Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46 results about "Optical triangulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

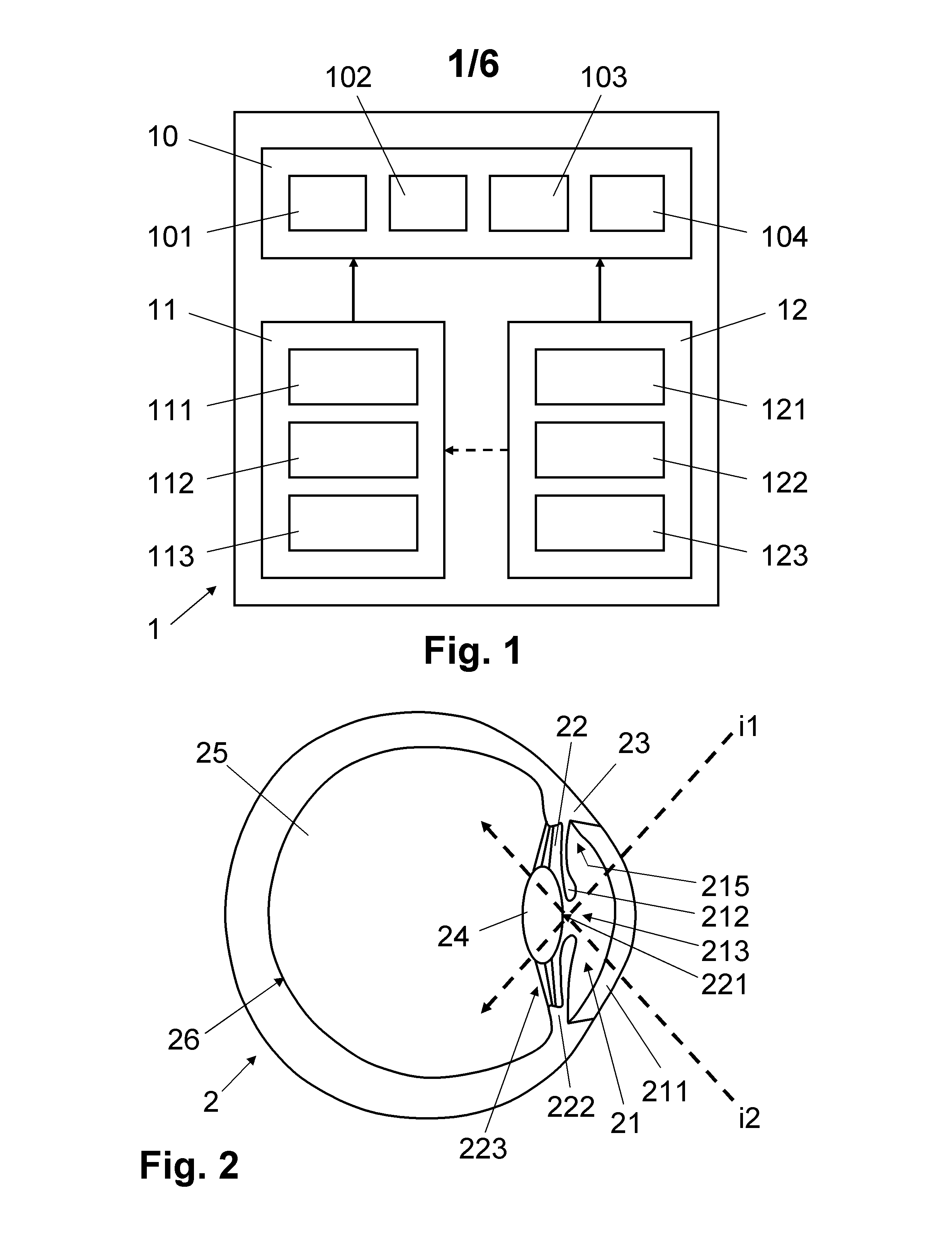

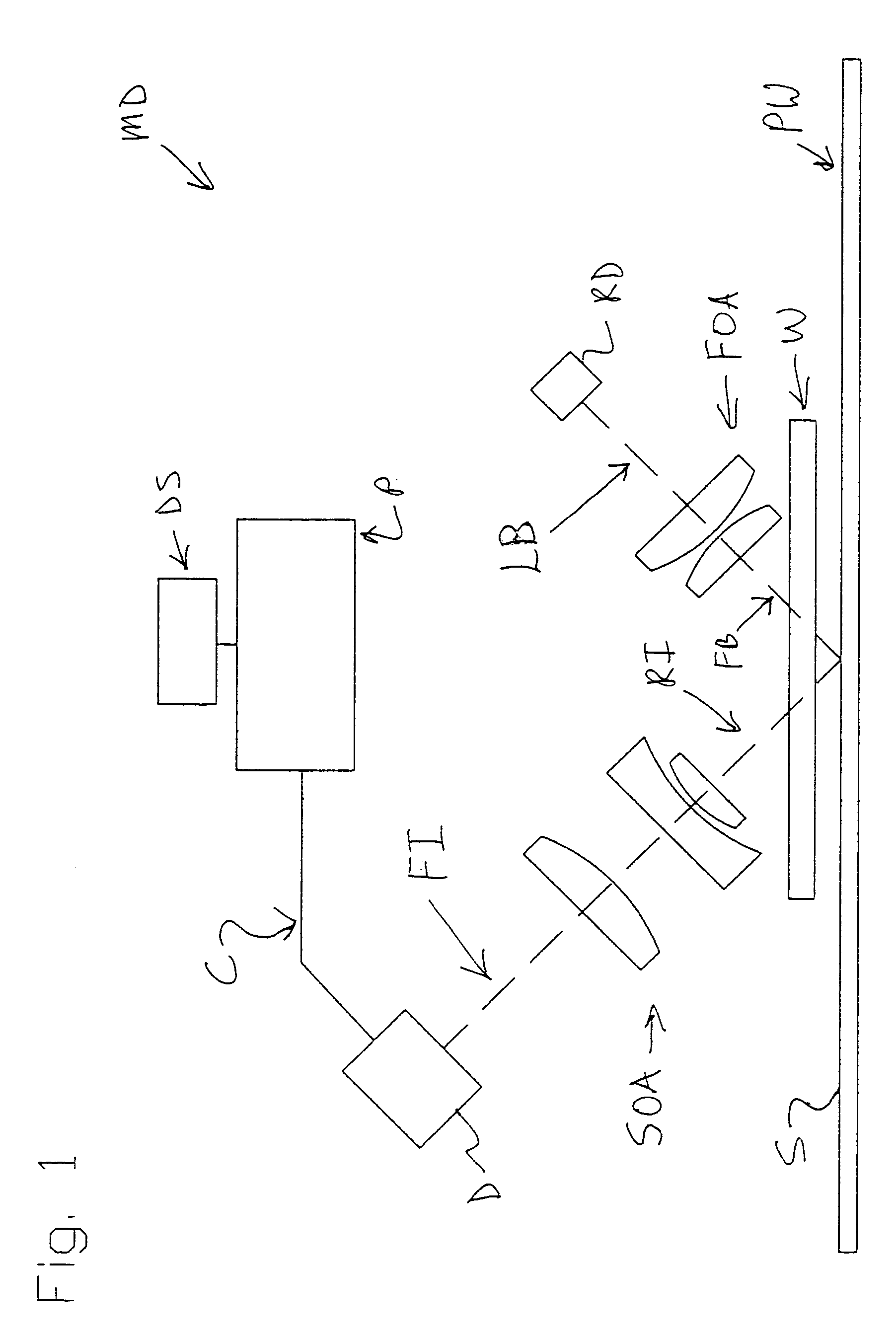

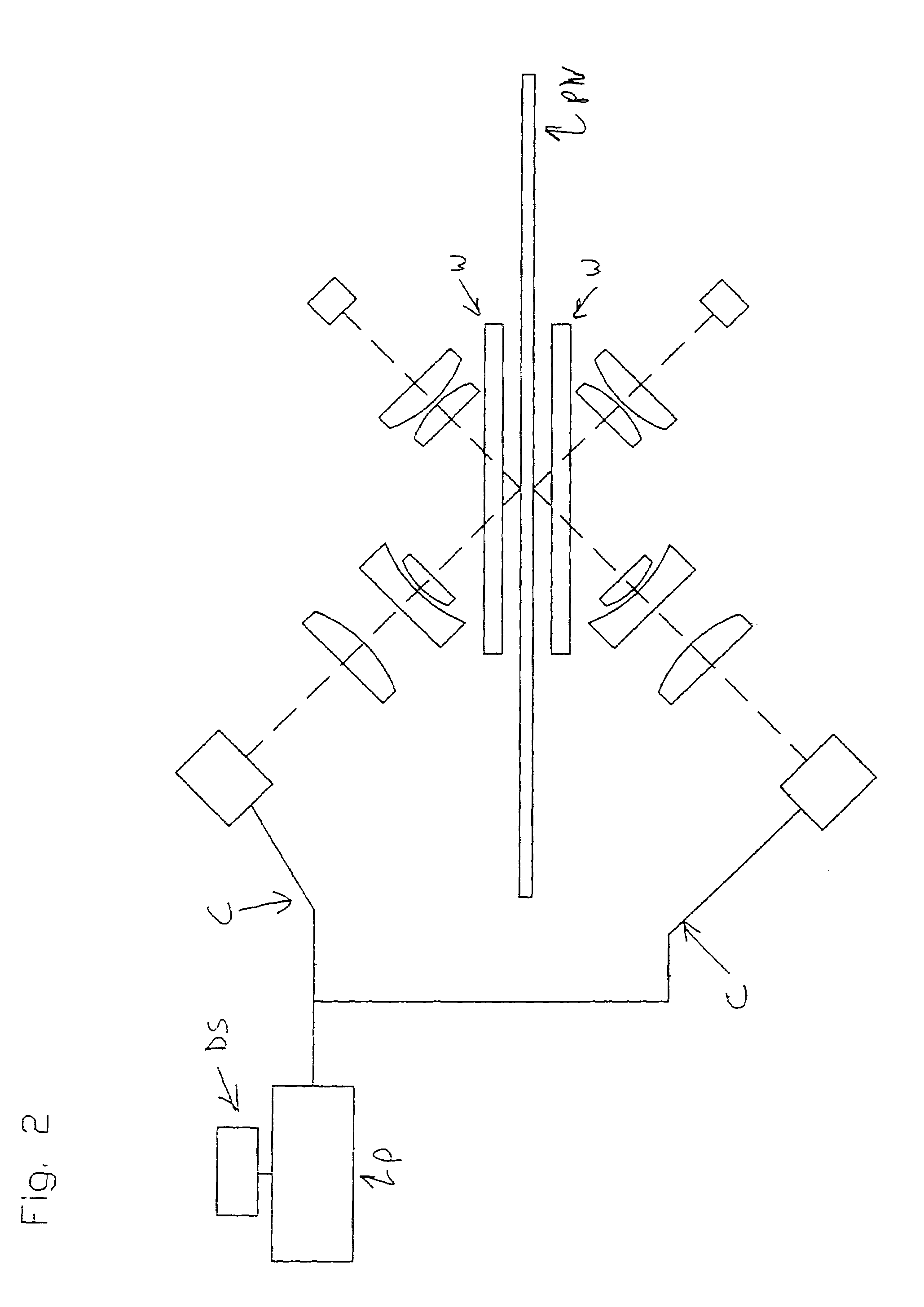

Device for Inspecting a Pipeline

ActiveUS20080105067A1Measurement of the interior contour of the pipeline can be carried out quicker and more preciselyMaterial analysis by optical meansStructural/machines measurementOptical triangulationTriangulation

A device to inspect a pipeline includes an optical system for contactless detection of an interior contour of the pipeline by optical triangulation, with the optical system being attachable to a carrier structure, which is insertable in a pipeline. The optical system includes at least n≧2 triangulation sensors or light section sensors disposed rotatably about a common axis of rotation and by the n triangulation sensors or n light section sensors being disposed about the common axis of rotation spaced the greatest possible distance apart angle-wise.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

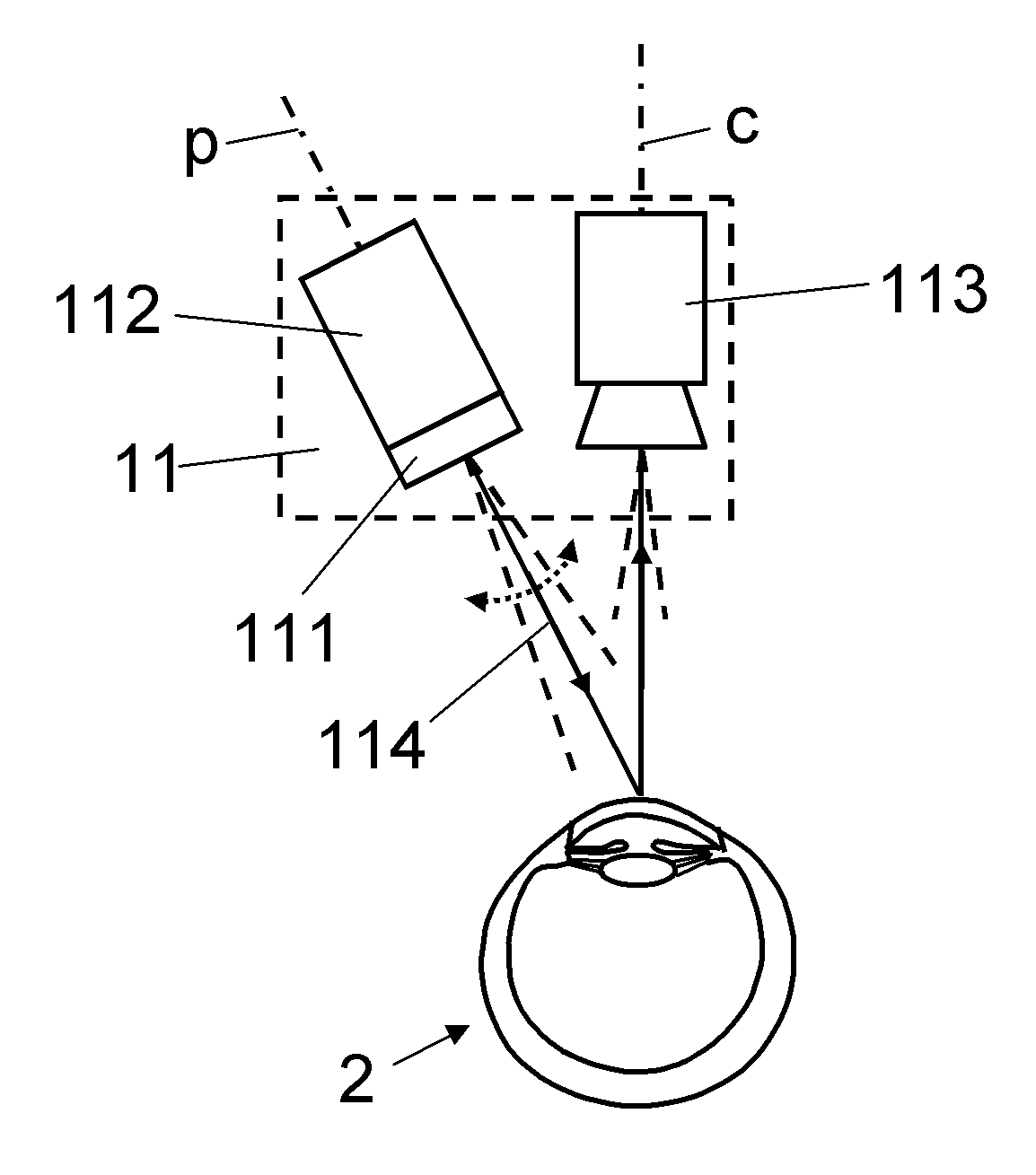

Ophthalmological measuring device and measurement method

ActiveUS20110032480A1Mitigation of impairmentImprove optical resolutionAcquiring/recognising eyesEye diagnosticsOptical triangulationMeasurement device

An opthalmological measuring device for determining geometric structures in an eye includes an optical, triangulating measurement system for determining at least one geometric reference in the eye by triangulation, and an optical, interferometric measurement system for determining geometric detailed structures in the eye by optical interferometry. The measuring device is designed to position the geometric detailed structures determined by the interferometric measurement system on the basis of the at least one geometric reference in the eye determined by the triangulating measurement system. This firstly allows the interferometric measurement system to register geometric detailed structures in the eye with a high optical resolution and at places that are not visible to the triangulating measurement system, and secondly allows the positioning of said geometric detailed structures in the eye on the basis of geometric references that are determined by the triangulating measurement system without significant movement artifacts.

