Main shaft balance device for toolroom machine

A technology of balancing device and machine tool, applied in the direction of manufacturing tools, metal processing machinery parts, metal processing equipment, etc., can solve the difficulty of further improving the lifting speed of the spindle unit, the high manufacturing cost of the lifting driving mechanism, and the load of the lifting driving mechanism. and other problems, to achieve the effects of excellent durability, lightening the load, and improving the lifting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

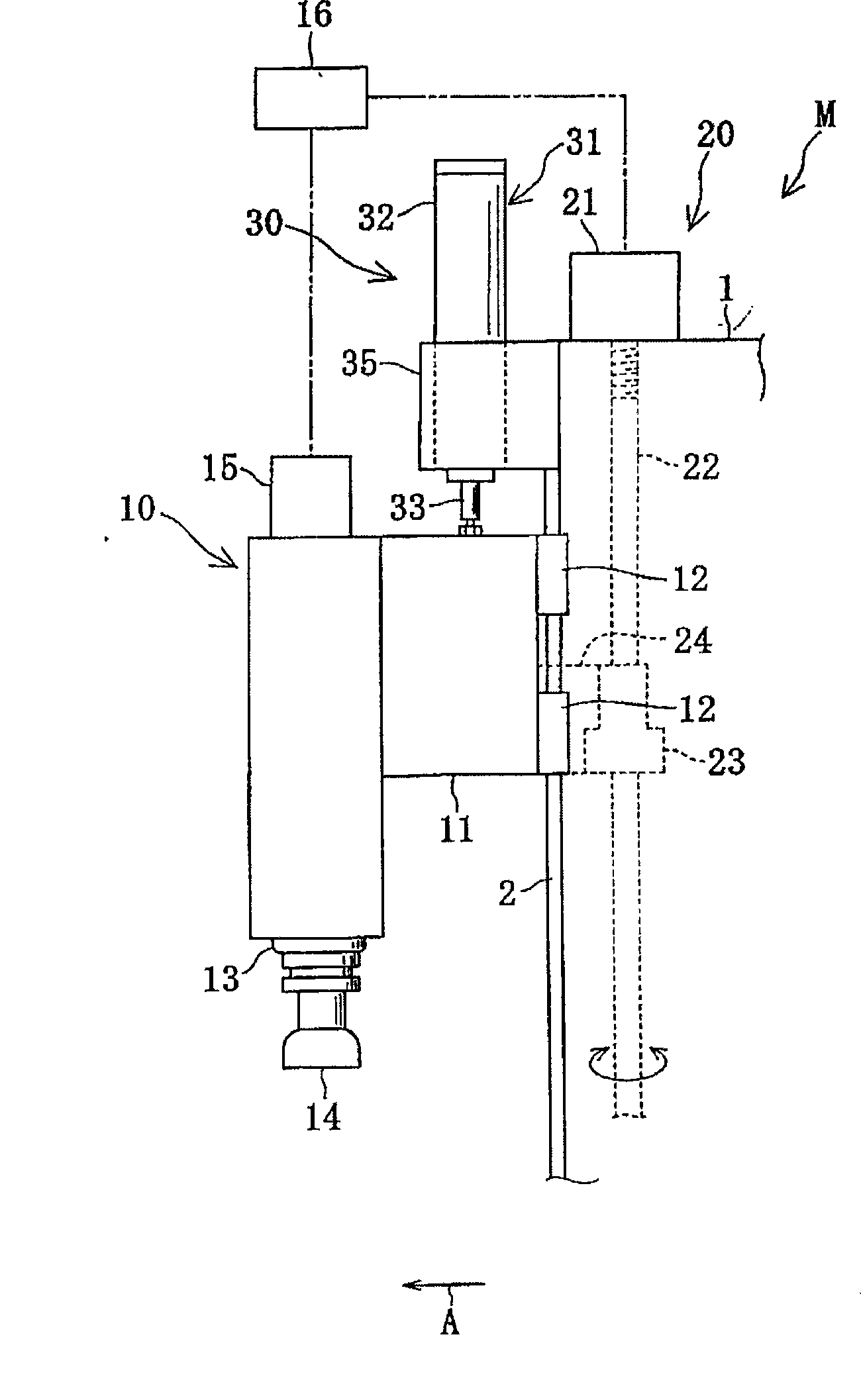

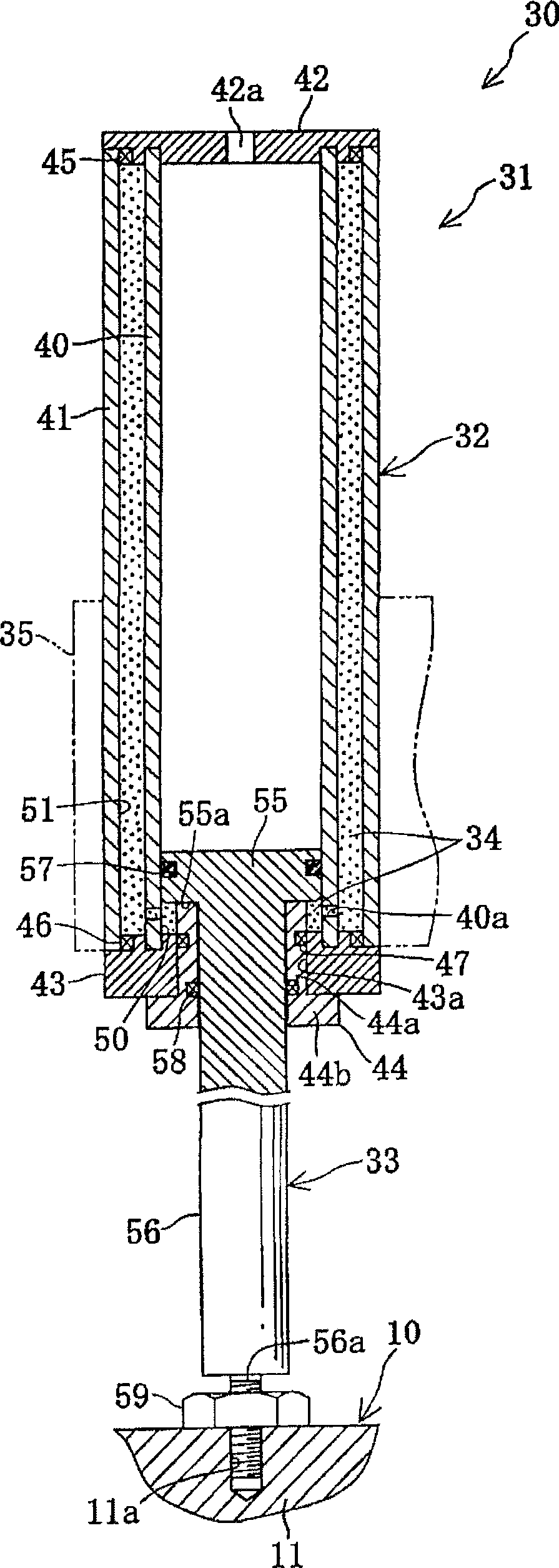

[0037] Such as figure 1 As shown, the spindle balancing device 30 for a machine tool provided by the present invention (hereinafter referred to as the spindle balancing device 30 ) is suitable for a machine tool M such as a vertical machining center. Additionally, the description will figure 1 The direction of the middle arrow A is taken as the front.

[0038] The machine tool M includes: a column body 1, a spindle unit 10 guided in the column body 1 in a liftable manner, and an elevating drive mechanism 20 for lifting and driving the spindle unit 10; The main shaft balancing device 30 (hereinafter referred to as the main shaft balancing device 30 ) has a gas spring 31 that supports the main shaft unit 10 and can reduce the load on the elevating drive mechanism 20 .

[0039] The front end of the cylinder 1 is provided with a vertical guide rail 2, and a slider 12 is fixedly installed on the rear end of the frame member 11 of the main shaft unit 10, and the slider 12 is buckl...

