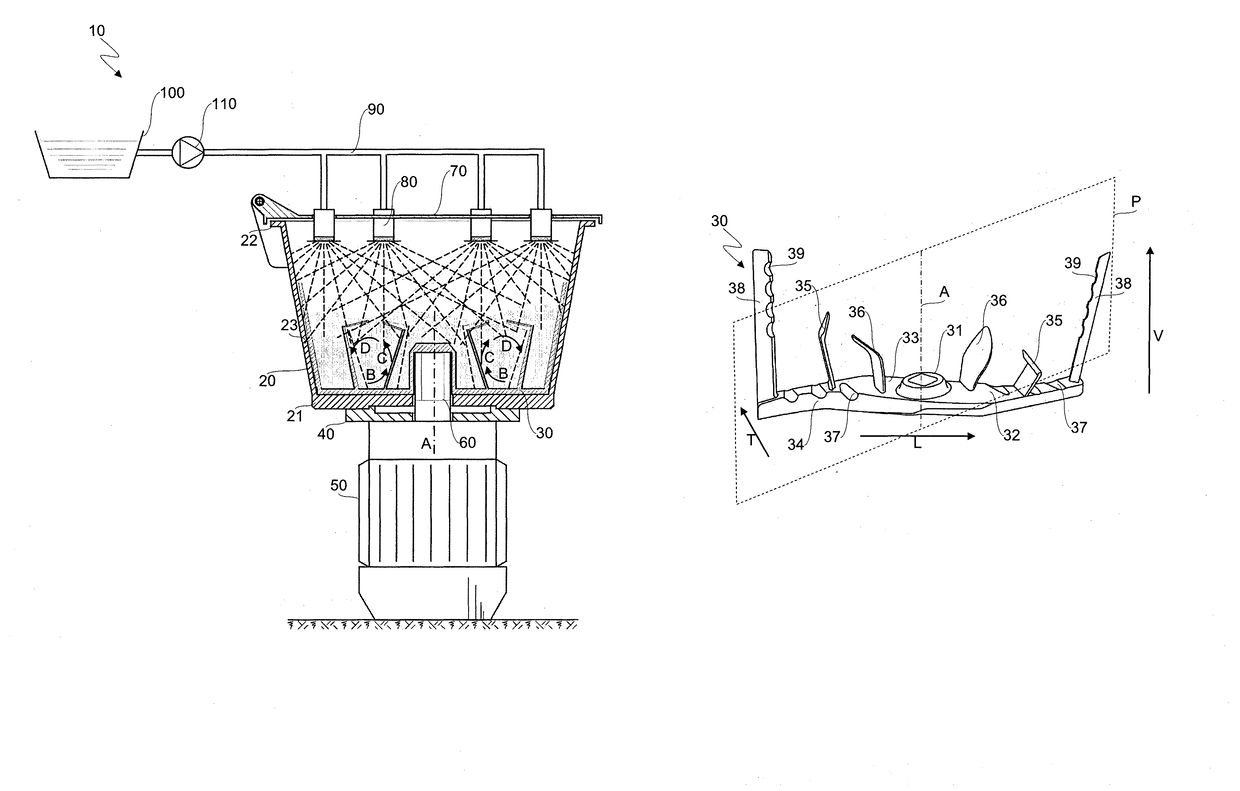

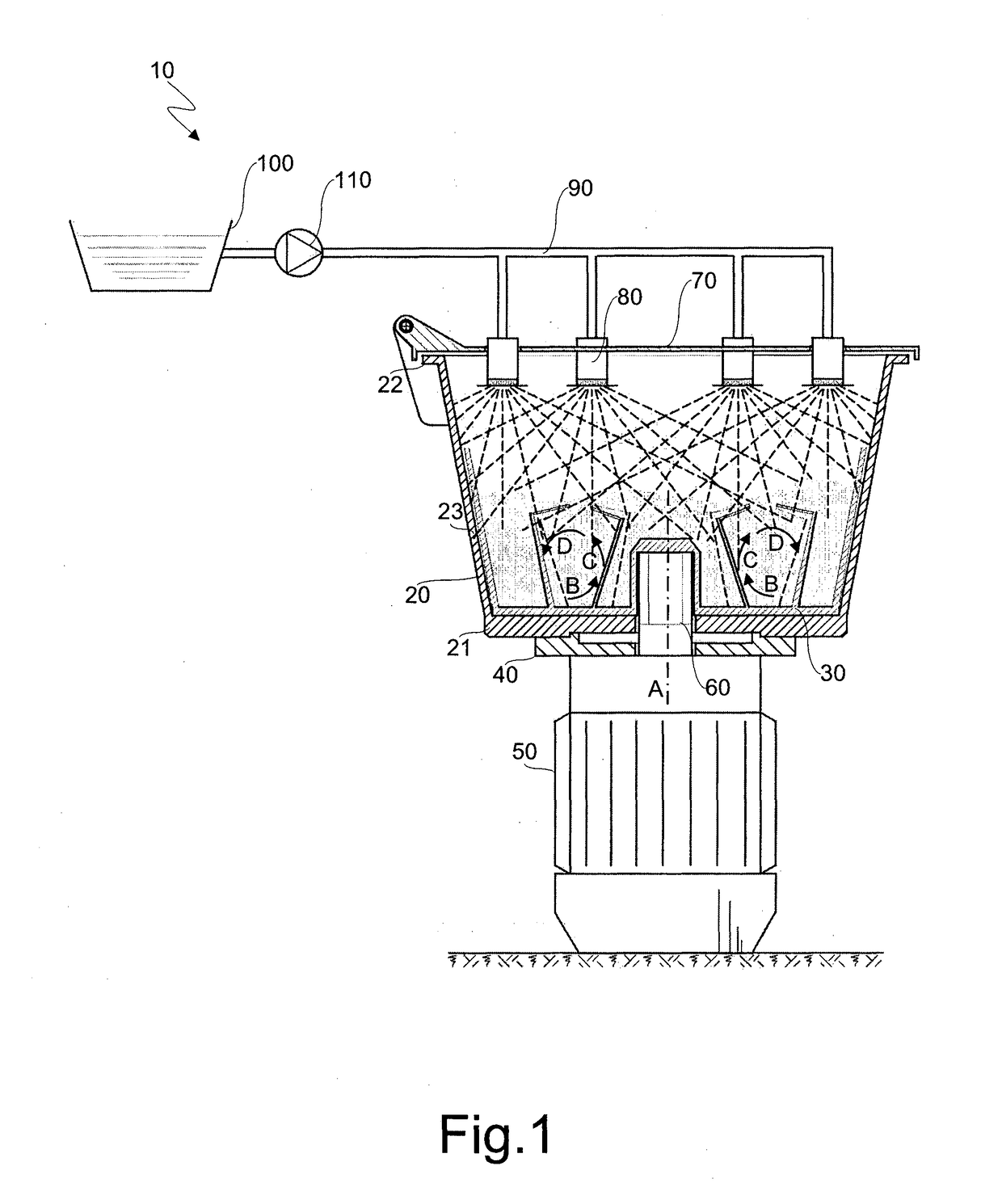

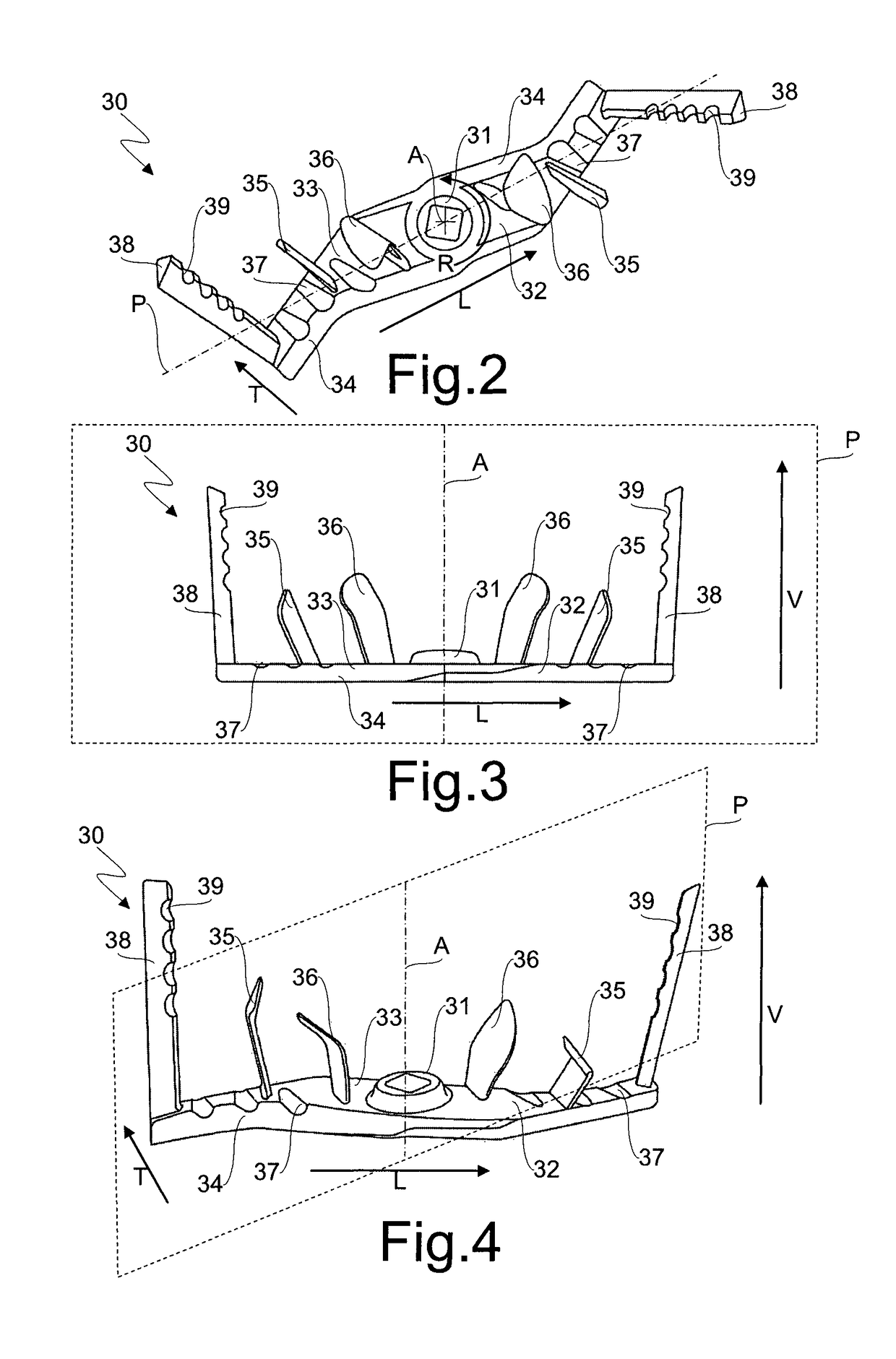

Dough kneader machine and related method of making an alimentary dough

InactiveUS9668486B2Maximize their hydration levelPromote hydrationMixing/kneading structural elementsRotary stirring mixersEngineeringMechanical engineering

The invention relates to a kneader machine for alimentary doughs including a container provided with a tight lid and a rotor rotatably arranged in the container about a vertical rotation axis (A), wherein the rotor has a flat base consisting of a plurality of arms and a plurality of mixing paddles which extend from the arms in a vertical direction (V), and wherein the arms of the rotor have beveled surfaces formed along their peripheries on the sides intended to face a rotation direction of