Operations exercitation simulator suitable for CNC toolroom machine

A technology of numerical control and simulation device, applied in the field of operation training simulation device, can solve the problems of lack of familiarity of new operators, high risks and costs, dangerous personnel, etc., to save training time, reduce expenditure on consumables, increase effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

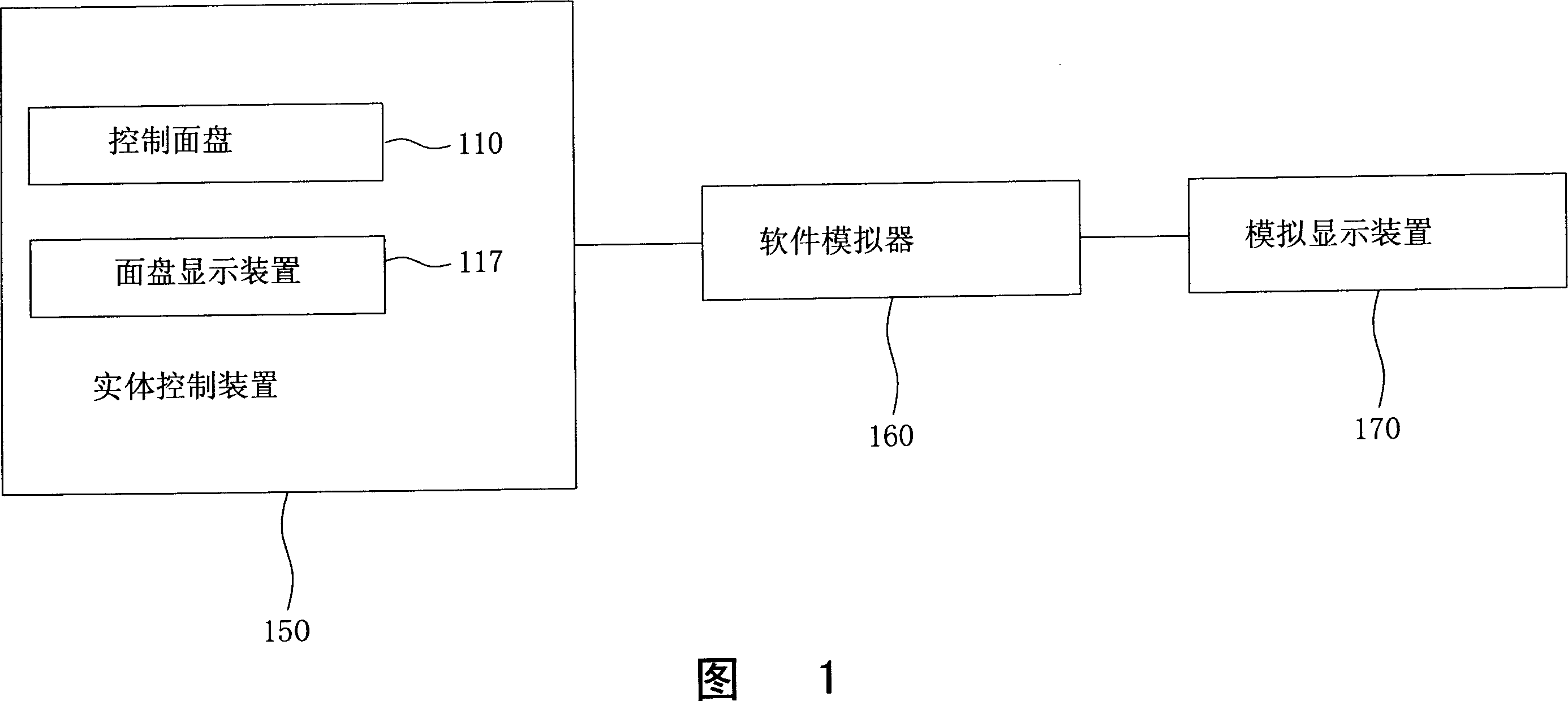

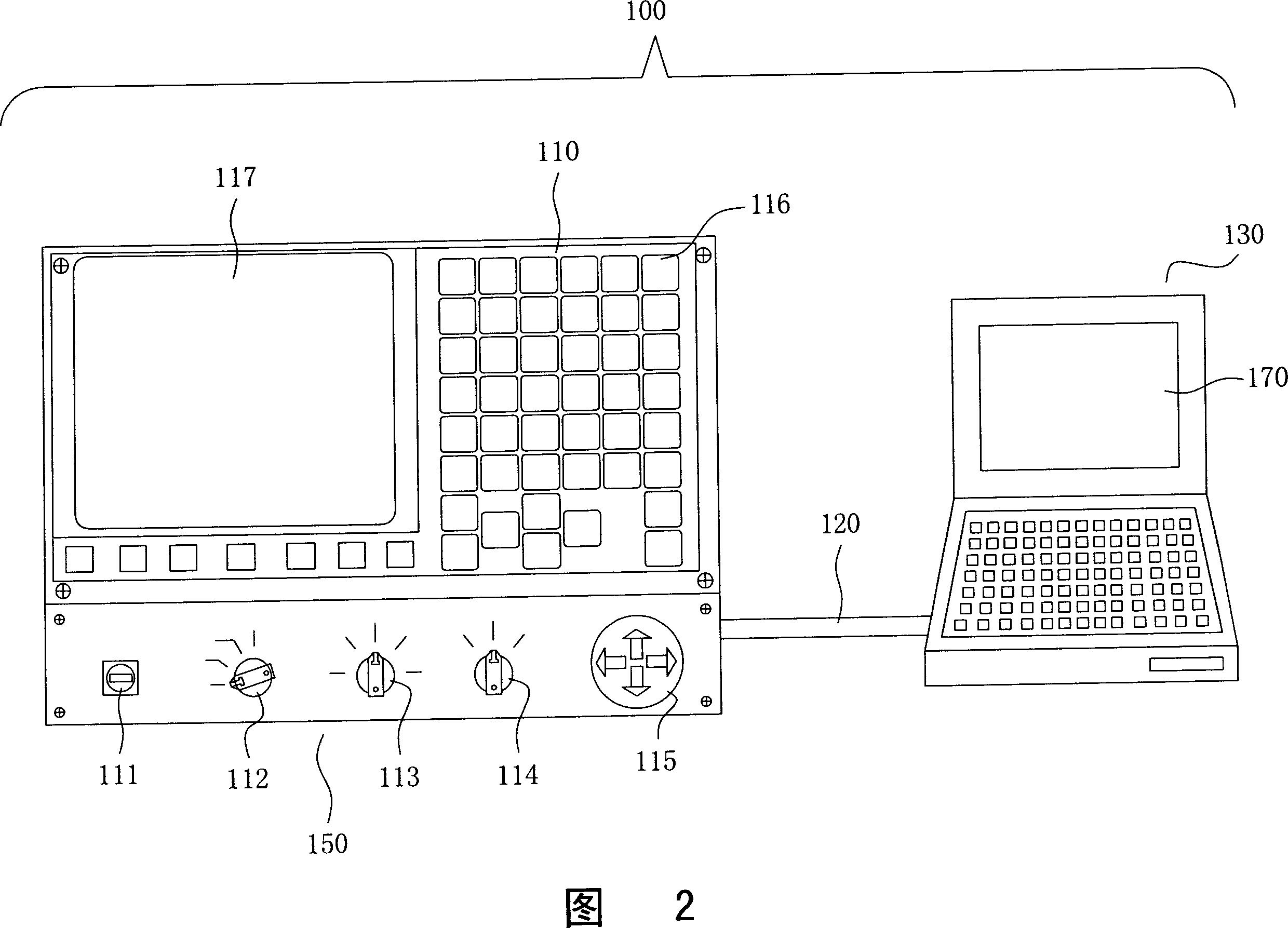

[0025] Please refer to FIG. 1 and FIG. 2 . FIG. 1 is a schematic block diagram of a system according to a preferred embodiment of the present invention. Fig. 2 is a combined schematic diagram according to a preferred embodiment of the present invention. An operation training simulation system 100 of a preferred embodiment of the present invention is used for training and simulating the operation of a CNC machine tool. It includes a physical control device 150 , a transmission device 120 , a software simulator 160 and a simulation display device 170 .