Owner:SIS SURGICAL INSTR SYST

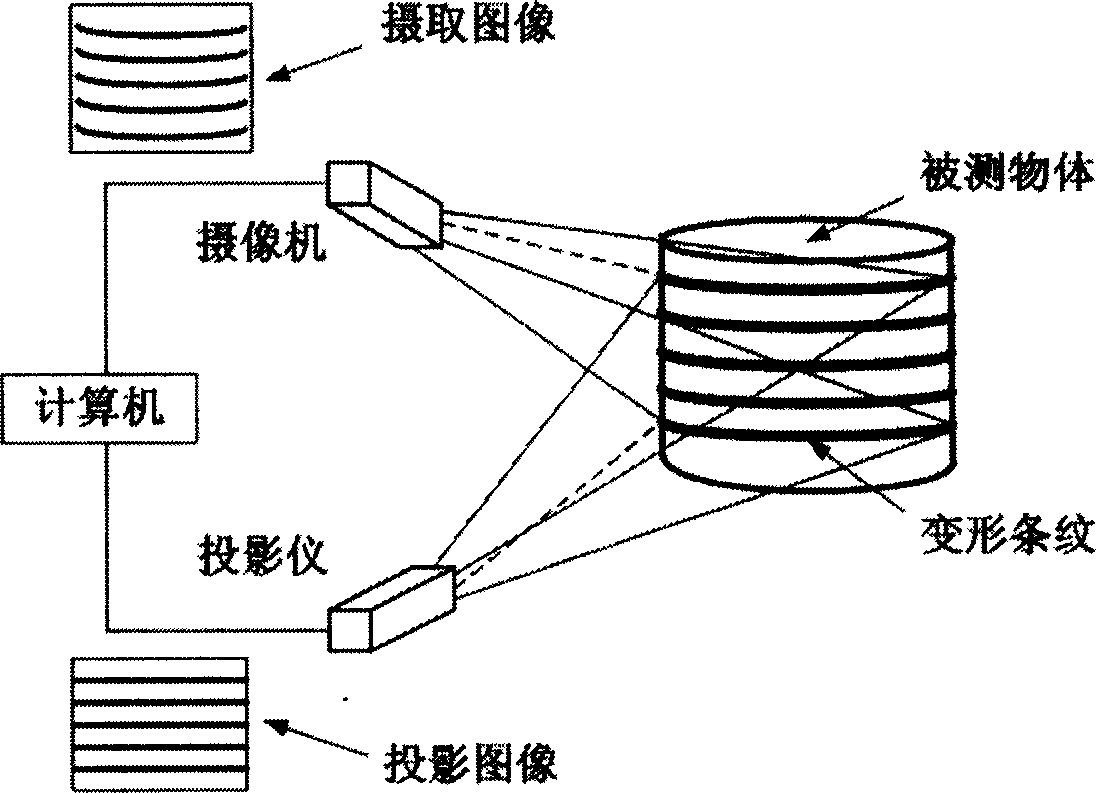

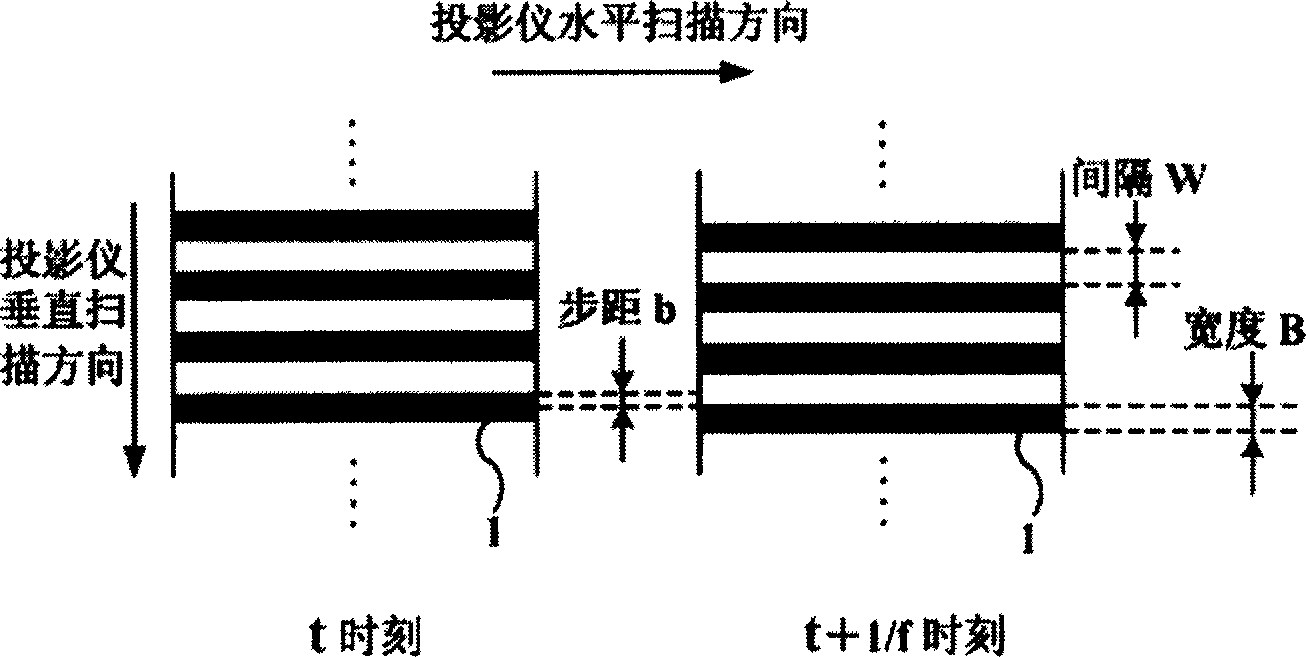

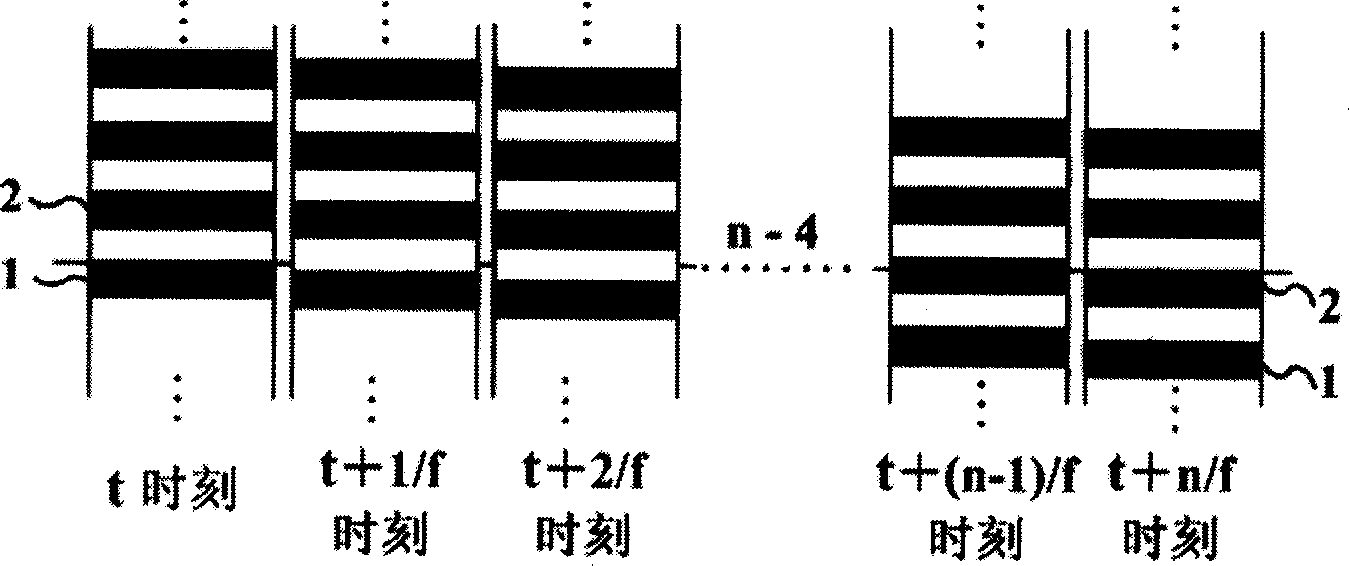

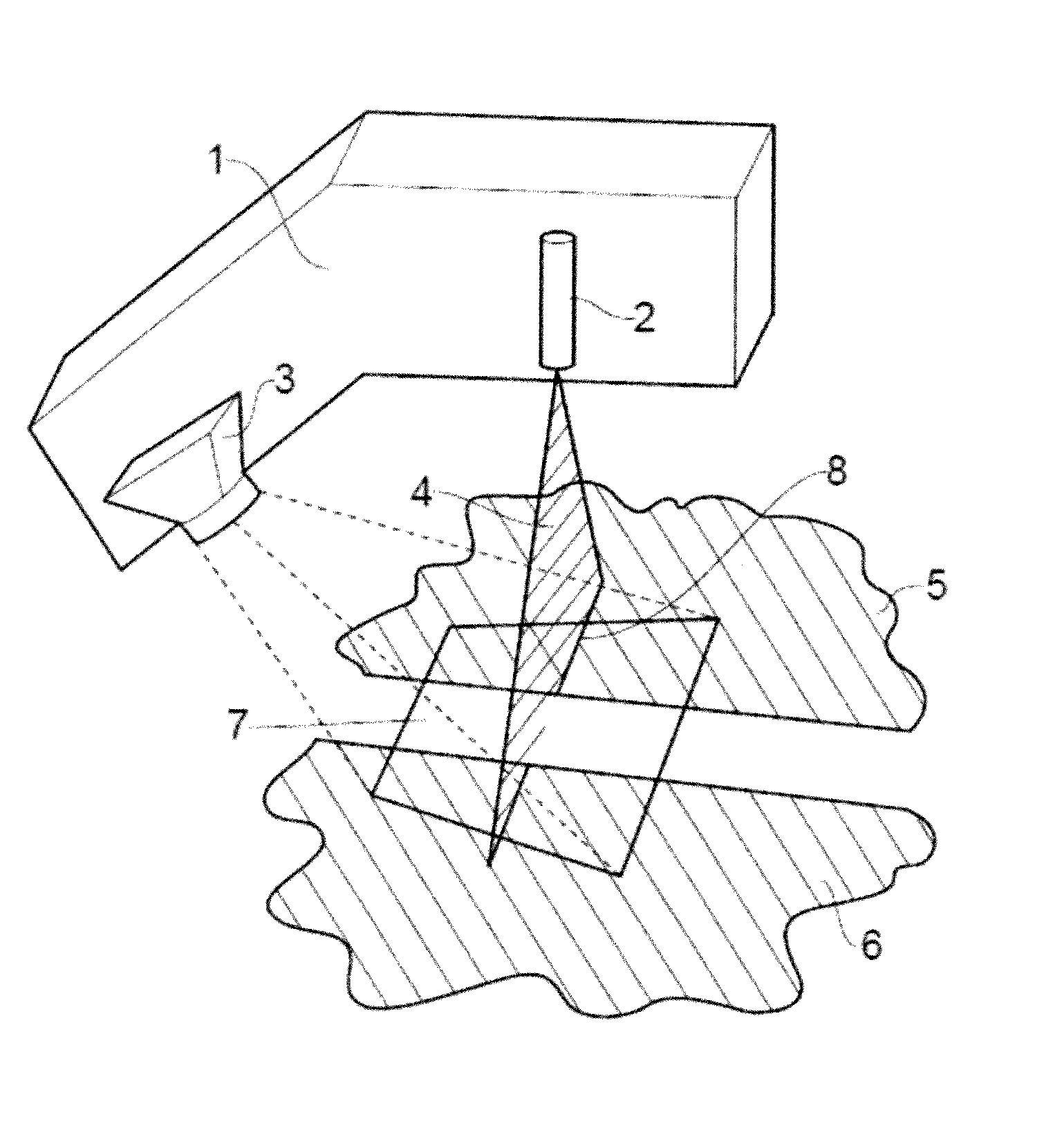

Method for realizing high resolution degree three-dimensional imaging by projector producing translation surface fringe

InactiveCN1786810AEasy to identifyImprove the ability to distinguishTelevision system detailsColor television detailsOptical triangulation3d image

The invention relates to a method to realize high analysis 3D imaging from projector generating gliding plane array stripe. By using the scanning method of gliding the plane array stripe, two-value structure light stripe array would be generated, the plane array stripe would step move along the vertical scanning direction according to step distance b and frequency f that could be captured by video camera and image collecting card. Using the method of optical triangular surveying, the 3D data would be gained and accumulated to realize 3D imaging. The invention could be used to make high analysis 3D imaging sensor.

