Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Multidimensional model" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A multidimensional model is composed of cubes and dimensions that can be annotated and extended to support complex query constructions. BI developers create cubes to support fast response times, and to provide a single data source for business reporting.

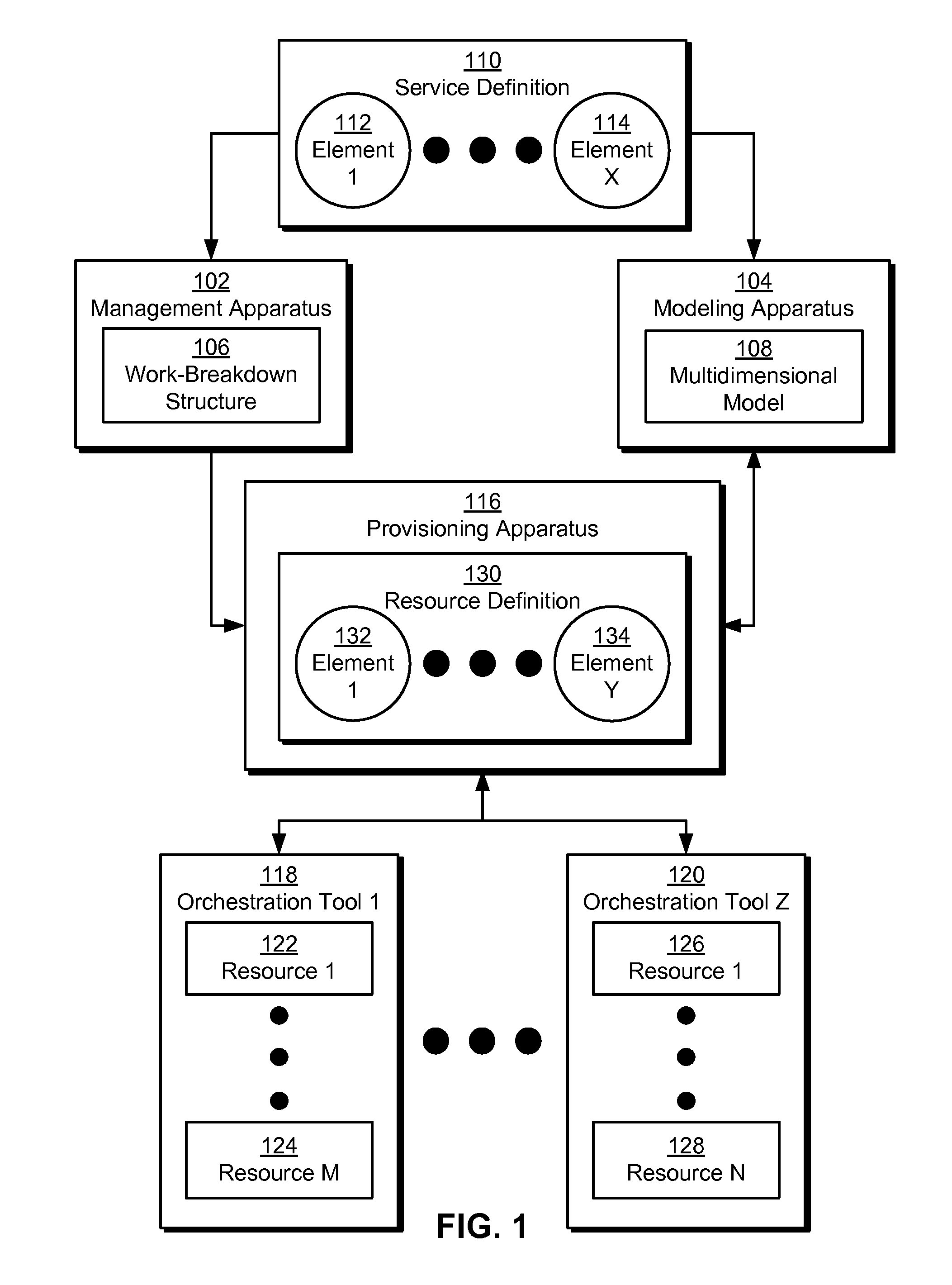

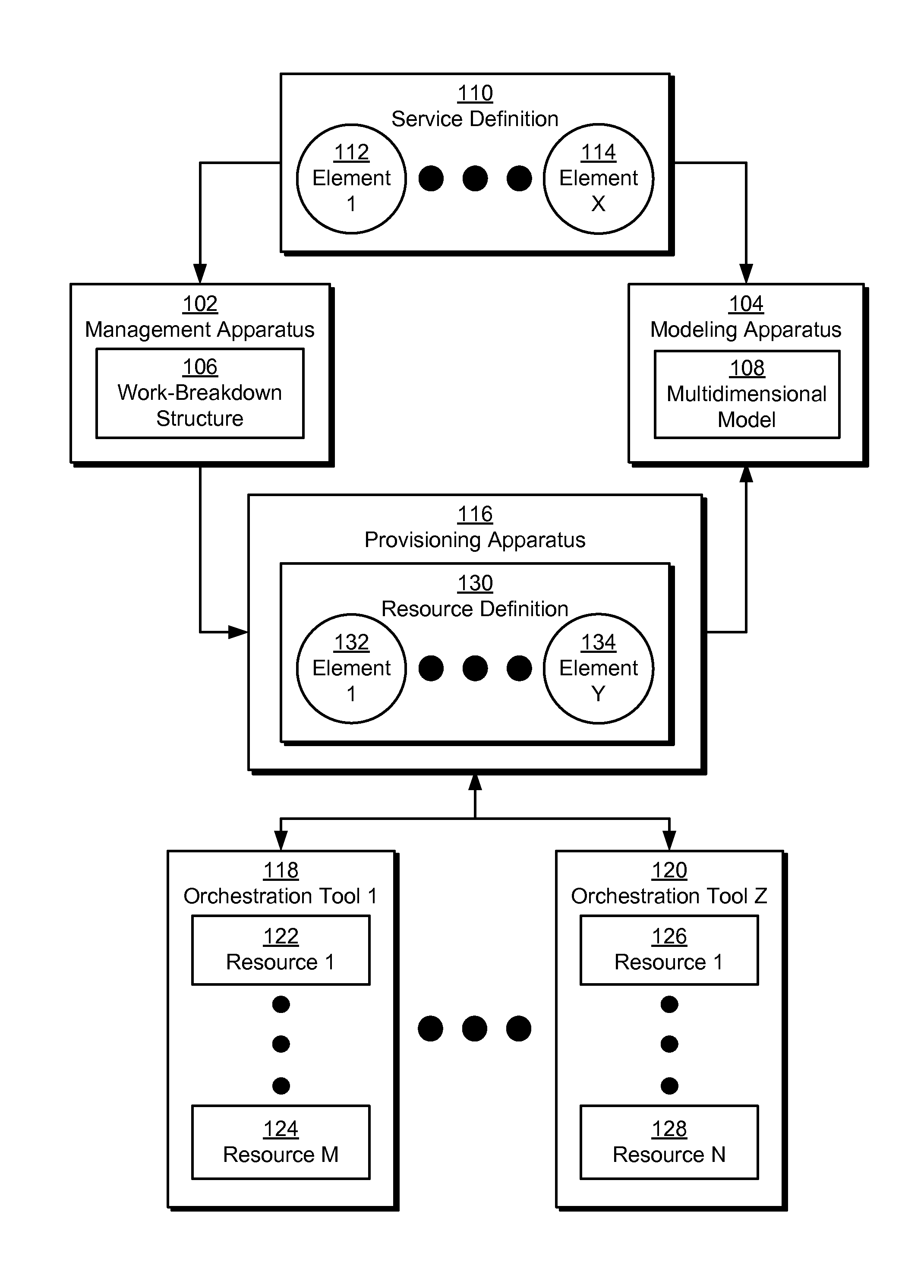

Multidimensional modeling of software offerings

ActiveUS20120215919A1Easy to deploySimple to executeDigital computer detailsProgram controlMultidimensional scalingSoftware engineering

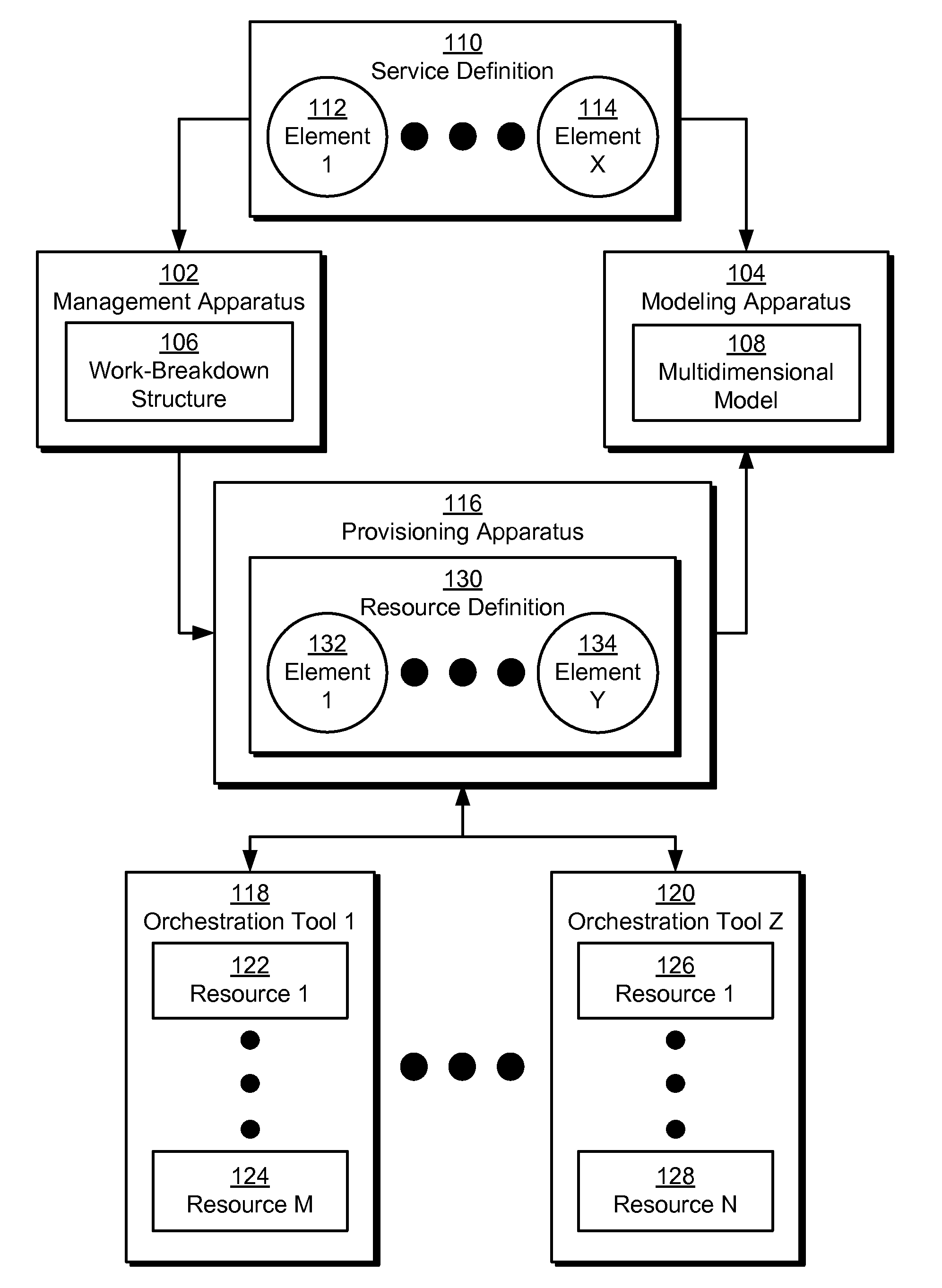

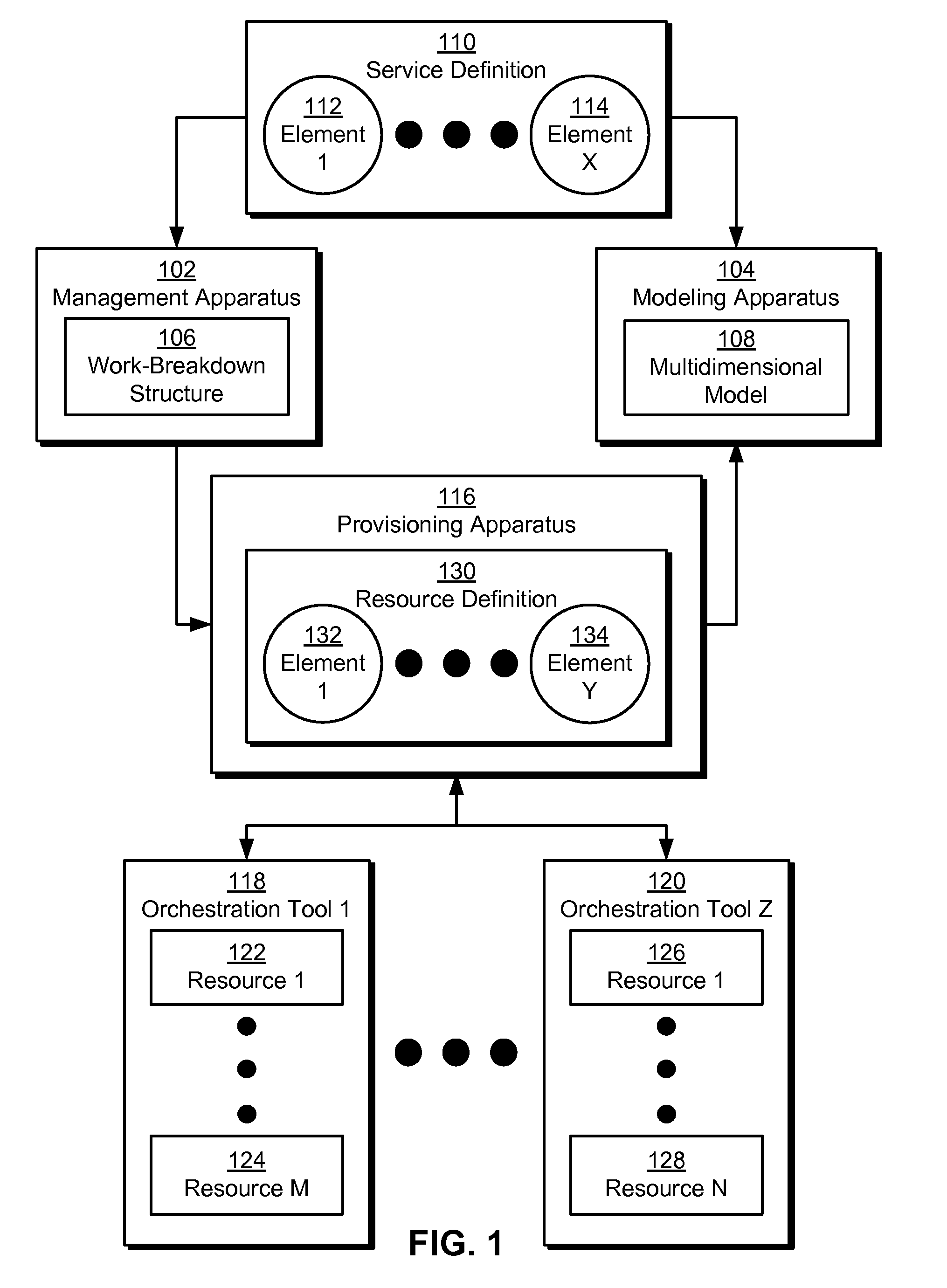

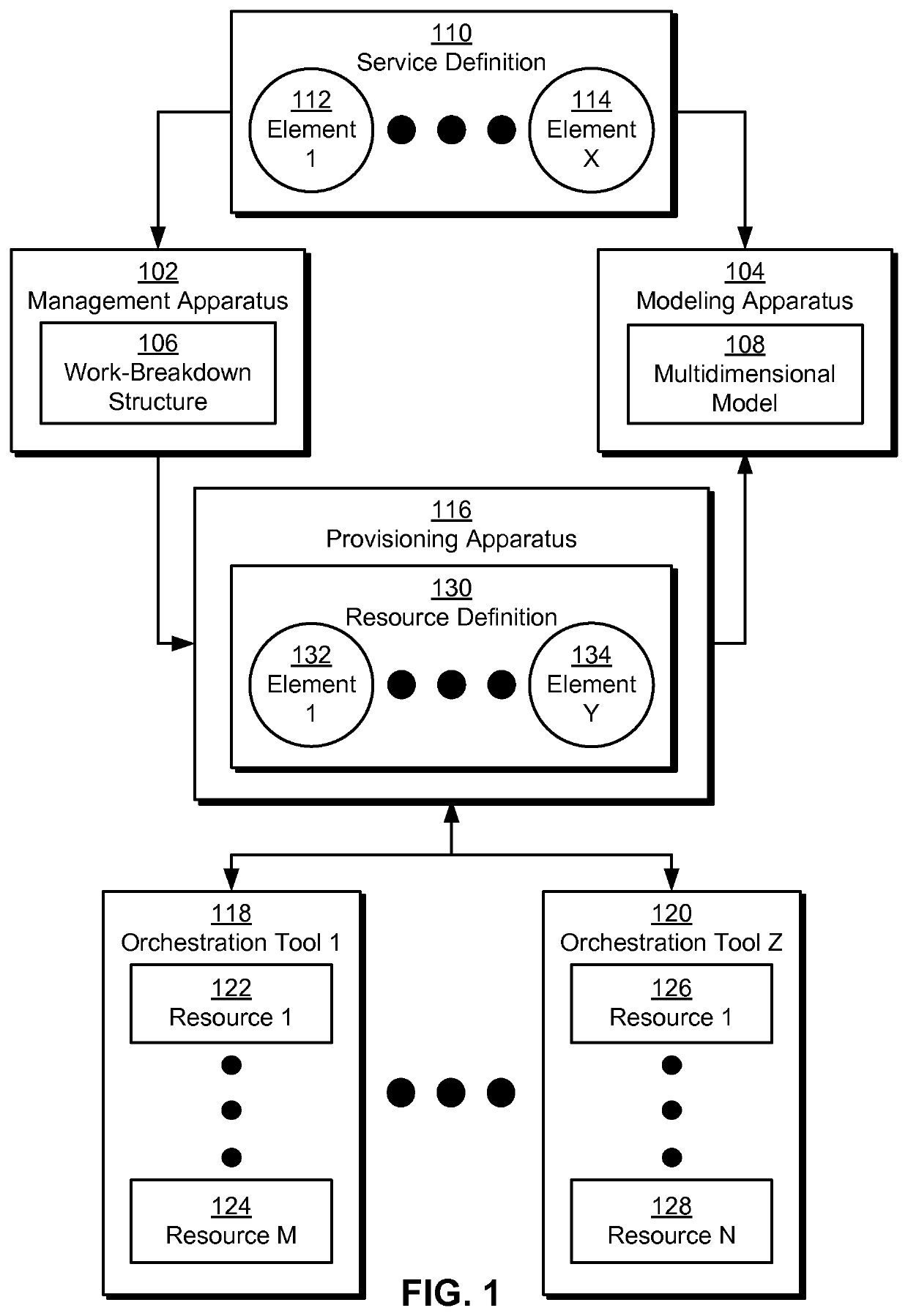

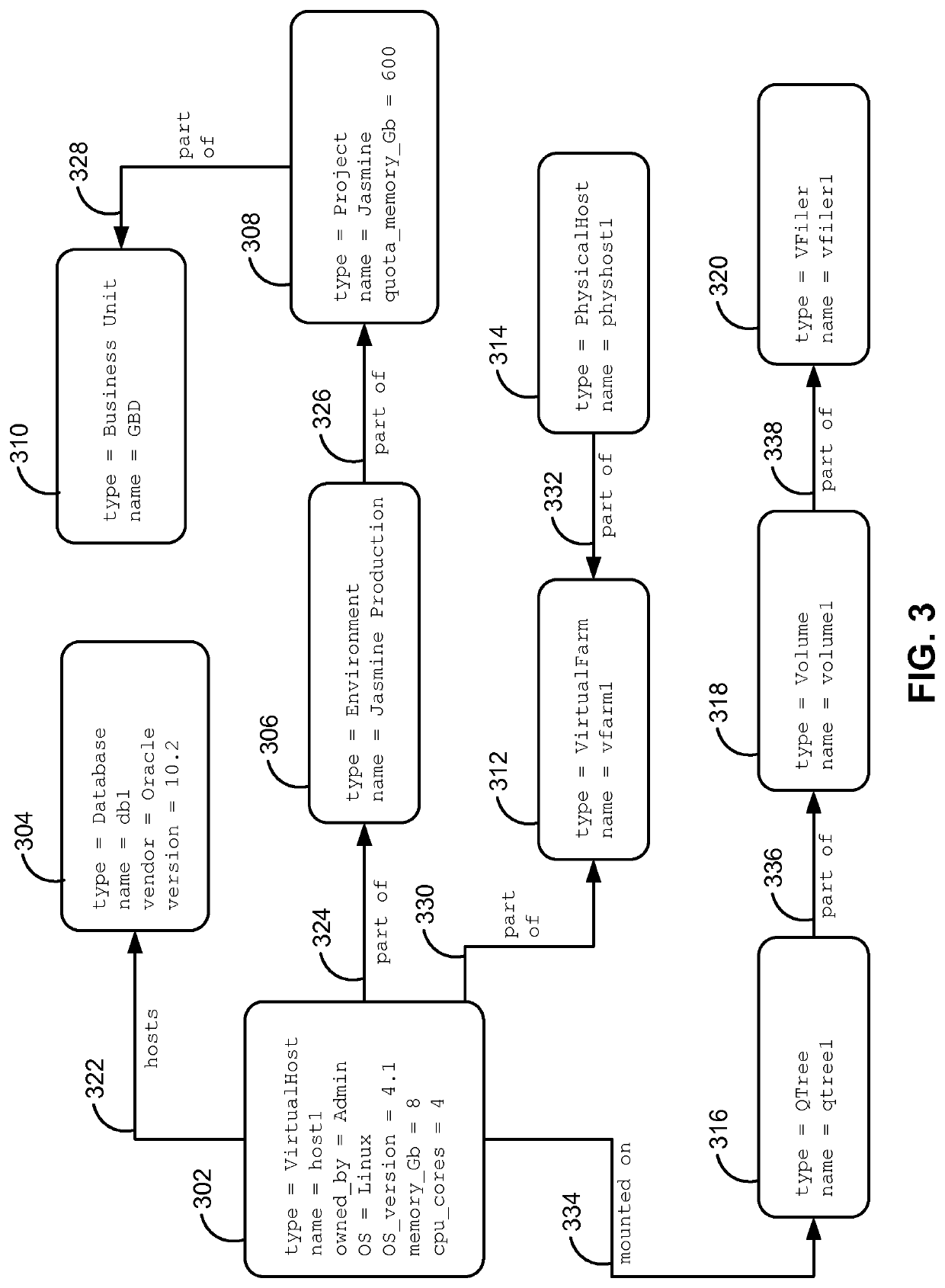

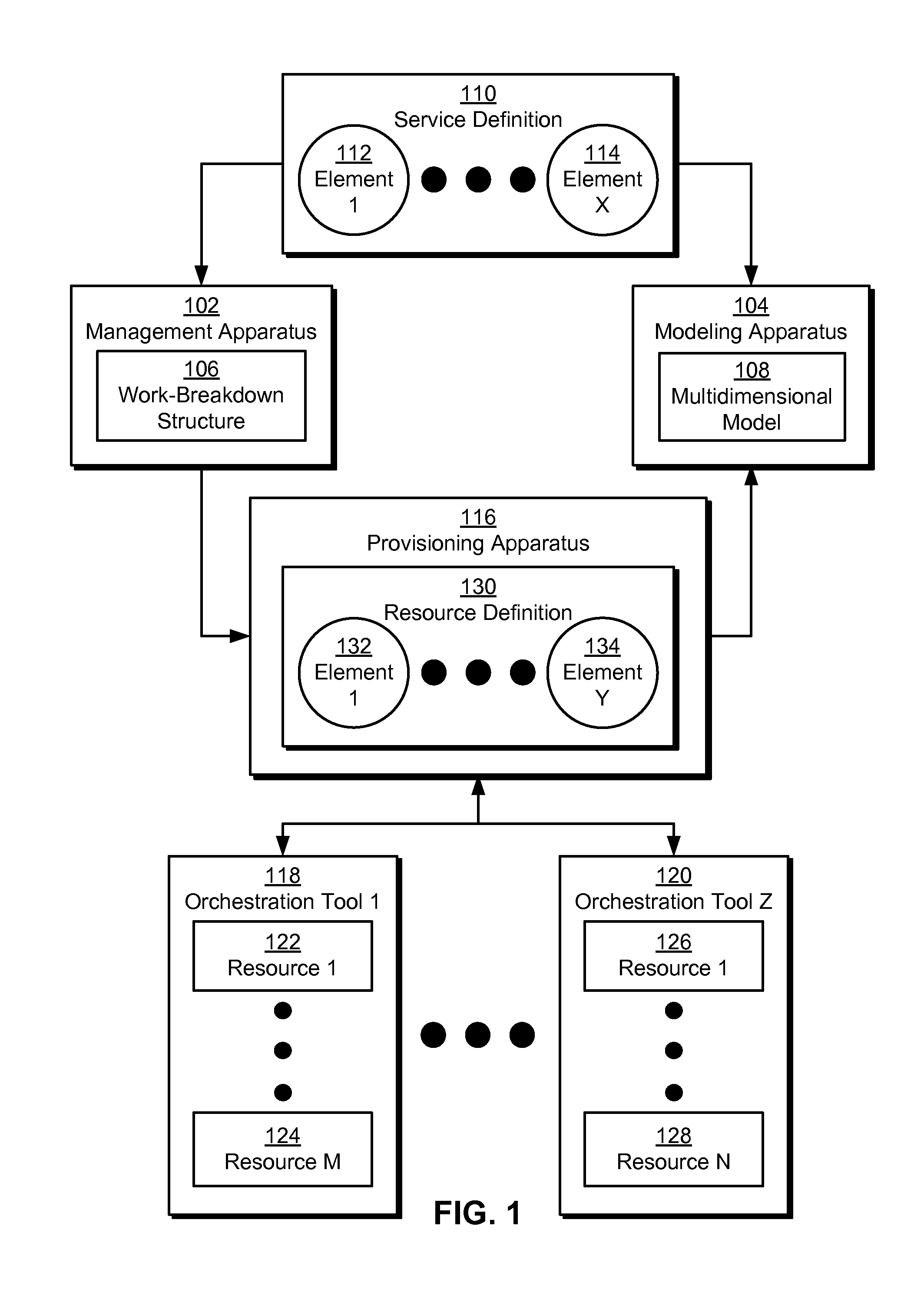

The disclosed embodiments provide a system that facilitates the deployment and execution of a software offering. During operation, the system obtains a service definition of the software offering and a resource definition of resources available for use by the software offering. Next, the system creates a multidimensional model of the software offering by mapping a first set of elements from the service definition to a second set of elements from the resource definition. Finally, the system uses the multidimensional model to manage the deployment and execution of the software offering without requiring manual configuration of the resources by a user.

