Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44 results about "Program quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

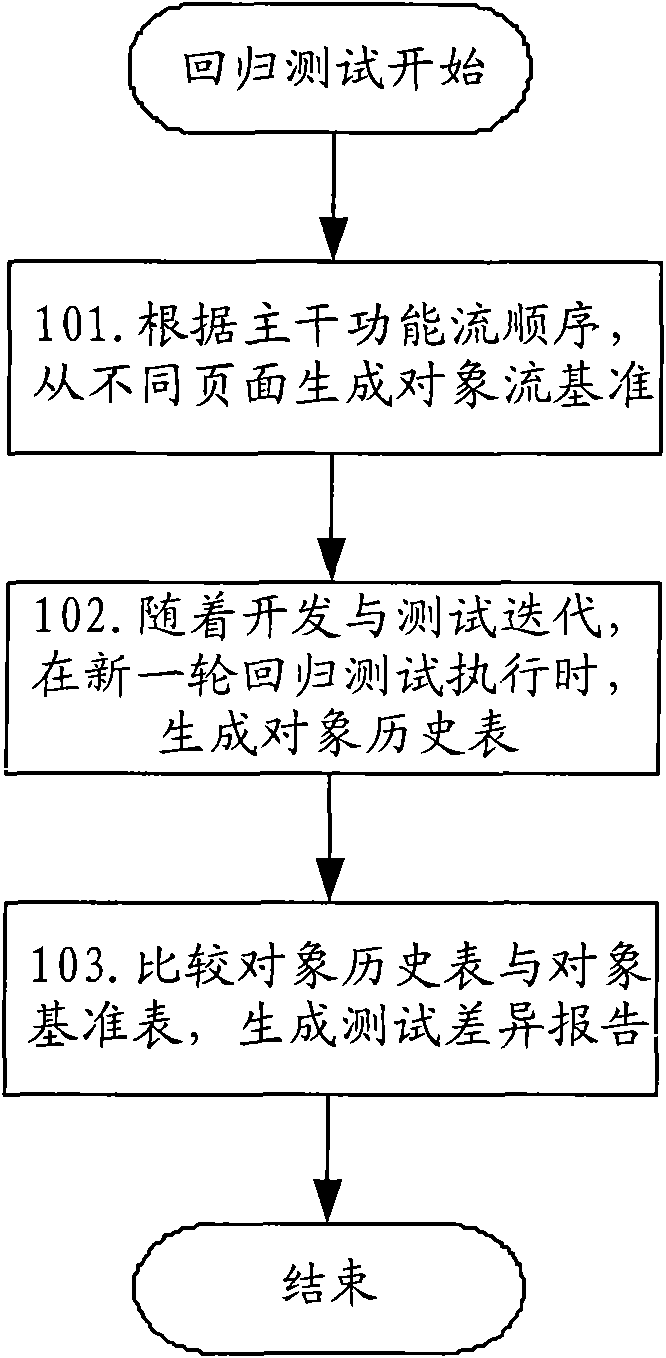

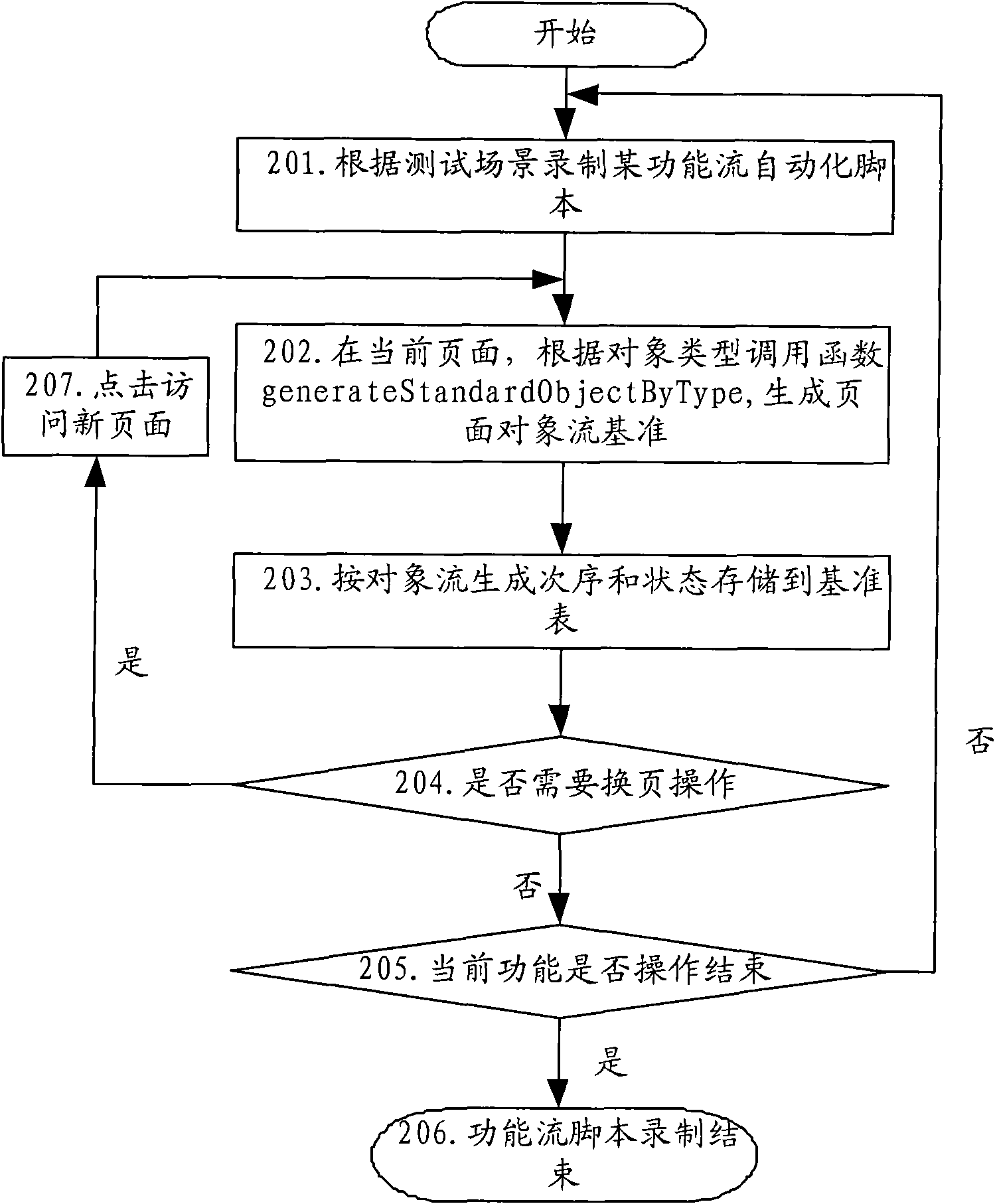

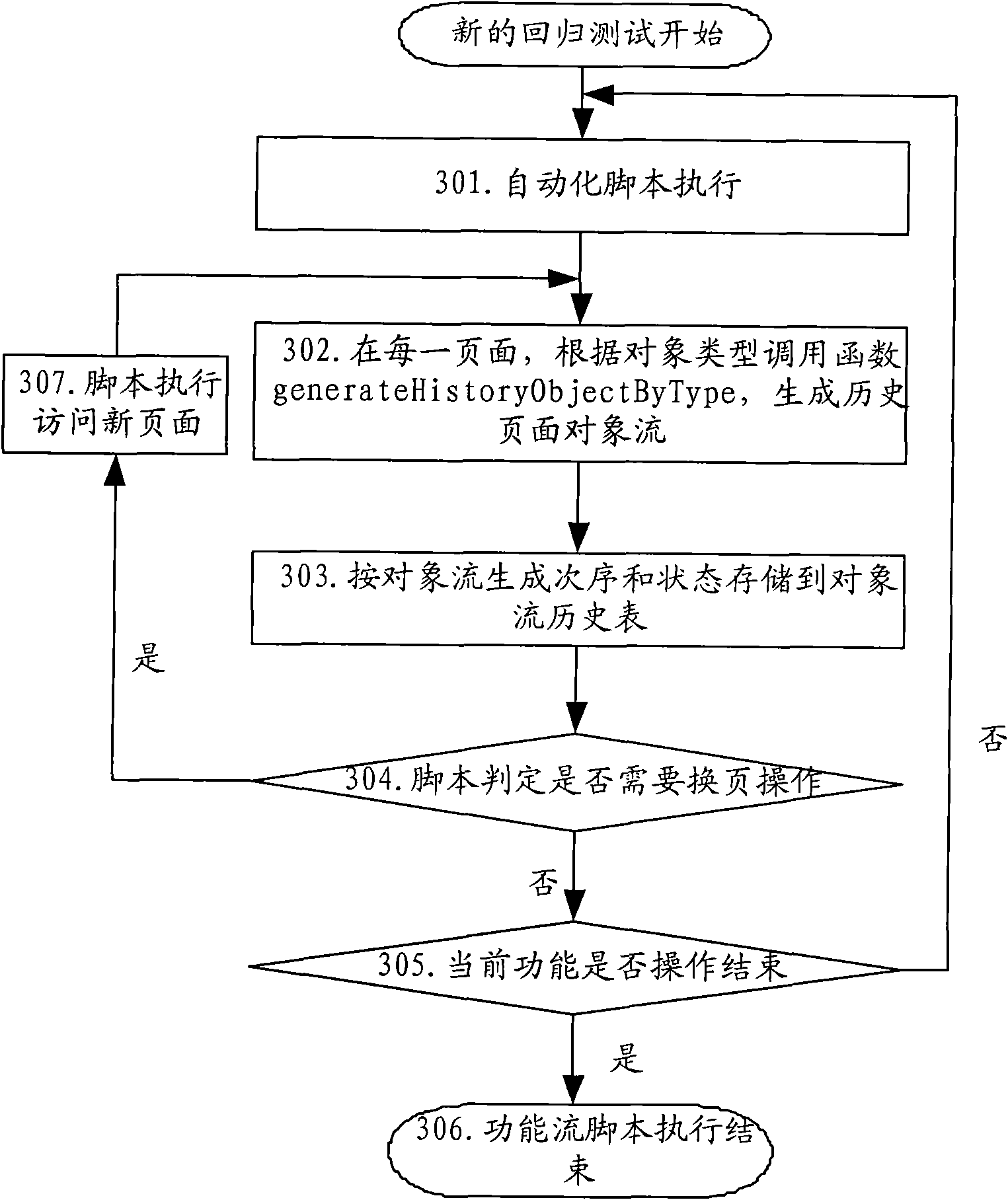

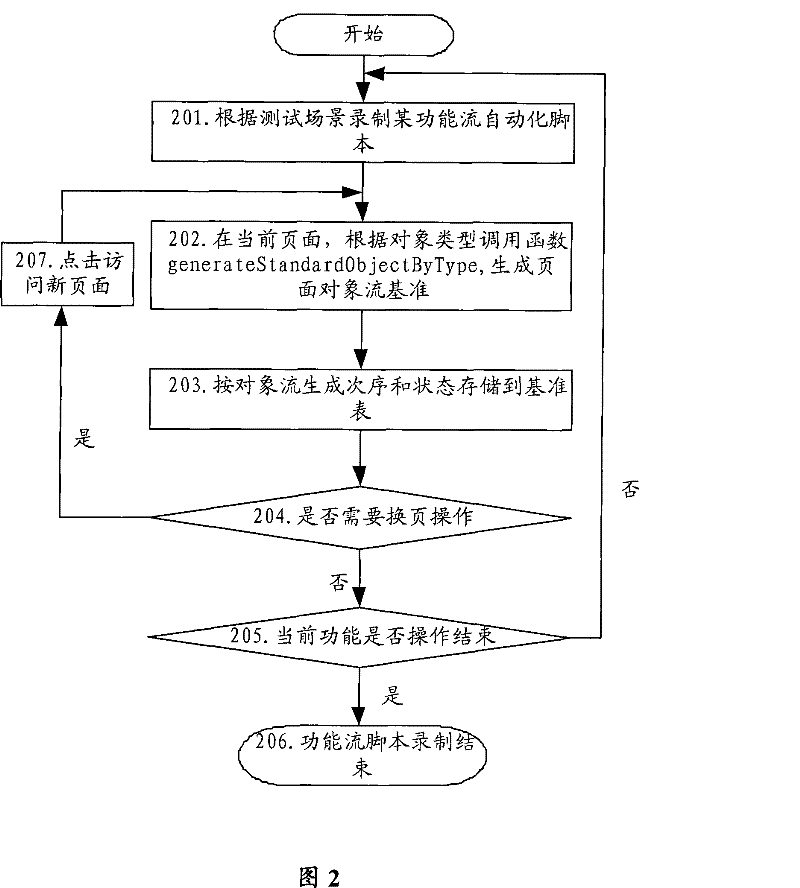

Method and system for using page-based object flow verification in regression test

InactiveCN101526916AQuality assuranceReduce manual testing timeSoftware testing/debuggingRegression testingProgramming language

The invention provides a method for using page-based object flow verification in a regression test, which comprises the following steps: recording a test automation script operated by a functional flow, and generating an object pivot table from different pages according to the operation sequence of a main functional flow; during the execution of a new round of regression test, generating an object historical table of an operation page of the function value; and contrasting the pivot table with the object historical table to determine whether the pivot table and the object historical table have differences in the same functional page and the sate and sequence of the same object and generating and outputting a test difference report. The invention provides a device for using the page-based object flow verification in the regression test. The invention can greatly reduce time for manual test and increase in the test number due to frequency program correction, ensures program quality and avoids test risks.

Owner:ALIBABA GRP HLDG LTD

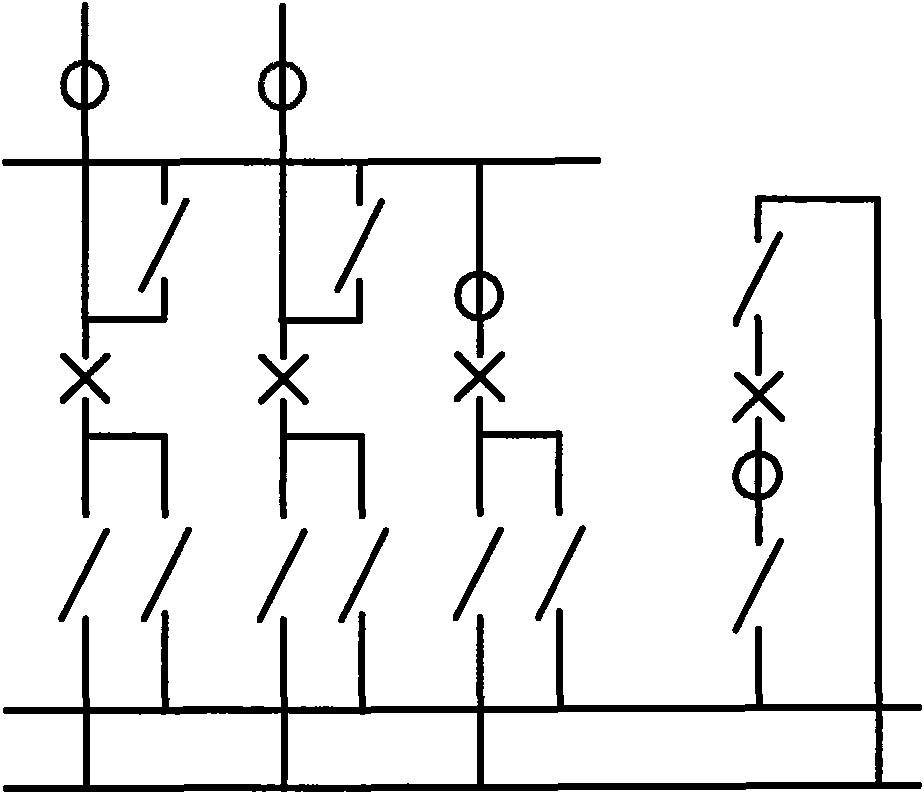

Object-oriented bus protection setting method

ActiveCN101609979AAdaptableQuality improvementEmergency protective circuit arrangementsProgram qualitySelf adaptive

An object-oriented bus protection setting method takes a bus voltage transformer in a main bus connection system, a bus coupler or section switch, a feeder switch and a stripe-spanning disconnecting switch as basic composition objects, firstly analyzes the topological structure of each basic composition object, and then forms a bus topological structure, and later takes the bus topological structure as the object so as to finish the differential composition logic of bus differential protection in accordance with a traditional method; by analyzing the configuration information of the basic composition objects, the self-adaptive construction of a bus differential protection scope is finished; each basic composition object respectively defines each type and simultaneously provides relative configuration information: parameter, input and output; according to the configuration information, the topological structure of a protected bus is formed, and then the self-adaptive construction of the bus differential scope, which is finished by analyzing the configuration information of the objects, is protected; and the bus adopting the bus protection setting method has very strong protection and adaptability, can conveniently achieve the bus protection of different main connection systems by modifying the configuration files, and is conducive to improving the program quality.

Owner:NR ELECTRIC CO LTD +1

Application program tracking and recording system and method, computer device and storage medium

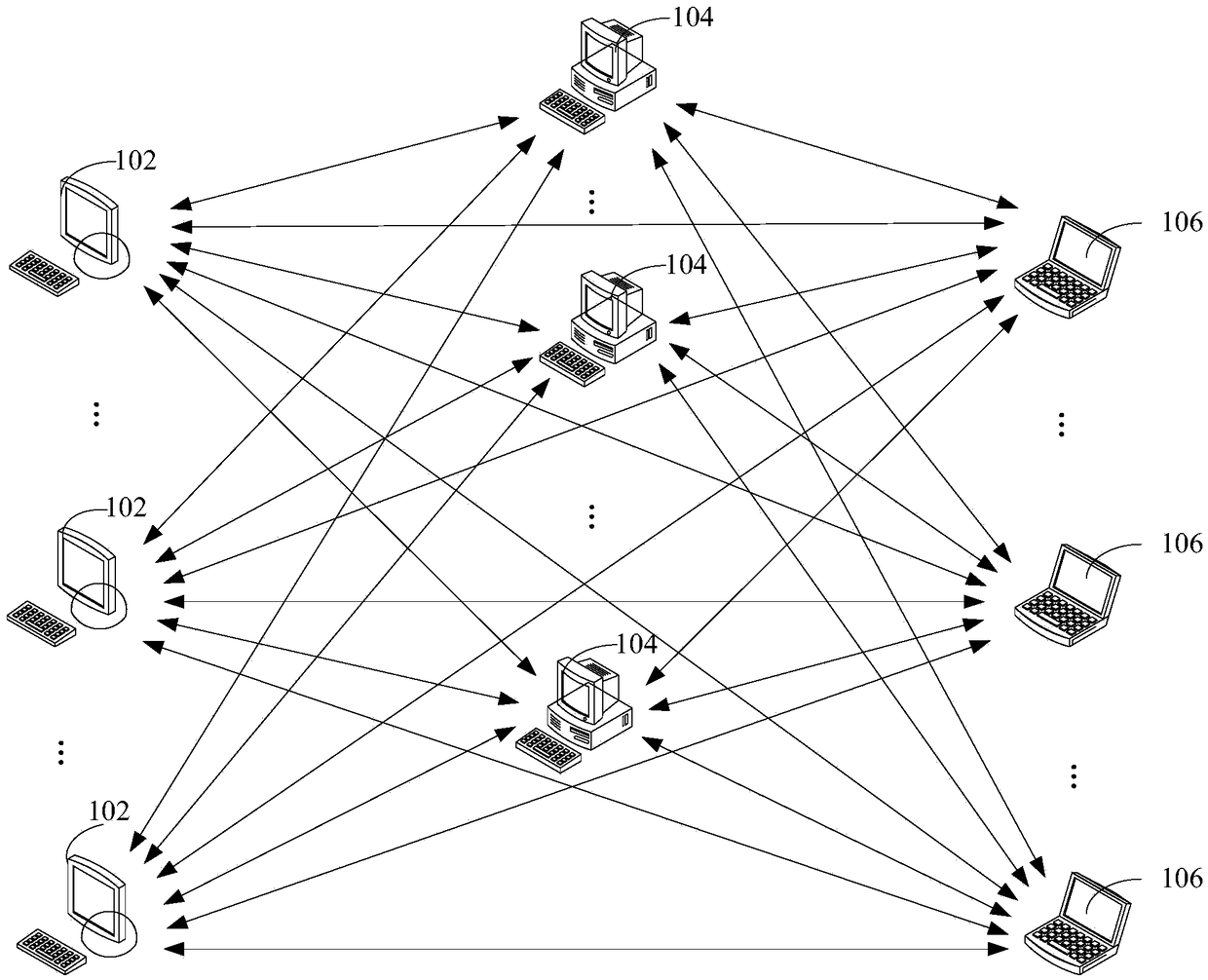

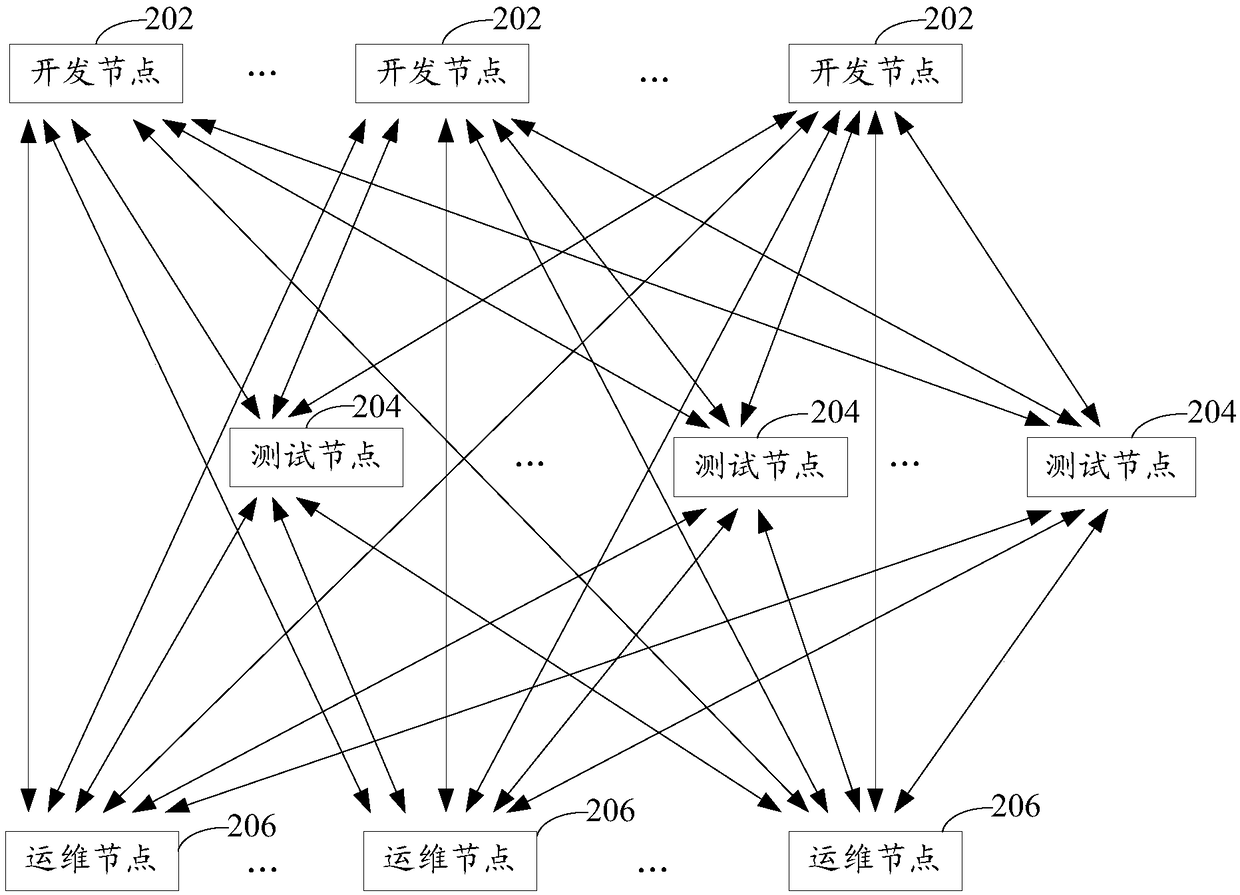

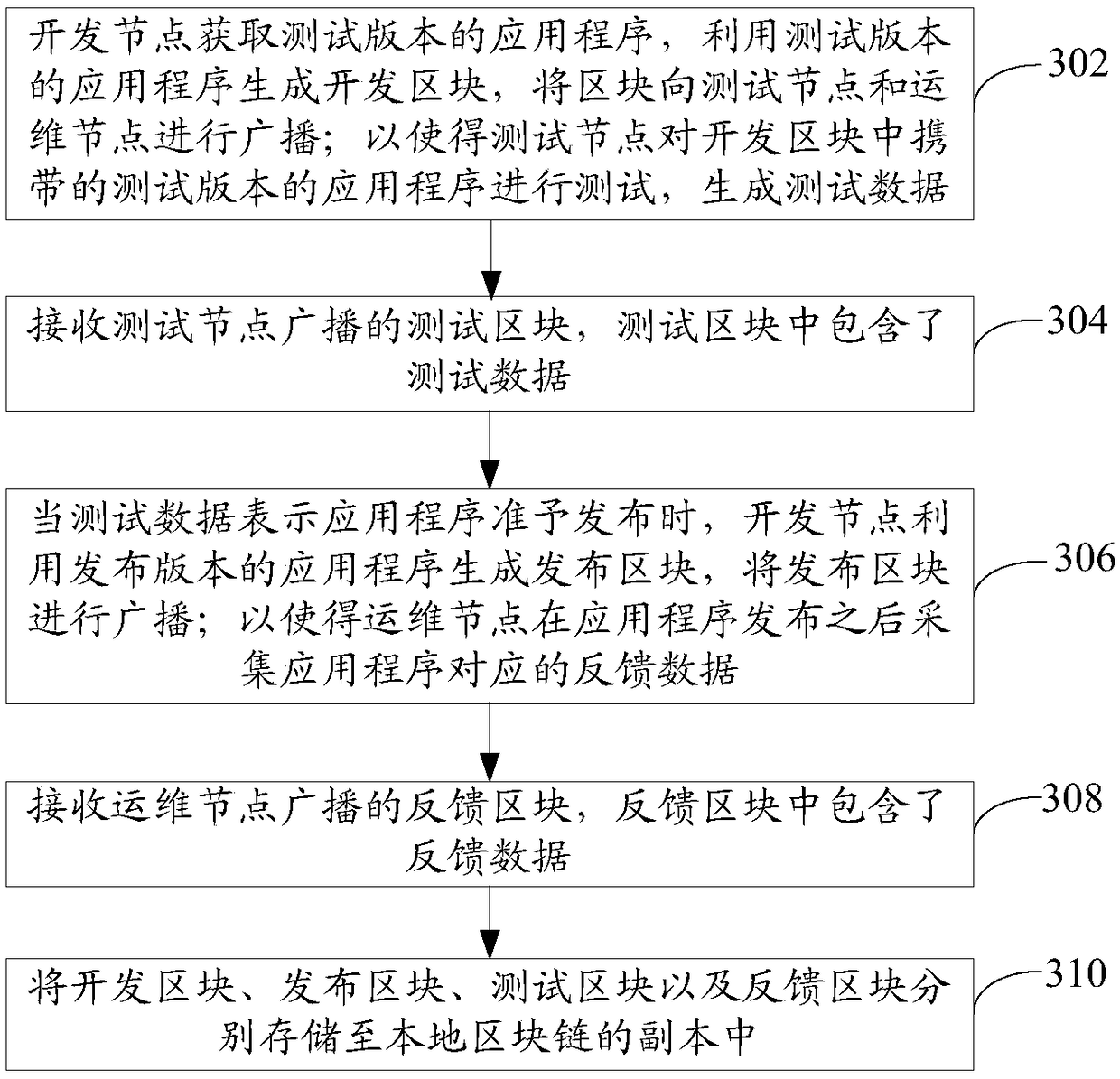

The invention relates to an application program quality traceability system and method, a computer device and a storage medium. The system comprises a development node, a testing node and an operationand maintenance node, wherein the development node is used for obtaining an application program of a test version, generating a development block by using the application program of the test versionand broadcasting the development block; the testing node is used for receiving the development block, analyzing the development block to obtain the application program of the test version, and testingthe application program of the test version to generate test data; when the test data represents that the application program is approved to be released, the development node is further used for generating an release block by using an application program of a release version and broadcasting the release block; the operation and maintenance node is used for collecting feedback data corresponding to the application program after the application program is released, generating a feedback block by using the feedback data and broadcasting the feedback block. By means of the system, the applicationprogram can be effectively tracked and recorded.