Owner:SHANGHAI JIAO TONG UNIV

Electric transmission and transformation equipment external insulated antifouling parameter photographic measurement method

ActiveCN102506825AAchieve reconstructionChange measurement methodPhotogrammetry/videogrammetryUsing optical meansElectric power transmissionOptical triangulation

The invention relates to an electric transmission and transformation equipment external insulated antifouling parameter measurement method and discloses an electric transmission and transformation equipment external insulated antifouling parameter photographic measurement method. The whole method comprises: 1) projecting laser onto the electric transmission and transformation equipment, and rotating a stereo camera to acquire multiple three-dimensional images of the electric transmission and transformation equipment; and 2) performing computer-assisted measurement of the antifouling parameter of the electric transmission and transformation equipment based on the multiple three-dimensional images. Based on photographic measurement and computer vision principles, the electric transmission and transformation equipment external insulated antifouling parameter measurement method provided by the invention can acquire the images with laser bars of the electric transmission and transformation equipment without contacting an object and can realize the reconstruction and measurement of the structural parameters of the electric transmission and transformation equipment on the basis of an optical triangulation measurement vision principle.

Owner:广东电网公司深圳供电局试验研究所 +1

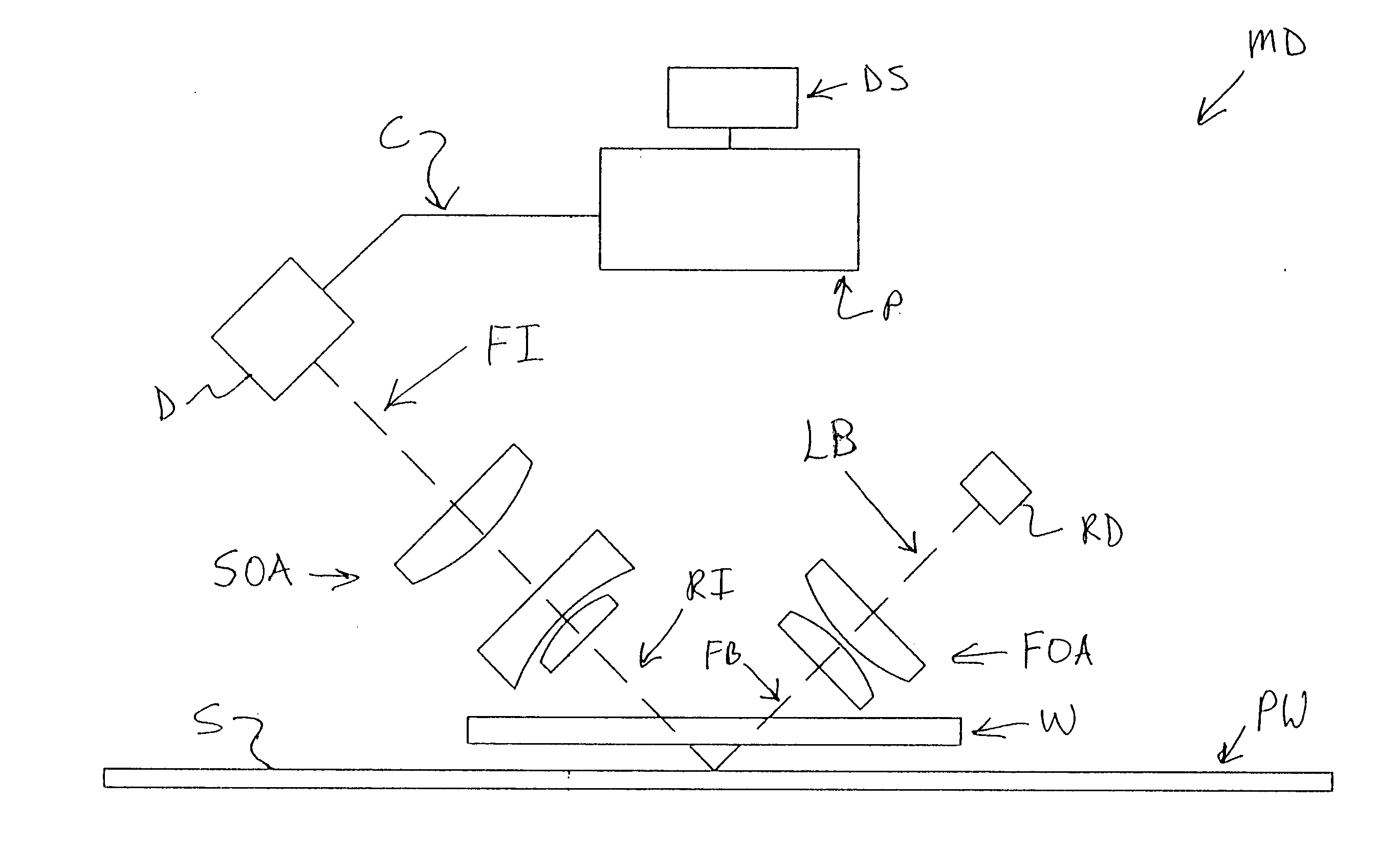

Optical triangulation device and method of measuring a variable of a web using the device

InactiveUS20060028657A1Avoid inaccuraciesHigh-frequency variationMaterial analysis by optical meansUsing optical meansOptical triangulationEngineering

Device and method of measuring a position of an irregular surface. The method includes projecting a spot along a first axis onto the irregular surface, focusing an image of the spot along a second axis onto a detector, wherein the second axis is non-coaxially arranged with respect to the first axis, processing signals from the detector, and calculating the position of the irregular surface based on at least one isolated desired frequency component of the signals. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:VOITH PATENT GMBH

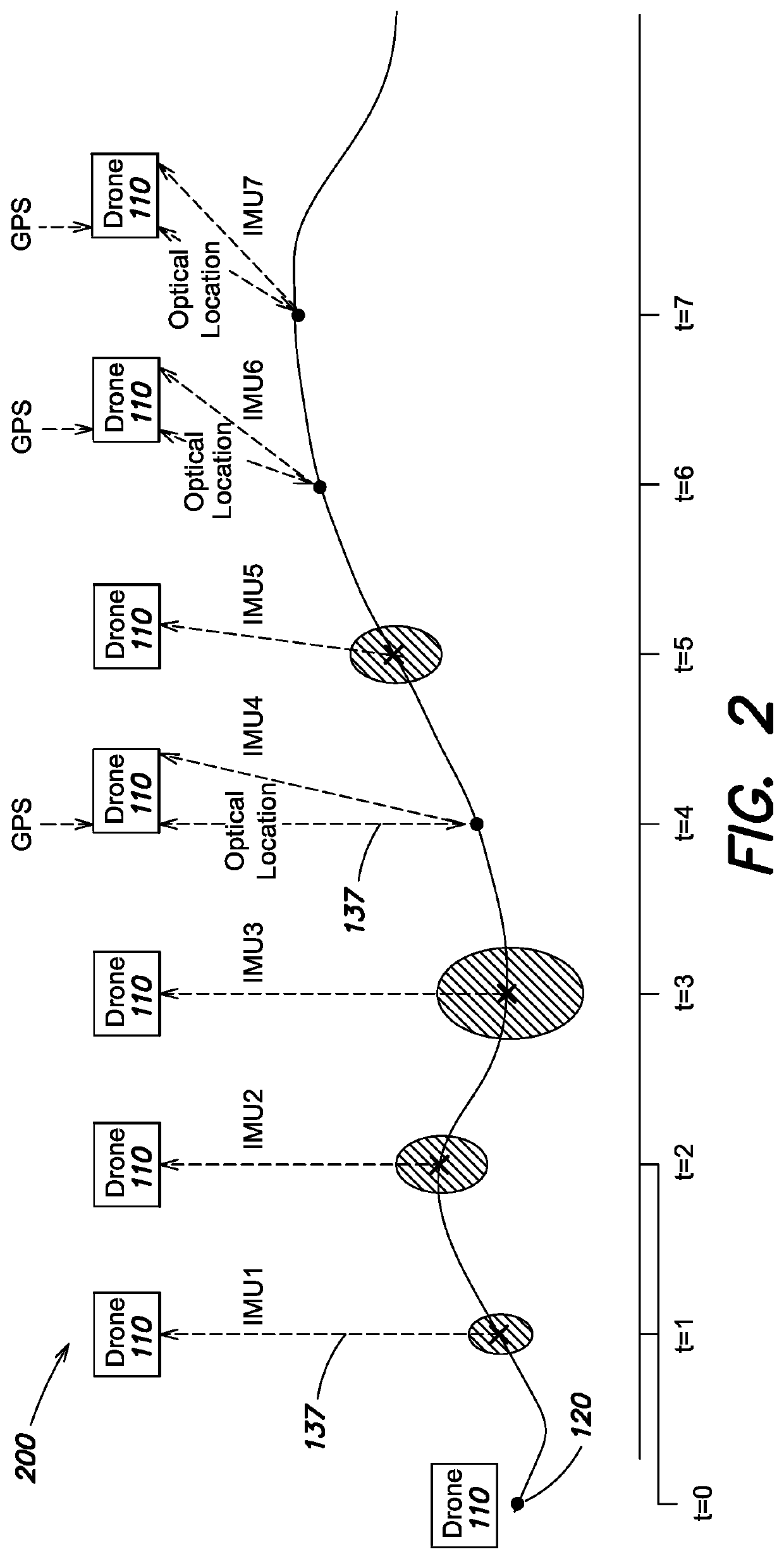

Systems and methods for autonomous machine tracking and localization of mobile objects

ActiveUS20200033128A1Error minimizationMinimize random errorNavigational calculation instrumentsUnmanned aerial vehiclesOptical triangulationEngineering

Disclosed are technologies for autonomous tracking. An initial coordinate of a beacon device carried by a user is registered as a dead reckoning waypoint with a drone configured to track the user. The drone receives IMU measurements from the beacon as the user moves. For each IMU measurement, a displacement vector characterizing user movement is calculated. Estimated beacon locations are calculated by dead reckoning, based on the displacement vectors and the dead reckoning waypoint. Later, an updated dead reckoning waypoint is calculated by obtaining the current location coordinate of the drone and performing optical triangulation to determine a relative position of the user with respect to the drone. The updated dead reckoning waypoint does not depend on previously estimated beacon locations, and accumulated IMU / estimation error is eliminated. Tracking continues, where subsequent estimated locations of the beacon are calculated by dead reckoning based on the updated dead reckoning waypoint.