Owner:INTUIT INC

Method and system for mapping multi-dimensional model to data warehouse schema

InactiveUS8099382B2Reduce complexityReduce probabilityDigital data processing detailsMulti-dimensional databasesData warehouseAnalysis data

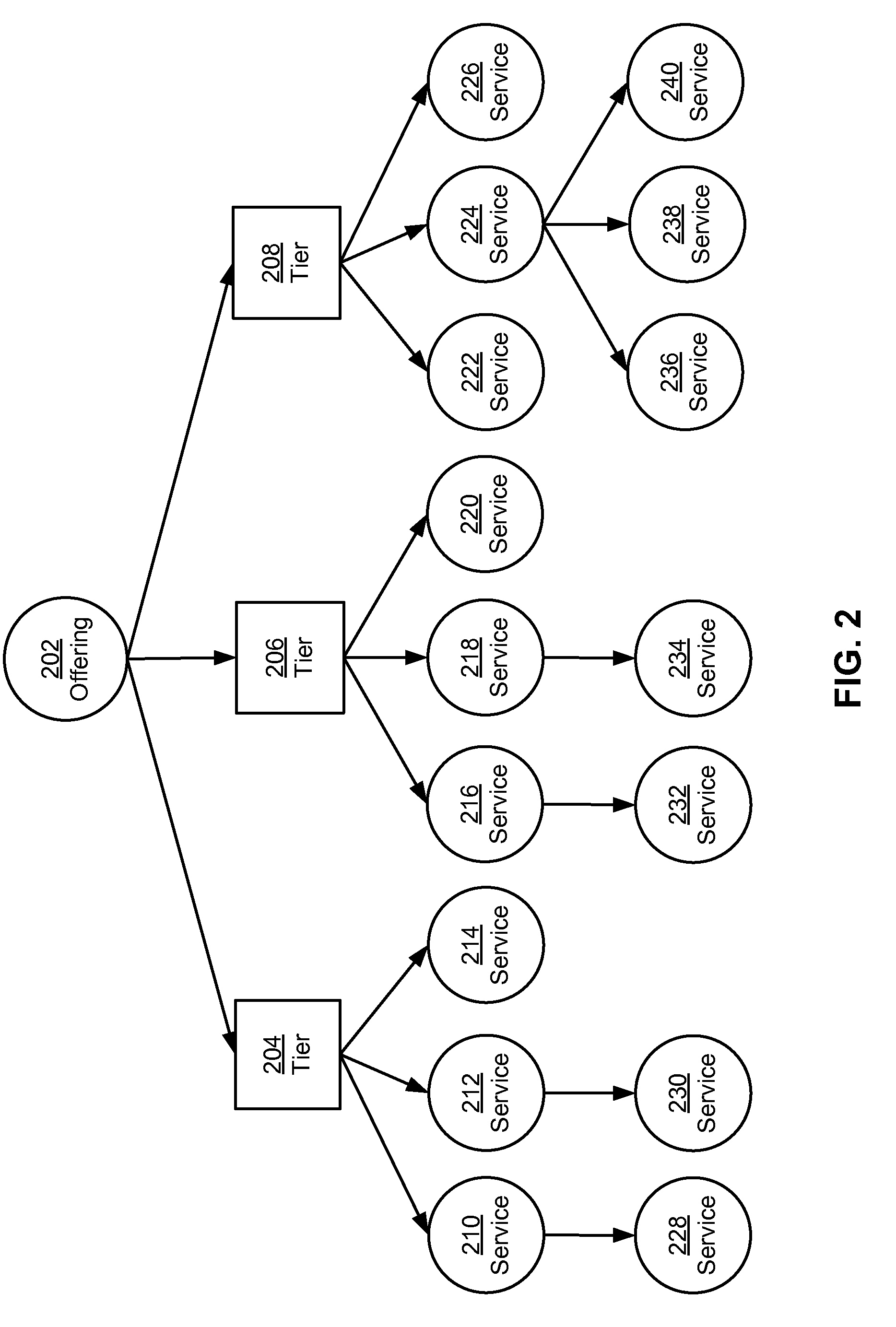

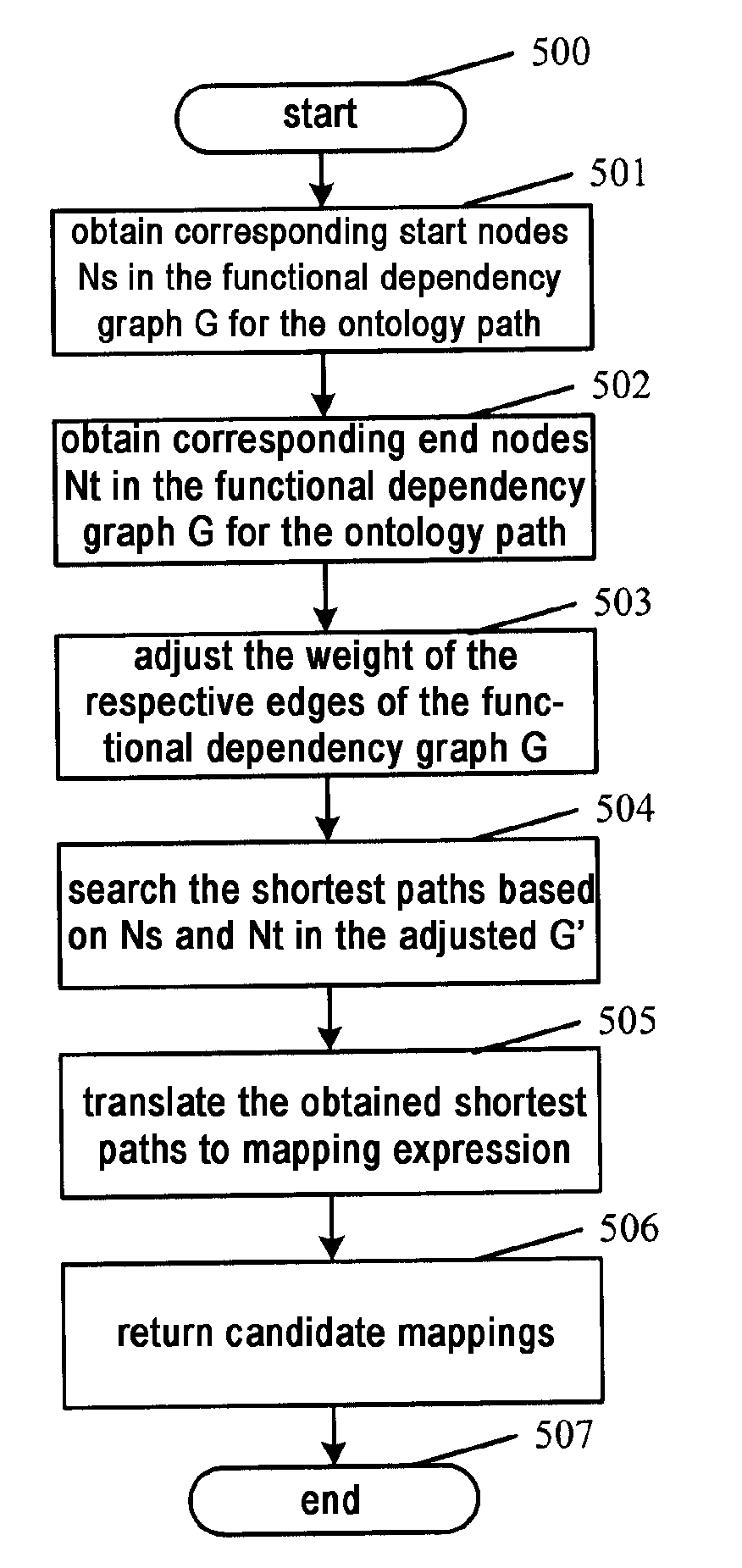

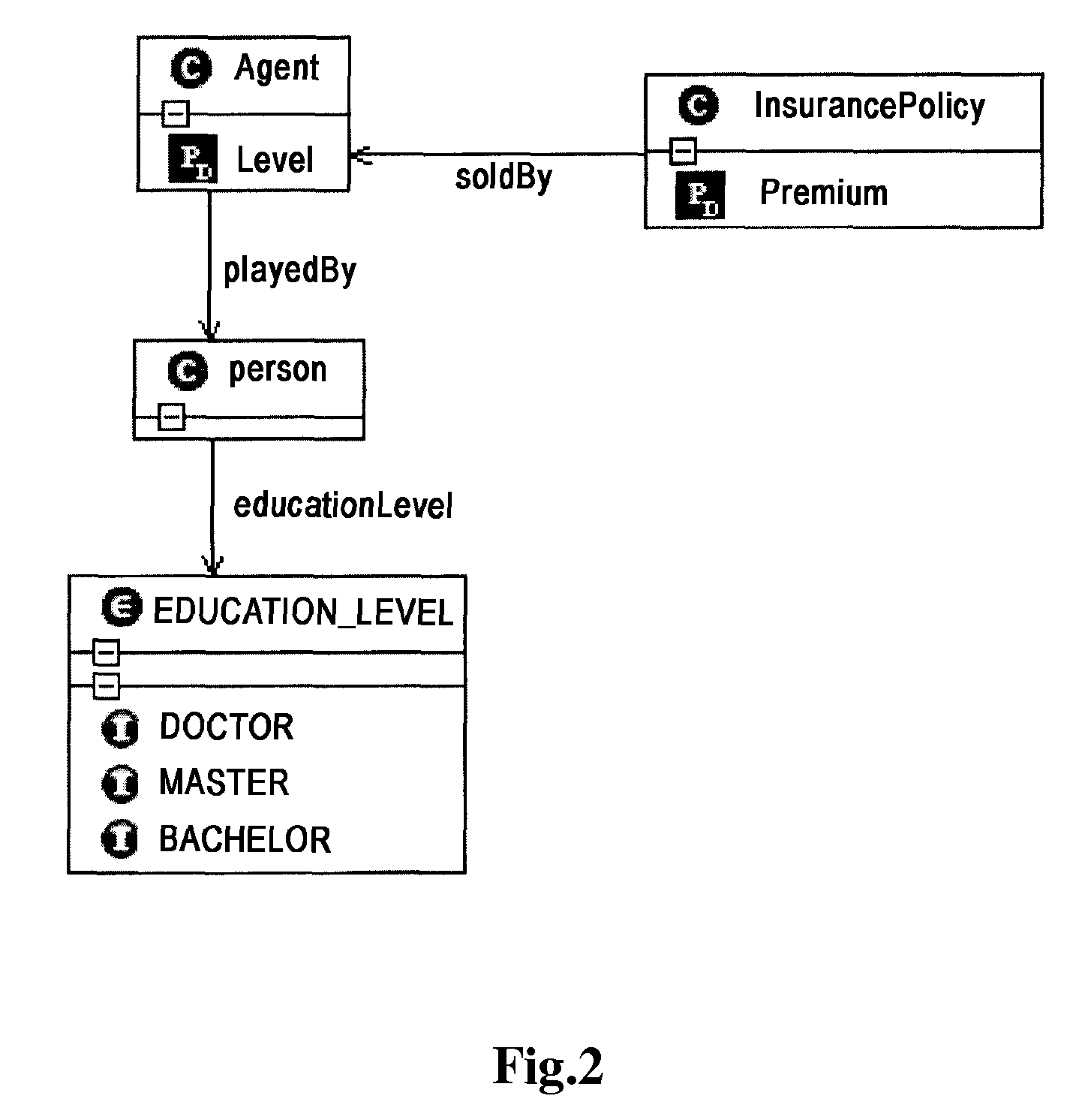

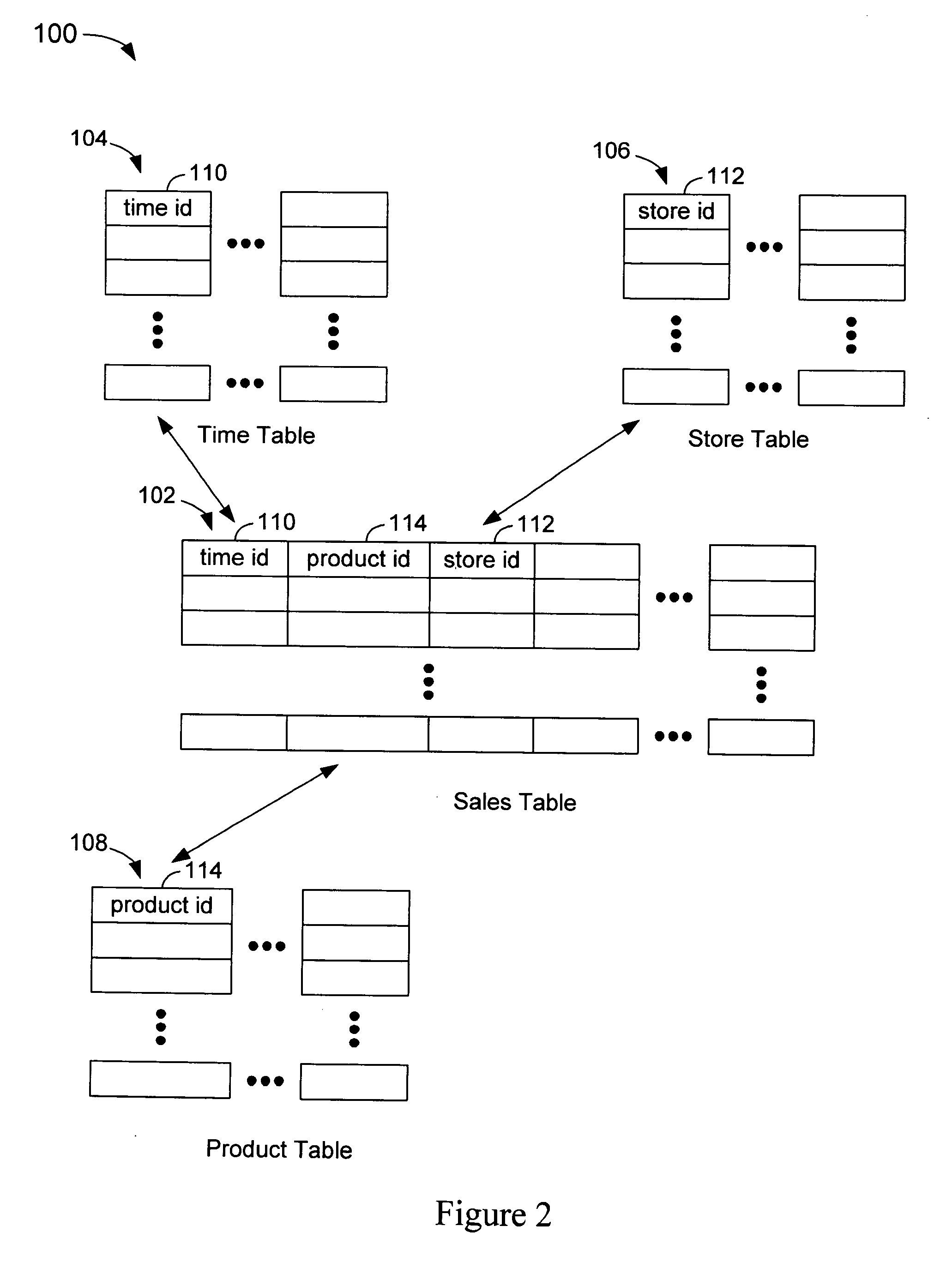

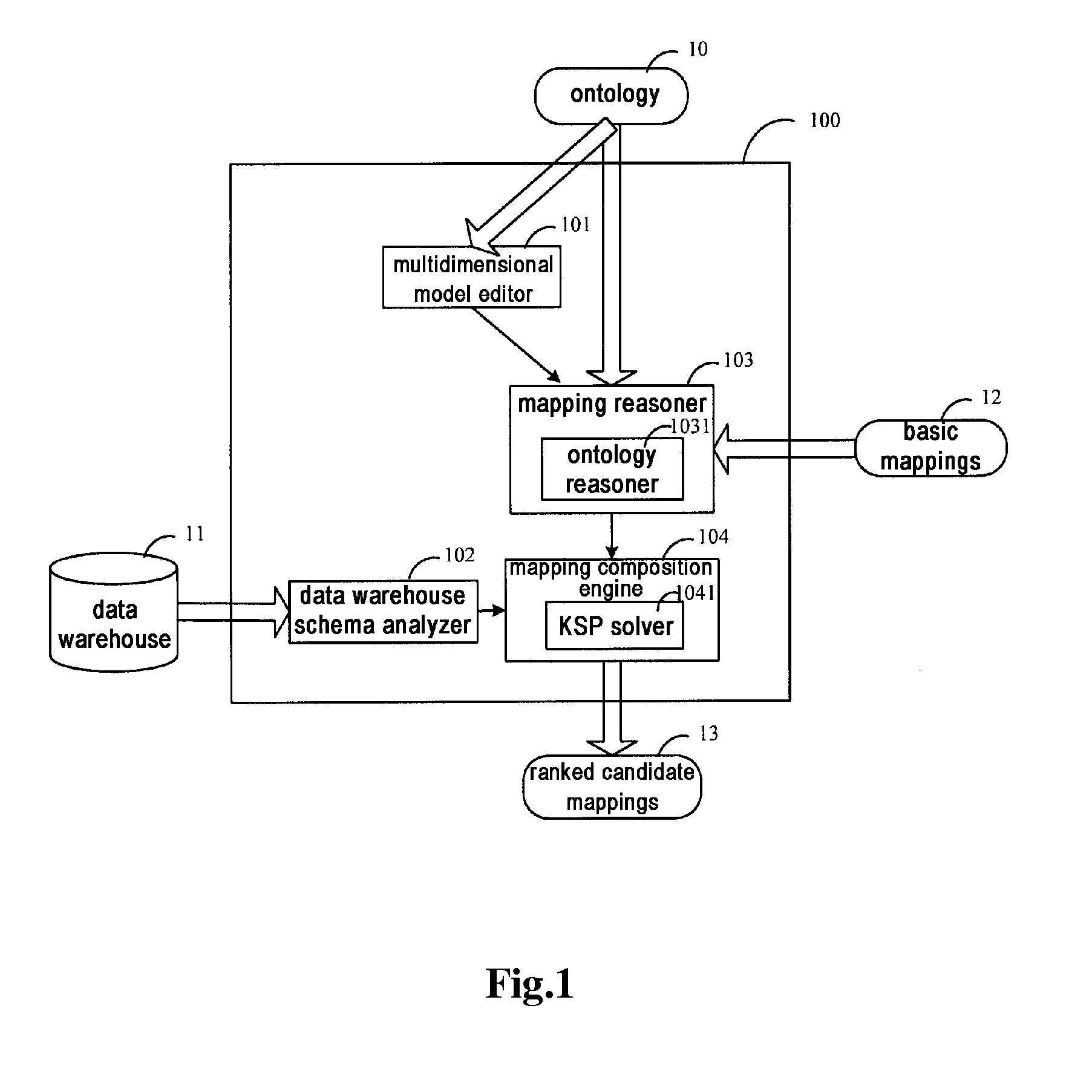

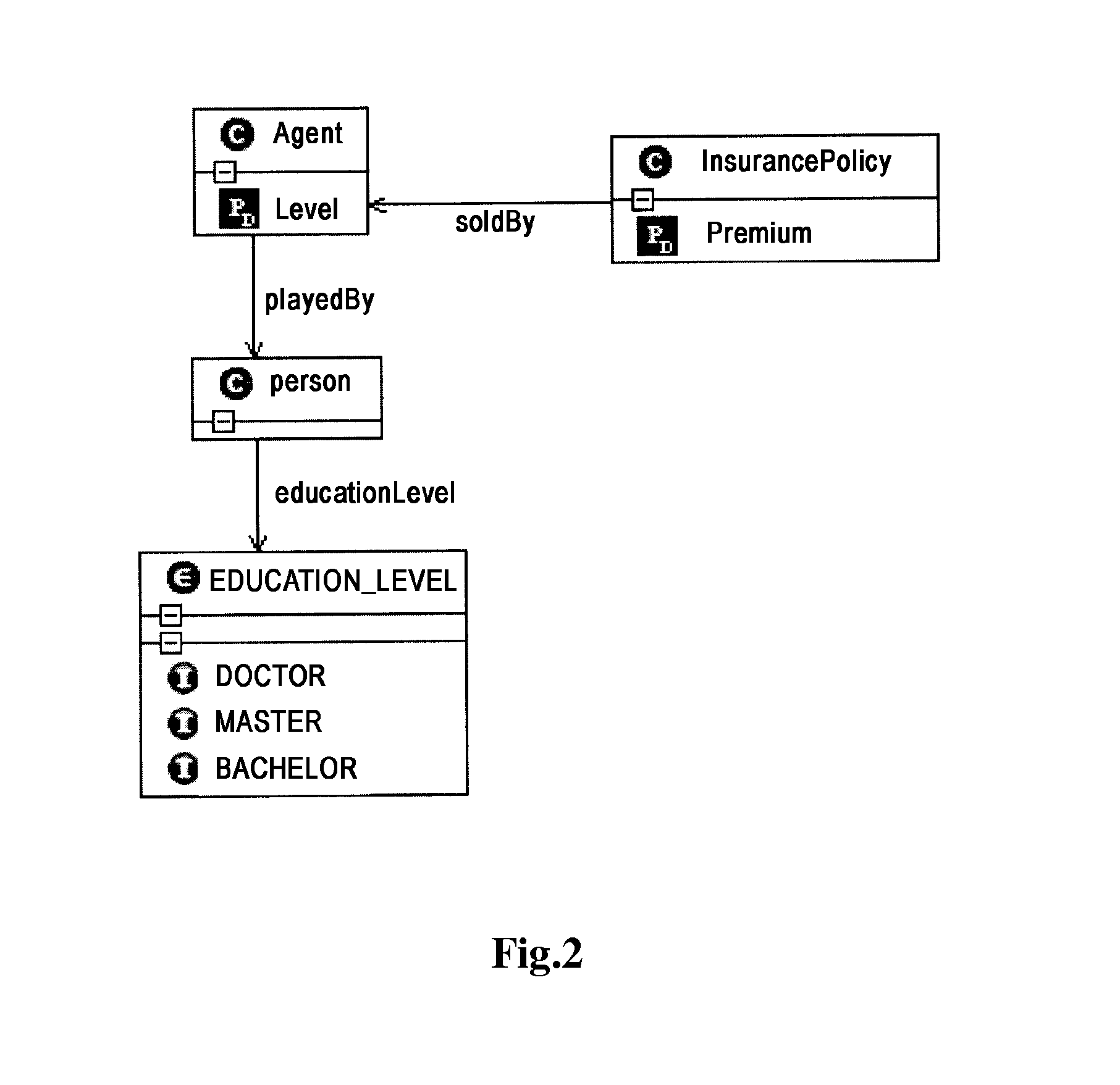

A system maps a multidimensional model to data warehouse schema. The system includes a multidimensional model editor for defining a multidimensional model based on a conceptual model; a mapping reasoner for generating more simple mappings from basic mappings by reasoning on the conceptual model so as to provide mappings for concerning elements in an ontology path in the multidimensional model; a data warehouse schema analyzer for generating a data structure capable of indicating information of the data warehouse schema by making an analysis on the information of the data warehouse schema; and a mapping composition engine for generating result mappings according to mappings for the concerning elements of the ontology path in the multidimensional model and by searching in the data structure paths corresponding to the concerning elements of the ontology path in the multidimensional model. A method and computer program product are also disclosed.

Owner:IBM CORP

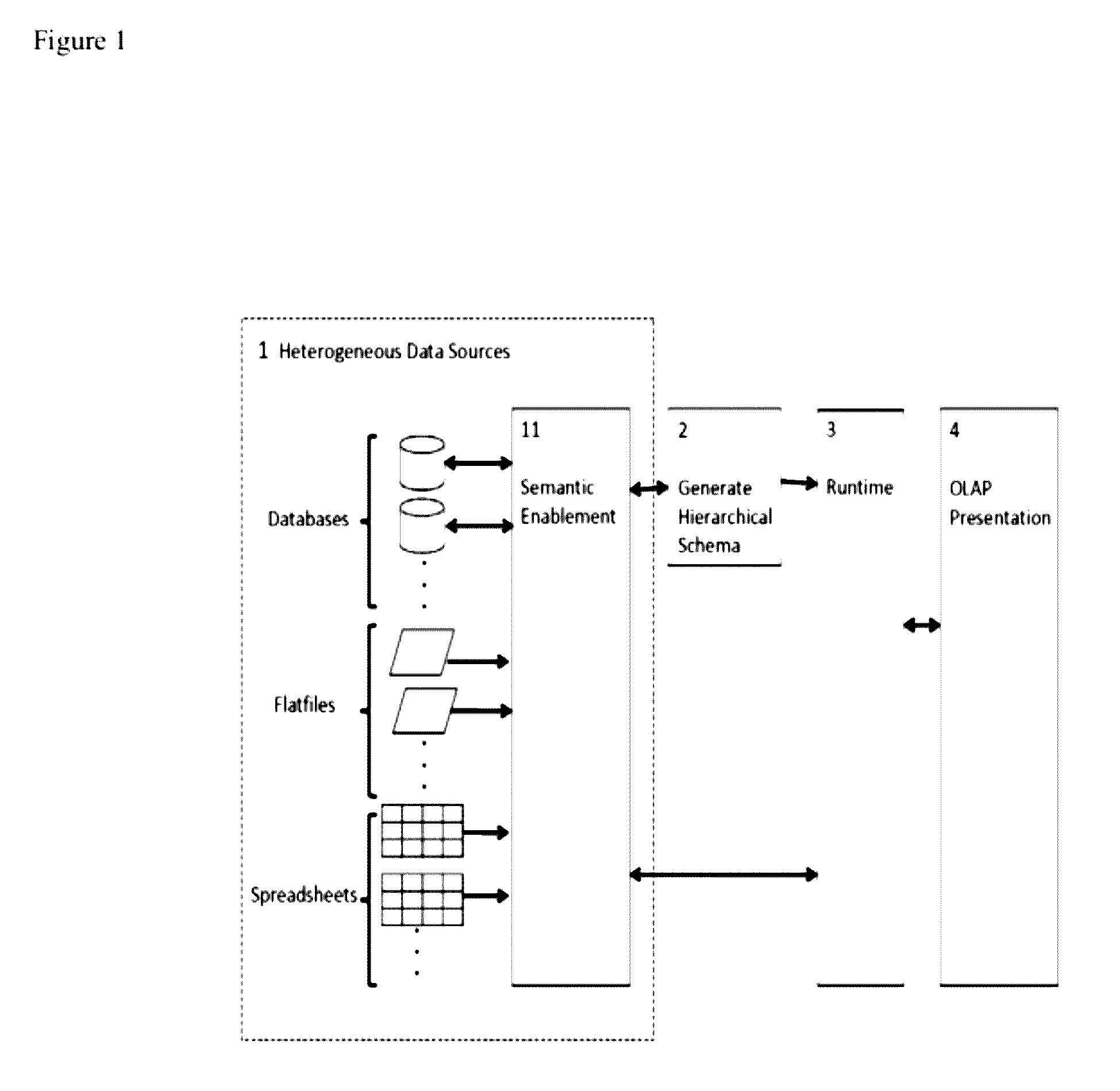

Automatic synthesis and presentation of OLAP cubes from semantically enriched data sources

ActiveUS9495429B2Digital data processing detailsMulti-dimensional databasesData sourceMulti dimensional data

This system comprises methods that simplify the creation of multidimensional OLAP models from one or more semantically enabled data sources. The system also comprises methods enabling interoperability between existing OLAP end-user interfaces, the system's representation of OLAP and the underlying data sources. This includes web-enabled OLAP interfaces.

Owner:MIRANKER DANIEL PAUL

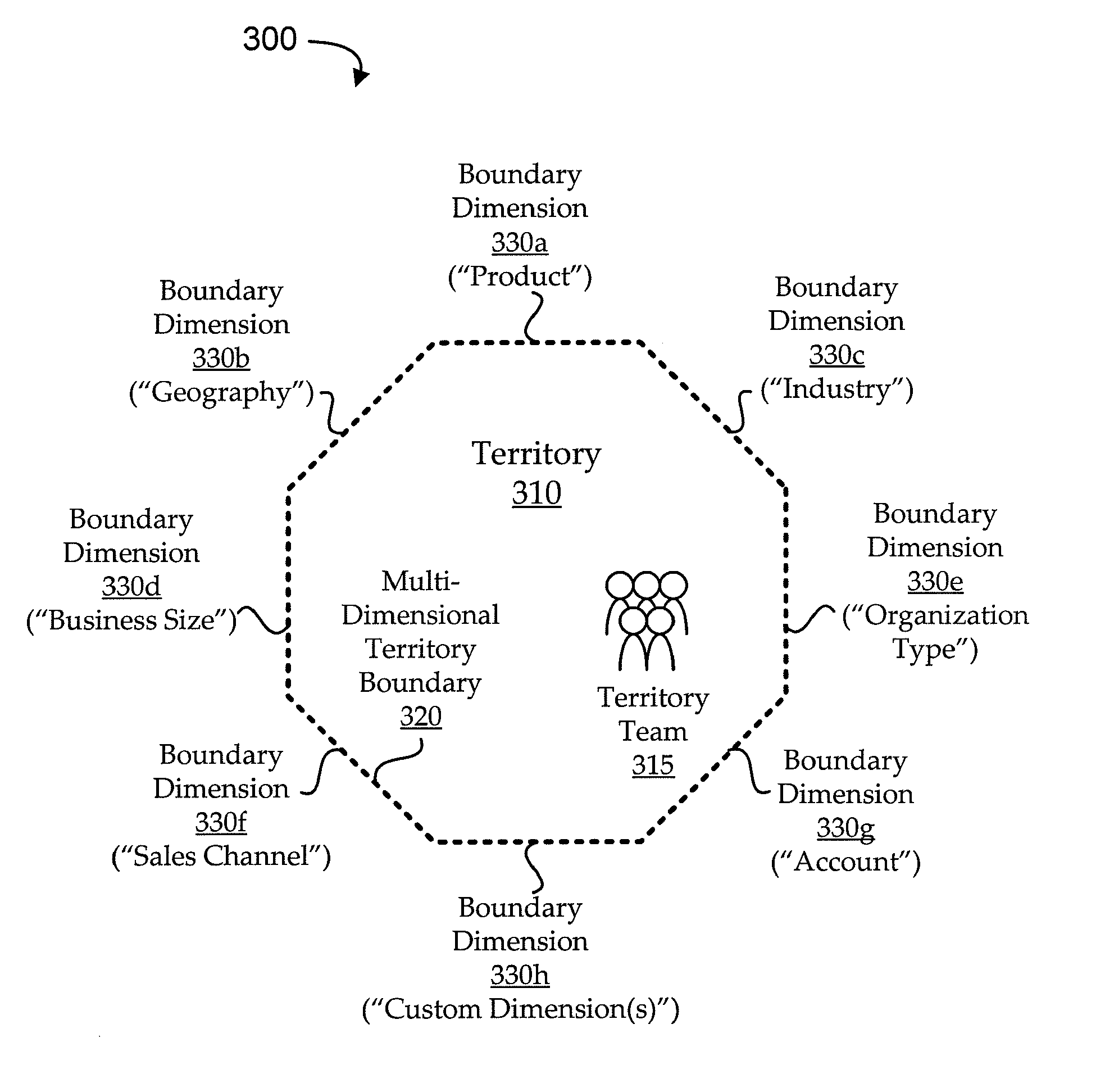

Reassignment and reconciliation for multi-dimensional sales territories

InactiveUS20110040697A1Minimizing and eliminating needImprove efficiencyResourcesData miningMulti dimensional

Embodiments of the invention provide systems and methods for using multi-dimensional modeling techniques to handle gaps, overlaps, and reassignments of opportunities for sales territory management. Embodiments use multi-dimensional modeling to define territories in such a way that accounts for applicable territory criteria as sets with logical boundaries, rather than as a defined rule-based architecture (e.g., as dimensions in a territory hypercube). The multi-dimensional model is de-normalized to capture the multi-dimensional nature of the sales territory definitions while, for example, flattening hierarchical trees and minimizing or eliminating the need for ordinal processing of the data. In some embodiments, the de-normalized territory definitions are used to facilitate efficient and reliable gap and / or overlap processing (e.g., detection, reconciliation, etc.). In other embodiments, the de-normalized territory definitions are used to optimize identification of territory regions where reassignment of opportunities is appropriate and / or to reassign opportunities in those regions.