Owner:深圳市牛鼎丰科技有限公司

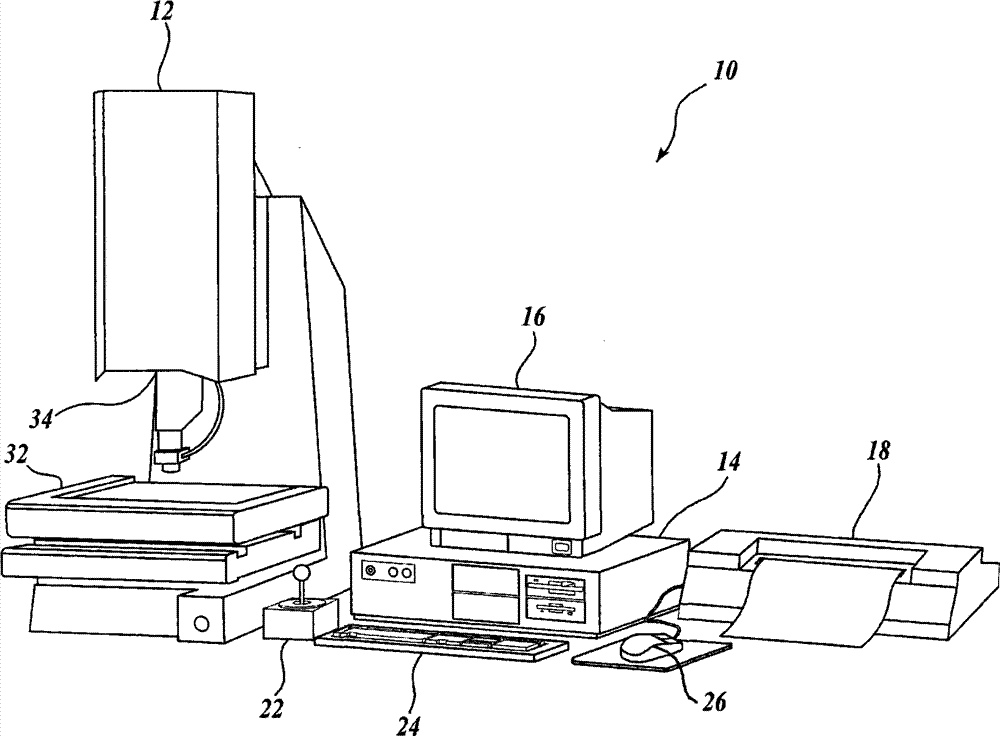

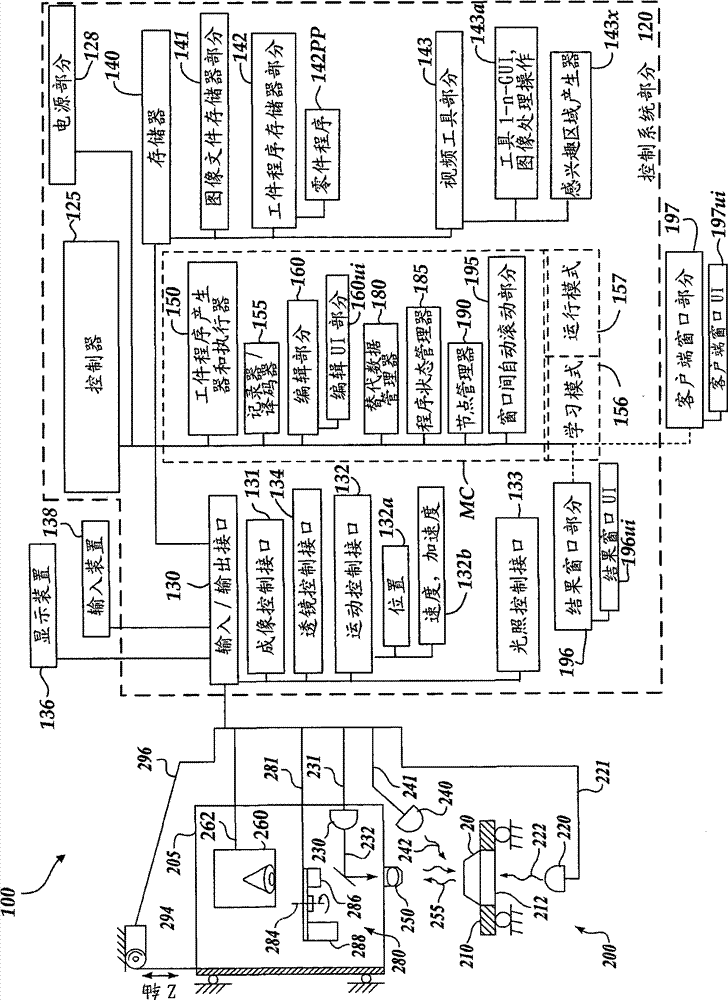

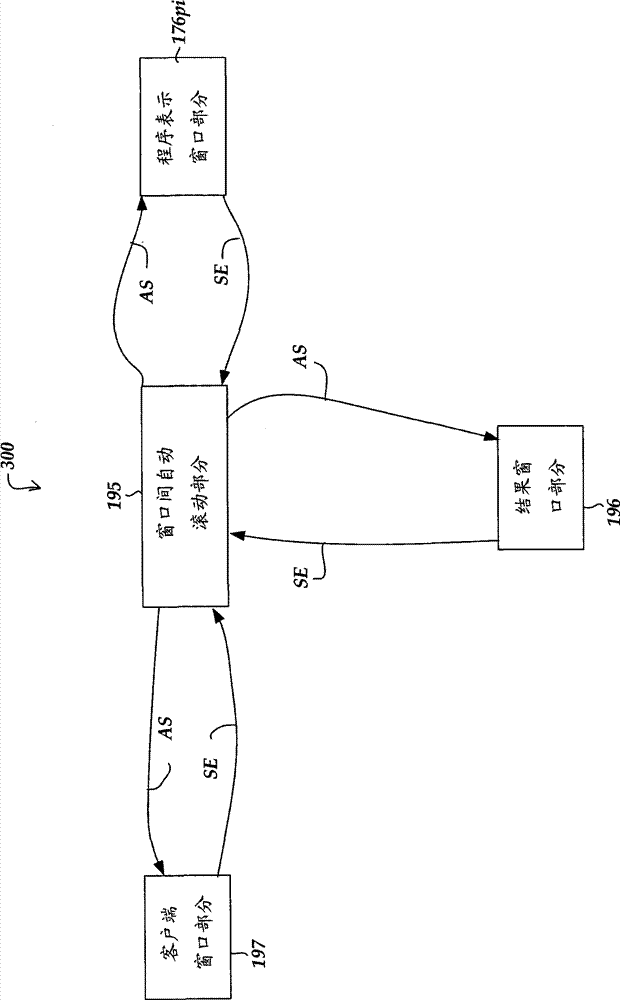

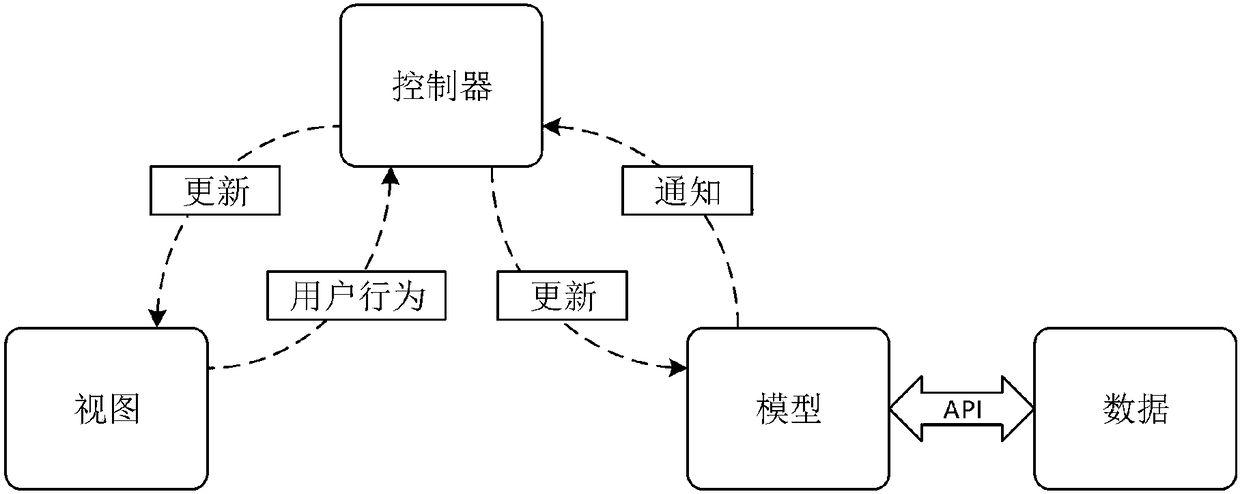

Machine vision system program editing environment including synchronized user interface features

A machine vision system program editing environment including synchronized selection and / or identification of related features in a plurality of different user interface windows is provided. In particular, one of the windows is an editing window where a part program representation is displayed for editing by a user. In one embodiment, a user may select data or another feature of interest in a window that is not the editing window (e.g., a results window, or graphical workpiece inspection feature display window) and the associated part program instruction representation is automatically highlighted and / or selected in the editing window. Conversely, a part program instruction representation may be selected by a user in the editing window and the associated results or feature in another window is automatically highlighted and / or selected. User interface navigation, rapid program quality assessment, and overall part program creation and editing efficiency are significantly enhanced in such an editing environment.

Owner:MITUTOYO CORP

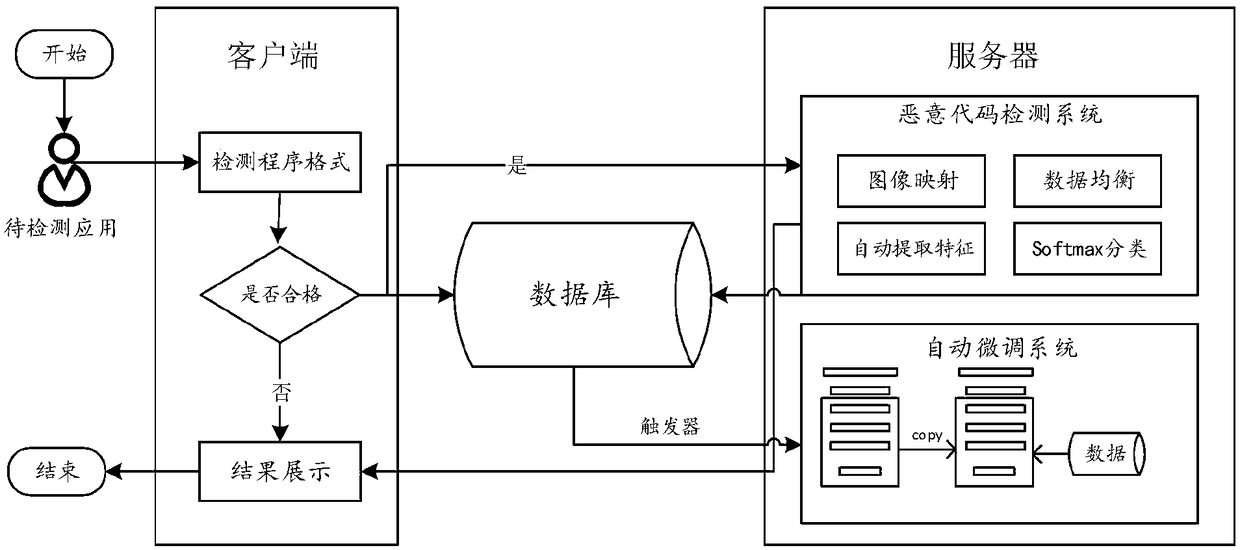

Automatic malicious code variation detection method

InactiveCN108460277AAvoid missing detectionVersatilePlatform integrity maintainanceExtensibilityMaintainability

The invention discloses an automatic malicious code variation detection method. The method comprises the following steps of: feeding a to-be-detected program into a program quality detection system, so as to detect whether the to-be-detected program is a strictly executable program or not: verifying simple features such as a size, a suffix and a naming rule of the program; storing the to-be-detected program which passes the program quality detection system in a database, and handing over the to-be-detected program to a malicious code variation detection system to carry out detection; and if the quantity of newly detected malicious codes stored in a database system achieves a preset threshold value, triggering a set trigger in the database system, so as to enable an automatic fine tuning system to start work. According to the method, a software component technology is flexibly applied to design and development of systems, so that the reliability and extensibility and maintainability ofthe systems are improved, the malicious code variation detection system perfect in function is realized, and the current manner of manually selecting malicious code to detect features is improved.

Owner:BEIJING UNIV OF TECH

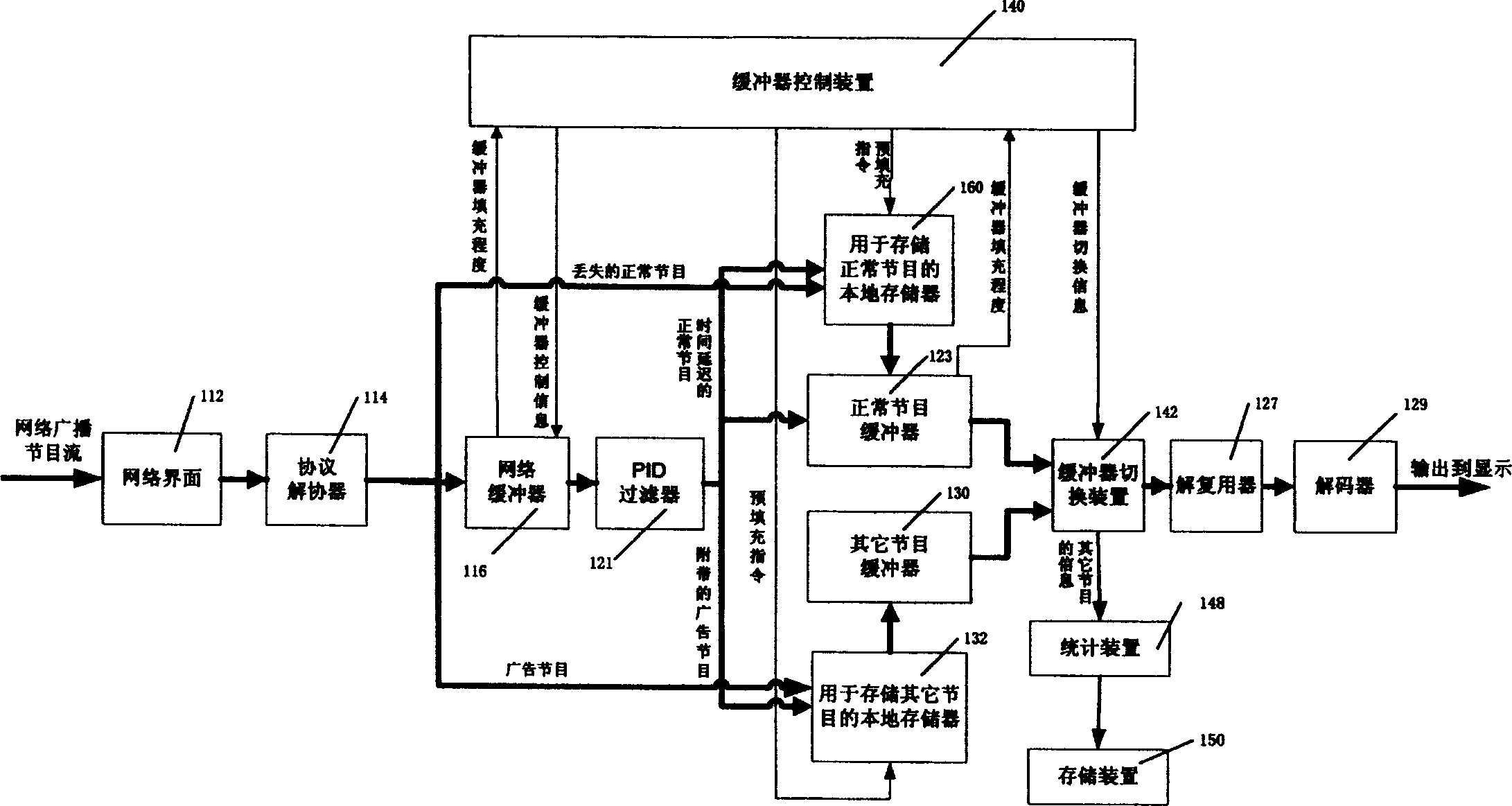

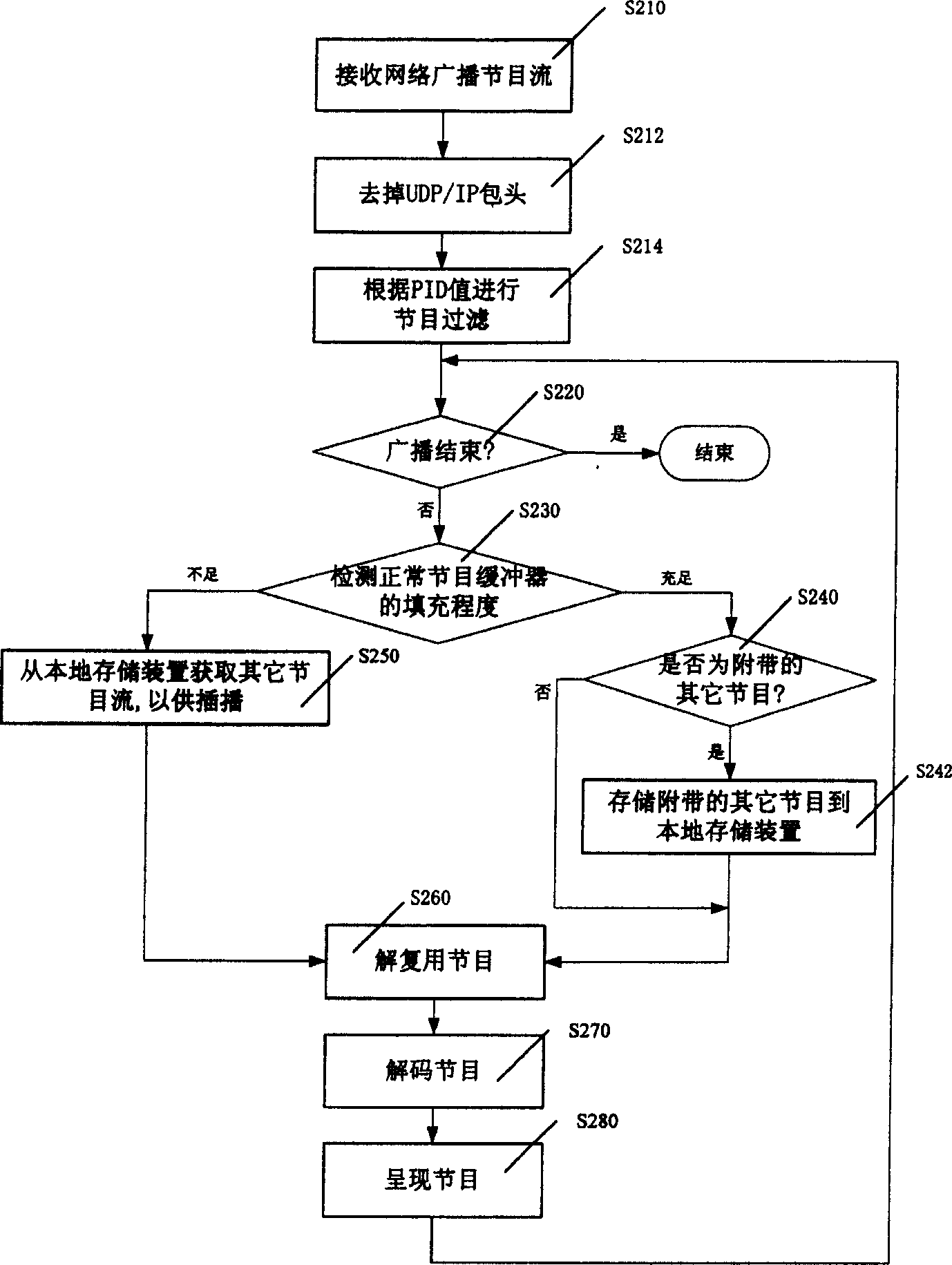

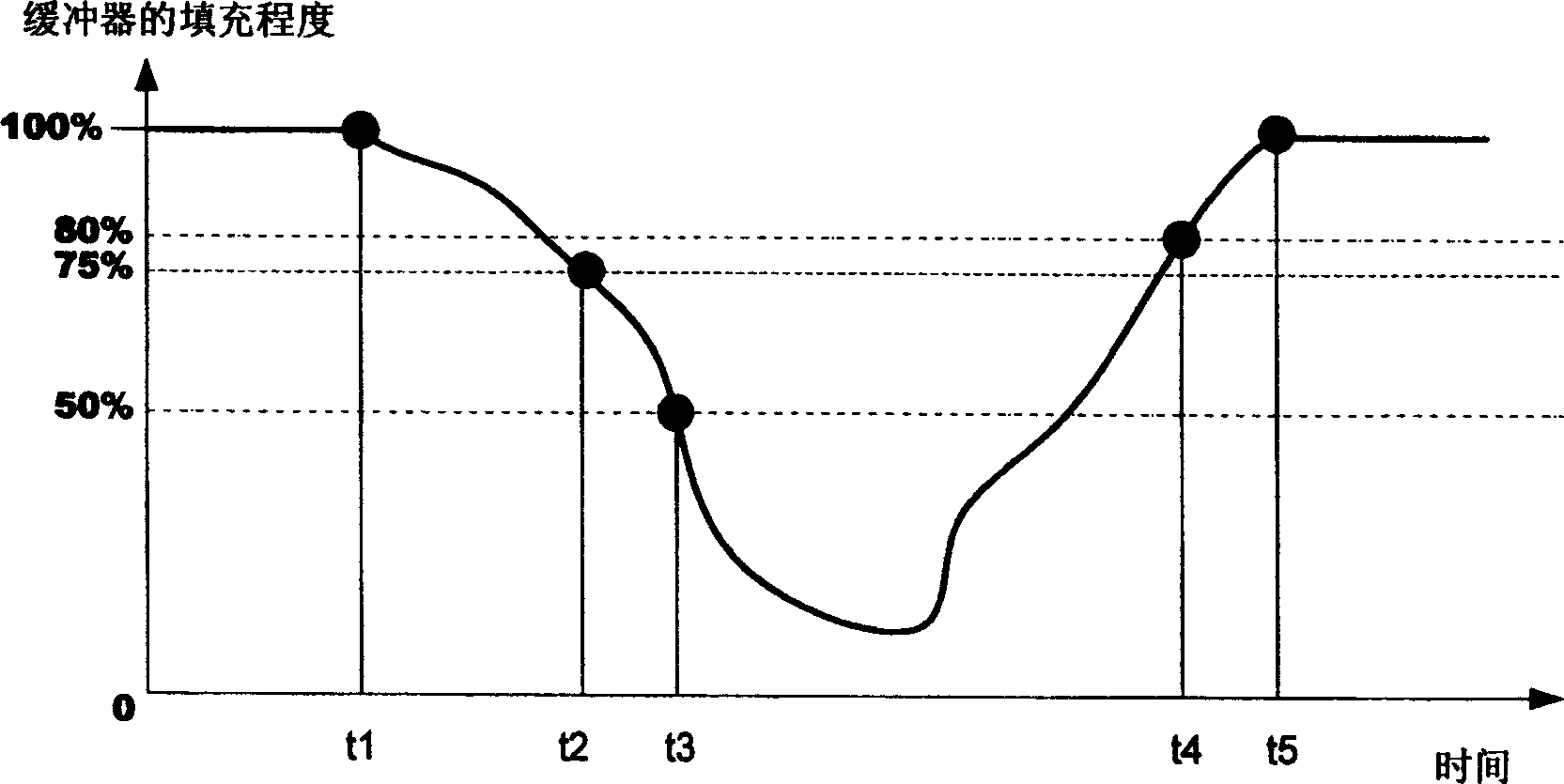

A broadcast method and system for digital program

InactiveCN1622616ATelevision system detailsAnalogue secracy/subscription systemsSignal qualityBroadcasting

