Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Toolroom" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A toolroom is a room where tools are stored or, in a factory, a space where tools are made and repaired for use throughout the rest of the factory. In engineering and manufacturing, toolroom activity is everything related to tool-and-die facilities in contrast to production line activity.

Cutting tool detection device and cutting tool detection method

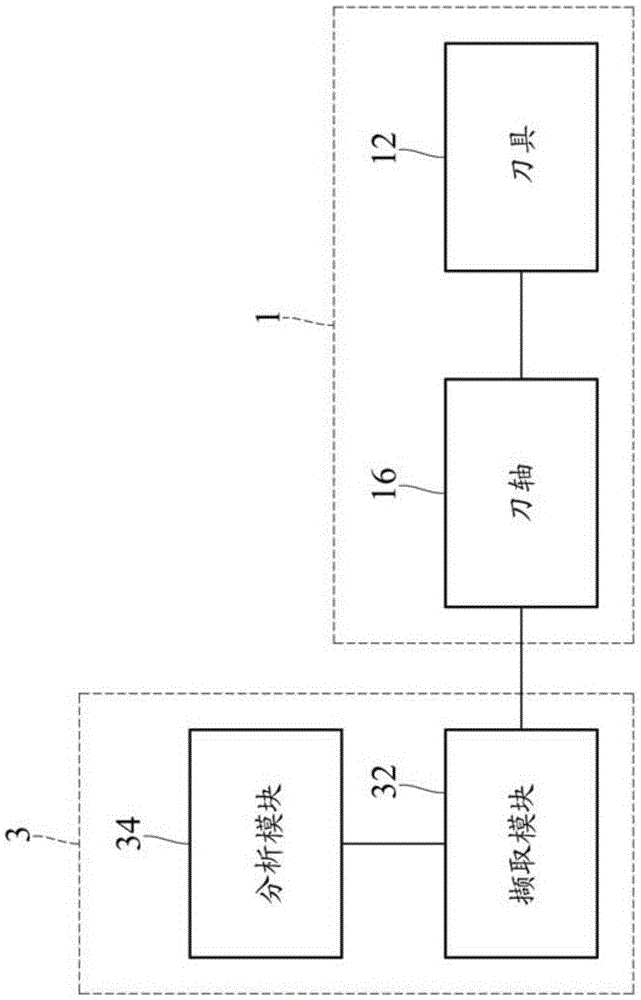

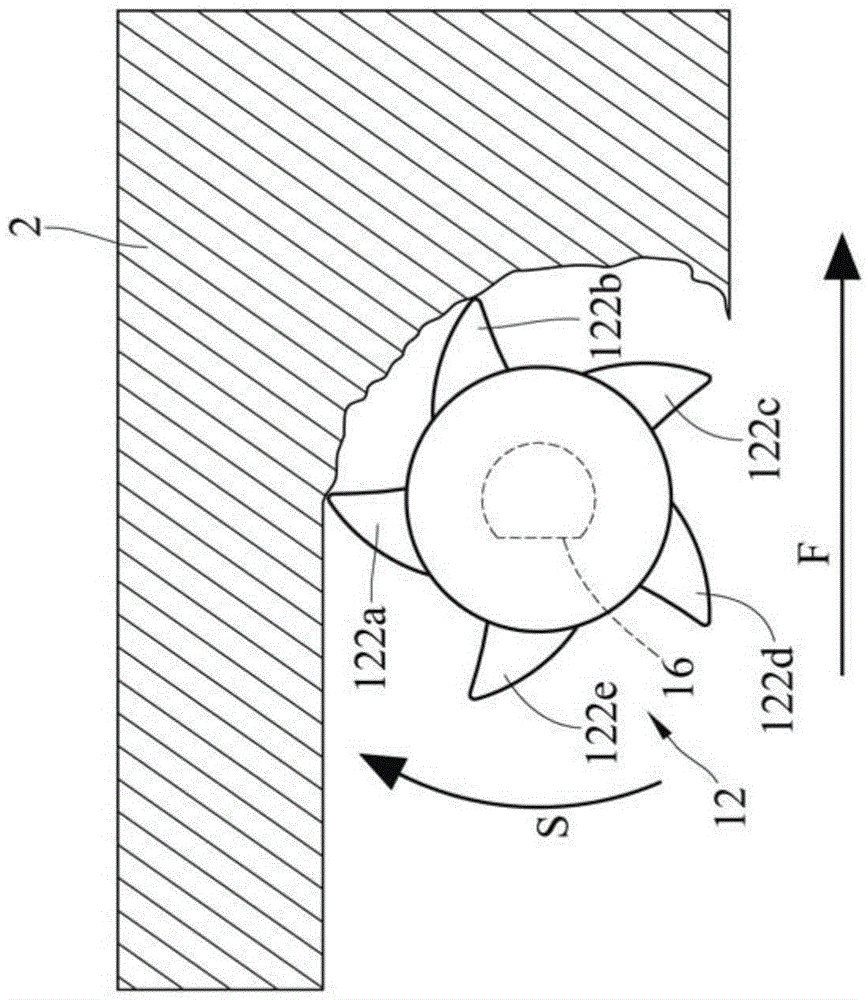

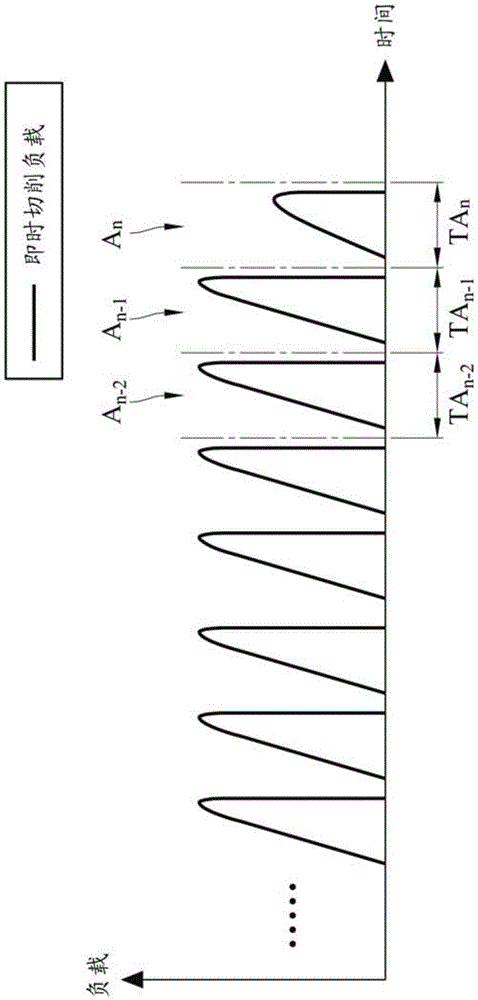

The invention discloses a cutting tool detection device and a cutting tool detection method. The cutting tool detection device is suitable for a toolroom machine with a cutter shaft. The cutter shaft is used for installing and driving a cutting tool in order to carry out cutting. The cutting tool detection device comprises a capturing module and an analyzing module. The analyzing module is electrically connected with the capturing module. The capturing module is used for capturing load signals of the cutter shaft. The analyzing module is used for receiving the load signals and capturing a characteristic load pattern, and comparing the feature load pattern with a standard load pattern in order to generate a judgment result.

Owner:IND TECH RES INST

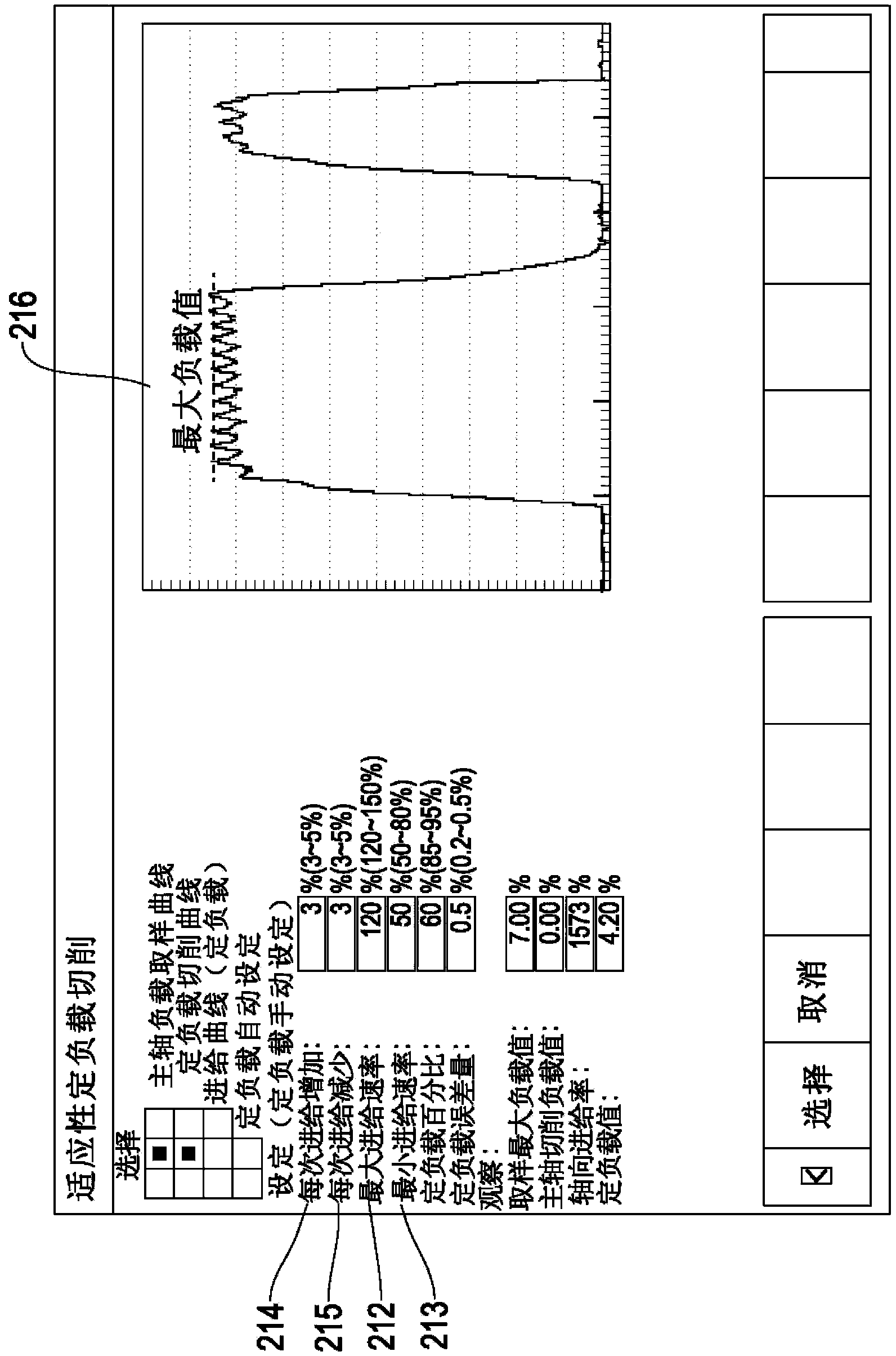

Method and system for controlling intelligent adaptability fixed load cutting of toolroom machine

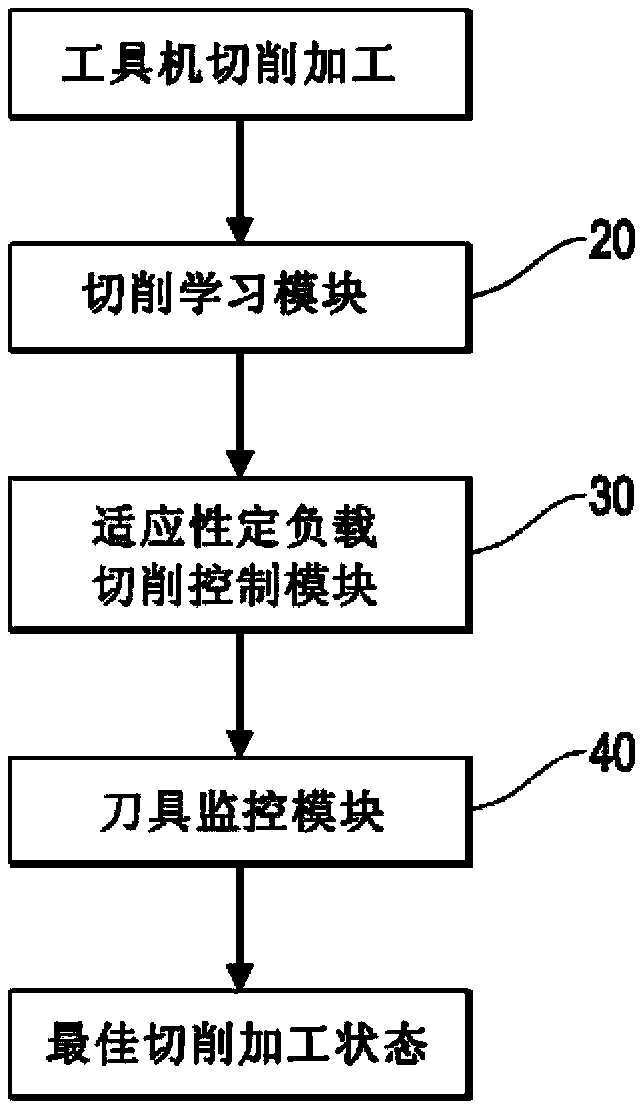

The invention discloses a method and system for controlling intelligent adaptability fixed load cutting of a toolroom machine. A cutting learning module, an adaptability fixed load cutting control module and a cutter monitor module are mainly built in a controller of the toolroom machine, the controller is provided with a database, the cutting learning module obtains the optimal cutting control parameter of the machine table of the toolroom machine and stores the parameter in the database, the adaptability fixed load cutting control module operates the load value of a main shaft of the machine table and the optimal cutting control parameter and adjusts the cutting speed of the machine table, and the cutter monitor module monitors the maximum load value of the main shaft. The controller controls the machine table to correspondingly adjust the cutting speed of cutting feed in the range of the optimal cutting control parameter to adapt to different cutting processing conditions, the fault of the machine table can be reduced, and manufacturing and maintenance cost can be lowered.

Owner:VICTOR TAICHUNG MACHINERY WORKS

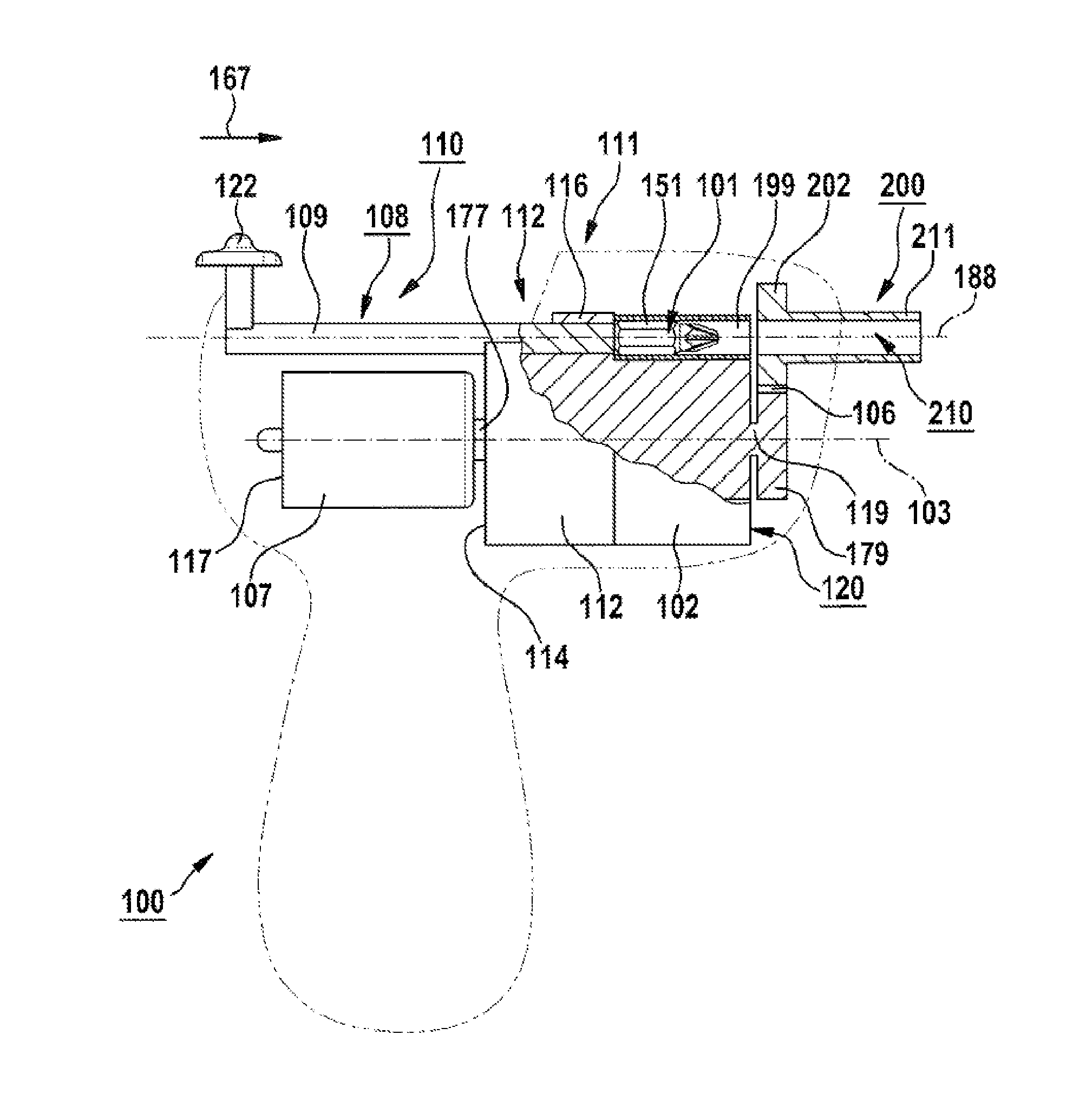

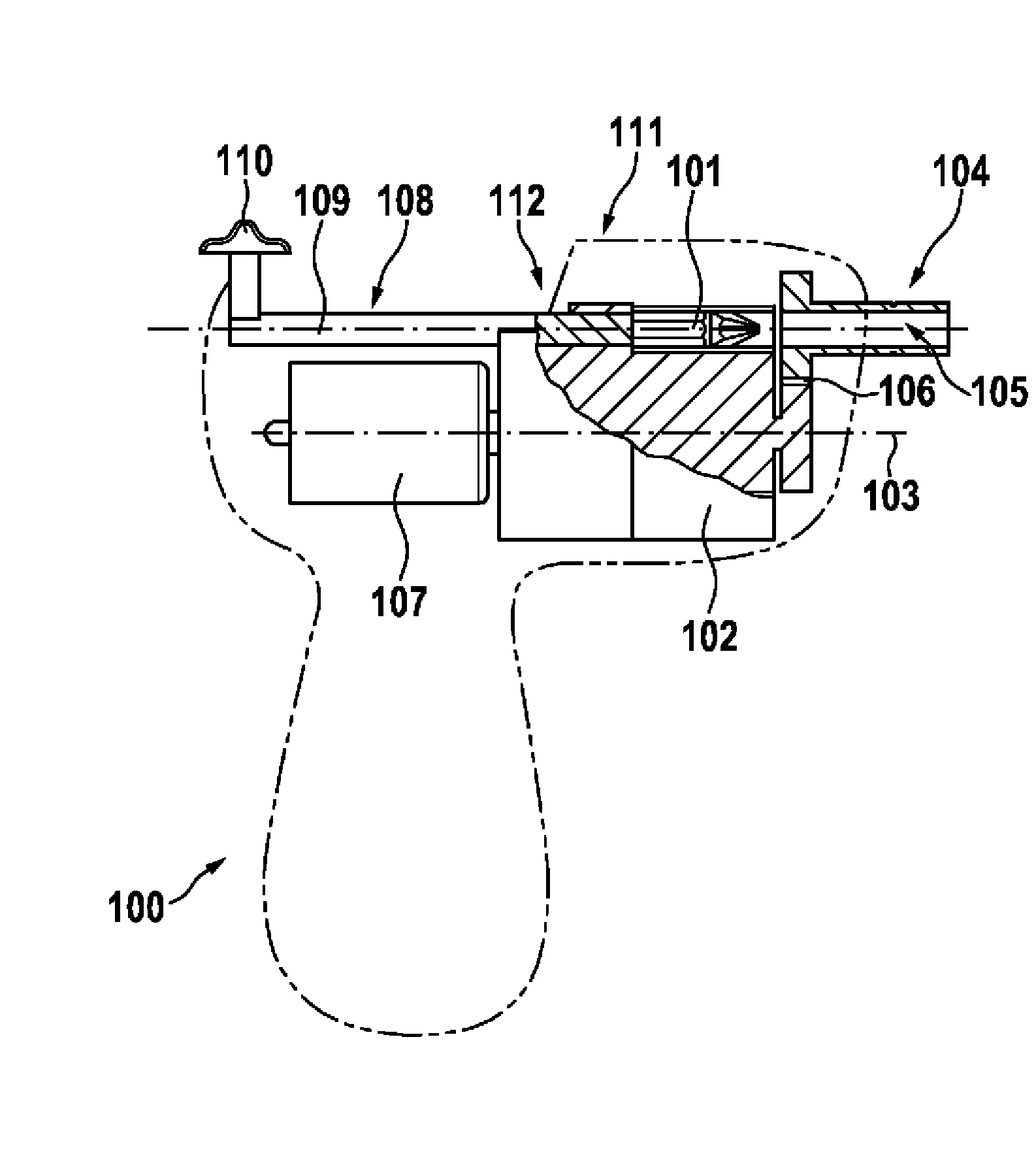

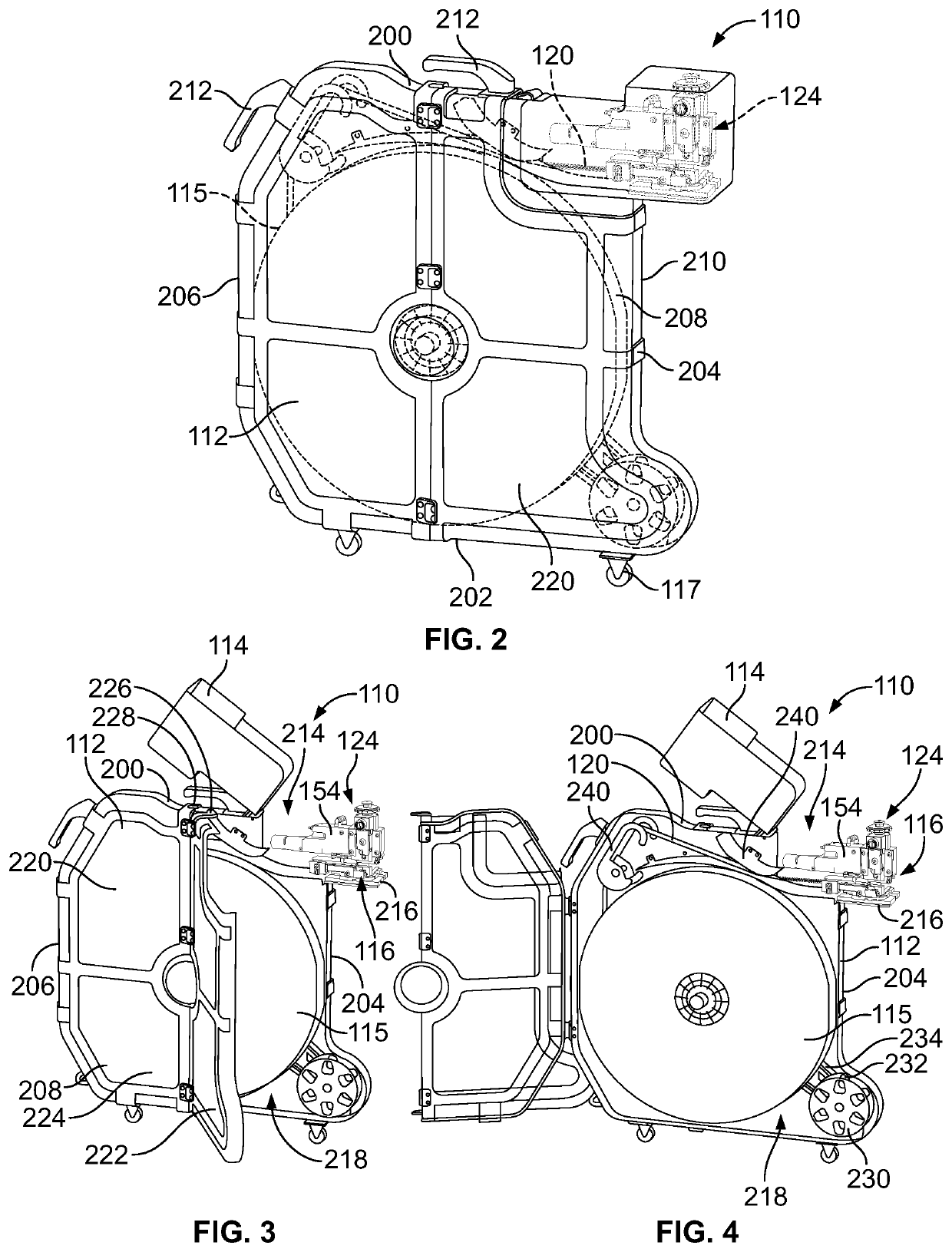

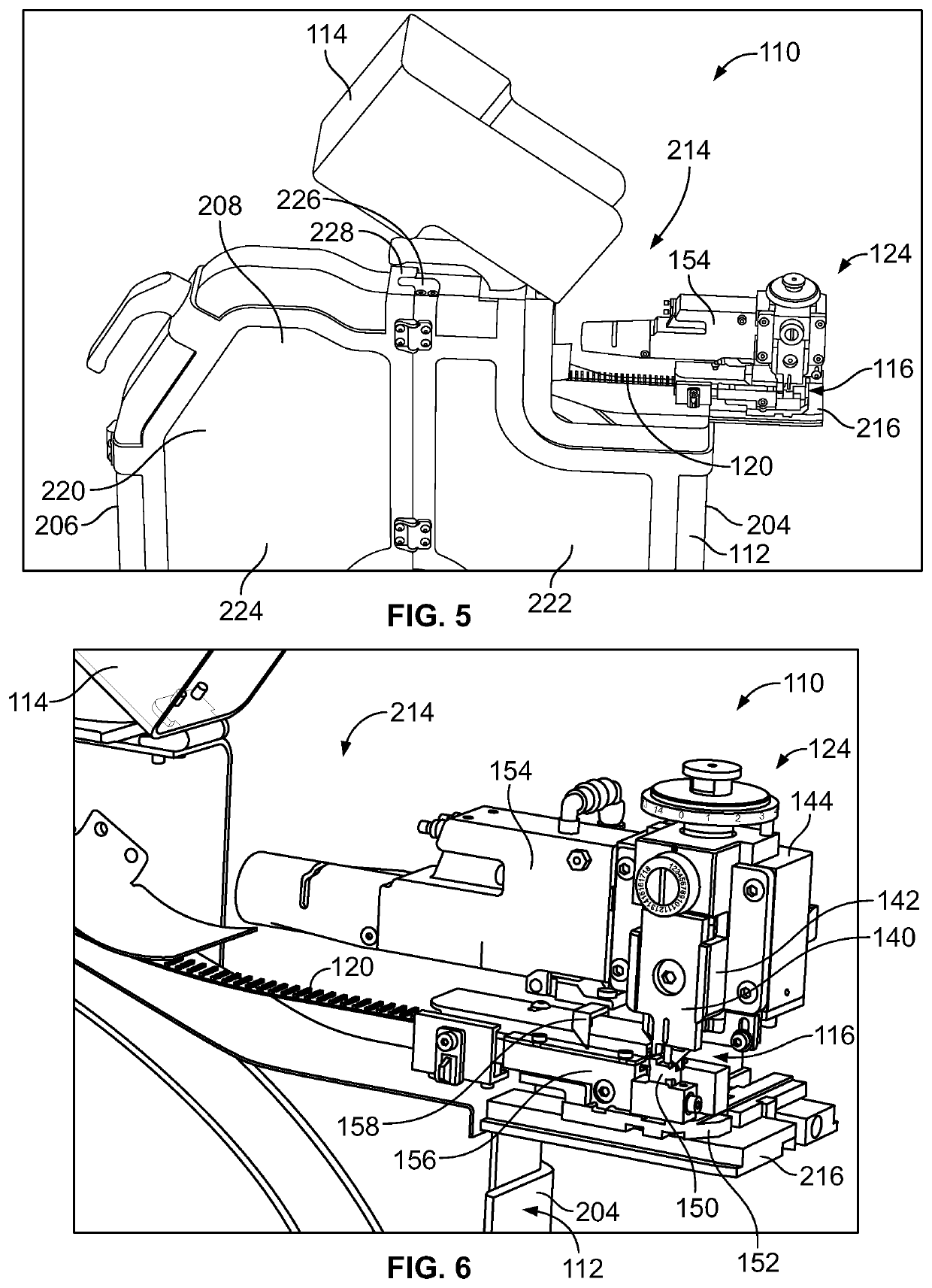

Hand power tool having a drum-type tool change magazine

A hand power tool includes a tool receiver configured to receive a tool. The tool has an outer polygonal coupling and the tool receiver has an inner receiver including, at least portionally, a rotary driver profile. The tool receiver is provided on an associated tool housing, in which there is a drum-type tool change magazine having at least one tool chamber configured to store the tool. The tool chamber is configured to be aligned so as to be flush with the tool receiver to enable the tool to slide from the tool chamber into the inner receiver or from the inner receiver into the tool chamber. An alignment element is configured to align the outer polygonal coupling as the tool slides from the tool chamber into the inner receiver to enable the outer polygonal coupling to slide into the rotary driver profile.