Owner:ORACLE INT CORP

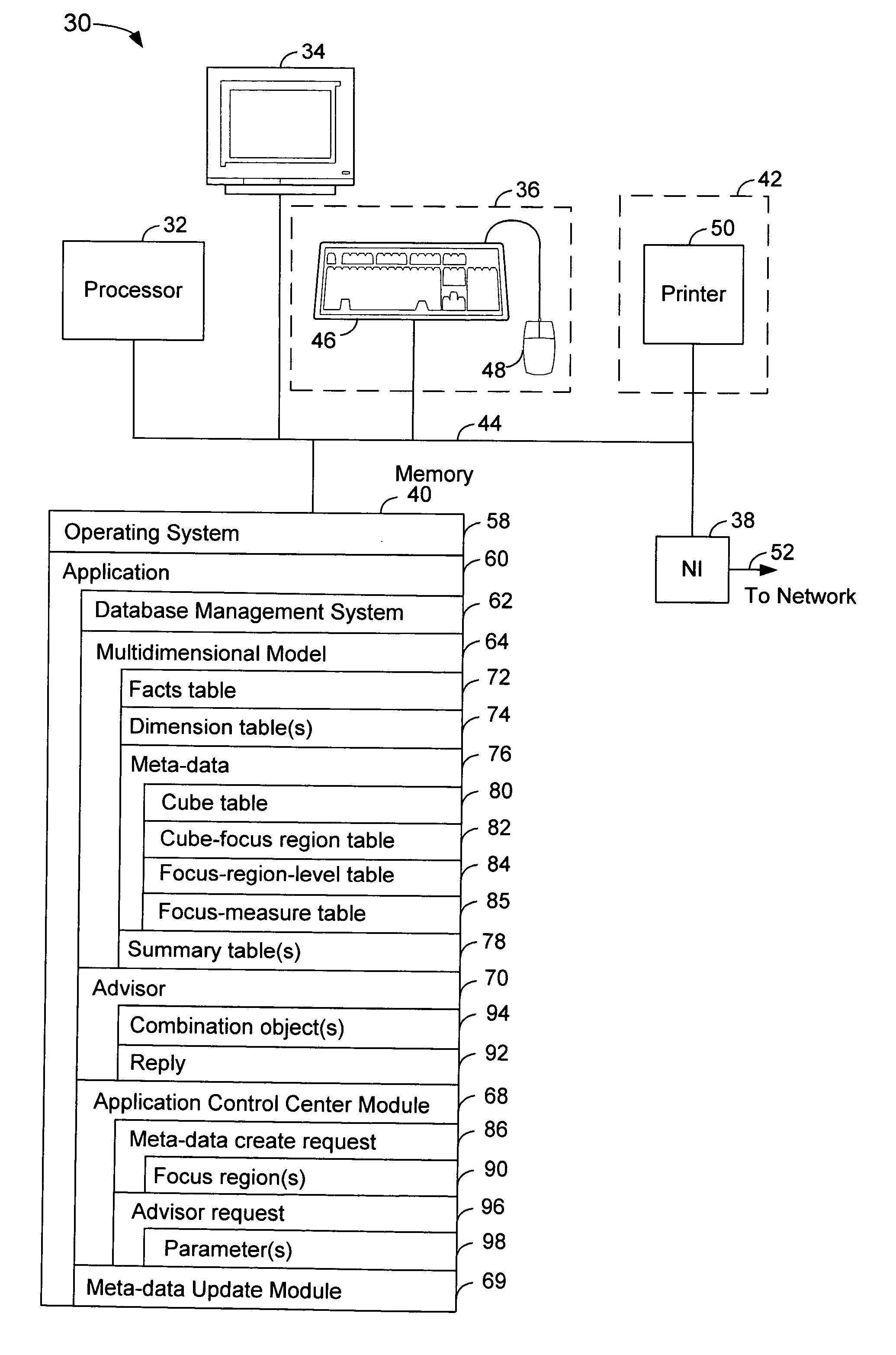

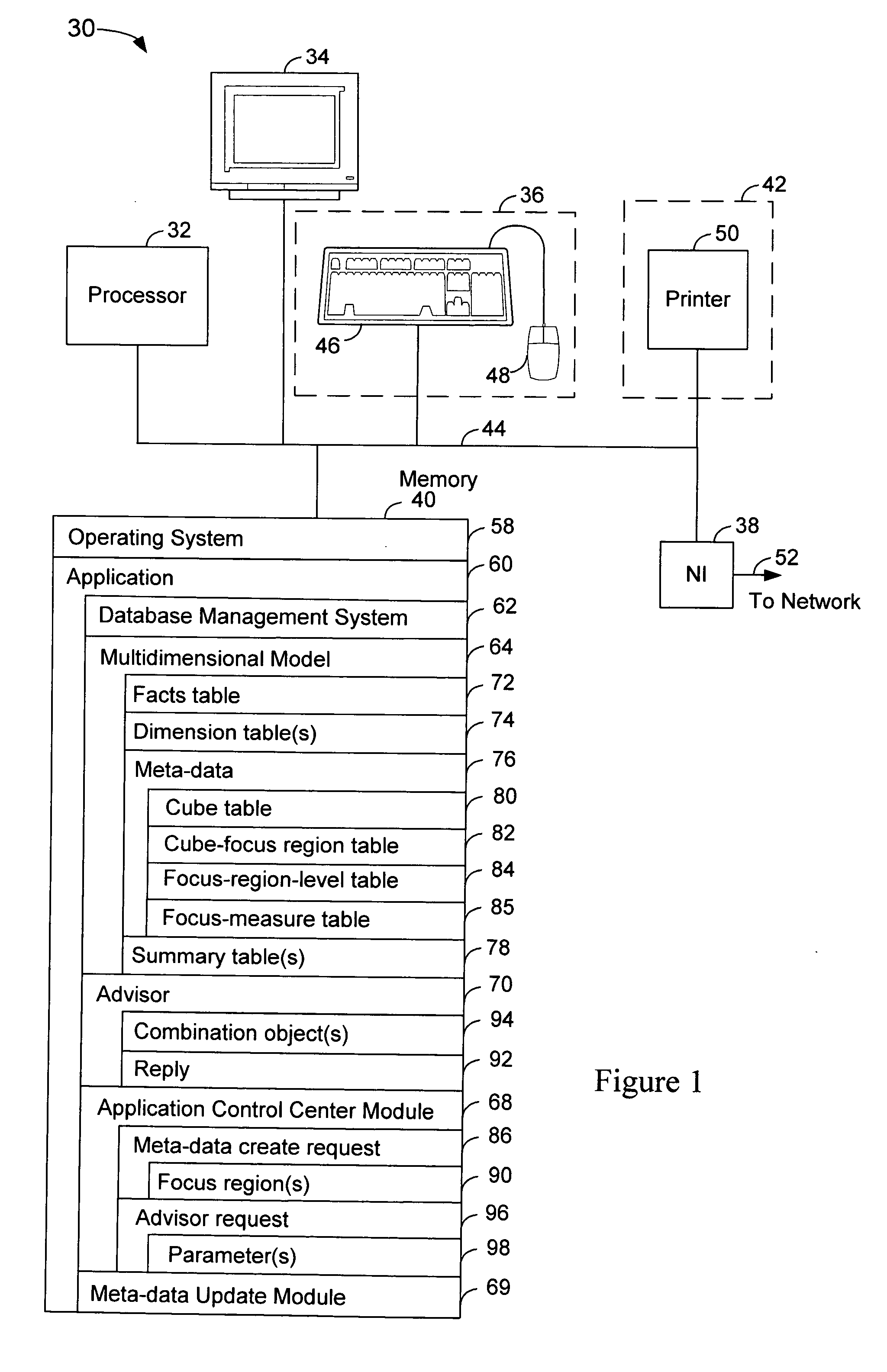

Model based optimization with focus regions

Various embodiments of a method, apparatus and article of manufacture for optimization of a multidimensional model in a model based performance advisor are disclosed. The multidimensional model comprises groups. Each group has one or more levels. One or more recommended slices associated with the groups are determined based on a focus region.

Owner:IBM CORP

Method and system for mapping multi-dimensional model to data warehouse schema

InactiveUS20080256121A1Reduce complexityReduce probabilityDigital data processing detailsMulti-dimensional databasesData warehouseAnalysis data

A system maps a multidimensional model to data warehouse schema. The system includes a multidimensional model editor for defining a multidimensional model based on a conceptual model; a mapping reasoner for generating more simple mappings from basic mappings by reasoning on the conceptual model so as to provide mappings for concerning elements in an ontology path in the multidimensional model; a data warehouse schema analyzer for generating a data structure capable of indicating information of the data warehouse schema by making an analysis on the information of the data warehouse schema; and a mapping composition engine for generating result mappings according to mappings for the concerning elements of the ontology path in the multidimensional model and by searching in the data structure paths corresponding to the concerning elements of the ontology path in the multidimensional model. A method and computer program product are also disclosed.

Owner:IBM CORP

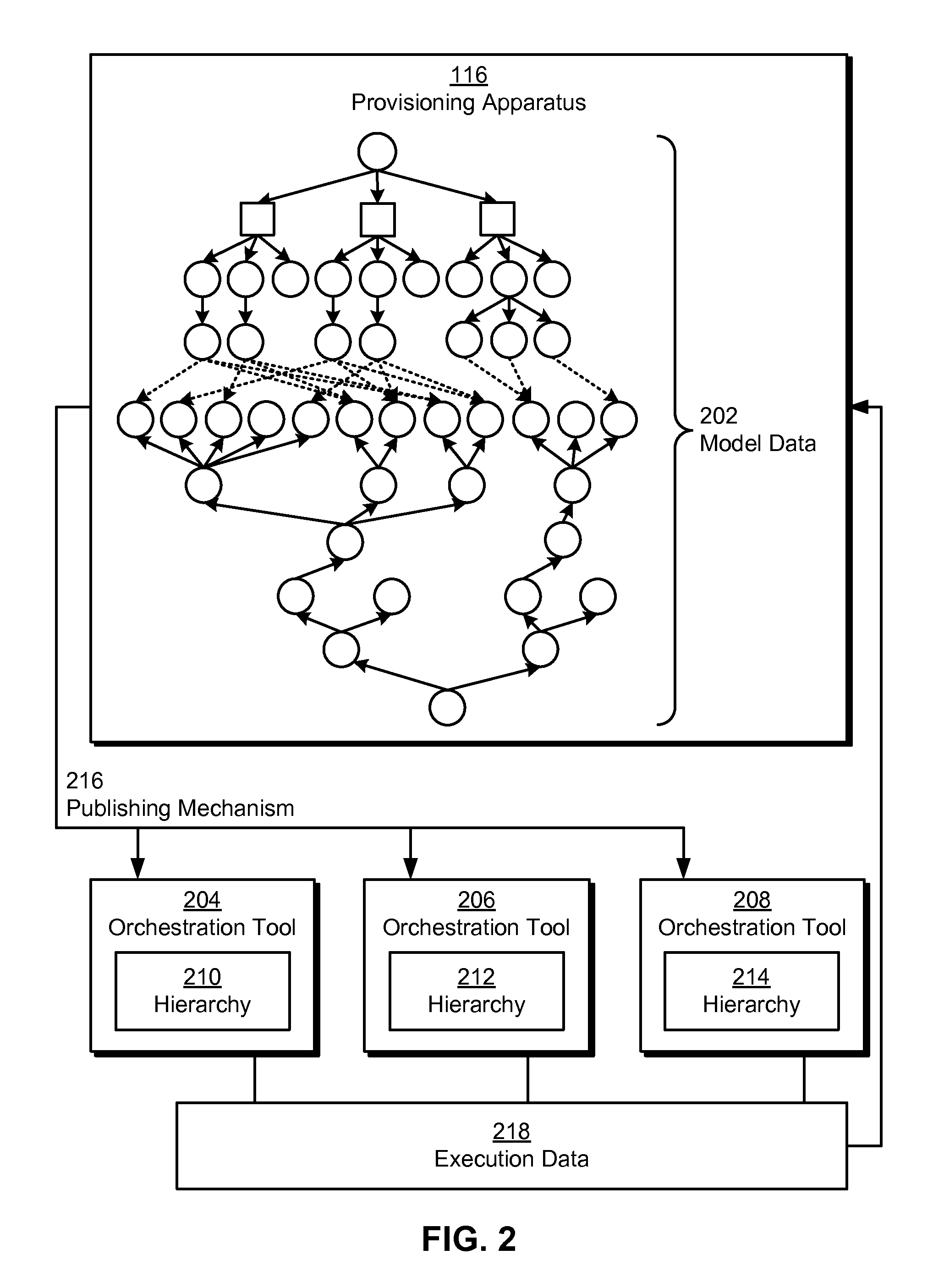

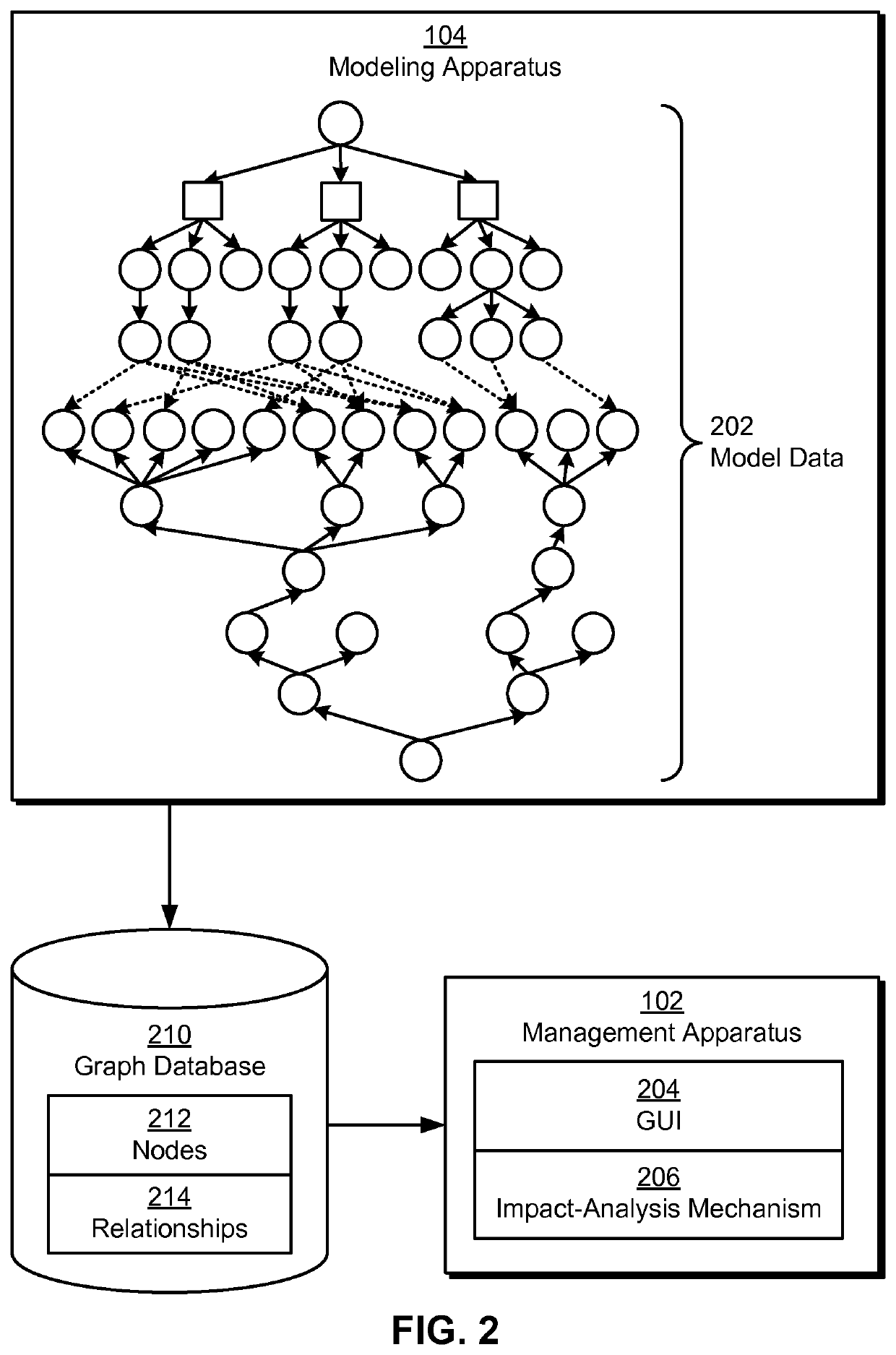

Publishing and updating of multidimensional models using orchestration tools for software offerings

InactiveUS20120222004A1Easy maintenanceSimple to executeResource allocationCommerceOrchestrationOperating system

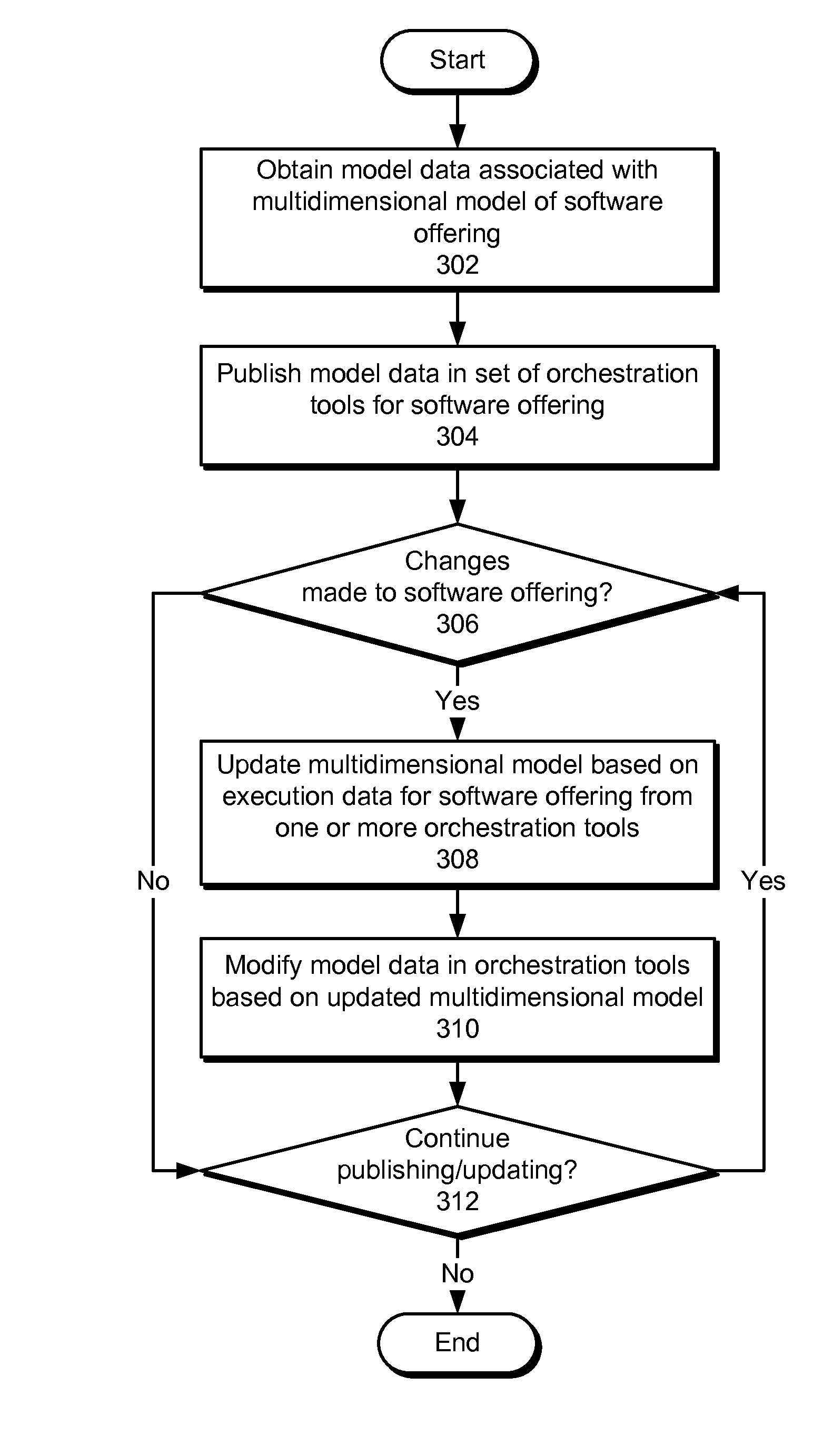

The disclosed embodiments provide a system that facilitates the maintenance and execution of a software offering. During operation, the system obtains model data associated with a multidimensional model of the software offering. Next, the system publishes the model data in a set of orchestration tools for the software offering, wherein the model data enables use of the multidimensional model in managing the execution of the software offering from the orchestration tools.

Owner:INTUIT INC

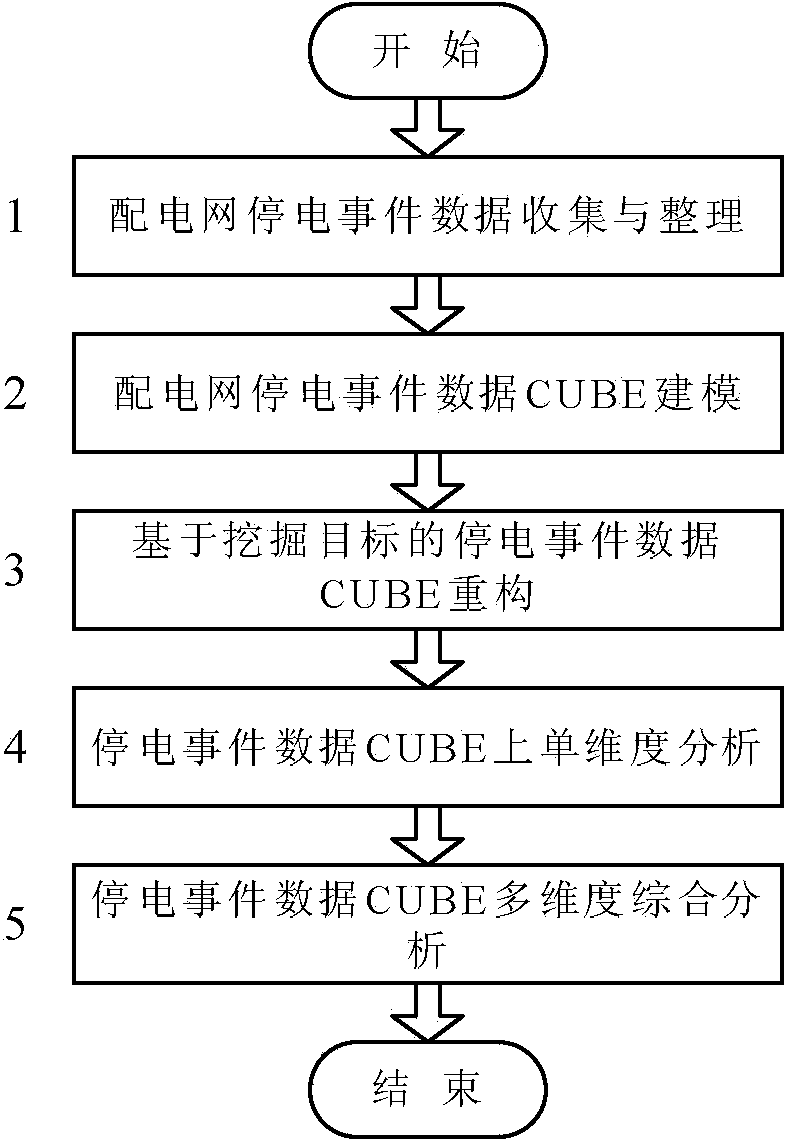

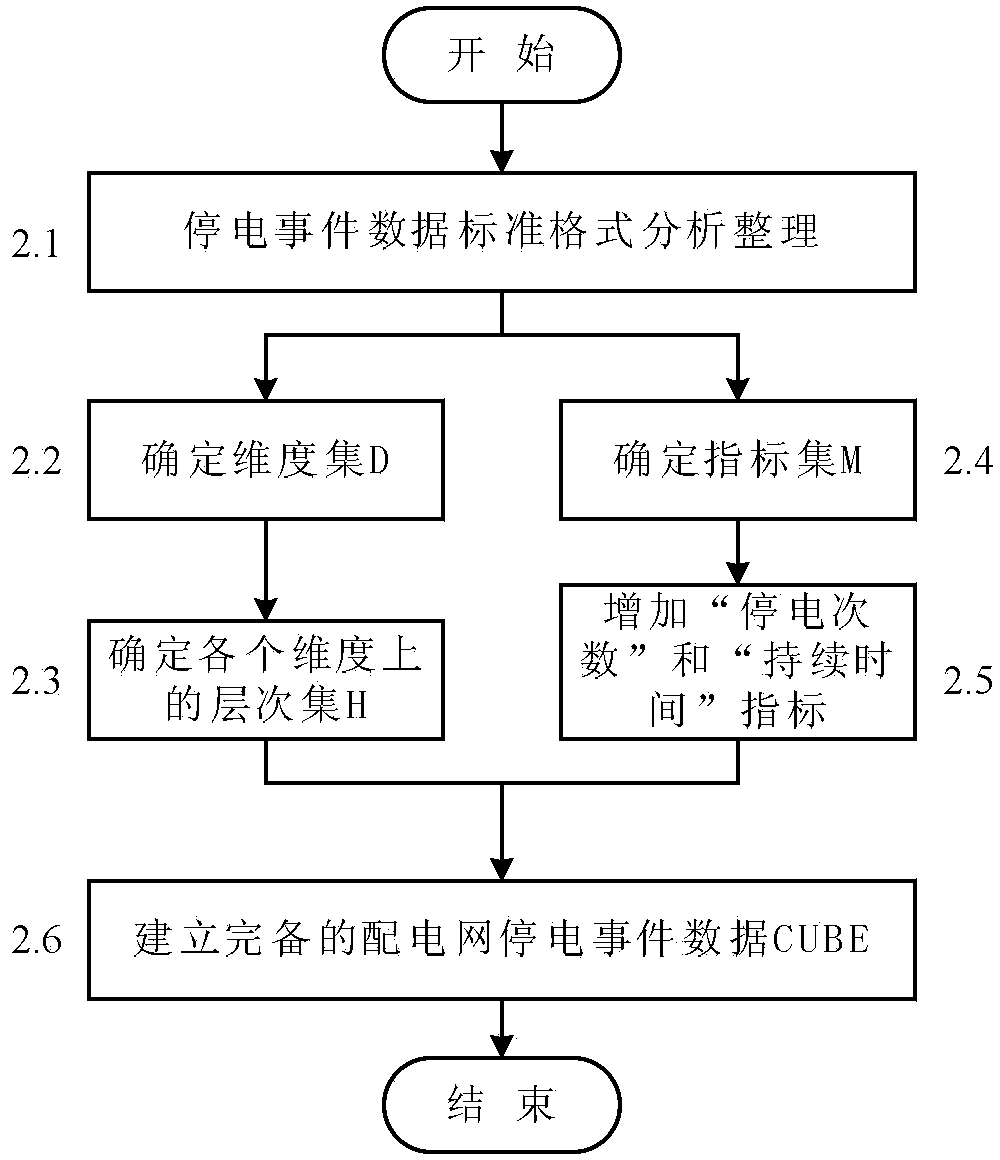

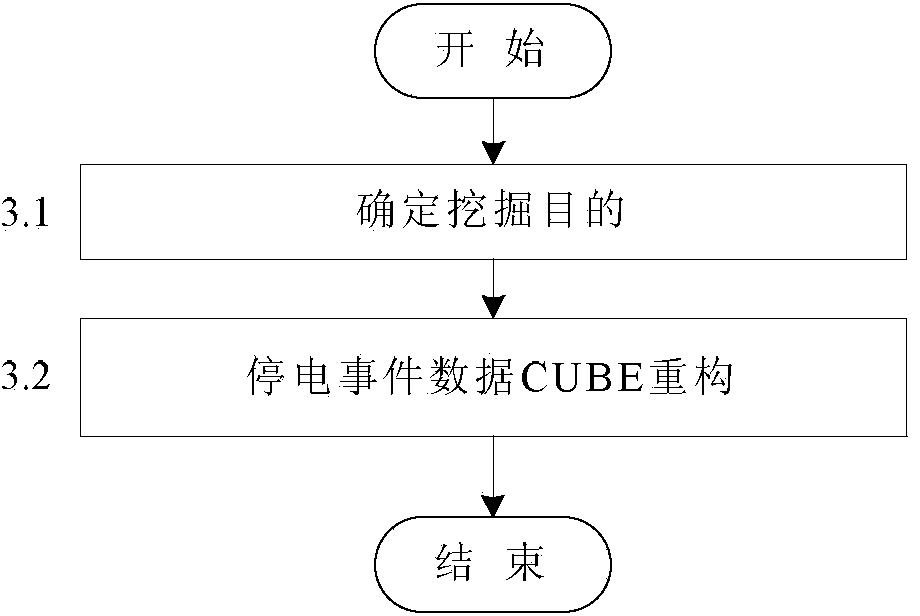

A method for mining a weak reliability link of a power distribution system based on multi-dimensional analysis

InactiveCN104182830ARaise the level of reliabilityEffectively discover regular featuresResourcesDistribution power systemElectric distribution network

There is provided a method for mining a weak reliability link of a power distribution system based on multi-dimensional analysis. The method comprises the steps of power distribution network power failure event data collecting and cleansing, power distribution network power failure event data CUBE modeling, mined target-based power failure event data CUBE reconstructing, single-dimensional analysis on power failure event data CUBE, multi-dimensional comprehensive analysis on power failure event data CUBE and the like. The method for mining a weak reliability link of a power distribution system based on multi-dimensional analysis breaks through the limitation that the power failure event data is only used for reliability index statistics in the traditional management of reliability of the power distribution network, establishes a multi-dimensional model for the power failure event data itself to execute analysis, and mines the weak reliability link of the power distribution system from multiple perspectives and different hierarchies, thus enabling to effectively find regular features of influence factors on the power failure event of the power distribution network and where the weak reliability link of the power distribution network is, which can not only provide direct guidance for a production-management work of the power distribution network, such as grass-roots operation-maintenance and the like, but also provide a valuable decision basis for each level of management unit of the power distribution system.

