Planetary screw and toolroom machine with planetary screw

A planetary screw and main screw technology, applied in mechanical equipment, transmission parts, belts/chains/gears, etc., can solve the problems of noise generated by planetary screw rotation, complex structure of planetary screw, troublesome lubricating oil filling, etc., to reduce friction , Improve production and assembly efficiency, and avoid the effect of smooth rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

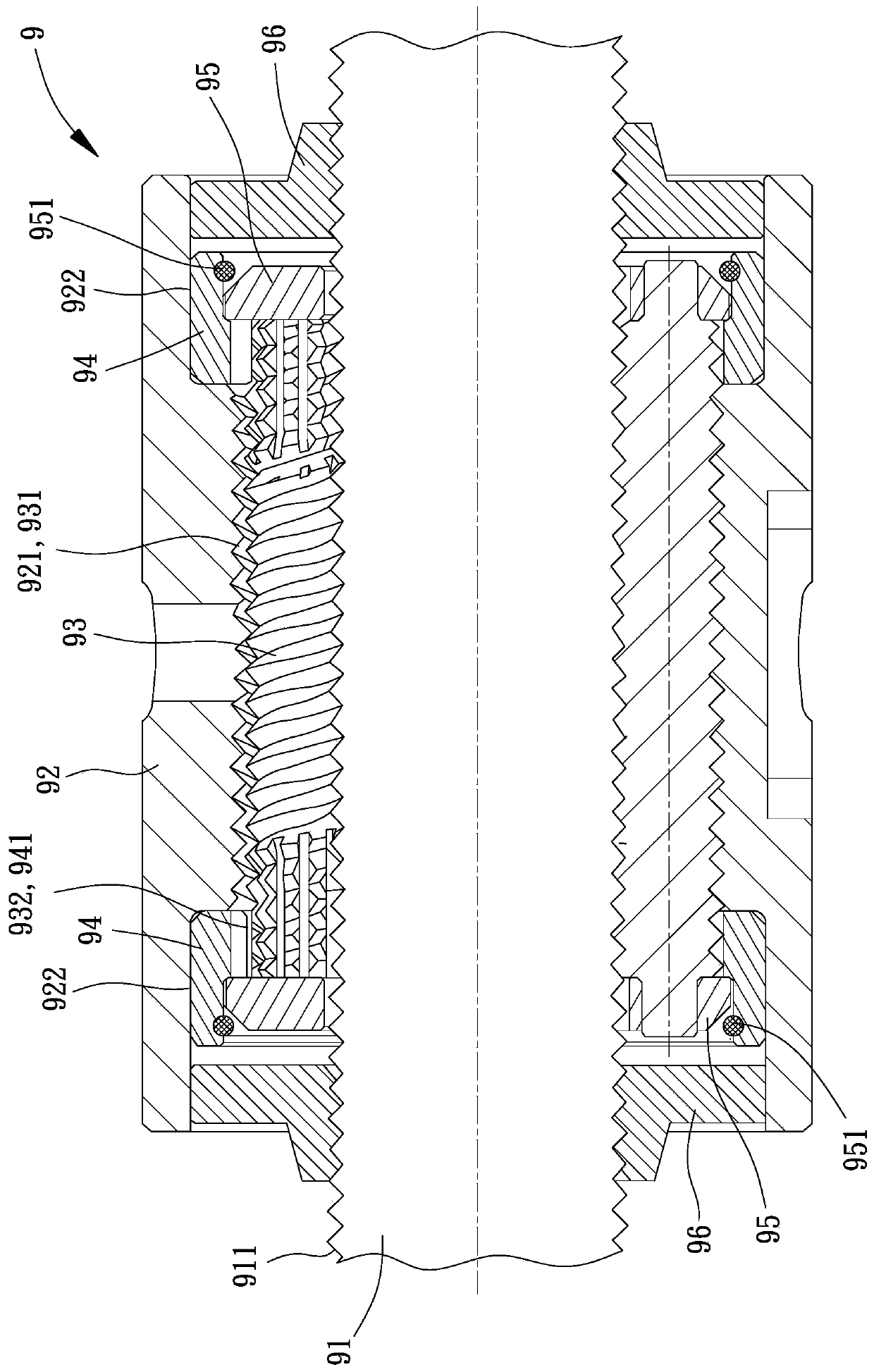

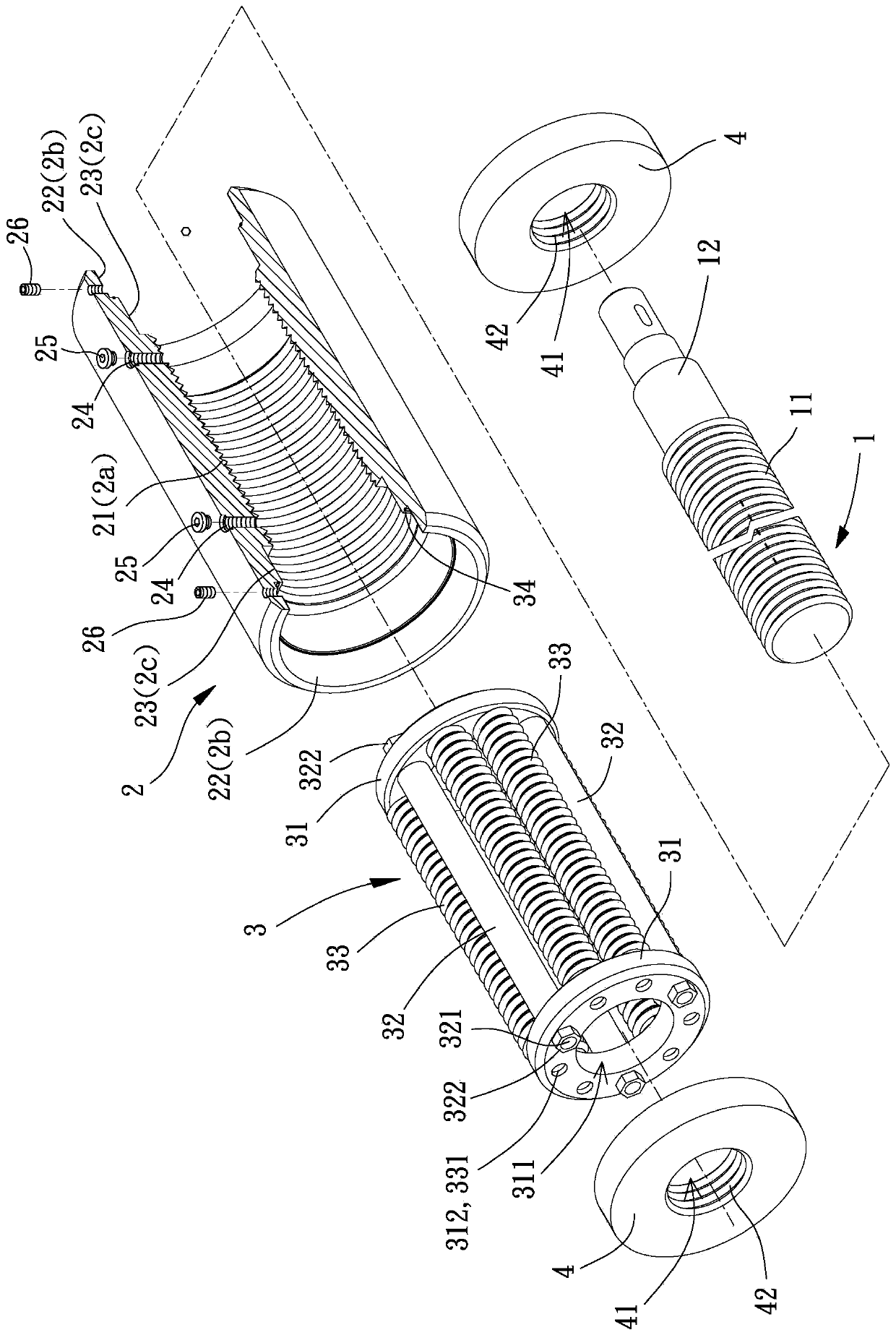