Owner:TG 17 LLC

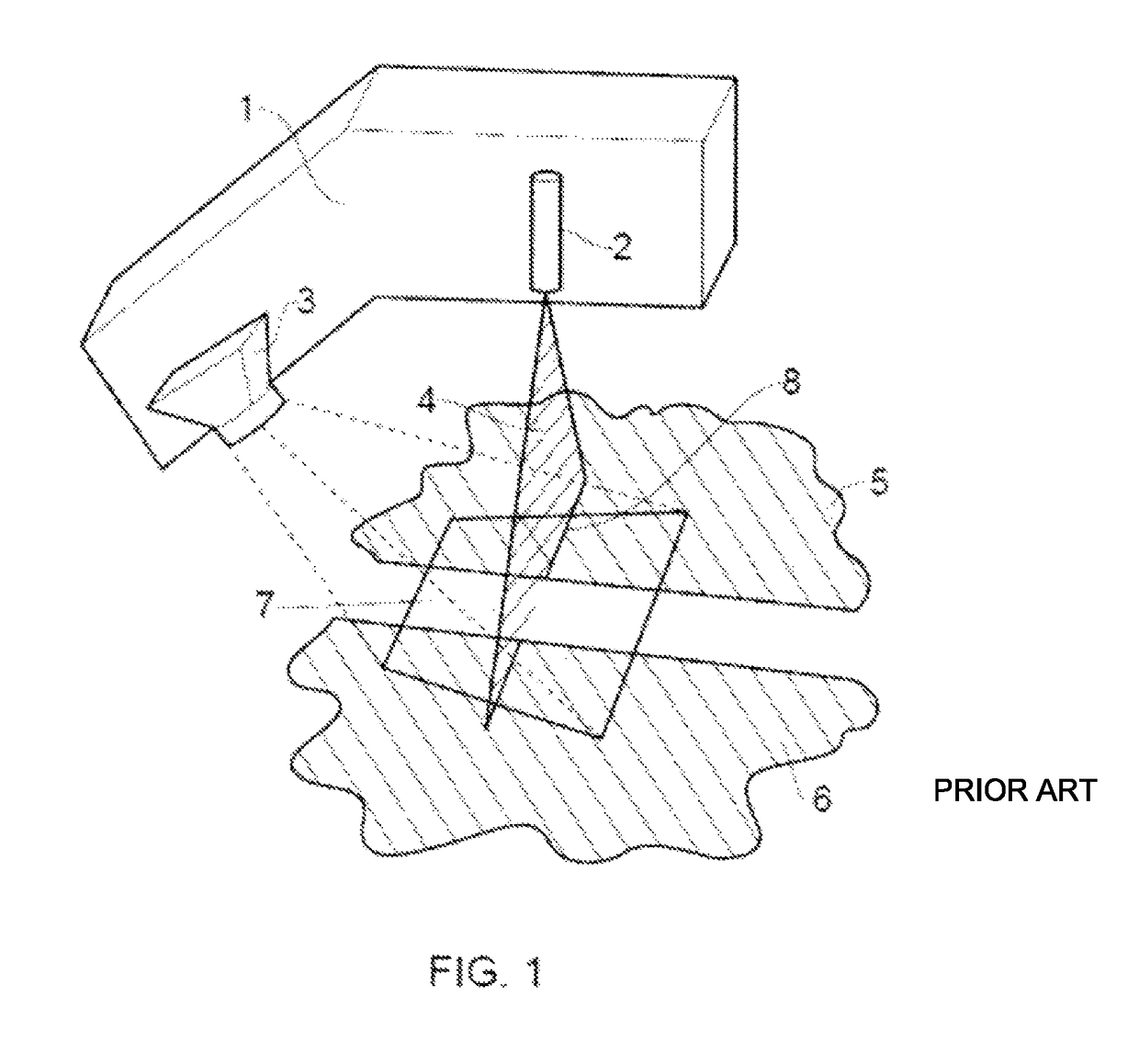

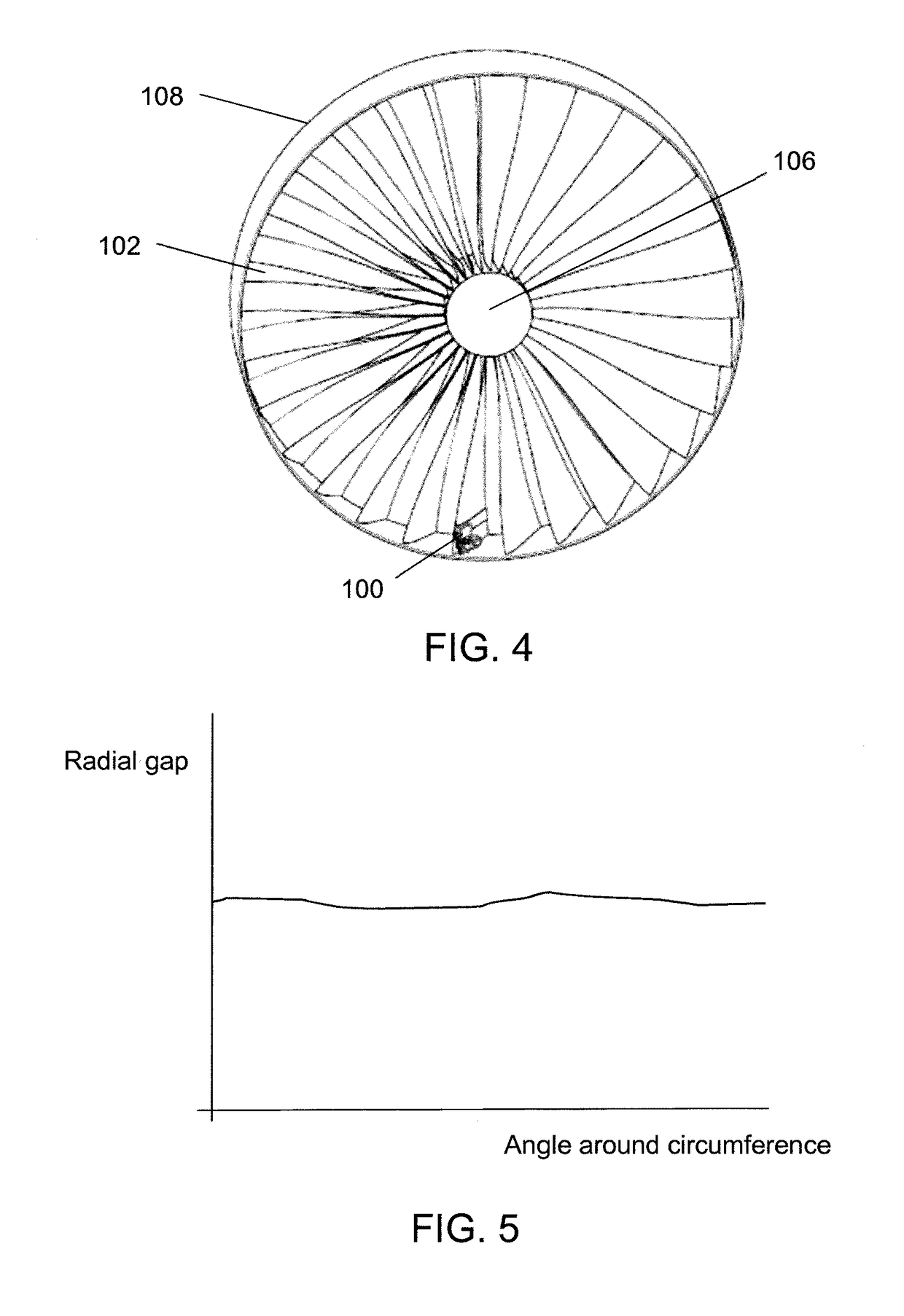

Positioning Device for an Optical Triangulation Sensor

ActiveUS20170003393A1Quick and efficientQuickly and repeatably mountOptical rangefindersMachines/enginesOptical triangulationTriangulation

A tool or attachment jig for mounting an optical triangulation sensor on a turbine blade in a position to measure the gap between the distal tip of the turbine blade and the adjacent shroud. The tool includes a device for indicating the orientation of the sensor. This means that the tool can match a measurement from the optical triangulation sensor with a position on the circumference of the shroud. By taking a plurality of measurements as the turbine blade is rotated with respect to the annular casing, an angular profile for the gap between the turbine blade and the casing can be obtained in a much quicker and more efficient way than a conventional system.

Owner:THIRD DIMENSION SOFTWARE

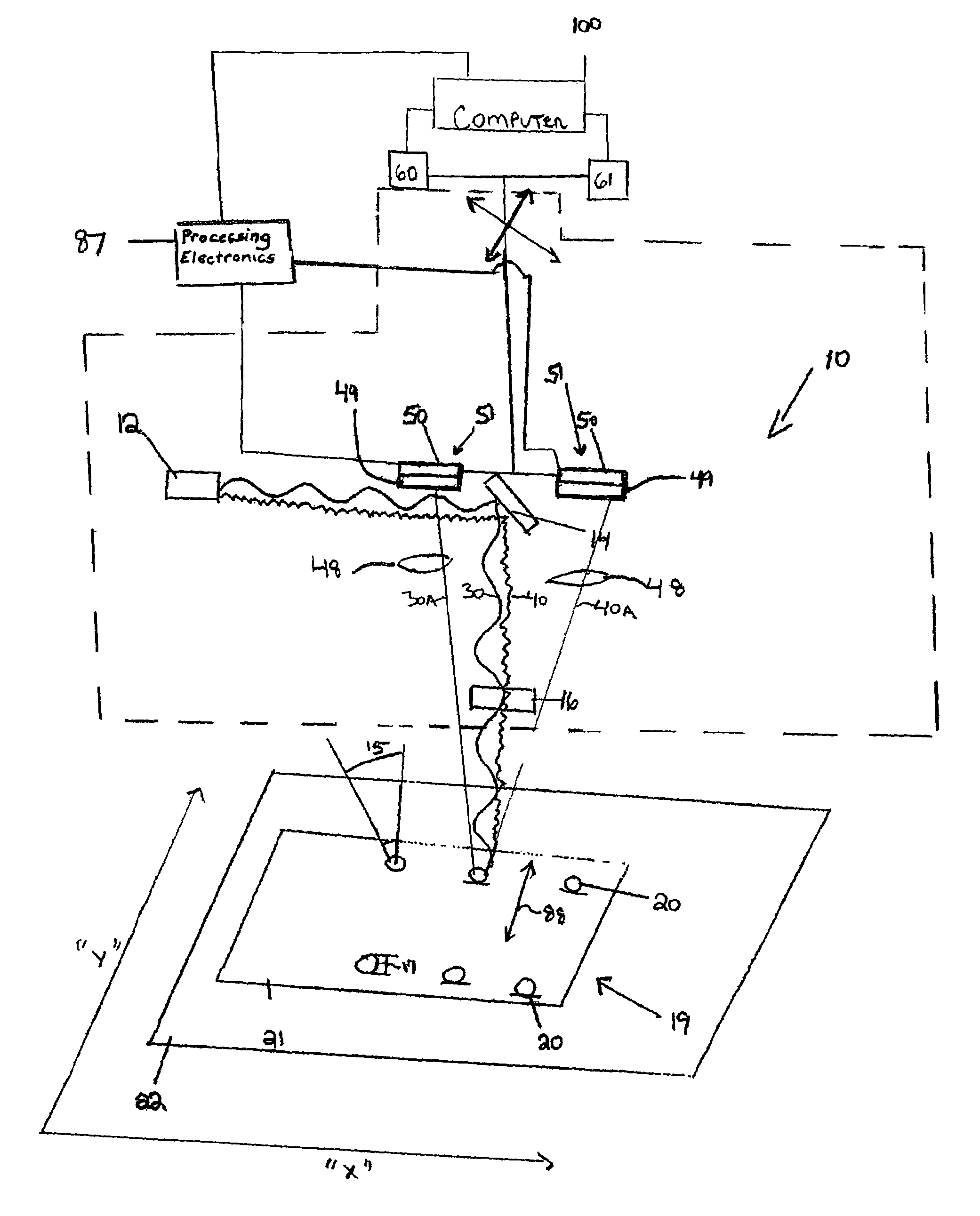

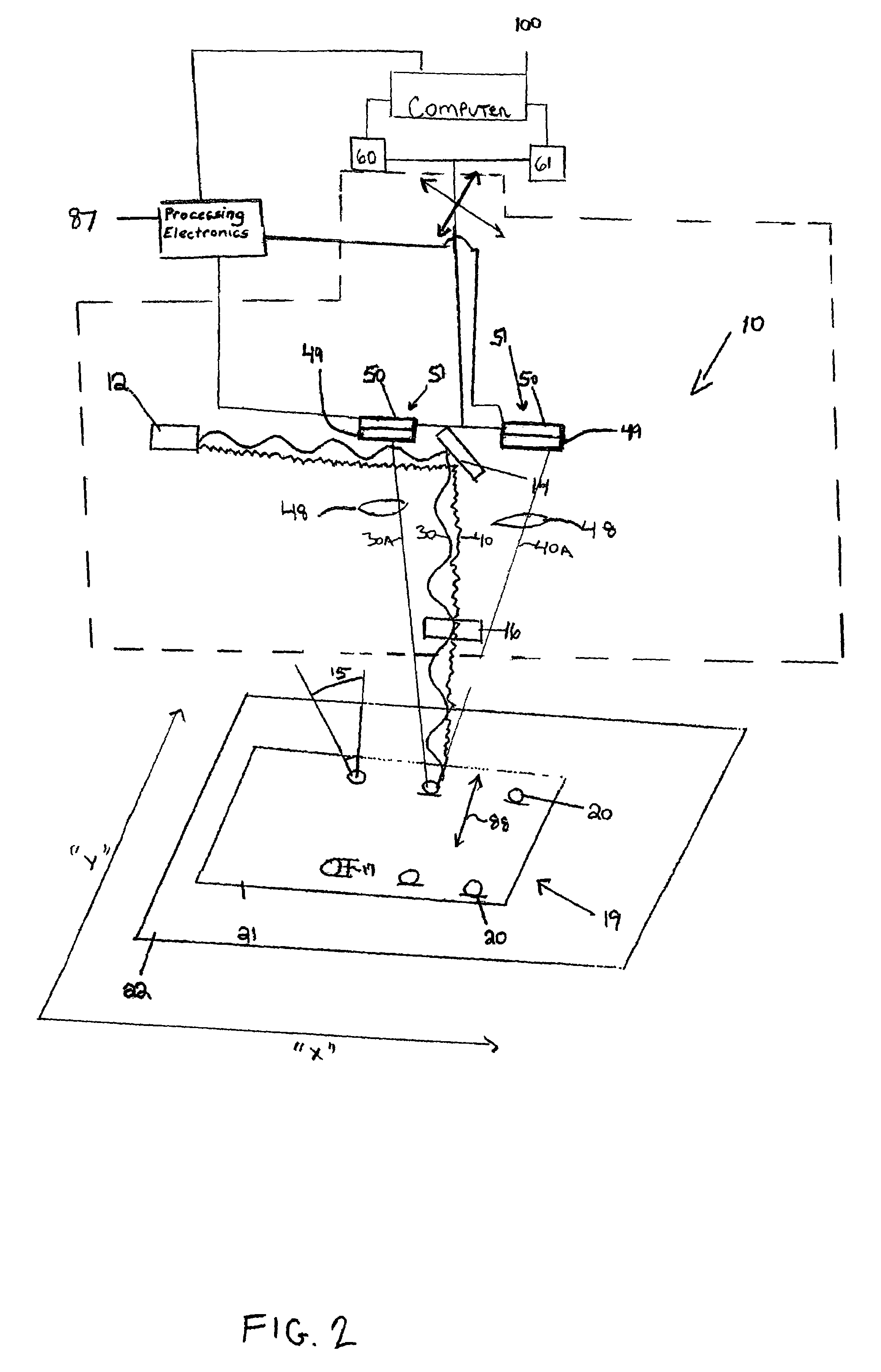

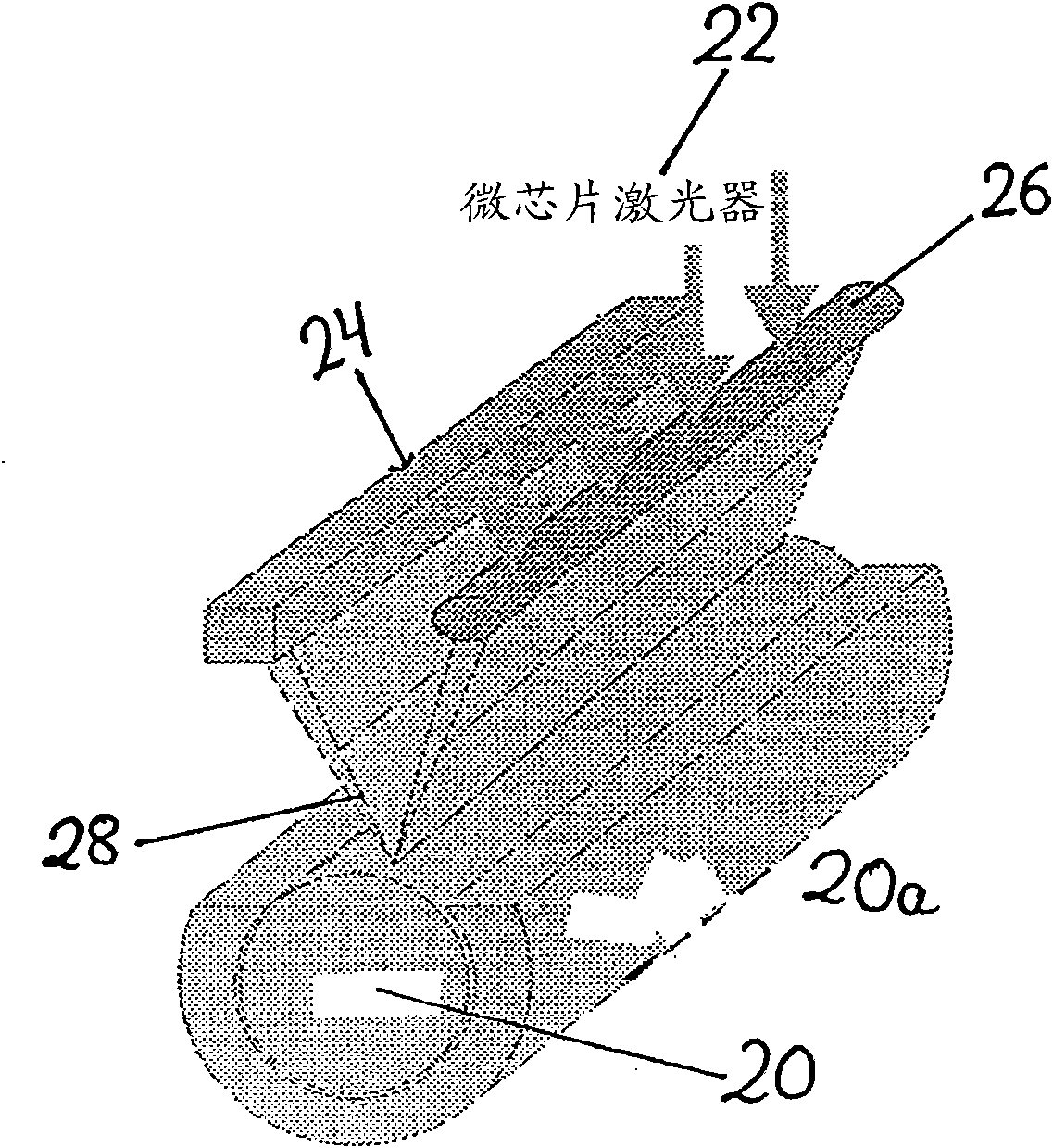

Laser triangulation method for measurement of highly reflective solder balls

A system and method of determining a height and / or position of at least one element on an area array device. A laser beam scans the area array device using at least two different laser light intensities. Reflected light is sampled, and the height and / or position of the element is determined using, e.g., optical triangulation.

