Feature-based skin mirror-image milling technology decision method

A technology of process decision-making and mirror milling, which is applied in the direction of electrical program control and digital control, can solve the problems of large dependence and achieve the effects of high degree of automation, reduced workload and reduced processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] A skin part is selected as an example, and the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

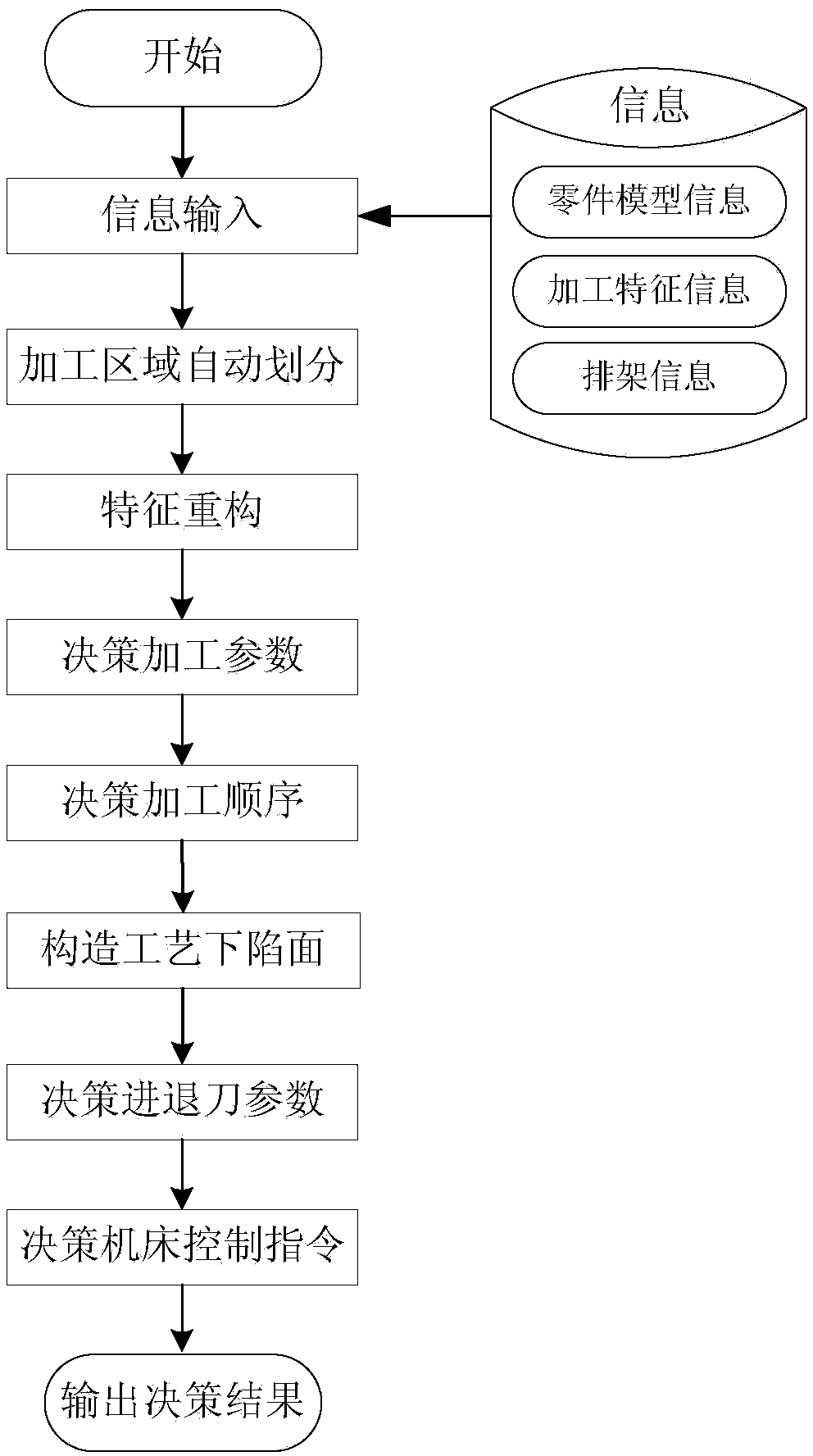

[0042] figure 1 It is a flow chart of the feature-based skin mirror milling process decision method of the present invention. As shown in the figure, the following steps are included:

[0043]1. Input the basic information required for process decision-making, including part model information, processing feature information and racking information.