Owner:天津天成恒创能源科技有限公司

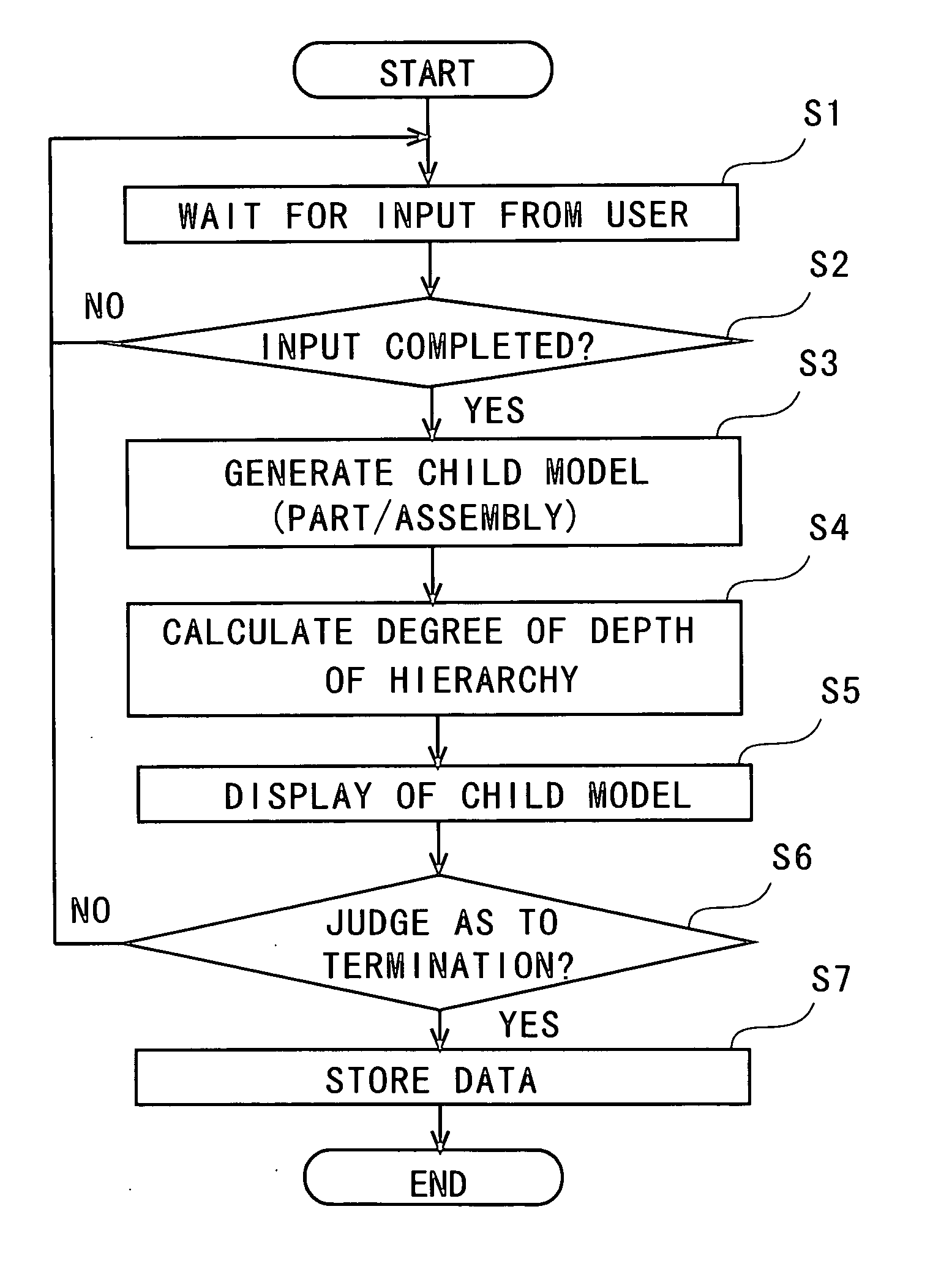

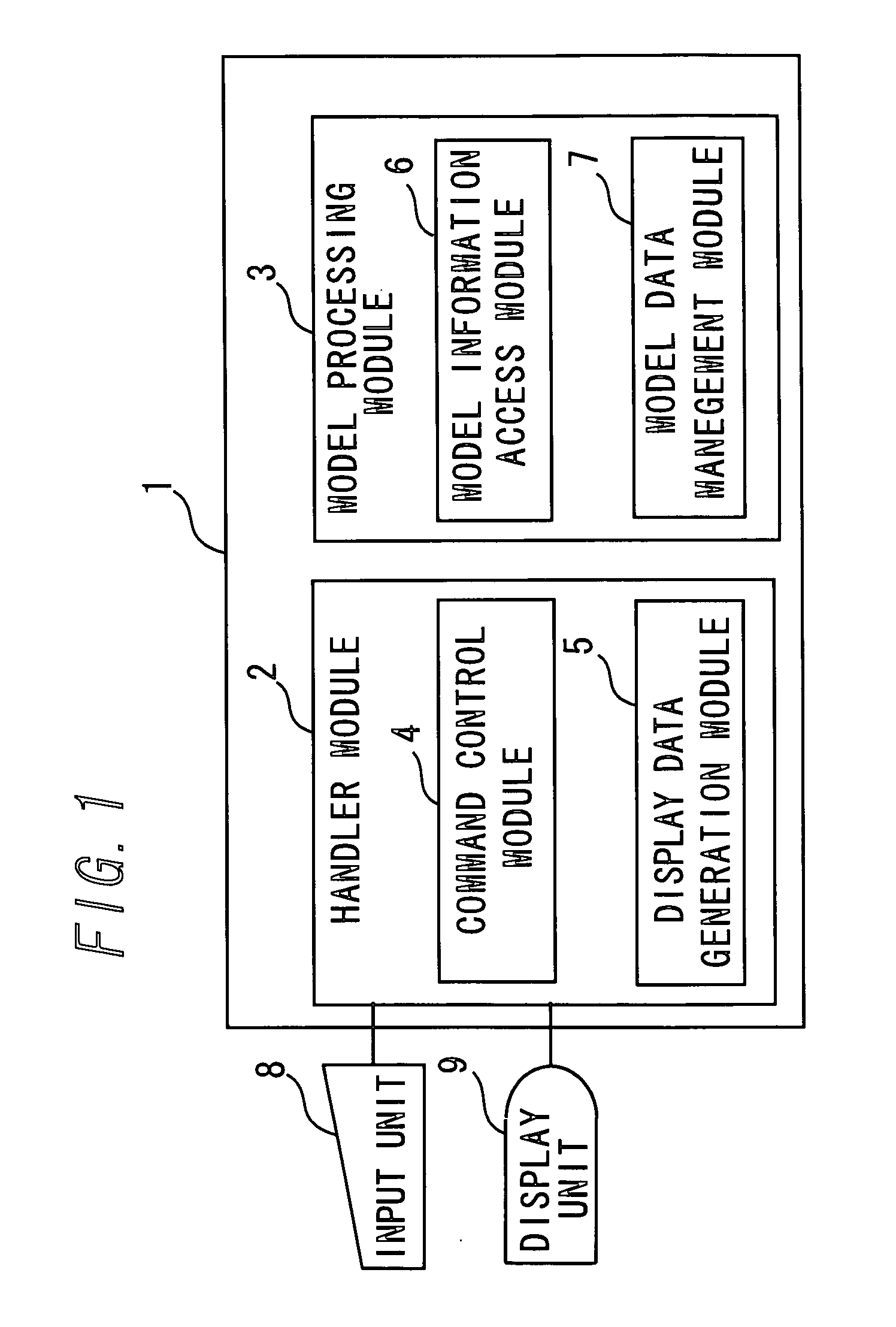

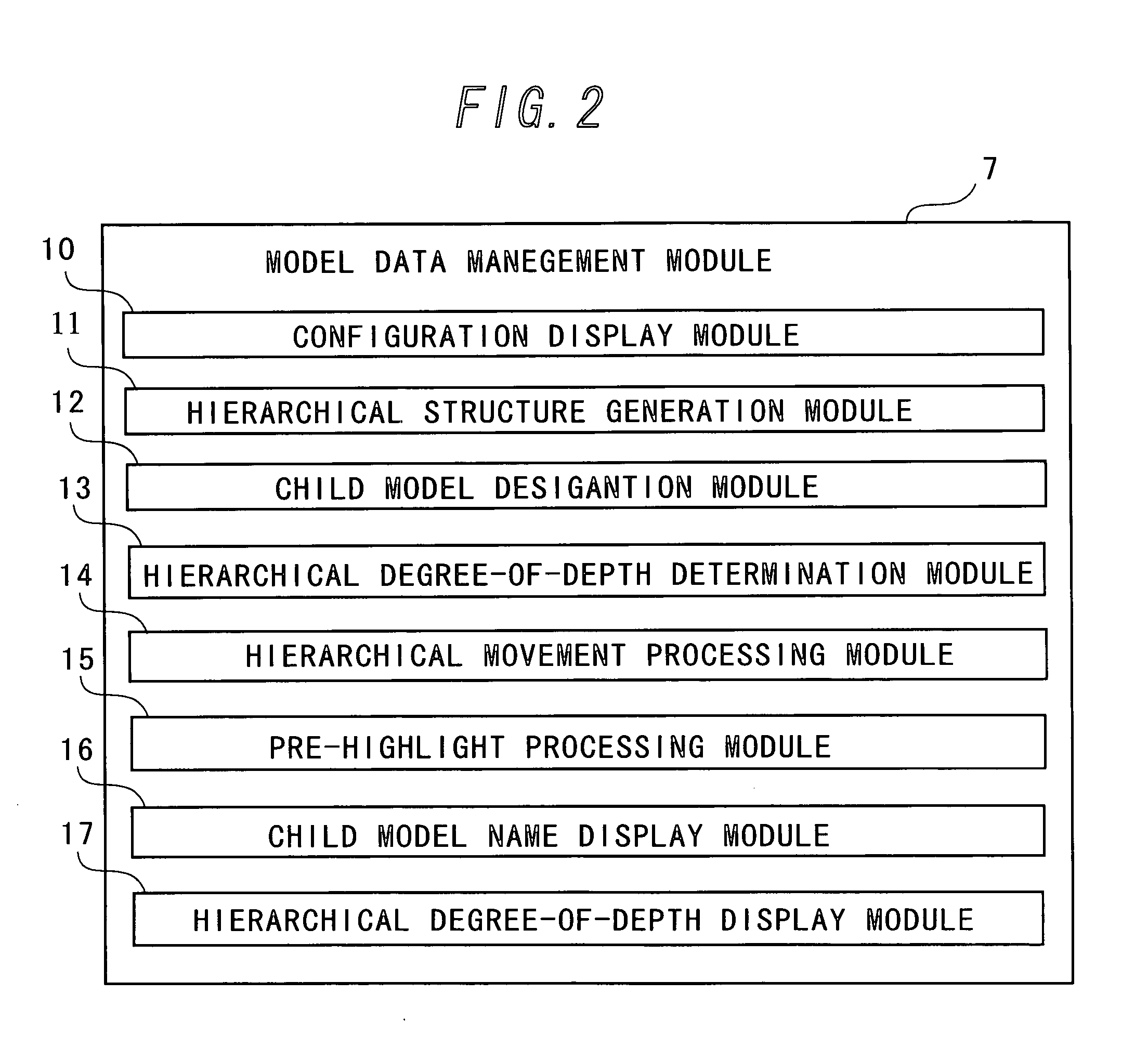

Storage medium readable by machine, storing design support program

InactiveUS20070203678A1Easy to masterComputer aided designSpecial data processing applicationsArtificial intelligenceMultidimensional model

A storage medium readable by a machine, storing a design support program, the program comprising a configuration displaying step of displaying a multidimensional model having a hierarchical structure configured by hierarchically combining parts on the basis of part data that define a multidimensional configuration of part, assembly data that define a part layout or assembly data that specify a layout of other pieces of assembly data, a child model designating step of designating as a processing object, based on input information from a user, a child model corresponding to part of the multidimensional model containing part data or assembly data, and an attribute information displaying step of displaying, by referring to the part data or assembly data corresponding to the child model designated in the child model designating step, an attribute of the child model that contains a position in a hierarchical structure for an image of the multidimensional model.

Owner:FUJITSU LTD

Graph databases for storing multidimensional models of software offerings

ActiveUS10528897B2Easy maintenanceSimple to executeDigital data processing detailsSoftware maintainance/managementTheoretical computer scienceEngineering

Owner:INTUIT INC

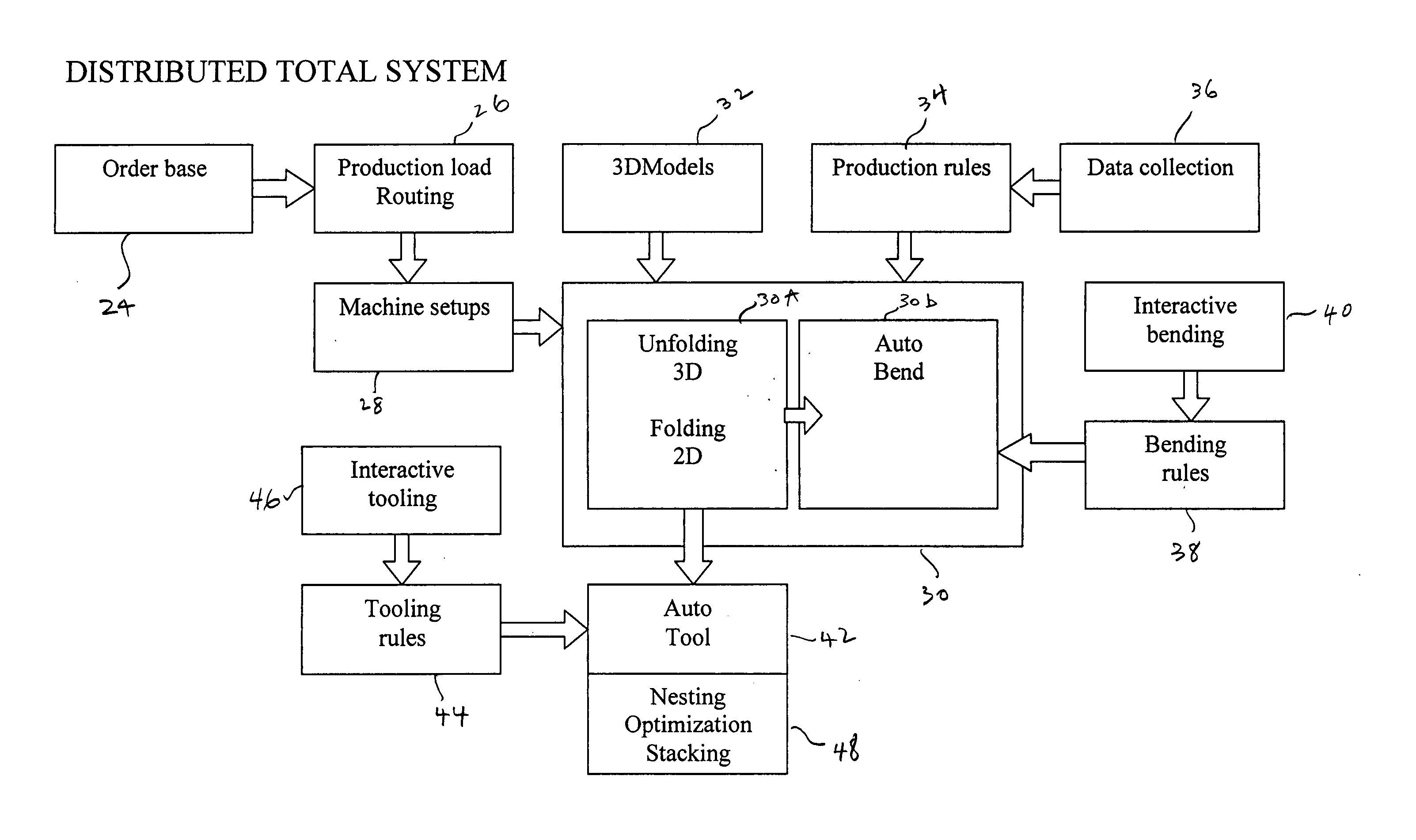

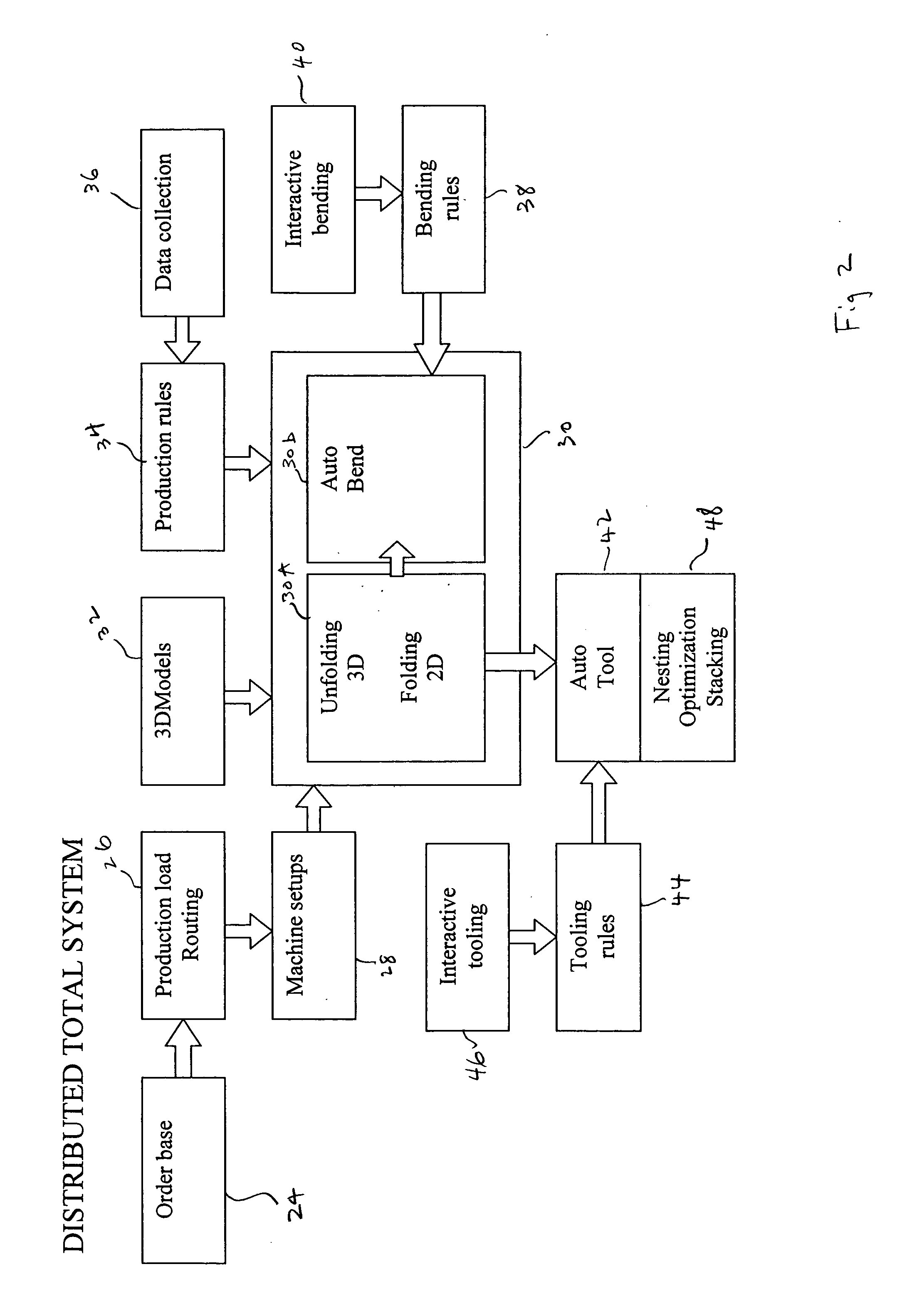

Flexible distributed manufacturing method and system therefor

ActiveUS20050137740A1Data processing applicationsTotal factory controlSelection systemMulti dimensional

In a manufacturing system that has a plurality of sheet fabrication machines, to enhance the efficiency of the system, there are provided a plurality of databases each for storing particular data relating to the machines, the types of materials to be used, the tooling of the machines, etc. of the system. When a multi-dimensional model of a component part to be produced by the system is input to the system, selective data is retrieved from the various databases so that at least one machine of the plurality of machines of the system is selected to produce the part from a worksheet of a chosen material. Concurrently, or shortly thereafter, a NC part program for programming the selected machine to execute the necessary operations in accordance with a flat drawing generated from the multi-dimensional model to fabricate the component part is generated based on selective data retrieved from the databases. With the NC part program, the selected machine performs the operations necessary for producing the component part from the sheet stock material chosen for the component part. If there are multiple component parts to be produced in the same production run, the system would sort the different parts and arrange for the ordered fabrication of the different parts by respective selected machines equipped with corresponding appropriate NC programs to eliminate any potential bottleneck or conflicts that may arise due to the fabrication of multiple parts by multiple machines during the same production run.

Owner:FINN POWER INT

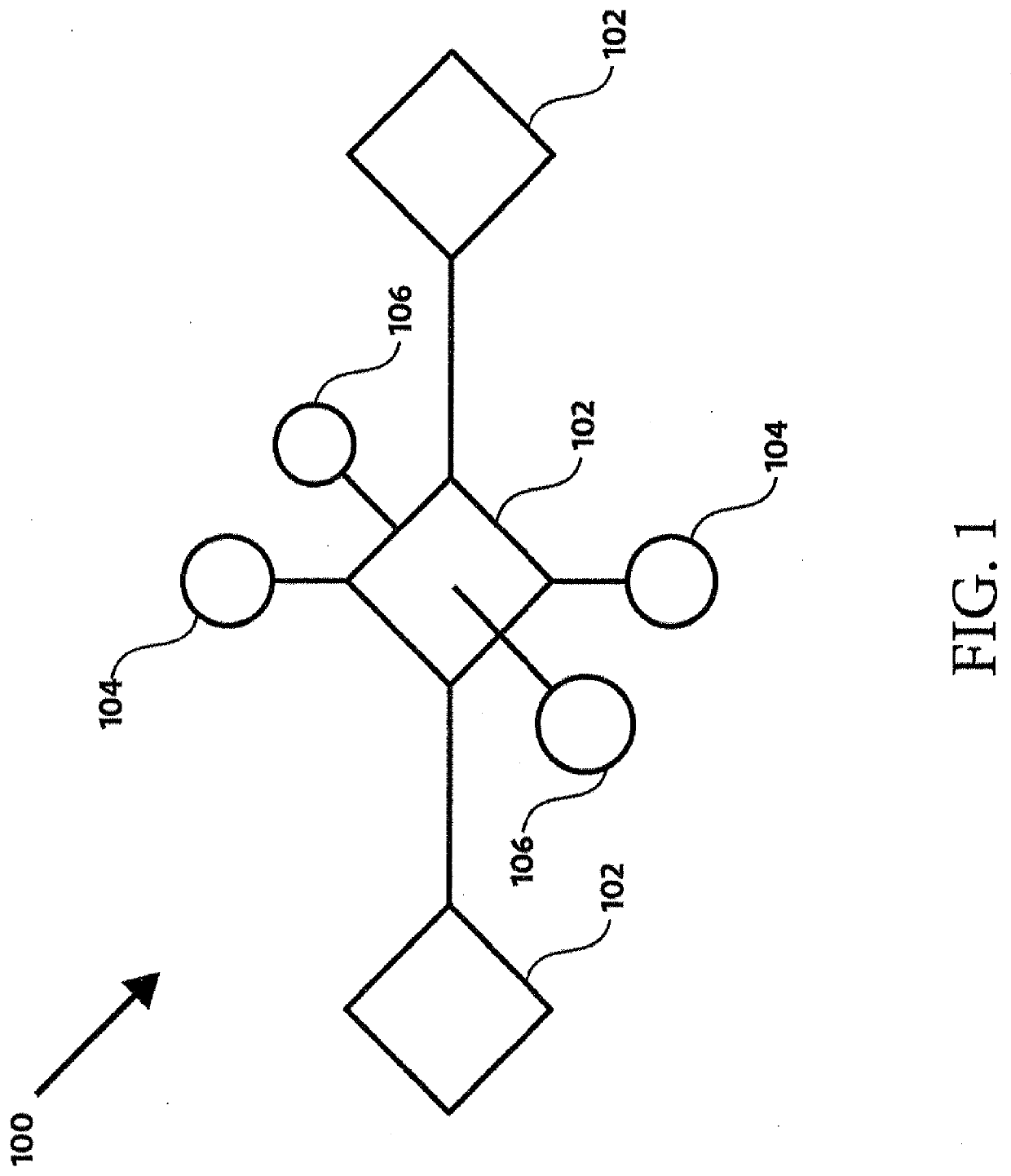

Multi-Dimensional Parsing Method and System for Natural Language Processing

ActiveUS20200243076A1Speed up the processEfficient communicationNatural language translationSemantic analysisSource textParsing

A method for translating a text written or otherwise communicated in a source natural language into a text written or otherwise communicable in target natural language, in reliance upon a multidimensional model, relies on determining the core concept in the sentences of the source text, and leverages the determined core concepts to create the target language translation. The method includes processing the source natural language text into sentences, then parsing the sentences, including assigning codes and / or directional operators to realize parsed sentences according to the model. The sentence models are then processed effect the actual translation to the target natural language text, and communicated.

Owner:KIM MIN KU

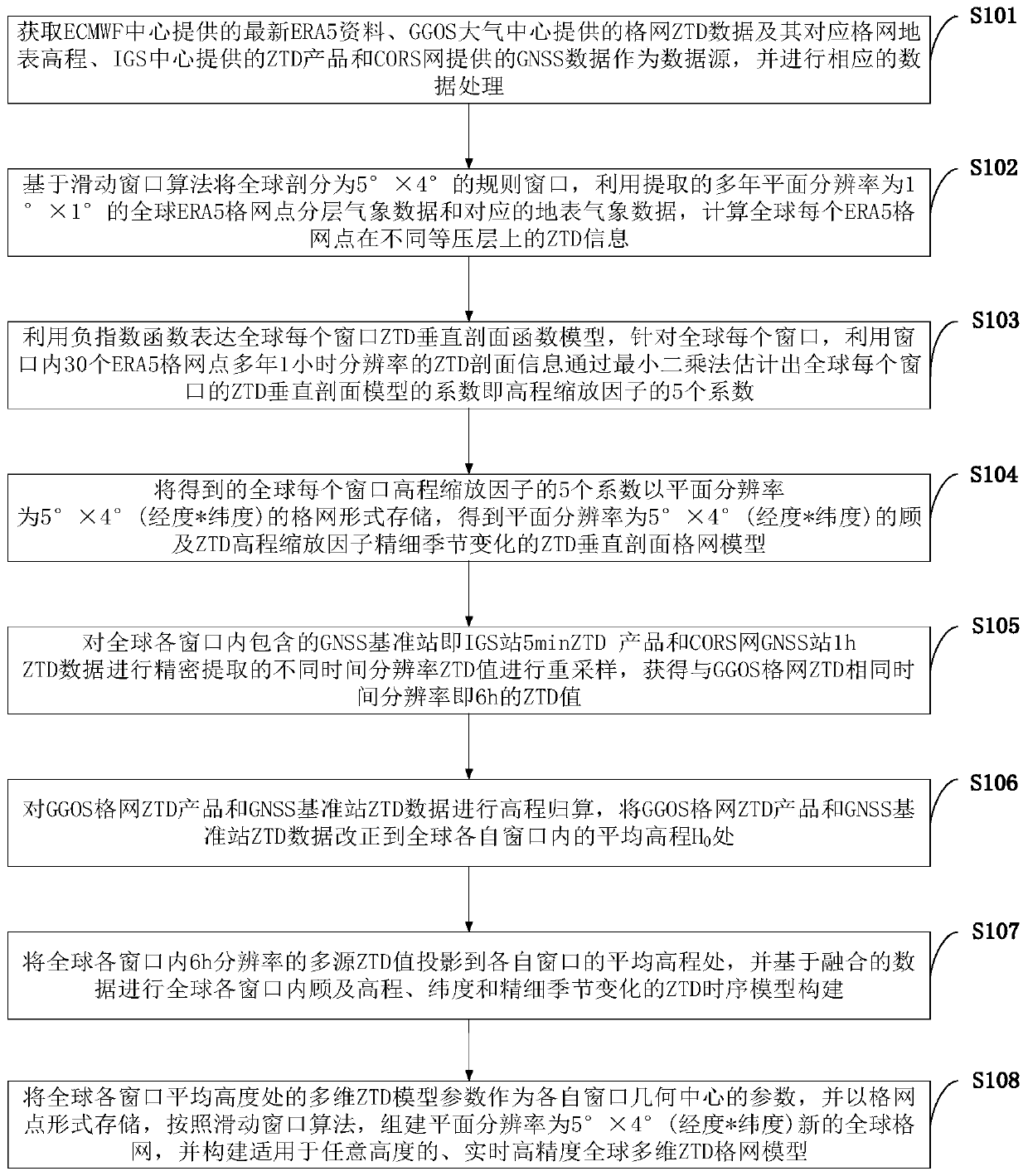

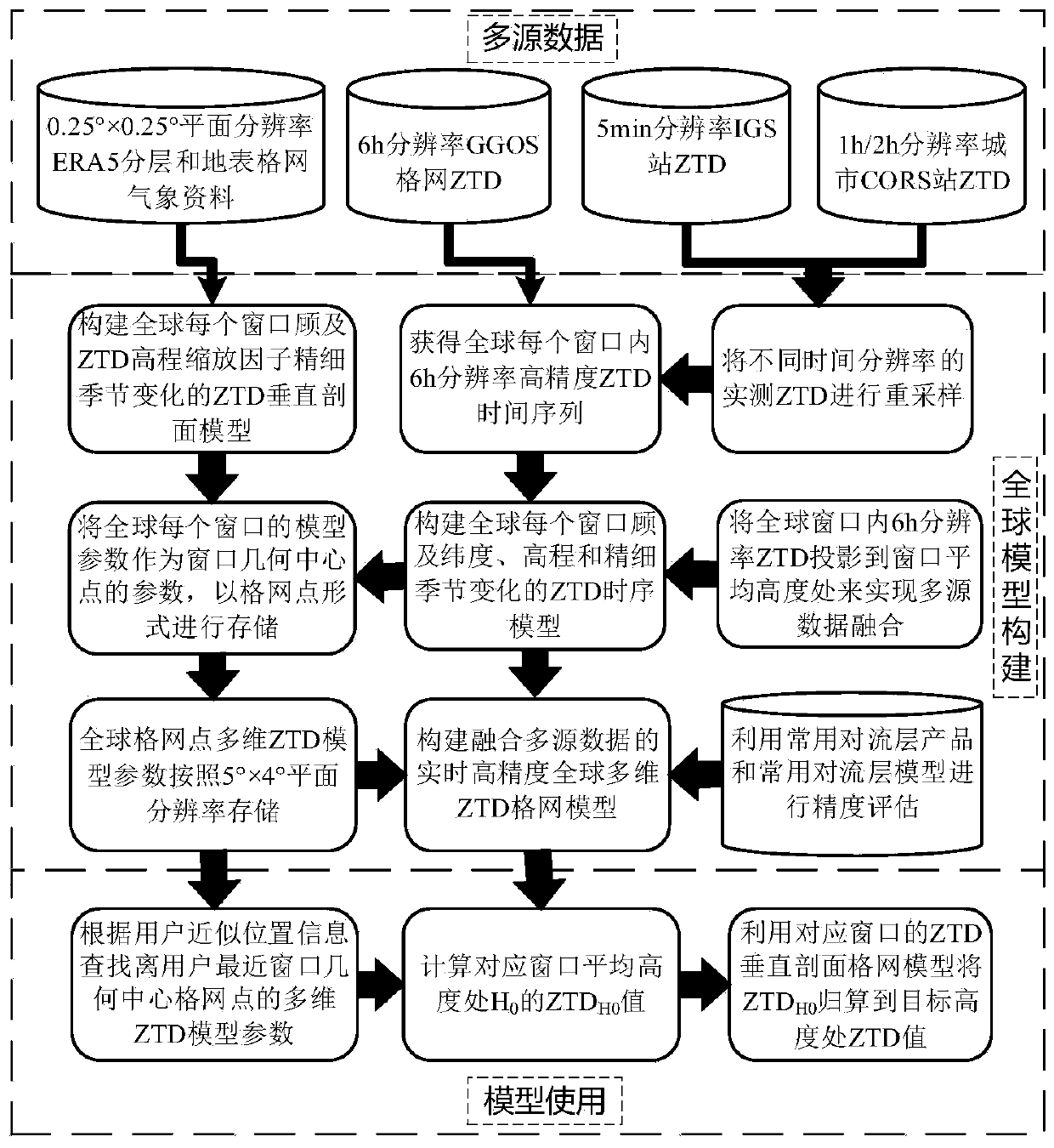

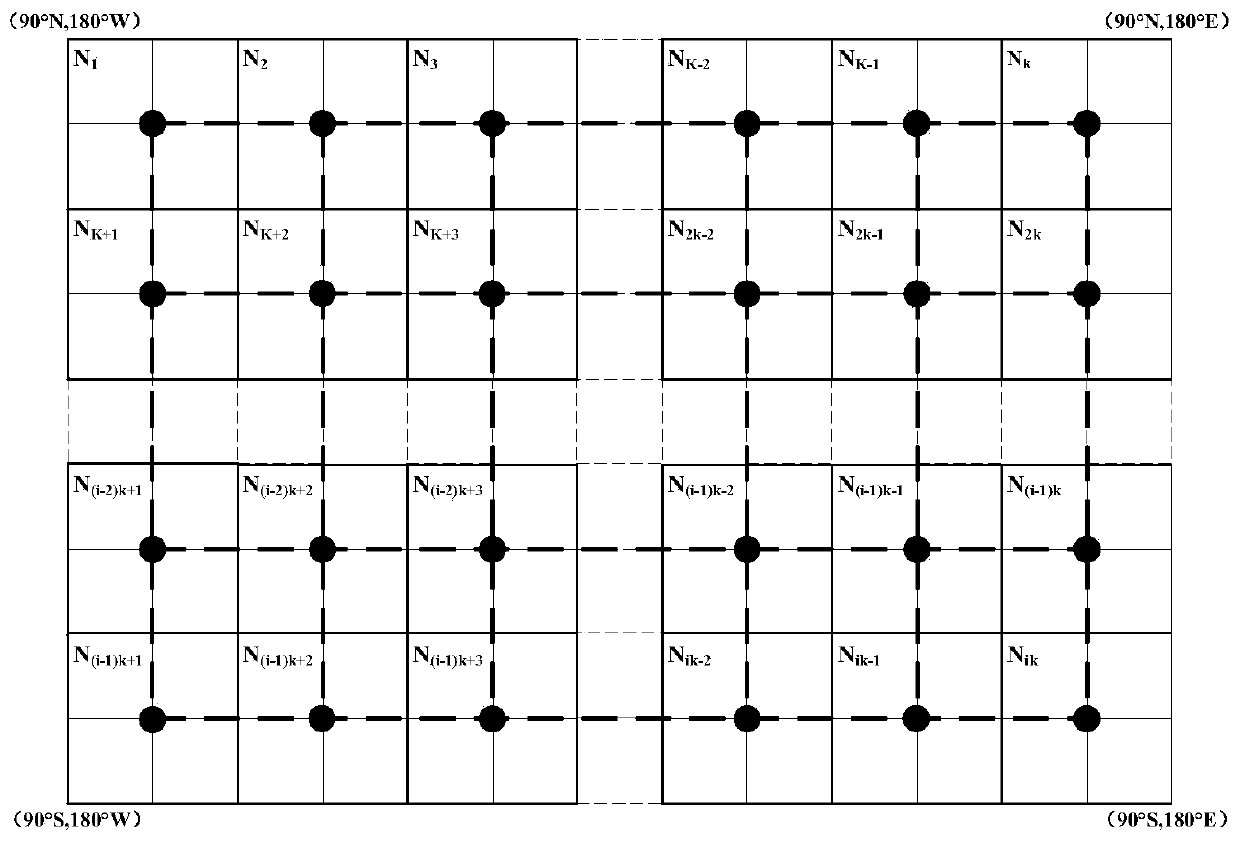

Real-time high-precision global multi-dimensional troposphere zenith delay grid model construction method