Embodiment 2

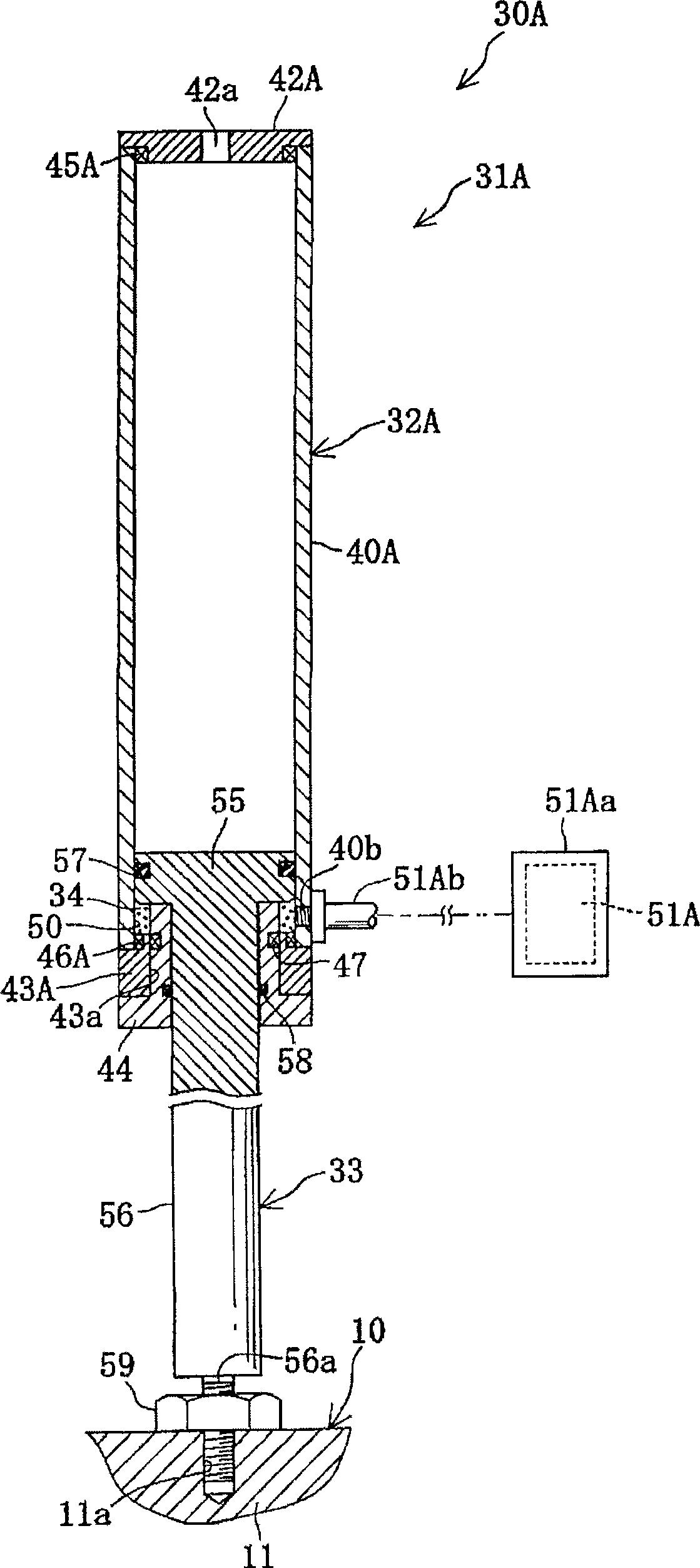

[0062] Such as image 3 As shown, the spindle balancing device 30A includes a gas spring 31A and a compressed gas filling chamber 51A provided independently of the gas spring 31A. The gas spring 31A is used instead of the gas spring 31 of the first embodiment, and is suitable for use in the machine tool M. In addition, the same code|symbol is used for the same part as Example 1, and description is abbreviate|omitted.

[0063] The gas spring 31A includes: a pneumatic cylinder body 32A, a connecting rod 33, and a compressed gas 34. The pneumatic cylinder body 32A, in the pneumatic cylinder body 32 of Embodiment 1, the outer cylinder 41 is omitted, and is formed to be opposite to the inner cylinder 40 and the upper end. Partially modified shapes of the wall member 42 and the lower end wall member 43 form the compressed gas operating chamber 50 inside the pneumatic cylinder body 32A.

[0064] The pneumatic cylinder body 32A includes: a cylinder member 40A, an upper end wall membe...

Embodiment 3

[0067] Such as Figure 4 As shown, the spindle balancing device 30B includes a gas spring 31B, and is adapted to be used in the machine tool M by replacing the gas spring 31 in the first embodiment with the gas spring 31B. The gas spring 31B includes: a pneumatic cylinder body 32B, a connecting rod 33B, and a compressed gas 34. The connecting rod 33B extends upward and downward from the pneumatic cylinder body 32B, and forms a compression chamber containing the compressed gas 34 in substantially the entire interior of the pneumatic cylinder body 32B. Gas actuating chamber 50B.

[0068] The pneumatic cylinder body 32B includes: a cylinder member 60 , an upper end wall member 61 and a lower end wall member 62 fixedly mounted on the upper and lower ends of the cylinder member 60 , and an upper link fixed on the upper end wall member 61 . The guide member 63 and the lower link guide member 64 fixed to the lower end wall member 62 . The cylinder member 60 and the upper and lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com