Owner:KONINK PHILIPS ELECTRONICS NV

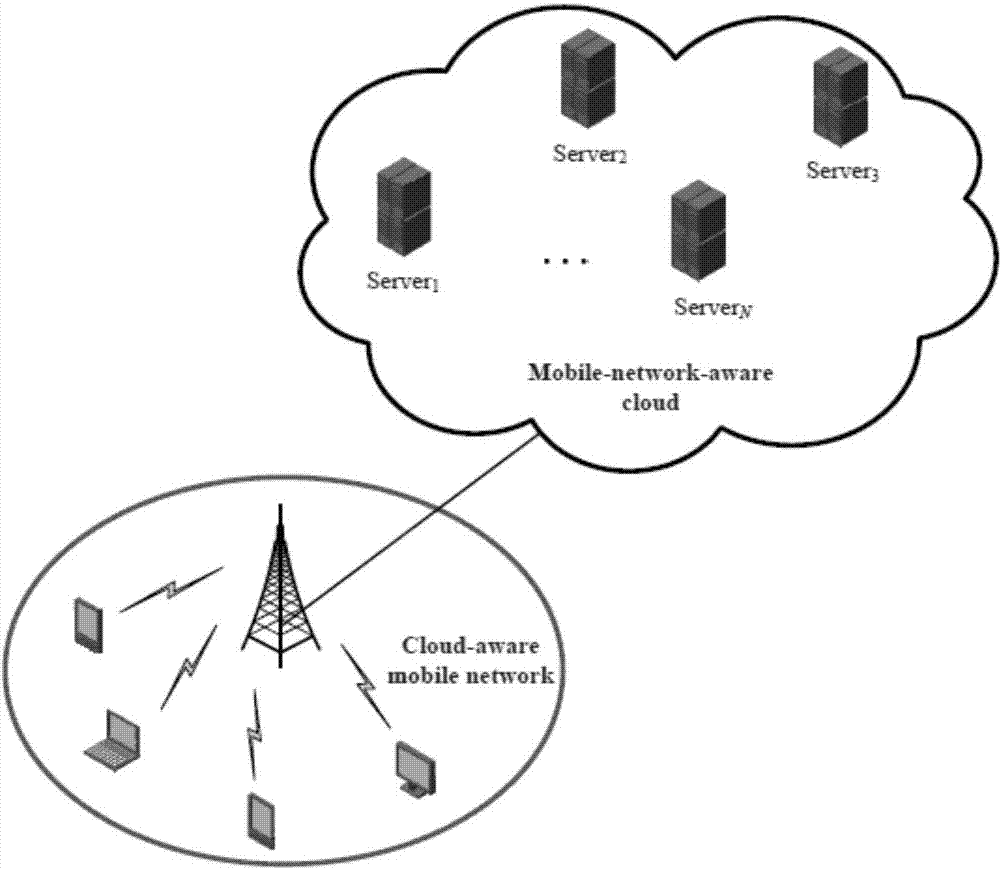

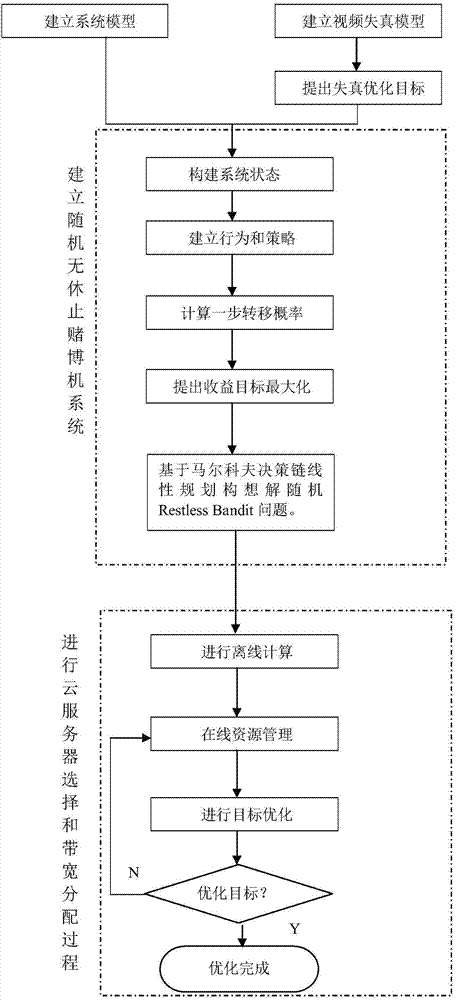

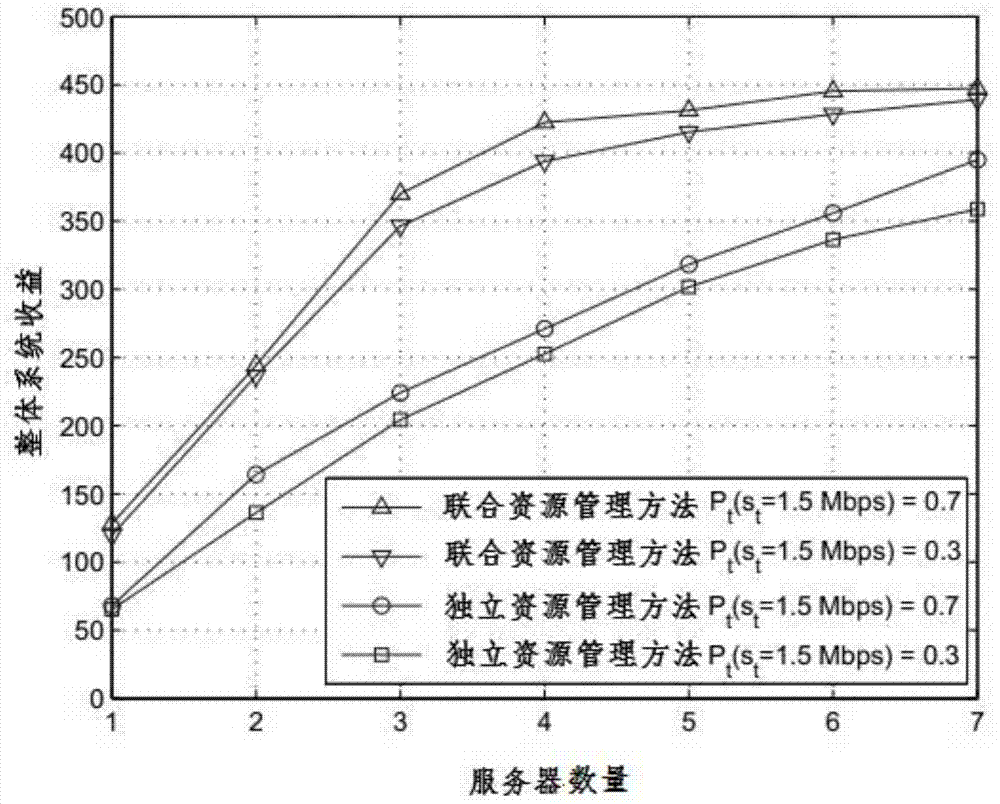

Computing and wireless resource cooperative dispatching method in mobile cloud video transmission

InactiveCN103888849ASolve management problemsGood use effectSelective content distributionVideo transmissionMobile cloud

The invention relates to a computing and wireless resource cooperative dispatching method in mobile cloud video transmission. The method comprises the steps that a system model, namely a cloud network abstract model is established; a video distortion model is established, an optimization target is provided; a random Restless Bandit system is established; and cloud service selecting and bandwidth distributing are carried out. The problem that in the prior art, system performance can be severely affected through respective and independent cloud and mobile resource management is solved, by combining a dynamic cloud network and wireless resource management, the end-to-end performance suitable for video transmission in a mobile cloud network computing system is improved, important video application layer parameters, namely the frame inner refresh rate are perfected, program quality is evaluated through distortion magnitude, and video distortion-preventing performance is improved.

Owner:BEIJING UNIV OF TECH

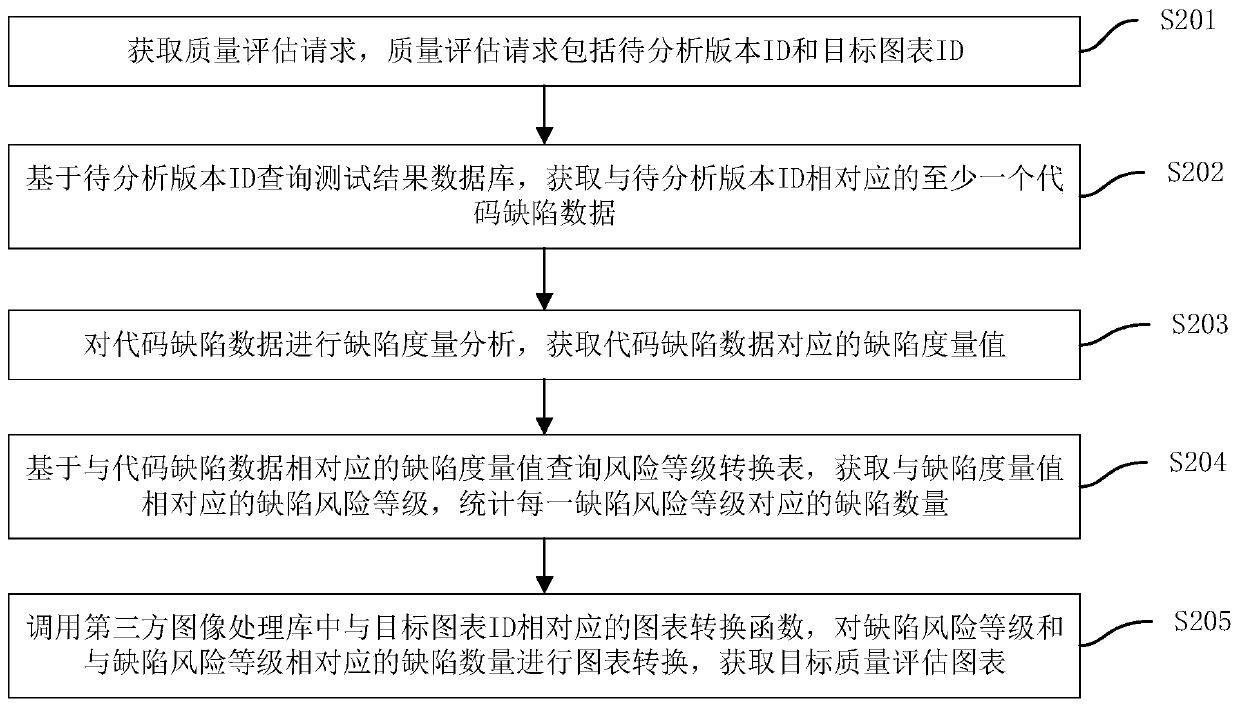

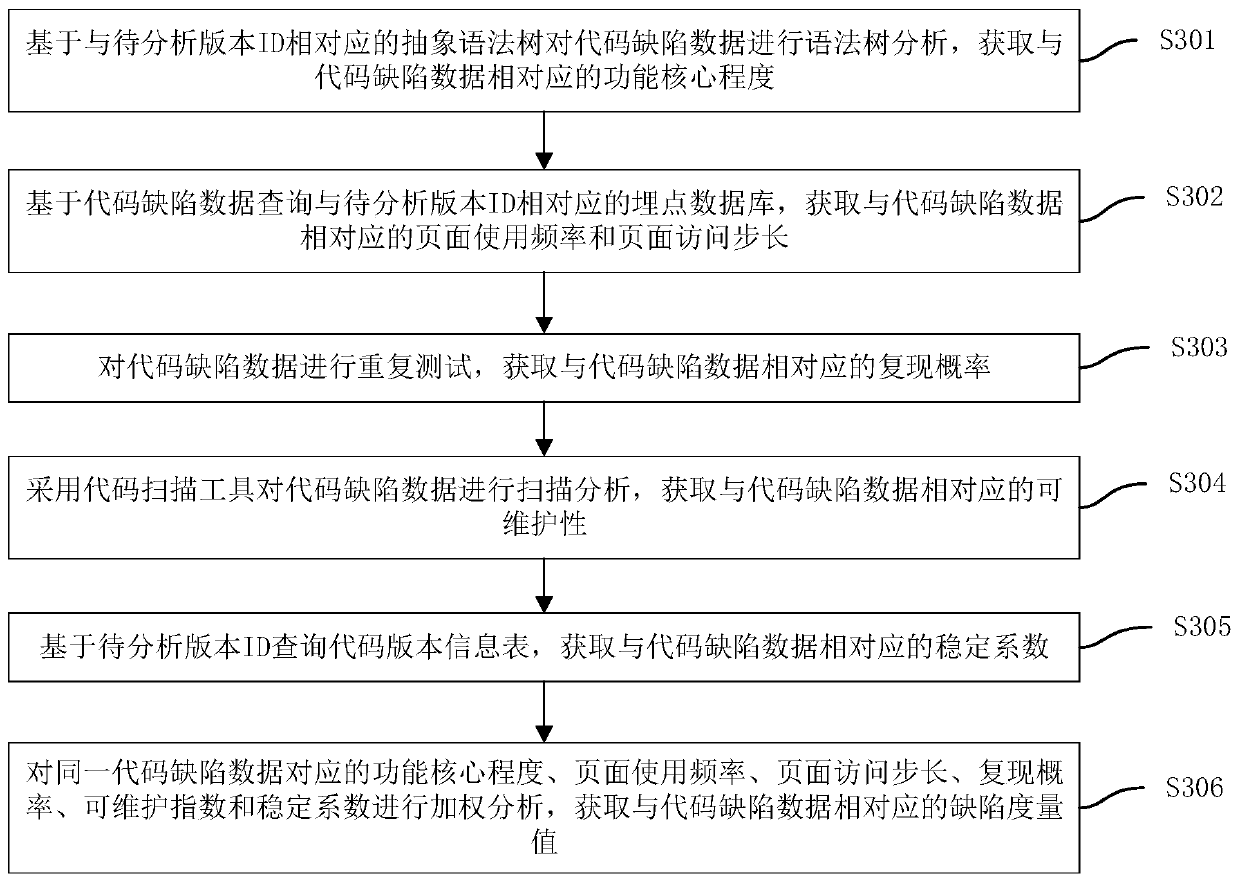

Software program quality evaluation method and device, computer equipment and storage medium

The invention discloses a software program quality evaluation method and device, computer equipment and a storage medium. The method comprises the following steps: obtaining a quality assessment request comprising a version ID to be analyzed and a target chart ID; querying a test result database based on the to-be-analyzed version ID, and obtaining at least one corresponding code defect data; carrying out defect measurement analysis on the code defect data to obtain a corresponding defect measurement value; querying a risk level conversion table based on the defect metric values, obtaining defect risk levels corresponding to the defect metric values, and counting the number of defects corresponding to each defect risk level; and calling a chart conversion function corresponding to the target chart ID in a third-party image processing library, carrying out chart conversion on the defect risk level and the defect number corresponding to the defect risk level, and obtaining a target quality assessment chart. The target quality evaluation chart obtained by the method can visually reflect the quality of the software program, so that the quality evaluation result has objectivity and intuitiveness.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

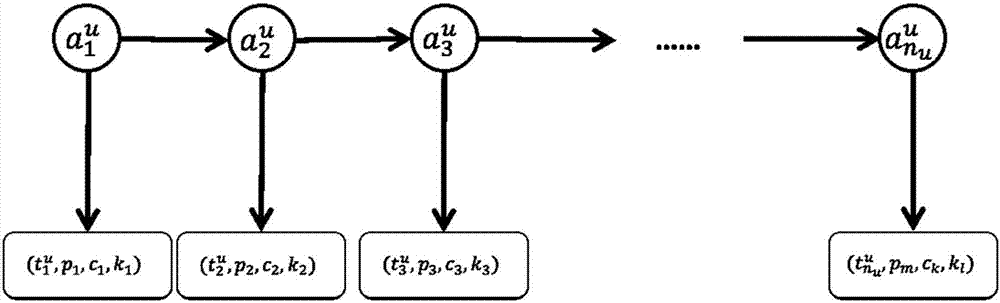

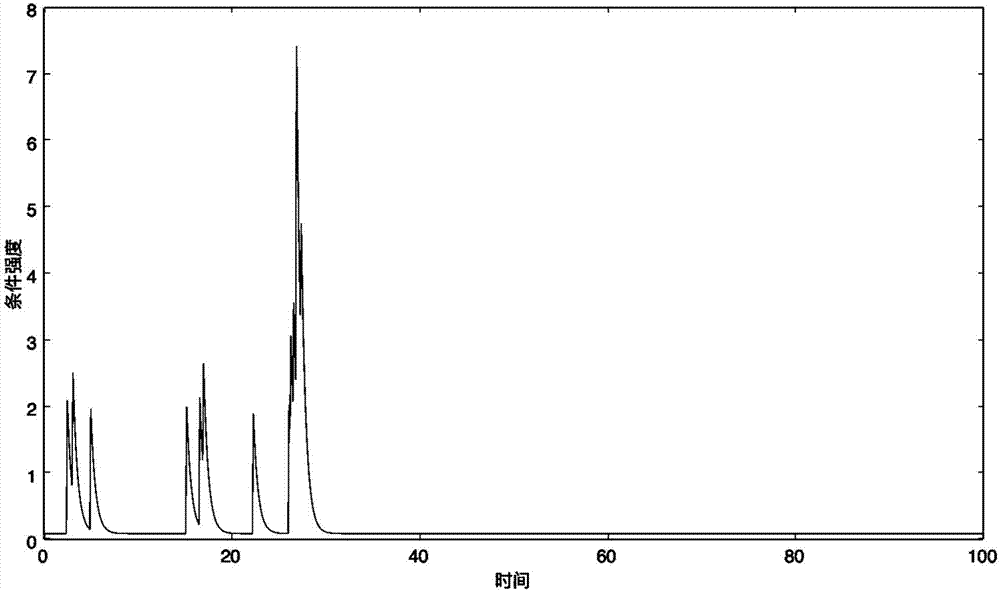

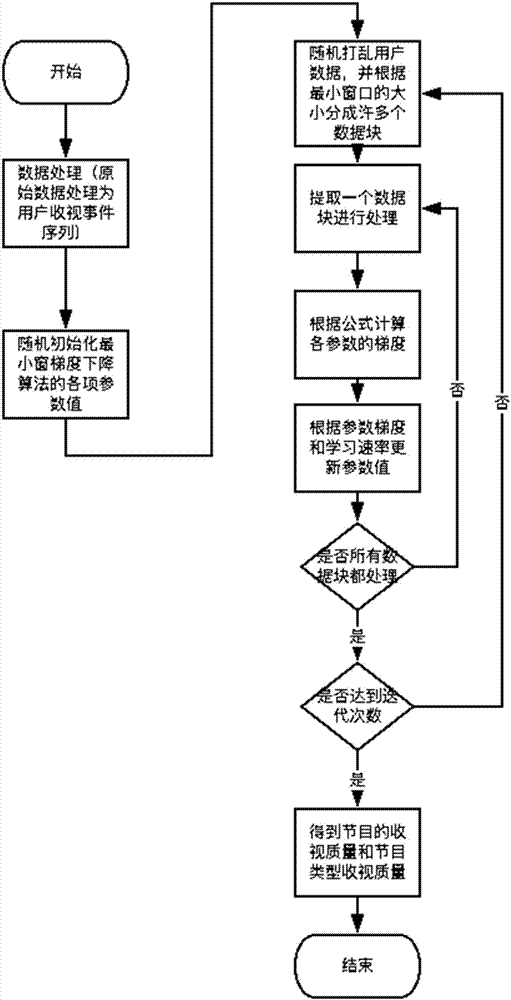

Program quality evaluation method based on Hawkes process

The invention provides a program quality evaluation method based on a Hawkes process. The method comprises the steps that the original data of a user viewing behavior are abstracted into a point process, wherein only the time point, the program number, the program type and the channel number of the user viewing are included; the influence of subjective and objective factors such as the user viewing wish, the user preference and the channel preference on the program quality evaluation is ruled out; the influence of objective factors such as the program type on the program quality evaluation is ruled out; and the behavior of each user's viewing program is modeled through a Hawkes model. According to the invention, the minimum window gradient descent algorithm is used; the parameters of the established model are acquired by calculating the user data; and the program quality and the program type are evaluated.

Owner:上海媒智科技有限公司

Video content control system with automatic content selection

InactiveUS20090328106A1Reduce exposureQuality improvementTelevision system detailsSpecific information broadcast systemsControl systemDecision table