ActiveCN111539109AImprove computing efficiencyImprove practicalityDesign optimisation/simulationSpecial data processing applicationsTroposphereAlgorithm

The invention belongs to the technical field of satellite navigation positioning system data processing and meteorology crossing and discloses a real-time high-precision global multi-dimensional troposphere zenith delay grid model construction method. A sliding window algorithm is introduced to divide the whole world into 5-degree * 4-degree regular windows, ERA5 data are utilized to construct a ZTD vertical section model considering fine seasonal changes of ZTD elevation scaling factors in all the windows of the whole world, and then a 5-degree * 4-degree global ZTD vertical section grid model is constructed. According to the method, multi-dimensional ZTD model parameters at the average elevation of all windows in the world serve as parameters of geometric centers of the windows and are stored in the form of grid points, a new global grid is built according to a sliding window algorithm, and a real-time high-precision global multi-dimensional ZTD grid model suitable for any height isbuilt. According to the real-time high-precision global multi-dimensional ZTD grid model established by the invention, the calculation efficiency of the model is well improved, and the practicabilityof the model is enhanced.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Revenue-based impact analysis using multidimensional models of software offerings

InactiveUS20120284067A1Easy maintenanceSimple to executeCommerceSoftware engineeringService component

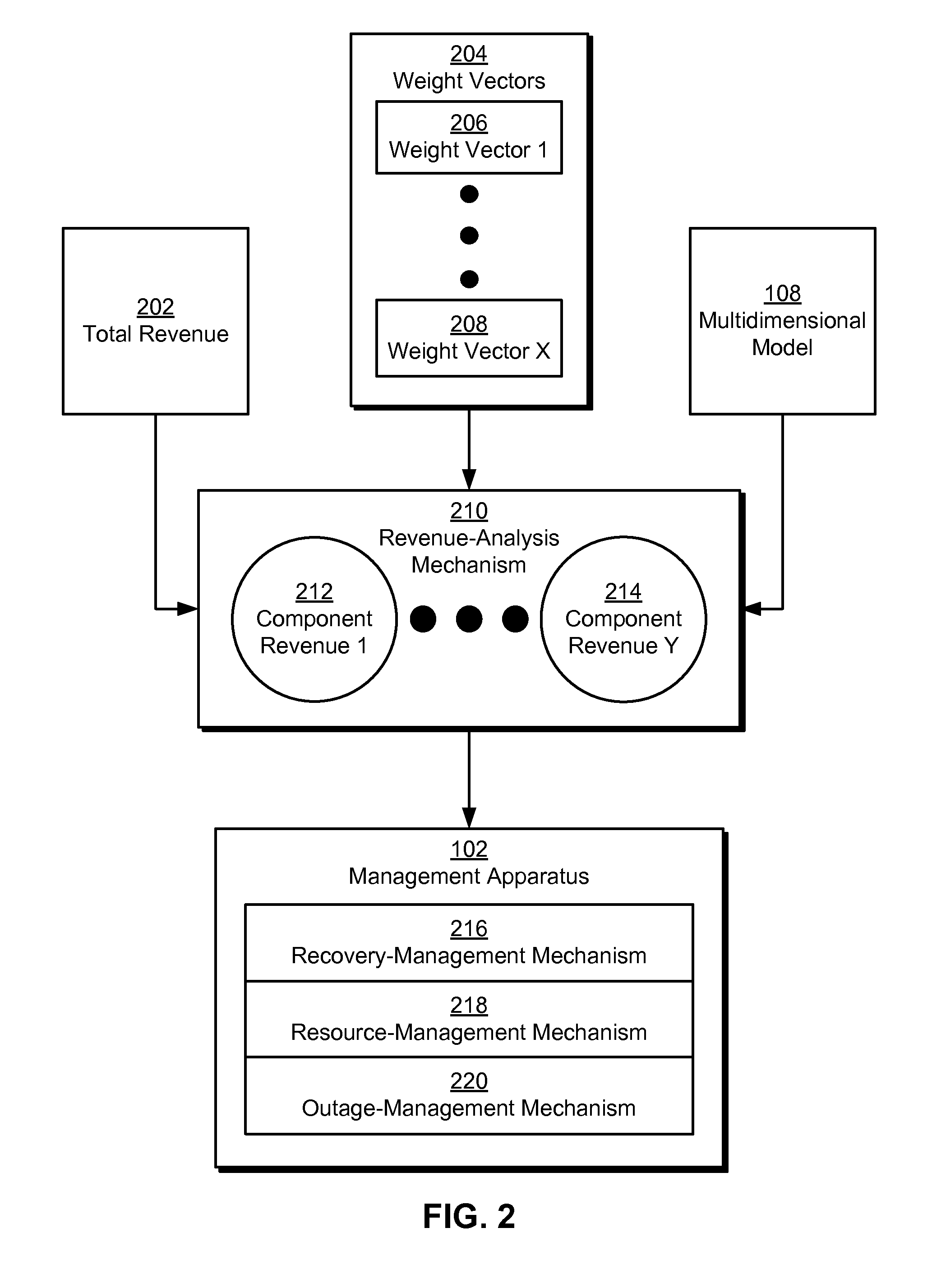

The disclosed embodiments provide a system that facilitates the maintenance and execution of a software offering. During operation, the system obtains a total revenue associated with the software offering and a set of weight vectors associated with a multidimensional model of the software offering, wherein each of the weight vectors comprises a set of revenue weights. Next, the system calculates a set of component revenues associated with a set of service components and a set of resources used by the software offering by applying the total revenue and the weight vectors to the multidimensional model. Finally, the system uses the component revenues to facilitate management of the software offering.

Owner:INTUIT INC

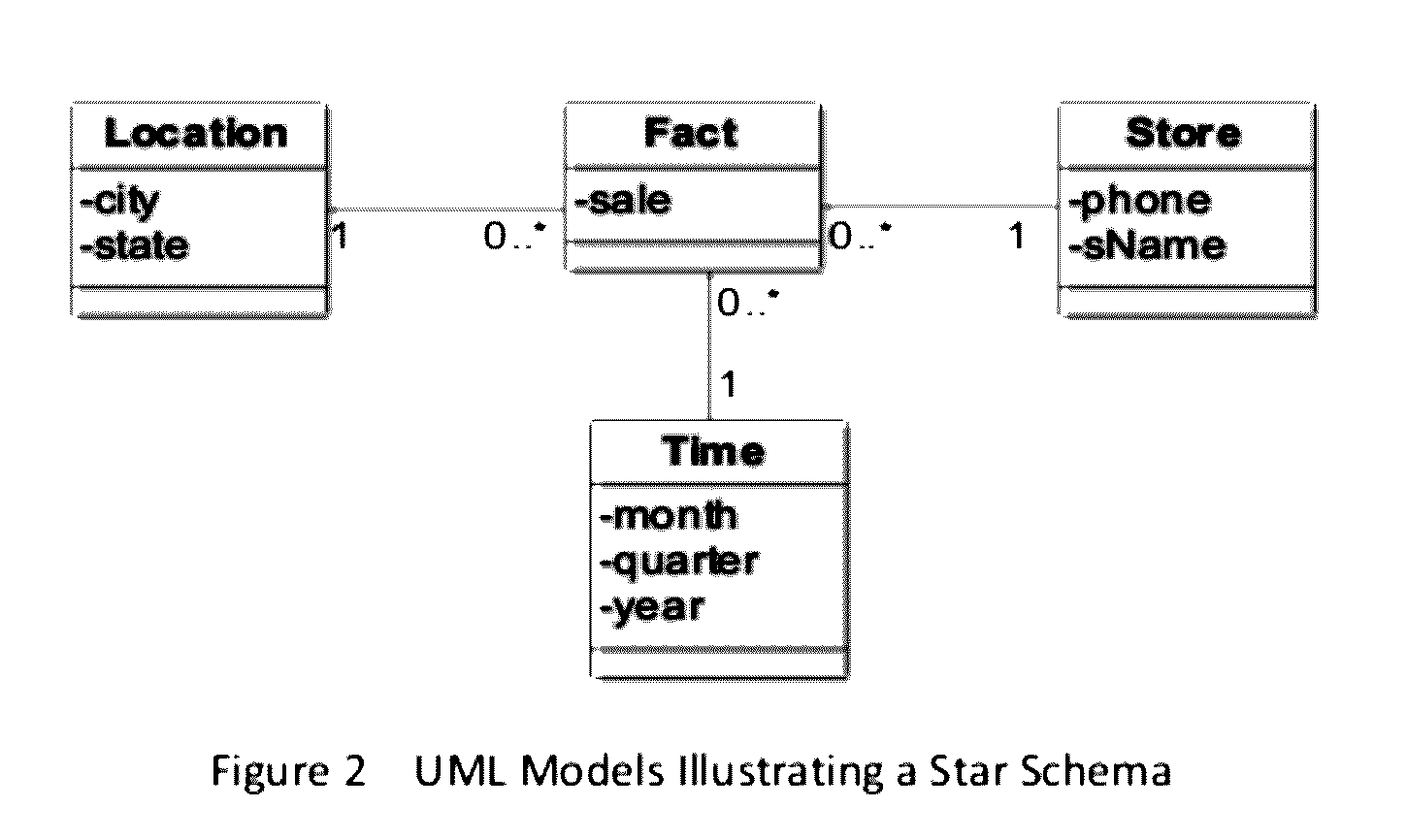

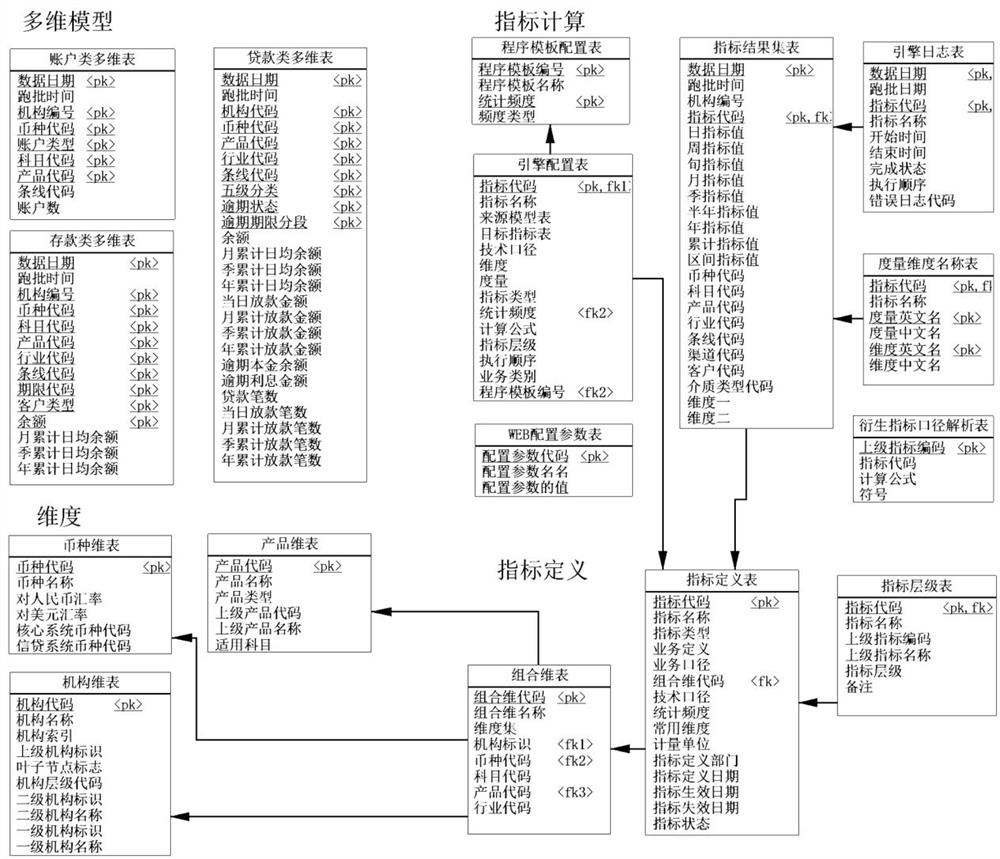

Data warehouse model construction system and method based on multi-dimensional theory

InactiveCN111078766AReduce designImprove construction efficiencyDatabase management systemsMulti-dimensional databasesSoftware engineeringPhysical model

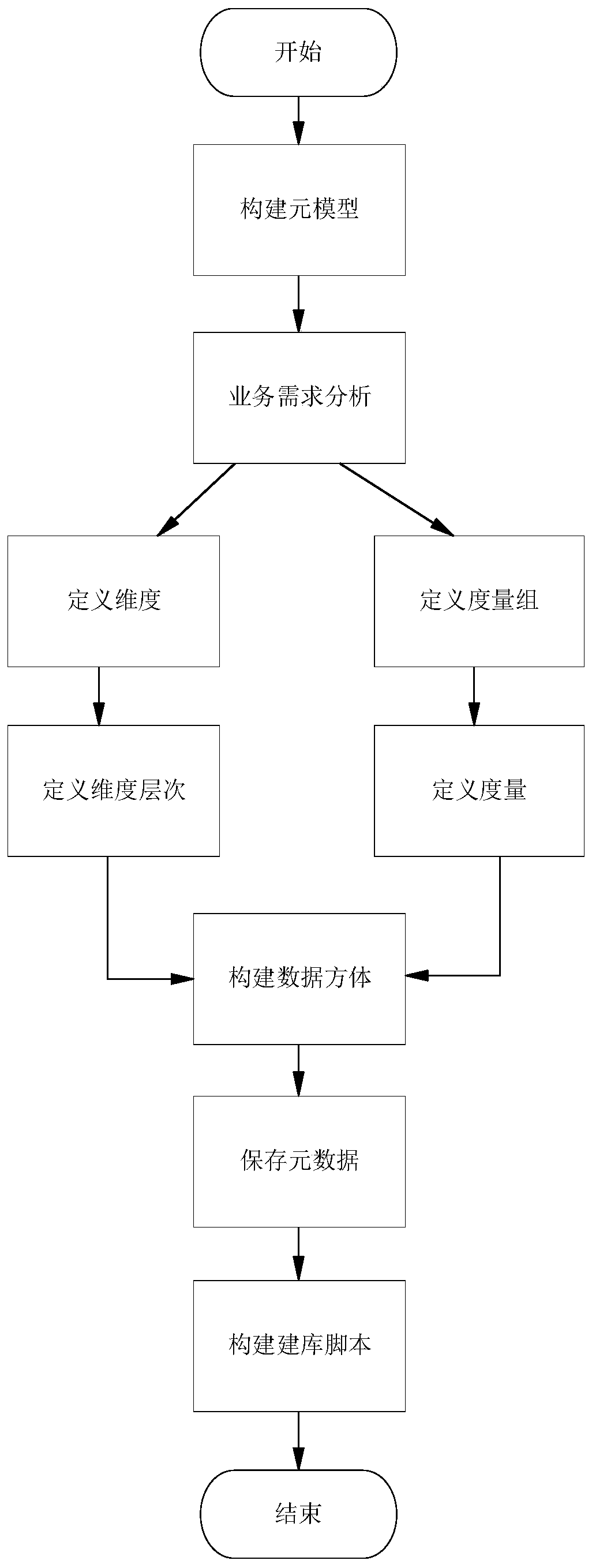

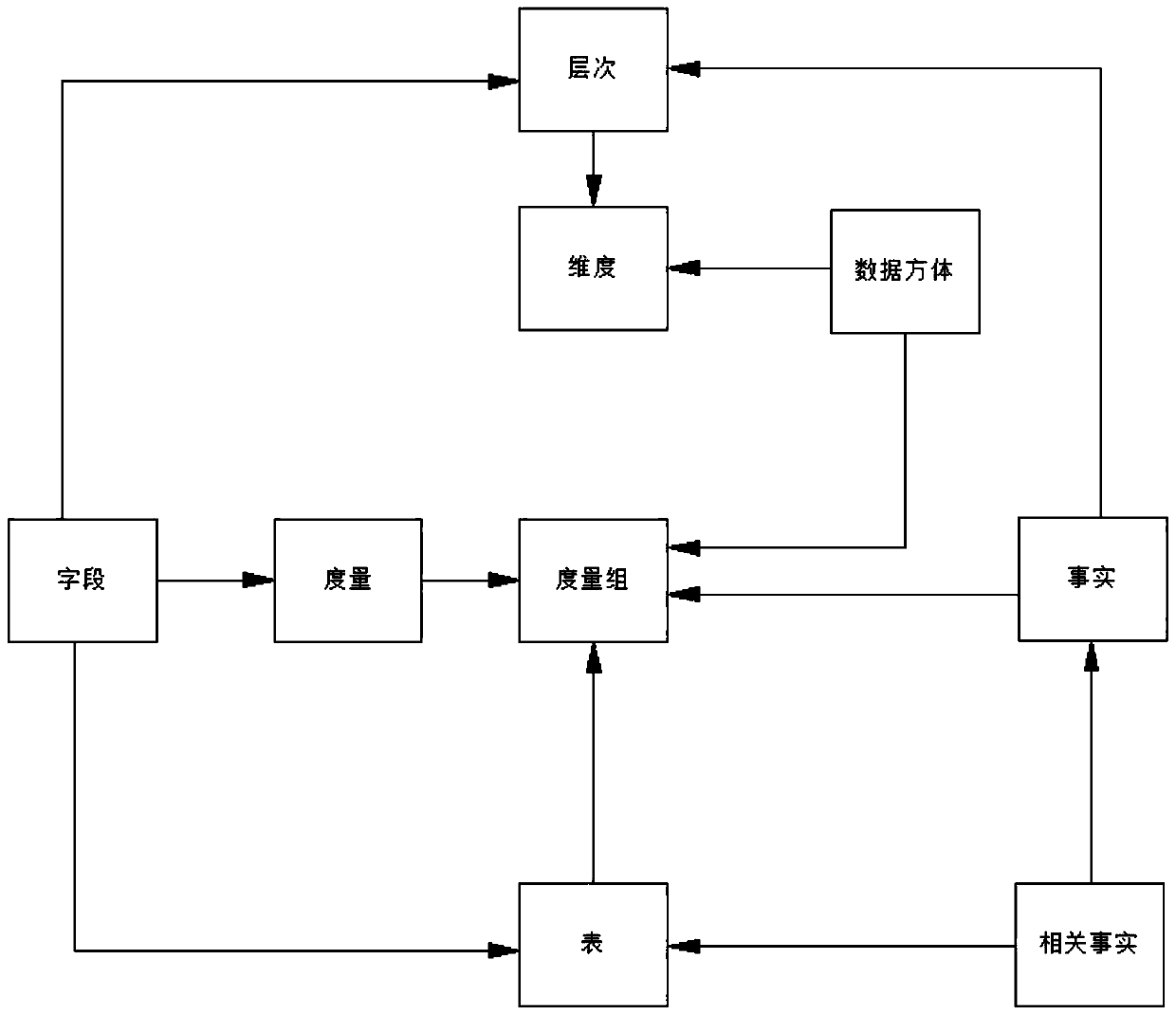

The invention discloses a data warehouse model construction system based on a multi-dimensional theory and a construction method thereof, and belongs to the field of data warehouses. The system and the method are improved on the basis of the multi-dimensional model design, and fully utilizes metadata to automatically construct a star-shaped multi-dimensional data model and shorten the data model design by precipitating the metadata of a design model in a meta-model. The system comprises a metadata model module, a dimension and hierarchy module, a measurement group and measurement module, a data cube module, a physical model module and the like. Automatic generation of a data warehouse physical model is realized by constructing a series of modules. The multi-dimensional design meta-model isindependently constructed, a traditional data model design tool is abandoned, automation of physical model scripts based on data model metadata is achieved, compared with traditional design, the datamodel design process is shortened, and the data warehouse construction efficiency is improved.

Owner:江苏艾佳家居用品有限公司

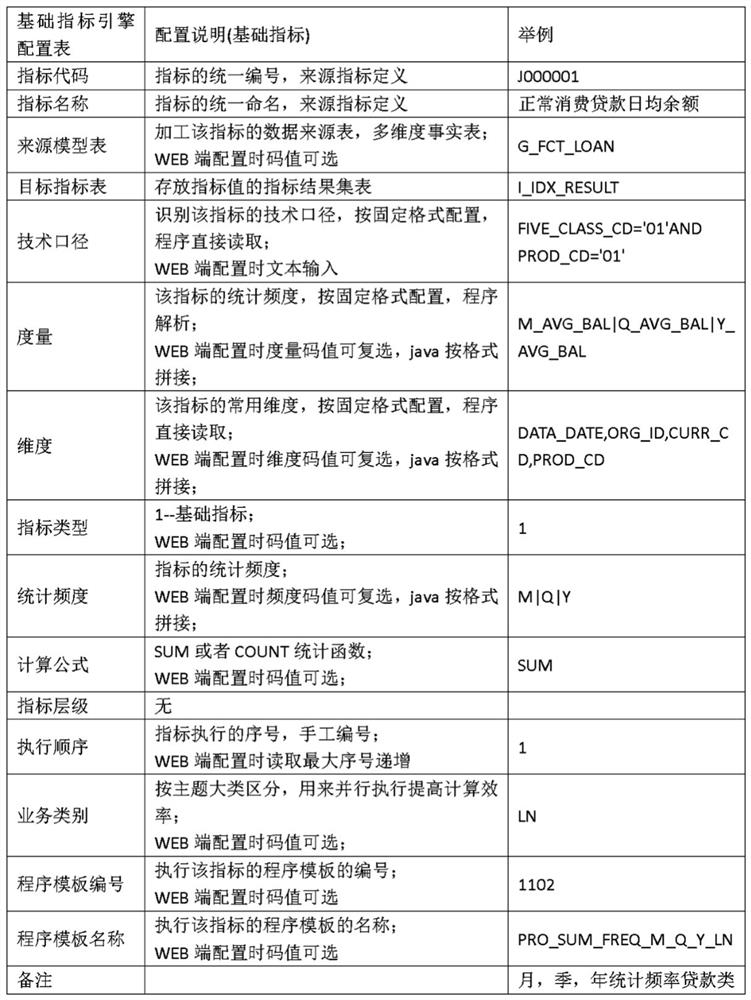

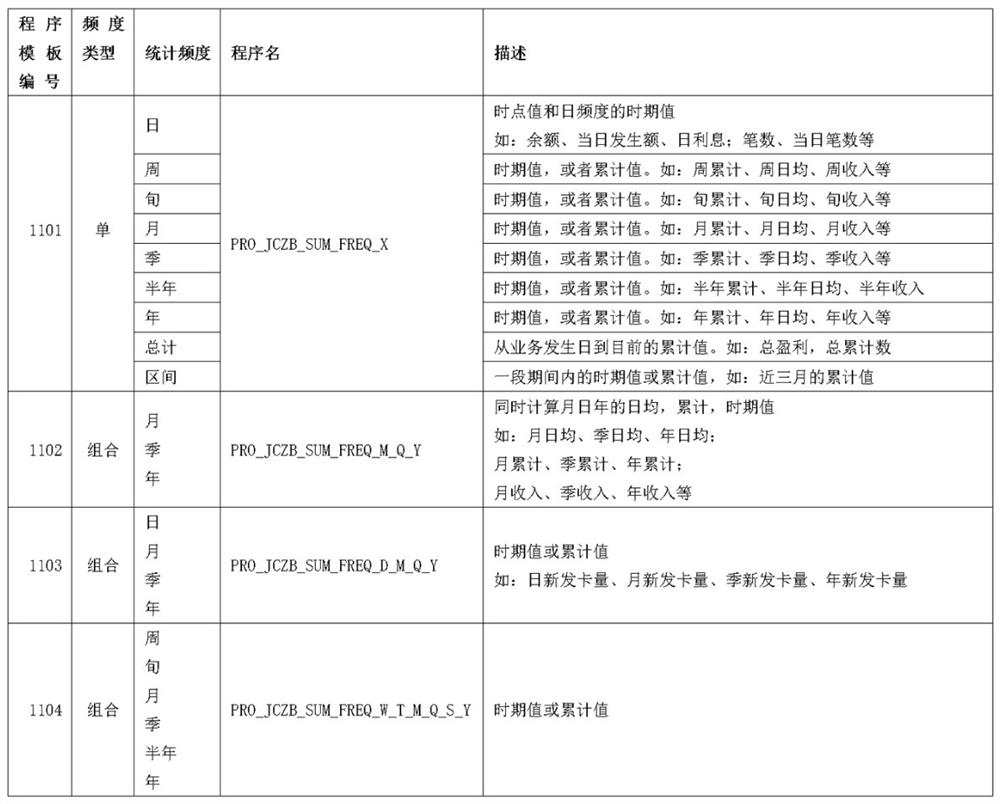

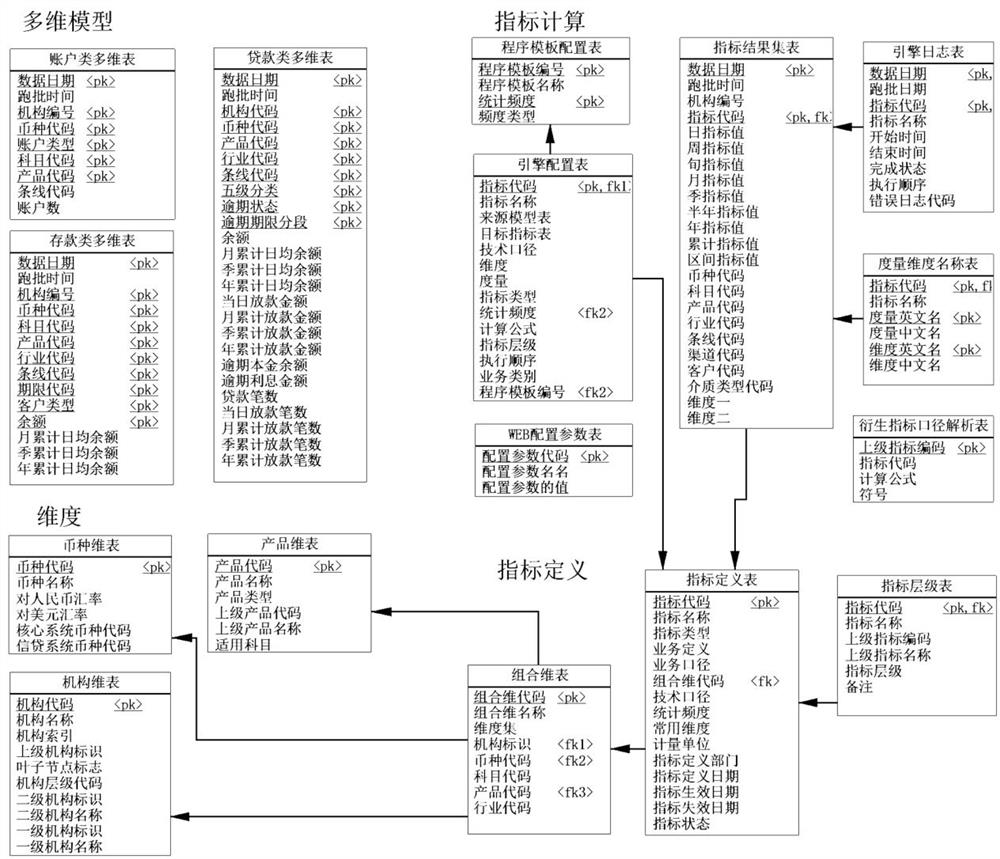

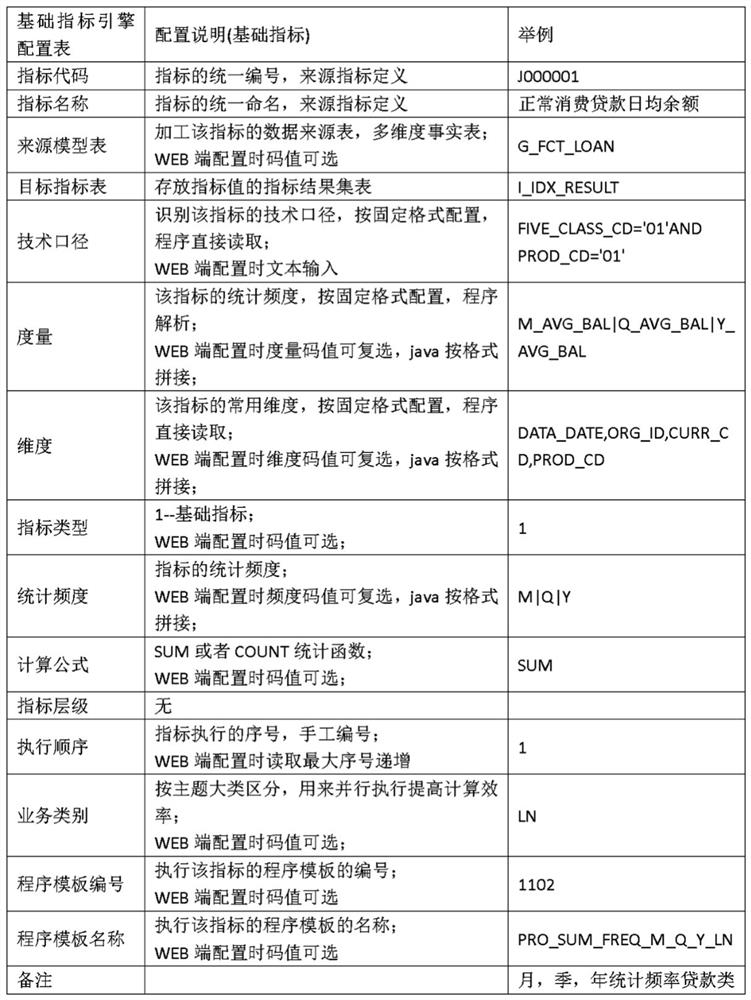

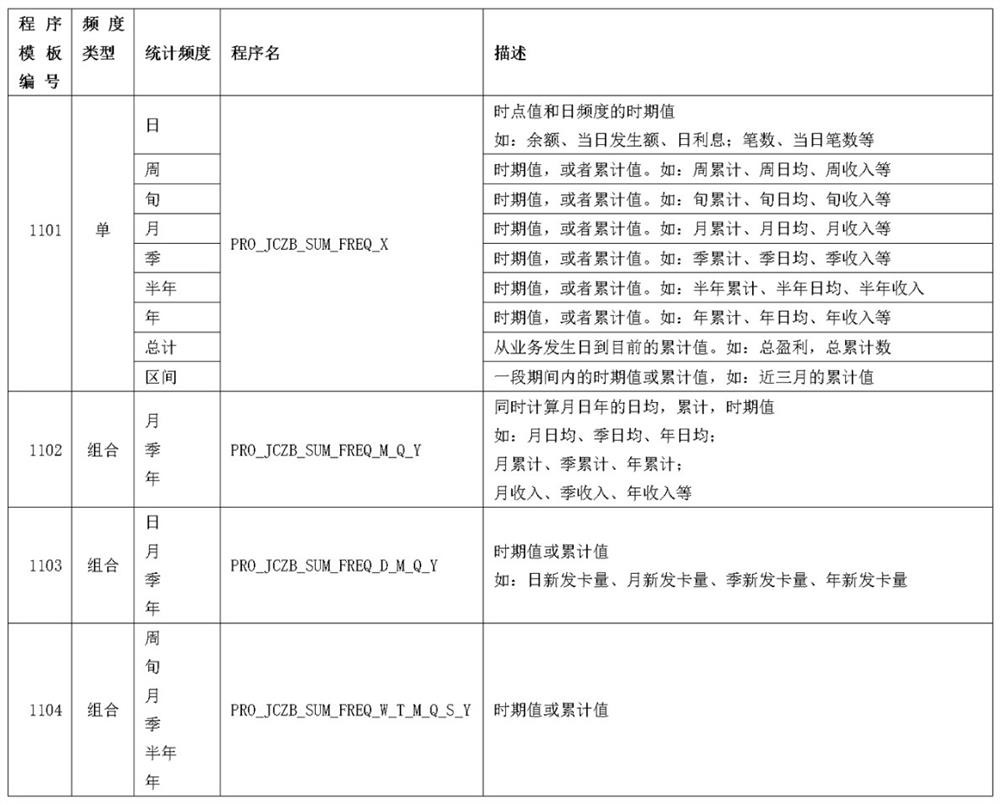

Index calculation engine implementation method based on multi-dimensional model

ActiveCN113255309AAvoid double countingCalculation logic is simpleFinanceText processingData OriginHard coding

The invention relates to the technical field of information, and provides an index calculation engine implementation method based on a multi-dimensional model. The method aims to solve the problems of different data index apertures, inaccurate data, data processing logic hard code stacking, repeated processing, batch running crossing dependence and long batch running operation time consumption. The main scheme comprises steps of constructing a multi-dimensional model table and a dimension table, and providing a data source for index calculation; according to the multi-dimensional model table, carrying out index calculation logic design, and obtaining a basic index engine configuration table, an addition and subtraction index engine configuration table and a multiplication and division index configuration table; calling the basic index engine configuration table, and calculating to obtain a basic index calculation result; calling an addition and subtraction index engine configuration table, and calculating to obtain an addition and subtraction index calculation result; and calling the multiplication and division index engine configuration table, and calculating the multiplication and division index engine configuration table to obtain a multiplication and division index calculation result; taking the obtained index calculation result as a data interface to provide services for the outside.