rotation (R) of the rotor. The mixing paddles have first and second mixing paddles configured so as to generate between them a whirling motion of the particles of the solid ingredients on a plane (P) passing through the rotation axis (A) of the rotor and perpendicular to its base. The invention also relates to a method of making an alimentary dough by using the kneader machine.

Owner:ARTECH

Production method of coarse-cereal hollow noodles

InactiveCN110839825AReduce brittlenessReduce penetrationFood freezingFood preservationEngineeringProcess engineering

The invention relates to a production method of coarse-cereal hollow noodles, belongs to the technical field of food processing, and mainly solves the technical problems that existing noodles are single in taste and high in use amount of additives such as salt and dietary alkali. According to the technical scheme, the production method includes the steps of firstly, adding, by weight, 100 parts ofcoarse cereal flour into stirring equipment, sequentially adding, by weight, 20 parts of starch and 35-50 parts of water of 20 DEG C, and evenly stirring; secondly, pressing into hollow noodles; thirdly, cutting the hollow noodles formed by pressing into noodles of 25-30cm, placing the cut noodles into a container, spraying edible oil into the container, and evenly stirring; fourthly, cooling toroom temperature; fifthly, performing split charging; sixthly, performing quick freezing for more than 2-3 hours. The production method has the advantages that the noodles produced by the method is good in food therapy effect and good in taste, and the production method is simple in process, mature in technology, easy to implement and the like.