Owner:ROBERT BOSCH GMBH

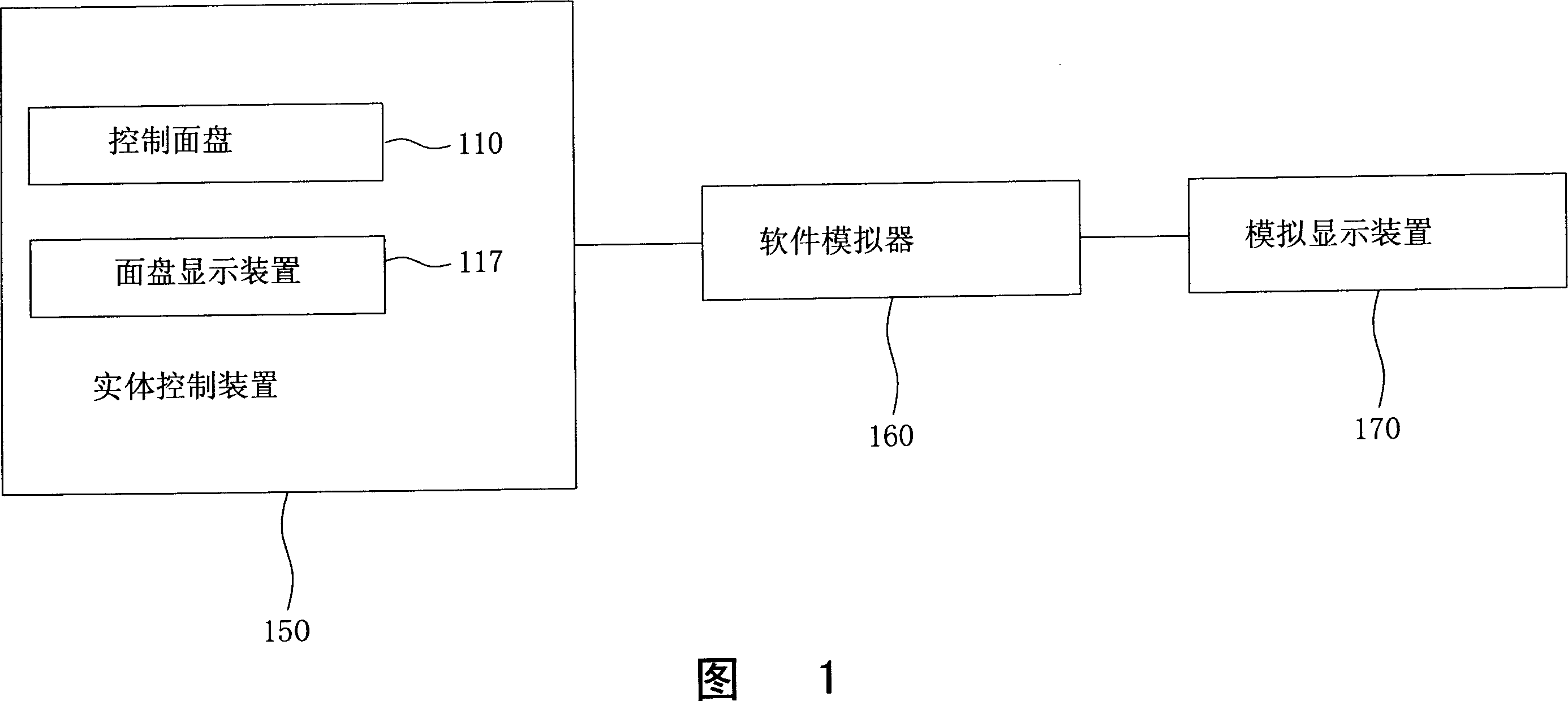

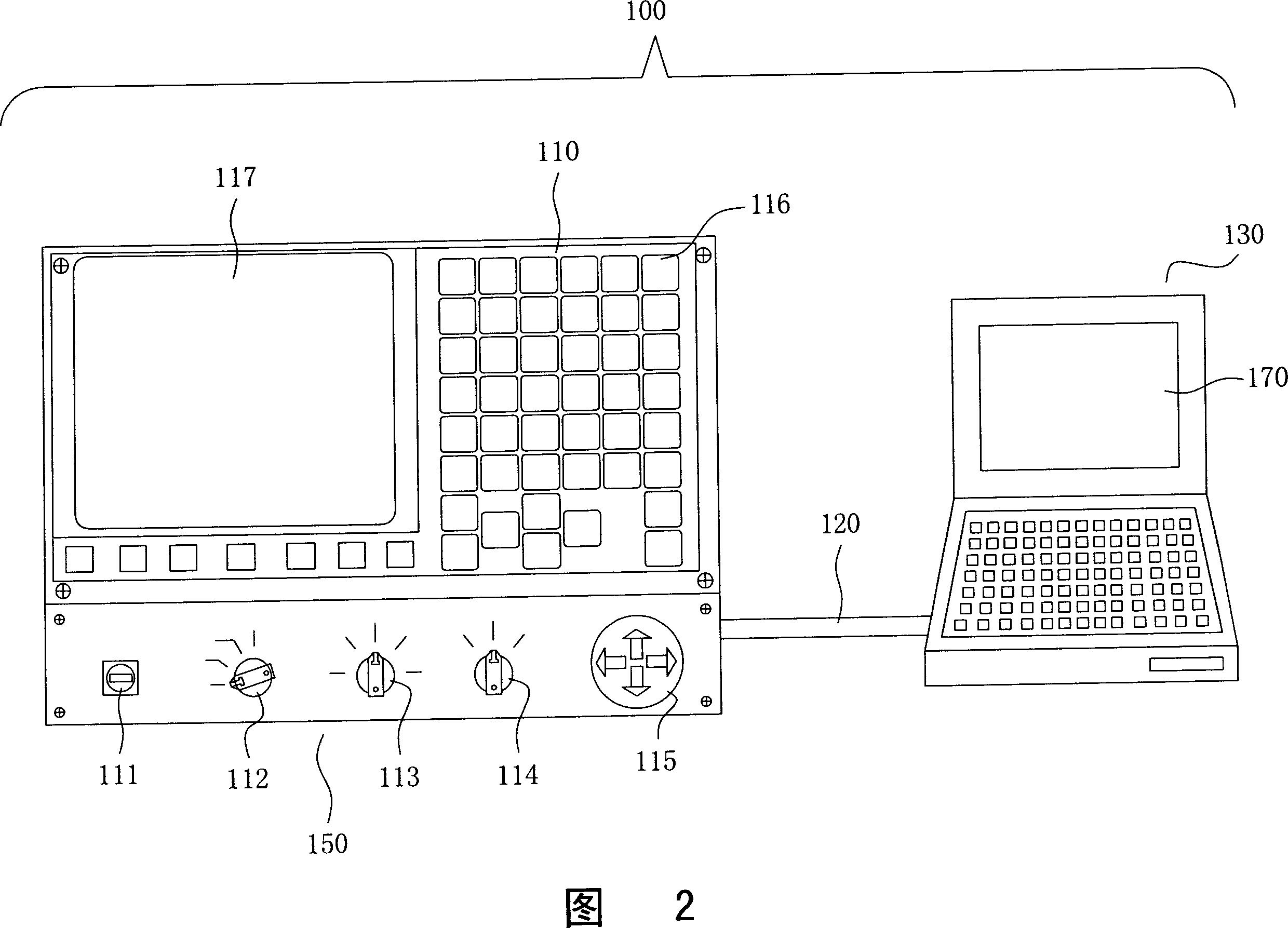

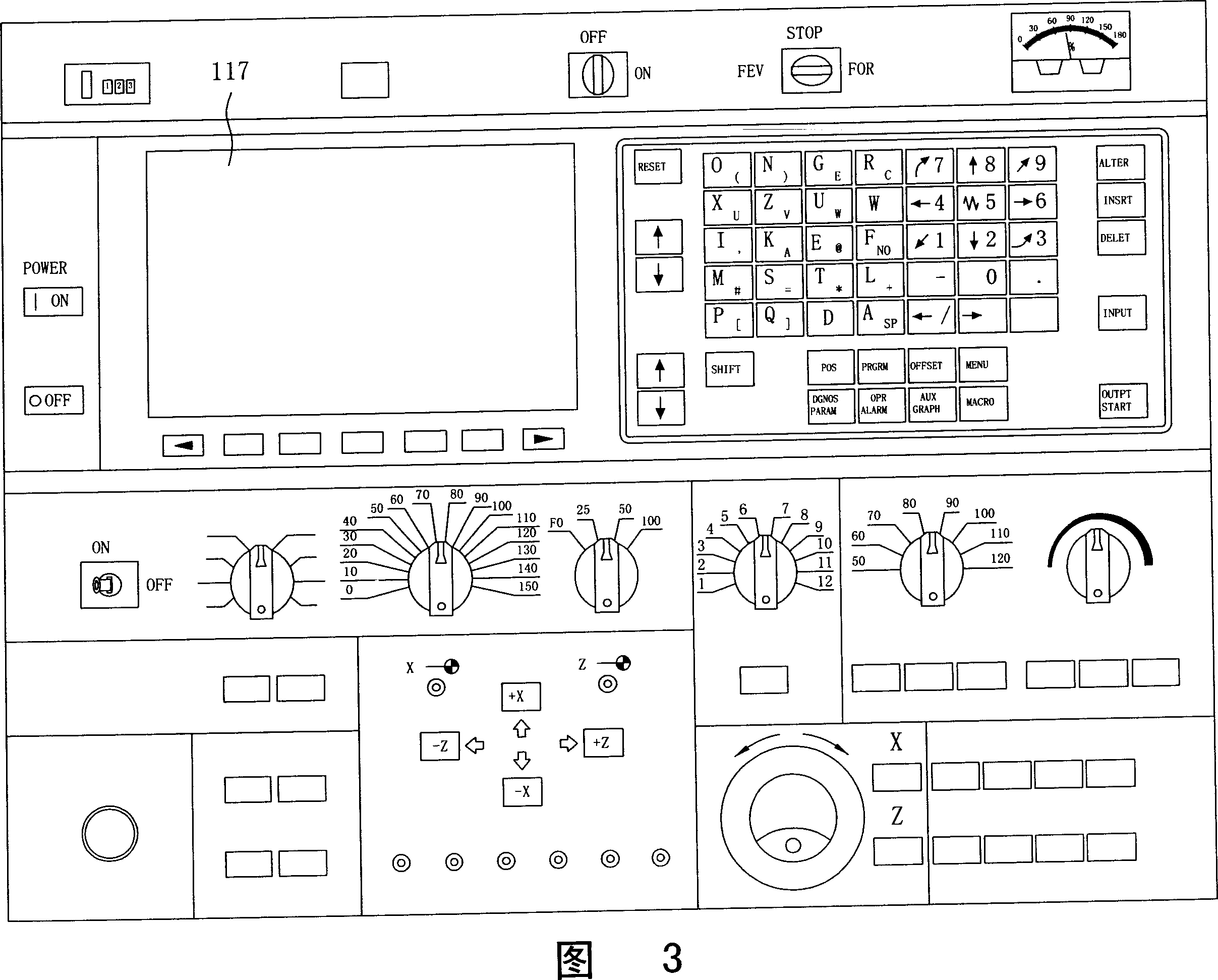

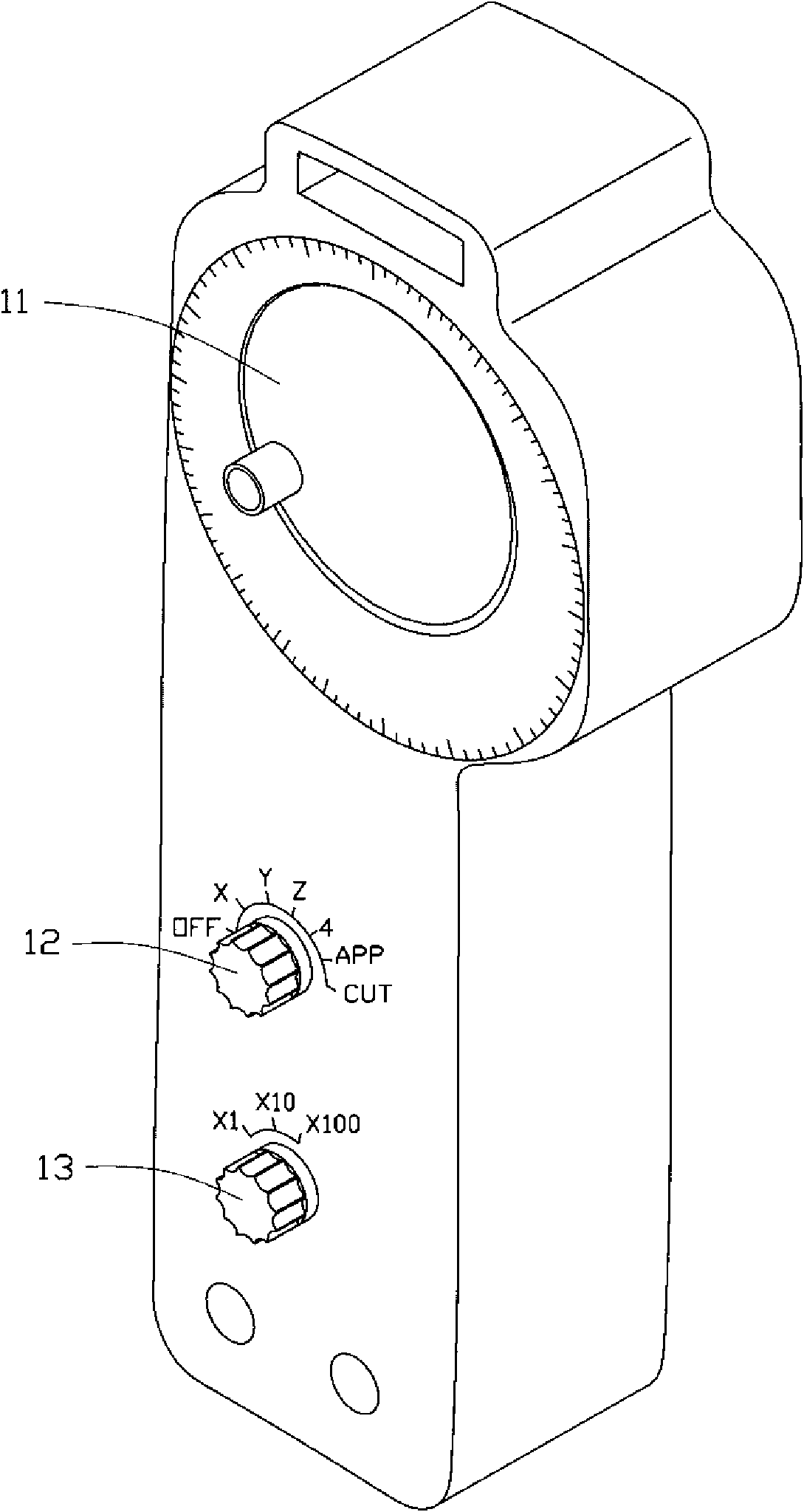

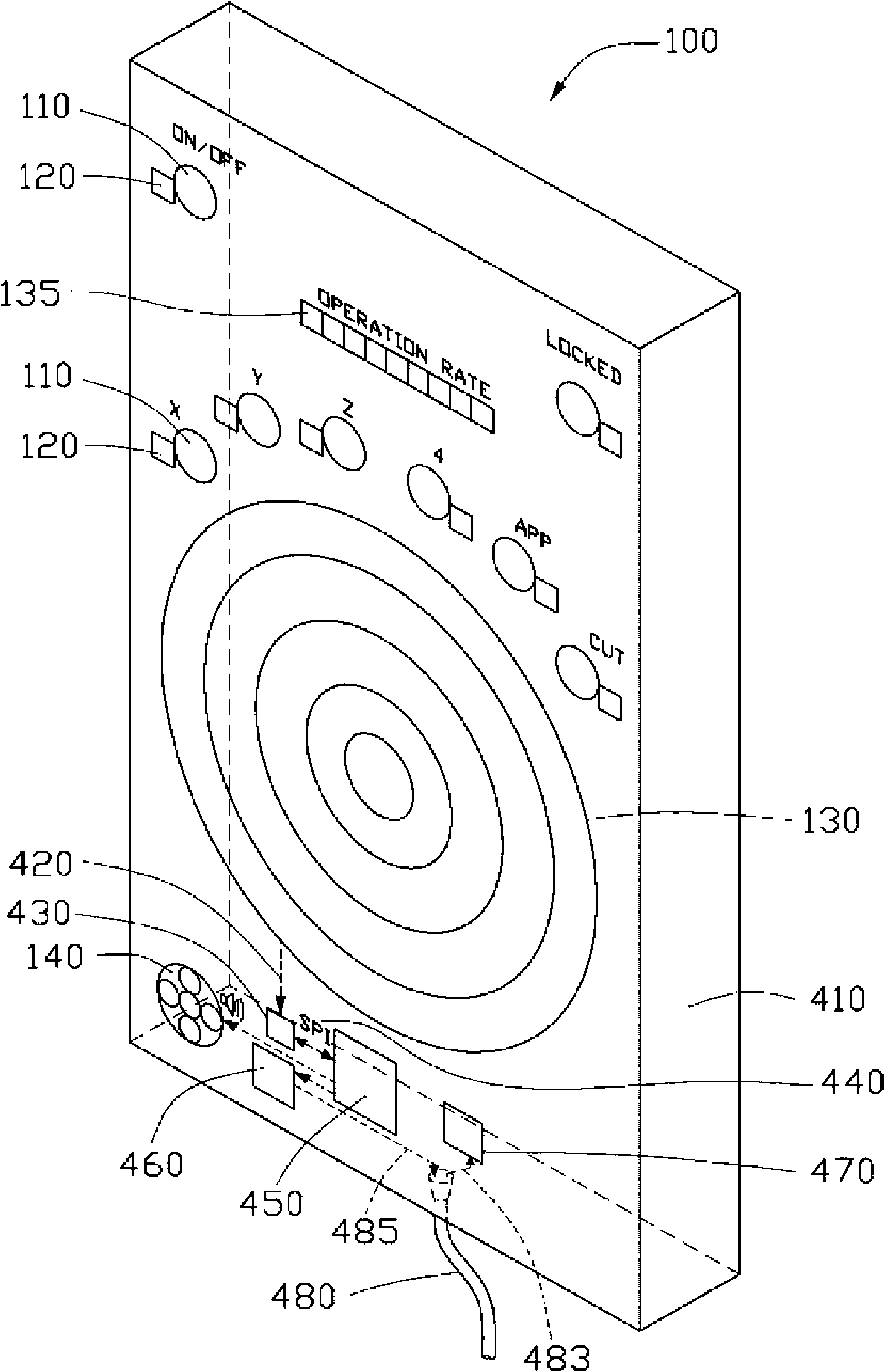

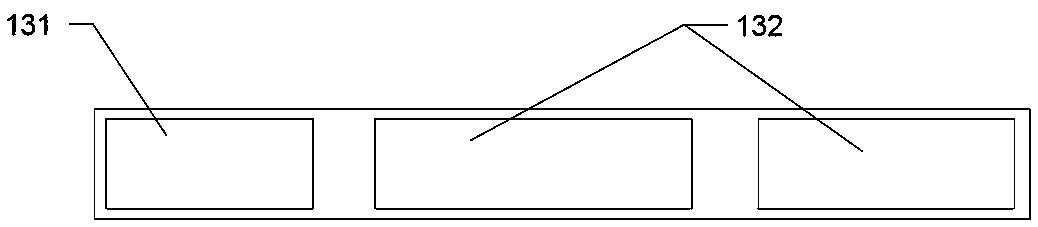

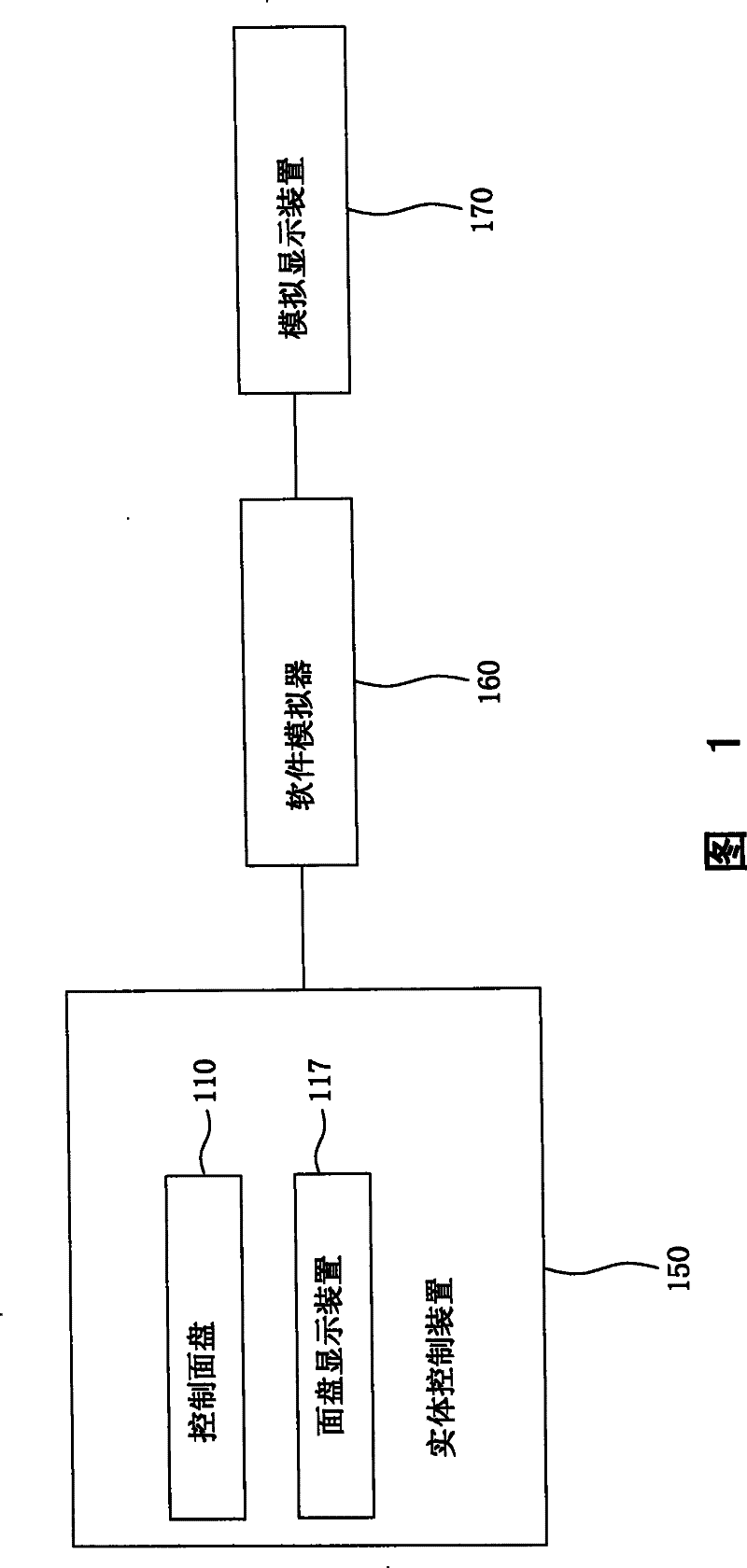

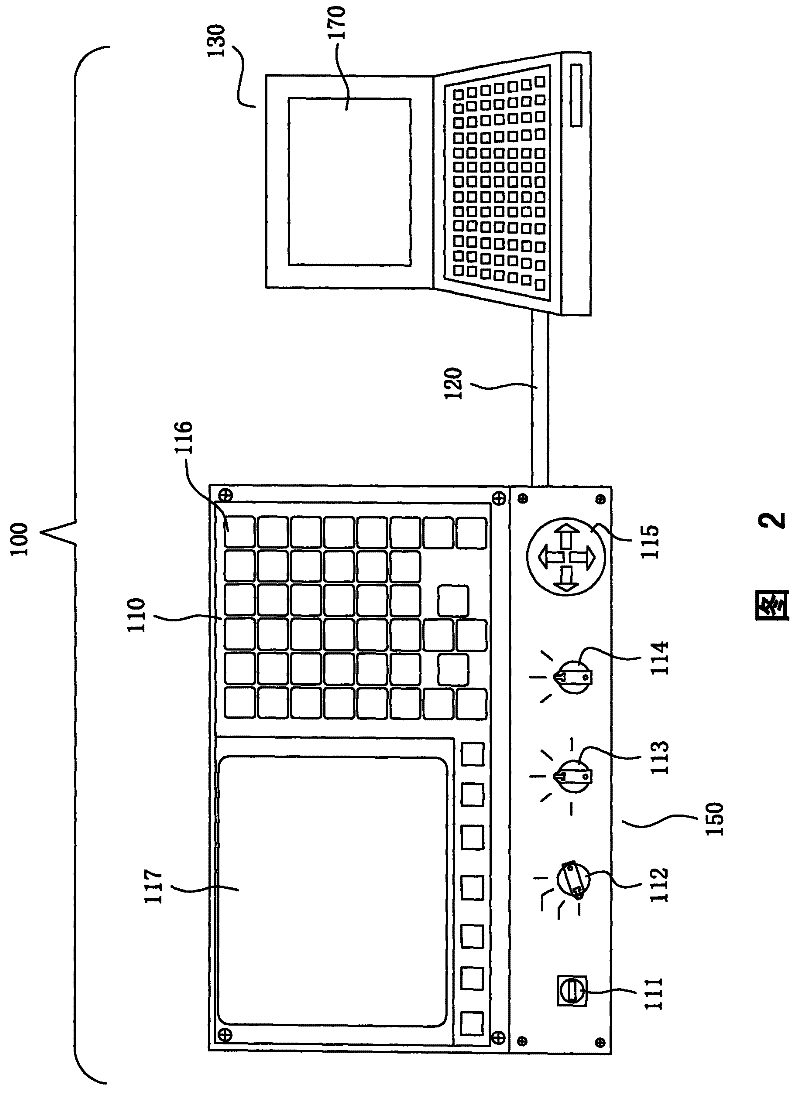

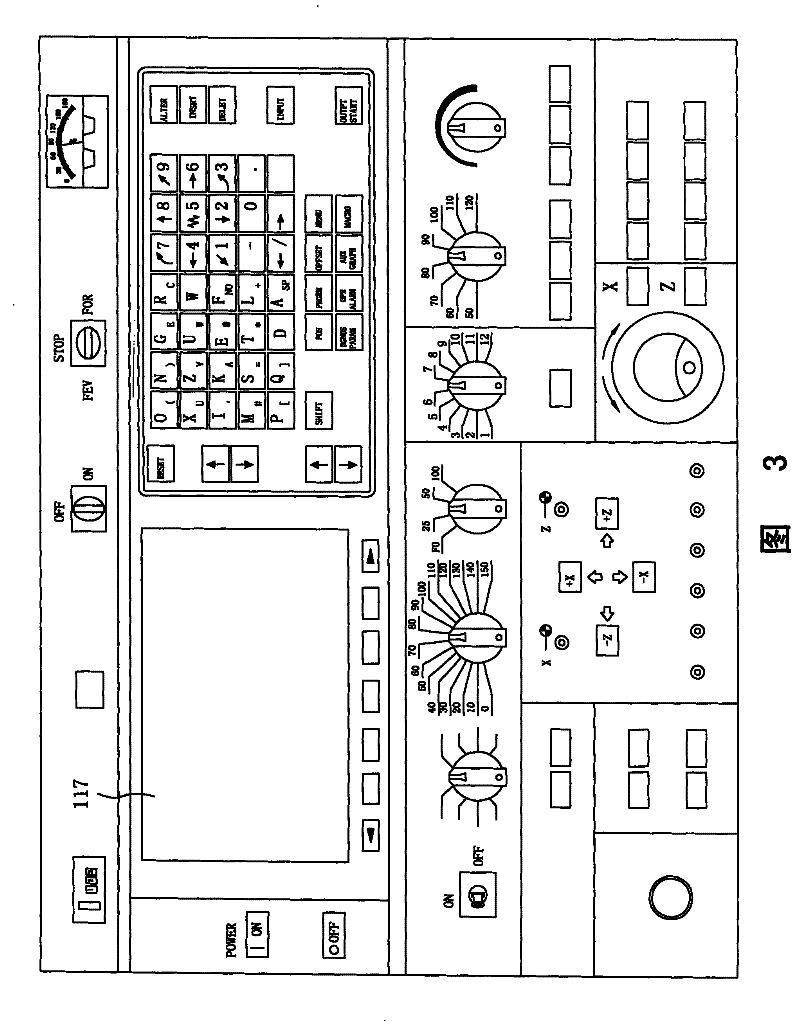

Operations exercitation simulator suitable for CNC toolroom machine

InactiveCN101097661AEasy to useReduce malfunctionEducational modelsDisplay deviceSoftware engineering

A kind of stimulation device of operation training for CNC machine tool includes control device for entity, software simulator, transmitting device and stimulating display device; the control device for entity provides operation command; the software simulator is connected with the control device, and generates the stimulation of operation action according to operating action command input by the control device for entity; the transmitting device connects with the control device for entity and the software simulator; the stimulating display device is connected with the software simulator and display the operating action stimulation generated by the software simulator.

Owner:REN AN INFORMATION TECH CO LTD