Owner:武汉众邦银行股份有限公司

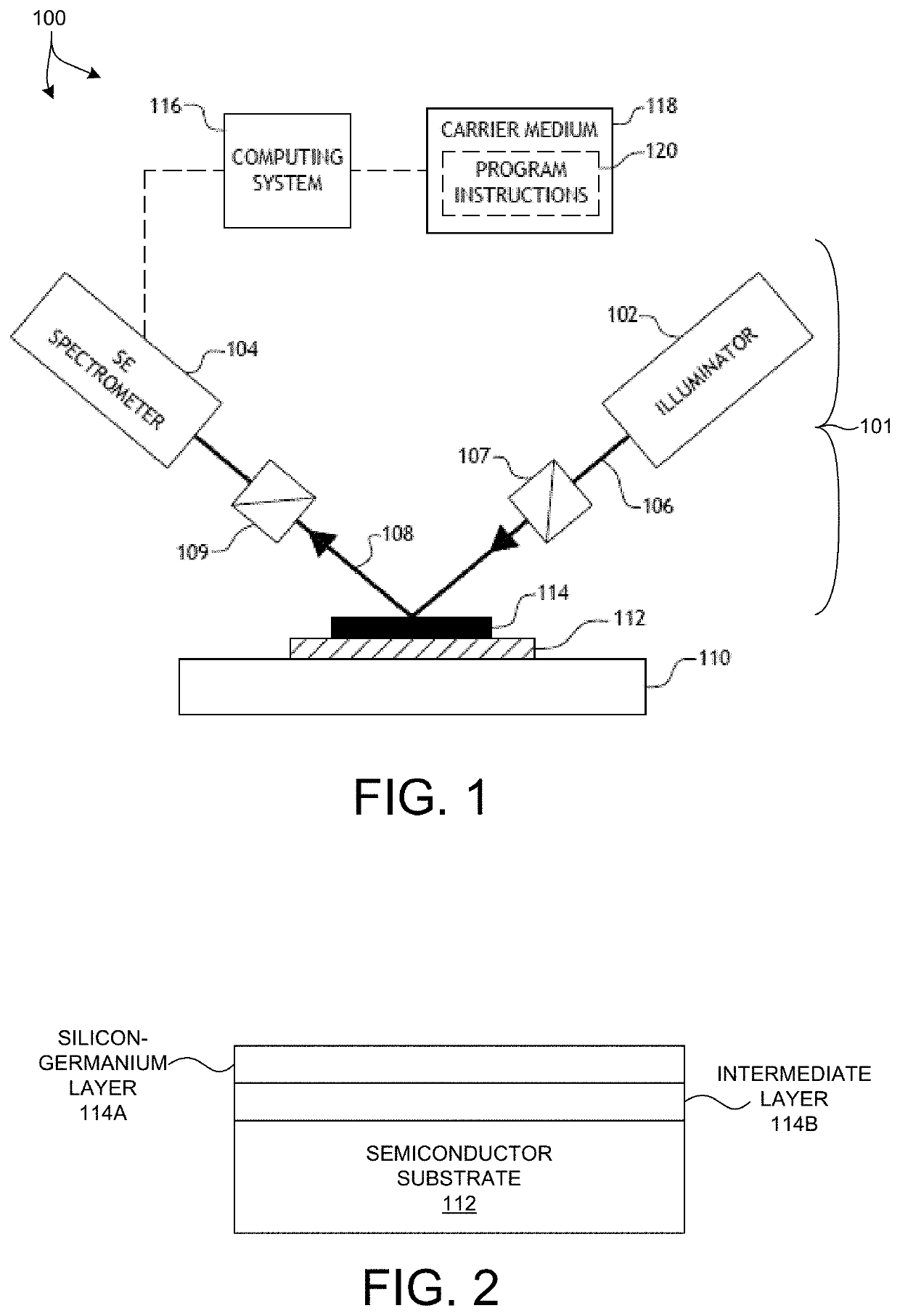

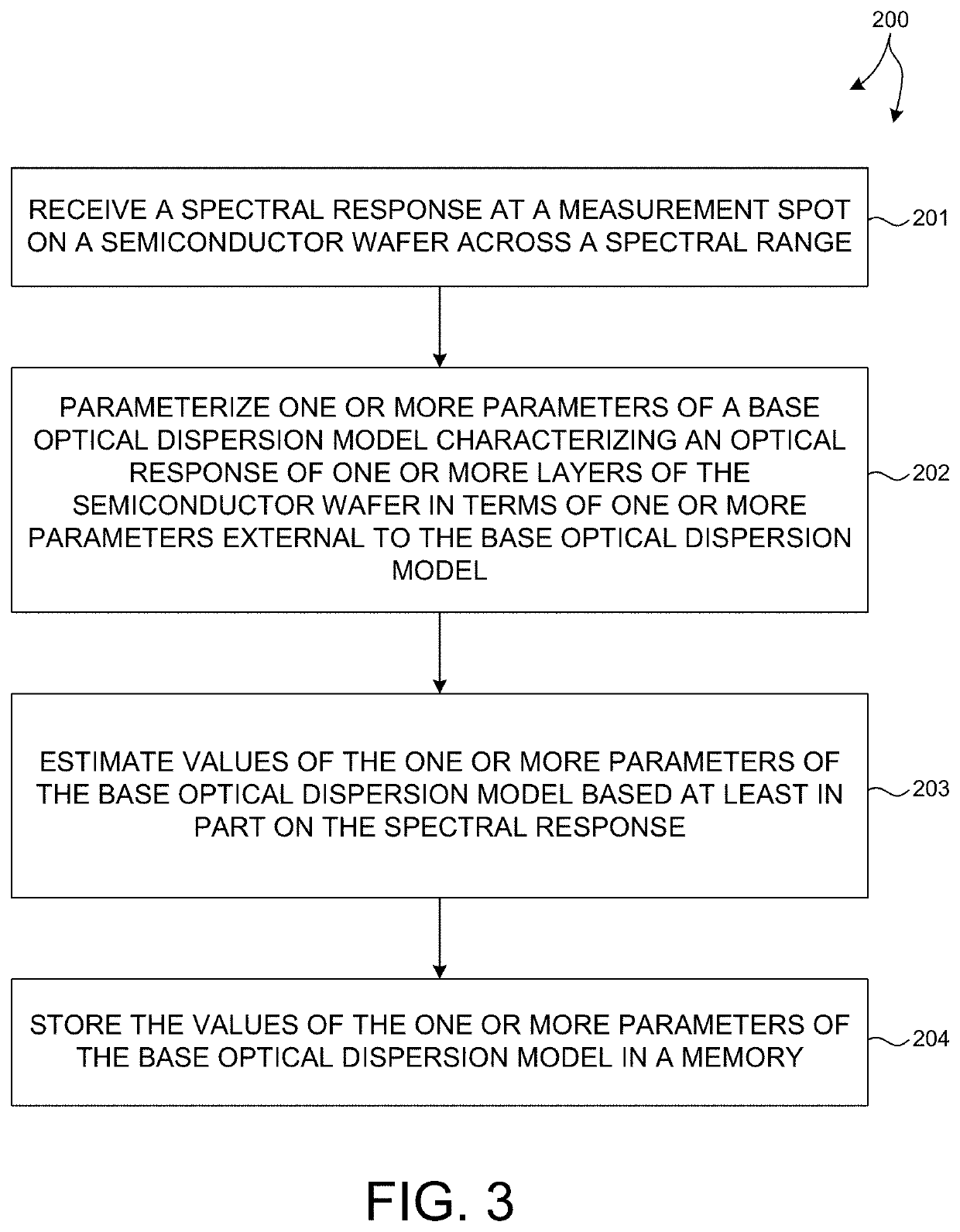

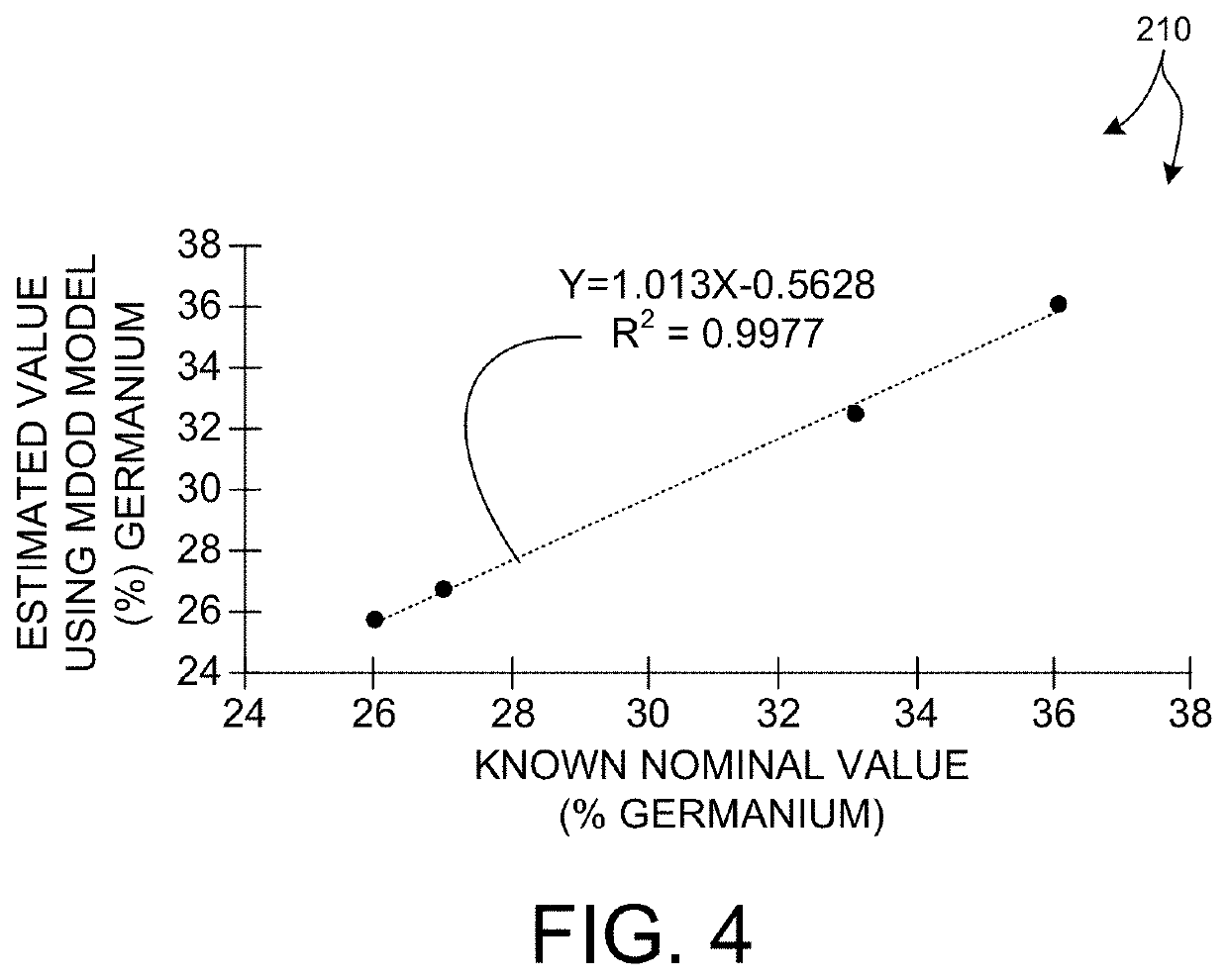

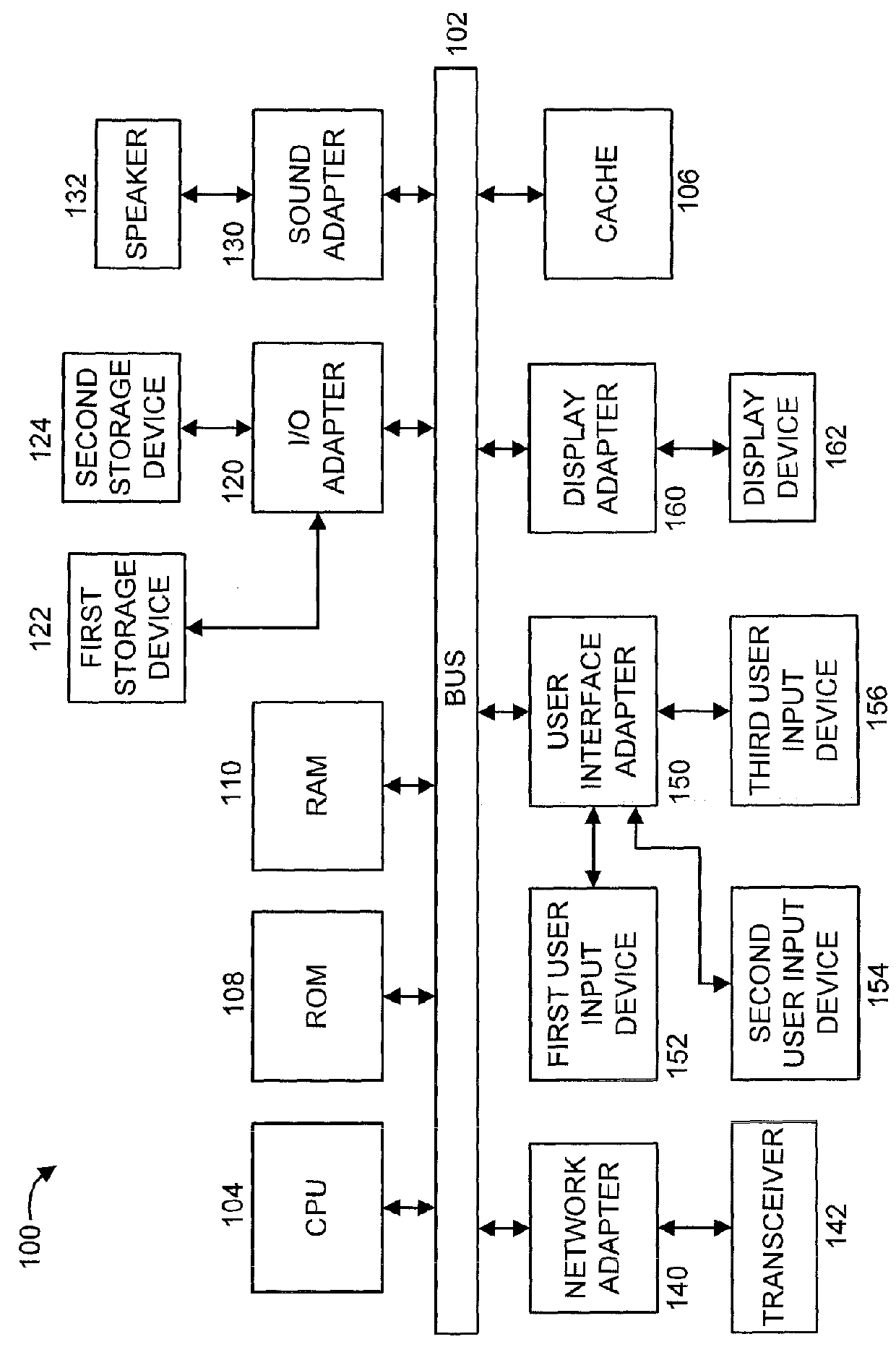

Multi-Dimensional Model Of Optical Dispersion

ActiveUS20200292467A1Robust and high throughputImage enhancementImage analysisLight dispersionComputational physics

Methods and systems for estimating values of parameters of interest from optical measurements of a sample early in a production flow based on a multidimensional optical dispersion (MDOD) model are presented herein. An MDOD model describes optical dispersion of materials comprising a structure under measurement in terms of parameters external to a base optical dispersion model. In some examples, a power law model describes the physical relationship between the external parameters and a parameter of the base optical dispersion model. In some embodiments, one or more external parameters are treated as unknown values that are resolved based on spectral measurement data. In some embodiments, one or more external parameters are treated as known values, and values of base optical dispersion model parameters, one or more external parameters having unknown values, or both, are resolved based on spectral measurement data and the known values of the one or more external parameters.

Owner:KLA TENCOR TECH CORP

Creating new cloud resource instruction set architecture

ActiveUS9967146B2Improve throughputDelay minimizationResource allocationData switching networksCloud baseSystem building

Owner:INT BUSINESS MASCH CORP

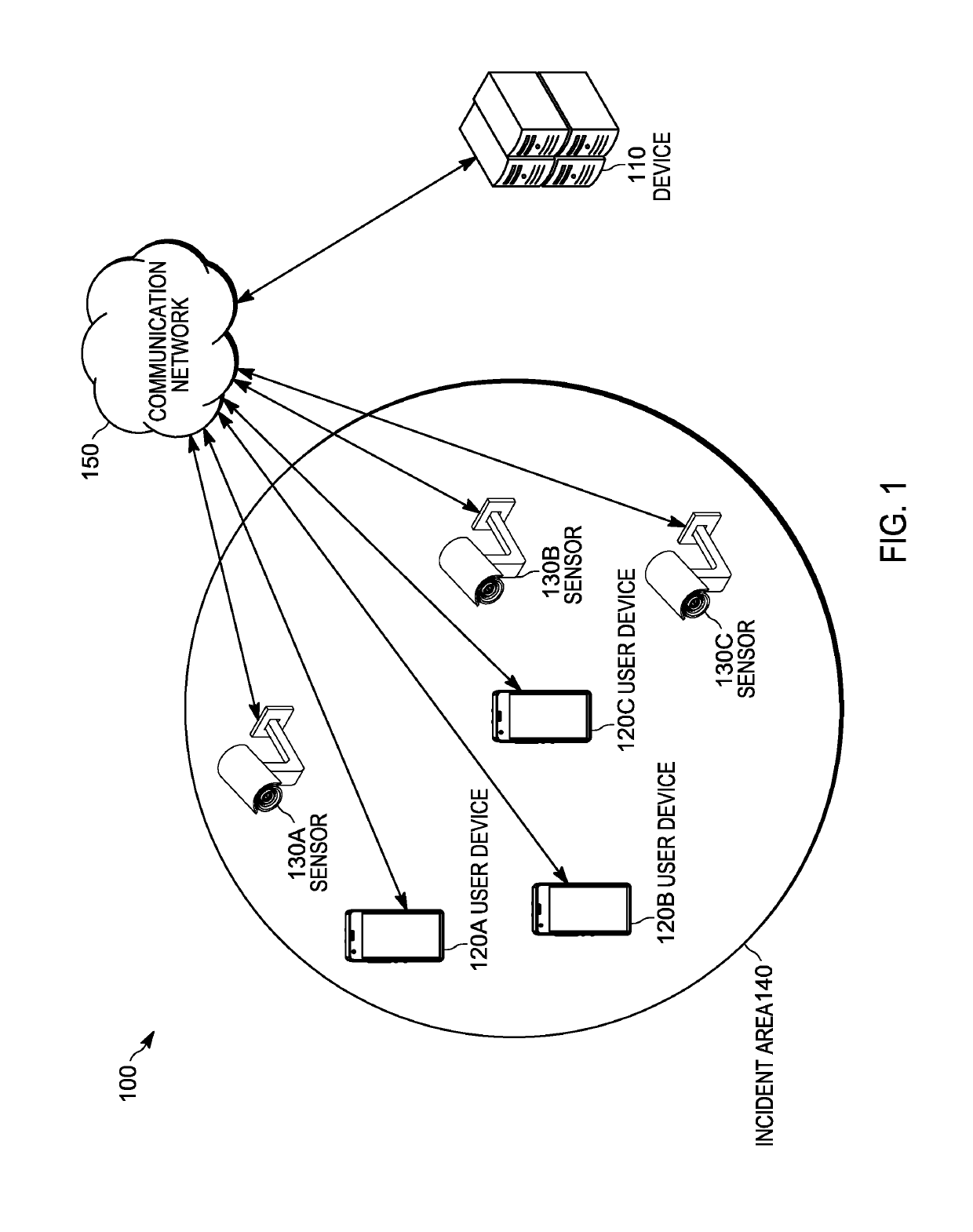

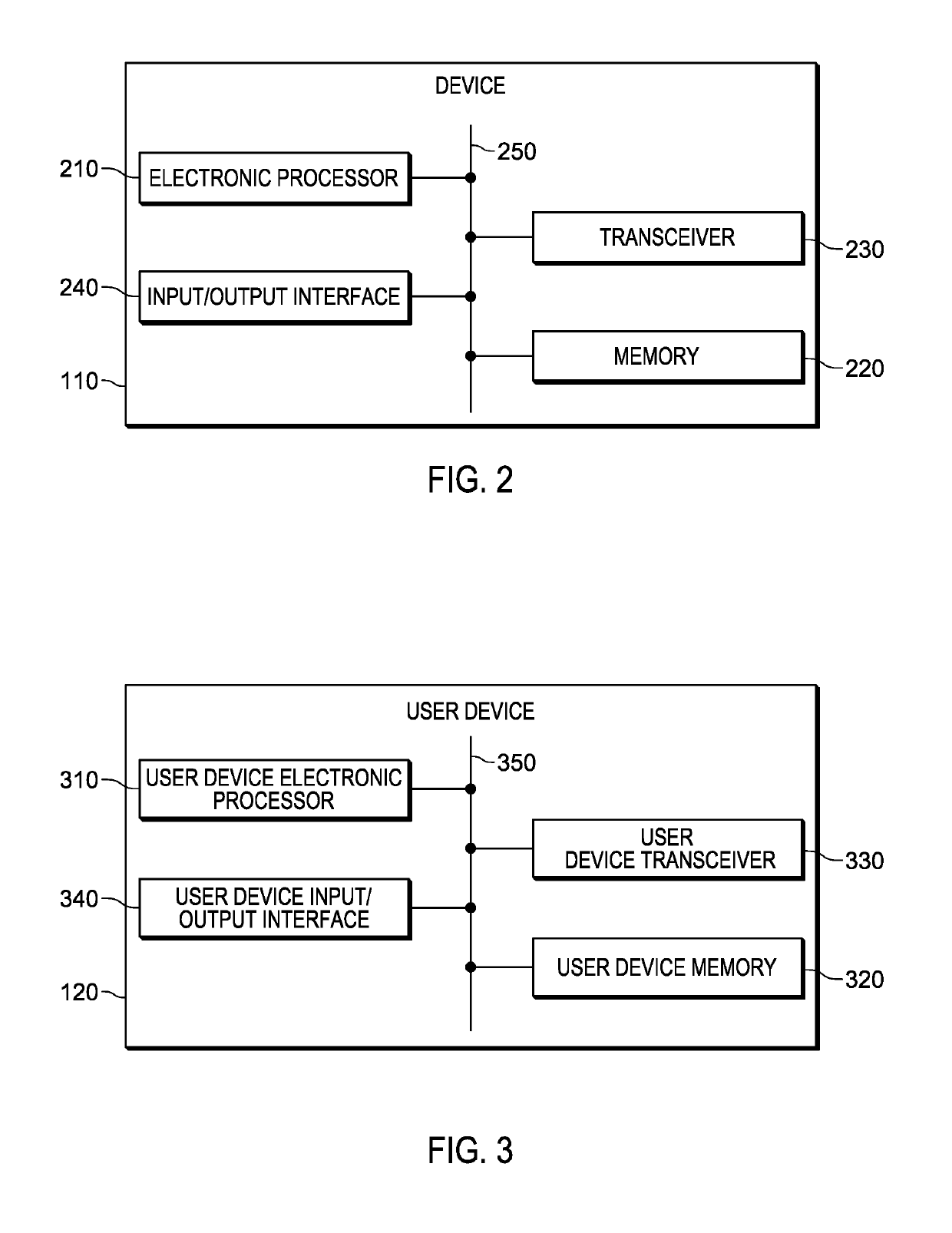

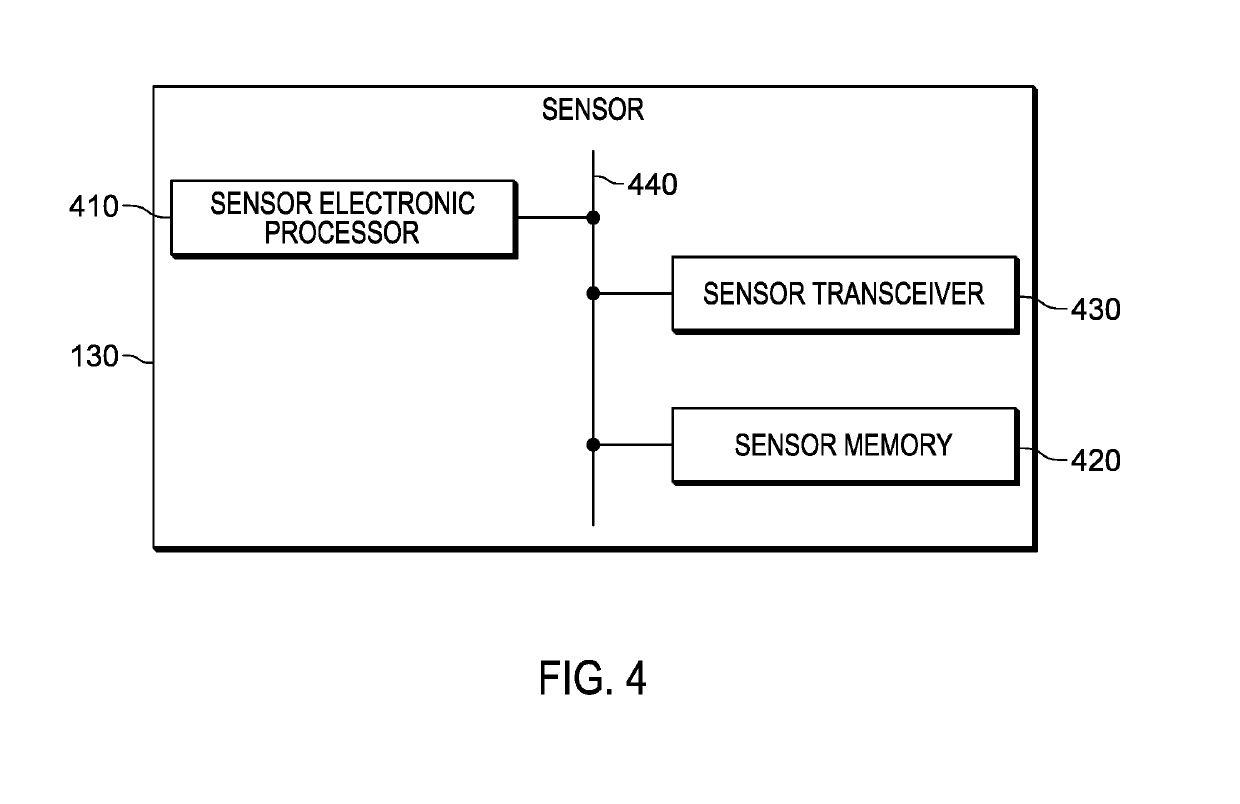

Method and device for providing safe zone information for incident area

Owner:MOTOROLA SOLUTIONS INC

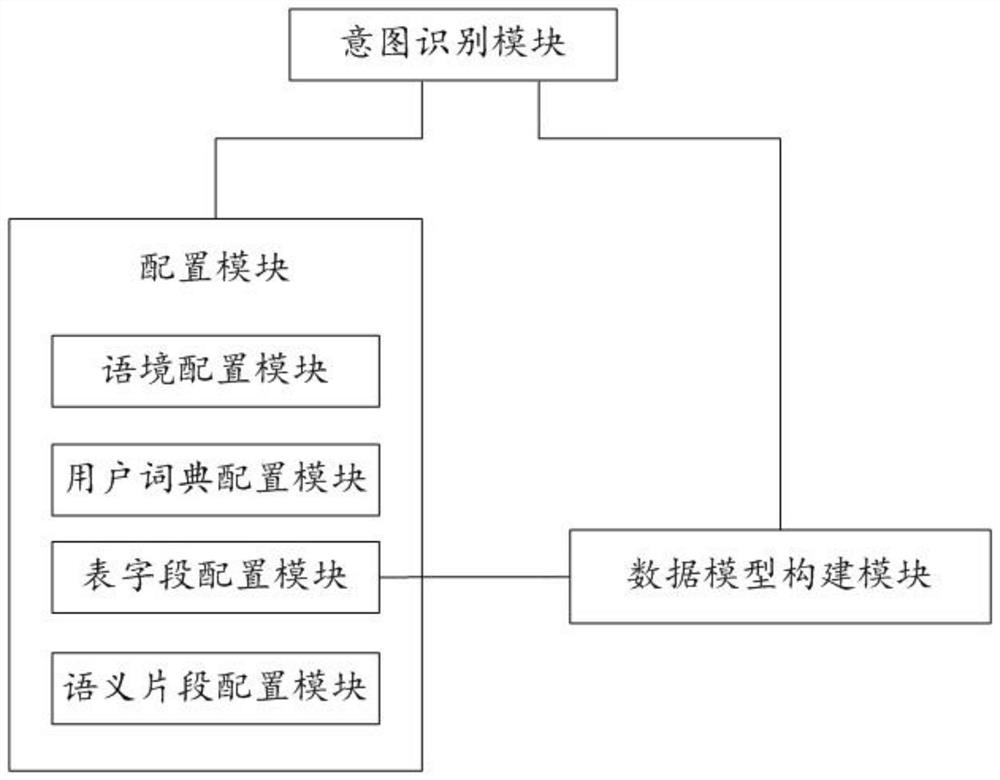

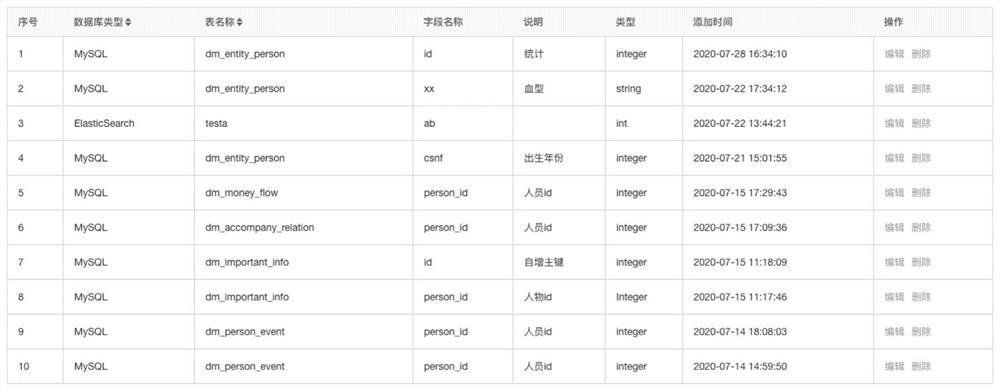

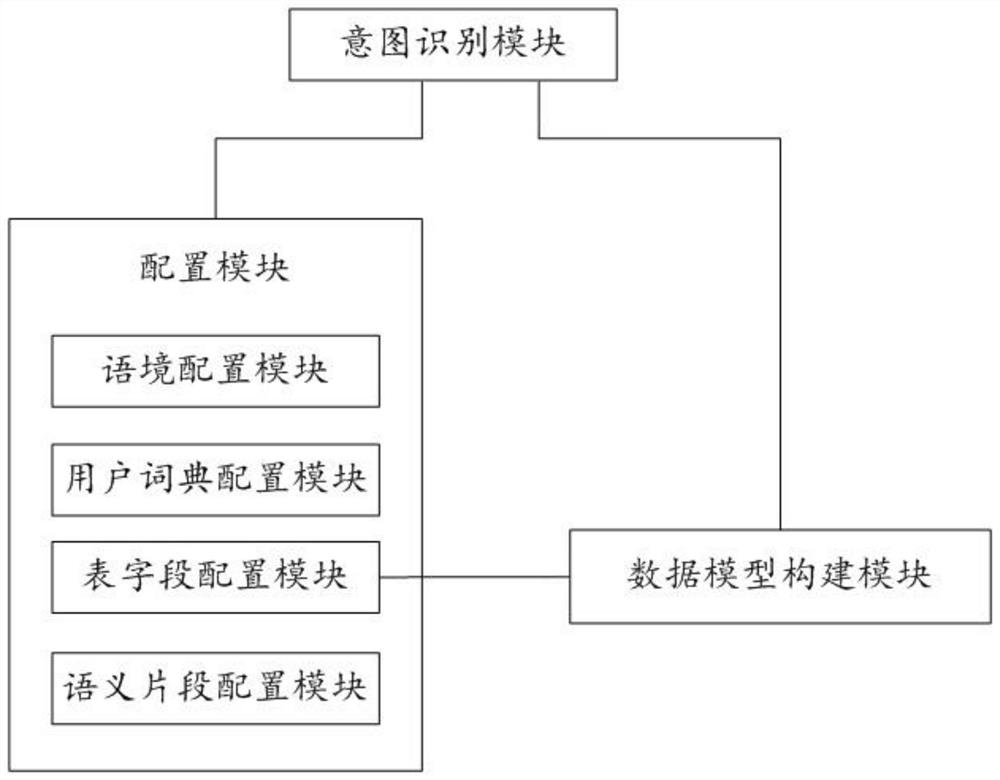

Multi-data-source NL2SQL system based on semantic rules and multi-dimensional model

ActiveCN112559550AIncrease success rateLower requirementSemantic analysisSpecial data processing applicationsTable (database)Data set

The invention discloses a multi-data-source NL2SQL system based on semantic rules and a multi-dimensional model, comprising a service layer for realizing NL2SQL, the service layer comprising: a configuration module for configuring matching rules; a data model construction module used for constructing a data model capable of generating SQL statements by utilizing the table and field information ofthe database; and an intention recognition module used for analyzing and matching the natural statement according to the matching rule to obtain table and field information of a database, and generating an executable SQL statement by utilizing the data model. The system does not depend on annotation corpora and models, and NL2SQL based on intention can be achieved through simple configuration of an interface; multi-selection nesting is supported through the data model construction module, and flexible configuration can be achieved; the requirement for a data set is reduced through the intention recognition module, and the success rate of SQL generation is increased. Therefore, by adopting the system provided by the invention, the business scene can be quickly constructed according to different projects.