Owner:刘俊魁

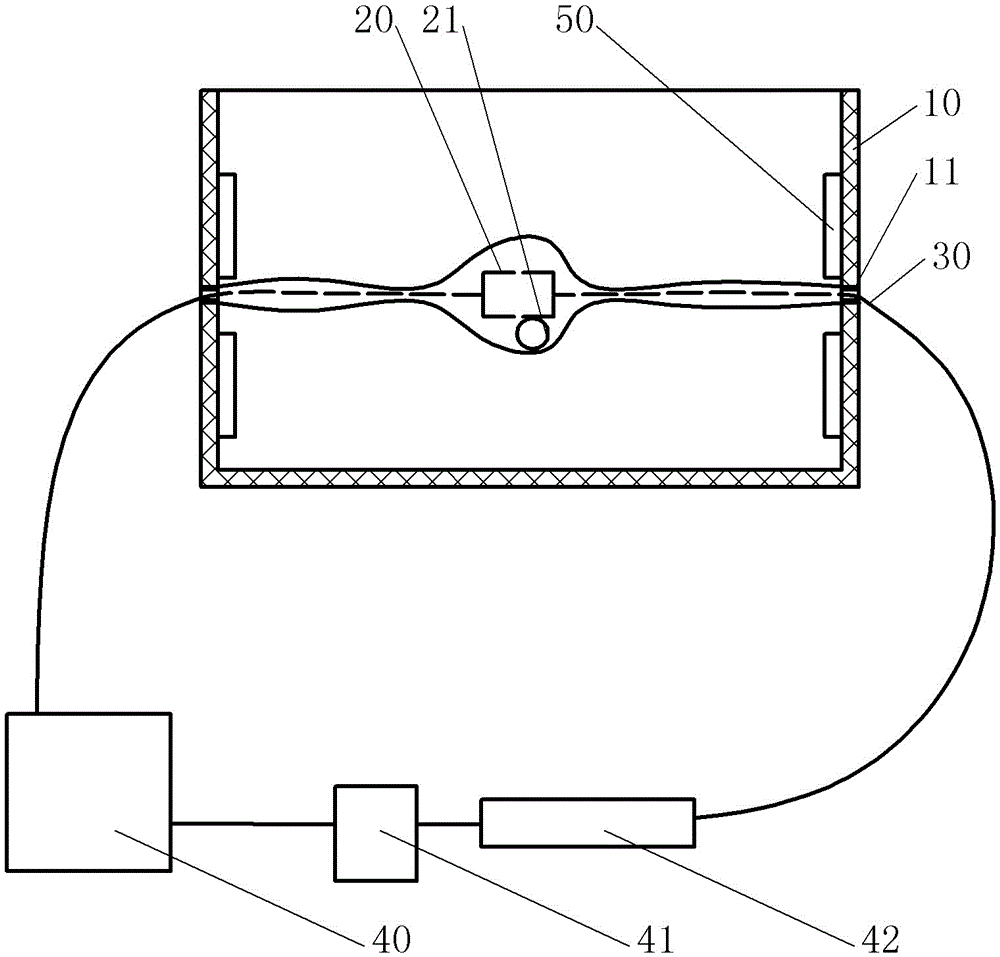

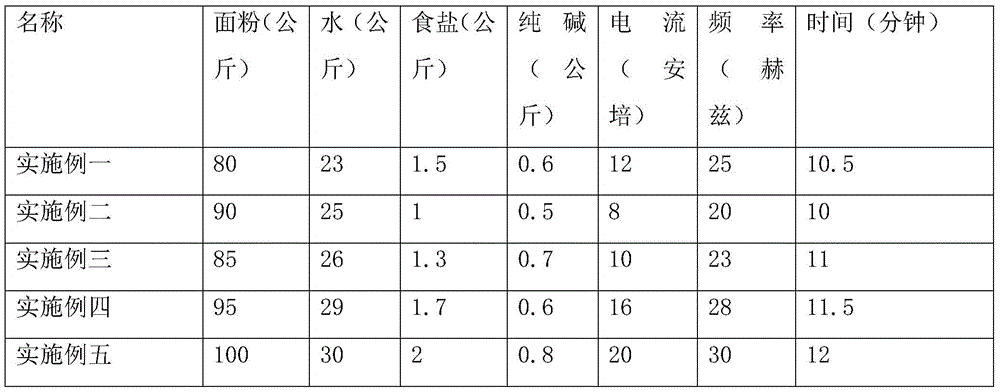

Flour mixing method for noodles processing

The invention discloses a flour mixing method for noodles processing. The method comprises the following steps: (1) addition of flour and water, in which, 80-100 parts by mass of flour and 23-30 parts by mass of water are added into a charging barrel of a flour mixing apparatus for noodles processing; (2) addition of salt, in which, 1-2 parts by mass of salt is added into the charging barrel of the flour mixing apparatus for noodles processing; (3) addition of soda ash, in which, 0.5-0.8 part of soda ash is added into the charging barrel of the flour mixing apparatus for noodles processing; (4) control of flour mixing, in which, an alternating current power supply is started, current of the alternating current power supply is adjusted to 8-20 A, frequency is adjusted to 20-30 Hz, and flour mixing time is 10-12 min; and (5) closing of the alternating current power supply and taking out of dough. Dough with different tastes is adjusted and prepared only through adjustment of the frequency of the power supply and current intensity. Besides, an operator participating in flour mixing is not required in a whole process, and the labor intensity is reduced.

Owner:CHONGQING YUXI FLOUR PROD

Dust removal device for processing of dough kneading machine and operation method of dust removal device

InactiveCN112450237AGuaranteed dust removal performanceThe dust removal direction can be adjustedMixing/kneading structural elementsDough mixing/kneading methodsDust controlEngineering

The invention discloses a dust removal device for processing of a dough kneading machine and an operation method of the dust removal device. The dust removal device comprises a machine body, wherein afixing post is fixedly arranged at the bottom of the machine body; a base is fixedly arranged at the bottom of the right side of the fixing post; a fastening block is connected to the surface of thefixing post in a sleeving way; a fastening rod is arranged on the right side of the front side of the fastening block in a penetrating way; a fixing plate is fixedly arranged on the left side of the fastening block; a transverse plate is fixedly arranged at the bottom of the left side of the fixing plate; a dust storage box is clamped and connected onto the top of the transverse plate; the bottomof the back side of the dust storage box communicates with a dust suction pump; the dust suction pump is positioned on the top of the left side of the fixing plate; and a support plate is rotationallyarranged on the surface of the upper end of the fixing plate. A dust suction cover is added in the dough kneading position, so that dust generated by dough kneading can be subjected to absorption treatment; influence of too much dust on operators and indoor environment quality can be avoided; the dust suction angle of the dust suction cover can be manually regulated; and the dust removal qualityis further effectively improved.