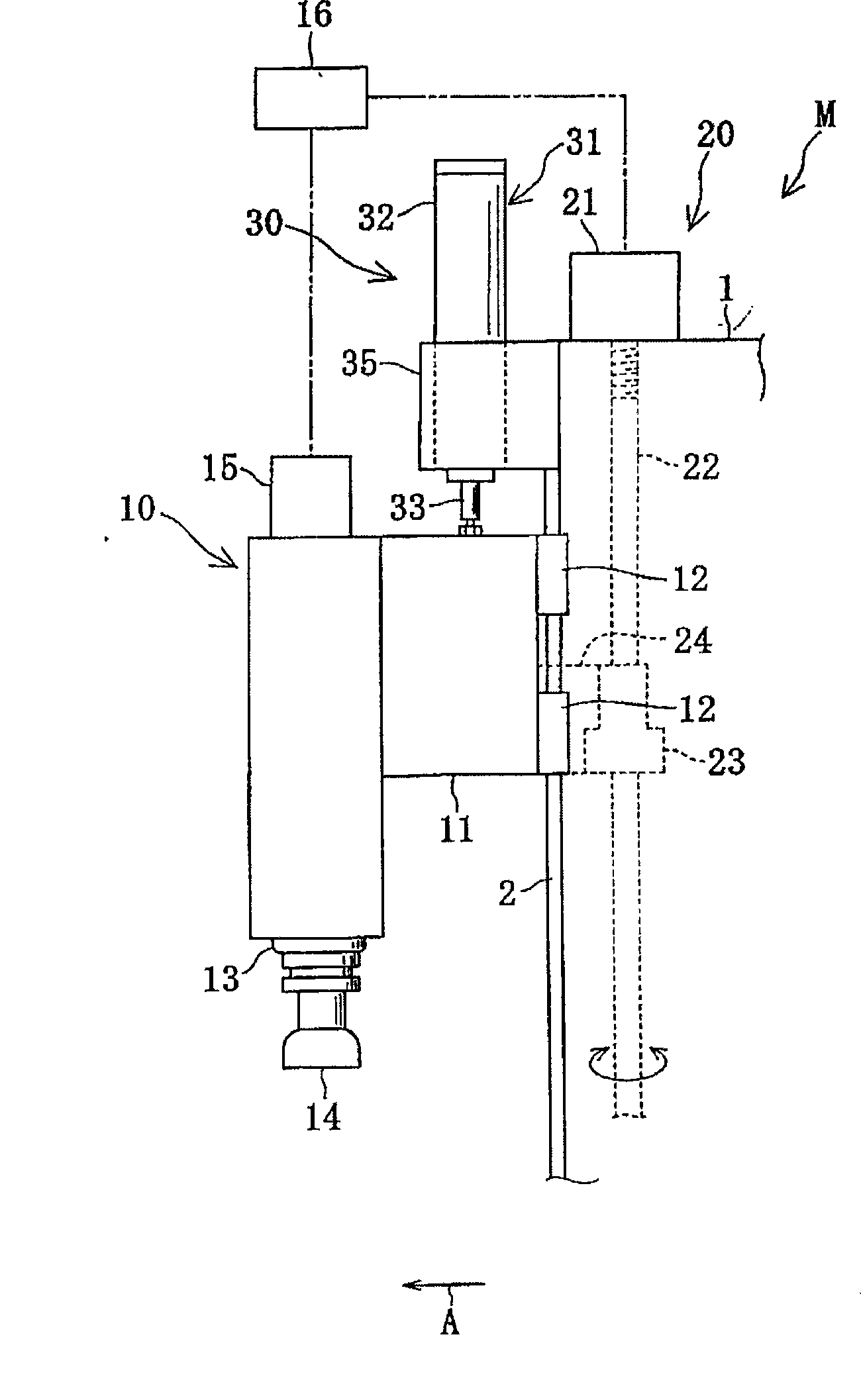

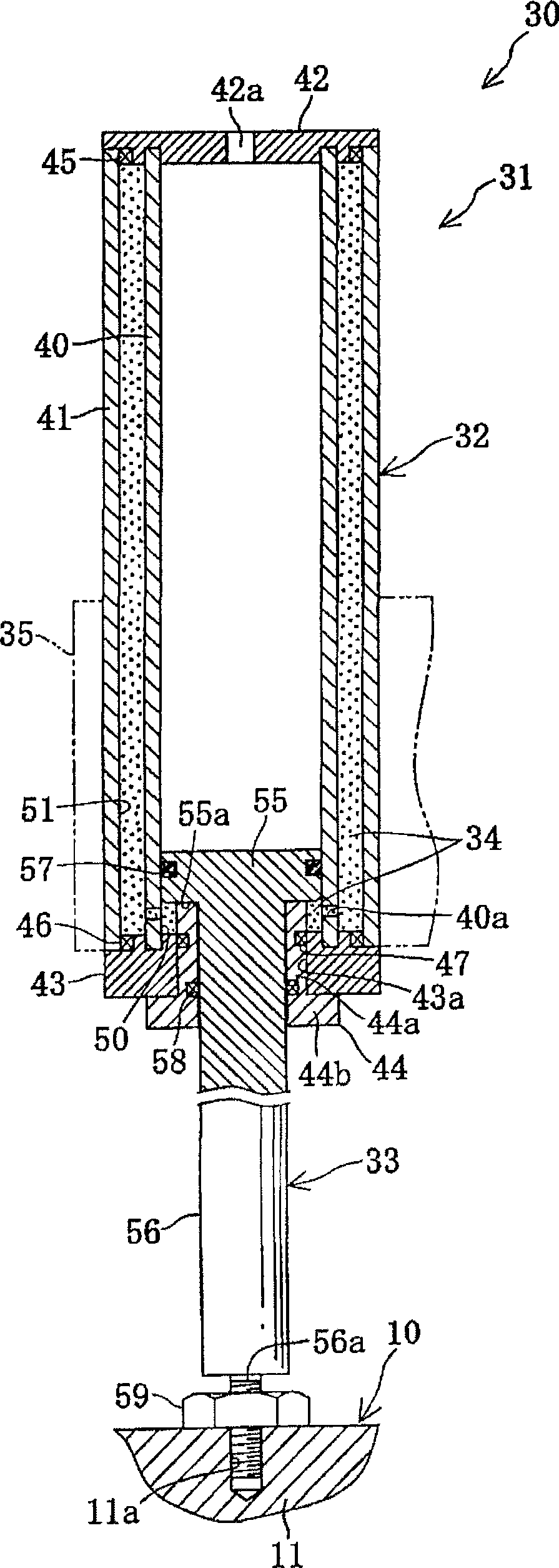

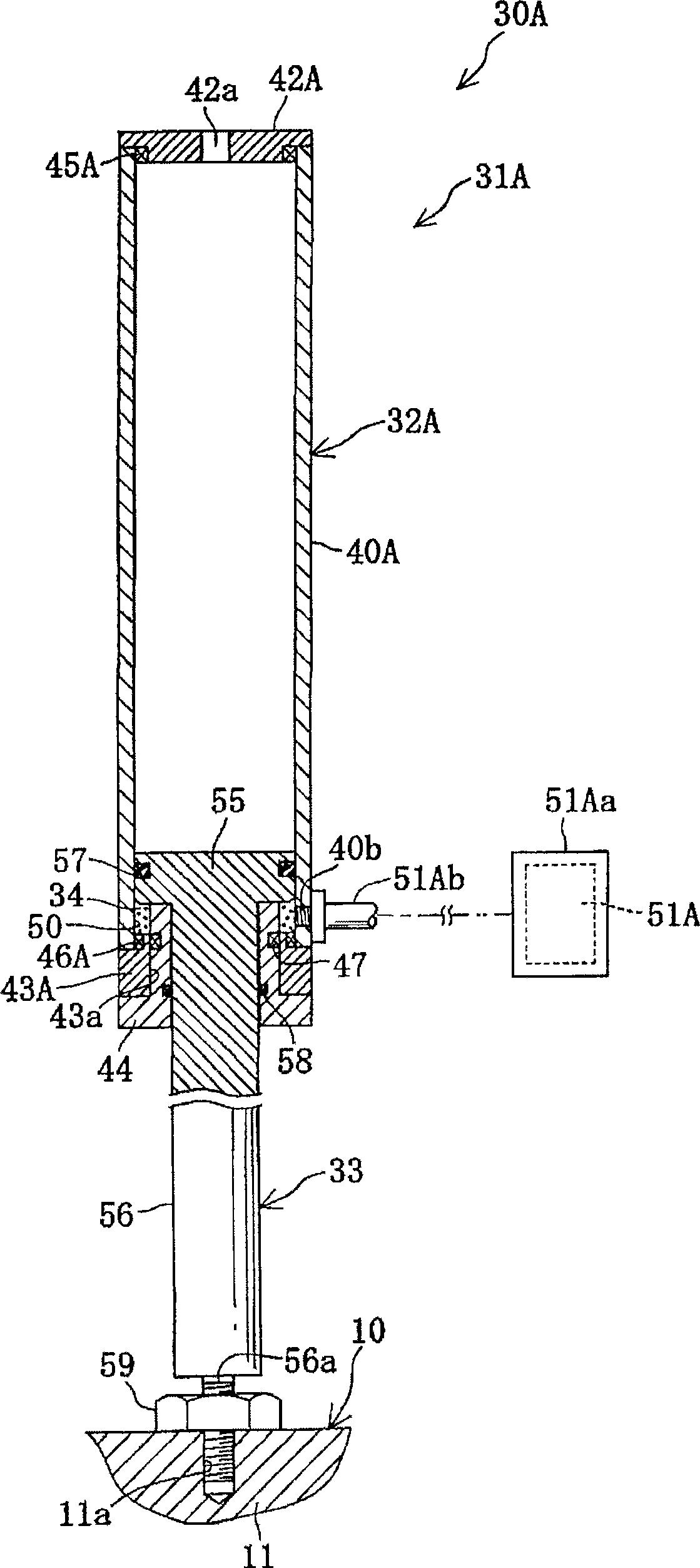

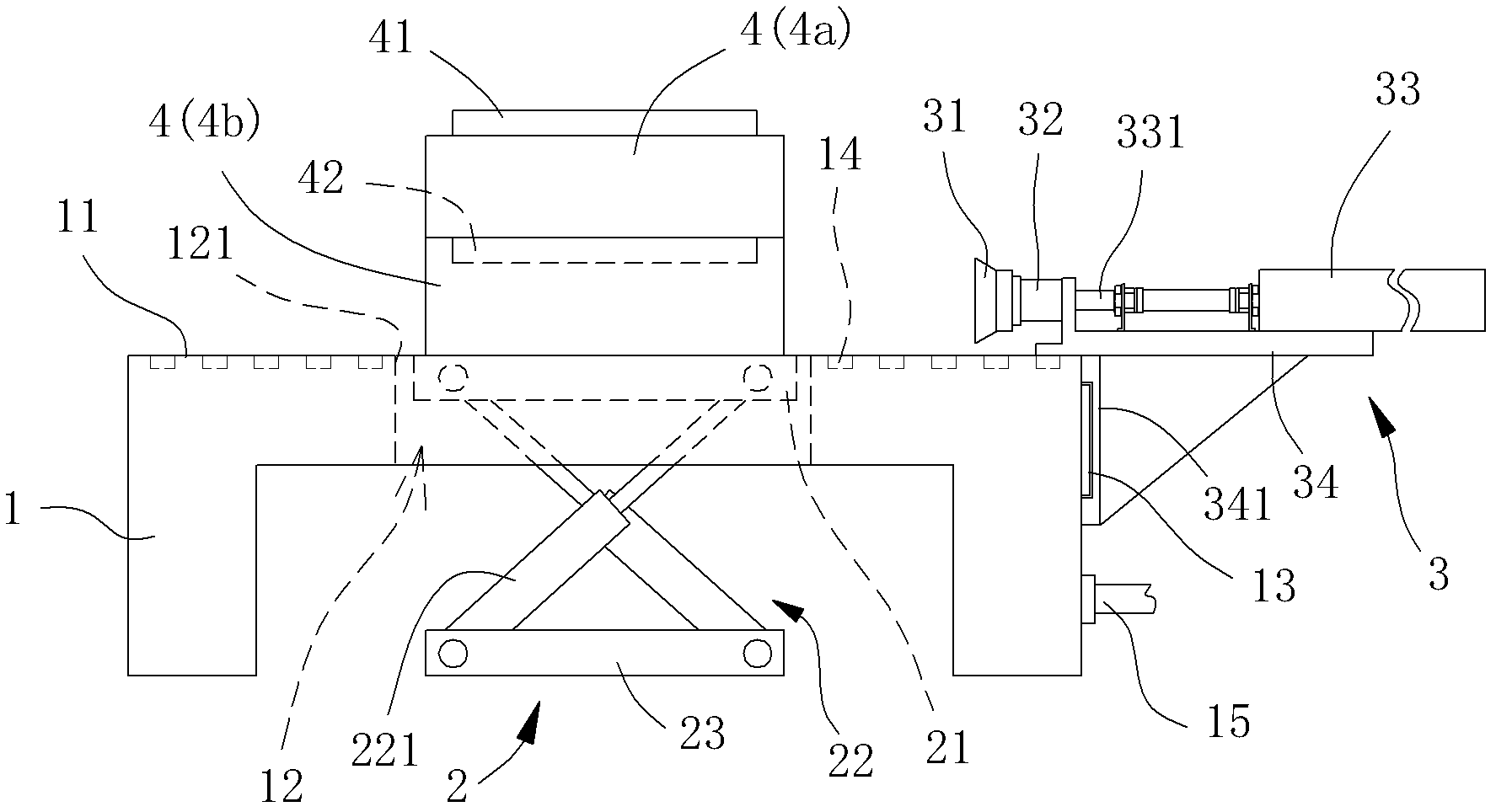

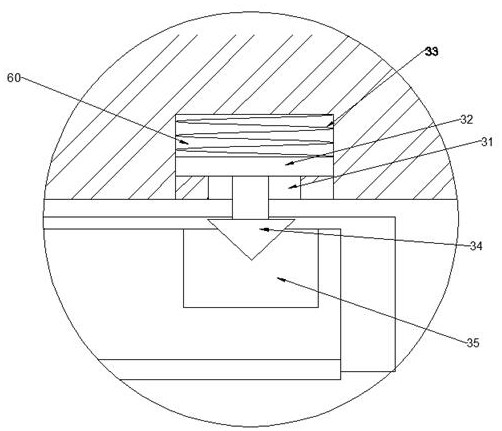

Main shaft balance device for toolroom machine

InactiveCN101394970AEnsure degrees of freedomEffective supportLarge fixed membersBoring/drilling componentsPull forceMiniaturization

A machine tool main spindle balancer that stably pulls and urges a main spindle unit upward to reliably and effectively reduce a load for lifting a means for lifting the main spindle unit, that can be easily applied to existing machine tools, that is excellent in durability and is downsized, and that can be constructed in a simple structure to make the balancer advantageous in production costs. The main spindle balancer (30) has a gas spring (31) having a cylinder body (32), a rod (33), and compressed gas. The gas spring (31) is placed above the main spindle unit (10). The lower end of the rod (33) is connected to the main spindle unit (10) so that the rod (33) can pull and urges the main spindle unit (10) upward by urging force acting on the rod (33) of the gas spring (31). The urging force by the gas spring (31) reduced a load on a lifting mechanism (20).