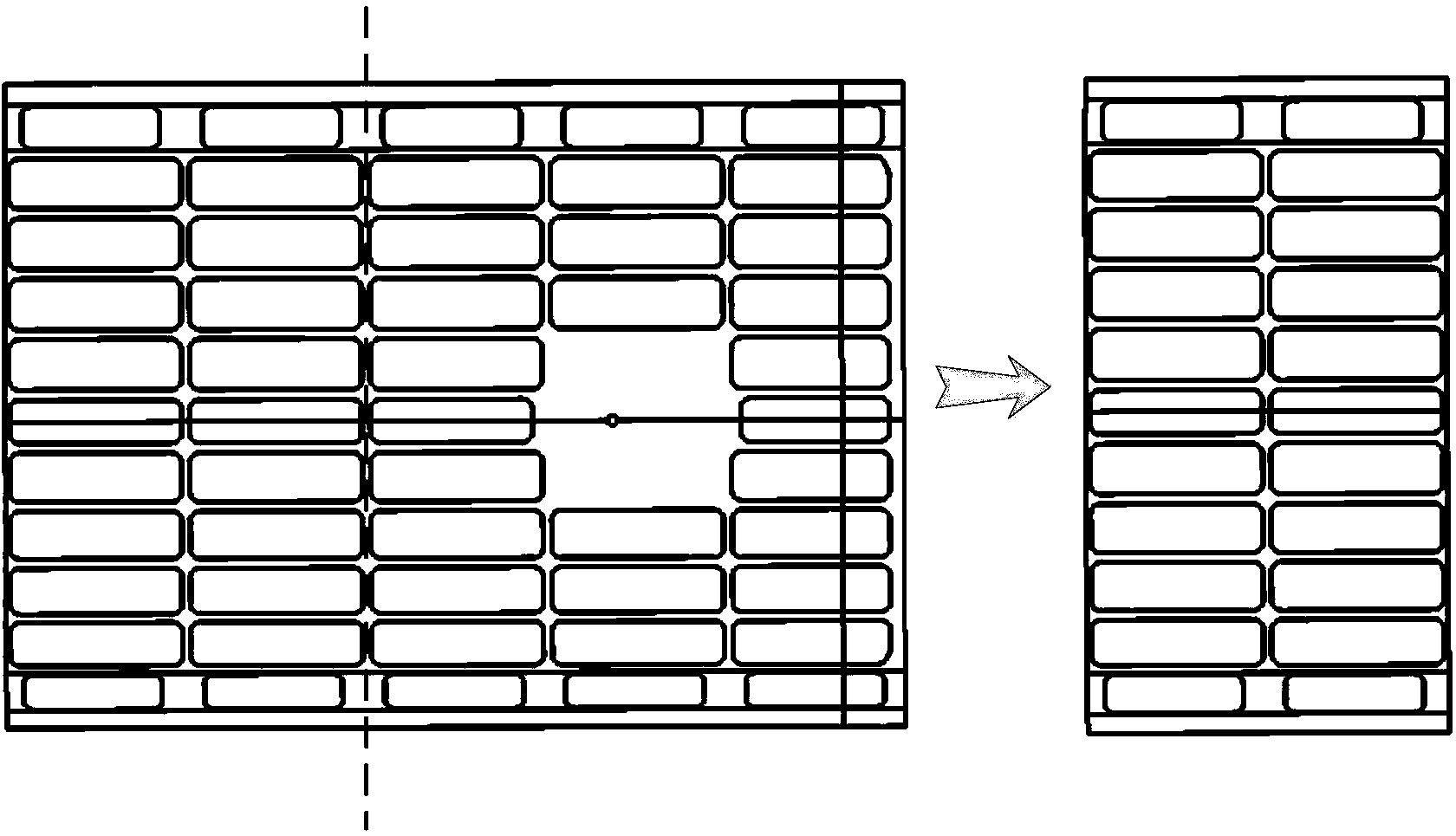

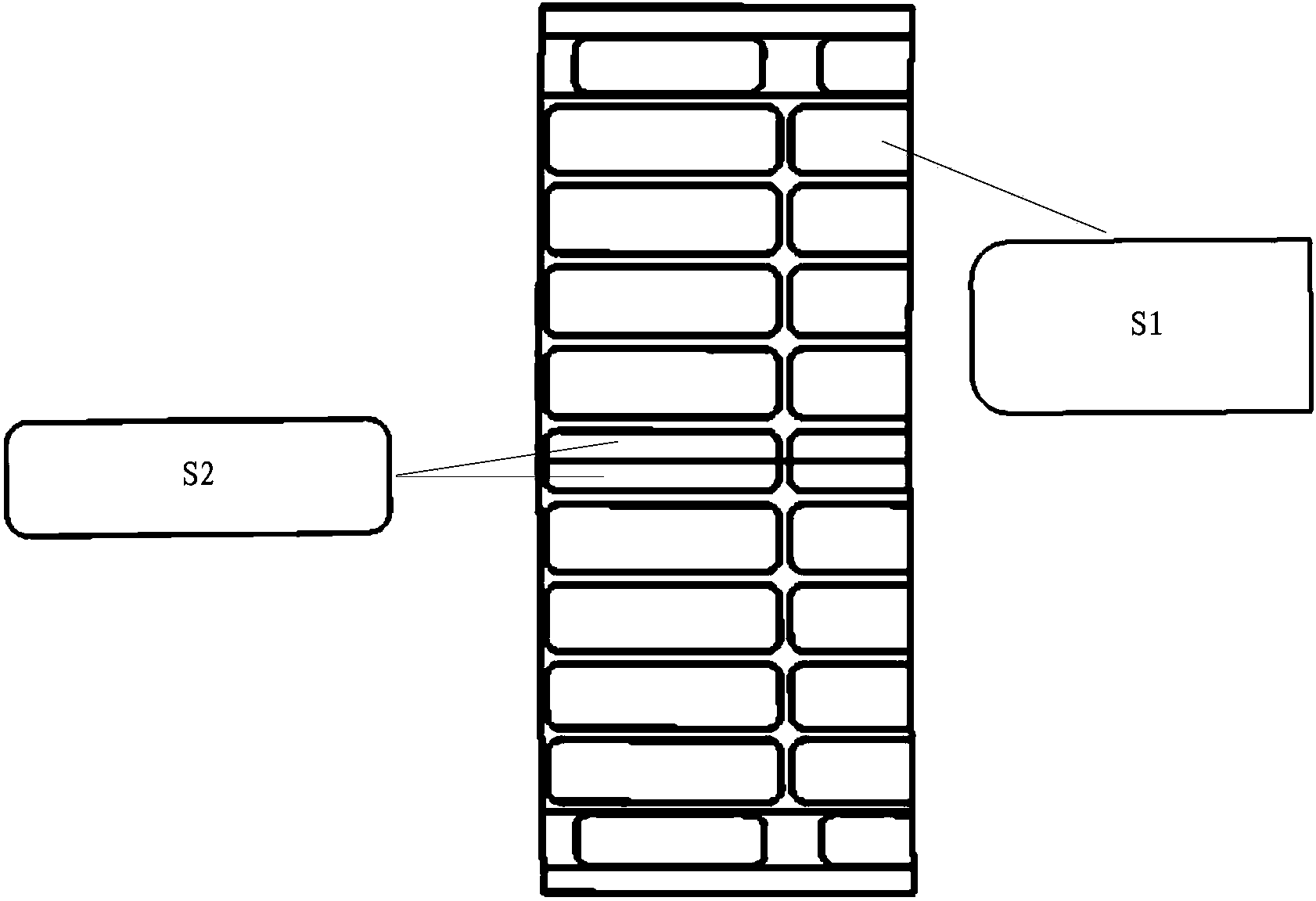

[0044] 2. Divide the processing area according to the input information. Due to the special process requirements of the skin mirror milling equipment and in order to ensure the rigidity of the parts during the processing, it is necessary to divide the skin according to the area division rules, and carry out partition processing according to the division area . The specific regional division rules are as follows:

[0045] First of all, in order to en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com