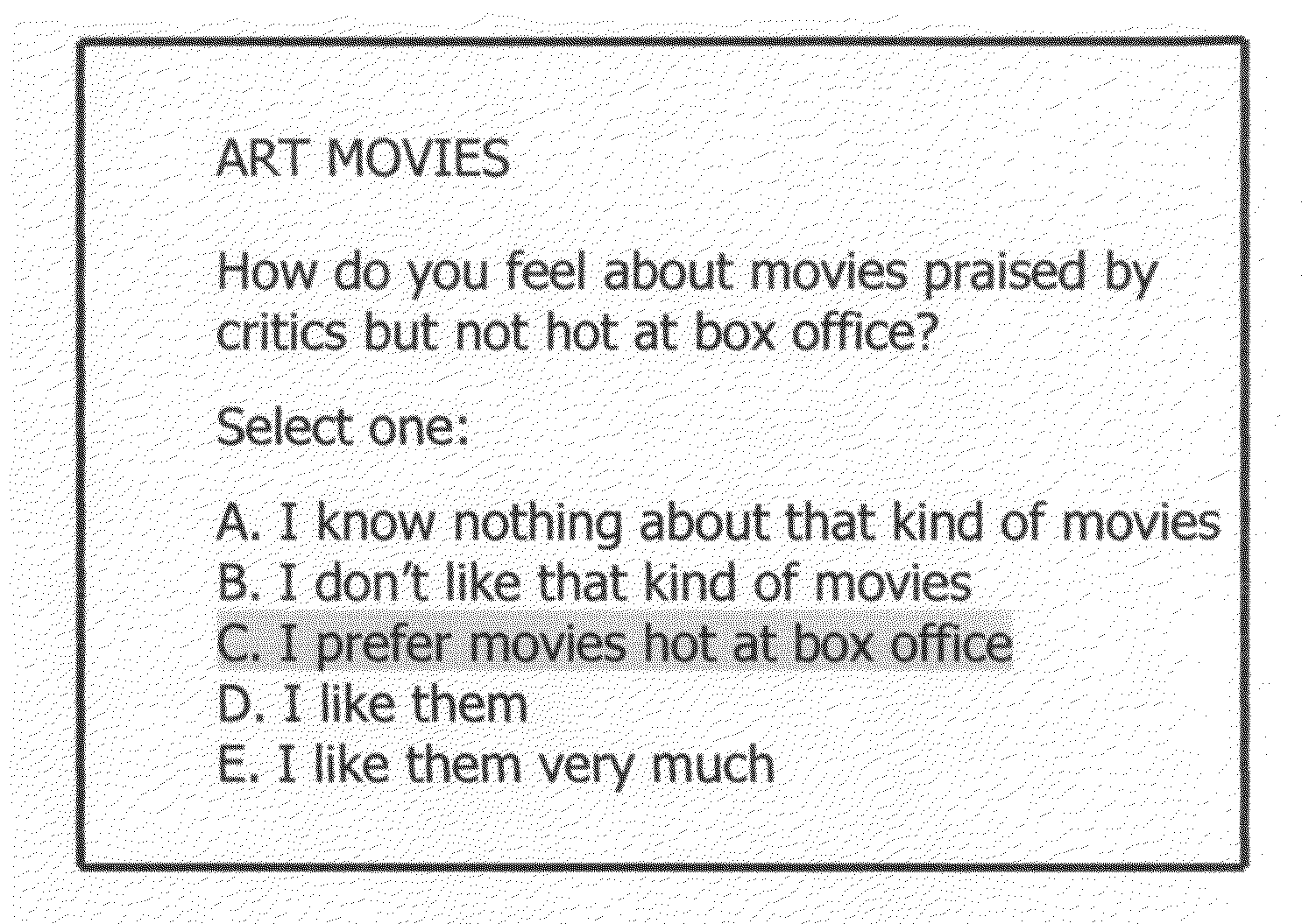

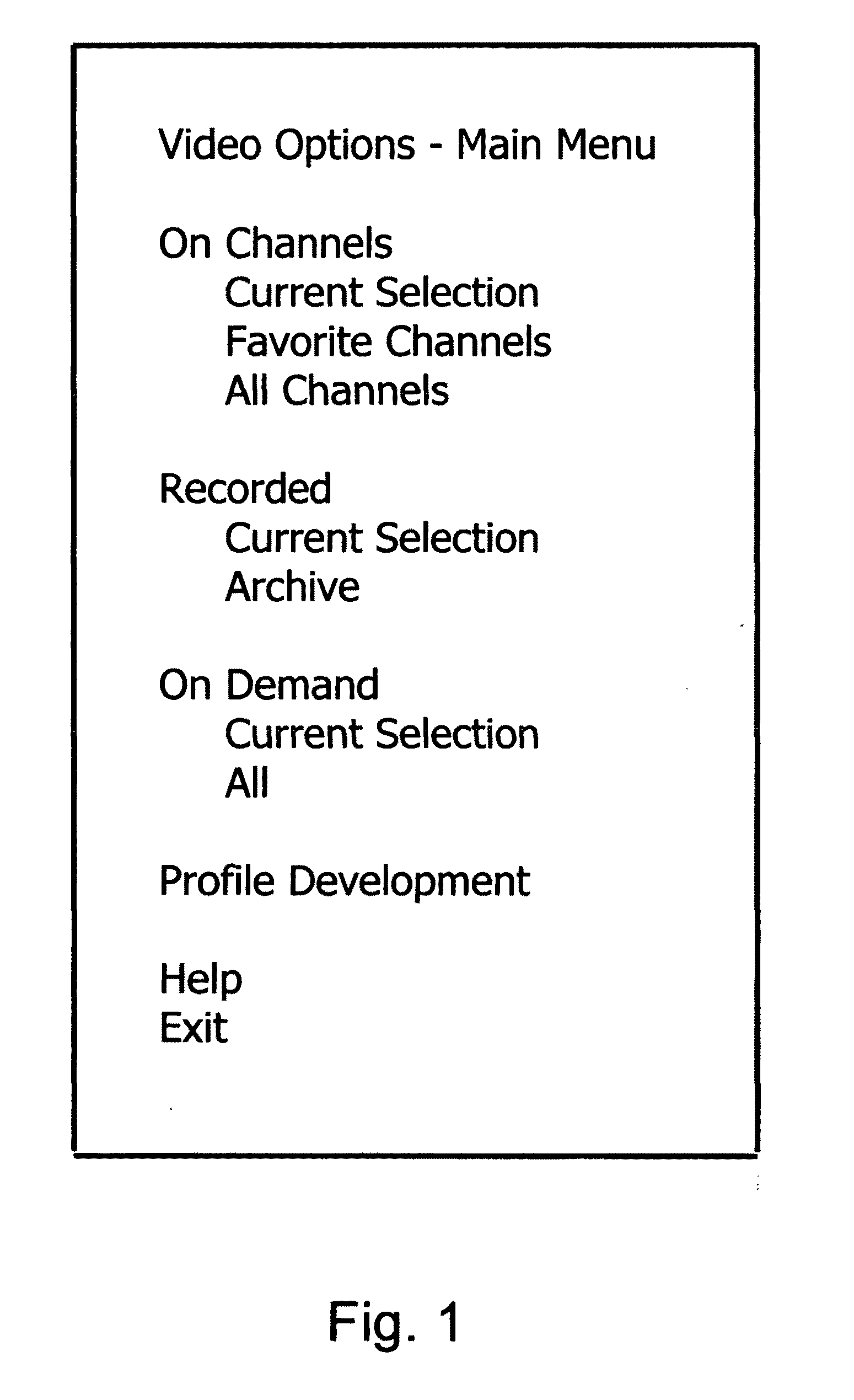

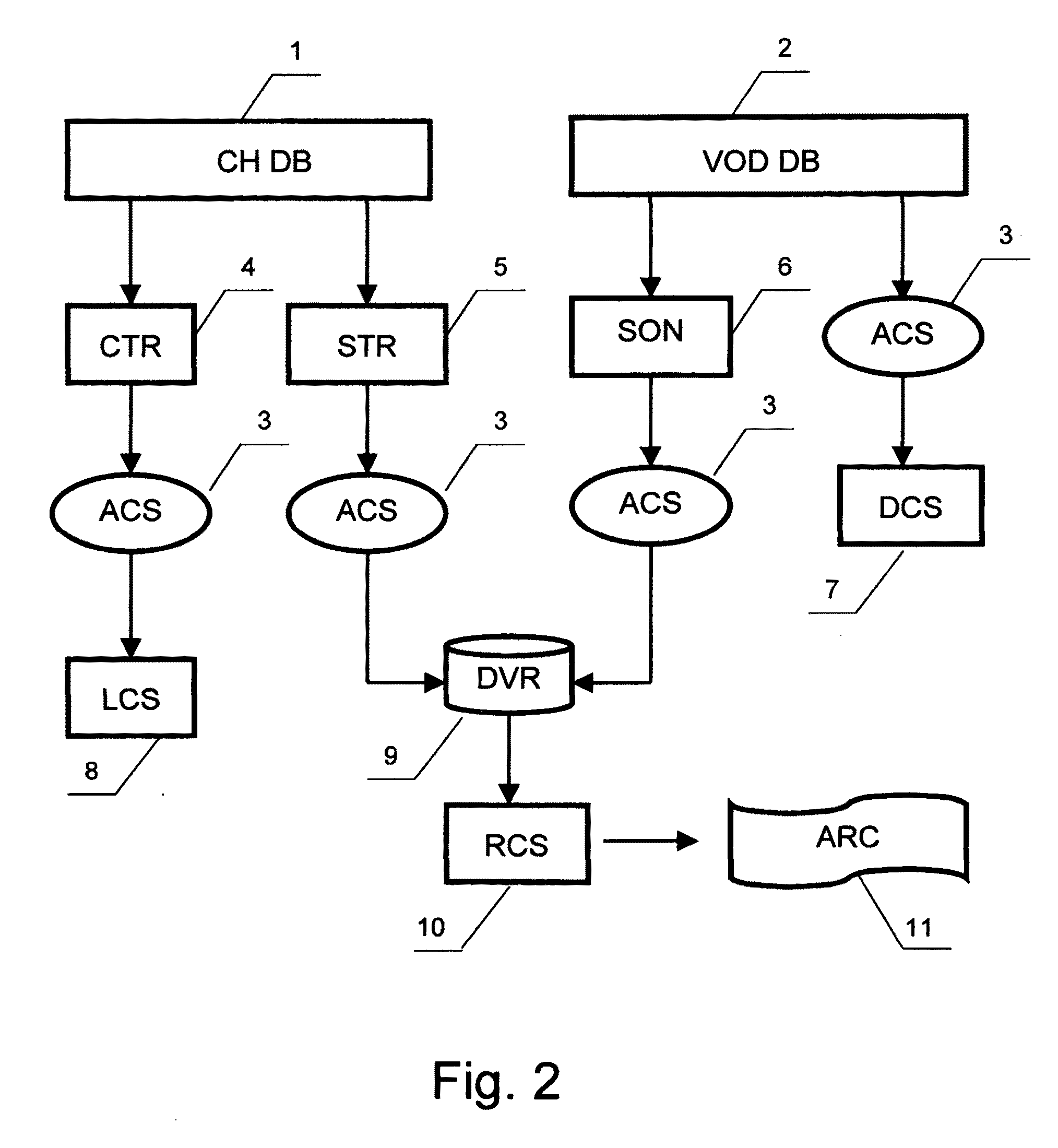

For selection of entertainment of the most personal interest to a user, a video content control system processes records of video programs against user data. A program record contains data pertinent to user preferences and an impartial rating of program quality or significance determined with no regard to preferences of individual users. The processing is defined by decision tables. For a particular combination of user data and program data pertinent to user preferences, a decision table specifies a value of change to be applied to the impartial rating to produce a personal rating as an increased, decreased or unchanged impartial rating. The system selects videos with the highest personal ratings, i.e. videos that are impartially the best and compliant with user preferences.

Owner:LEVITAN GUTMAN

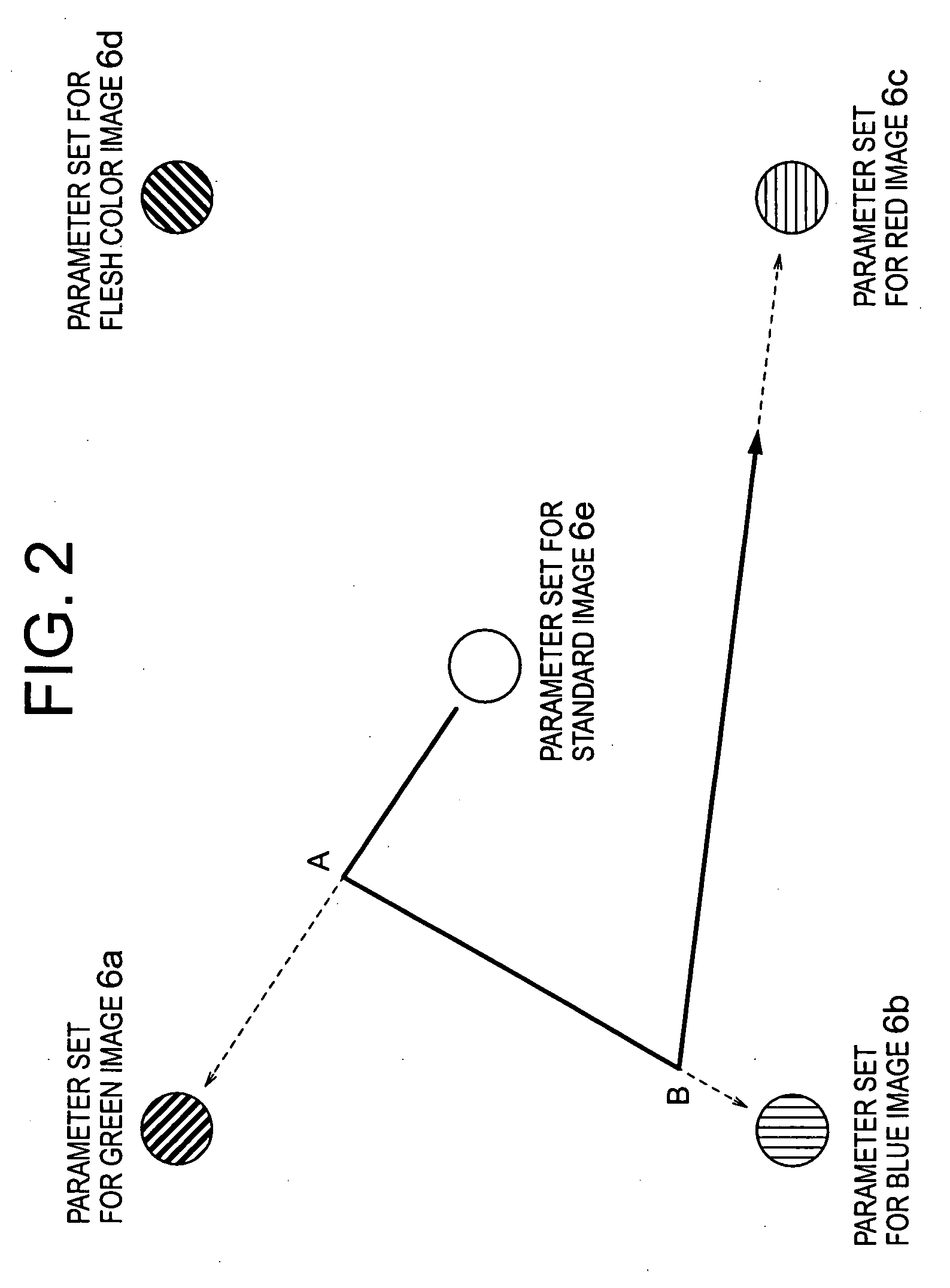

Image processing apparatus, image processing method, and image processing program

InactiveUS20070242898A1Television system detailsCharacter and pattern recognitionImaging processingComputer graphics (images)

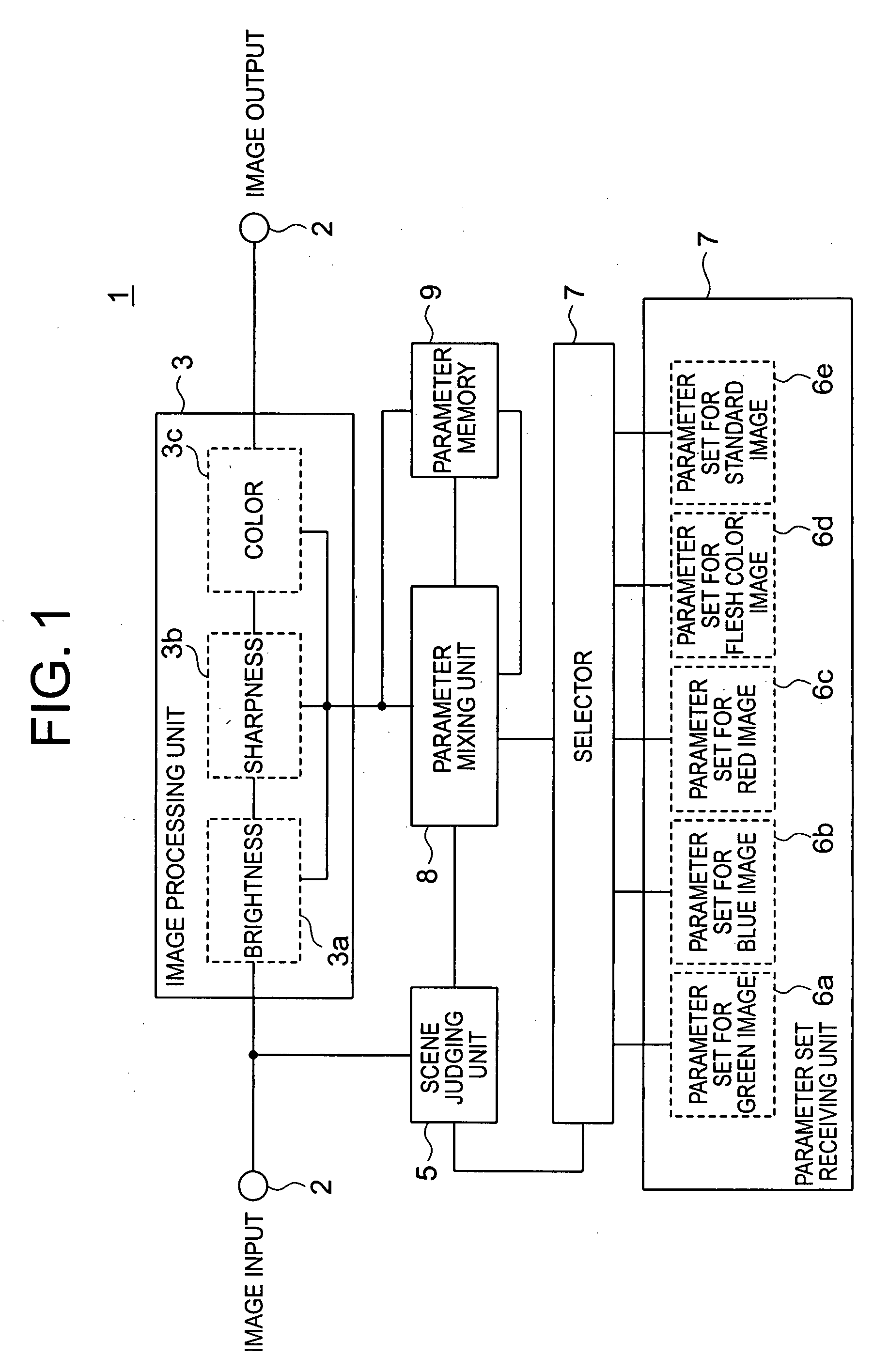

Quality of an image inputted from a video input terminal is adjusted at an image processing unit using a parameter set fitted for the image selected from a plurality of parameter sets received in a parameter set receiving unit. The using parameter set is stored in a parameter memory. A scene judging unit generates a hue histogram of each frame. When a change of the parameter set is necessary, a parameter mixing unit gradually replaces values of the parameter set stored in the parameter memory with a new parameter set selected by a selector. The replaced parameter set is stored in the parameter memory and is used in the image processing unit for adjusting the image quality.

Owner:PIONEER CORP

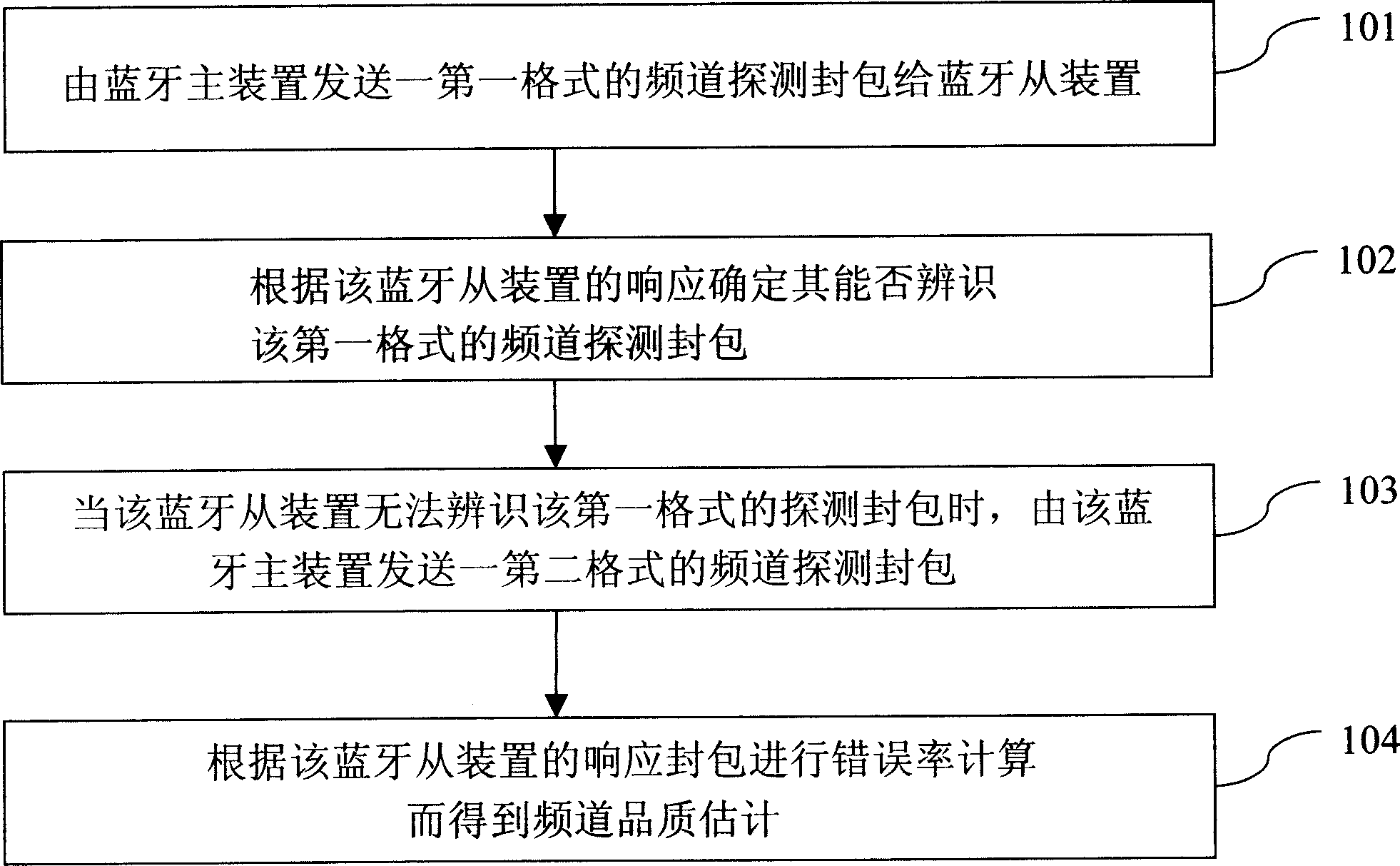

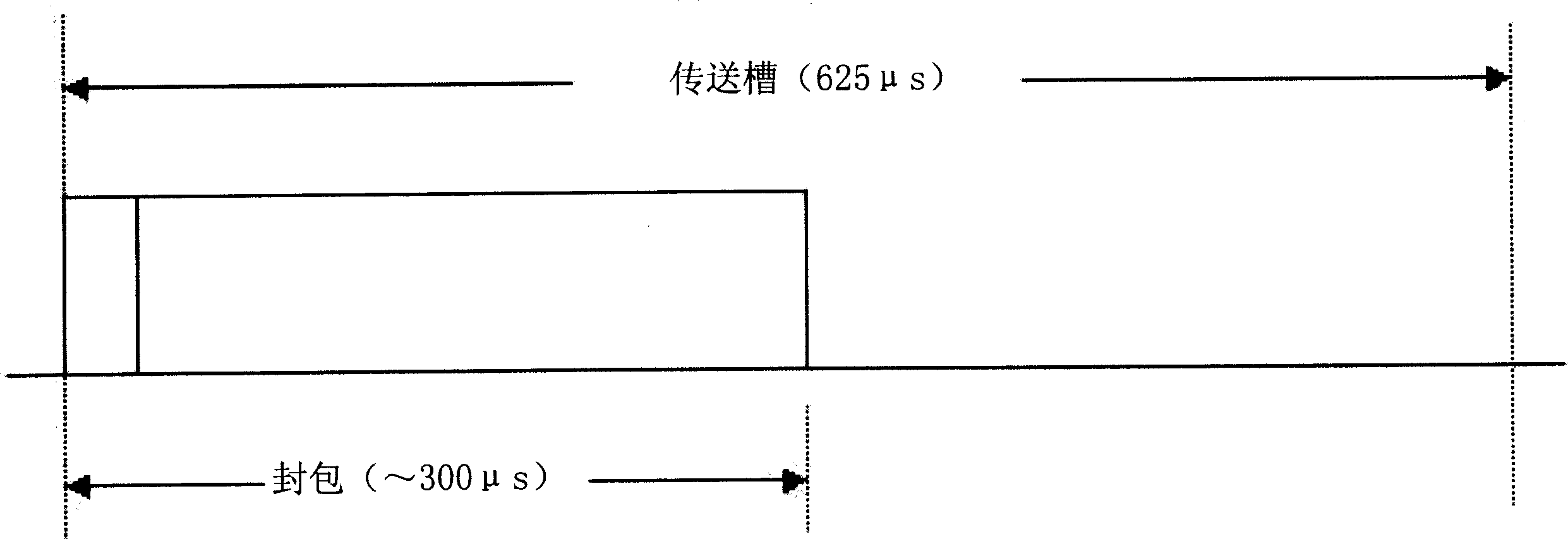

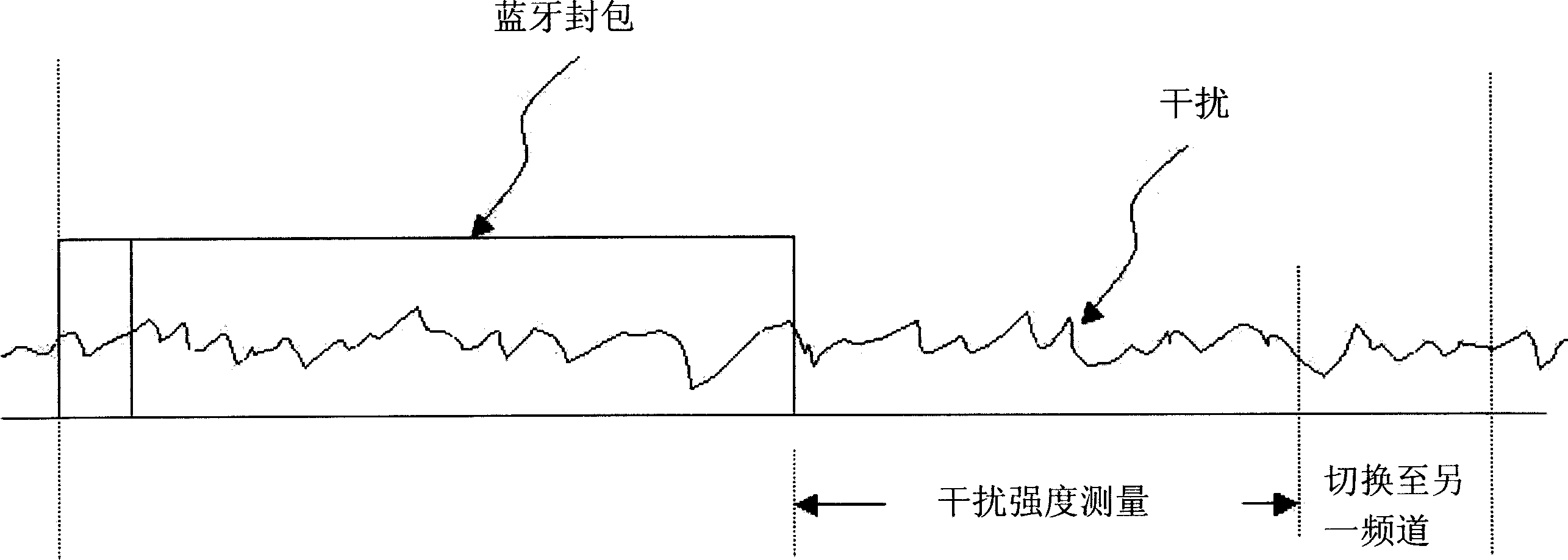

Quality upgrading method for fast Blue Tooth wireless network band

ActiveCN1909390AQuickly and accurately determineInterference signal strength is smallNear-field transmissionFast blueBluetooth

The invention relates to a method for refreshing the program quality in blue-tooth wireless network, wherein it comprises: when the blue-tooth main device transmits in useful program, fixing the quality of signal channel to transmit one transmission groove; the main device makes all blue teeth of blue-tooth wireless network into one frequency hopping mode; at the later half of transmission groove, the main device, based on one unavailable program and one useful program switches the program, and receives and calculates out the interference strength of unavailable programs and useful program; at least, before the start point of next receiving groove, the main device switches the program to useful one, to complete refreshing program quality.

Owner:MICROCHIP TECH INC

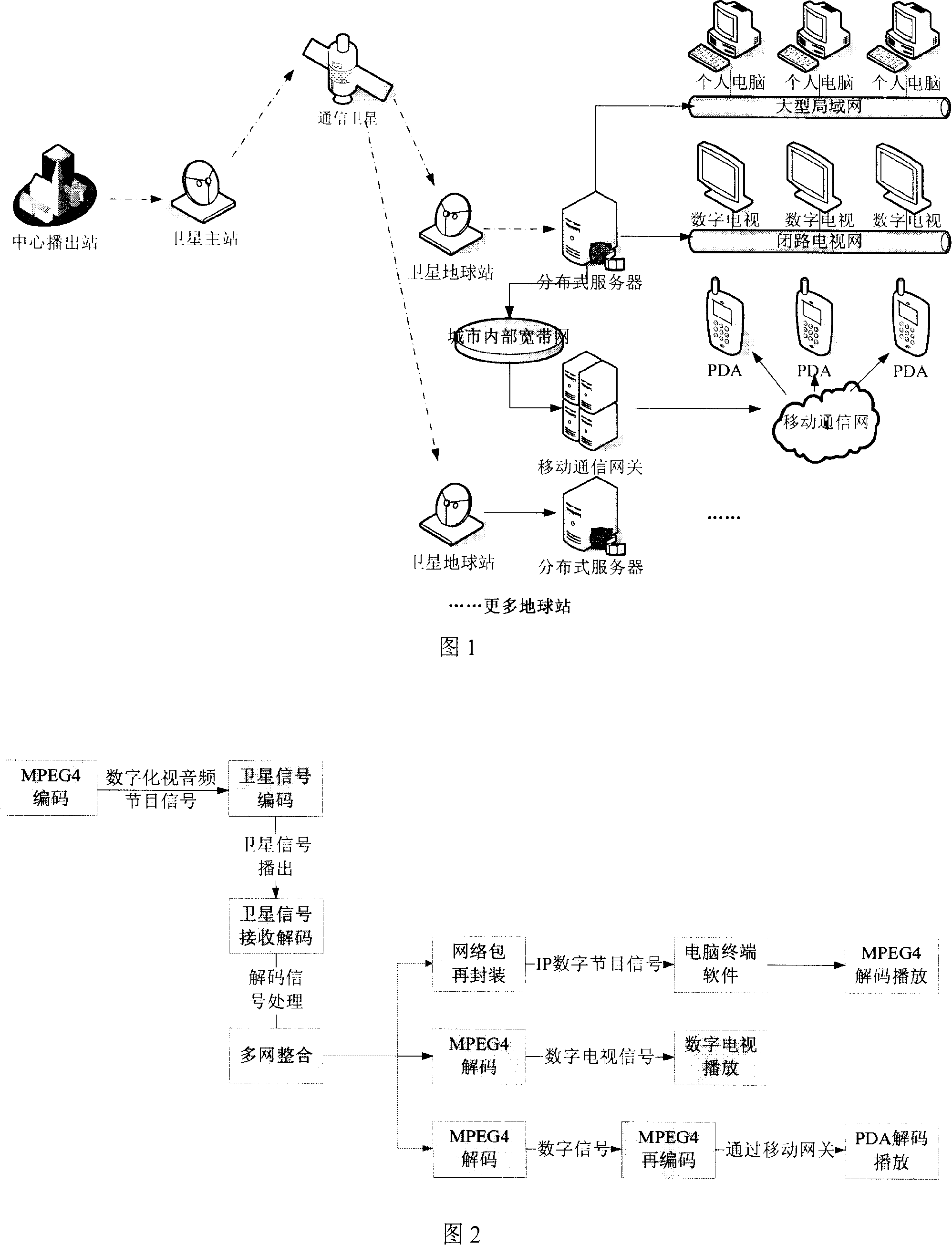

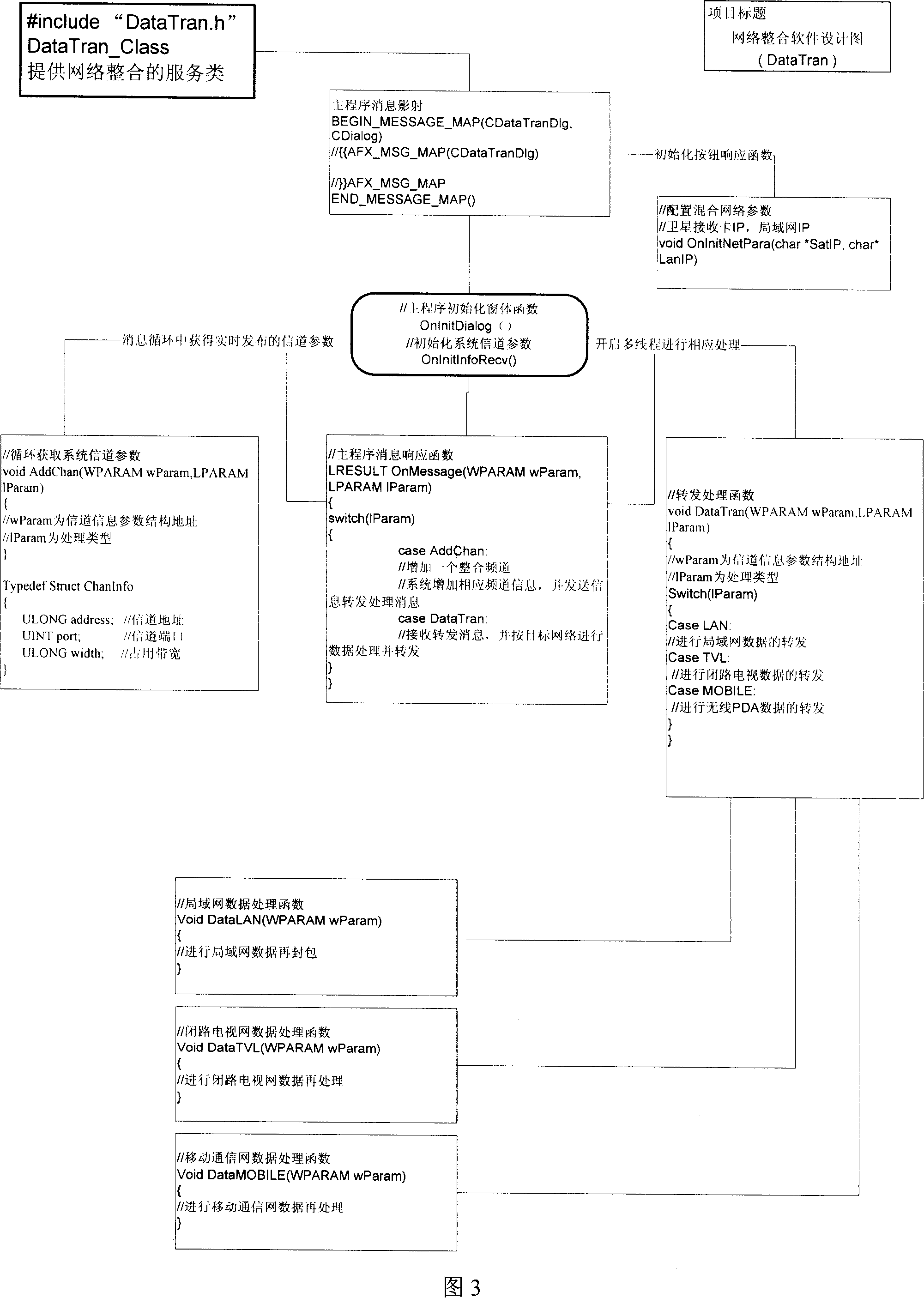

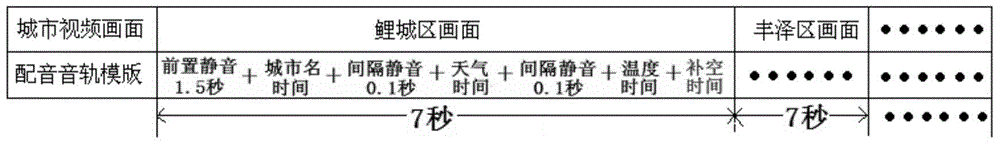

Unlimited multi-in-one multimedia distribution platform

InactiveCN101127895ASolve bottlenecksQuality assurancePulse modulation television signal transmissionTransmissionTechnology of televisionThe Internet