Owner:PASCAL ENG

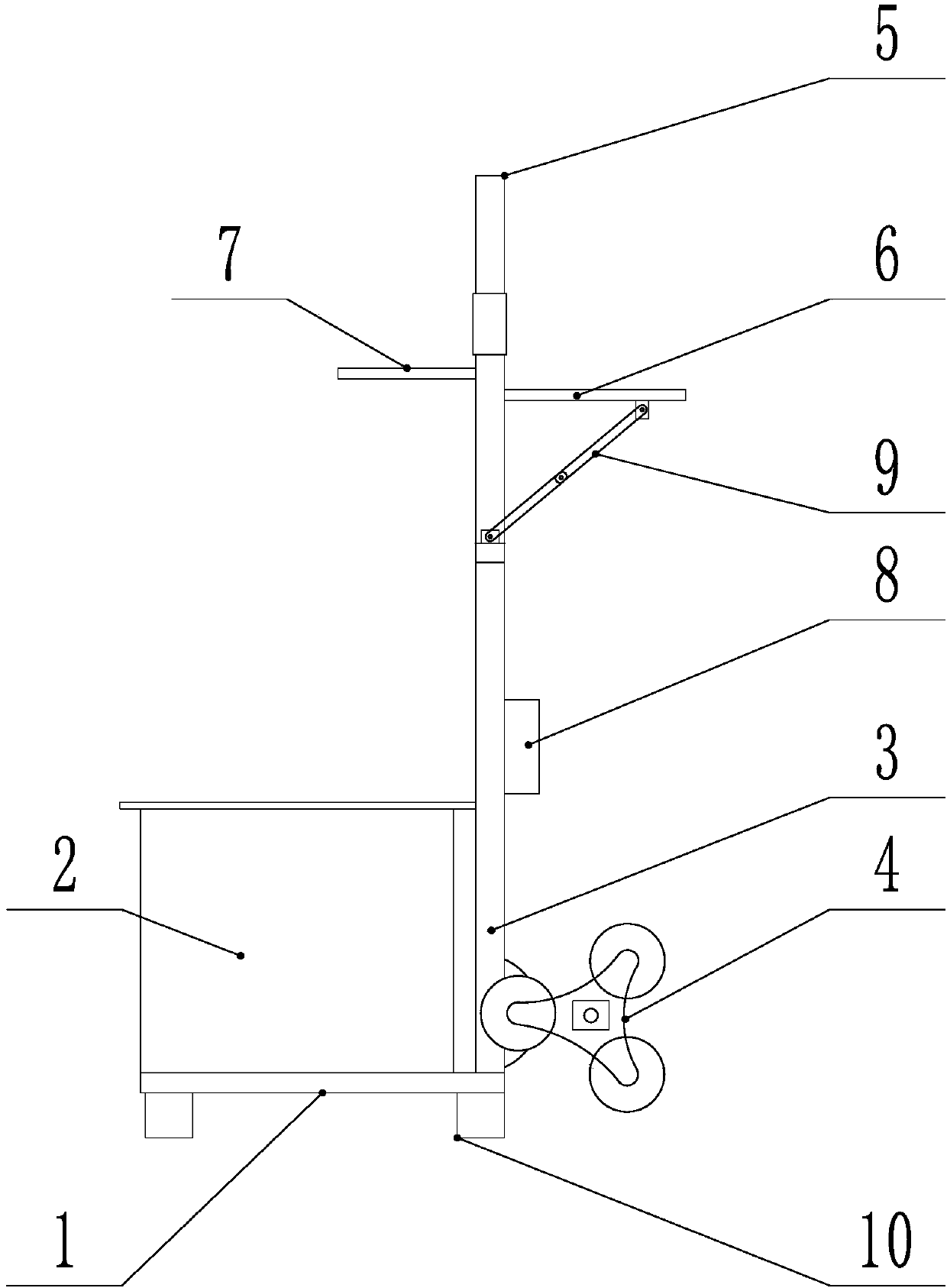

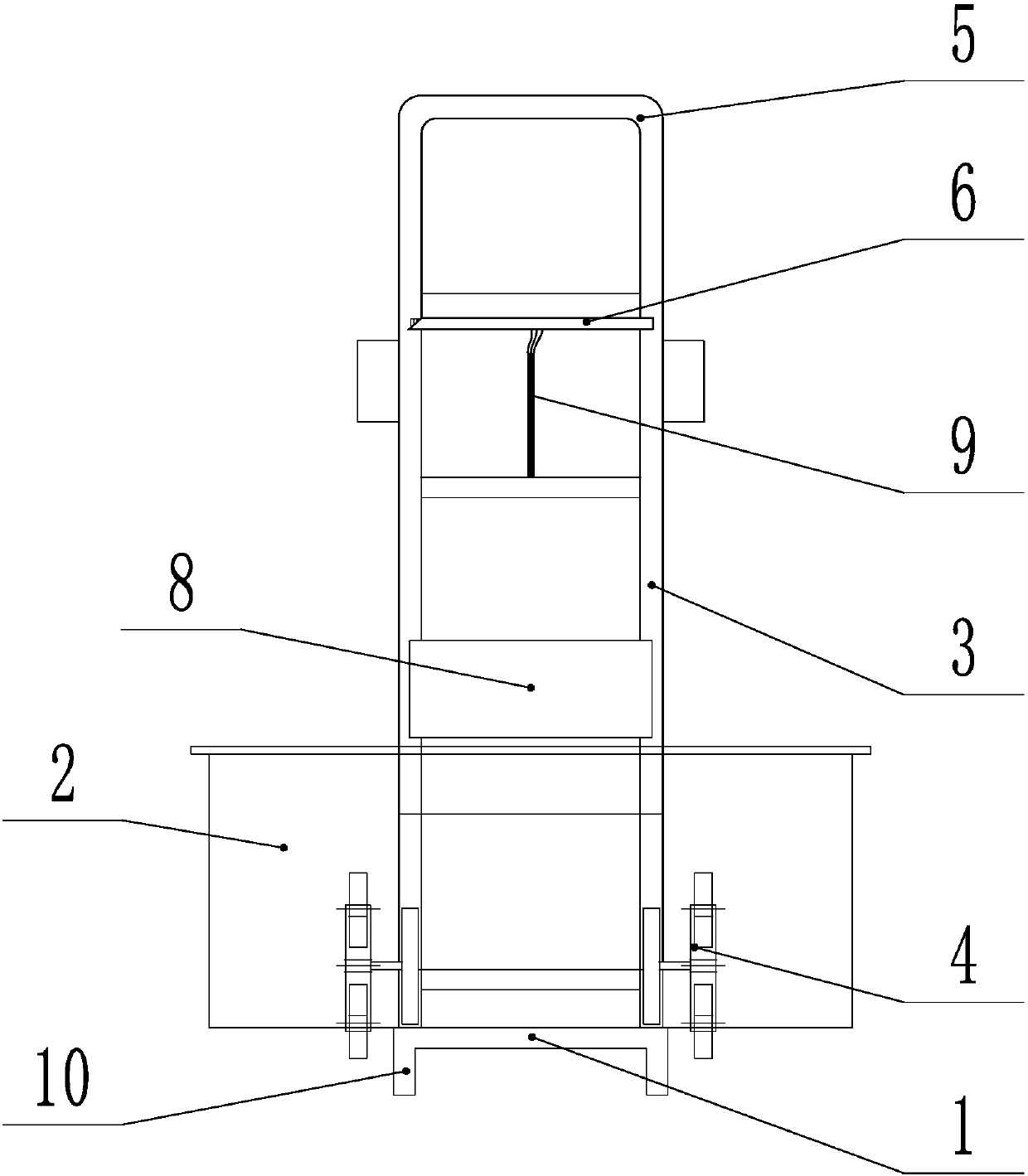

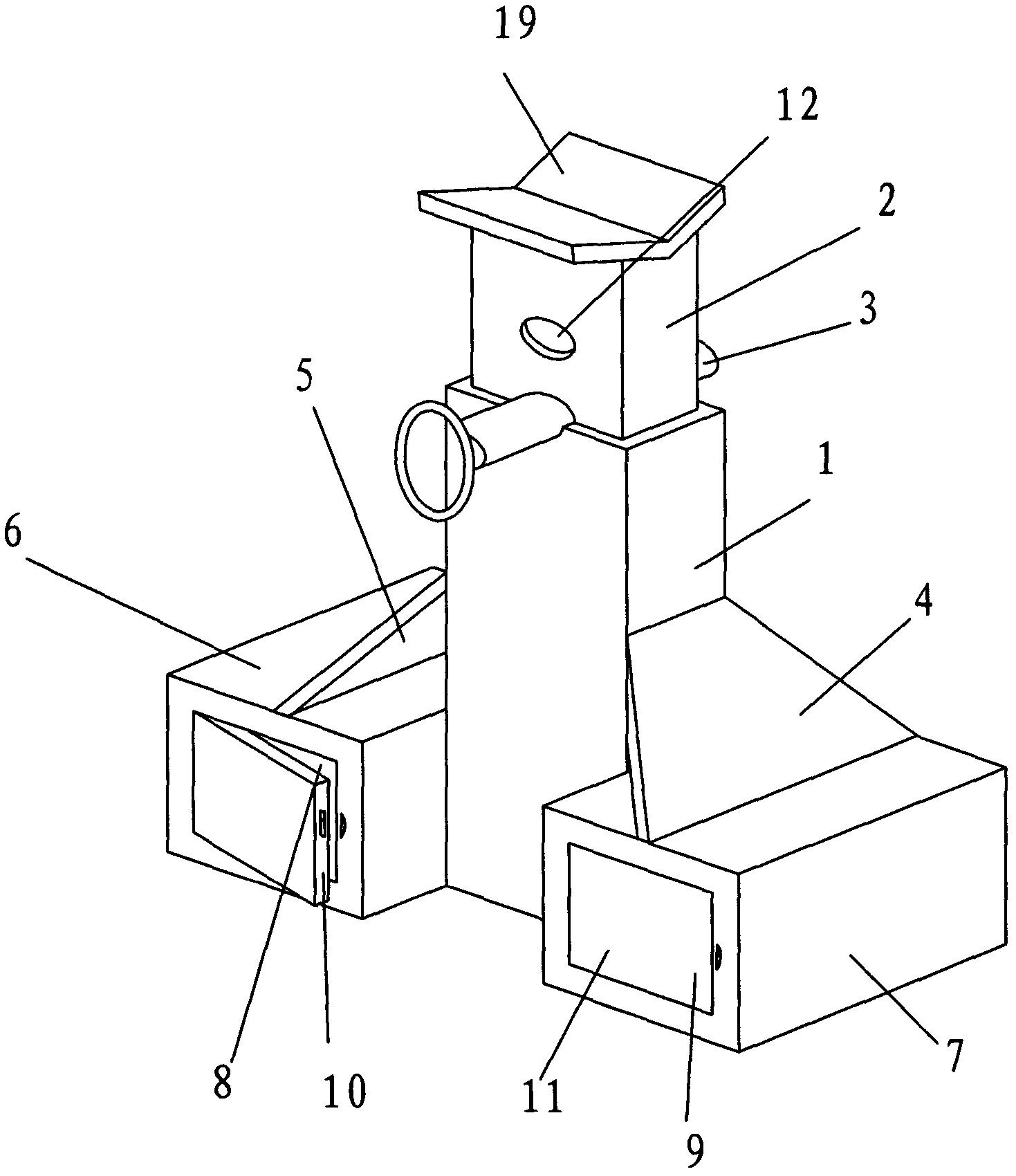

Transformer substation operation and maintenance pull rod tool cart of three-idler-wheel structure

PendingCN107719420AReduce workloadReduce the intensity of handling workHand carts with one axisHand cart accessoriesCartTroubleshooting

The invention provides a transformer substation operation and maintenance pull rod tool cart of a three-idler-wheel structure, and relates to the field of transformer substation operation and maintenance. Currently, when power failure and power transmission operation is normally conducted, a tool chamber is far from a primary equipment area, many operation tools exist and need to be carry many times, and the additional workload of operation team personnel is increased. The transformer substation operation and maintenance pull rod tool cart comprises a baseboard, a vertical support, an object storage box, two sets of trundles and a pull handle, an operating ticket clamp is arranged at the right side of the middle of the support, an operating ticket platform capable of turning downwards is arranged at the right side of the upper portion of the support, an insulating rod electroscope placing platform is arranged at the left side of the upper portion of the support, both sets of trundles are of the three-idler-wheel structure in which every two idler wheels are spaced by 120 degrees in a vertical plane, and one idler wheel is connected to the right side of the lower portion of the support; a two-connecting rod foldable supporting structure is arranged between the lower portion of the operating ticket platform and the support. By means of the transformer substation operation and maintenance pull rod tool cart of the three-idler-wheel structure, carrying multiple tools is achieved simultaneously, a multifunctional processing platform is provided, the carrying workload is reduced,the carrying work intensity is lowered, so that an operation and maintenance fault is more conveniently processed, and the processing time is shortened.

Owner:DAISHAN POWER SUPPLY CO STATE GRID ZHEJIANG ELECTRIC POWER CO +2

Hand-operated wheel

InactiveCN101561673ALow costNot easy to wearProgramme controlComputer controlKey pressingSemiconductor chip

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

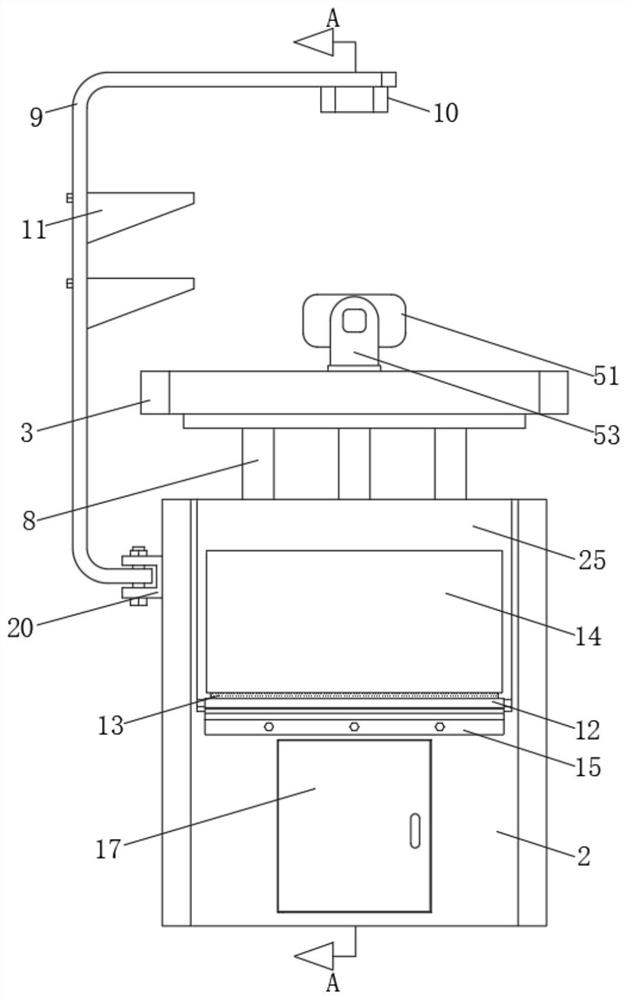

Auxiliary device for new energy automobile part detection

The invention discloses an auxiliary device for new energy automobile part detection. The auxiliary device for new energy automobile part detection comprises a box body, a lifting mechanism and a partfixing mechanism, wherein the box body is a regular-quadrangular-prism box, a lifting cavity, a power supply chamber and a tool chamber are formed in the box body, the lifting cavity is located at the top end of the power supply chamber and formed in the top end of the box body, a top plate is fixed to the top end of the lifting cavity through bolts, the power supply chamber is located at the left side of the tool chamber, a power supply is installed in the power supply chamber, a first box door is formed in the left side surface of the power supply chamber, and a second box door is formed inthe right side surface of the tool chamber; and the lifting mechanism comprises a guide rod, a lifting plate, a first servo motor and a lead screw, the end part of the guide rod and the end part of the lead screw are both installed at the bottom end of the top plate. The auxiliary device for new energy automobile part detection can automatically and accurately adjust the height of a detection table, so that the part detection efficiency can be increased, and the fatigue feeling of workers can be reduced.

Owner:SUZHOU TRACEABILITY STANDARD CERTIFICATION & INSPECTION CO LTD

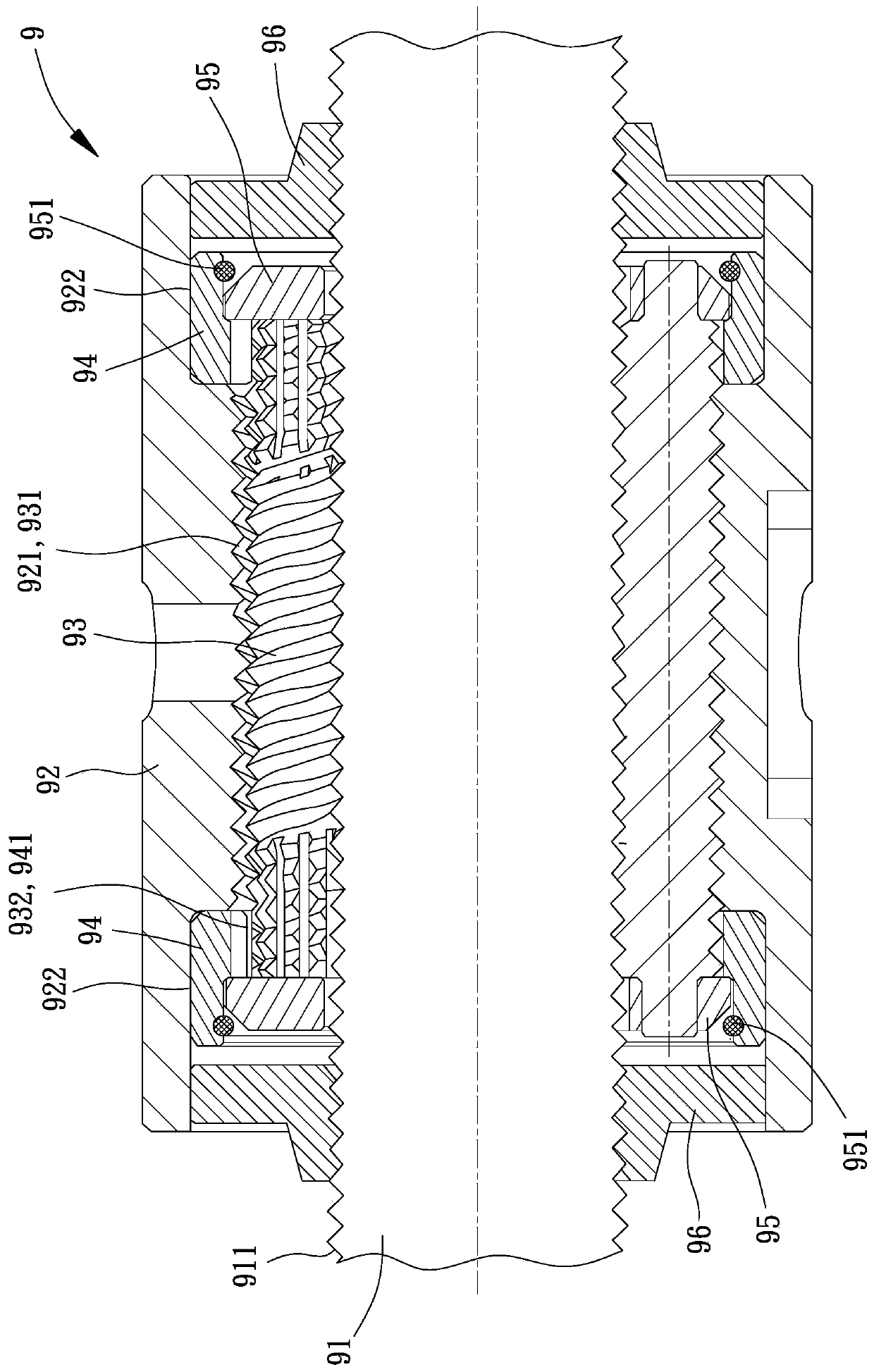

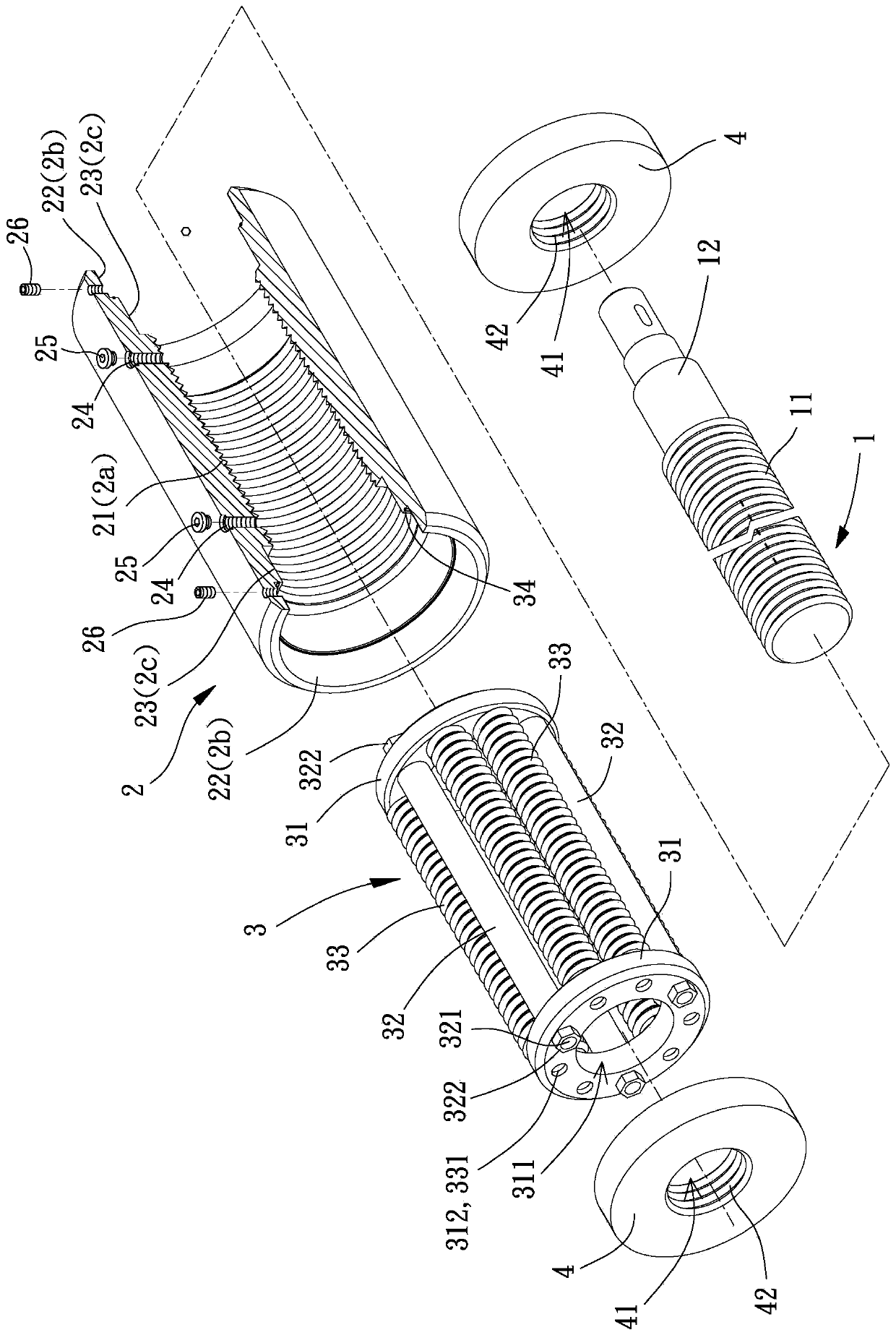

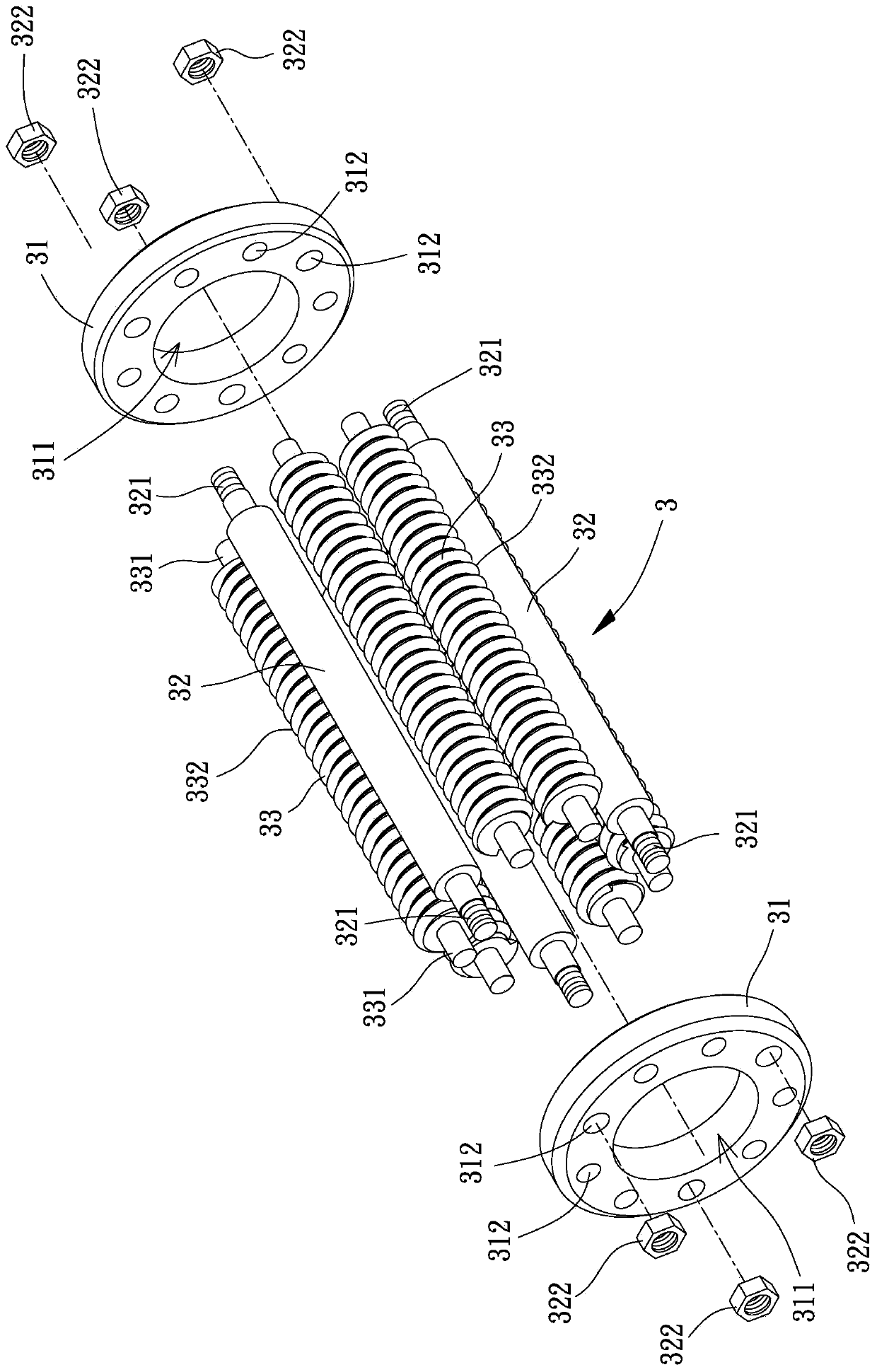

Planetary screw and toolroom machine with planetary screw

InactiveCN111219465AReduce processing costsReduce noiseGearingGear lubrication/coolingEngineeringToolroom

The invention provides a planetary screw and a toolroom machine with the planetary screw. The planetary screw and the toolroom machine with the planetary screw are used for solving the problems of complex structure and rotary noise of an existing planetary screw. The planetary screw comprises a main screw, a nut and a planet group, wherein the main screw is provided with an external thread and a connecting part; the nut is provided with a hole for penetrating through two end surfaces of the nut, and the inner wall surface for forming the hole is provided with an internal thread; and the planetgroup is provided with a supporting structure, the supporting structure is used for supporting a plurality of rolling columns to position and rotate on the supporting structure, the multiple rollingcolumns are the same with one another and provided with external threads, and the external threads of the multiple rolling columns mesh with the external thread of the main screw and the internal thread of the nut. The planetary screw can be used for the toolroom machine.