Owner:滕丽阳

Automatic bread maker, ingredient box and bread making method

ActiveUS9572351B2Save preparation timeMeet needsDough/pre-mixesDough preparationCooking & bakingAdditive ingredient

A method of making bread uses an automatic bread maker and an ingredient box. The method includes: put the bread ingredient with flour and baking powder according to proper formula into the accommodating room of the ingredient box and packaged; then place the ingredient box faced down in the hanging rack above the baking pan inside the automatic bread maker, operate the bread maker to make the sawtooth blade of the hanging rack pierced the film of the ingredient box and the bread ingredient inside fell down into the baking pan, then water the baking pan; close the housing of the automatic bread maker and turn on the baking pan, the bread ingredient is processed with working dough of mixing, stirring and kneading; get the baking pan out, and remove the bread of baked and shaped.

Owner:TSANN KUEN ZHANGZHOU ENTERPRISE CO LTD

Production equipment and technology of egg round flat cakes

InactiveCN108606021AImprove the degree of automated productionIncrease productivityMixing/kneading structural elementsPre-baking dough treatmentEngineeringOperating environment

The invention relates to the field of food processing, provides production equipment and technology of egg round flat cakes, and aims to solve the problem of improving the mouth feel of the egg roundflat cakes. According to the production equipment and technology of the egg round flat cakes provided by the invention, the production equipment comprises a premixing device, a feeding device, a tunnel furnace and a conveying device, wherein the premixing device is connected with the feeding device through a pipeline; the feeding device is connected with the tunnel furnace through the conveying device; and a mold is arranged on the conveying device. After being premixed and stirred, raw materials are subjected to multistage roasting, so that finished products of the egg round flat cakes can beobtained, the automated production degree of the egg round flat cakes is increased, the operating environment of workers is improved, and the production efficiency of the egg round flat cakes is improved; and besides, multistage roasting is performed, so that the water ratio of the egg round flat cakes is stabilized to be within a stable and reasonable range, the mouth feel of the egg round flatcakes is improved, and the egg round flat cakes are more crisp and beautiful in appearance.

Owner:广州新瑞生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com