The utility model relates to an unrestraint multi-network multimedia issued platform, which is a program broadcast and receive system utilizing the network communication, the multimedia coding and decoding and IP digital television technology; wherein, the network communication comprises the internet, the satellite network and the mobile communication network. The satellite network is used as a leader network, combines dominances of internet and the mobile communication network, makes intersite distributed servers to be divided platforms of a central broadcasting station by using a distributed cascade connection, and provides video and audio program services for actual terminal users. The utility model has the advantages of breaking through shortcomings of low issued program quality on the internet and not smooth information transmission for big data size programs, overcoming a recessive of high cost for specialty TV station rebroadcast, and making up a widespread coverage multi-area platform with low cost.

Owner:上海航天计算机系统工程有限公司

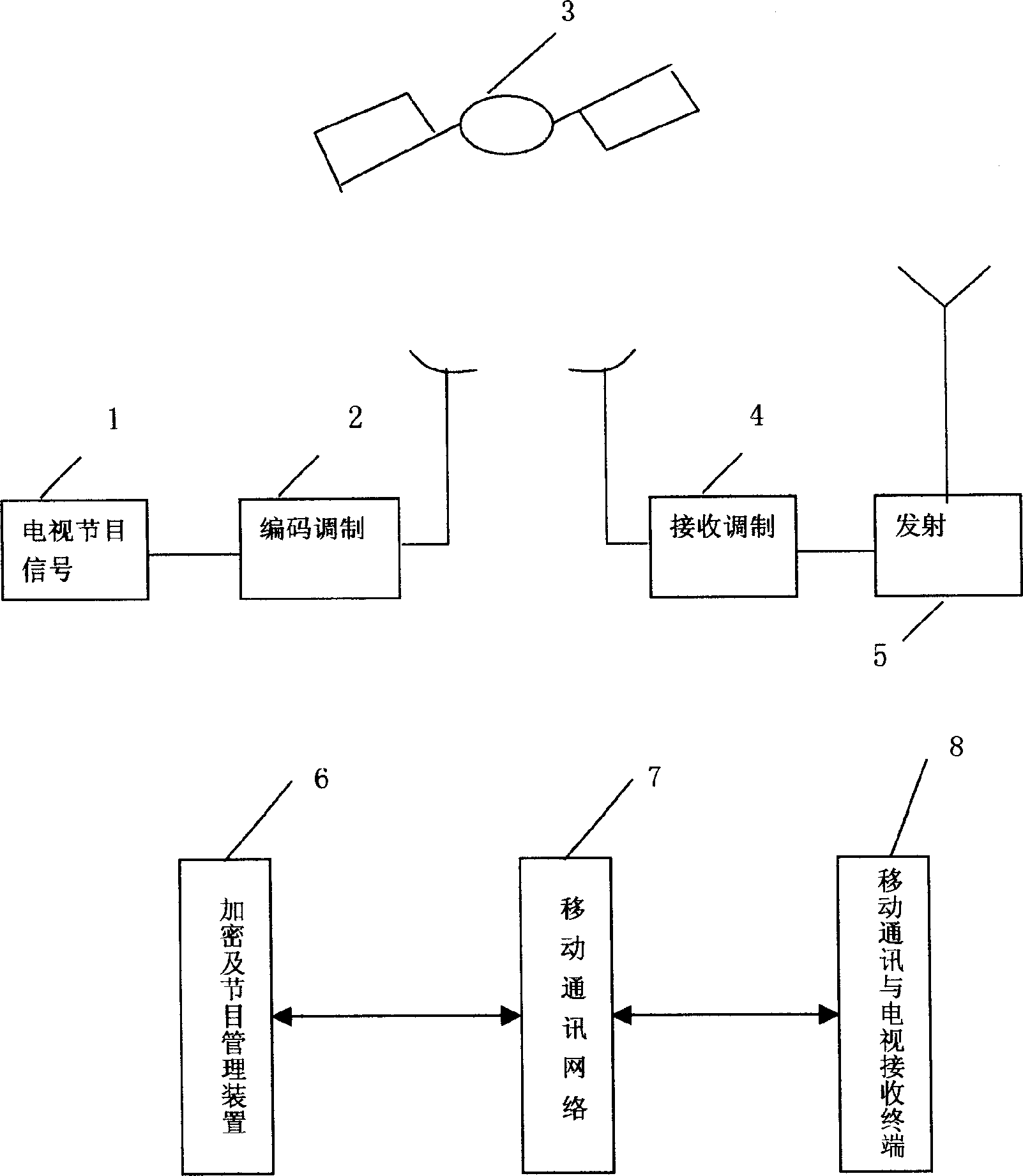

Automatic processing method and system for city window weather dubbing

ActiveCN104967789AUniform amplitudeSmooth connectionTelevision system detailsColor television detailsProgram qualityComputer science

The invention discloses an automatic processing method for city window weather dubbing of a TV weather forecast program. The method comprises the following steps: translation: translating city weather codes to obtain city names and weather and / or temperature entries; matching: matching the translated entries with the corresponding storage entries in a voice library; synthesizing: synthesizing the matched storage voice entries into audio data according to the sequence of the city name and weather and / or temperature; and time setting: by inserting mute date before and behind the entry audio data to generate dubbing data, enabling the time length of the dubbing data to be equal to a set time length. The invention also discloses a system adopting the method. The automatic dubbing synthesized voice is good in effect and can replace human voice, thereby improving program quality, avoiding external influence, freeing hosts, preventing mistake making and improving work efficiency by times.

Owner:福建省泉州市气象局

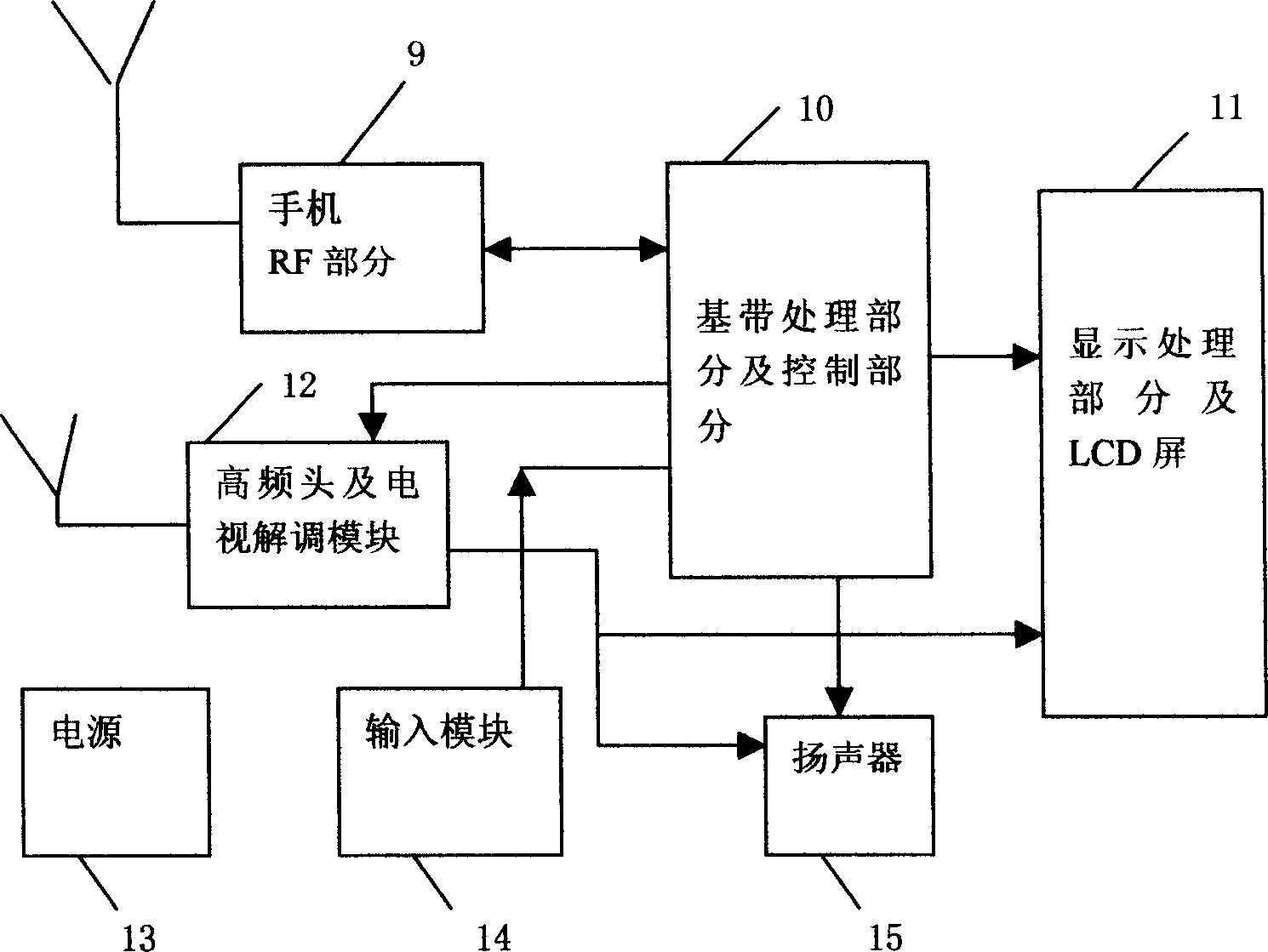

Digital videocast system capable of mobile reception

InactiveCN1764274AAvoid restrictionsQuality improvementGHz frequency transmissionAnalogue secracy/subscription systemsProgram qualityDigital television

The invention discloses a digital TV broadcast system for mobile receive, which comprises: the satellite signaling device modulates the TV program and sends to satellite transponder for broadcast; the signal differential device modulates the broadcast signal again and takes surface-wave digital TV broadcast. Wherein, there is traditional mobile communication function as well as receiving the surface-wave digital TV signal in receive terminal; terminal also receives key for enciphered program from management device to decipher the program. This invention has low require to network, well program quality, and low charge.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

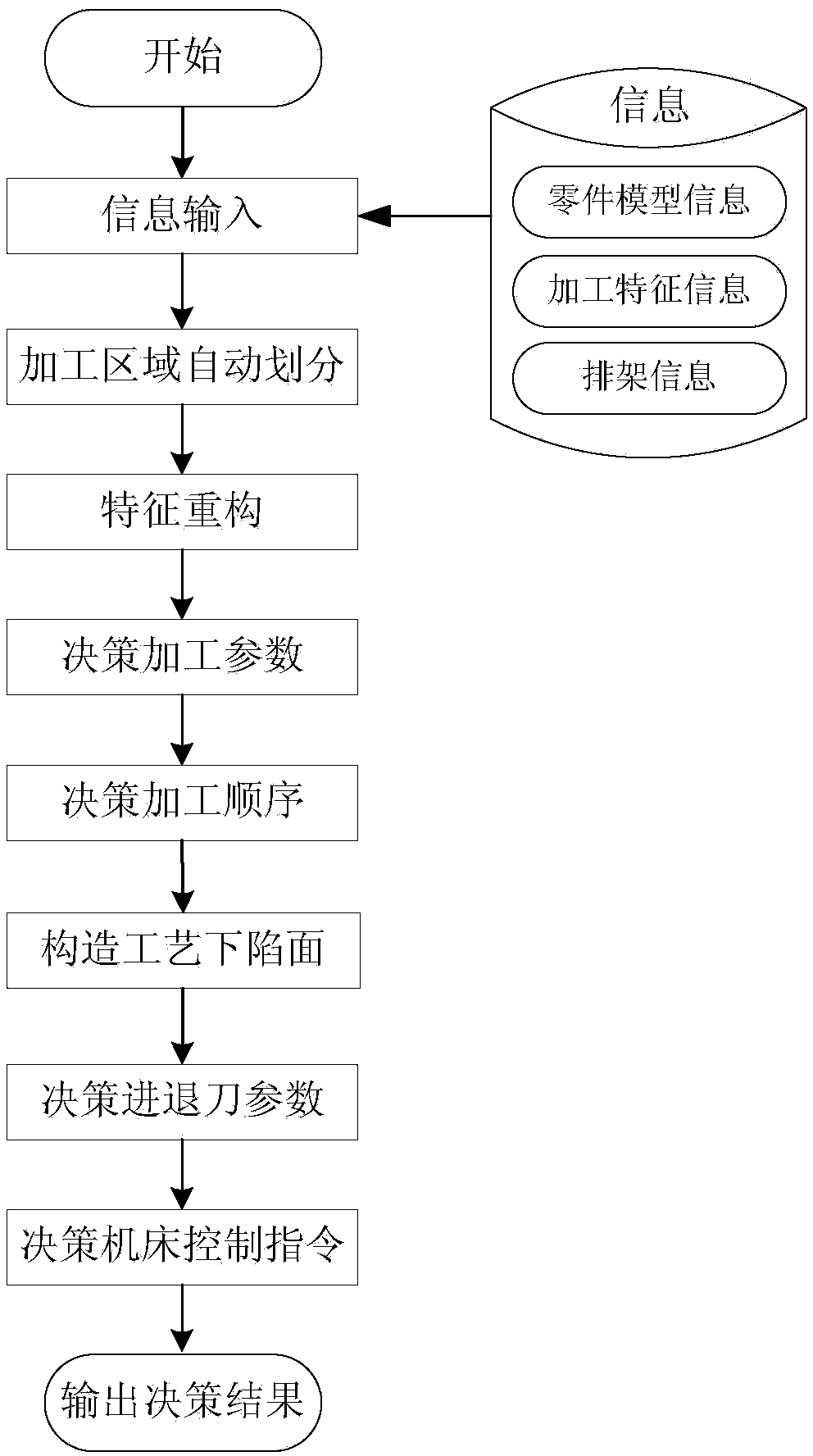

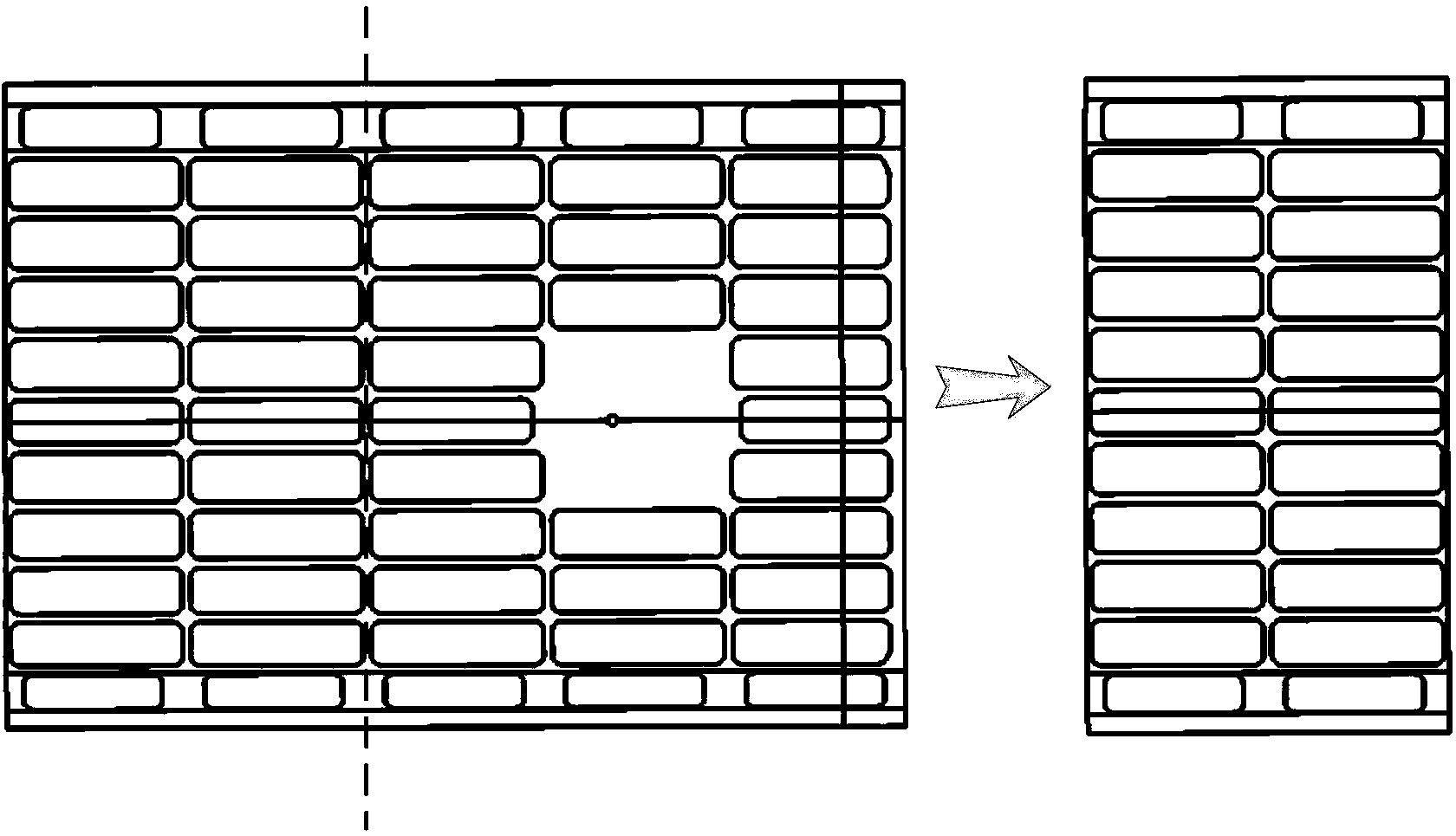

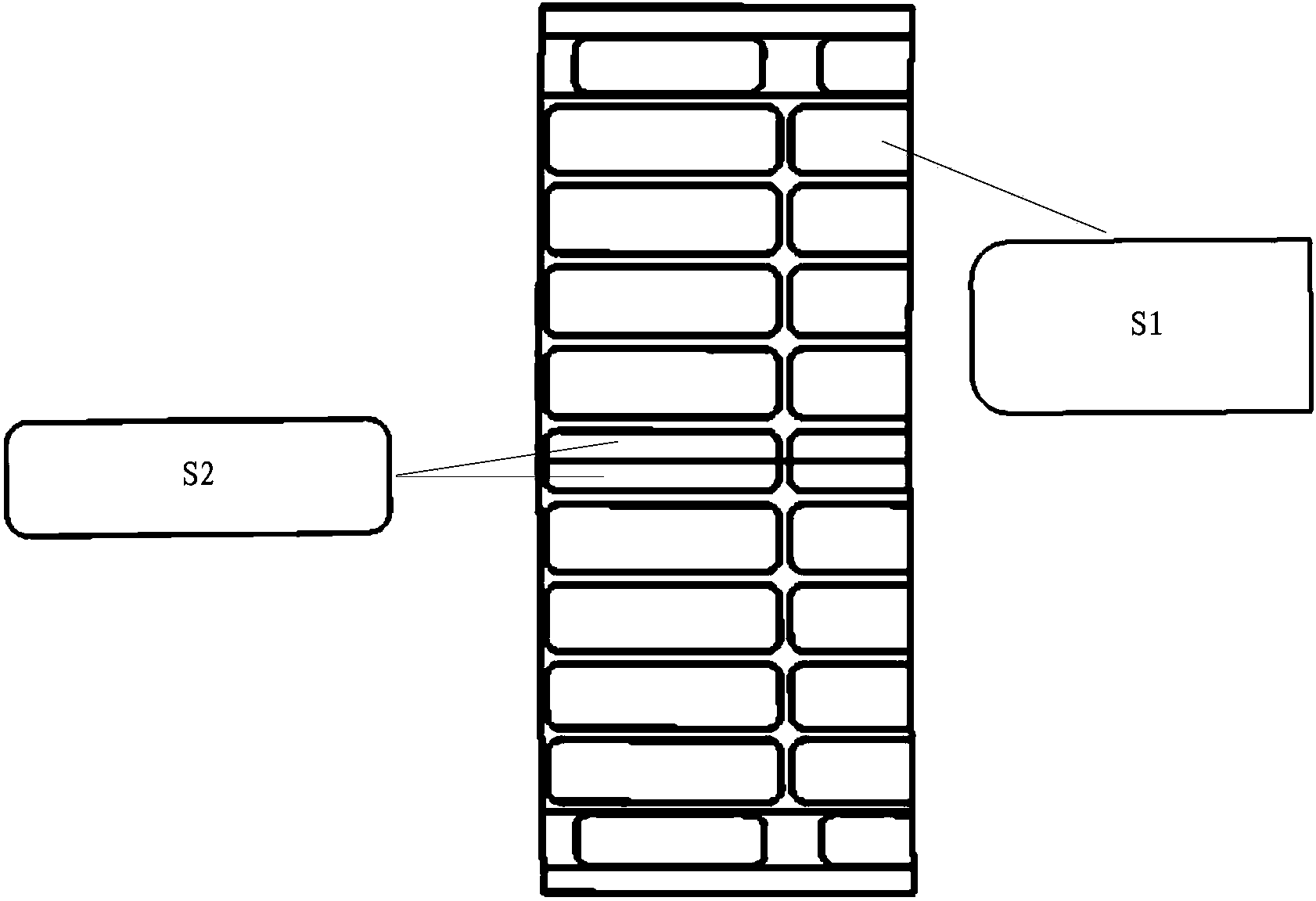

Feature-based skin mirror-image milling technology decision method

ActiveCN104331020AReduce workloadImprove processing efficiencyNumerical controlProduction scheduleNumerical control

A feature-based skin mirror-image milling technology decision method includes, firstly, inputting part information, processing feature information and bent frame information, and automatically dividing a processing area according to area division rules; secondly, performing feature reconstruction on each divided area according to recessed-surface reconstruction rules; thirdly, ranking reconstructed features, and automatically deciding processing sequence and technological parameters; fourthly, constructing a technological recessed surface according to the technological parameters; finally, automatically deciding engagement and retraction parameters and machine-tool control commands for processing features according to skin mirror-image milling programming specifications. The method has the advantages that effective information link connection during skin part numerical control programming is realized by feature-based automatic technology decisions, feature-based numerical control programming in skin mirror-image milling is realized by combining the skin mirror-image milling numerical control programming specifications, dependency of programming on human experiences is weakened, programming standardability is guaranteed, programming quality and efficiency are improved, and production schedule is guaranteed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

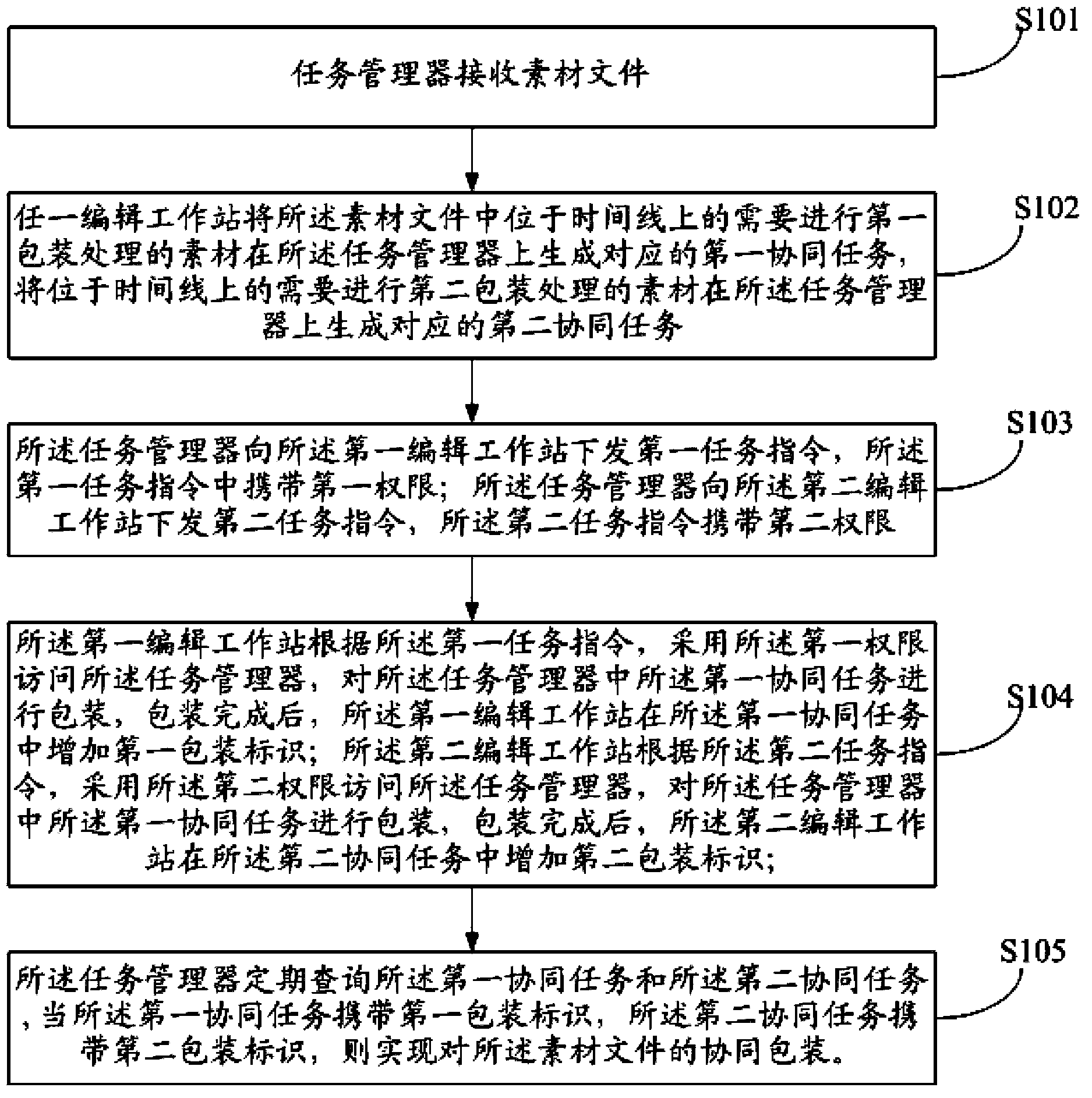

Method based on time line segment collaborative package

InactiveCN103680559AQuality improvementImprove editing efficiencyCarrier editingCarrier indexing/addressing/timing/synchronisingWorkstationTime line

The invention discloses a method based on time line segment collaborative package. The method comprises the steps that any editing workstation generates a corresponding first collaborative task for a material needing first package processing on a time line on a task manager, and generates a corresponding second collaborative task for a material needing second package processing on the time line on the task manager; a first editing workstation visits the task manager and packages the first collaborative task; the first editing workstation adds an editing package logo in the edited collaborative task; at the same time, a second editing workstation visits the task manager and packages the corresponding other collaborative task; and the second editing workstation adds an editing package logo in the edited collaborative task, and collaborative package is carried out on the material documents. By carrying out task dividing on the time line, a collaborative effect of many people is realized. According to the advantage and the ability of editing staff, reasonable work allocation is realized, and the editing efficiency and the program quality are improved.