Owner:CHUAN HONG PRECISION TOOL MFG

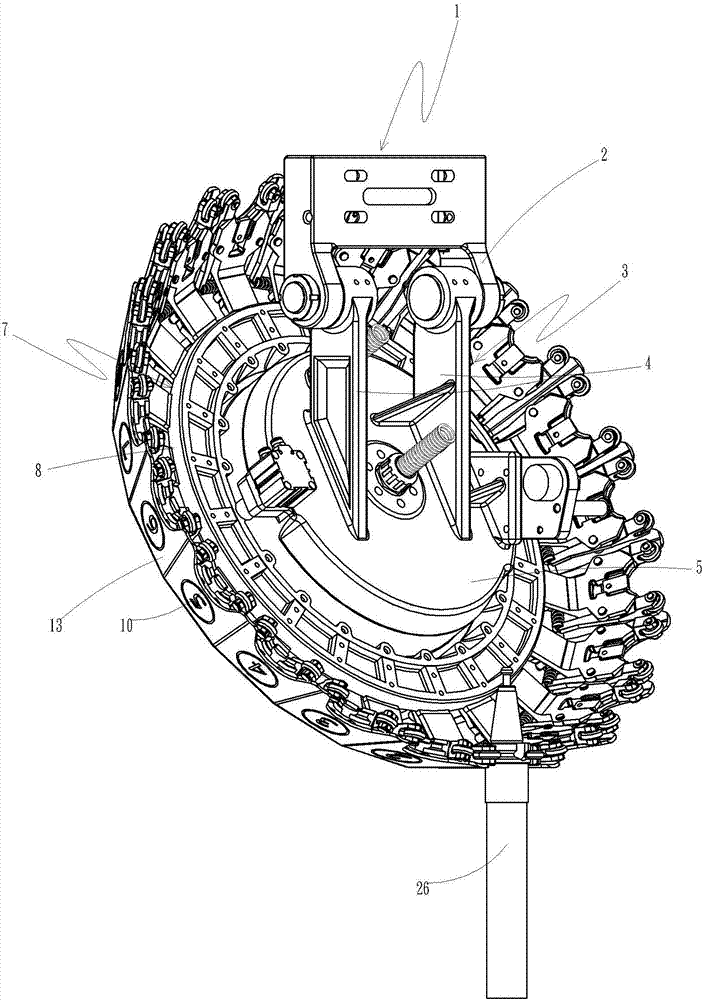

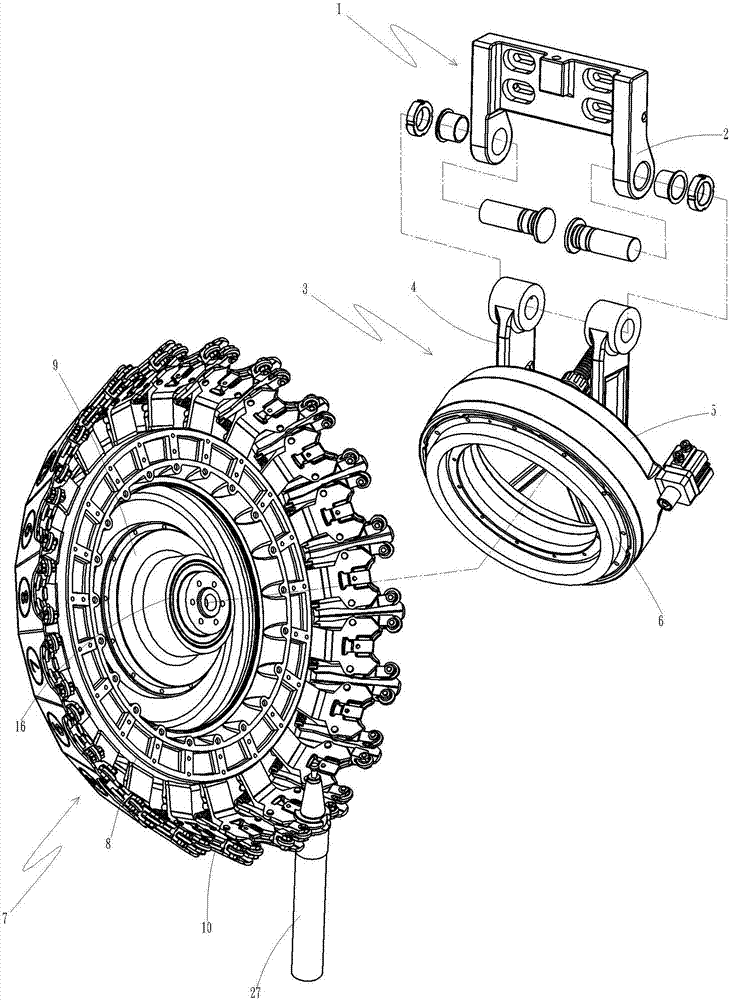

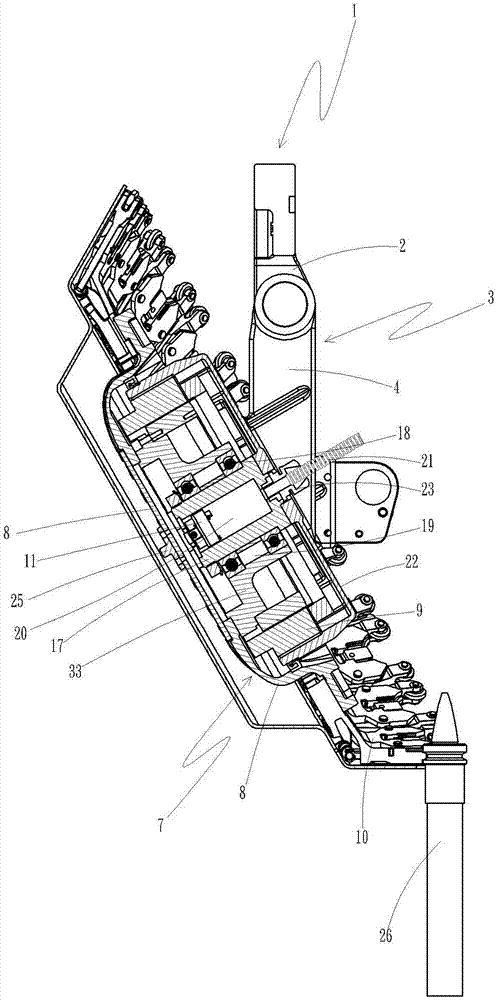

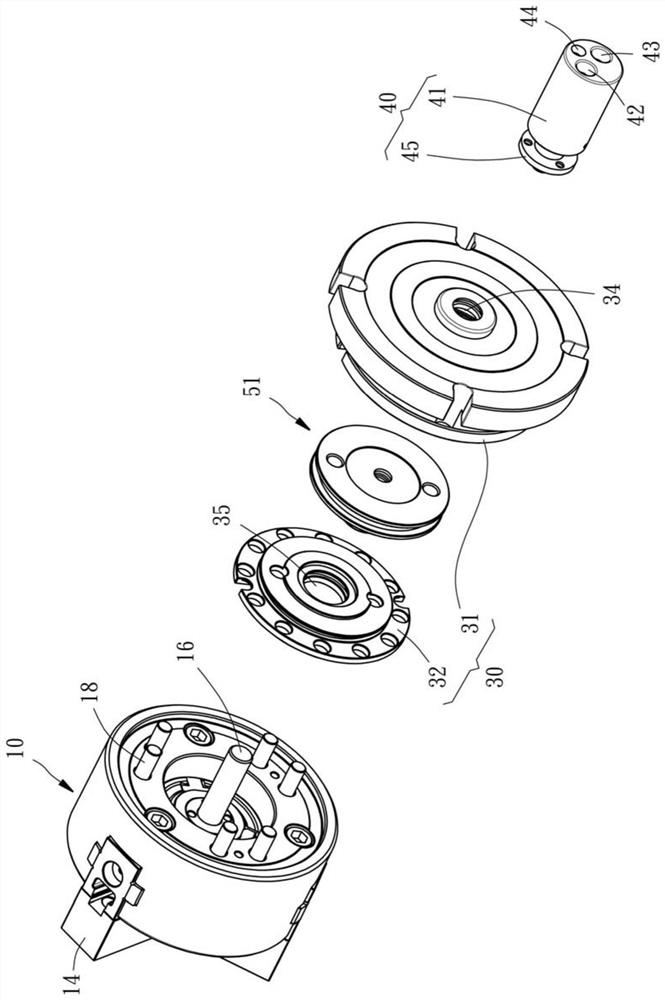

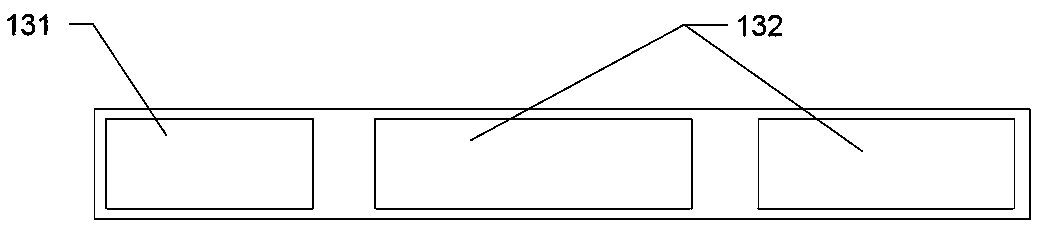

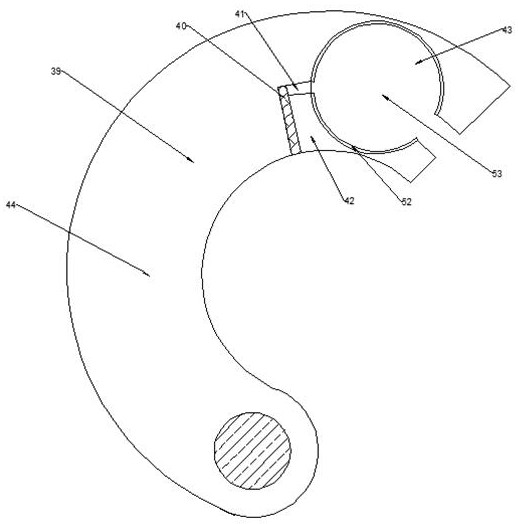

Tool magazine structure of direct-drive type servo motor controlled cutter disc

ActiveCN107052874AReduce wearReduce noisePositioning apparatusMetal-working holdersStructural engineeringToolroom

The invention provides a tool magazine structure of a direct-drive type servo motor controlled cutter disc. The tool magazine structure adopts a direct-drive type servo motor to directly drive a cutter disc rotating group, so that the tool magazine structure is simple in structure, low in loss coefficient, low in use cost and low in running noise. The tool magazine structure is arranged at a toolroom machine. The tool magazine structure is characterized in that the tool magazine structure comprises a fixing seat, a cutter disc seat body and a cutter containing disc group; two pivoting lugs are arranged on one side of the fixing seat; the fixing seat is combined with the toolroom machine; the cutter disc seat body is provided with pivoting arms; a cutter disc seat is fixedly arranged at the ends of the pivoting arms, and is internally provided with the direct-drive type servo motor; the pivoting arms are in pivoting combination with the pivoting lugs of the fixing seat correspondingly; the cutter containing disc group is provided with a cutter containing disc; a cutter disc mounting seat is fixedly arranged on the rear side of the center position of the cutter containing disc; a plurality of cutter and claw groups are annularly arranged at the periphery of the cutter containing disc; each cutter and claw group is provided with a cutter correspondingly; the cutter disc mounting seat is connected with the cutter disc seat body through the direct-drive type servo motor; and the cutter containing disc group is driven to rotate or stop by the direct-drive type servo motor electromagnetically.

Owner:昆山北钜机械有限公司

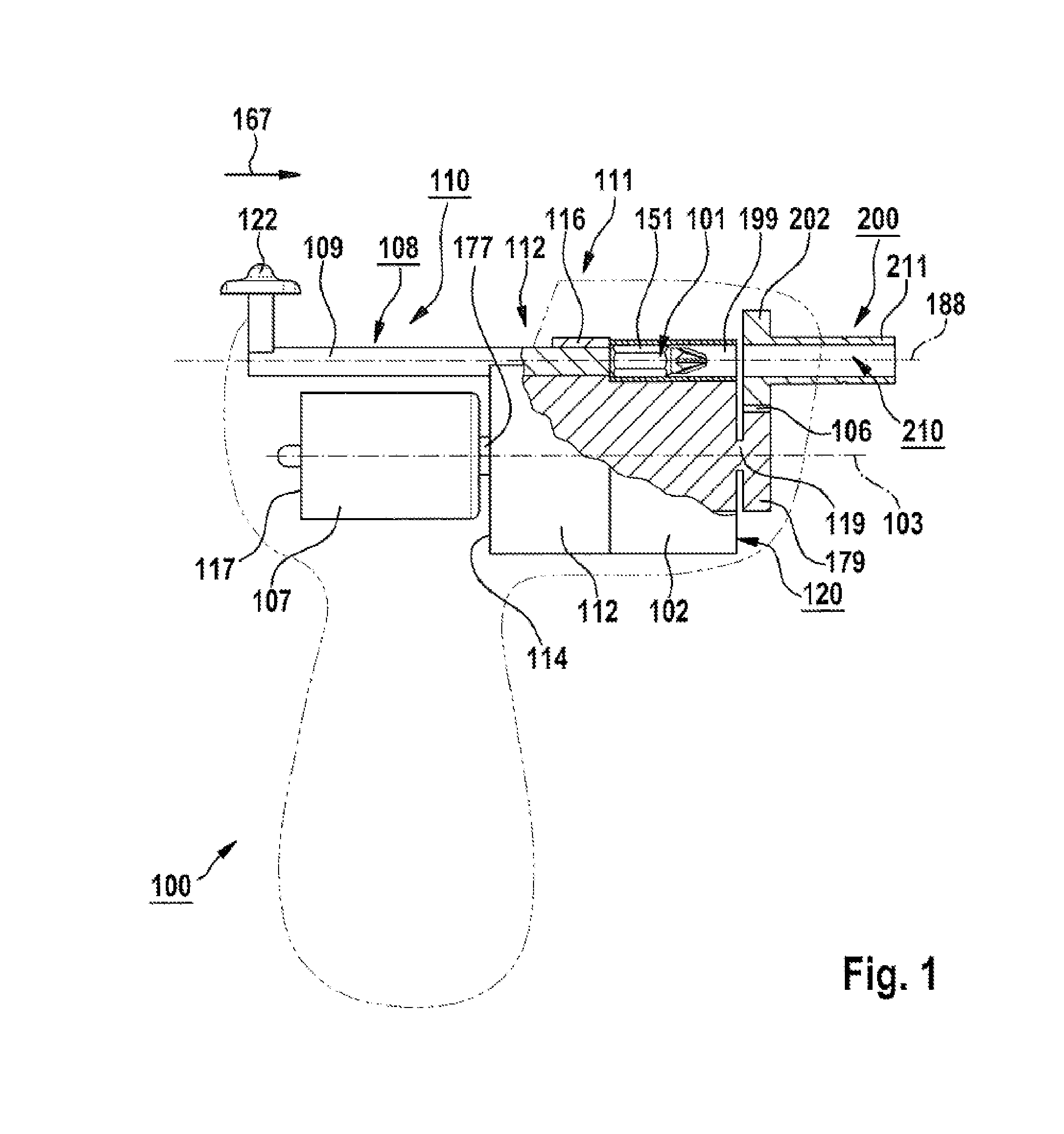

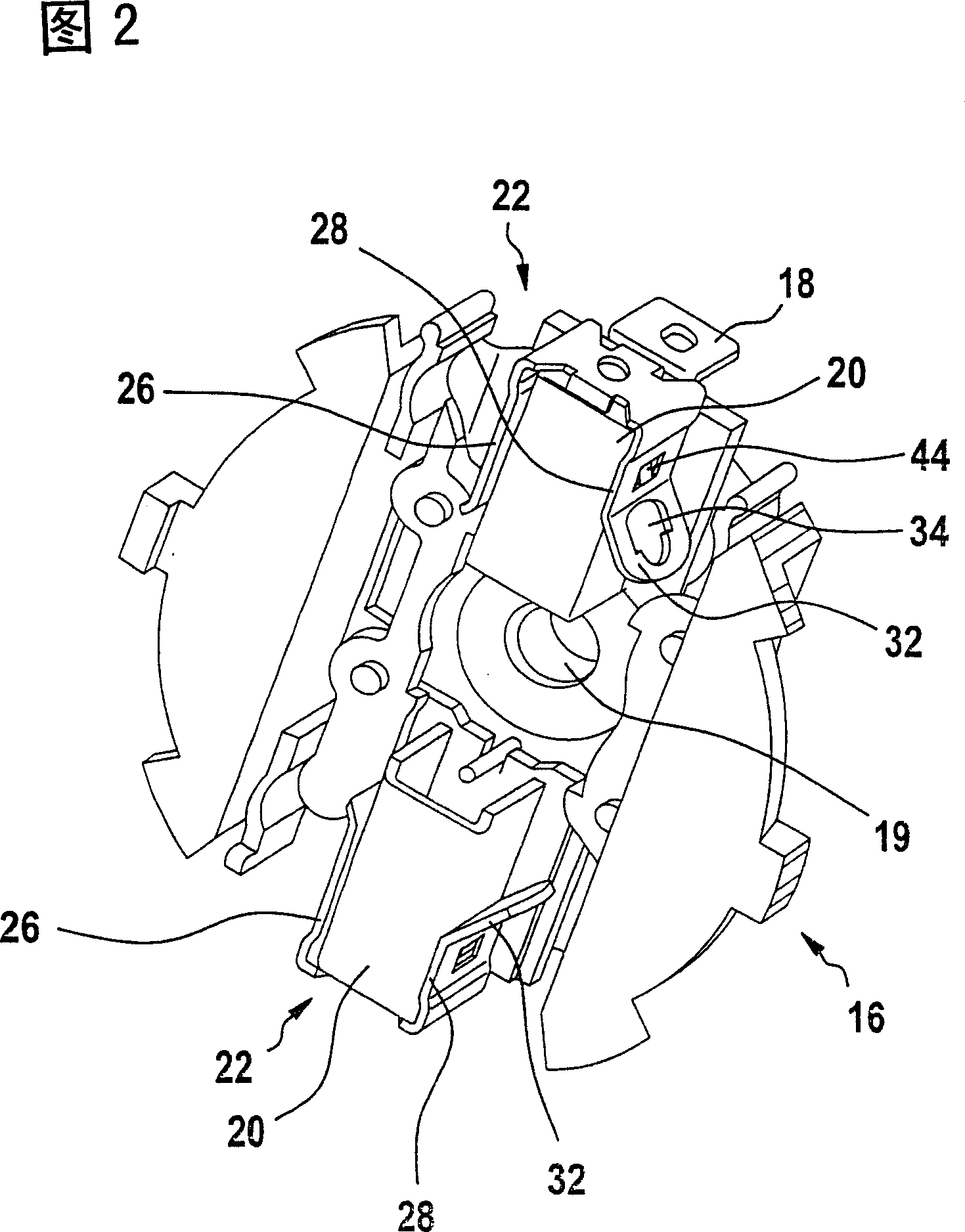

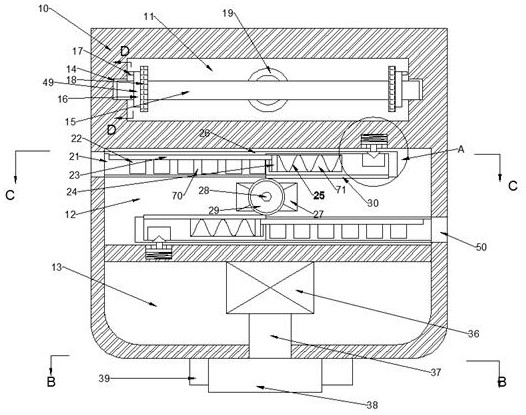

Motor-powered machine tool, in particular a hand-held machine tool

ActiveCN103209807AGood and sure guideSimple and precisely madeTool changing apparatusSpannersHand heldEngineering

The invention relates to a motor-powered machine tool (10), in particular a hand-held machine tool, comprising a drum-like tool-changing magazine (12) having tool chambers, which is arranged inside a housing (24), wherein in a change position one of the tool chambers of the tool-changing magazine (12) is aligned with a tubular tool holder (14; 54), and further comprising a sliding element (15) for sliding a tool (101) from the tool-changing magazine (12) into the tool holder (14; 54) and from the tool-changing magazine (12) back into the tool holder (14; 54), said sliding element being movable in a longitudinal direction of the tool holder (14; 54). According to the invention, the sliding element (15) is coupled with a gearbox system (20) comprising at least one toothed gear (18, 18a, 18b, 19, 19a, 19b), the rotational motion of which is translated into linear movement of the sliding element (15).