Owner:RUDOLPH TECHNOLOGIES INC

Method for dynamically measuring width of steel billet by using laser displacement sensors

ActiveCN104215179AMeet the precision requirementsSimplify measurement techniquesUsing optical meansOptical triangulationMetallurgy

The invention discloses a method for dynamically measuring width of a steel billet by using laser displacement sensors. The method includes that 1, two laser displacement sensors are mounted on two sides of a roller way respectively before the steel billet is swept, and a camera is adopted to photograph the steel billet currently moving on the roller way; 2, an industrial control computer sequentially calculates discrete width value of the current steel billet and correspondingly displays matched width curve, discrete width value and video images capable of showing the surface of the steel billet currently moving on the roller way in real time through a display screen; 3, the industrial control computer compares planed steel billet width with the discrete width value acquired by calculating the steel billet currently moving on the roller way; when width difference value acquired through subtraction of the planned steel billet width and the discrete width value exceeds a set difference value range, an optical triangular measuring device is allowed to give out sound for alarming, the discrete width value Width is enabled to be in one-to-one correspondence to corresponding billet number, planned steel billet width and mark digit to form relevant data, and the relevant data formed correspondingly in real time are stored. By the method, measuring technical means is simplified, and requirements on accuracy in actual measuring of steel billet width are met.

Owner:XINXING DUCTILE IRON PIPES XINJIANG

Optical triangulation sensor

ActiveUS20100195116A1Facilitate accurate locationGood orientationUsing optical meansOptical triangulationLight beam

An optical e.g. laser triangulation sensor is disclosed in which a configuration of an output light beam is controlled using a mask (19) in front of a light source. The configuration may include a plurality of coplanar spatially separated planar light beams. The mask may be movable to provide different light beam configurations. Masking parts of the light beam enables unwanted features on the measurement surface to be omitted. Also disclosed is a guide element (200) for an optical sensor for facilitating hole diameter measurement. The guide element has contact surfaces (212, 214, 216) lying on a virtual conical surface which abut the hole edge to enable consistent placement of the light beam with respect to the hole centre. Also disclosed is a guide element (300) for an optical sensor having an aperture for framing surface features (e.g. rivet) to permit accurate location of the light beam therewith.

Owner:THIRD DIMENSION SOFTWARE

Device for inspecting a pipeline

ActiveUS7612878B2Measurement of the interior contour of the pipeline can be carried out quicker and more preciselyMaterial analysis by optical meansStructural/machines measurementOptical triangulationTriangulation

A device to inspect a pipeline includes an optical system for contactless detection of an interior contour of the pipeline by optical triangulation, with the optical system being attachable to a carrier structure, which is insertable in a pipeline. The optical system includes at least n≧2 triangulation sensors or light section sensors disposed rotatably about a common axis of rotation and by the n triangulation sensors or n light section sensors being disposed about the common axis of rotation spaced the greatest possible distance apart angle-wise.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Cross-flow fan-blade radial-circle-jump-degree non-contact online diagnostic device and method

InactiveCN103644863AImprove detection efficiencyLow costUsing optical meansOptical triangulationInformation processing

The invention provides a cross-flow fan-blade radial-circle-jump-degree non-contact online diagnostic device and method. The device includes a sensor module, a signal conditioning processing module, a power module, a one-chip-microcomputer central information processing unit module, an LCD diagnosis display module and an acousto-optic alarm module. In the method, non-contact online measurement of circle-jump-degree parameters at a plurality of positions of a cross-flow fan blade is performed through a laser displacement sensor using a laser triangulation method as the principle to diagnose whether the cross-flow fan blade is qualified. The laser triangulation method is based on a classical optical triangulation principle. When an object plane moves, the movement direction forms an inclined angle with the optical axis of a receiving optical path. The cross-flow fan-blade radial-circle-jump-degree non-contact online diagnostic device is capable of online diagnosis of the radial circle jump degree of the cross-flow fan blade and has the advantages of being high in automation degree, reliable in diagnosis and high in diagnosis efficiency. The device is capable of realizing noncontact diagnosis of cross-flow fans of different specifications.

Owner:JIANGSU UNIV

Optical Device for Measuring the Displacement Velocity of a First Moving Element with Respect to a Second Element

InactiveUS20070229798A1Accurately determineOptical rangefindersUsing optical meansOptical triangulationLight beam

An optical device for measuring the displacement velocity of a first movable element in relation to a second element which is fixed to one of said elements and comprises two lasers transmitting two incident beams towards the other elements. The device including photosensitive linear arrays for front and rear detection which are substantially perpendicular to each other. Additional front and rear photosensitive linear arrays are disposed at a distance from the photosensitive front and rear linear arrays. A processing circuit is connected to the photosensitive linear arrays and determines the longitudinal and / or transversal displacement velocity of the movable element. The circuit also determines the distance between the device and the other element by means of optical triangulation and corrects the longitudinal and / or transversal displacement velocity value according of the said distance.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

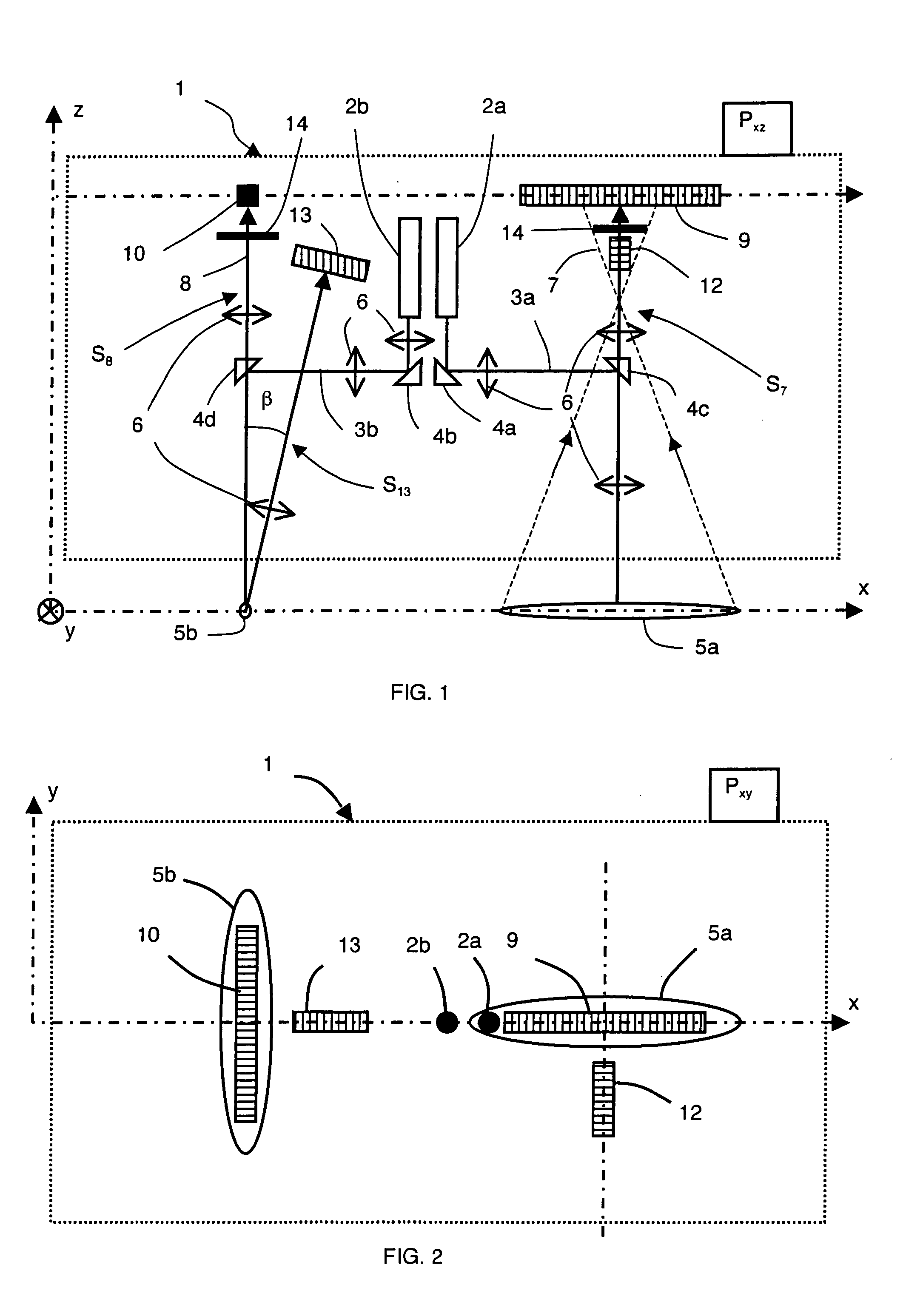

Optical measuring device using optical triangulation

InactiveUS7616327B2Great measurement precisionImprove reliabilityPhotometryPhotomechanical treatmentOptical triangulationBeam splitter

An optical triangulation measuring device includes an emmiter that emits two alternating light beams with different wavelengths along the same path; a beam splitter; an optical separator that directs the alternating split beams towards the surfaces from which they are reflected; an optical combiner that collects the beams and directs them along a path; optronic sensors that receive two light images and to deliver a signal indicating the position of the energy barycenter a time synchronizer for the two alternating beams and the two images on the optronic sensors; and a processor for processing the signals from the optronic sensors in order to supply information relating to the position and inclination of the surface.

Owner:SAGEM DEFENSE SECURITE SA

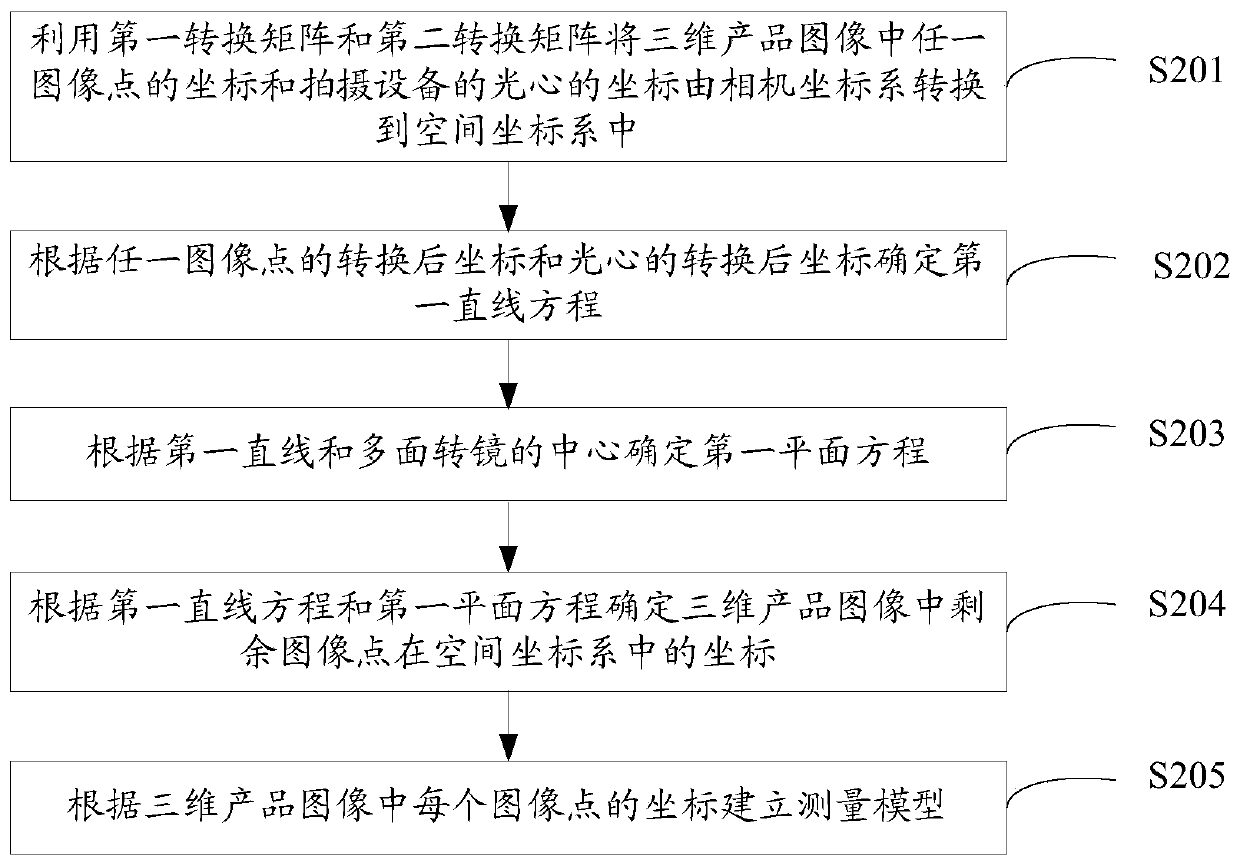

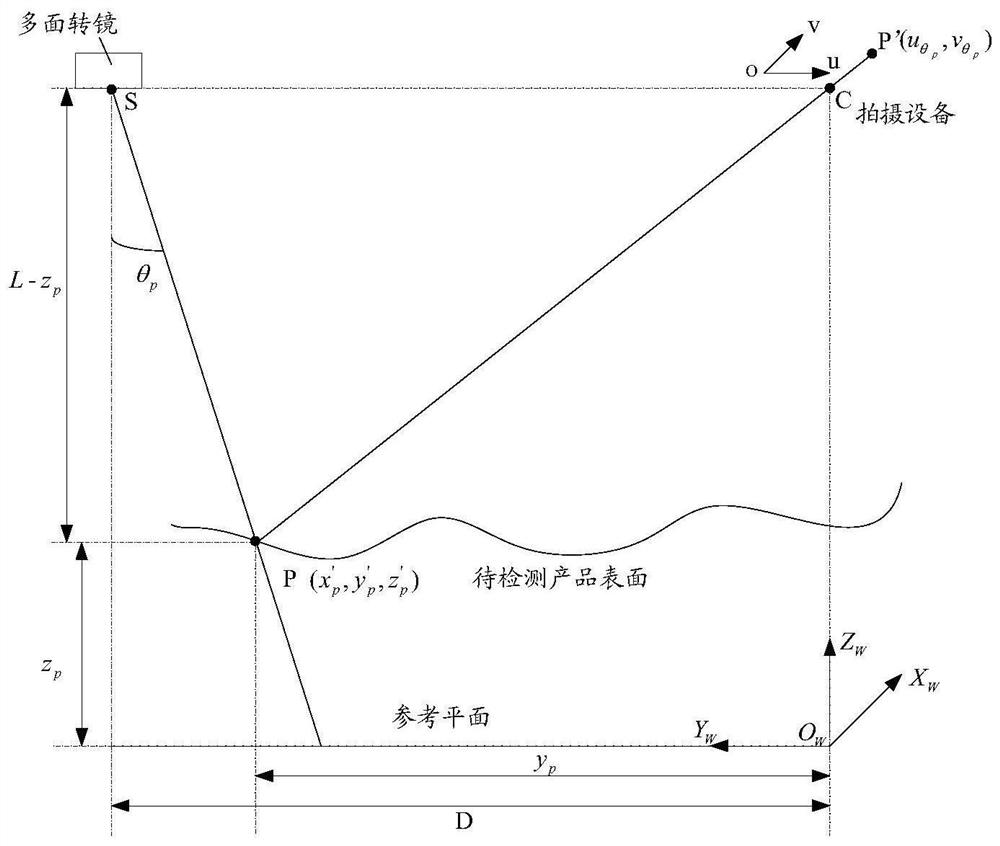

Product quality detection method and device

ActiveCN109829883AReduce computing pressureImprove accuracyImage analysisCharacter and pattern recognitionOptical triangulationSpot welding