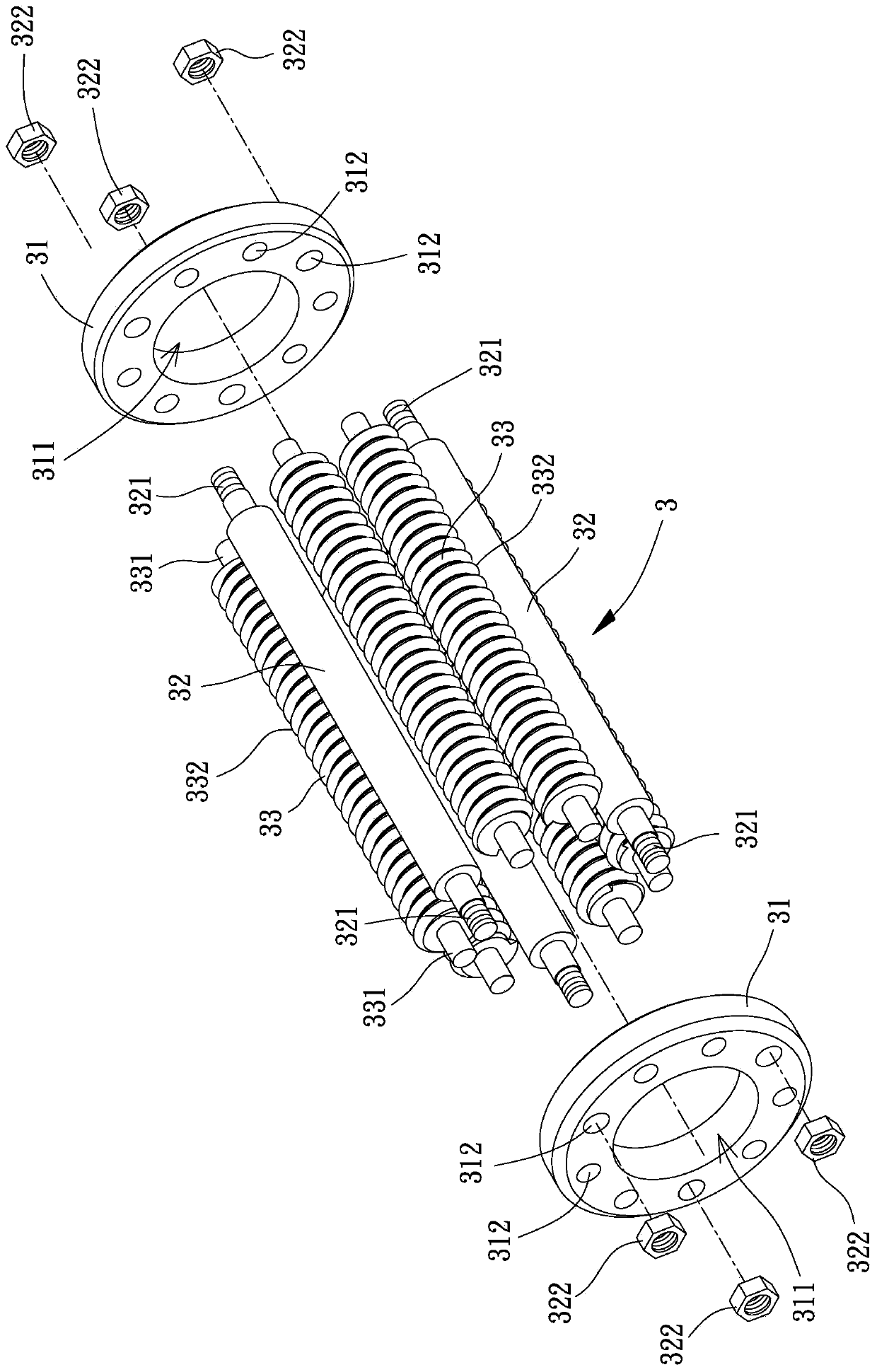

[0063] In order to make the above-mentioned and other objects, features and advantages of the present invention more obvious and understandable, the preferred embodiments of the present invention are listed below, together with the accompanying drawings, and are described in detail as follows:

[0064] Directionality or similar terms used throughout the invention, such as "front", "rear", "left", "right", "upper (top)", "lower (bottom)", "inner", "outer" , "side", etc., mainly refer to the directions of the drawings, and each direction or its approximate terms are only used to assist in explaining and understanding the various embodiments of the present invention, and are not intended to limit the present invention.

[0065] Approximate terms such as "combination", "combination" or "assembly" mentioned throughout the present invention mainly include forms that can be separated without destroying components after connection, or that components cannot be separated after connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com