Owner:ROBERT BOSCH GMBH

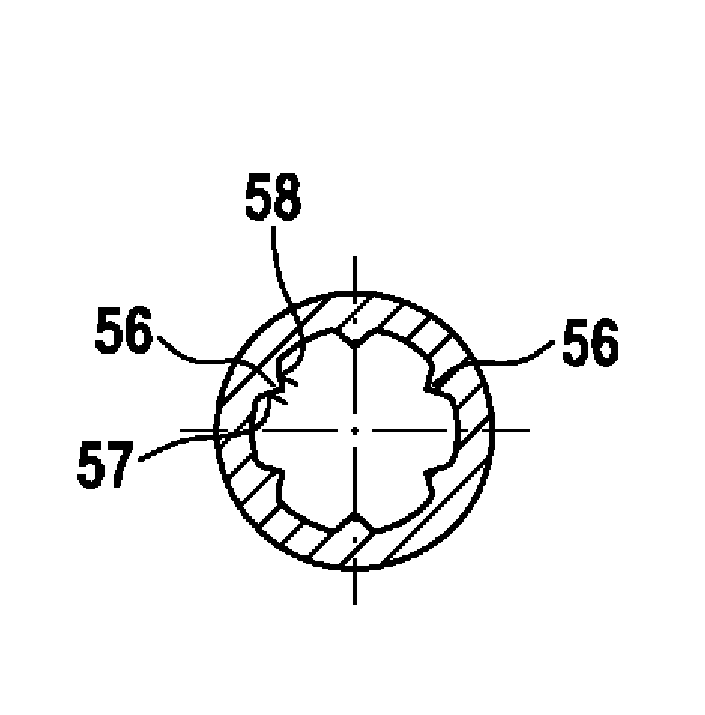

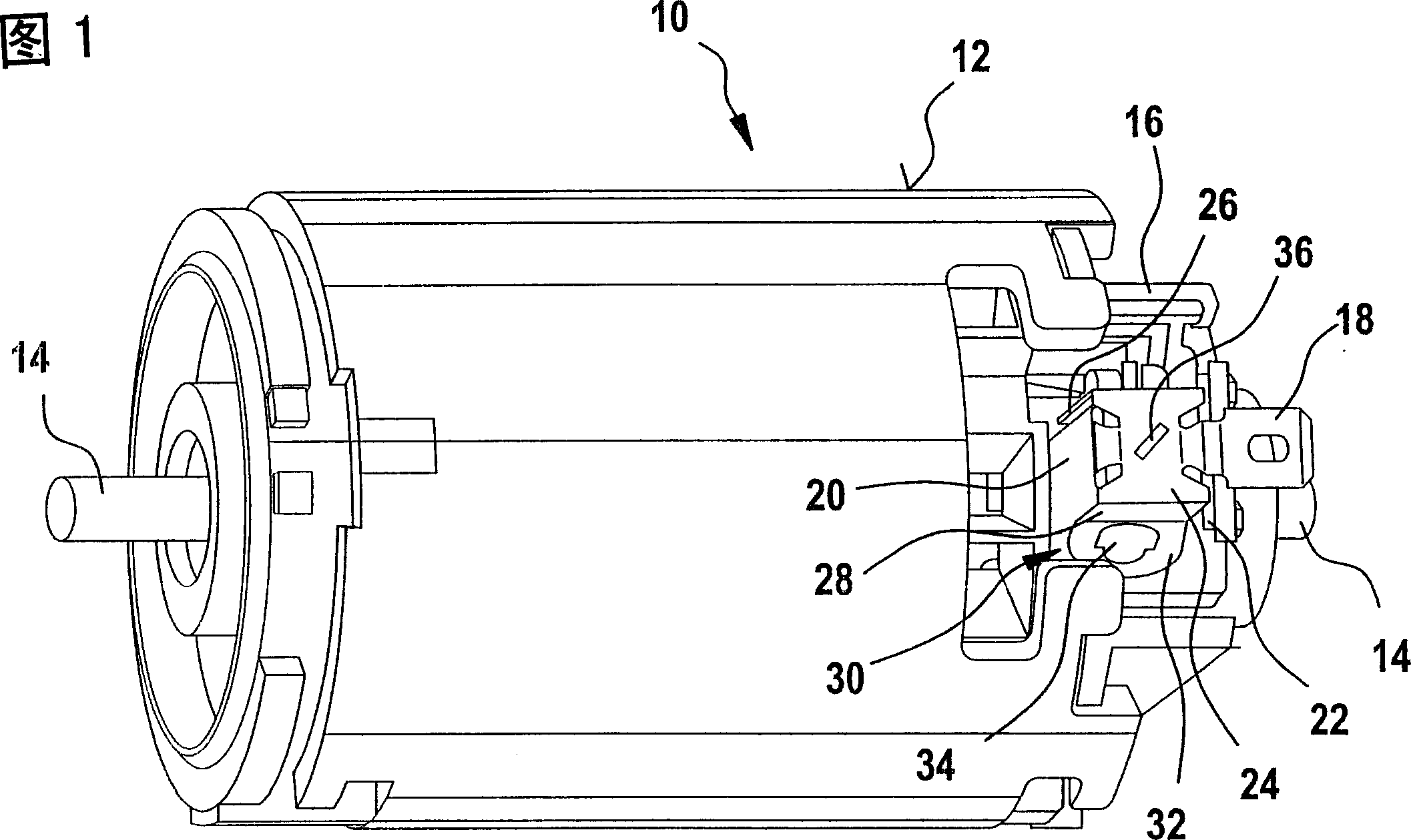

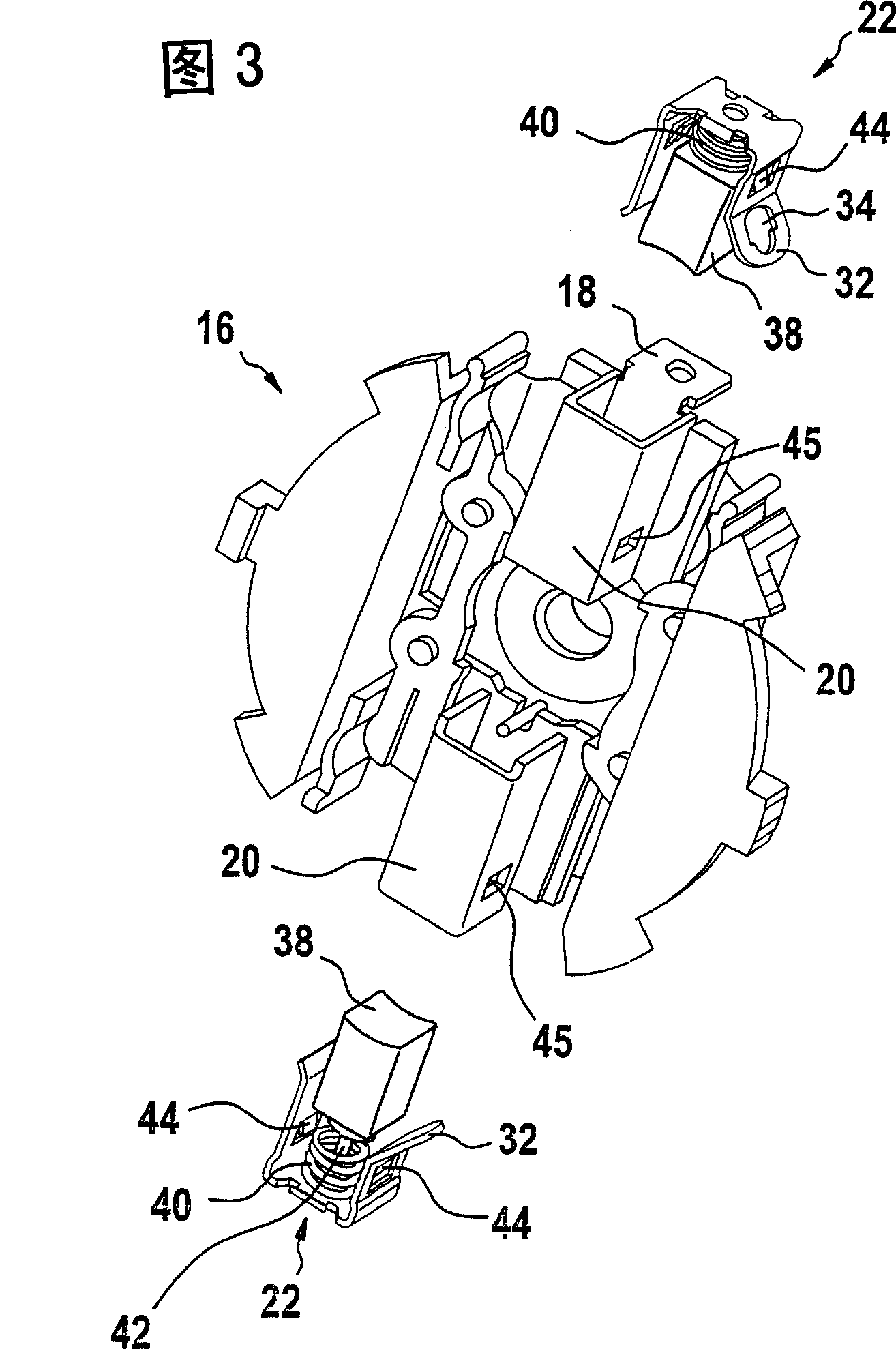

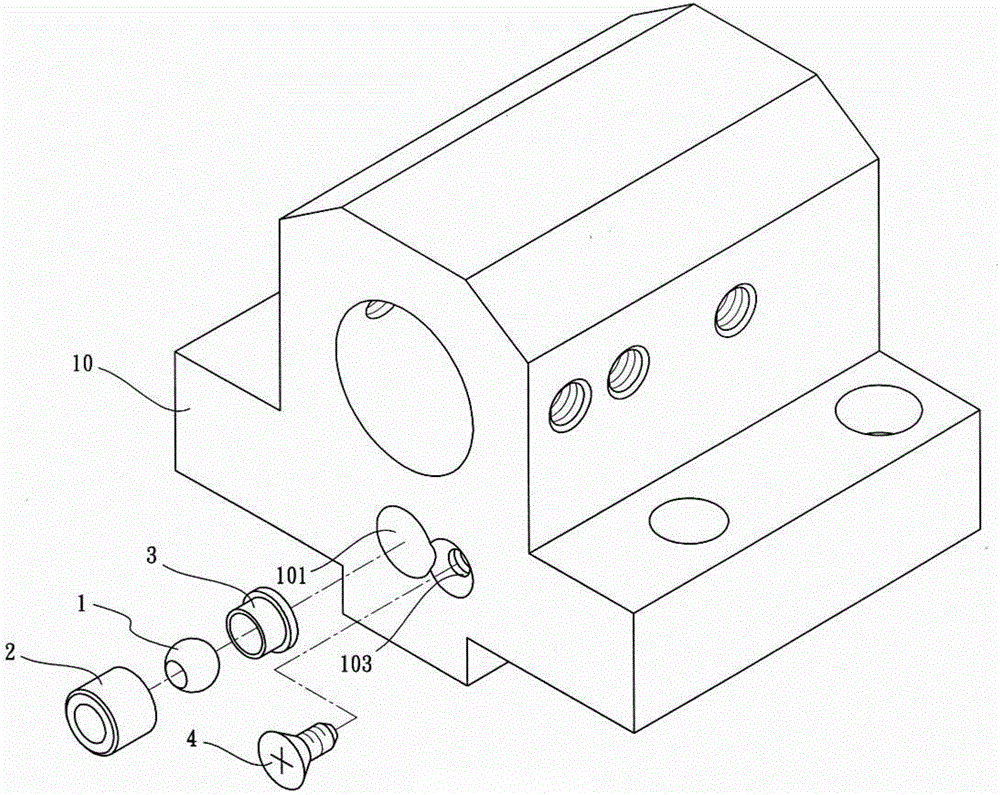

Electric motor for hand toolroom machines

InactiveCN1320735CEasy to fixRotary current collectorManufacturing dynamo-electric machinesDetentHand held

The invention relates to an electric motor (10) comprising a rotor, in addition to replaceable carbon brushes (38). One end of said brushes can be connected to a current source and the other end can be electrically connected to the rotor. The carbon brushes (38), each of which is mounted in a brush holder (20) so that it can be displaced longitudinally, are secured axially, in particular in a spring-loaded manner by a respective detent cap (22). The maintenance of said motor is facilitated by the fact that the detent cap (22) can be fixed to the brush holder (20) in a non-positive and / or positive fit and comprises at least one separate engagement element (34, 36) for a tool (46) that releases the detent cap (22) from the brush holder (20).

Owner:SCINTILLA AKTIENGES

Electric motor for hand toolroom machines

InactiveCN1663097AQuick and reliable removalEasy to fixRotary current collectorManufacturing dynamo-electric machinesToolroomEngineering

The invention relates to an electric motor (10) comprising a rotor, in addition to replaceable carbon brushes (38). One end of said brushes can be connected to a current source and the other end can be electrically connected to the rotor. The carbon brushes (38), each of which is mounted in a brush holder (20) so that it can be displaced longitudinally, are secured axially, in particular in a spring-loaded manner by a respective detent cap (22). The maintenance of said motor is facilitated by the fact that the detent cap (22) can be fixed to the brush holder (20) in a non-positive and / or positive fit and comprises at least one separate engagement element (34, 36) for a tool (46) that releases the detent cap (22) from the brush holder (20).

Owner:SCINTILLA AKTIENGES

Maintenance enterprise intelligent tool management system based on RFID technology

ActiveCN112668355AQuick Batch ManagementReduce labor costsDigital data protectionRecord carriers used with machinesInformatizationSoftware system

The invention discloses a maintenance enterprise intelligent tool management system based on the RFID technology. The maintenance enterprise intelligent tool management system comprises a management system database server, a handheld terminal, various maintenance tools with RFID tags, intelligent tool cabinets arranged in workshops, and an intelligent tool management software system. The intelligent tool management software system comprises a tool cabinet management software system deployed on a tool cabinet industrial personal computer, a terminal software system deployed on a handheld terminal and a tool room tool management software system deployed on a tool room computer. And the tool room tool management software system exchanges data with the management system database server to store and call the data. The informatization degree is high, complex and various maintenance tools are subjected to informatization statistics, classification, planning and use, the maintenance efficiency is greatly improved, and safety accidents caused by tool loss in the maintenance process are reduced.

Owner:武汉中车四方维保中心有限公司

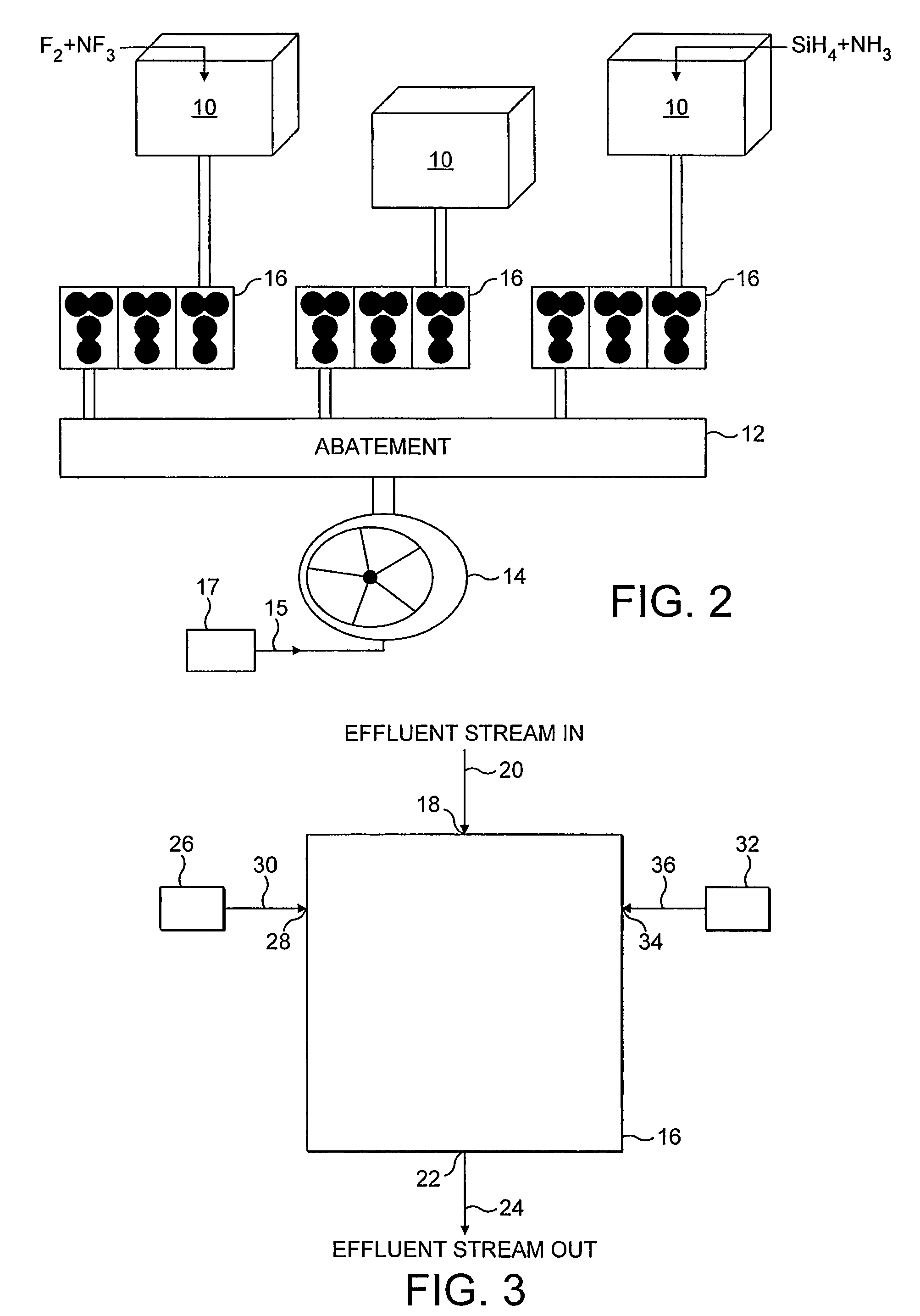

Gas abatement

ActiveUS8647580B2Improve efficiencyImprove processing efficiencyCombination devicesExhaust apparatusVacuum pumpingLiquid-ring pump

System for treating an effluent fluid stream from a process tool including a vacuum pump (16) for drawing an effluent stream from the process tool chamber, an abatement device (12) for treating the effluent stream and a liquid ring pump (14) for at least partially evacuating the abatement device (12). During use, the abatement device (12) converts one or more components of the effluent stream, for example F2 or a PFC, into one or more liquid-soluble a compounds, for example HF, that are less harmful to the environment. The liquid ring pump (14) receives the effluent stream and a liquid, and exhausts a solution of the liquid and the liquid-soluble component of the effluent stream. The liquid ring pump (14) thus operates as both a wet scrubber and an atmospheric vacuum pumping stage.