Owner:北京智源人工智能研究院

Multi-dimensional data association and analysis method and device, storage medium and computer equipment

PendingCN111930860AEasy to analyzeRelational databasesMulti-dimensional databasesEngineeringMulti dimensional data

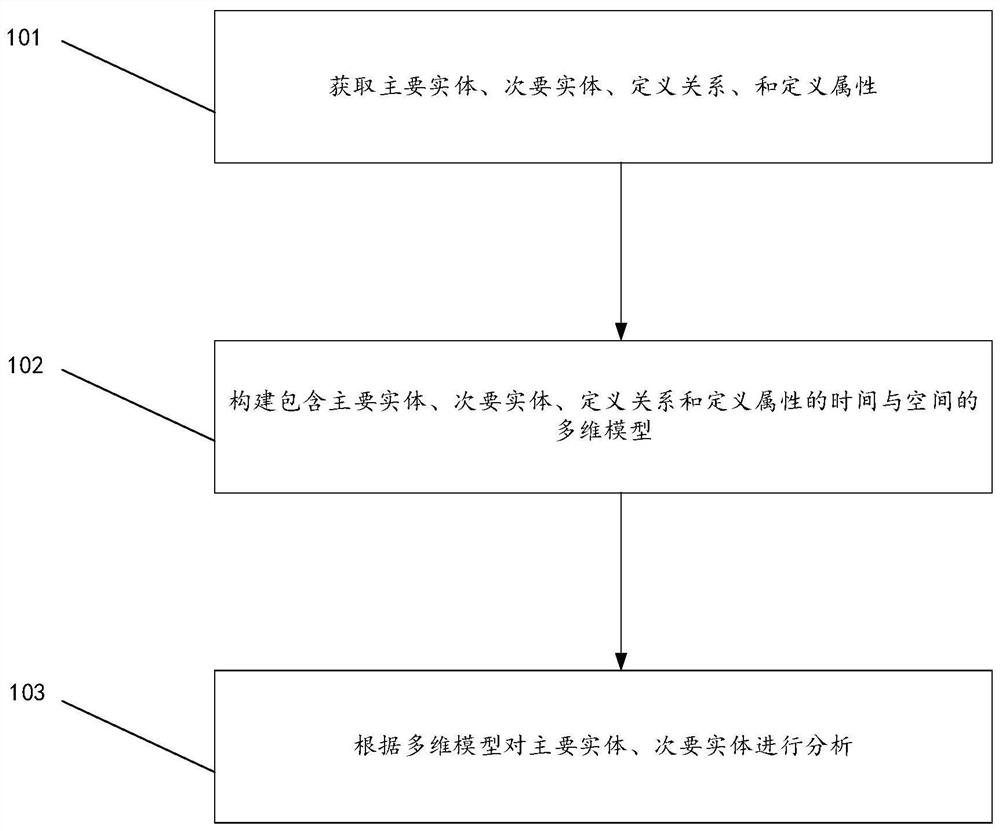

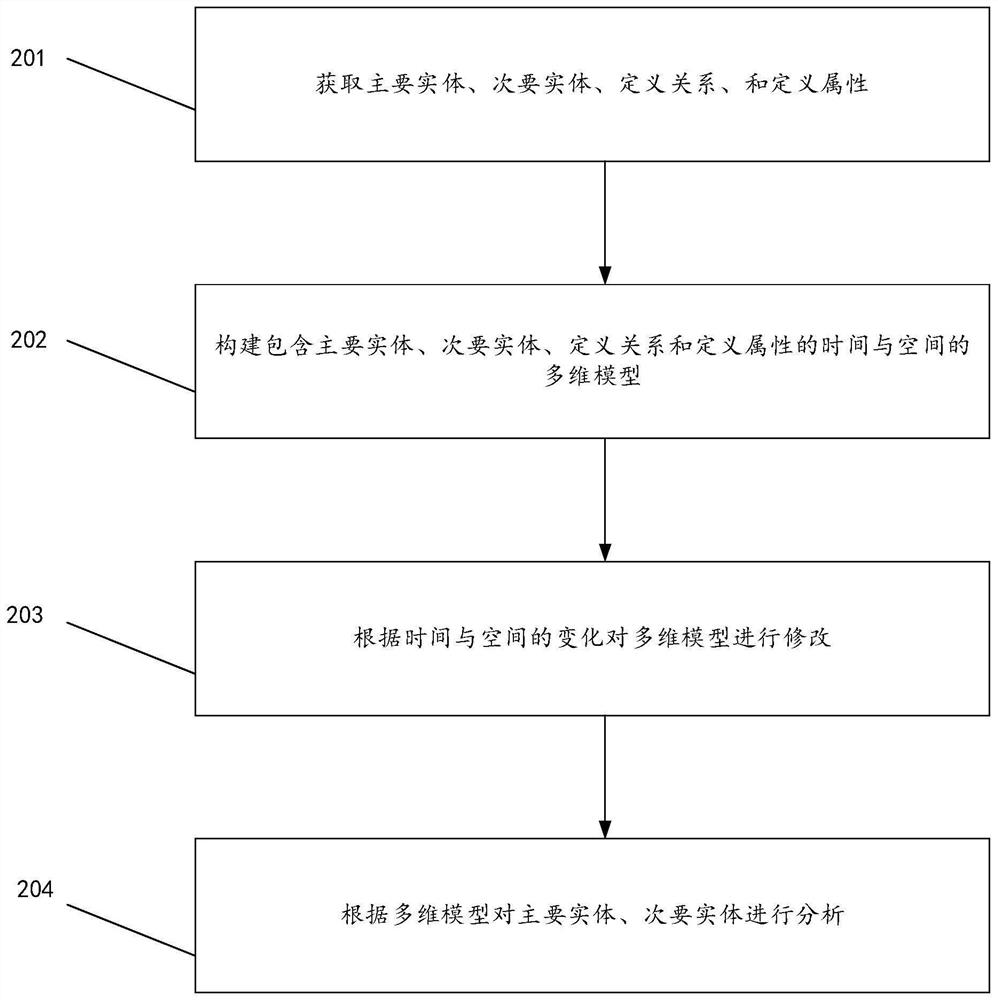

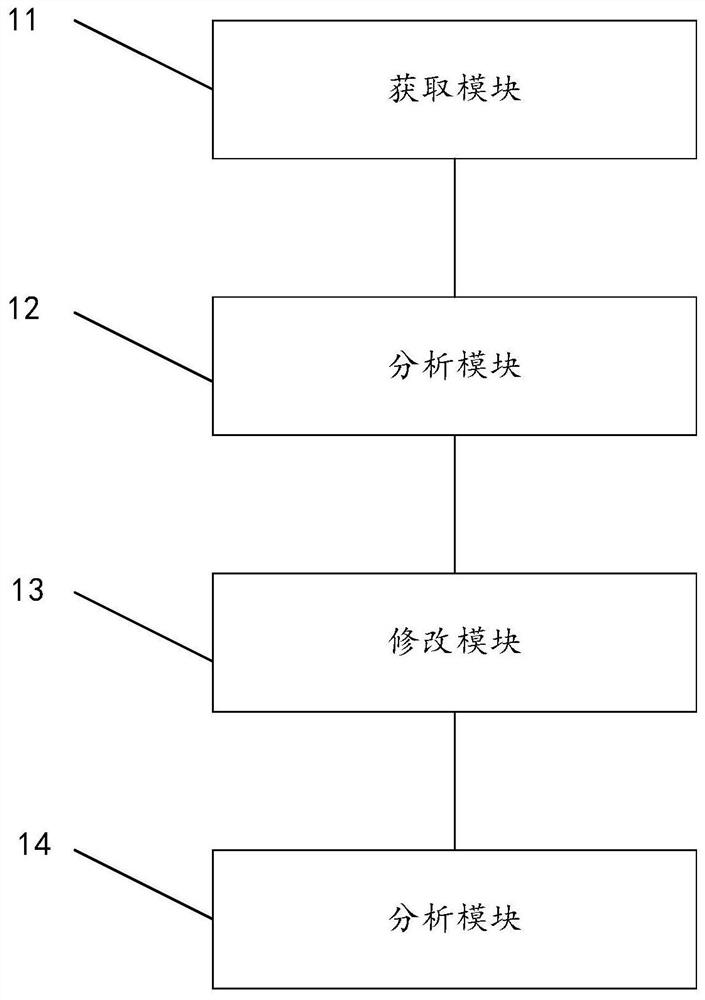

The embodiment of the invention provides a multi-dimensional data association and analysis method and device, a storage medium and computer equipment. The method comprises the following steps: collecting a primary entity, a secondary entity, a definition relationship and a definition attribute; constructing a time and space multi-dimensional model containing the primary entity, the secondary entity, the definition relationship and the definition attribute; analyzing the primary entity and the secondary entity according to the multi-dimensional model; and analyzing the primary entity and the secondary entity according to the multi-dimensional model, thereby making up the defects of the existing knowledge model and providing convenience for knowledge analysis.

Owner:GUANGZHOU UNIVERSITY +1

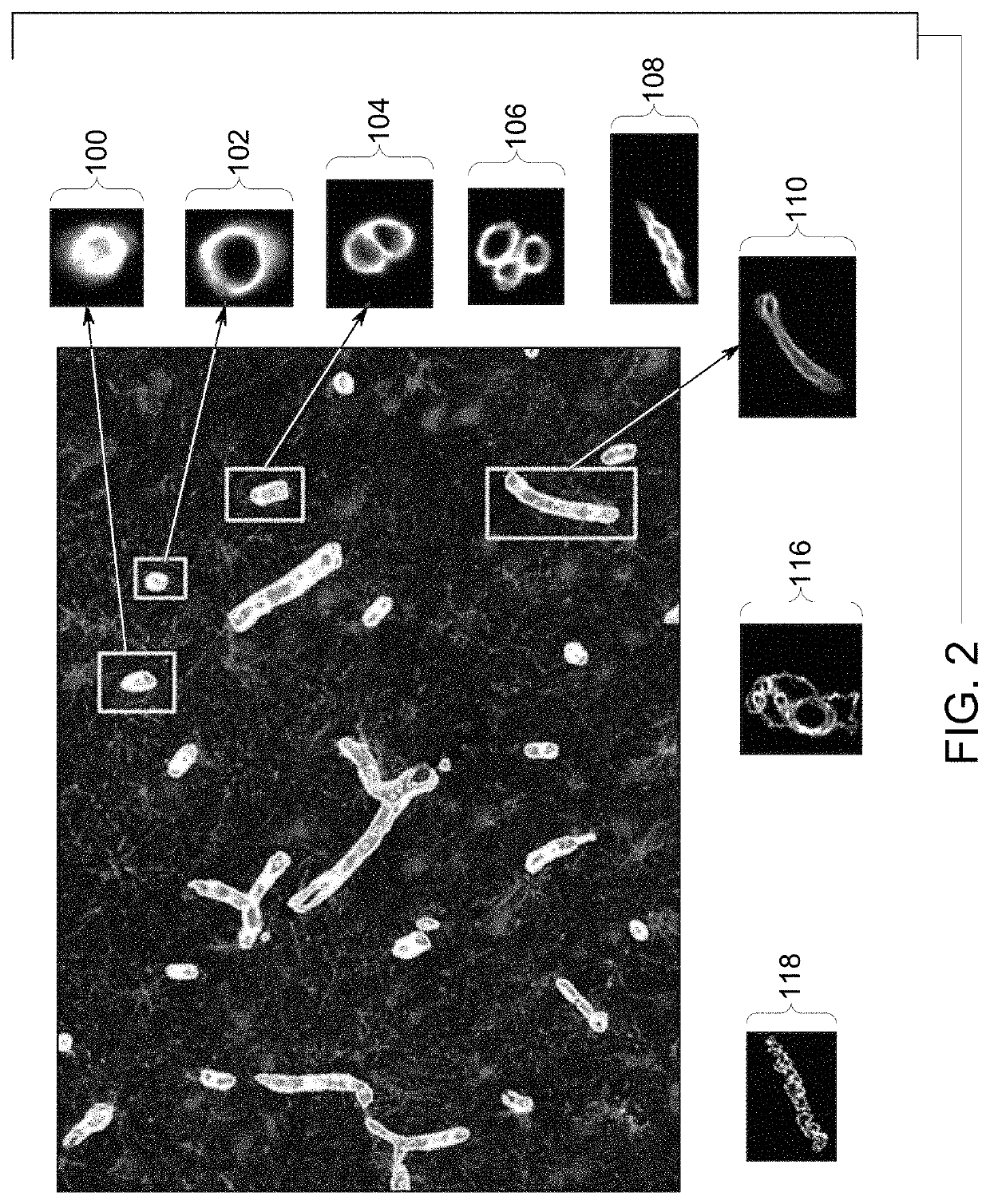

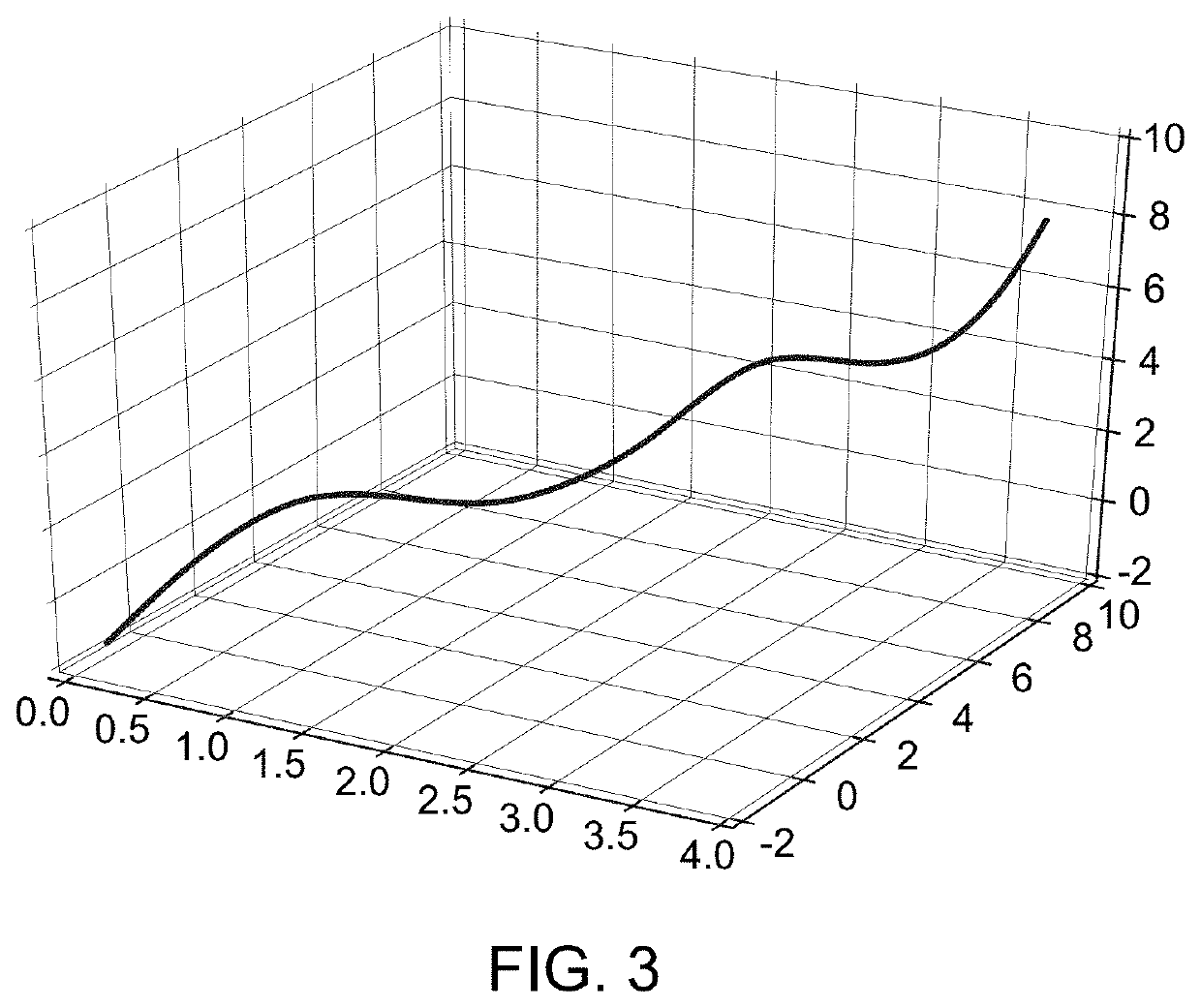

Methods of systems of generating virtual multi-dimensional models using image analysis

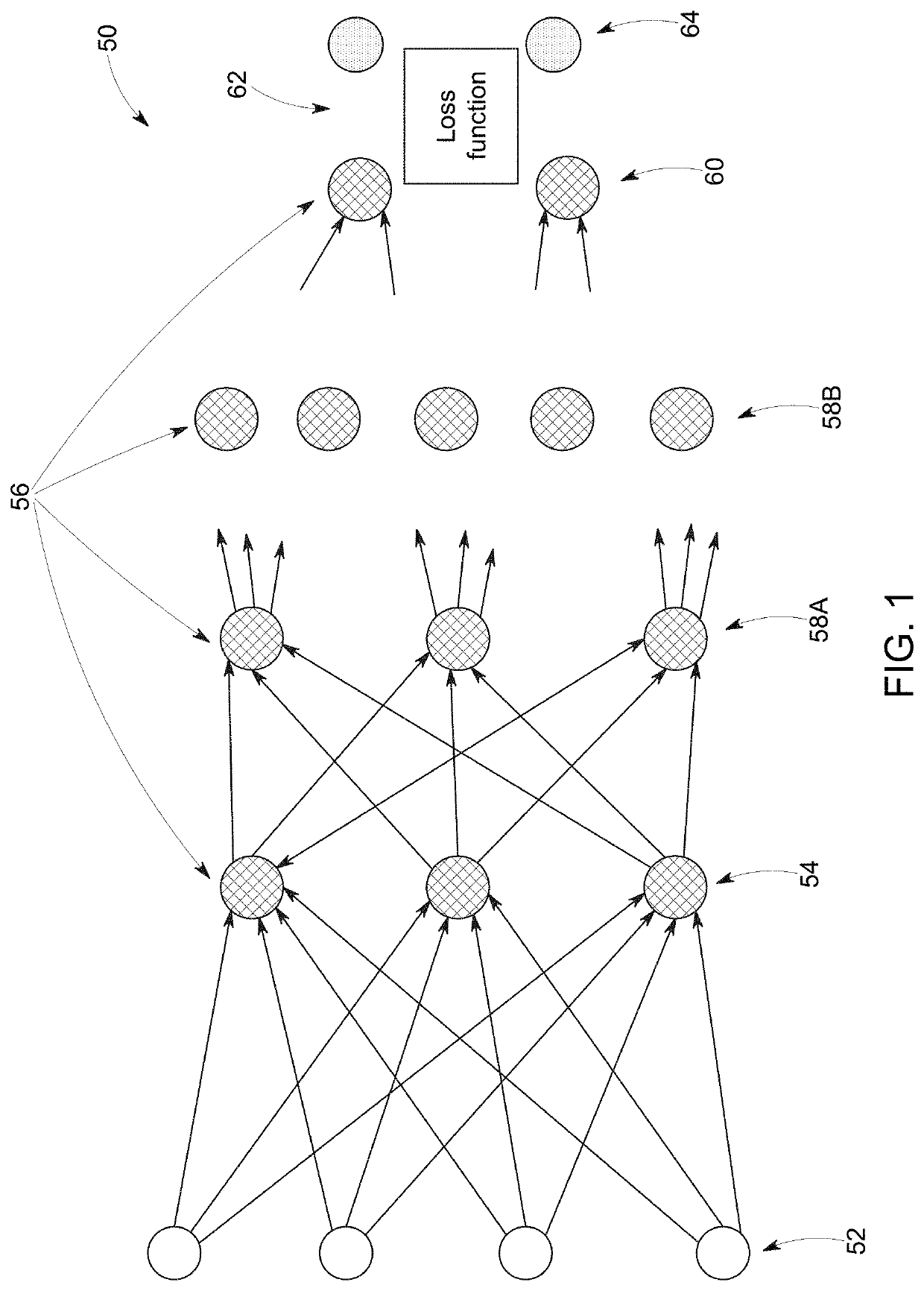

The present approach relates to the use of trained artificial neural networks, such as convolutional neural networks, to classify vascular structures, such as using a hierarchical classification scheme. In certain approaches, the artificial neural network is trained using training data that is all or partly derived from synthetic vascular representations.

Owner:GENERAL ELECTRIC CO

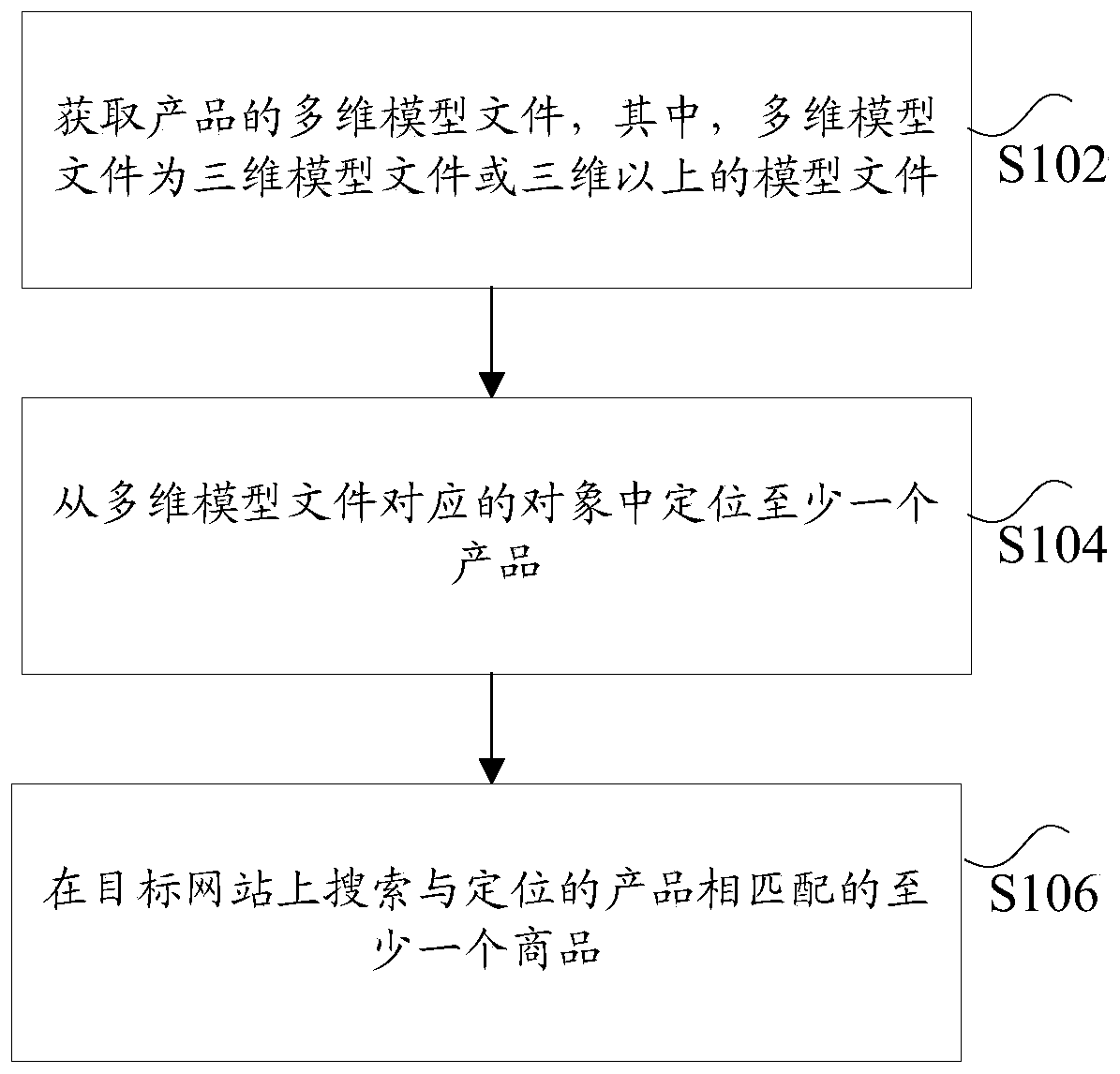

Commodity searching method and device

ActiveCN111177525AImprove accuracyDigital data information retrievalBuying/selling/leasing transactionsWeb siteAlgorithm

Owner:ALIBABA GRP HLDG LTD

Multi-dimensional parsing method and system for natural language processing

ActiveUS11250842B2Speed up the processEfficient communicationNatural language translationSemantic analysisSource textParsing

A method for translating a text written or otherwise communicated in a source natural language into a text written or otherwise communicable in target natural language, in reliance upon a multidimensional model, relies on determining the core concept in the sentences of the source text, and leverages the determined core concepts to create the target language translation. The method includes processing the source natural language text into sentences, then parsing the sentences, including assigning codes and / or directional operators to realize parsed sentences according to the model. The sentence models are then processed effect the actual translation to the target natural language text, and communicated.