Owner:CHINA DIGITAL VIDEO BEIJING

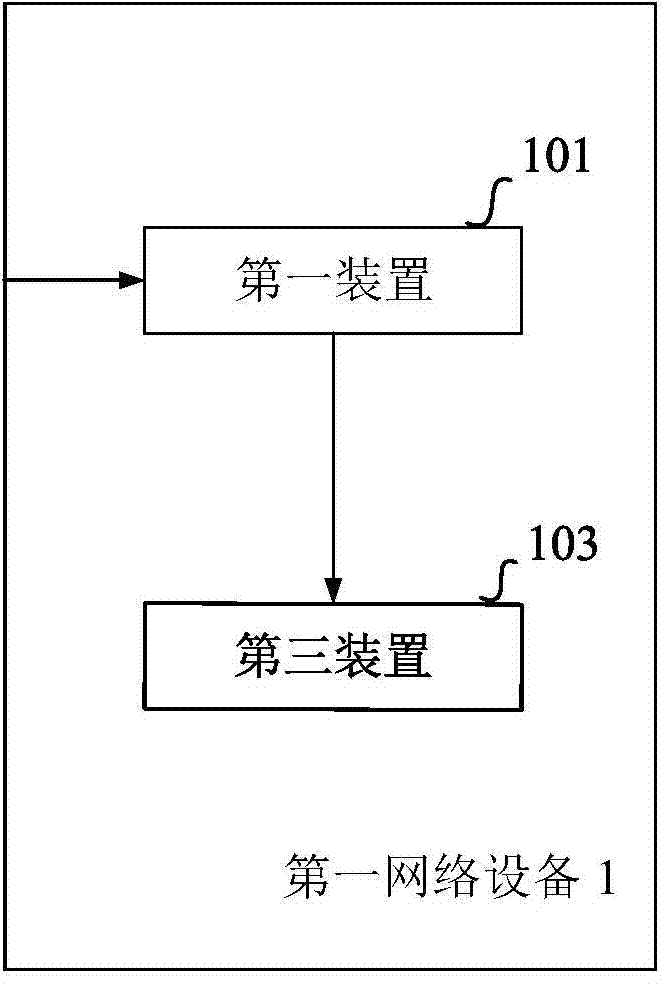

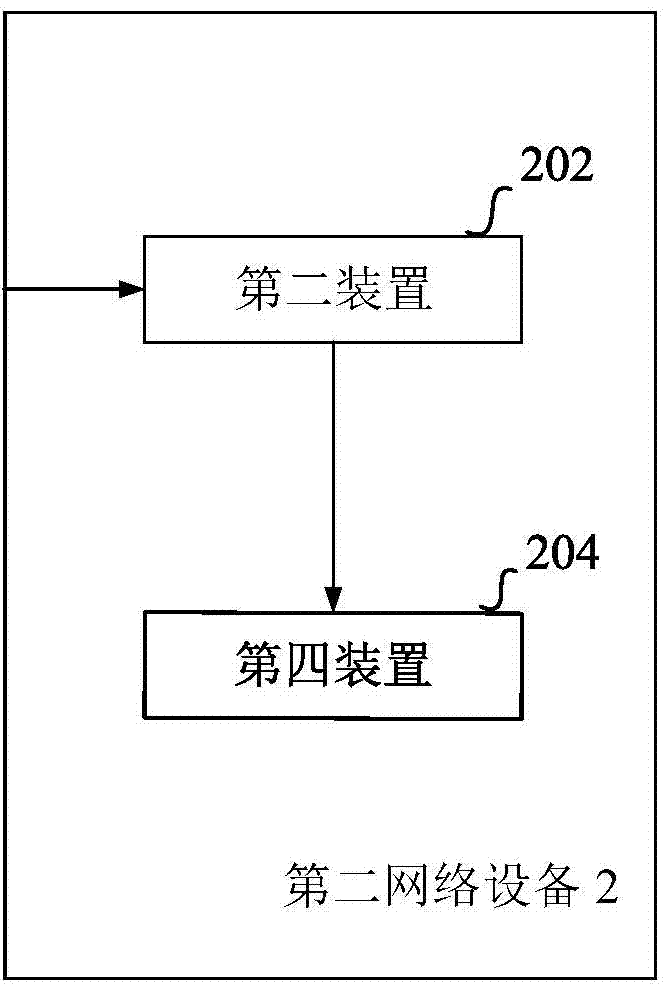

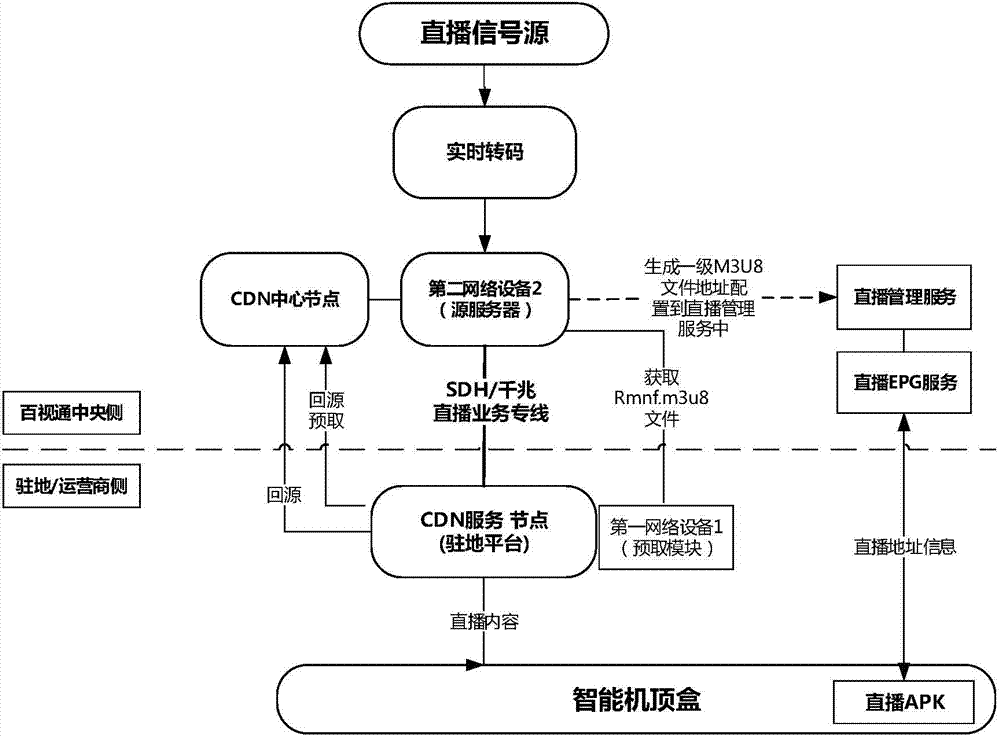

Method and device for pre-acquiring live program information from CDN (Content Delivery Network)

ActiveCN104333781AImprove program access experienceGuarantee the quality of live broadcast serviceSelective content distributionQuality of serviceResource utilization

The invention aims at providing method and device for pre-acquiring live program information from CDN (Content Delivery Network). The method comprises the following steps: acquiring a second two-stage M3U8 file and a third two-stage M3U8 file corresponding to a live program, wherein the third two-stage M3U8 file is determined based on the second two-stage M3U8 file and the live delay information corresponding to the live program; acquiring the live program information from the live program, corresponding to the second two-stage M3U8 file and the third two-stage M3U8 file, so as to meet the subsequent related live requests. Compared with the prior art, the method has the advantages that the (delayed) live program information is pre-obtained through an one-stage M3U8 file and a two-stage M3U8 file, and thus, the bandwidth resource utilization rate can be raised, and the program access experience of a user can be improved; the pre-obtaining method can be used for effectively solving the problem of network jittering, in order to ensure the live program quality for a user.

Owner:百视通网络电视技术发展有限责任公司

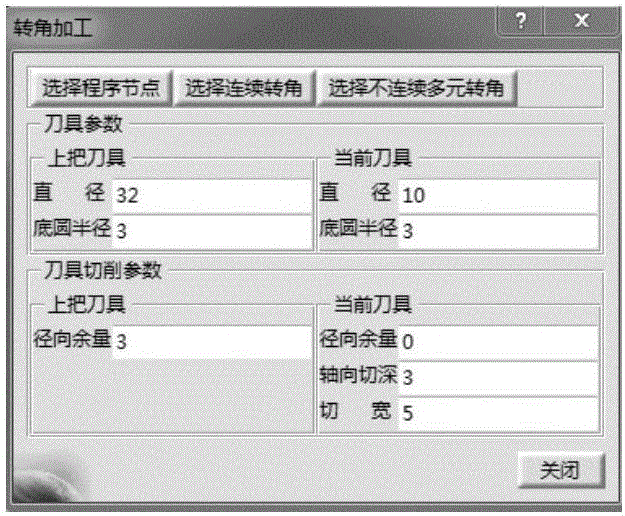

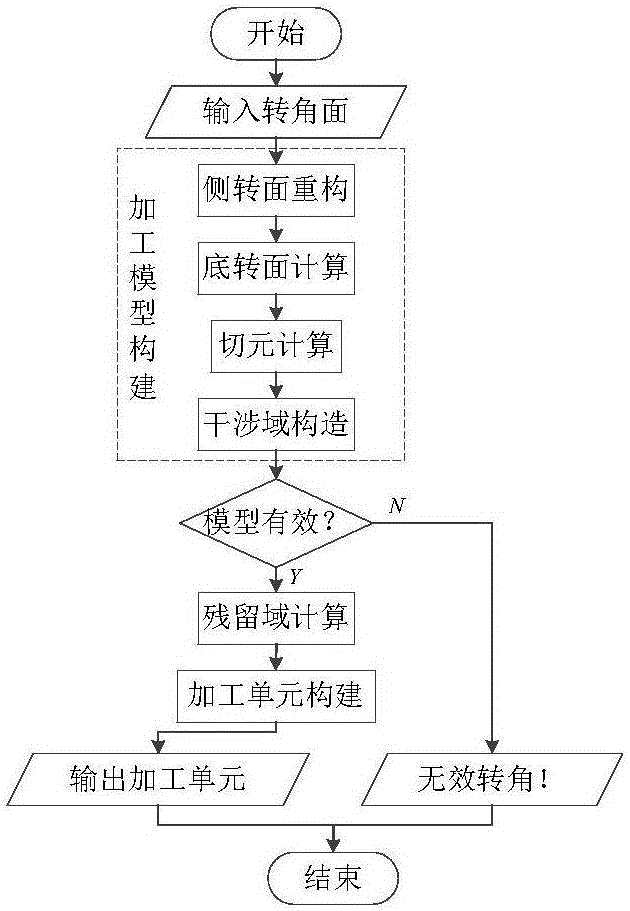

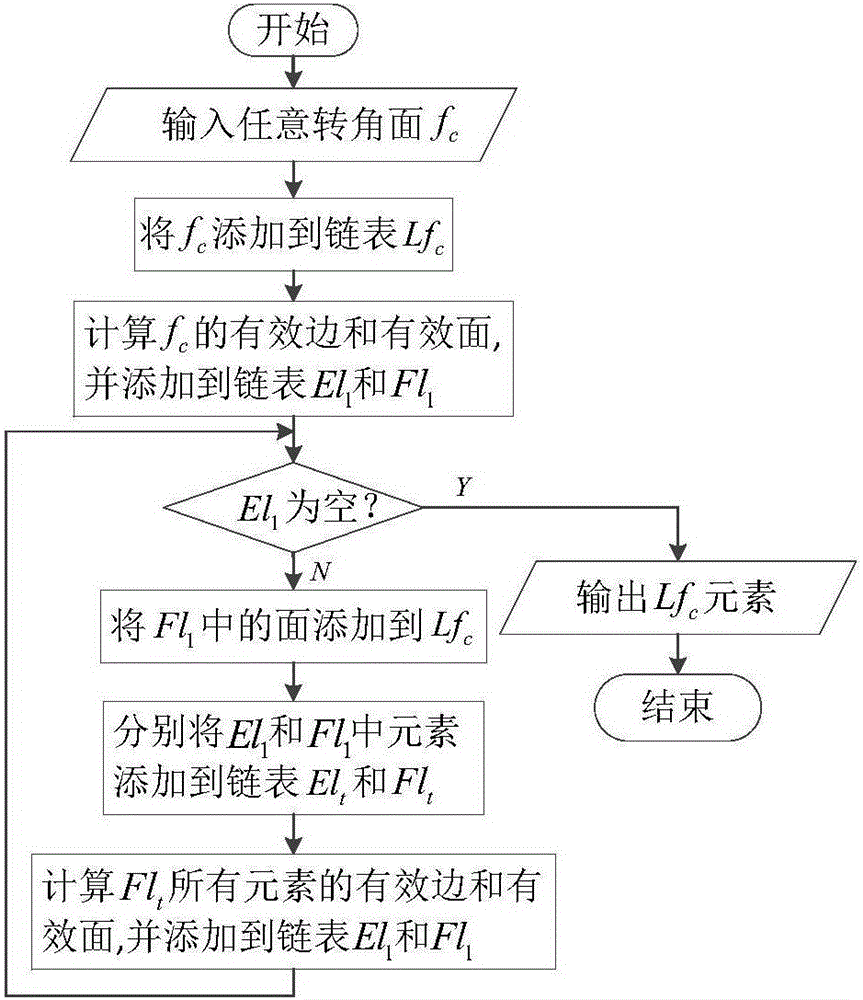

Corner numerical control processing automatic programming method for aircraft complicated structural component

InactiveCN105022346AQuality improvementImprove programming efficiencyProgramme controlComputer controlNumerical controlProgram quality

The invention discloses a corner numerical control processing automatic programming method for an aircraft complicated structural component, which comprises the steps of 1) side steering plane calculation; 2) cutting element calculation; 3) interference domain construction; 4) residual domain calculation; and 5) processing unit construction. Therefore, automatic programming of a corner processing numerical control program can be realized. According to the corner numerical control processing automatic programming method, the programming personnel need not to carry out tedious interactive operations or complicated geometric parameter calculation, programming for the corner processing numerical control program can be completed by only interactively selecting any one corner plane, and problems of low or unstable program quality and the like caused by a practice that technicists carry out programming interactively in a mode of relying on experience are effectively avoided. The corner numerical control processing automatic programming method can significantly improve the efficiency and the quality of corner processing, shorten the product development period and improve the market competitiveness of products.