Owner:EDWARDS LTD

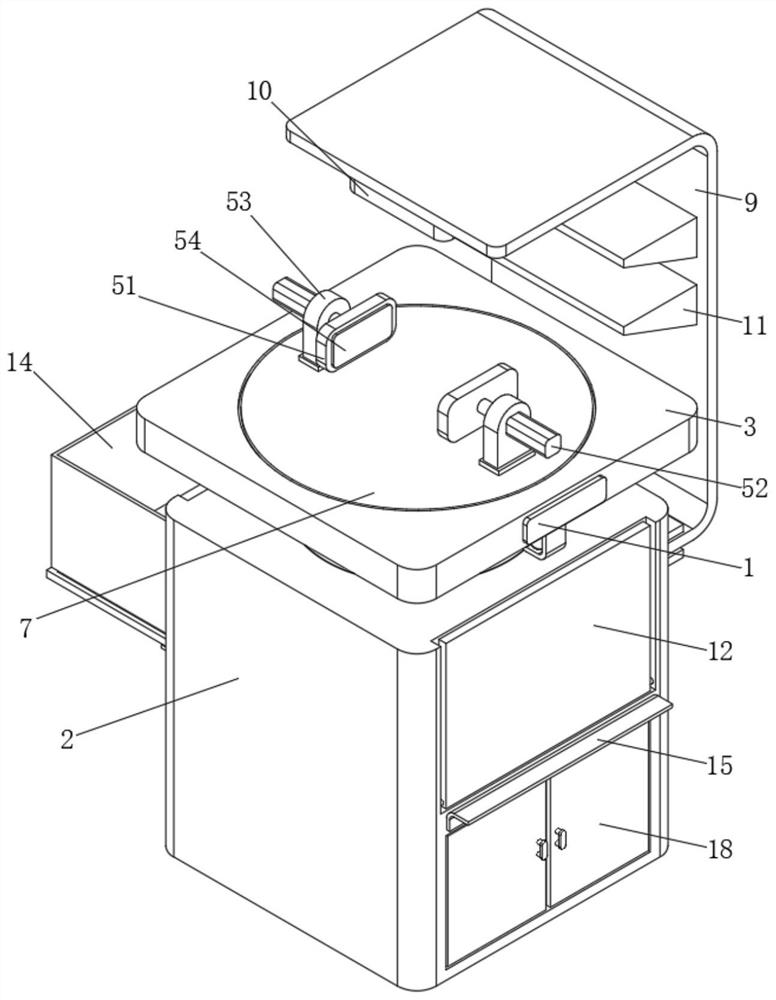

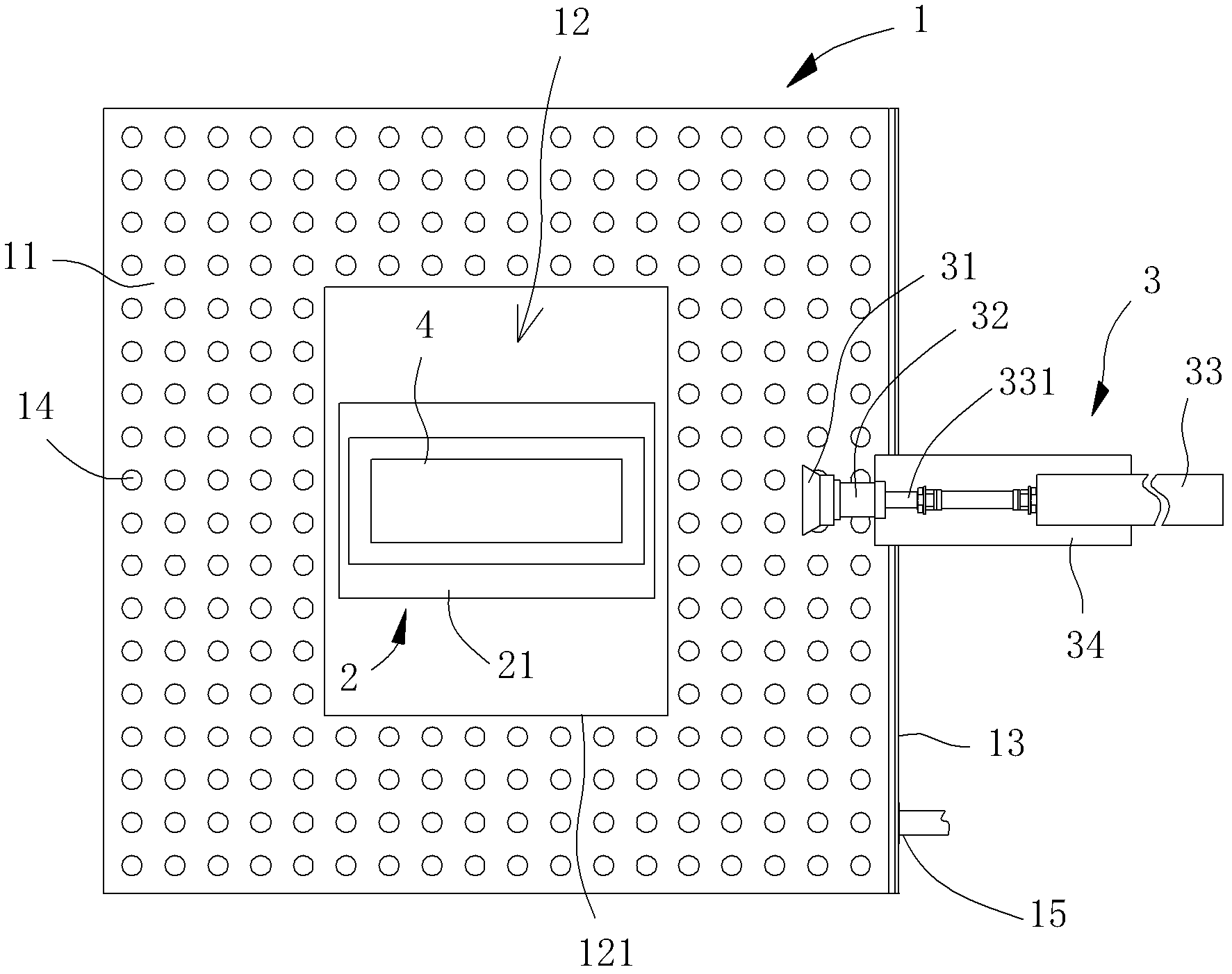

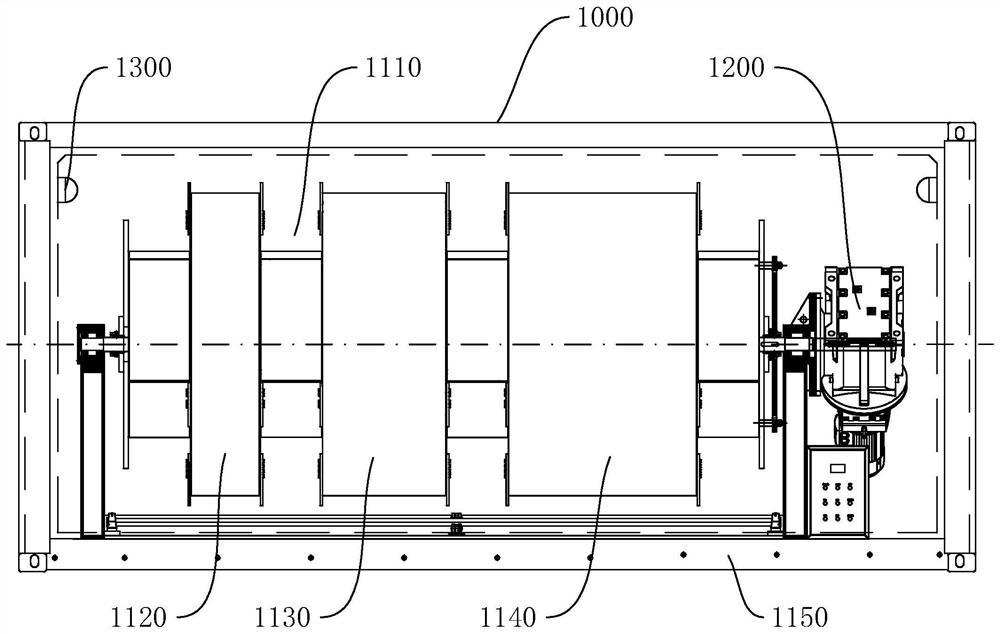

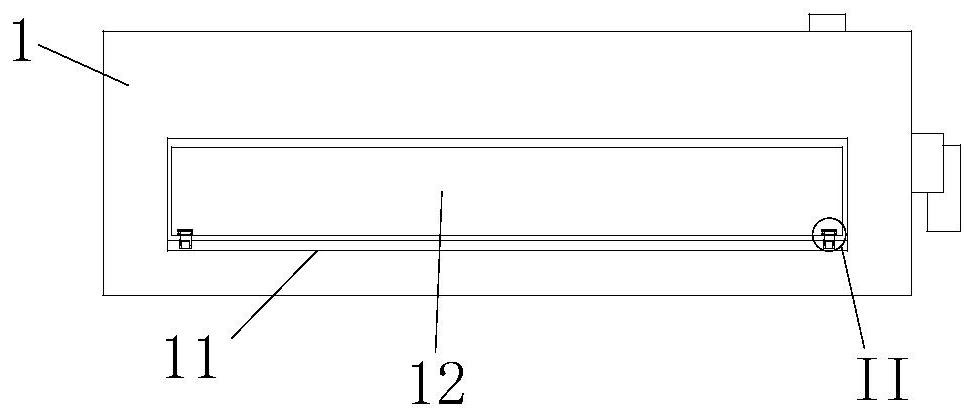

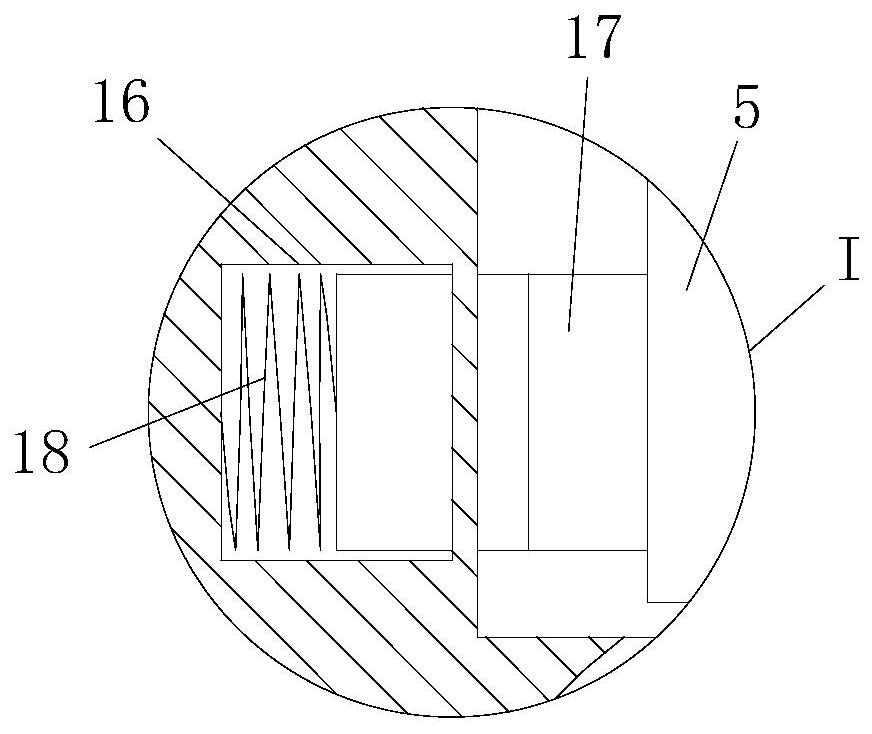

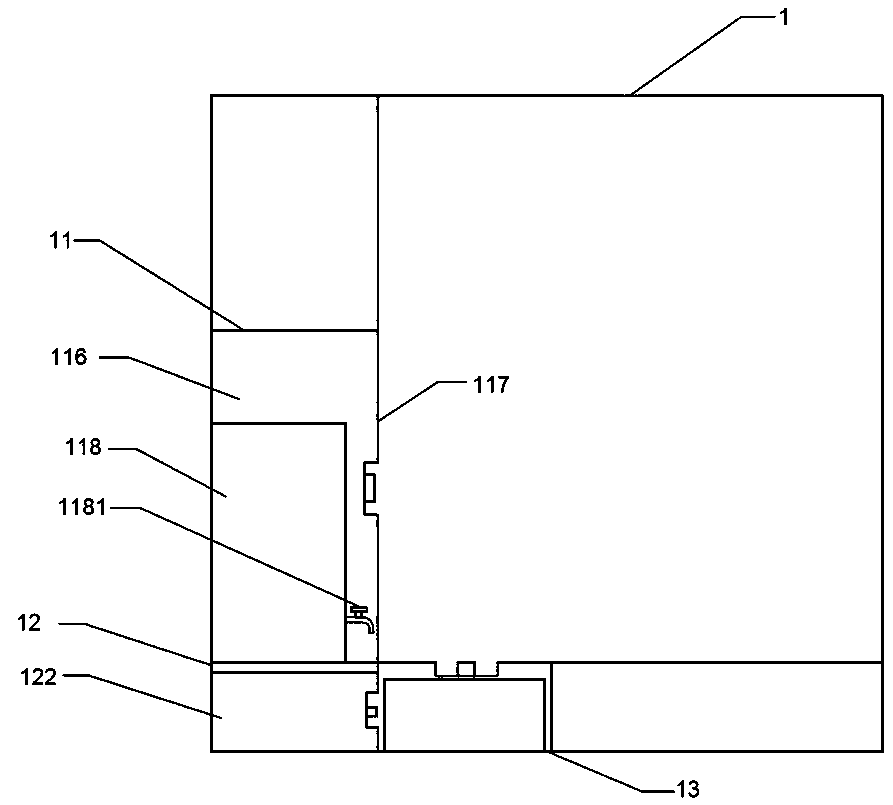

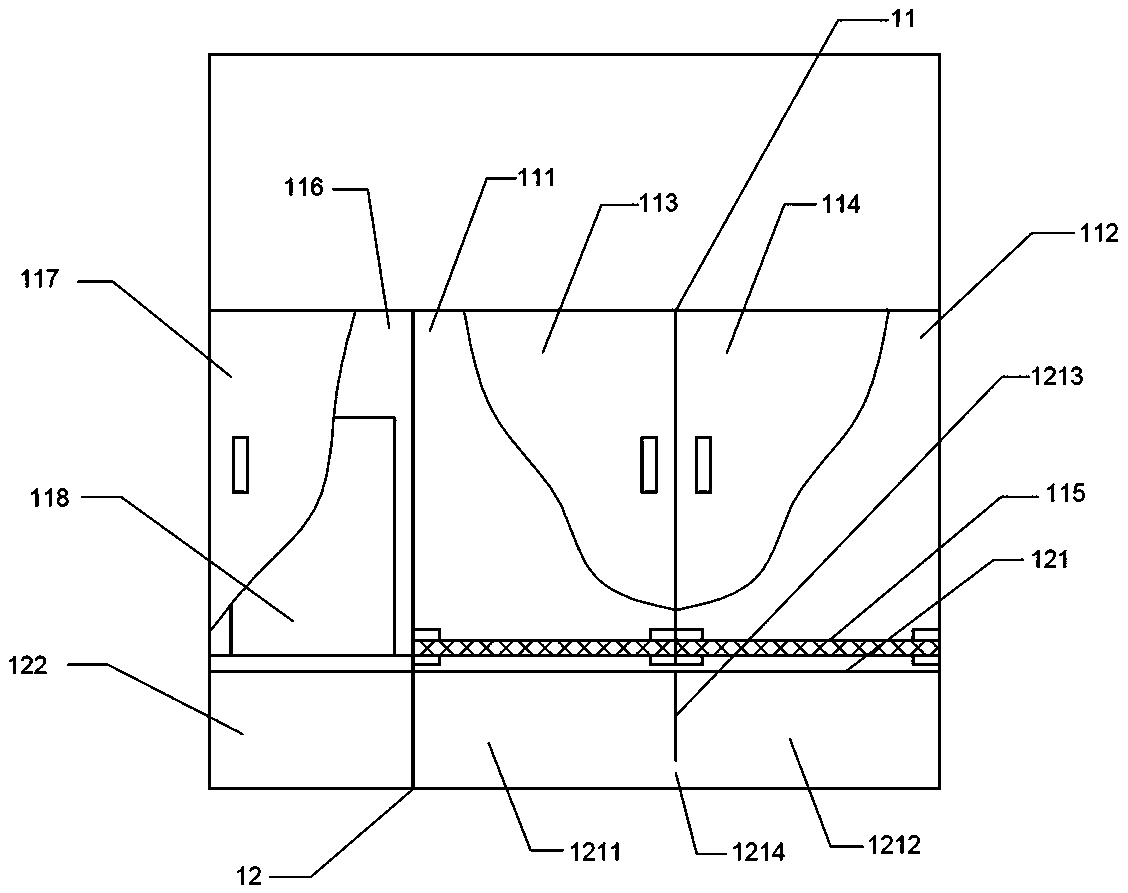

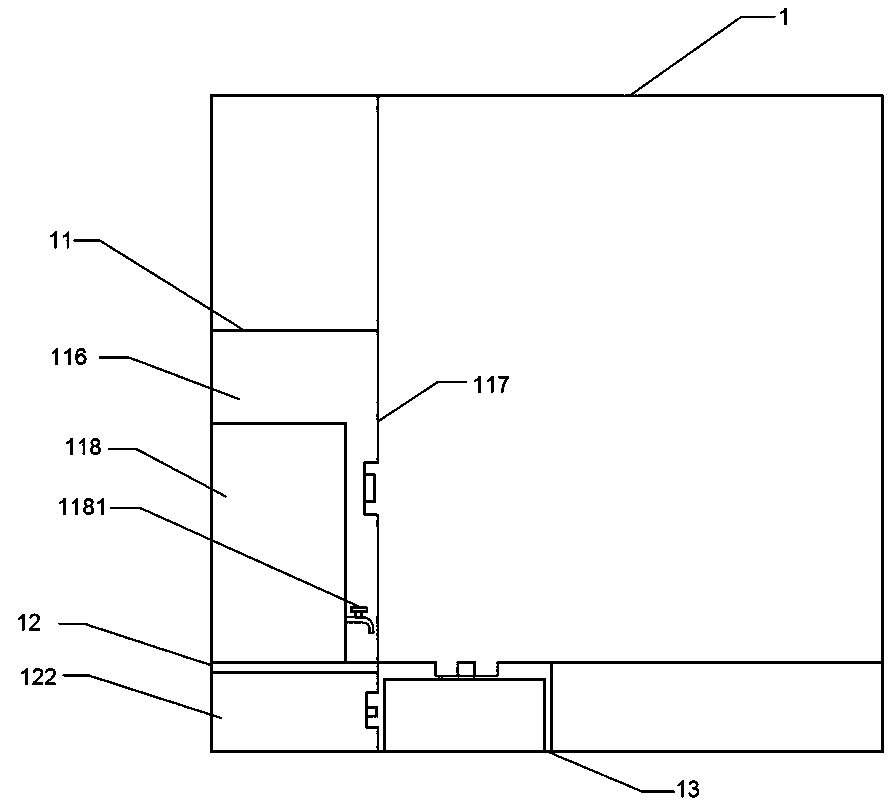

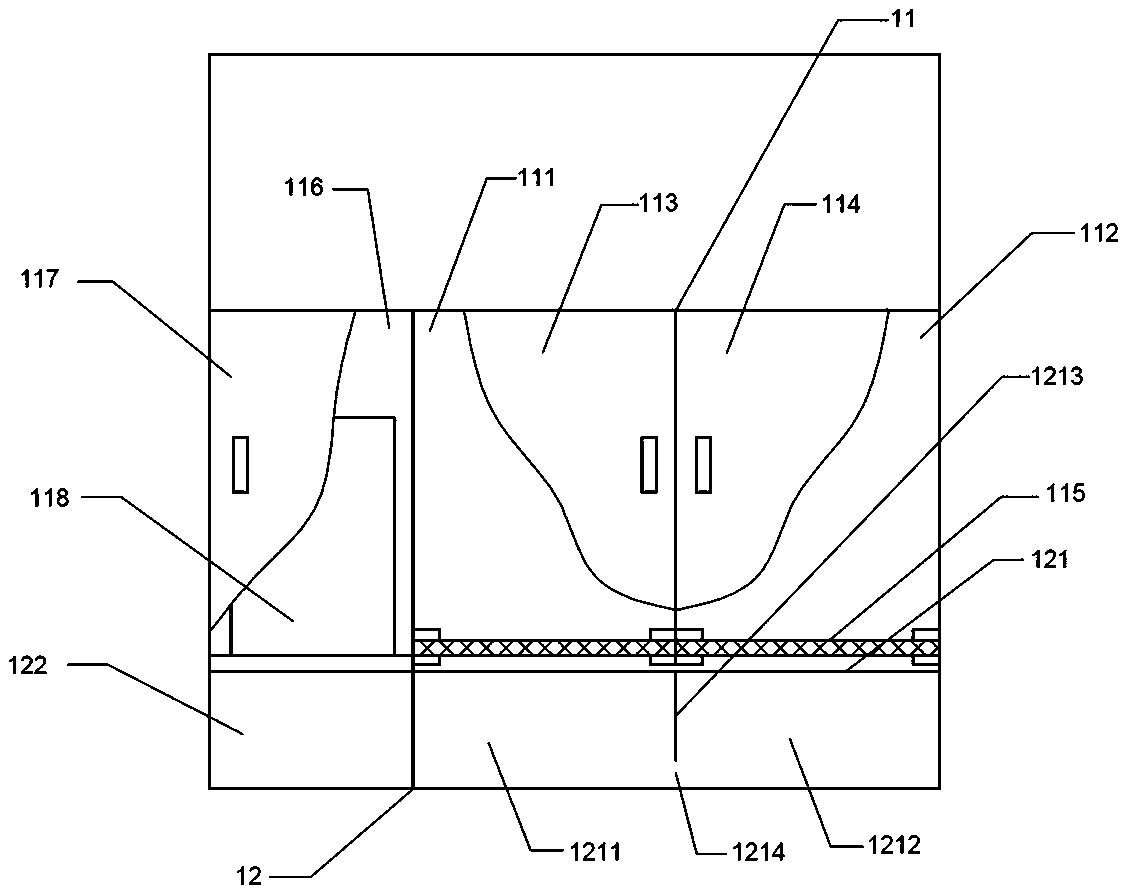

Assembling device of reconfigurable toolroom machine

ActiveCN103182695AGood machining precisionImprove efficiencyMetal-working hand toolsToolroomEngineering

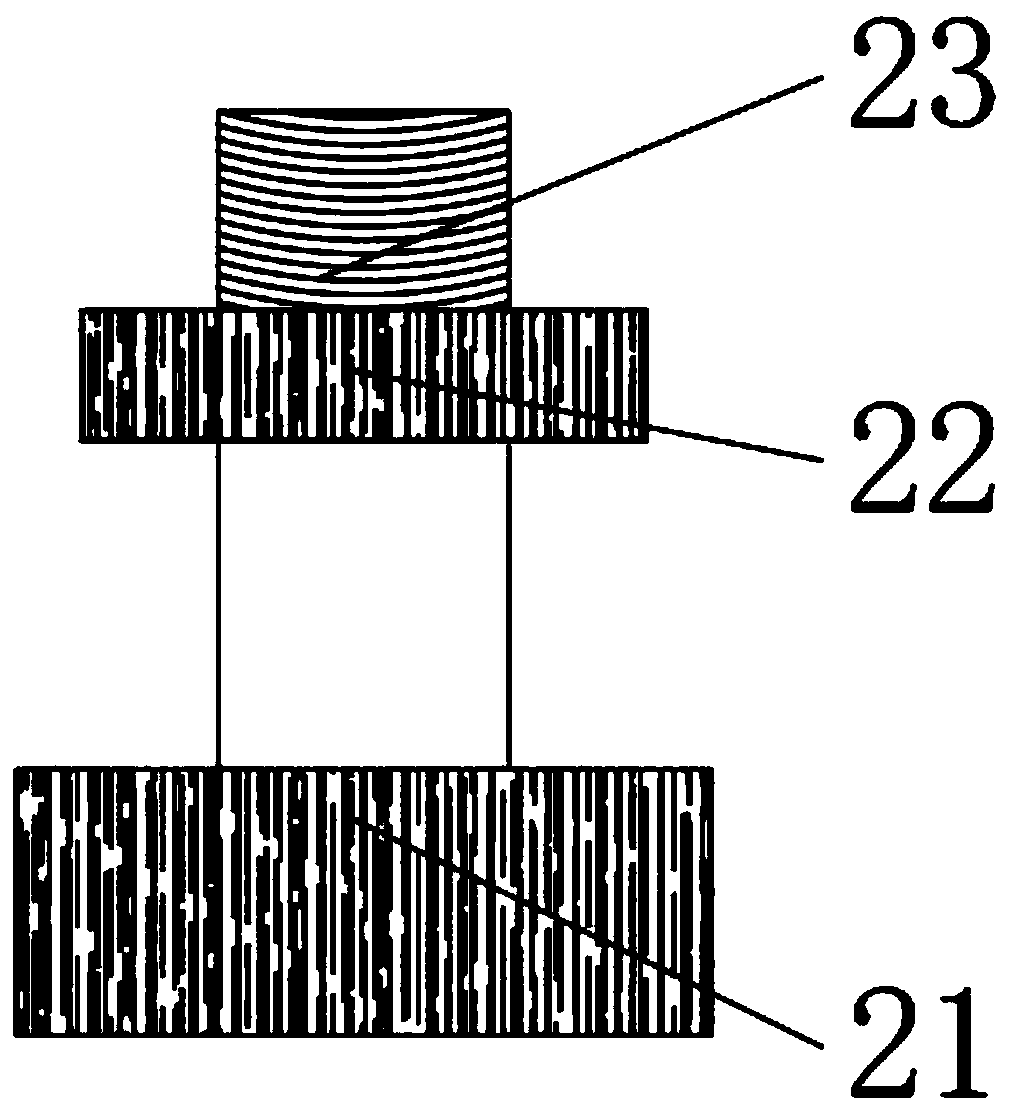

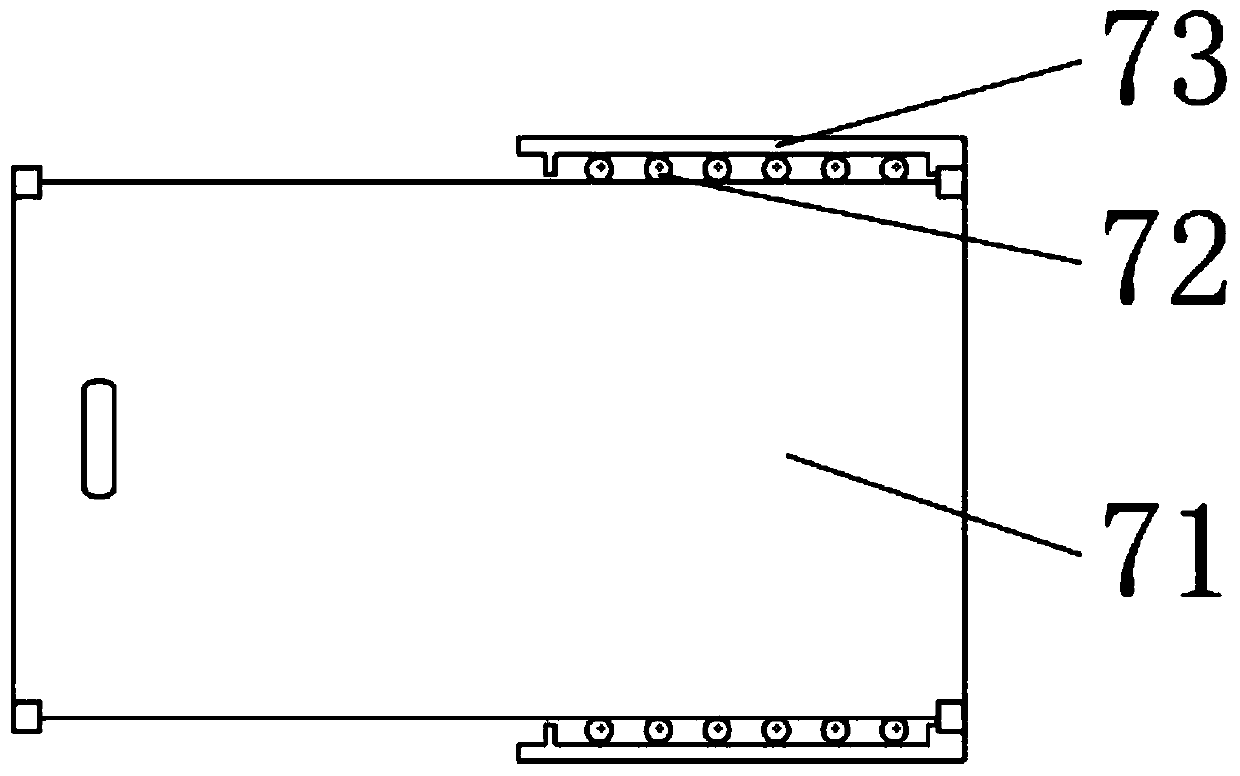

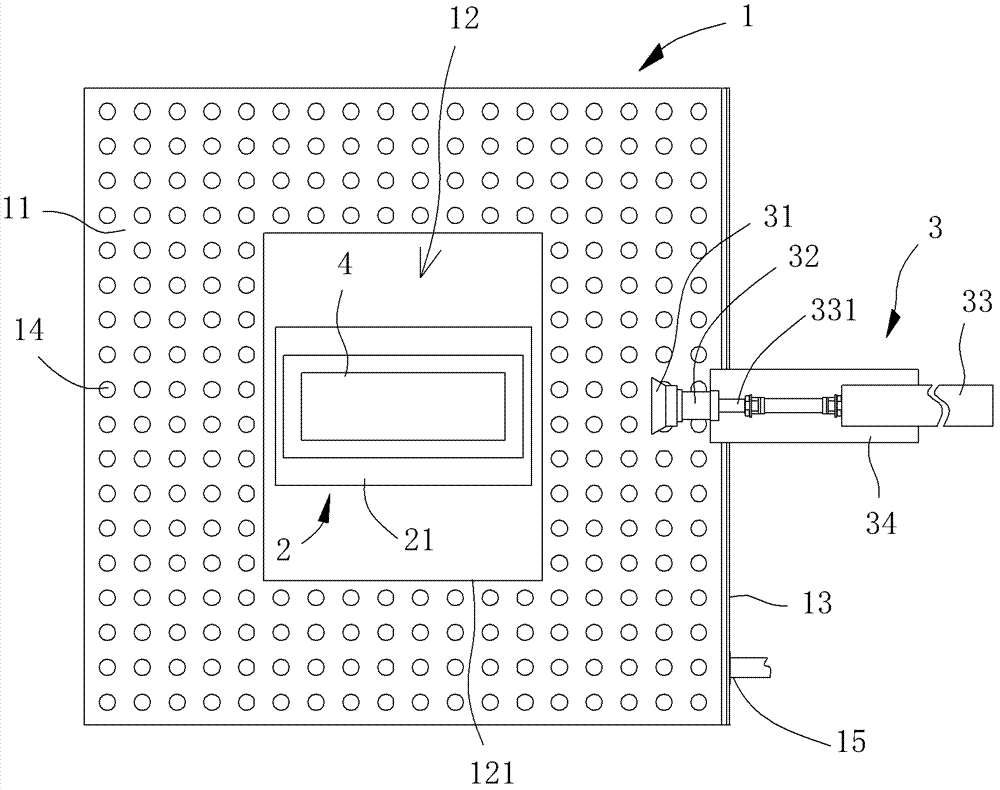

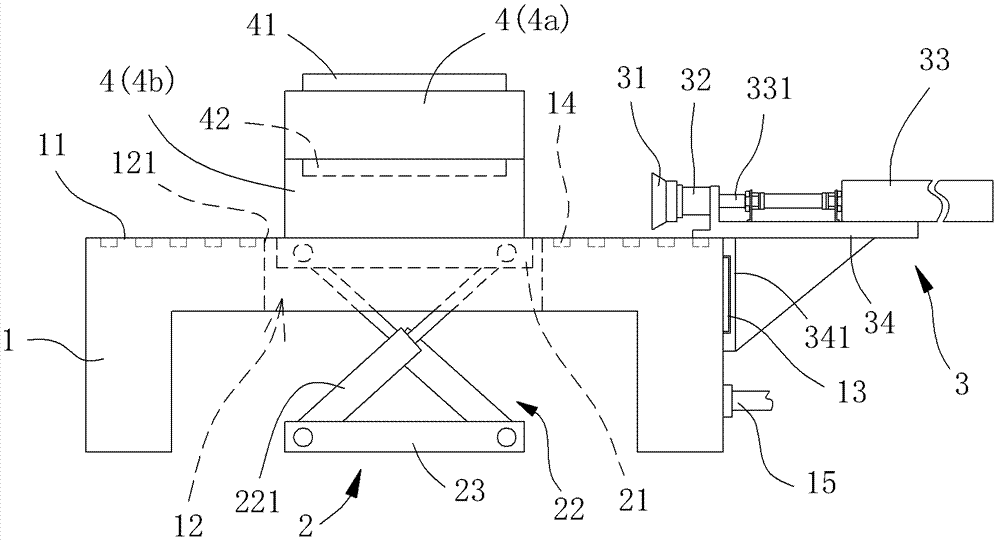

The invention relates to an assembling device of a reconfigurable toolroom machine. The assembling device comprises a bearing pedestal, a lifting module and an adsorbing module, wherein the top of the bearing pedestal is provided with a bearing surface, the bearing pedestal is provided with an accommodating groove, and a guide part is arranged at one side of the bearing pedestal; the lifting module is arranged in the accommodating groove and is provided with a carrying disc and a power source, wherein the power source is used for driving the carrying disc to lift; and the adsorbing module is arranged on the guide part in a sliding combination manner. The assembling device of the reconfigurable toolroom machine can be used for accurately positioning all components of the reconfigurable toolroom machine when being used for reassembly and maintaining favorable machining precision without manual calibration, thereby promoting the reassembly efficiency.

Owner:METAL INDS RES & DEV CENT

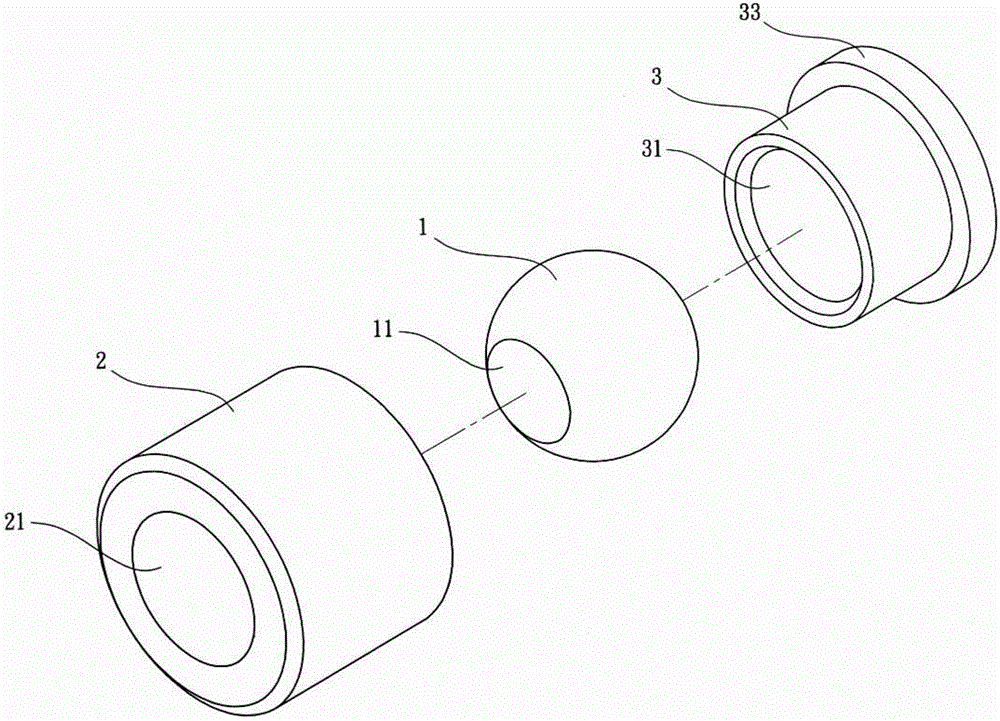

Water guiding device of toolroom machine

InactiveCN104416416AQuickly adjust the spray hole angleAccurate injectionSpraying apparatusMaintainance and safety accessoriesToolroomEngineering

The invention discloses a water guiding device of a toolroom machine. A water guiding seat is mounted on the toolroom machine. The water guiding device comprises a water ball, a pressure guide sleeve, a leakage-proof component, and a pan-head screw, wherein a water spout hole penetrates through the water ball; an accommodating hole penetrates through the pressure guide sleeve, and the water ball is accommodated in the accommodating hole; a water guiding hole penetrates through the leakage-proof component and is communicated with the accommodating hole, and one end of the leakage-proof component penetrates through the accommodating hole and presses against the edge of the water ball; and the pan-head screw can be locked on a water searching seat, and the head of the pan-head screw presses against the top of the pressure guide sleeve. The water ball can rotate relative to the pressure guide sleeve to adjust the angle corresponding to the water guiding seat of the water spout hole, the liquid can be accurately injected to a target in order to achieve fast and accurate adjustment.