The embodiment of the invention provides a product quality detection method and device. The method comprises the steps that detection equipment generates a three-dimensional product image which corresponds to a to-be-detected product and comprises a welding spot area according to images shot by shooting equipment under different light sources and different visual angles; a measurement model for measuring the spot welding area in the three-dimensional product image is established according to an optical triangulation method; And preliminary detection is performed on the spot welding area in thethree-dimensional product image by using the measurement model. And for the to-be-detected product passing the preliminary detection, the to-be-detected product is detected again by using the first classification model. And only the to-be-detected product passing the preliminary detection is detected again, so that the calculation pressure of the detection equipment can be reduced. And then determining which defect the to-be-detected product has by using the confirmation processing logic corresponding to the at least one defect type obtained after re-detection. In the re-detection process, the used confirmation processing logic is targeted, and any person does not intervene in the whole processing process.

Owner:GEER TECH CO LTD

Laser triangulation method for measurement of highly reflective solder balls

A system and method of determining a height and / or position of at least one element on an area array device. A laser beam scans the area array device using at least two different laser light intensities. Reflected light is sampled, and the height and / or position of the element is determined using, e.g., optical triangulation.

Owner:RUDOLPH TECHNOLOGIES INC

Ophthalmological measuring device and measurement method

ActiveUS20110222021A1Mitigation of impairmentImprove optical resolutionAcquiring/recognising eyesEye diagnosticsOptical triangulationMeasurement device

An ophthalmological measuring device for determining geometric structures in an eye includes an optical, triangulating measurement system for determining at least one geometric reference in the eye by triangulation, and an optical, interferometric measurement system for determining geometric detailed structures in the eye by optical interferometry. The measuring device is designed to position the geometric detailed structures determined by the interferometric measurement system on the basis of the at least one geometric reference in the eye determined by the triangulating measurement system. This firstly allows the interferometric measurement system to register geometric detailed structures in the eye with a high optical resolution and at places that are not visible to the triangulating measurement system, and secondly allows the positioning of said geometric detailed structures in the eye on the basis of geometric references that are determined by the triangulating measurement system without significant movement artifacts.

Owner:SIS SURGICAL INSTR SYST

Optical triangulation sensor

ActiveUS8274662B2Accurate and repeatable calculationUsing optical meansOptical triangulationTriangulation

Owner:THIRD DIMENSION SOFTWARE

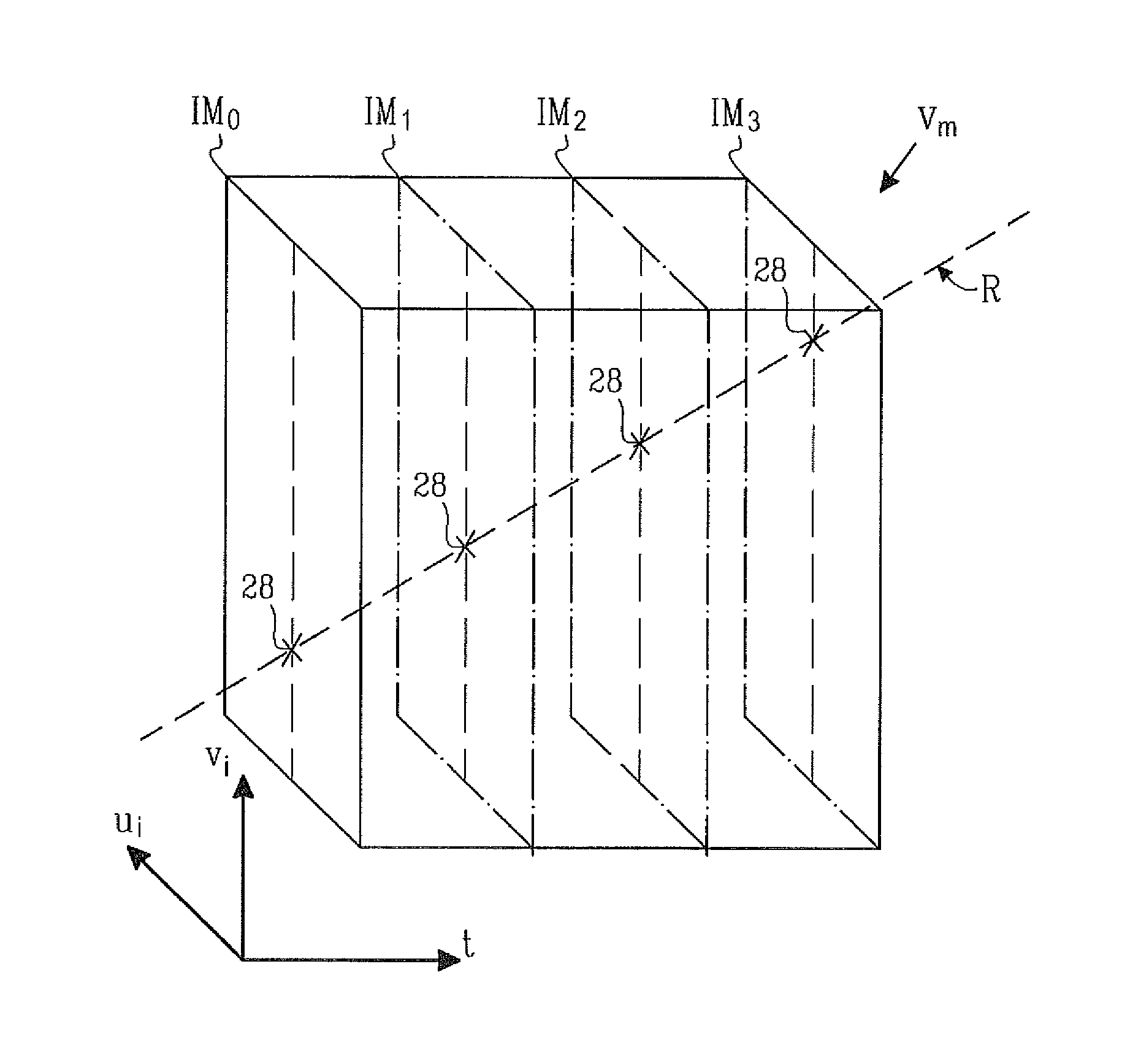

Optical triangulation

ActiveUS20100310126A1Sure easyQuality improvementCharacter and pattern recognitionUsing optical meansOptical triangulationSpacetime

The present invention relates to a method for determining the extension of a trajectory in a space-time volume of measure images. The space-time volume of measure images is generated by a measuring method utilizing a measuring system comprising a first light source and a sensor. The measuring method comprises a step of, in a predetermined operating condition of the measuring system, moving a measure object along a first direction of movement in relation to the measuring system while the first light source illuminates the measure object whereby the sensor generates a measure image of the measure object at each time instant in a set of at least two subsequent time instants, thus generating said space-time volume of measure images wherein a feature point of the measure object maps to a trajectory in the space-time volume.

Owner:SICK IVP

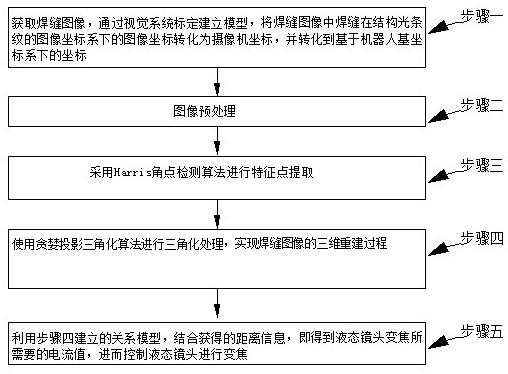

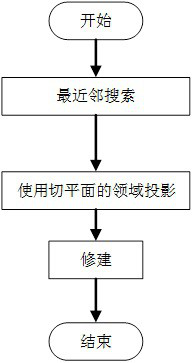

Feature extraction and three-dimensional reconstruction method of weld shape based on laser scanning

PendingCN113379902ANo damageImprove visualizationImage enhancementImage analysisOptical triangulationFeature extraction

The invention discloses a feature extraction and three-dimensional reconstruction method of a weld shape based on laser scanning, and belongs to the field of image recognition. An existing appearance detection method has the problems that information is lost in the image analysis process, and welding accuracy and efficiency are difficult to guarantee. A laser scanning-based weld shape feature extraction and three-dimensional reconstruction method comprises the following steps: designing an optical structure system according to a laser scanning principle and an optical triangulation method principle, and calculating change information of horizontal and vertical positions of a weld through a geometrical relationship; preprocessing through a welding seam recognition algorithm, and performing feature point recognition on the preprocessed welding seam image; and deriving the deviation of the actual welding seam center point according to the position change of the welding seam image center point, and restoring the whole three-dimensional image after welding by performing three-dimensional reconstruction on the identified image point cloud data. The method has the advantages of high identification accuracy and high identification efficiency.