Owner:BEIHANG UNIV +1

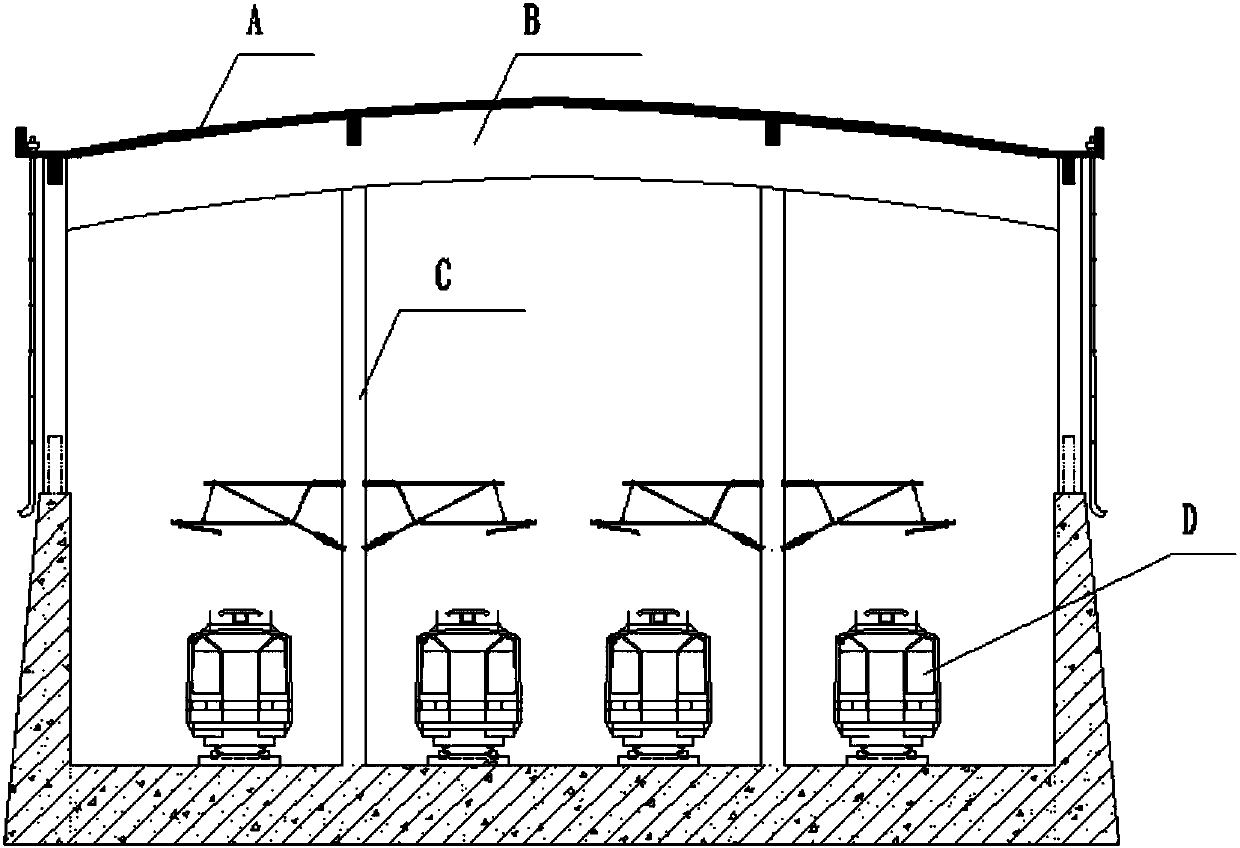

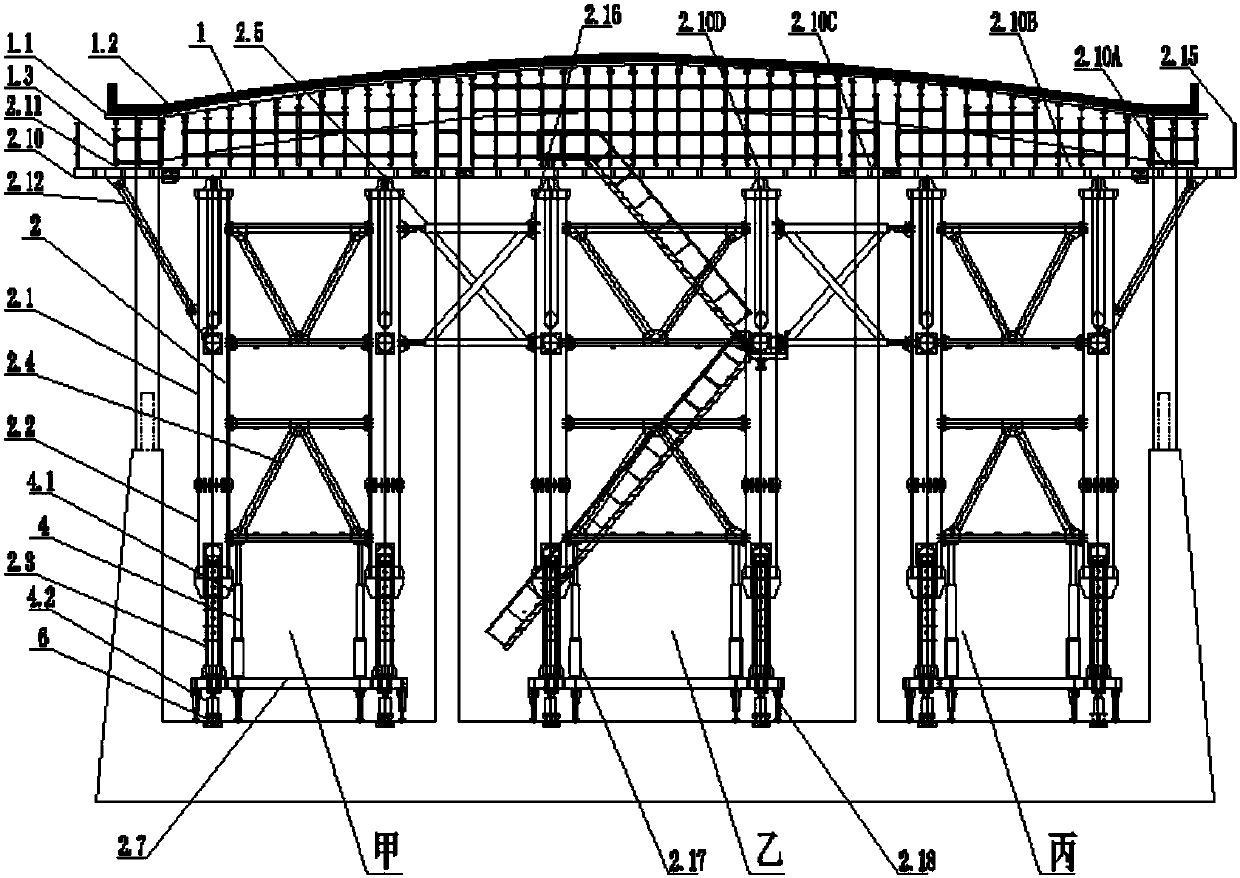

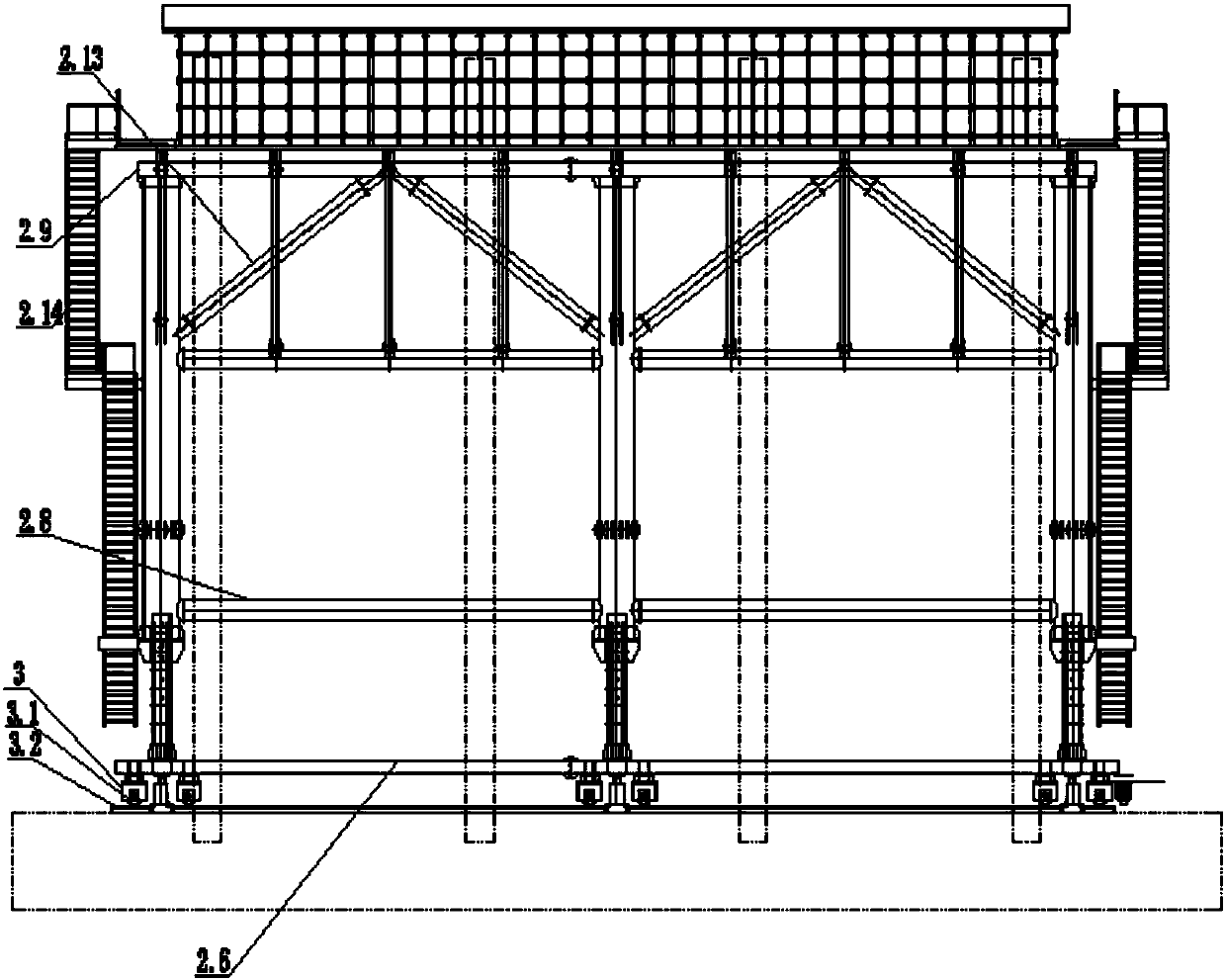

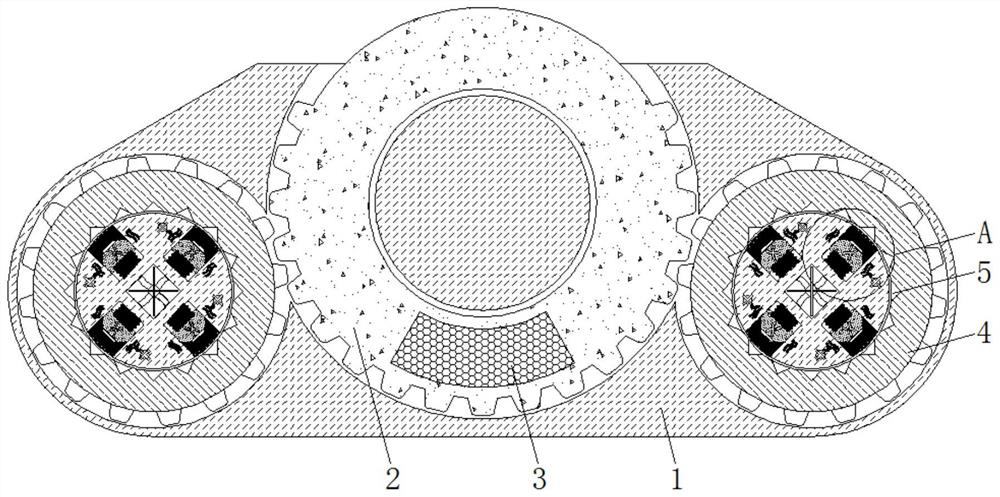

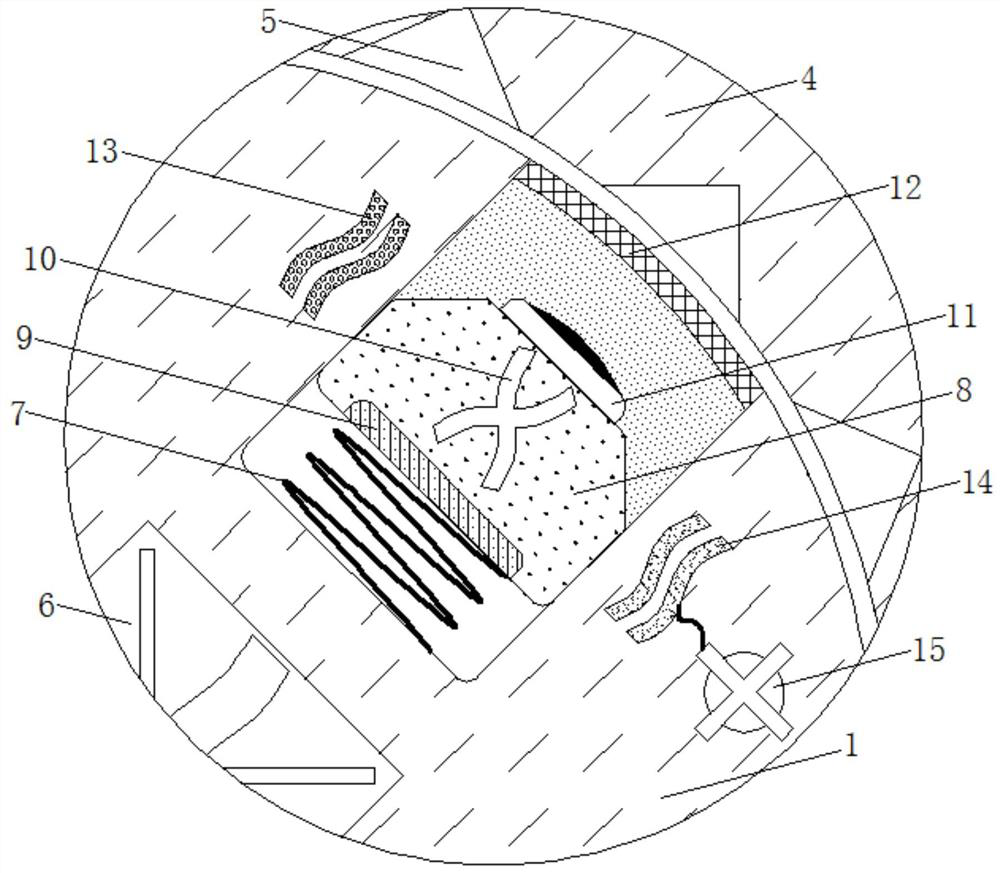

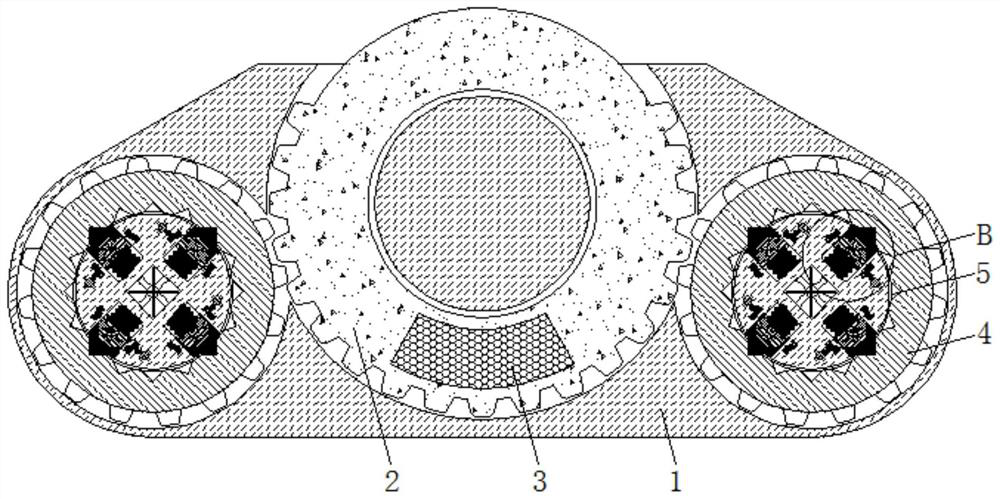

Station canopy construction movable framework and station canopy construction method

InactiveCN107939040AQuick demolitionQuick installationForms/shuttering/falseworksControl systemArchitectural engineering

The invention discloses a mobile formwork for station canopy construction and a construction method for a station canopy, comprising a left warehouse formwork, a middle warehouse formwork and a right warehouse formwork. The formwork includes the formwork system, gantry system, walking system, hydraulic system, control system and bottom support for the canopy of the construction station; the formwork systems of the left warehouse, middle warehouse and right warehouse formwork are in order connection; the formwork can be separated and adjusted, which can not only solve the problem that the ordinary integral formwork cannot pass through the column and beam structure, but also realize the function of the integral formwork, save time and effort, avoid delaying the construction progress, and solve the problem of It solves the problem that the quality of the traditional construction scheme of the station canopy is difficult to control. The technical scheme is applicable to the construction of rain-proof sheds for stations with various spans, and can ensure the construction quality of the canopy. The overall structure of the formwork is simple and simple, the stress is clear, and the safety is high.

Owner:SHANDONG TIEYING CONSTR ENG

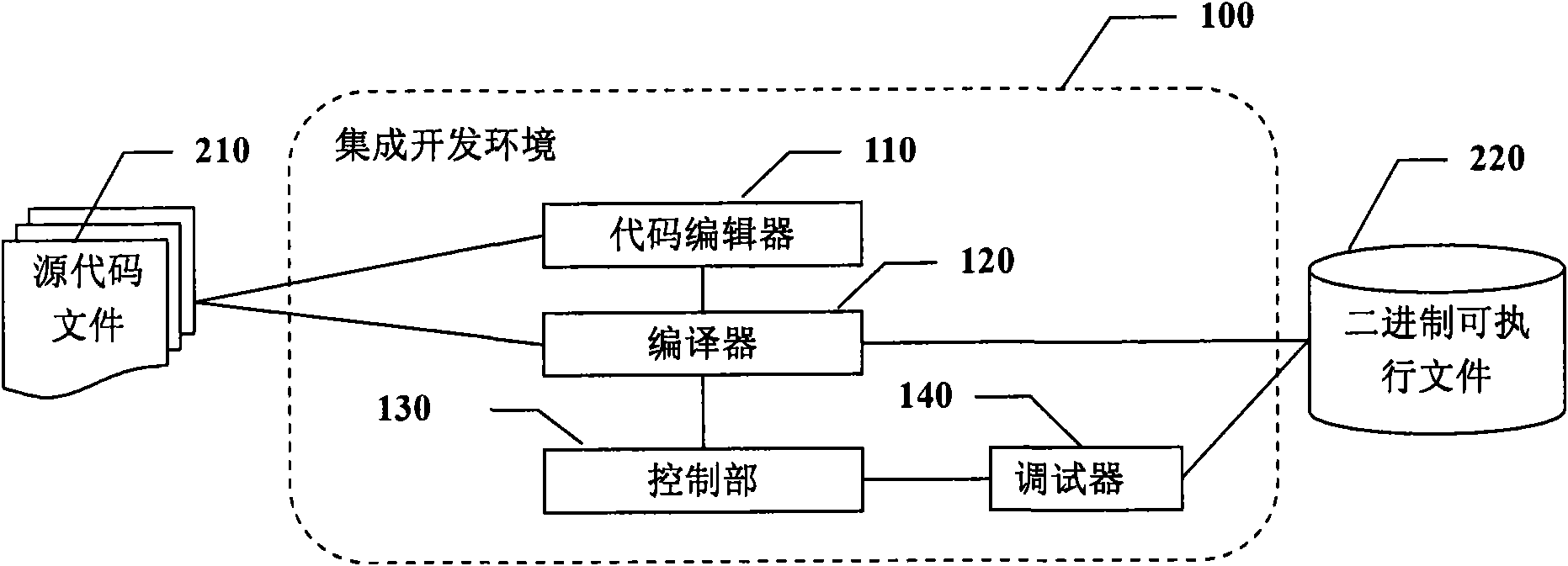

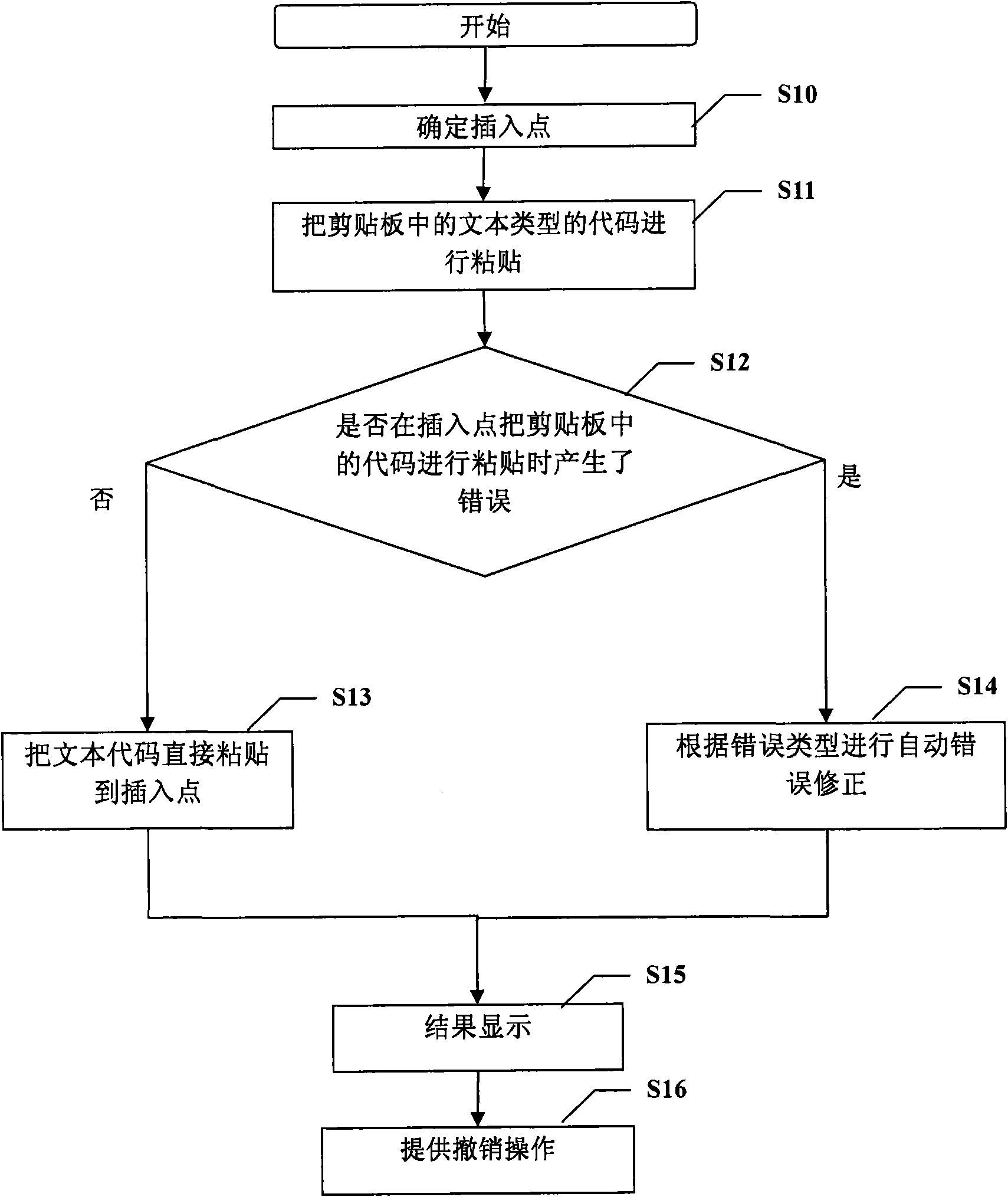

Paste method capable of automatically correcting errors and device thereof

InactiveCN101599041AImprove development efficiencyQuality improvementSoftware testing/debuggingCompilation errorInformation analysis

The invention discloses a paste method capable of automatically correcting errors and a device thereof, which are used for improving the program quality and the development efficiency. The method comprises the following steps: inserting Chinese text formatting source codes in a clipboard into an appointed position of a file; parsing the source codes and codes around the appointed position of the file to obtain corresponding code information; analyzing whether the insertion operation can generate errors or not based on the code information and obtaining the types of the generated errors; and correcting the errors according to the obtained types. The method can avoid the problems caused by taking variables representing different meanings as a variable for use because of paste, improve the program quality, automatically correct other compile errors and improve the development efficiency.

Owner:PANASONIC CORP

Program production storage table capable of automatically adjusting levelness

The invention discloses a program production storage table capable of automatically adjusting levelness. The invention relates to the technical field of broadcast program production equipment. The program production storage table includes a shell, the middle part of the shell is movably connected with a rotating block; a gravity block is fixedly connected to the inner wall of the bottom of the rotating block, gears meshed with the outer side of the rotating block are movably connected to the two sides of the shell, clamping grooves which are evenly distributed are formed in the inner sides ofthe gears, electromagnets are fixedly connected to the positions, close to the middles of the gears, of the inner wall of the shell, and springs which are evenly distributed are fixedly connected to the positions, close to the outer sides of the electromagnets. The invention discloses the program production storage table capable of automatically adjusting levelness. The gravity block and the rotating block are matched for use; no matter what platform the storage table is placed on, due to the fact that the gravity block is located in the middle of the bottom of the rotating block, the rotatingblock can automatically rotate to the horizontal state under the action of the gravity of the gravity block, the effect of automatically adjusting the rotating block to the horizontal state is achieved, the shooting quality of advertisements is effectively guaranteed, and the program quality can be improved.

Owner:顾成英

Communication multithreading technology

InactiveCN103823659AReadableEasy to liftSpecific program execution arrangementsProgram qualityComputer science

The invention discloses a communication multithreading technology which includes the steps of firstly, defining a WCF service contract, and building a WCF service project; secondly, realizing a WCF service, and building a class inheritance WCF service interface; thirdly, defining a delegation class, and declaring at the location of a delegation event; fourthly, starting the WCF service; fifthly, using the delegation event, declaring the class of a WCF service delegation message, and declaring the delegation event of an interface thread; sixthly, guiding into a thread pool, and opening another thread. The communication multithreading technology has the advantages that cross-platform communication can be achieved; coding methods are high in readability and easy to expand; large amount of If-Else (Switch) statement used in a program can be avoided; program stability and stable communication among threads are achieved; program quality and efficiency are increased.

Owner:苏州博远容天信息科技股份有限公司

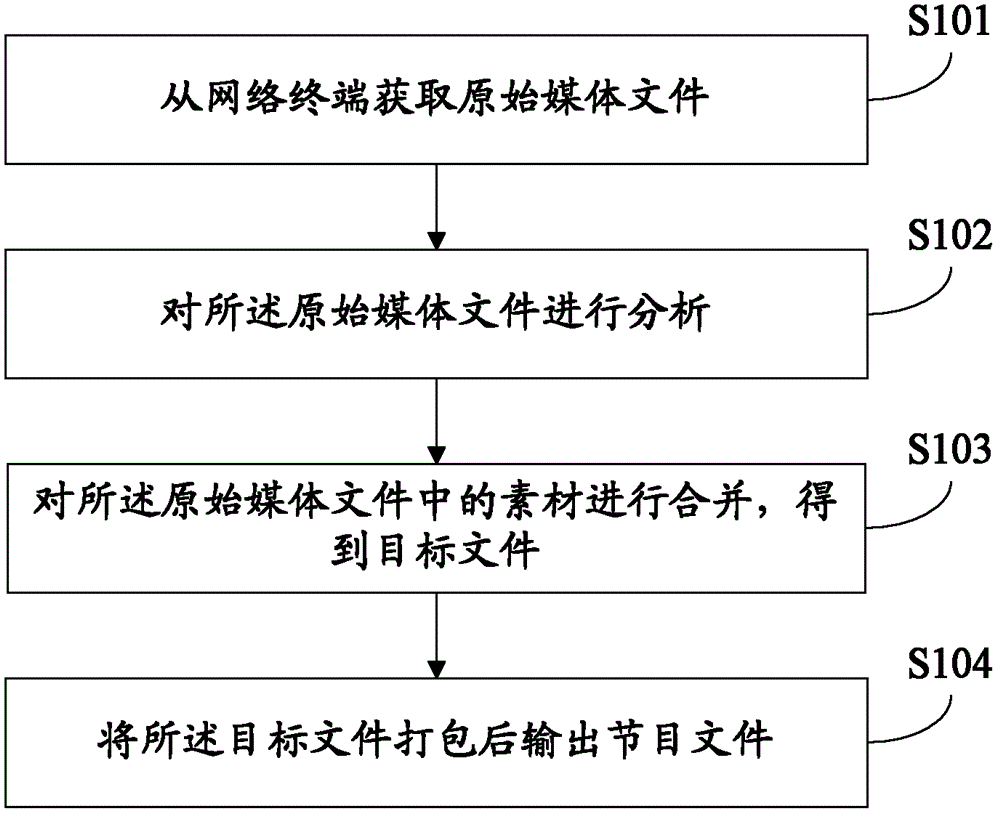

Method for synthesizing video and audio files

ActiveCN102752633AQuick mergeImprove production efficiencySelective content distributionNetwork terminationComputer graphics (images)

An embodiment of the invention discloses a method for synthesizing video and audio files. The method comprises the steps of obtaining original media files from a network terminal; analyzing and merging original media files, importing materials in original media files into a time line, and obtaining main editing materials; packaging switched or overlapped portions of main editing materials on the time line into new materials, and obtaining sub-editing materials; conducting sequential merging of main editing materials and sub-editing materials to generate object files; and outputting program files after packaging object files. According to the embodiment, materials on the sequential time line are merged, in-and-out point portions, overlapped portions, special technique portions, subtitle portions and the like of all materials form materials in a uniform format, and materials are output after being packaged, so that rapid merging of media files are guaranteed and the producing efficiency is greatly improved on the condition of no program quality loss.

Owner:CHINA DIGITAL VIDEO BEIJING

Method and system for using page-based object flow verification in regression test

InactiveCN101526916BQuality assuranceReduce manual testing timeSoftware testing/debuggingRegression testingProgramming language

The invention provides a method for using page-based object flow verification in a regression test, which comprises the following steps: recording a test automation script operated by a functional flow, and generating an object pivot table from different pages according to the operation sequence of a main functional flow; during the execution of a new round of regression test, generating an object historical table of an operation page of the function value; and contrasting the pivot table with the object historical table to determine whether the pivot table and the object historical table have differences in the same functional page and the sate and sequence of the same object and generating and outputting a test difference report. The invention provides a device for using the page-based object flow verification in the regression test. The invention can greatly reduce time for manual test and increase in the test number due to frequency program correction, ensures program quality and avoids test risks.

Owner:ALIBABA GRP HLDG LTD

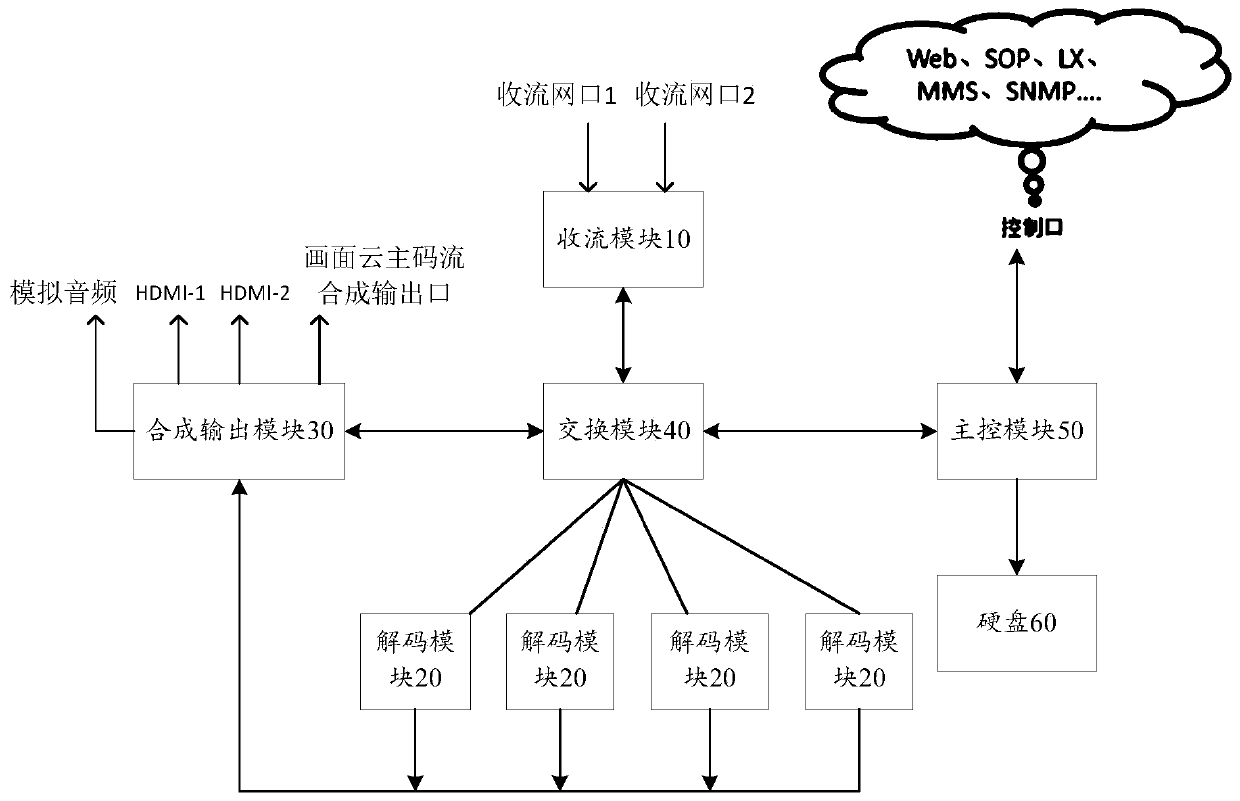

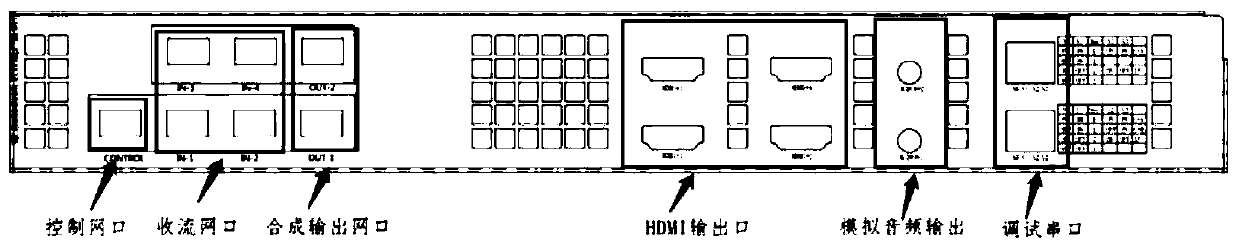

Ultra-high-definition audio-visual program quality monitoring device based on hard decoding

InactiveCN110602489ATake advantage of image qualityImprove the display effectTelevision systemsSelective content distributionTranscodingData exchange

The invention provides an ultra-high-definition audio-visual program quality monitoring device based on hard decoding, which comprises a stream receiving module, a decoding module, a synthesis outputmodule, an exchange module and a main control module; the stream receiving module is used for acquiring a code stream of an audio / video to be monitored; the decoding module is used for decoding or transcoding the code stream to obtain decoded audio and video data or transcoded audio and video data; the synthesis output module is used for sending the decoded audio and video data to a display end; the main control module is used for accessing the control platform, providing a man-machine interaction function and carrying out recording operation by utilizing the transcoded audio and video data; and the exchange module is used for data exchange among the plurality of modules. The technical problems that in the prior art, the processing capacity for high-definition programs is insufficient, andthe stability is poor are solved.