Owner:黄永裕

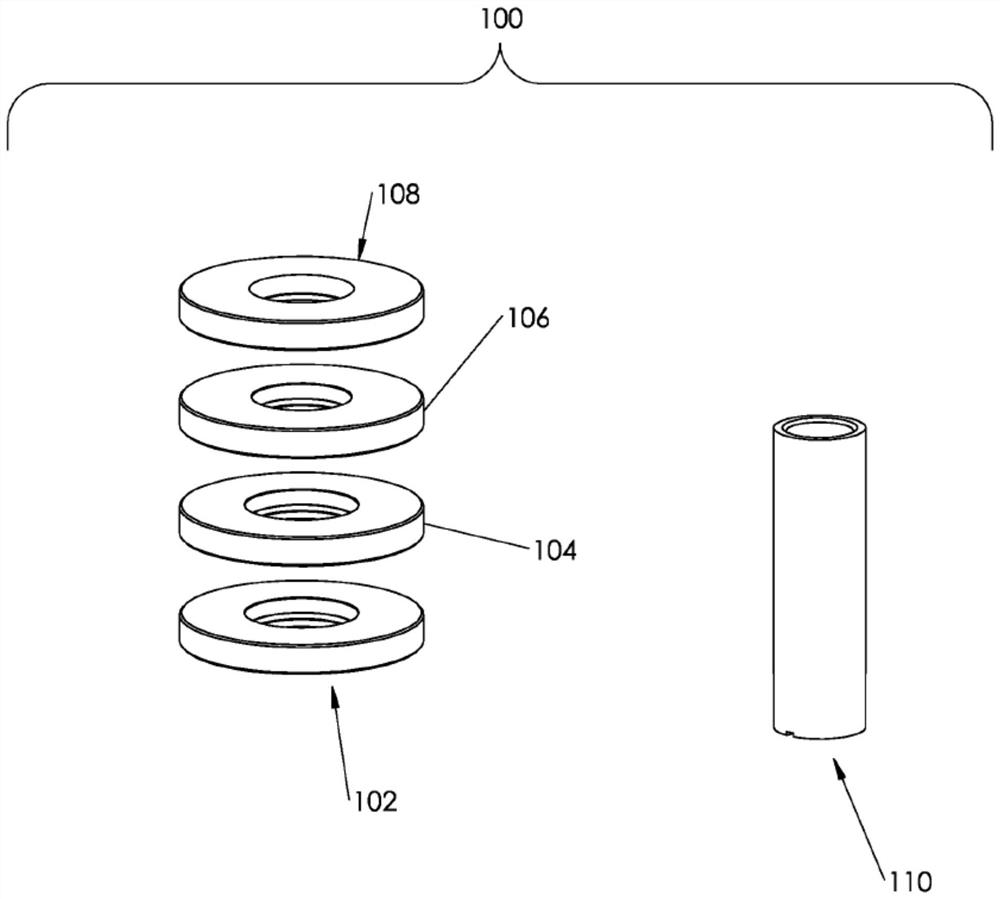

Terminal cassette assembly

A terminal cassette assembly for a terminal crimping machine includes a cassette housing having a terminal reel chamber holding a terminal reel and a crimp tooling chamber holding crimp tooling with a terminal reel door and a crimp tooling cover, respectively. The crimp tooling includes lower tooling including an anvil and upper tooling including a wire crimper. At least one of the upper tooling and the lower tooling are held in position relative to the terminal crimping machine by the cassette housing when the cassette housing is coupled to the terminal crimping machine.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

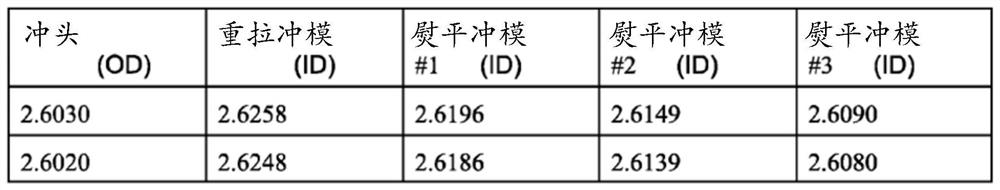

Can production tool, process for controlling can weight, cost, and dimensions

The present invention teaches a process of measuring and grinding tools in can / cylindrical body production, allowing reduced production downtime, reduced cost and a predictive tool wear capability, which process allows more accurate stocking of tool inventory by means of tracking individual tools in use and providing advanced diagnostics to the tool room. This includes not just out-of-spec alarms from QA but also predictive alarms regarding cans produced by each tool, in-spec can weights and wall thicknesses, information on tool sizes being used in production, tools in inventory, pulled from inventory and other stock balancing information. The invention further teaches a system of equations for prioritizing grinding to maintain optimum tool inventory levels.

Owner:인터그레이티드패키징솔루션즈엘엘씨

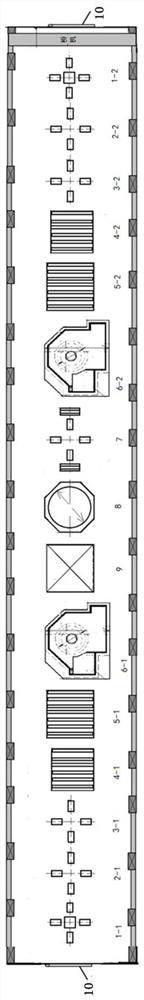

Combined and multi-task water turbine runner on-site processing factory design method

PendingCN113829080ASave engineering investmentOther manufacturing equipments/toolsHydro energy generationWater turbineProcess engineering

The invention relates to a combined and multi-task water turbine runner on-site processing factory design method which is characterized in that only one runner on-site processing factory is arranged to simultaneously meet the on-site processing progress of two or more different runners and two types of multiple sets of large and heavy parts, that is, only one on-site runner processing factory needs to be arranged; and through the design of machining stations, working procedures, equipment configuration and ancillary facilities of large and heavy parts, different runners can be machined in a combined mode, machining of a plurality of runners and a lower rack center body can be achieved at the same time in a multi-task mode, and the problem that a plurality of on-site processing factories need to be arranged is solved. Besides, the combined and multi-task runner on-site processing factory can share one processing factory, and also can share a bridge crane, a processing station with low utilization rate and ancillary facilities such as a transformation power distribution room, a compressed air room, an office rest room, a tool room, a temporary storage room, a toilet and the like, so that the engineering investment is greatly saved.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

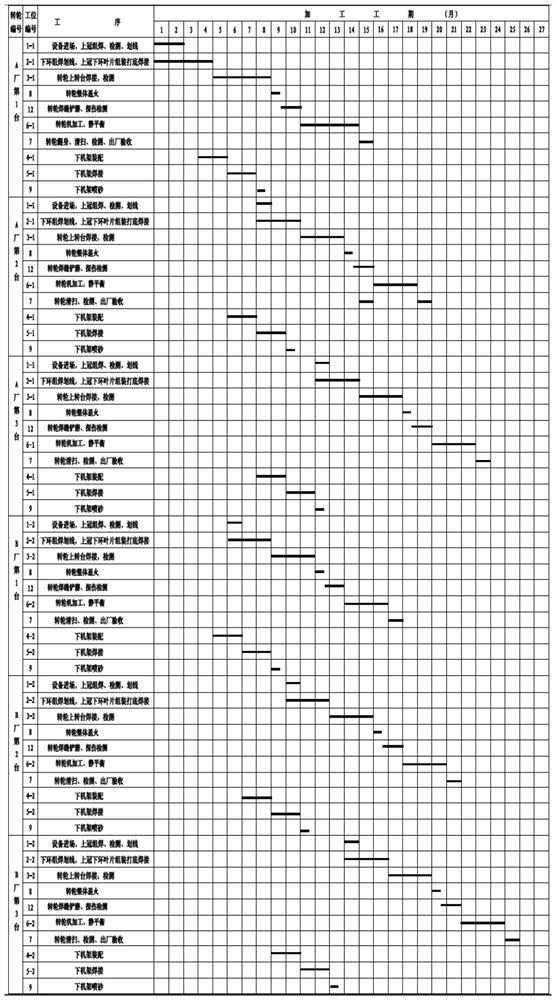

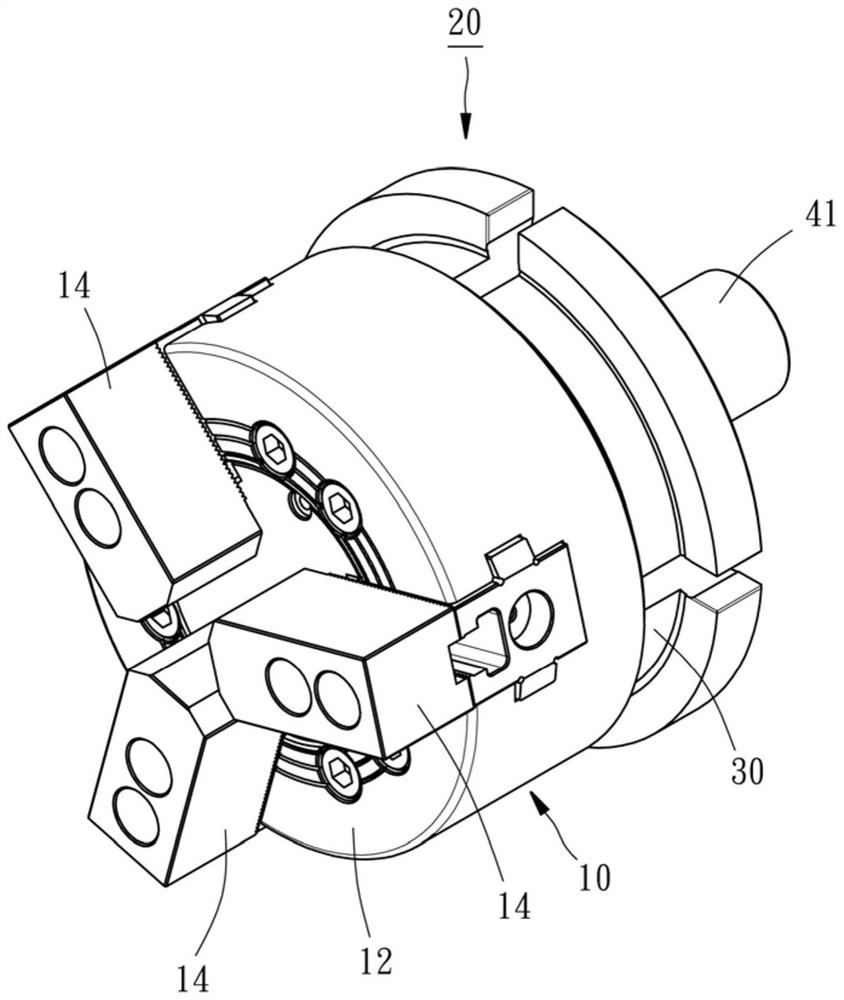

Hydraulic drive for machine tool chucks

ActiveCN108425900BTo achieve the effect of hydraulic driveServomotor componentsFluid-pressure actuator componentsEngineeringToolroom

The invention provides an oil pressure driving device for a toolroom machine chuck. The oil pressure driving device comprises a chuck connecting seat, an oil distributing valve and a piston. Oil storage space and a shaft hole communicating with the oil storage space are formed in the chuck connecting seat. The oil distributing valve is provided with a valve body and an oil distributing shaft. Thevalve body communicates with compressed fluid outside, and the oil distributing shaft penetrates the shaft hole of the chuck connecting seat and guides the compressed fluid into the oil storage space.The piston is movably arranged in the oil storage space of the chuck connecting seat, and oil storage space is divided into a first chamber and a second chamber through the piston. Thus, when oil pressure is generated in the first chamber or the second chamber in a reciprocating manner, the piston or the chuck connecting seat can generate relative displacement, and then the toolroom machine chuckis driven by the piston or the chuck connecting seat.

Owner:上海瑞麒美贸易有限公司 +1

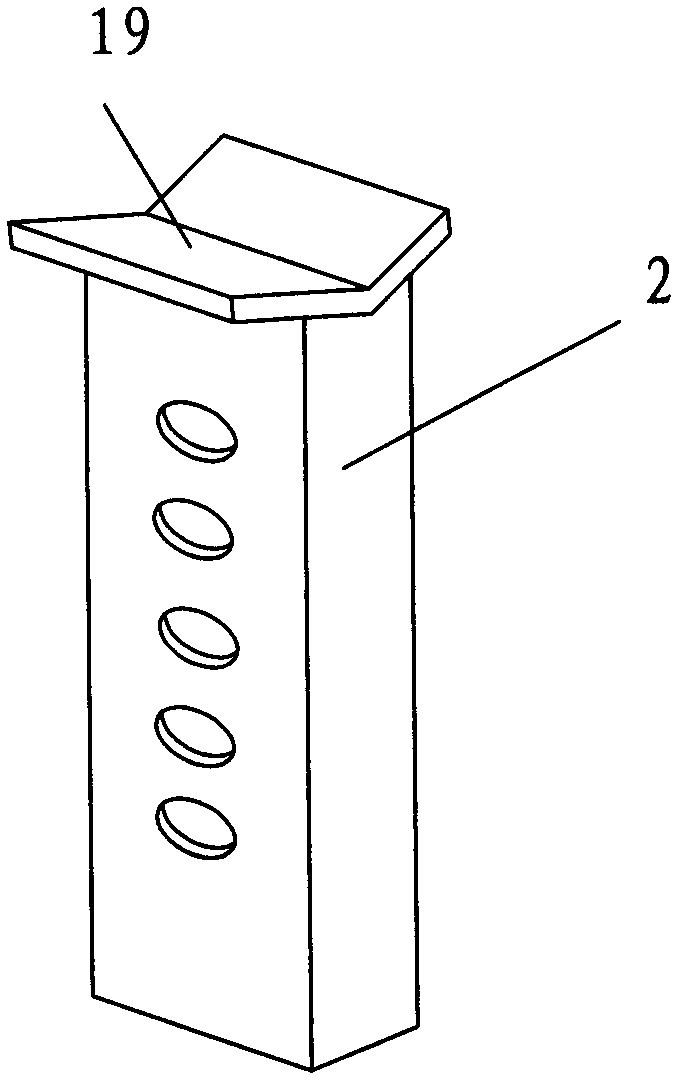

Square tube type vehicle support with toolrooms

InactiveCN102490697AIncrease the bearing areaSupport vehicle safetyVehicle fittings for liftingEngineeringToolroom

The invention discloses a square tube type vehicle support with a toolrooms. The square tube type vehicle support with the toolrooms is characterized in that a first square tube supporting pad and a second square tube supporting pad are welded to two side faces of a square tube base pillar respectively, and the upper plane of the first square tube supporting pad and the upper plane of the second square tube supporting pad are in reinforced welding with the left side face and the right side face of the square tube base pillar respectively through a left welding reinforcing plate and a right welding reinforcing plate. A square tube base pillar cavity and a square tube height adjusting pillar form a moving pair, a flexible pin shaft is in positioning connection with a circular-arc-surface inserted pin seat and random even-distribution inserted pin holes evenly distributed on the square tube height adjusting pillar, a mid-concaved supporting head portion is welded above the square tube height adjusting pillar, a cavity of the first square tube supporting pad and a cavity of the second square tube supporting pad are respectively assembled with a first door and a second door into a first toolroom and a second toolroom, and a first door lock catch, a first lock catch opening button, a second door lock catch and a second lock catch opening button are arranged at the positions of the doors of the two toolrooms.

Owner:常熟市藕渠针织机械厂

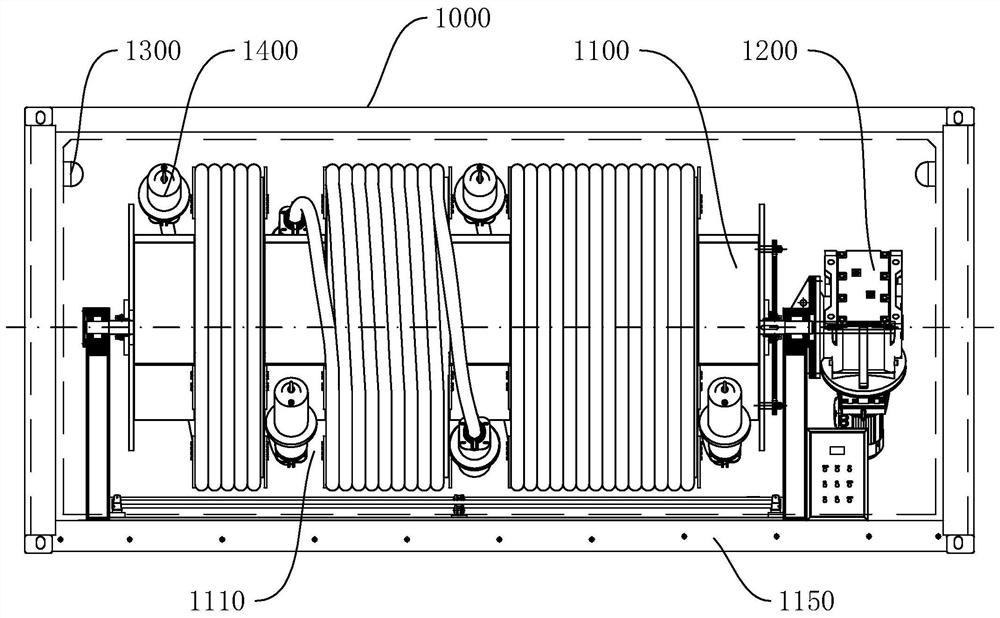

Integrated device and method for first-aid repair of high-voltage cable line

PendingCN112886465AMeet the needs of useEasy transferCable junctionsApparatus for joining/termination cablesEngineeringStructural engineering

The invention discloses an integrated device for first-aid repair of a high-voltage cable line. The integrated device comprises a compartment body, a cable reel, a tool chamber, and a reducing joint main body; a first-aid repair cable is wound on the cable reel, cable plugging heads are connected to the two ends of the first-aid repair cable, the cable reel is connected with a driving device, and the driving device is used for driving the cable reel to rotate so as to unfold or fold the first-aid repair cable; the tool chamber comprises a generator set chamber and a tool cabin, a generator set is arranged in the generator set chamber to provide a power supply, and the tool cabin is arranged at the rear part of the tool chamber; two ends of the reducing joint main body are respectively provided with a first connecting hole and a second connecting hole, the diameter of the first connecting hole is larger than that of the second connecting hole, the first connecting hole is communicated with the second connecting hole, and two cables can be respectively inserted from the first connecting hole and the second connecting hole to realize connection. According to the integrated device for emergency repair of the high-voltage cable line, equipment is highly integrated, the reducing joint body capable of being flexibly transferred is configured, connection of a large-section cable and a small-section emergency repair cable on site can be met, and the application range is wide.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

Test auxiliary device for electric power maintenance

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

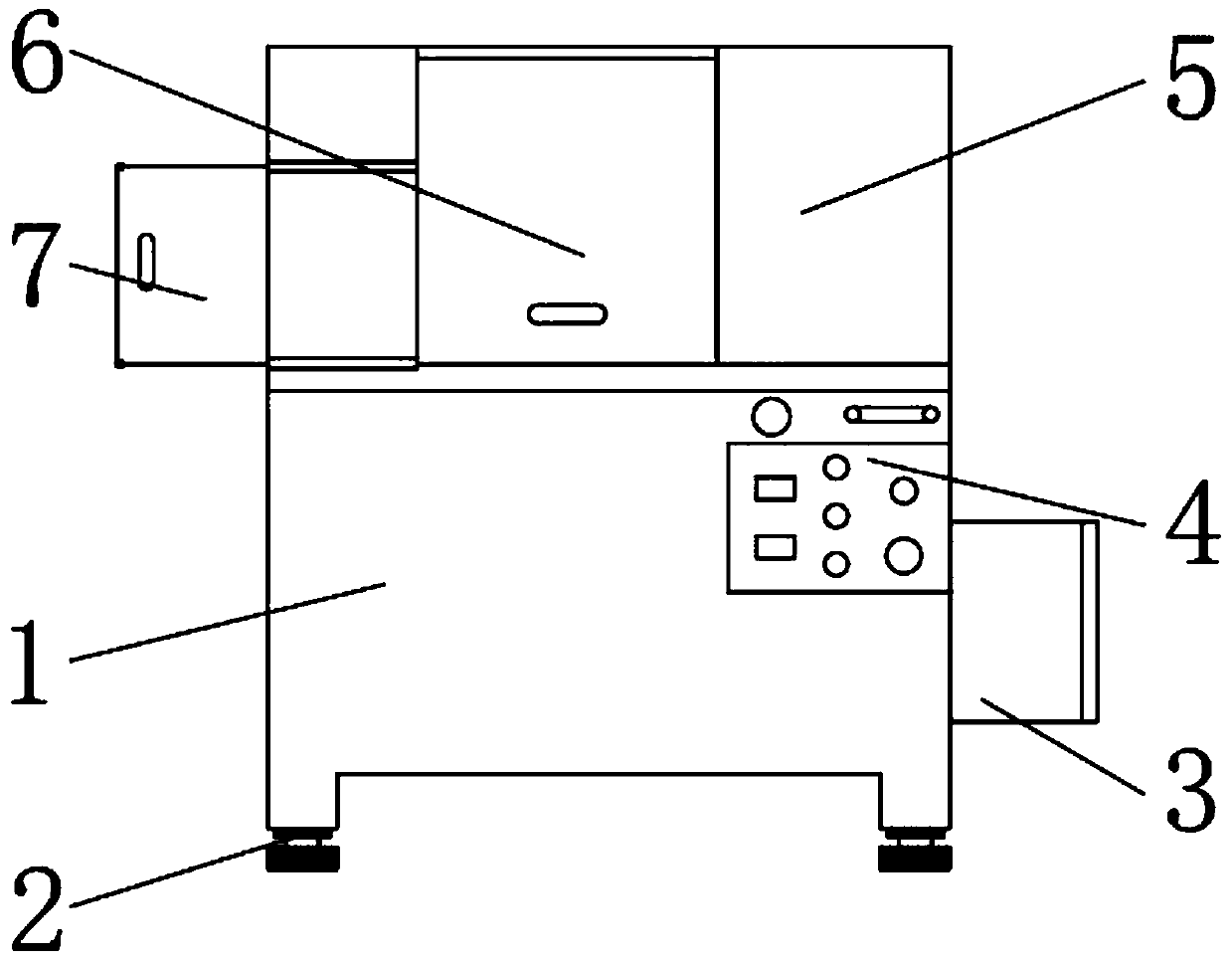

Efficient horizontal centrifugal grinding machine

PendingCN110788733ASimple structureEasy to operateEdge grinding machinesPolishing machinesEngineeringToolroom

The invention discloses an efficient horizontal centrifugal grinding machine. The efficient horizontal centrifugal grinding machine comprises a centrifugal grinding machine body, wherein a stable adjusting structure is arranged on the outer surface of the lower end of the centrifugal grinding machine body; an electric appliance box is fixedly arranged on the outer surface of one side of the centrifugal grinding machine body; a control panel is arranged on the outer surface of the front end of the centrifugal grinding machine body; a grinding tool chamber is arranged on the outer surface of theupper end of the centrifugal grinding machine body; and a dustproof protection door is arranged on the outer surface of the middle of the grinding tool chamber. According to the efficient horizontalcentrifugal grinding machine, the stable adjusting structure and an isolation observation structure are arranged, people can conveniently and rapidly adjust the flatness of the ground according to theplacing position, stable placing of the grinding machine is guaranteed, use of people is facilitated, people can conveniently observe the grinding condition of an internal workpiece under the condition that the personal safety of people is guaranteed, use of people is facilitated, and a better use prospect is brought.

Owner:苏州双州电子科技有限公司

Assembling device of reconfigurable toolroom machine

ActiveCN103182695BGood machining precisionImprove efficiencyMetal-working hand toolsToolroomEngineering

The invention relates to an assembling device of a reconfigurable toolroom machine. The assembling device comprises a bearing pedestal, a lifting module and an adsorbing module, wherein the top of the bearing pedestal is provided with a bearing surface, the bearing pedestal is provided with an accommodating groove, and a guide part is arranged at one side of the bearing pedestal; the lifting module is arranged in the accommodating groove and is provided with a carrying disc and a power source, wherein the power source is used for driving the carrying disc to lift; and the adsorbing module is arranged on the guide part in a sliding combination manner. The assembling device of the reconfigurable toolroom machine can be used for accurately positioning all components of the reconfigurable toolroom machine when being used for reassembly and maintaining favorable machining precision without manual calibration, thereby promoting the reassembly efficiency.

Owner:METAL INDS RES & DEV CENT

Refitted lift car structure for use of high-storey residential community cleaning worker

InactiveCN107720503AReduce workloadSimple modification structureBuilding liftsStructural engineeringResidential community

A refitted lift car structure for use of a high-storey residential community cleaning worker comprises a lift car and further comprises a first refitted chamber arranged on the side portion of the lift car and a second refitted chamber arranged at the bottom of the lift car. The first refitted chamber comprises an upper tool chamber and a lower assistive device chamber. The second refitted chambercomprises a sundry storage chamber horizontally communicating with the lower assistive device chamber. The refitted lift car structure is simple in structure arrangement and convenient to use, the cleaning worker can reasonably use the lift resource, use of persons such as other residents is not affected while work of the cleaning worker is facilitated, the workload of the cleaning worker is greatly lowered, the working condition of the cleaning worker is improved, and the working efficiency of the cleaning worker is improved.

Owner:杭州钜丰物业管理有限公司南浔分公司

Multifunctional knapsack equipment for electric power construction climbing

InactiveCN111641148AGuaranteed the inconvenience when picking up toolsSecurity inconvenienceStoolsApparatus for overhead lines/cablesEngineeringStructural engineering

The invention discloses multifunctional knapsack equipment for electric power construction climbing. The equipment includes a work box, and a lifting chamber, a tool chamber and a rotating chamber aresequentially arranged in the work box from top to bottom. Front-back sliding grooves are formed in the left wall body and the right wall body of the lifting chamber. A moving shaft is mounted in thefront-back sliding grooves in a sliding manner, lifting devices are symmetrically arranged on two end faces of the moving shaft, the lifting devices comprise adjusting eyes formed in the side wall surfaces of the lifting chamber, a hollow rotating shaft is rotatably mounted on one end surface of the moving shaft, and the maintenance personnel wear the equipment according to regulations. Accordingto the invention, maintenance tools can be automatically pulled out, inconvenience is guaranteed when the maintenance personnel take the tools, the tools are prevented from falling off when the maintenance personnel take the tools, multi-directional maintenance can be conducted, the limitation of traditional maintenance is broken through, and meanwhile the equipment further has a lifting functionand can lift arms to prevent workers from feeling tired due to the fact that the arms are lifted for a long time.

Owner:福州市长乐区德林森电子科技有限公司

Lift car refit structure which is conveniently used by clean-keeping personnel

InactiveCN107697776AReduce workloadSimple modification structureBuilding liftsToolroomMechanical engineering

The invention discloses a lift car refit structure which is conveniently used by clean-keeping personnel. The lift car refit structure comprises a lift car, and further comprises a first refit chamberwhich is formed in the lateral part of the lift car and a second lift chamber which is formed in the bottom of the lift car; the first refit chamber comprises an upper tool chamber and a lower auxiliary chamber, and the second refit chamber comprises a sundry storage chamber which is horizontally communicated with the lower auxiliary chamber. The lift car refit structure is simple in structural arrangement and convenient to use, the clean-keeping personnel can reasonably utilize elevator resources, the use of elevators by other personnel like residents is not influenced while the work of theclean-keeping personnel themselves is facilitated, the work burden of the clean-keeping personnel is greatly relieved, the work condition of the lift car refit structure is improved, and the work efficiency of the lift car refit structure is improved.

Owner:杭州钜丰物业管理有限公司南浔分公司

Operations exercitation simulator suitable for CNC toolroom machine

The present invention relates to a kind of stimulation device of operation training for computer numerical control (CNC) machine tool comprising control device for entity, software simulator, transmitting device and stimulating display device; the control device for entity provides operation command; the software simulator is connected with the control device, and generates the stimulation of operation action according to operating action command input by the control device for entity; the transmitting device connects with the control device for entity and the software simulator; the stimulating display device is connected with the software simulator and display the operating action stimulation generated by the software simulator.

Owner:REN AN INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com