Owner:HARBIN UNIV OF SCI & TECH

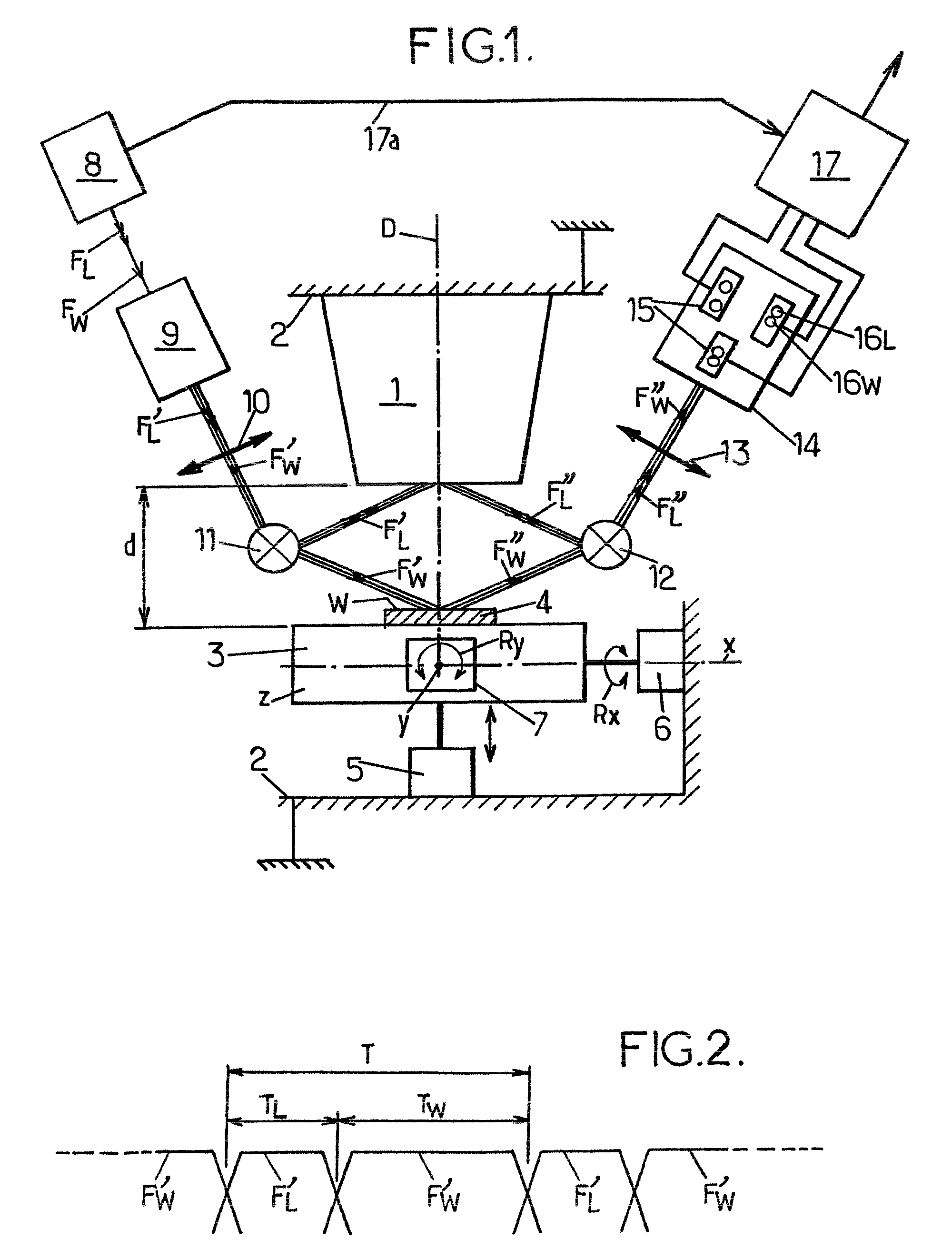

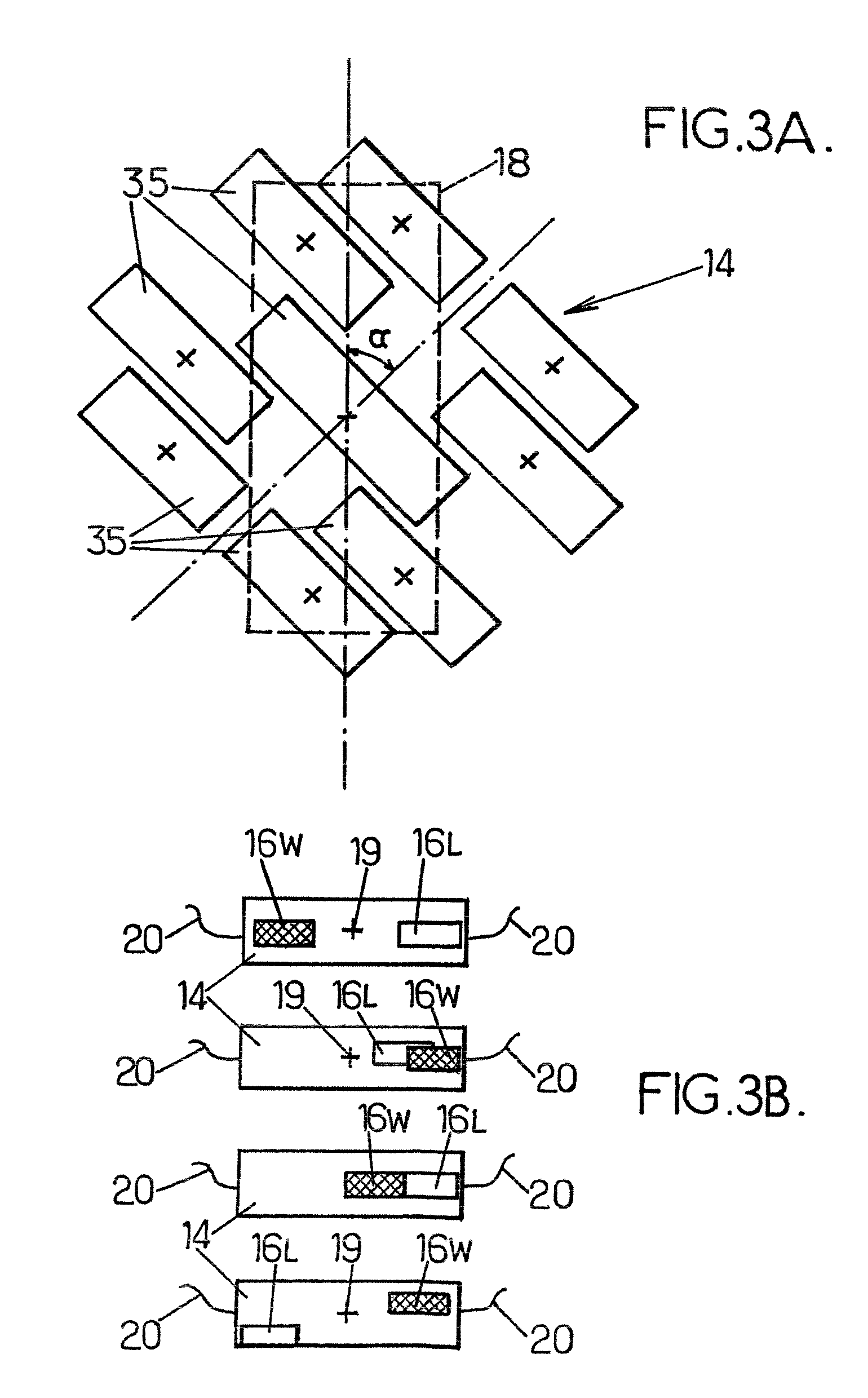

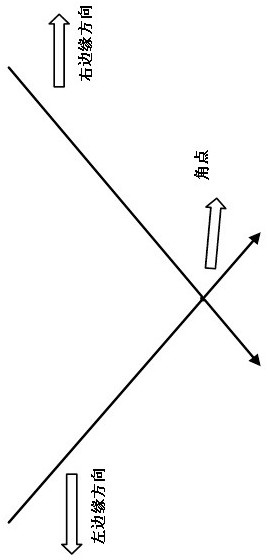

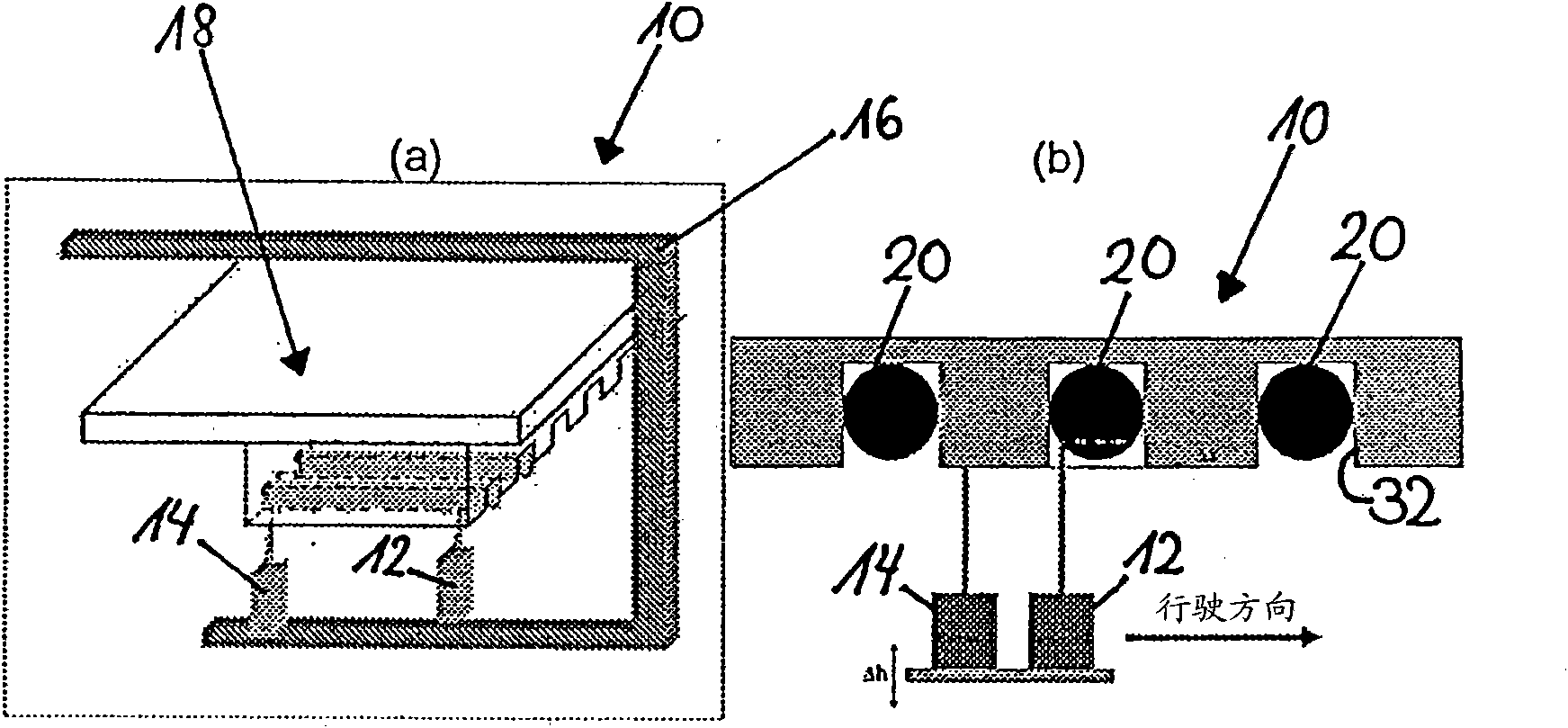

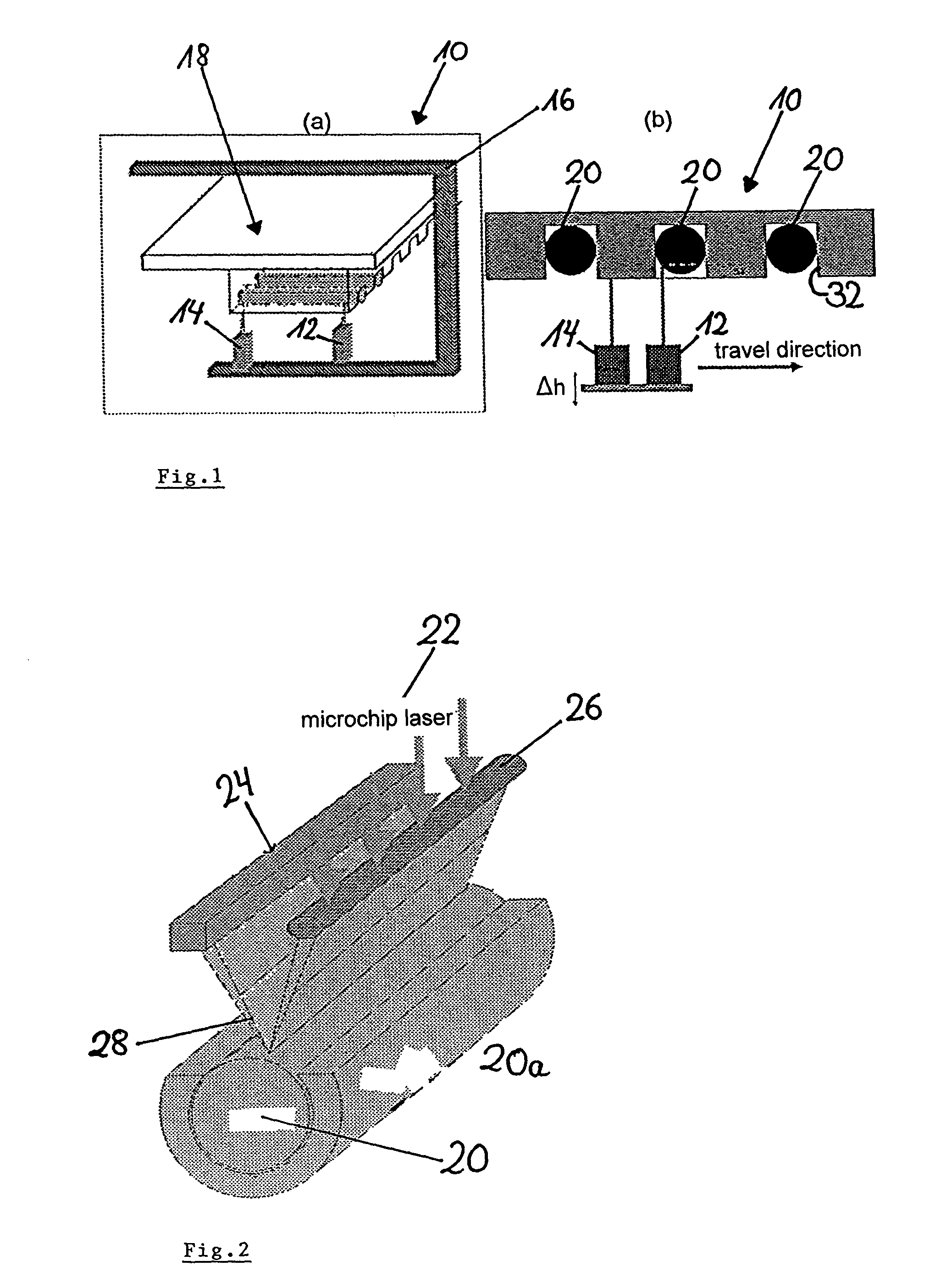

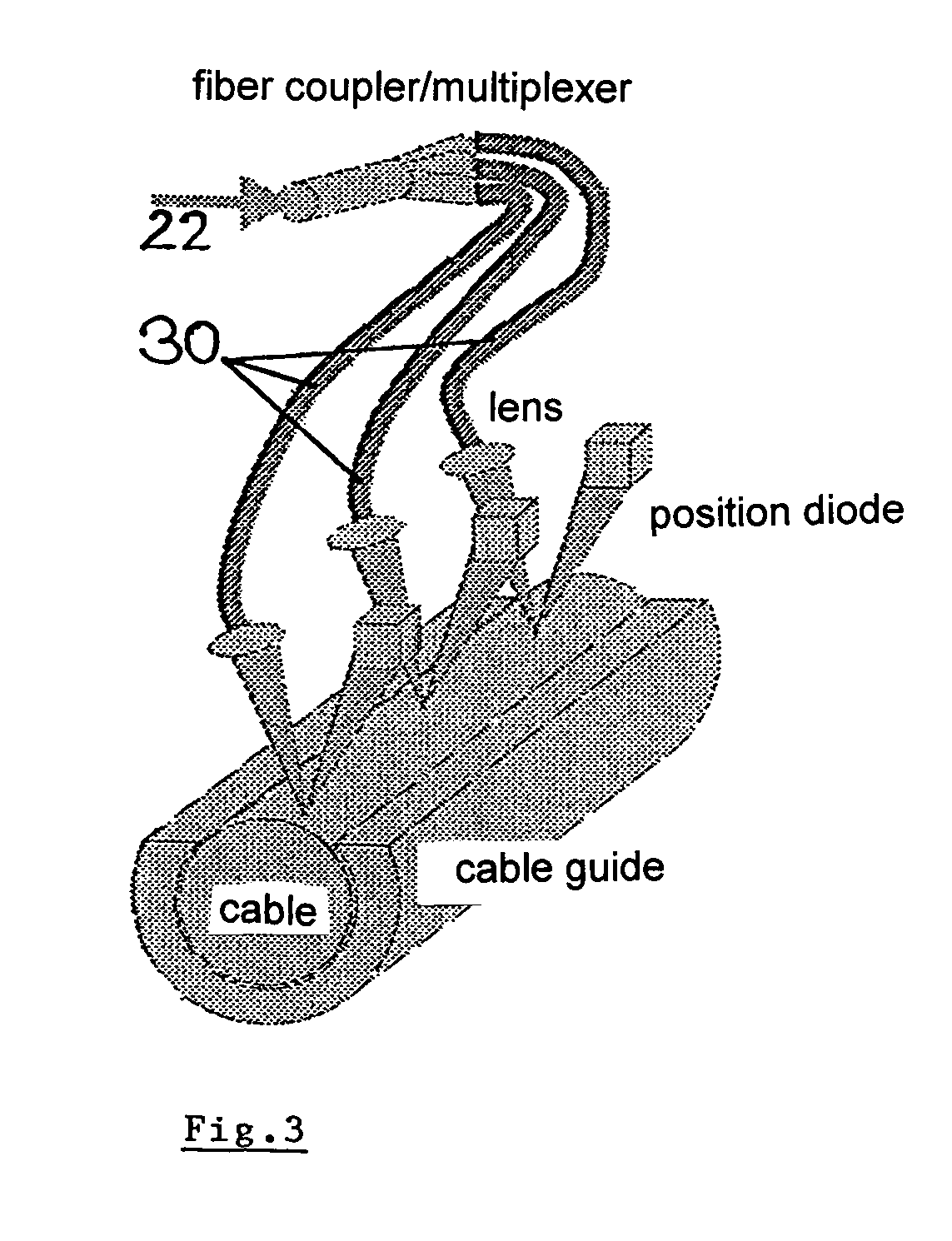

Method and apparatus for the contactless measurement of an offset of the functional components of a travel path of a magnetic levitation railway driven by a linear motor

InactiveCN101990625ARailway vehiclesManufacturing dynamo-electric machinesOptical triangulationGrating

Disclosed is a method for the contactless measurement of an offset of the functional components of a travel path of a magnetic levitation railway driven by a linear motor with the help of at least one optical triangulation system (10) that can be moved along the travel path. Said method is characterized in that at least two triangulation sensors (12, 14) per measuring instrument for the functional components are moved along the travel path at a determined speed and alternately operate as a measurement sensor and as a reference sensor, i.e. using a radiation source in the ultraviolet, visible, or infrared spectral range, said triangulation sensors (12, 14) being fixedly mounted on a movable support (16) and being geometrically offset. In said method, the diffusely reflected light is absorbed at a specific angle of observation, and the position of the light incident on the measurement sensor is used for determining the offset, said process being carried out at a scanning rate that detects measurement points within a screen of < 1.5 mm.