Owner:KIM MIN KU

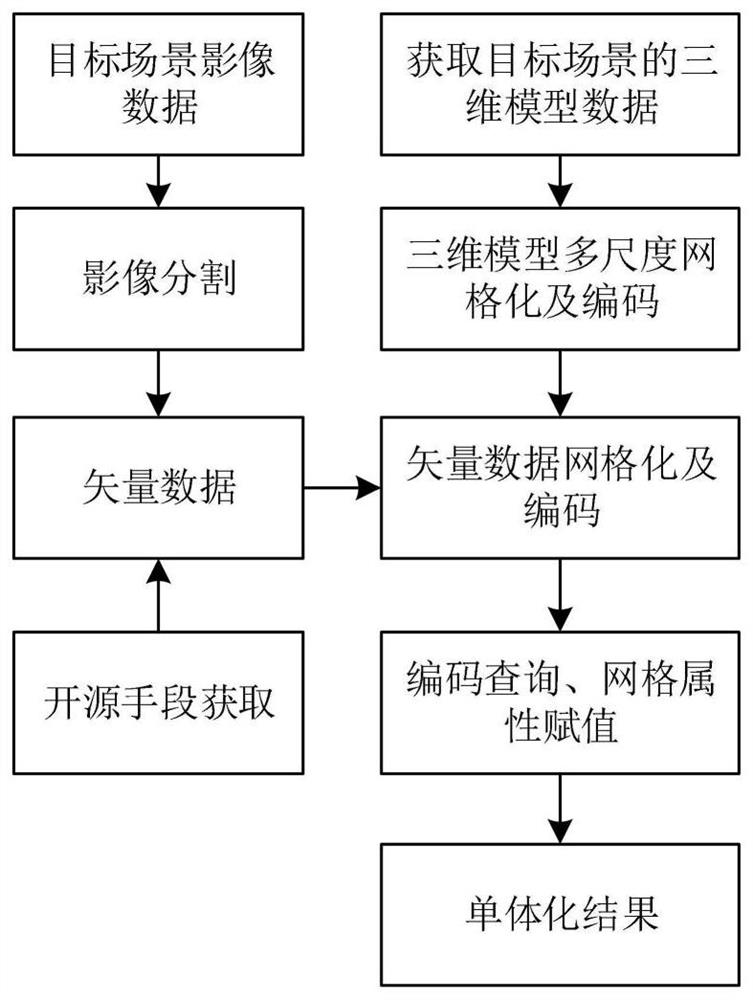

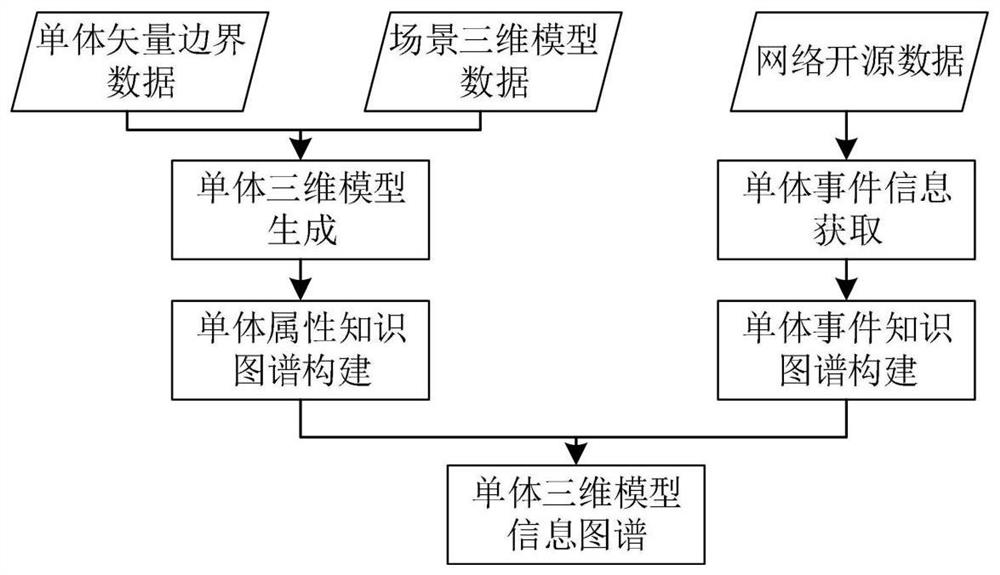

Three-dimensional model monomer method and device

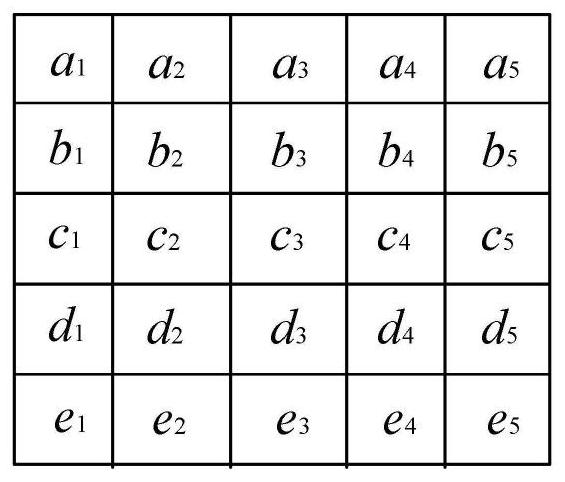

ActiveCN114049462AImprove processing efficiencyMonolithic fastGeometric image transformationGeographical information databasesAlgorithmThree-dimensional space

The invention discloses a three-dimensional model monomer method and device, and belongs to the technical field of information. According to the technical scheme, on the basis of a multi-scale integer coding method of a three-dimensional space, a three-dimensional model monomerization problem is converted into a coding query problem, the data processing efficiency can be improved, the calculation amount can be reduced, and rapid monomerization of the three-dimensional model is achieved; position information of a hot event is extracted and is associated with a single three-dimensional model, a knowledge graph taking the event as the center and a knowledge graph taking the geographic space position as the center are respectively constructed, associated and fused, and finally a single multi-dimensional model and geographic space information containing total elements are obtained, so that important support is provided for command decision making.

Owner:中国人民解放军61646部队

An implementation method of index calculation engine based on multi-dimensional model

ActiveCN113255309BAvoid double countingCalculation logic is simpleFinanceText processingData OriginHard coding

The invention relates to the field of information technology, and provides a method for realizing an index calculation engine based on a multidimensional model. The main purpose is to solve the problems of different data indicators, inaccurate data, data processing logic hard code stacking, repeated processing, cross-dependency of running batches, and long time-consuming calculations of running batches. The main scheme includes building multidimensional model tables and dimension tables to provide data sources for indicator calculations; designing indicator calculation logic based on multidimensional model tables, and obtaining basic indicator engine configuration tables, addition and subtraction indicator engine configuration tables, and multiplication and division indicator configuration tables; Call the basic indicator engine configuration table to calculate the basic indicator calculation results; call the addition and subtraction indicator engine configuration table to calculate the addition and subtraction indicator calculation results; call the multiplication and division indicator engine configuration table to calculate the multiplication and division indicator engine configuration table. Multiplication and division indicator calculation results. Then use the obtained indicator calculation results as a data interface to provide external services.

Owner:武汉众邦银行股份有限公司

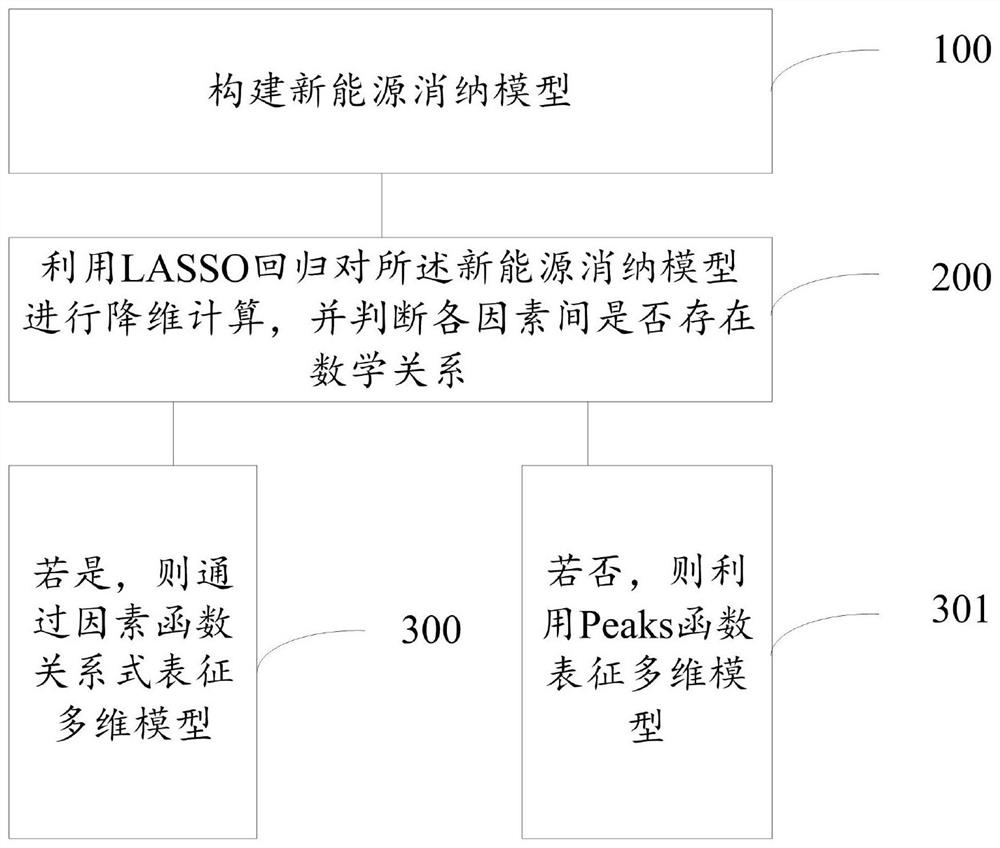

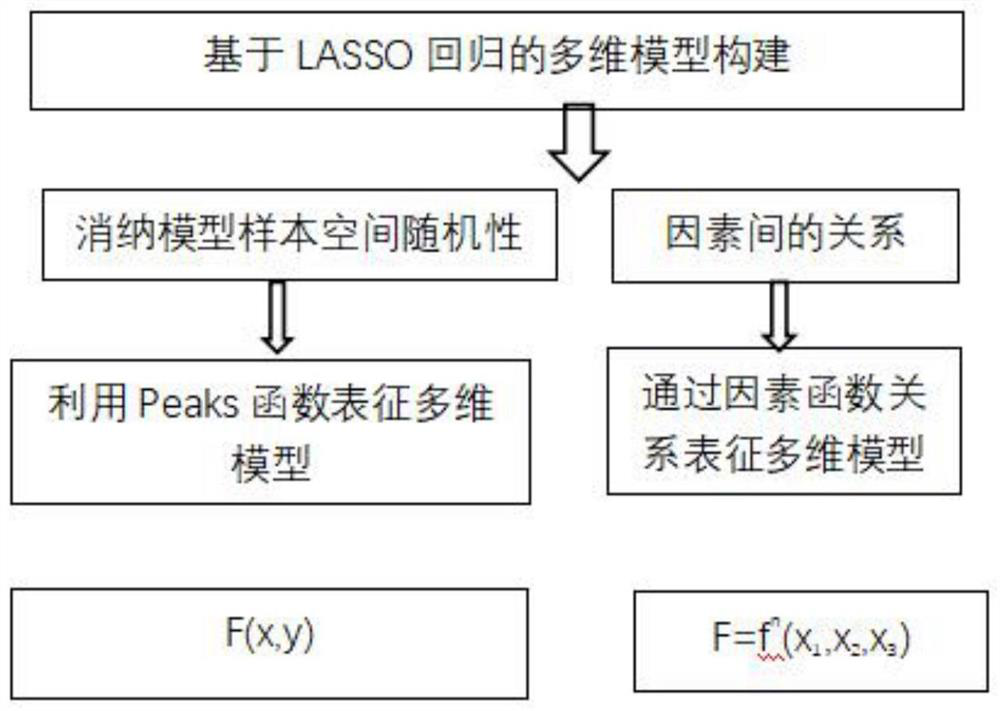

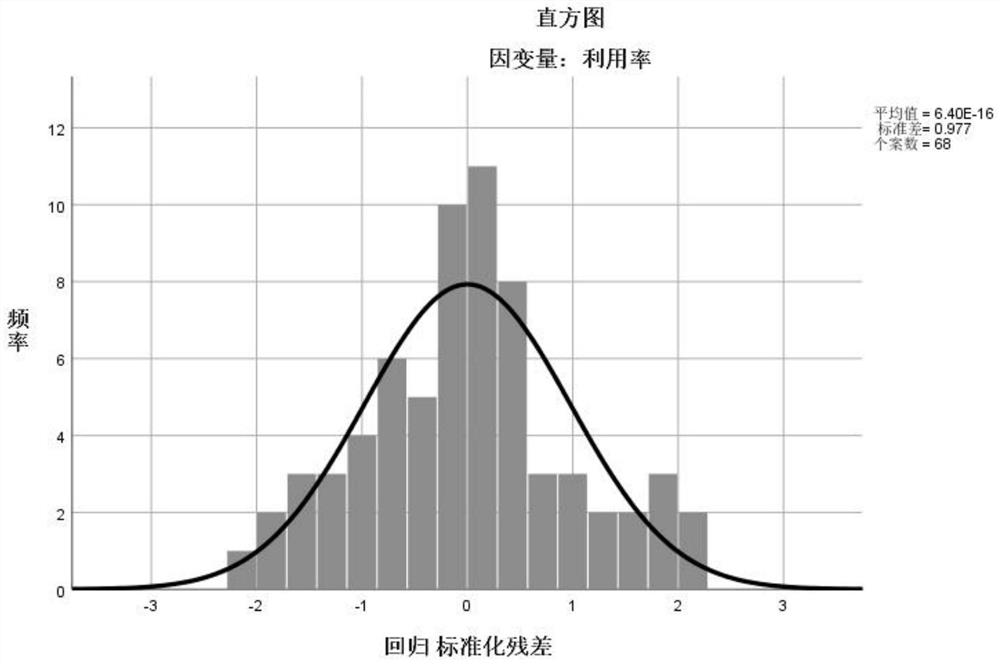

Method and system for determining new energy consumption model based on LASSO regression

PendingCN114597965ASingle network parallel feeding arrangementsInformation technology support systemAlgorithmDimensionality reduction

The invention relates to a method and system for determining a new energy consumption model based on LASSO regression. The method comprises the following steps: constructing a new energy consumption model; performing dimension reduction calculation on the new energy consumption model by using LASSO regression, and judging whether a mathematical relationship exists among factors: if yes, representing a multi-dimensional model through a factor function relational expression; and if not, representing the multi-dimensional model by using a Peaks function. The multi-dimensional new energy response surface model based on LASSO regression can vividly describe the condition that the new energy utilization rate changes along with factors, and has important significance for researching the influence of multiple uncertain factors on the new energy utilization rate.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

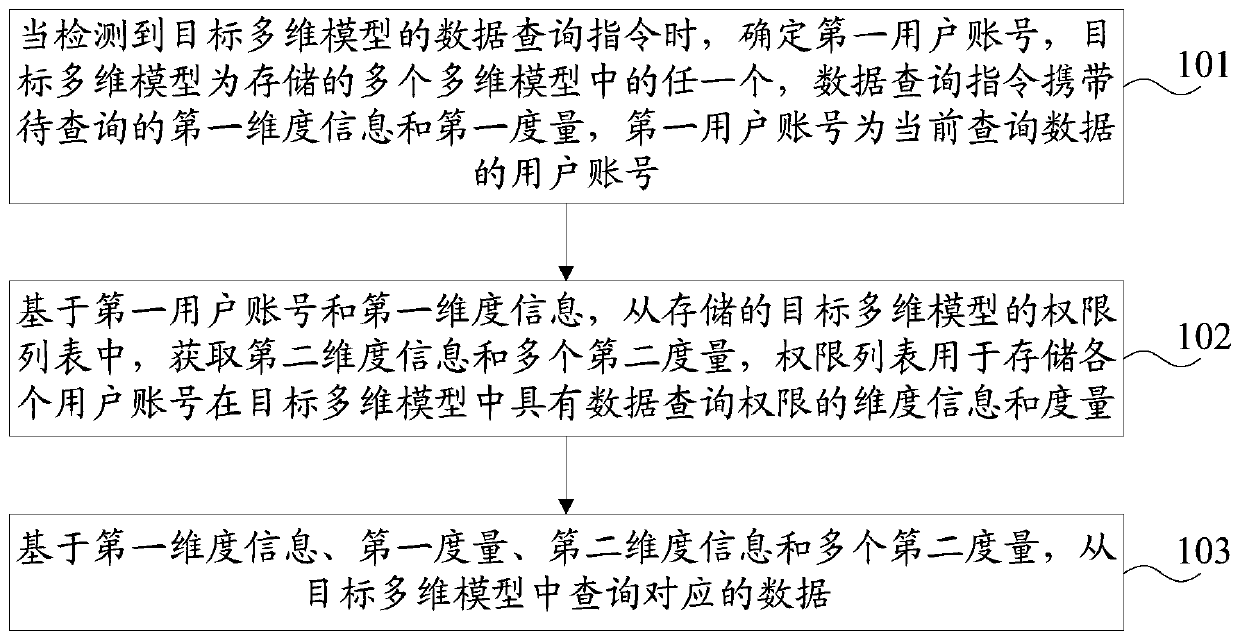

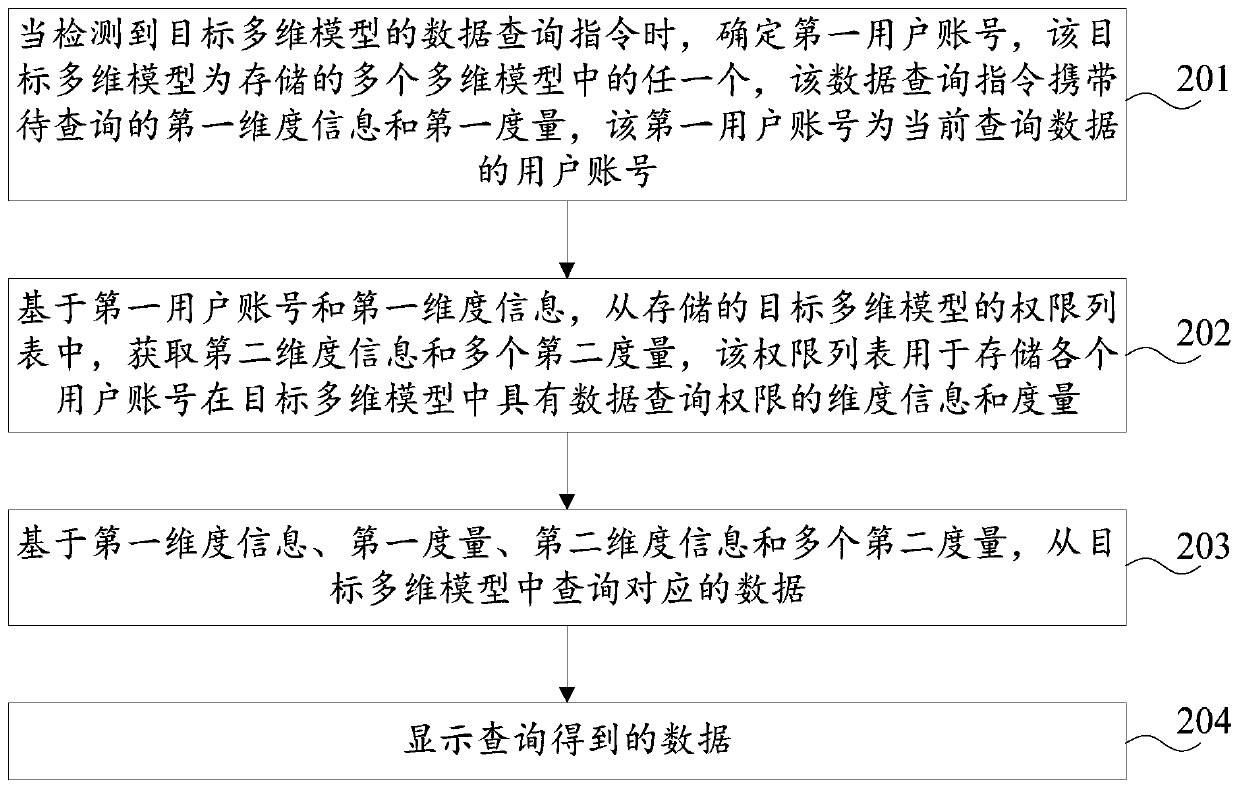

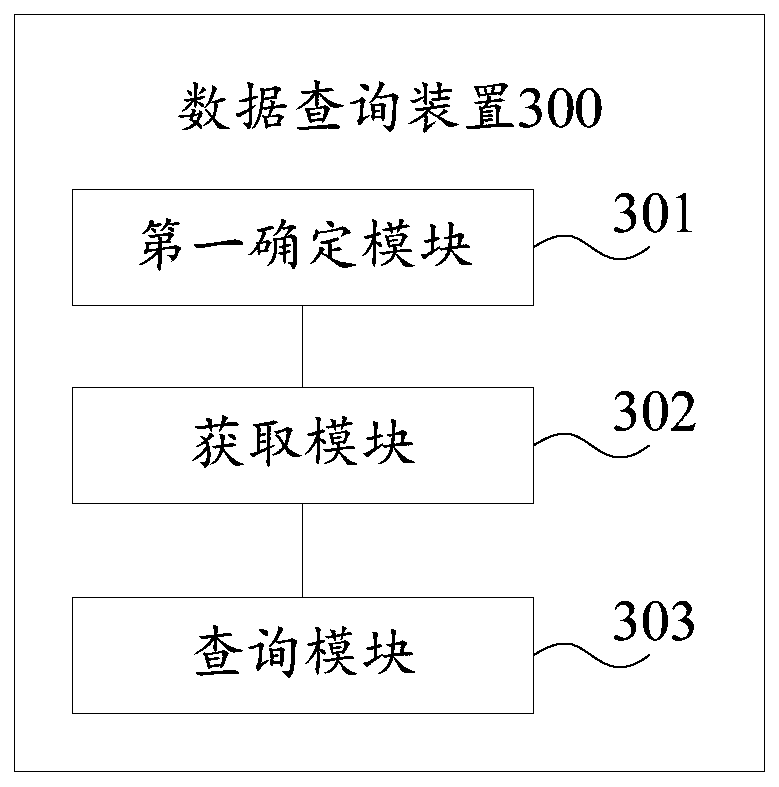

Data query method and device

ActiveCN106682180BImprove securityDigital data protectionMulti-dimensional databasesInformation processingData mining

The invention discloses a data inquiry method and device and belongs to the technical field of information processing. The method includes the following steps: when a data inquiry command of a target multidimensional model is detected, a first user account is determined, wherein the target multidimensional model refers to any one of a plurality of stored multidimensional models, the data inquiry command carries to-be-inquired first dimension information and a first metric, and the first user account is the user account of current inquired date; based on the first user account and the first dimension information, the second dimension information and a plurality of second metrics are obtained from a permission list of the stored target multidimensional models; based on the first dimension information, the first metric, the second dimension information and the second metrics, the corresponding data in the target multidimensional model is inquired. When a user inquires the date of the target multidimensional model, the inquiry permission of the user can be determined according to the permission list, the corresponding data in the target multidimensional model can be inquired according to the inquiry permission, and therefore the data safety is improved.

Owner:GUANGZHOU HUADUO NETWORK TECH

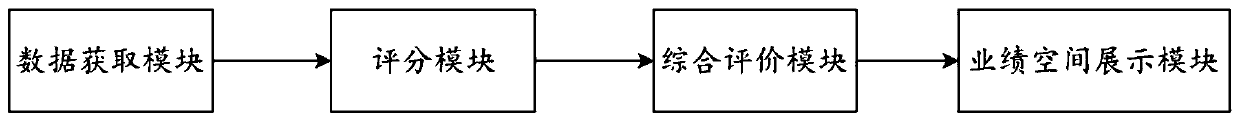

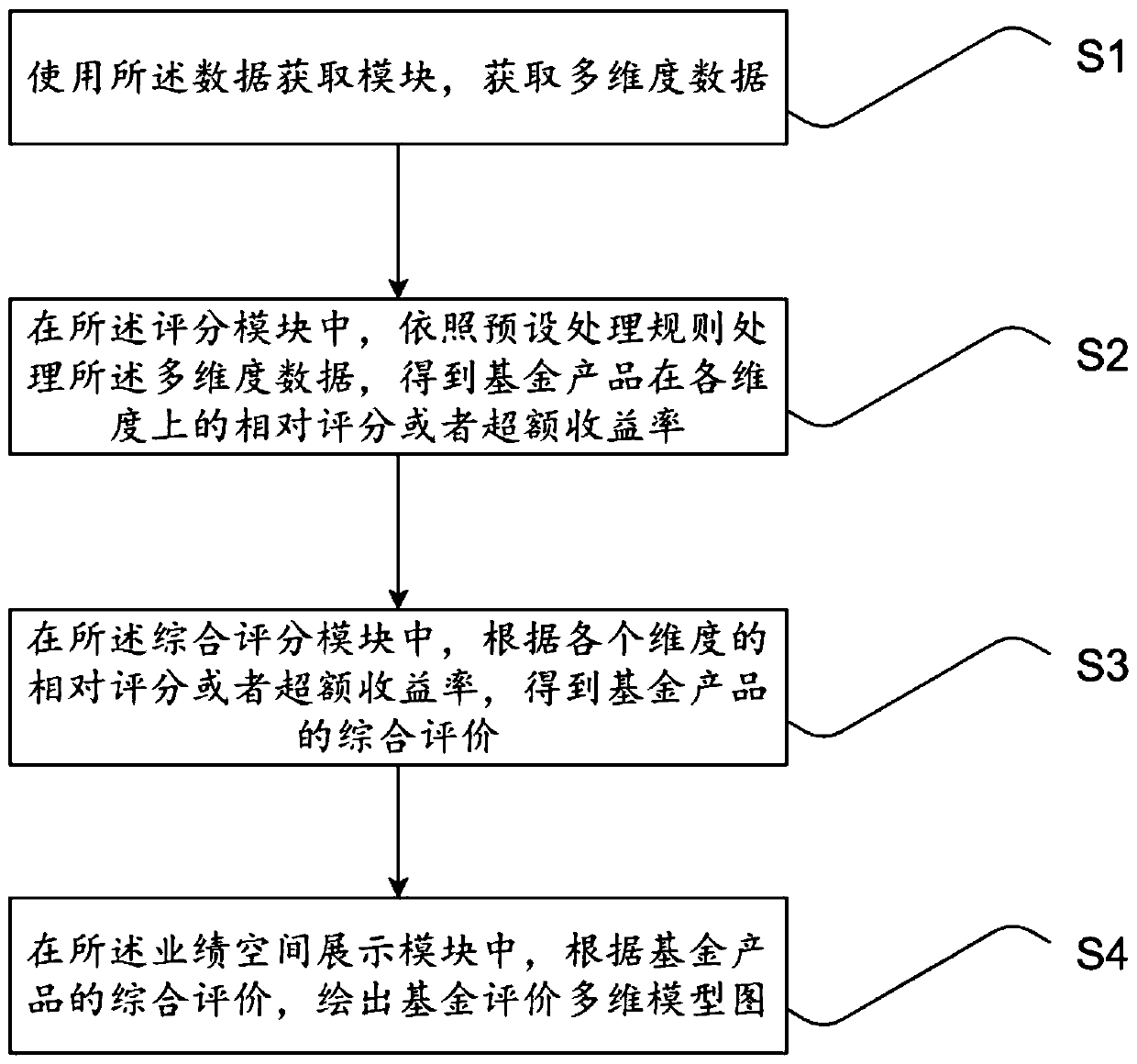

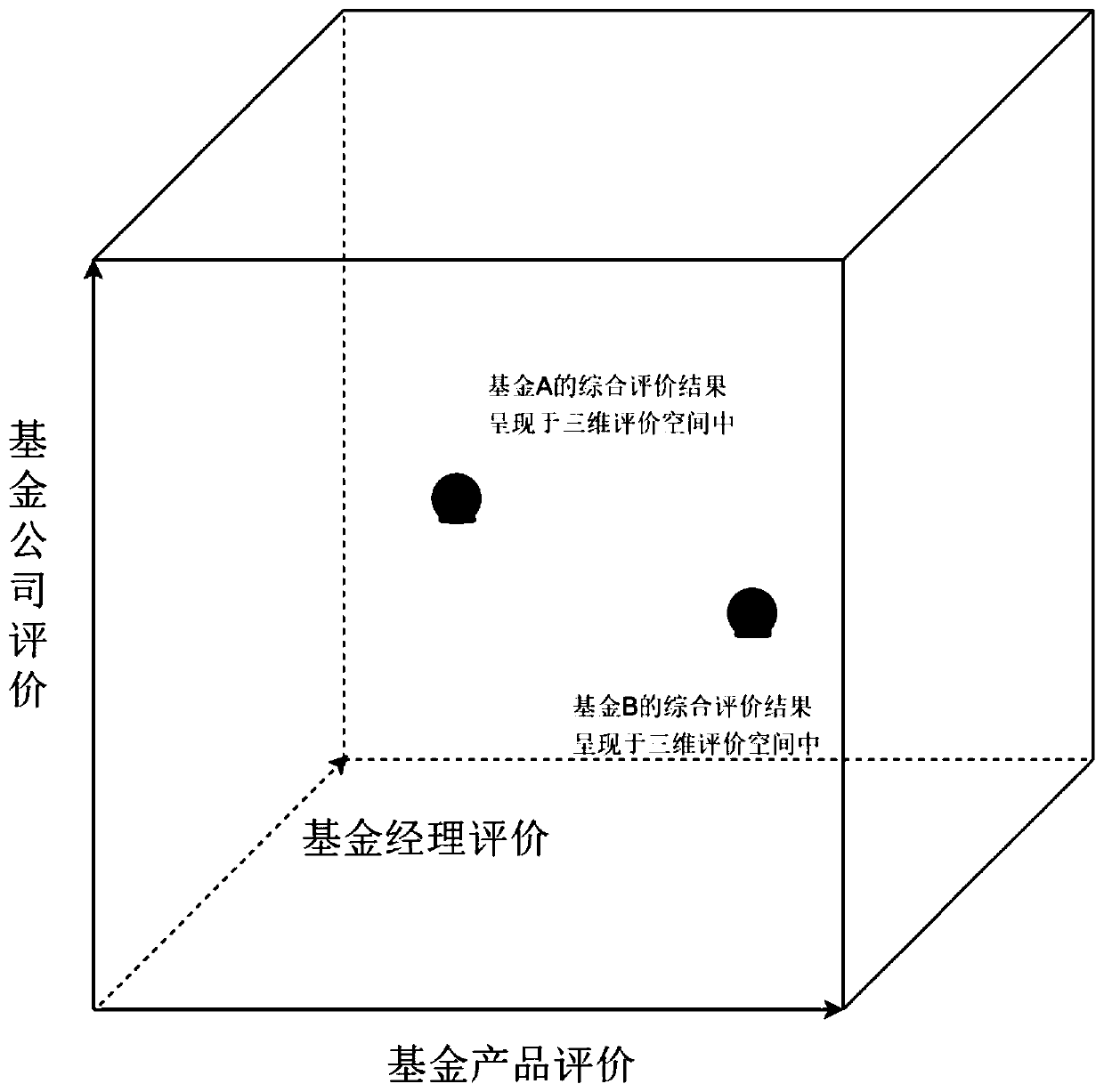

Multi-dimensional fund evaluation system and method

The invention discloses a multi-dimensional fund evaluation system and method, and belongs to the technical field of securities investment fund analysis and evaluation. The evaluation system comprisesa data acquisition module, a scoring module, a comprehensive evaluation module and a performance space display module. The evaluation method comprises the following steps: acquiring multi-dimensionaldata by using the data acquisition module; in the scoring module, obtaining a relative score or an excess yield of a fund product in each dimension; in the comprehensive evaluation module, obtainingcomprehensive evaluation of the fund product according to the relative score or the excess yield of each dimension; and in the performance space display module, drawing a fund evaluation multi-dimensional model graph according to the comprehensive evaluation of the fund product. The relative performance of the fund product is dynamically and stereoscopically displayed through three dimensions of the fund product, the fund manager and the fund company, so that the fund product can be analyzed and evaluated in multiple dimensions by investment, and fund investment decisions can be better made.

Owner:林树

Multi-data source nl2sql system based on semantic rules and multi-dimensional model

ActiveCN112559550BIncrease success rateLower requirementSemantic analysisSpecial data processing applicationsTable (database)Data set

The invention discloses a multi-data source NL2SQL system based on semantic rules and multidimensional models, including a business layer for realizing NL2SQL, and the business layer includes: a configuration module for configuring matching rules; a data model building module for Build a data model that can use the table and field information of the database to generate SQL statements; the intention recognition module is used to parse and match the natural sentences according to the matching rules to obtain the table and field information of the database, and use the data model to generate executable The SQL statement. The system does not rely on labeled corpus and models, and can realize intent-based NL2SQL through simple interface configuration; the data model building module supports multi-choice nesting, which can be flexibly configured; the intent recognition module reduces the requirements for data sets and improves SQL Generated success rate. Therefore, by adopting the system provided by the present invention, business scenarios can be quickly constructed according to different projects.

Owner:北京智源人工智能研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com