Owner:北京市博汇科技股份有限公司

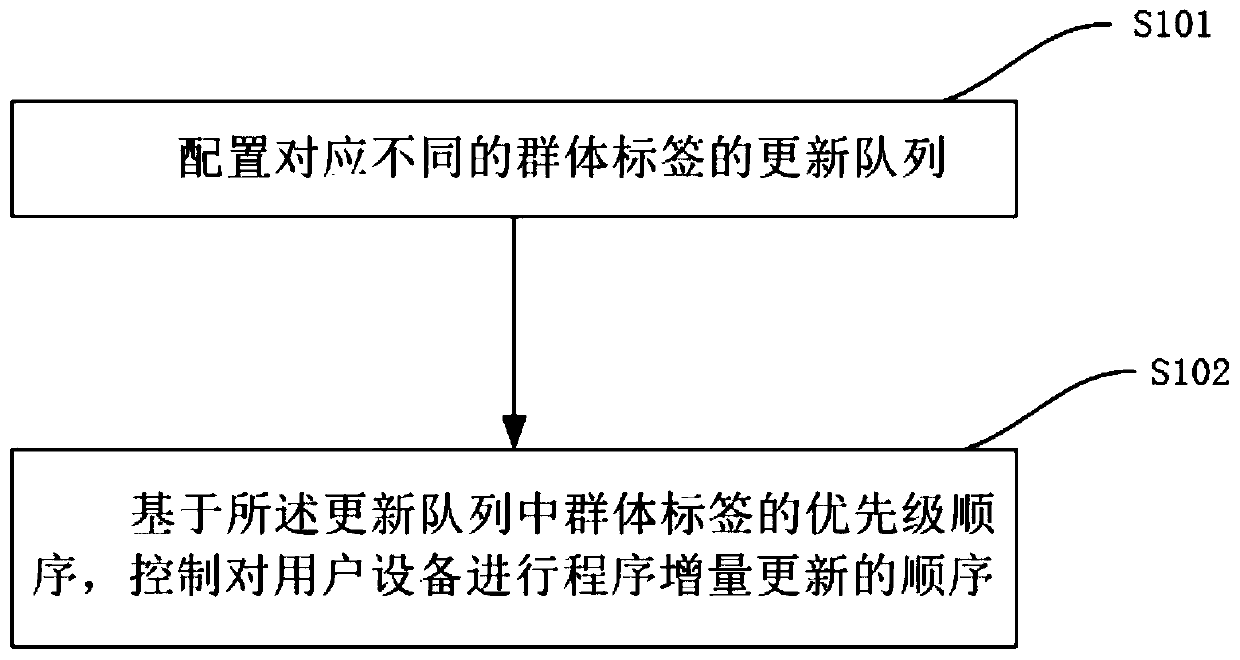

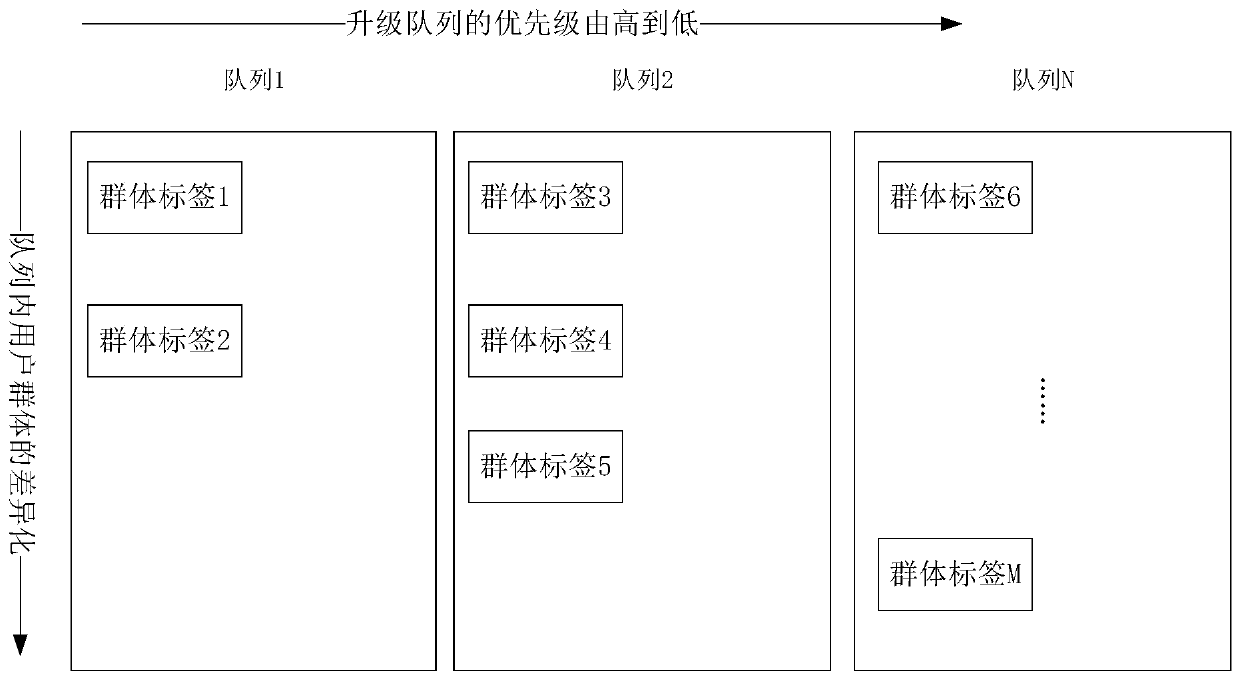

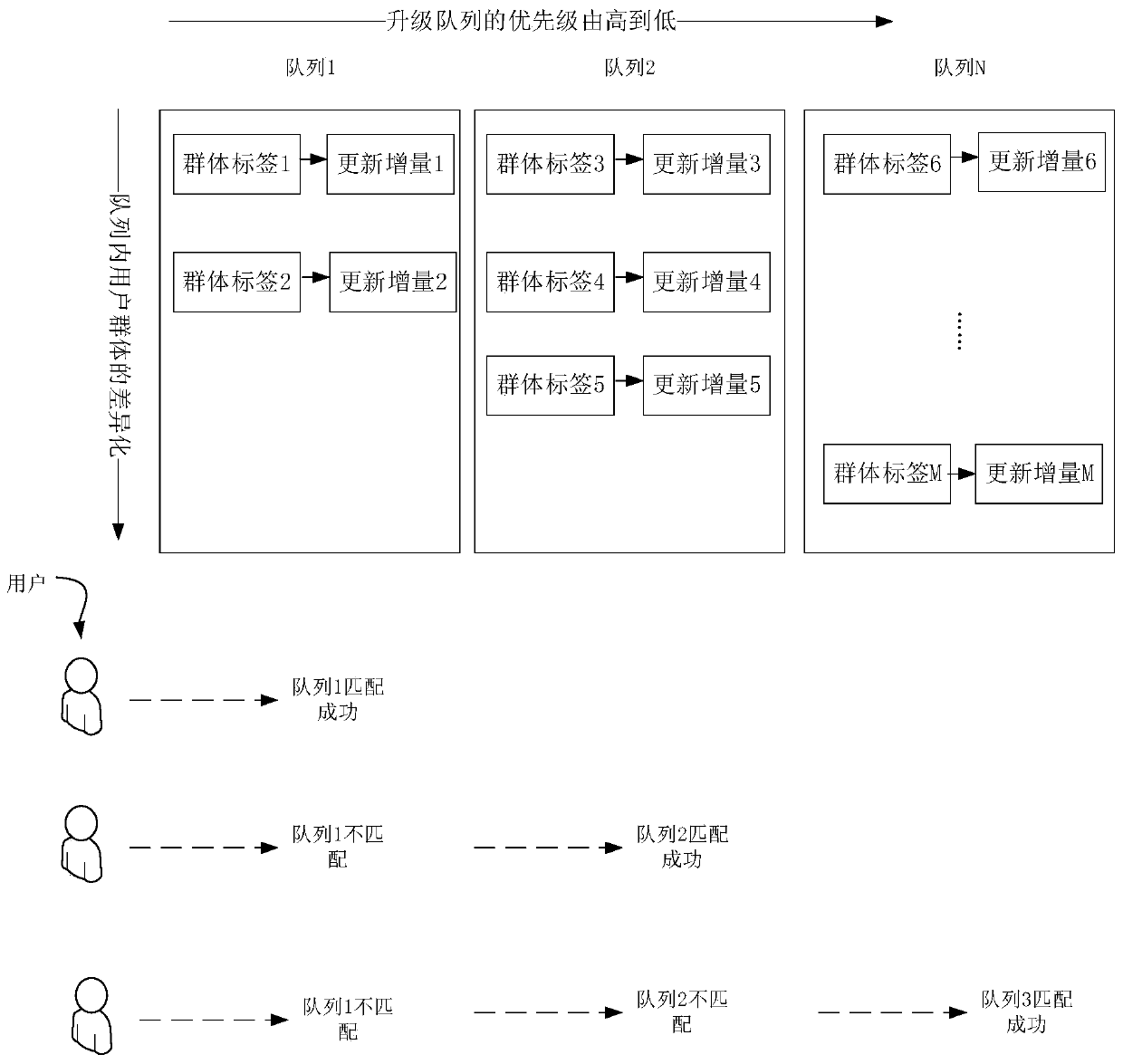

Control program increment updating method and device and electronic equipment

The invention discloses a method and device for controlling program increment updating and electronic equipment, and aims to control the program increment updating sequence of user equipment on the basis of the priority sequence of group tags in an updating queue by configuring the updating queue corresponding to different group tags. By controlling the sequence of program increment updating on the user equipment, the differentiation of program updating among different user equipment is realized, the flexibility of program publishing and updating is improved, and the influence caused by the problems of program quality and the like can also be reduced.

Owner:SHANGHAI QIFU INFORMATION TECH CO LTD

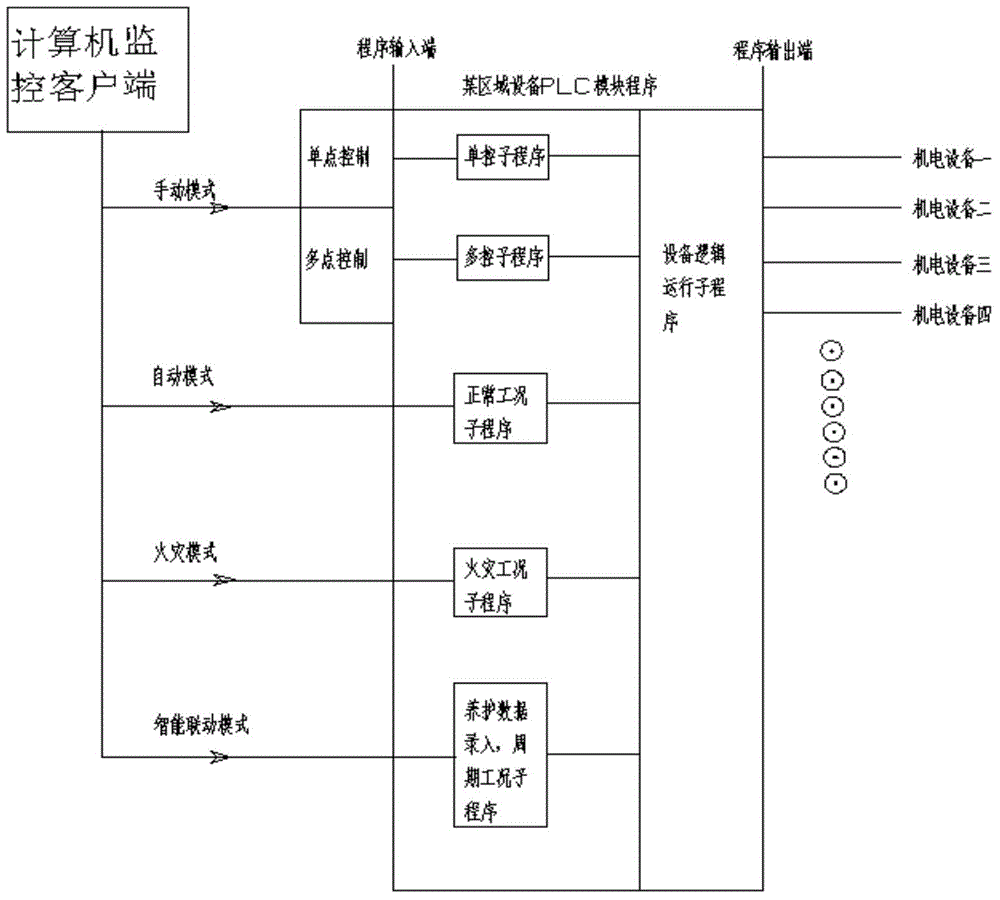

Tunnel monitoring PLC module programming method

InactiveCN105022330AReduce program debugging timeLow costProgramme control in sequence/logic controllersModularityComputer module

The invention provides a tunnel monitoring PLC module programming method. The method comprises the following steps that an equipment monitoring system provides a modular program interface for a computer client to call; when the computer requests a dynamo-electric equipment monitoring operation event, a PLC system performs corresponding equipment control according to the modular program; and the PLC system further transmits the control result to the computer client in a real-time manner for the computer client to display the dynamo-electric equipment operation state. The program debugging time of engineering personnel can be greatly shortened. Relatively good working efficiency can be achieved. A relatively high program quality and relatively high dynamo-electric equipment monitoring efficiency can be further realized. In terms of operations, attention should be paid only to hardware instead of program problems. The operation cost is greatly reduced. The operation efficiency is improved. The method has popularization significance in large and medium-sized tunnel dynamo-electric equipment monitoring.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

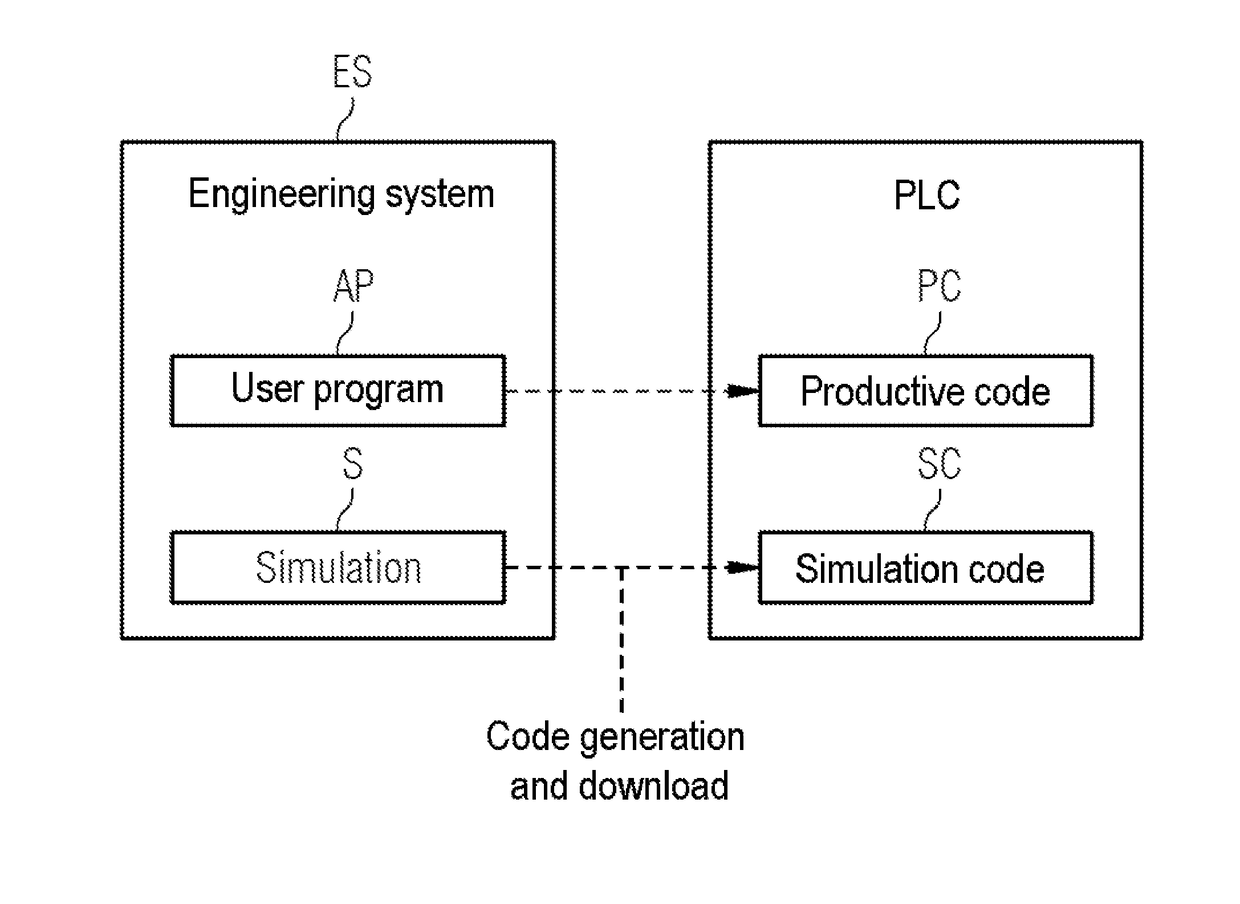

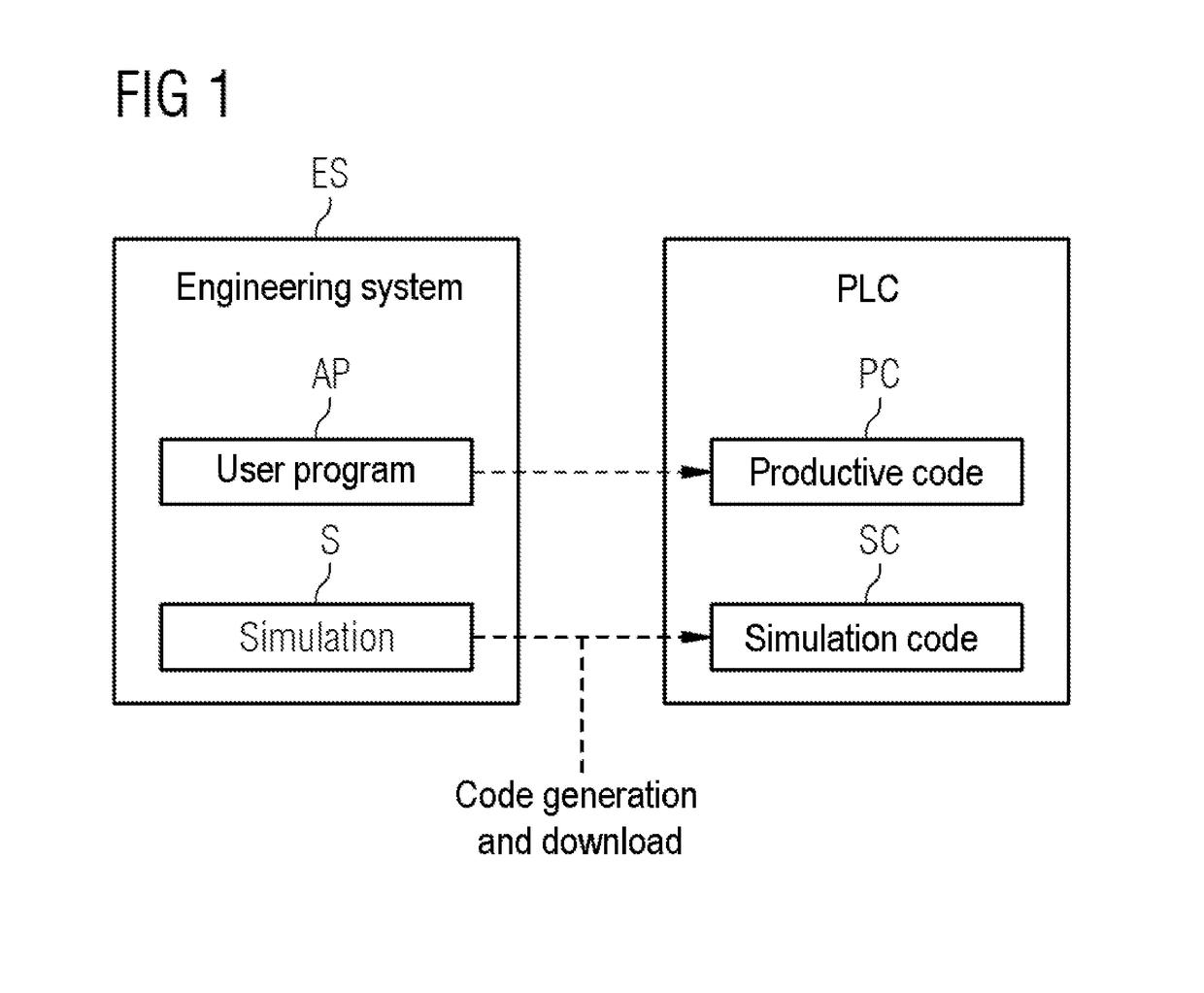

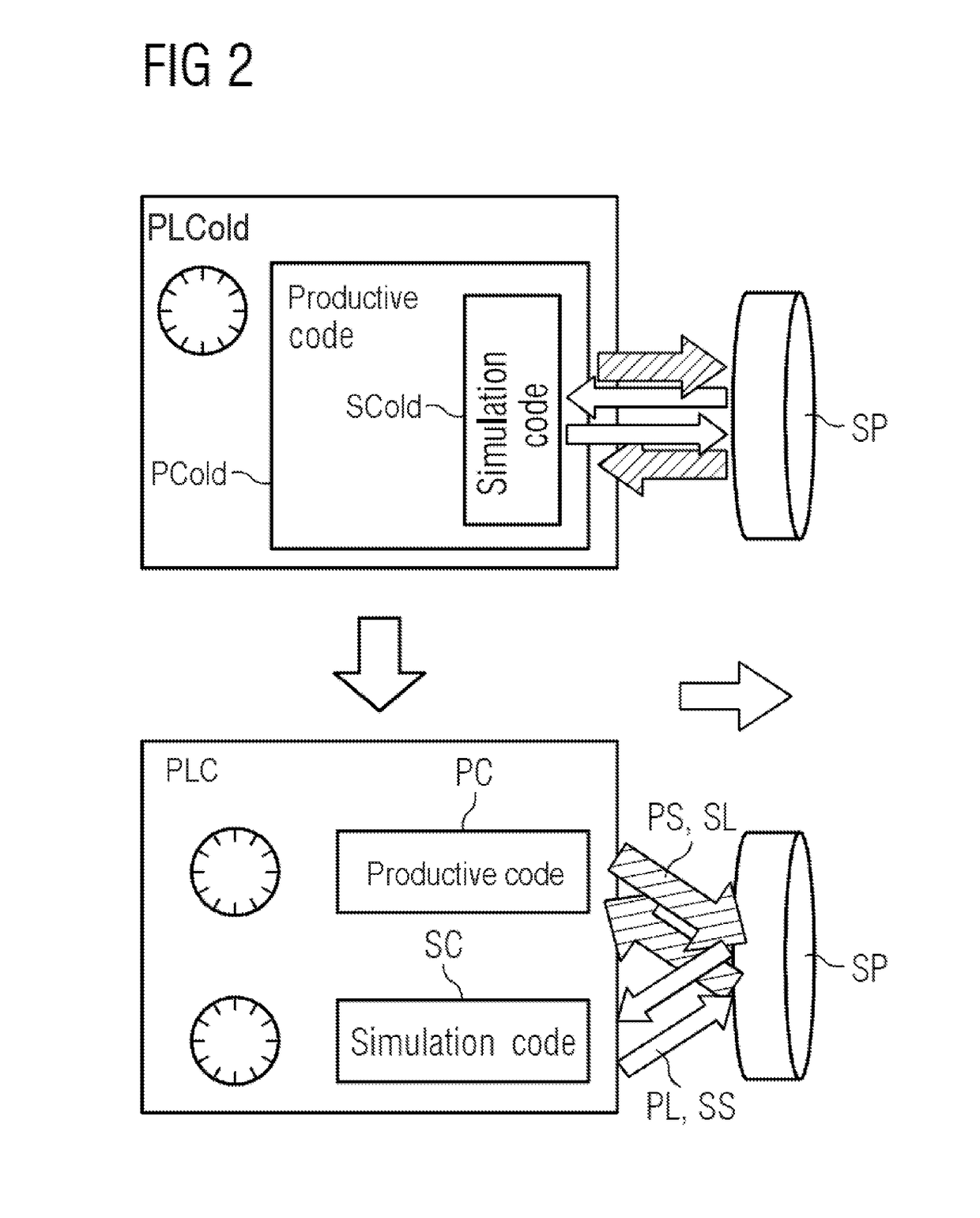

System and simulator for the disengageable simulation of installations or machines within programmable logic controllers

InactiveUS20180203973A1Avoid disadvantagesImprove the level ofGeometric CADLogical operation testingProgrammable logic controllerProgrammable Interrupt Controller

Provided is a system and a simulator for the disengageable simulation of installations or machines within programmable logic controllers, in which control program and simulation program are strictly separate within the same processing environment, wherein the direction of access for the input / output memory area during normal operation and the consistent reversal thereof in the simulation part are ensured, and which involves the simulation program being executed between the program cycles, with a virtual clock being stopped during the simulation. As a result, the test on an unaltered user program in the PLC avoids errors in the startup or test phase through code changes, and a timing response as in the genuine installation, particularly in the event of tests on timers and under race conditions, achieves a higher level of program quality through better test results.

Owner:SIEMENS AG

Interactive type direct broadcasting platform and direct broadcasting interacting method

ActiveCN106534995AImprove interactivityAdd funSelective content distributionThird partyProgram fragment

The invention relates to an interactive type direct broadcasting platform and a direct broadcasting interacting method. The direct broadcasting platform comprises a program party server for transmitting multimedia programs, a third-party server for receiving multimedia programs and pushing program to audiences, and multimedia program playing terminals of audiences, wherein the third-party server has a pushing module for pushing multimedia programs to the audiences, and a multimedia program fragmenting module for fragmenting the received multimedia programs. A multimedia aggregation module for aggregating the multimedia fragments and the multimedia program fragments uploaded by the multimedia program playing terminals is arranged on the third-party server, other third-party servers or the multimedia program playing terminals, and the multimedia aggregation module sends the aggregated fragments to the program party server, the third-party server, other third-party servers or the multimedia program playing terminals through a feedback module. Interaction between audiences and program party and direct broadcasting programs is realized, and the program enjoyment is increased. Program arrangement and process can be changed through interaction, and the program quality can be improved.

Owner:SHANGHAI GANGJU INFORMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com