Owner:DRAKA IND CABLE

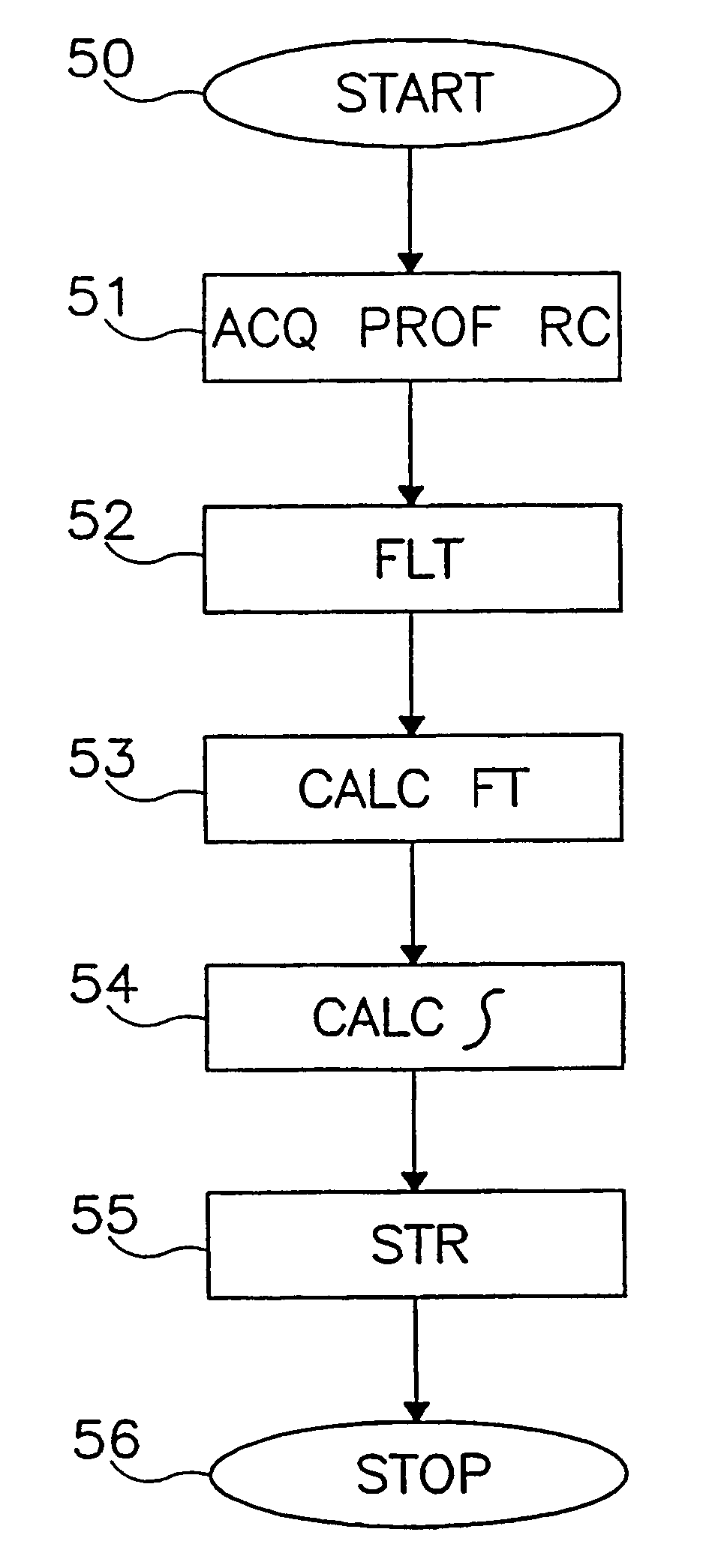

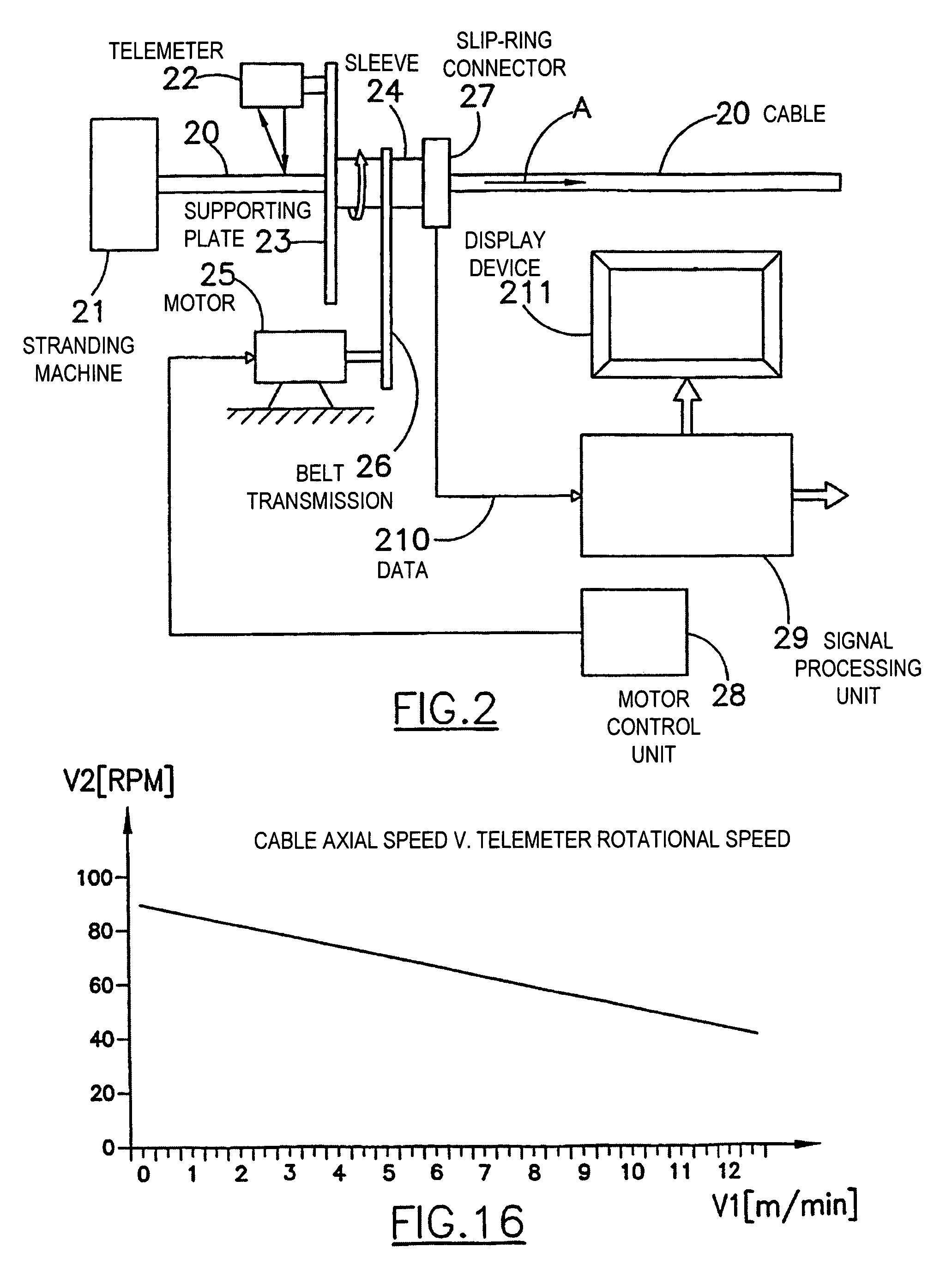

Method and apparatus for monitoring cable stranding

InactiveUS7634372B2Accurate monitoringHigh resolutionSpectral/fourier analysisMaterial analysis by optical meansOcean bottomOptical triangulation

A method and a related apparatus for monitoring an external surface of stranded cables, such as submarine cables for optical telecommunications, and electrical energy cables, provide for telemetrically acquiring a profile of the cable external surface by means of a laser optical triangulation technique, obtaining a spectrum of the telemetrically-acquired profile and comparing the obtained spectrum to a previously measured reference spectrum corresponding to a cable free of defects, thereby deducing the presence of defects by differences in the spectra.

Owner:PRYSMIAN CAVI E SISTEMI ENERGIA

Positioning device for an optical triangulation sensor

ActiveUS9013716B2Increase rangeAccurate locationOptical rangefindersUsing optical meansOptical triangulationLight beam

The invention provides a positioning device for locating a planar light beam emitted by an optical triangulation sensor across a diameter of a hole formed in a surface of an object. The positioning device has an adjustable guiding element which is capable of locating an optical triangulation sensor at the same distance away from holes have a range of diameters. The guiding element is movably mounted relative to a platform that is fixed to the optical triangulation sensor. The guiding element comprises a body which is insertable into the hole, the body having a pair of contact surfaces for contacting diametrically opposed portions of the hole, the pair of contact surfaces being opposed to each other in a direction orthogonal to the plane of the planar light beam.

Owner:THIRD DIMENSION SOFTWARE

Contactless measurement of an offset of the functional components of a travel path of a magnetic levitation railway

InactiveUS8358423B2Broaden the field of applicationImprove precisionRadiation pyrometryRailway vehiclesOptical triangulationMeasurement point

Disclosed is a method for the contactless measurement of an offset of the functional components of a travel path of a magnetic levitation railway driven by a linear motor with the help of at least one optical triangulation system (10) that can be moved along the travel path. Said method is characterized in that at least two triangulation sensors (12, 14) per measuring instrument for the functional components are moved along the travel path at a determined speed and alternately operate as a measurement sensor and as a reference sensor, i.e. using a radiation source in the ultraviolet, visible, or infrared spectral range, said triangulation sensors (12, 14) being fixedly mounted on a movable support (16) and being geometrically offset. In said method, the diffusely reflected light is absorbed at a specific angle of observation, and the position of the light incident on the measurement sensor is used for determining the offset, said process being carried out at a scanning rate that detects measurement points within a screen of <1.5 mm.

Owner:DRAKA IND CABLE

Optical triangulation measurement apparatus and method

PendingUS20220082372A1Facilitated DiffusionQuantity minimizationTelevision system detailsImage analysisOptical triangulationTriangulation

An apparatus and method for inspecting an object by optical triangulation, where the signal of interest in a captured image corresponds to an interaction between a light beam and an environment surrounding the object rather than between a light beam and the object itself. The surrounding environment may be configured to interact in a manner that is detectable by filling it with a flowable scattering medium, e.g. a gas, mist or vapour comprising a suspension of fine particles in air. Light that is scattered by the flowable scattering medium is visible in a captured image. Where the flowable scattering medium is not present, e.g. because the object blocks it, the scattered signal is less. A boundary of a scattered signal region may thus provide information about the location of an object.

Owner:THIRD DIMENSION SOFTWARE

Optical triangulation device and method of measuring a variable of a web using the device

InactiveUS7345772B2Avoid inaccuraciesHigh-frequency variationMaterial analysis by optical meansUsing optical meansOptical triangulationEngineering

Device and method of measuring a position of an irregular surface. The method includes projecting a spot along a first axis onto the irregular surface, focusing an image of the spot along a second axis onto a detector, wherein the second axis is non-coaxially arranged with respect to the first axis, processing signals from the detector, and calculating the position of the irregular surface based on at least one isolated desired frequency component of the signals.

Owner:VOITH PATENT GMBH

Positioning device for an optical triangulation sensor

ActiveUS10209361B2Quick and efficientQuickly and repeatably mountOptical rangefindersMachines/enginesOptical triangulationTurbine blade

A tool or attachment jig for mounting an optical triangulation sensor on a turbine blade in a position to measure the gap between the distal tip of the turbine blade and the adjacent shroud. The tool includes a device for indicating the orientation of the sensor. This means that the tool can match a measurement from the optical triangulation sensor with a position on the circumference of the shroud. By taking a plurality of measurements as the turbine blade is rotated with respect to the annular casing, an angular profile for the gap between the turbine blade and the casing can be obtained in a much quicker and more efficient way than a conventional system.

Owner:THIRD DIMENSION SOFTWARE

Optical thread profiler

An apparatus configured to measure at least one physical characteristic of a threaded surface (e.g., an internally threaded surface) of an object is provided. The apparatus uses optical triangulation to perform non-contact characterization of the threaded surface. The apparatus can be used to characterize various aspects of the threaded surface, including generating the measurements required to produce a longitudinal cross-sectional profile of the threaded surface.

Owner:QUEST INTEGRATED LLC

Product quality testing method and device

ActiveCN109829883BReduce computing pressureImprove accuracyImage analysisCharacter and pattern recognitionOptical triangulationProcess engineering

Owner:GEER TECH CO LTD

High-precision laser displacement sensor that can prompt the focus direction

ActiveCN104197845BHigh measurement accuracyEasy to implementUsing optical meansOptical triangulationBeam splitter

The invention provides a high-precision laser displacement sensor capable of prompting the focus direction, which belongs to the technical field of machinery. It solves the problems of cumbersome adjustment and low adjustment accuracy of existing sensors. The high-precision laser displacement sensor that can prompt the focus direction includes a housing, and the housing is connected with a dual-frequency laser, beam splitter 1, field mirror and photocell, and the beam splitter 1 is used to receive the output from the dual-frequency laser. Laser, the housing also has a triangular ranging sensor mechanism for receiving one of the light beams at the light output end of the beam splitter, and an off-axis beam displacement sensor mechanism for receiving the other beam at the light output end of the beam splitter. The triangular ranging sensing mechanism can detect whether the light beam reflected by the measured object can be projected, and the above-mentioned off-axis beam displacement sensing mechanism can make the light beam reflected by the measured object enter the photocell to form a light spot through the field mirror. The sensor is easy to adjust and has high precision.

Owner:海宁科海光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com