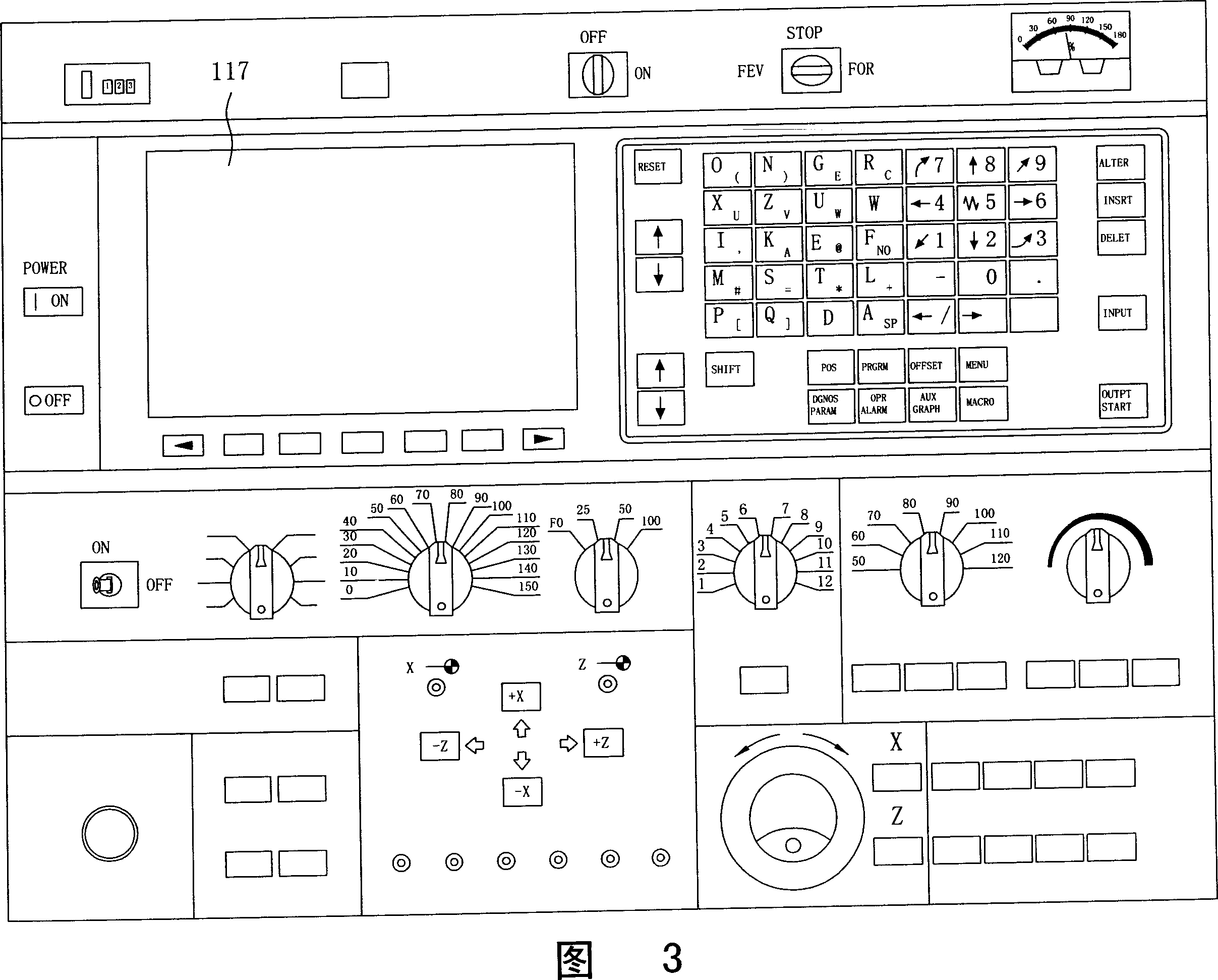

[0026] The physical control device 150 also includes a control panel 110 and a panel display device 117 . The physical control device 150 provides an operation interface, which is the same as the control interface of the actual machine tool. Therefore, the physical control device 150 can provide a real and practical control feeling during the training process.

[0027] The control panel 110 can include an execution operation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com