Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37 results about "Multi criteria decision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi criteria decision analysis is concerned with a variety of different types of decision problems, including deterministic problems, decision making under uncertainty and fuzziness, dynamic problems and group decisions. Over the years multi criteria decision analysis has developed strong links...

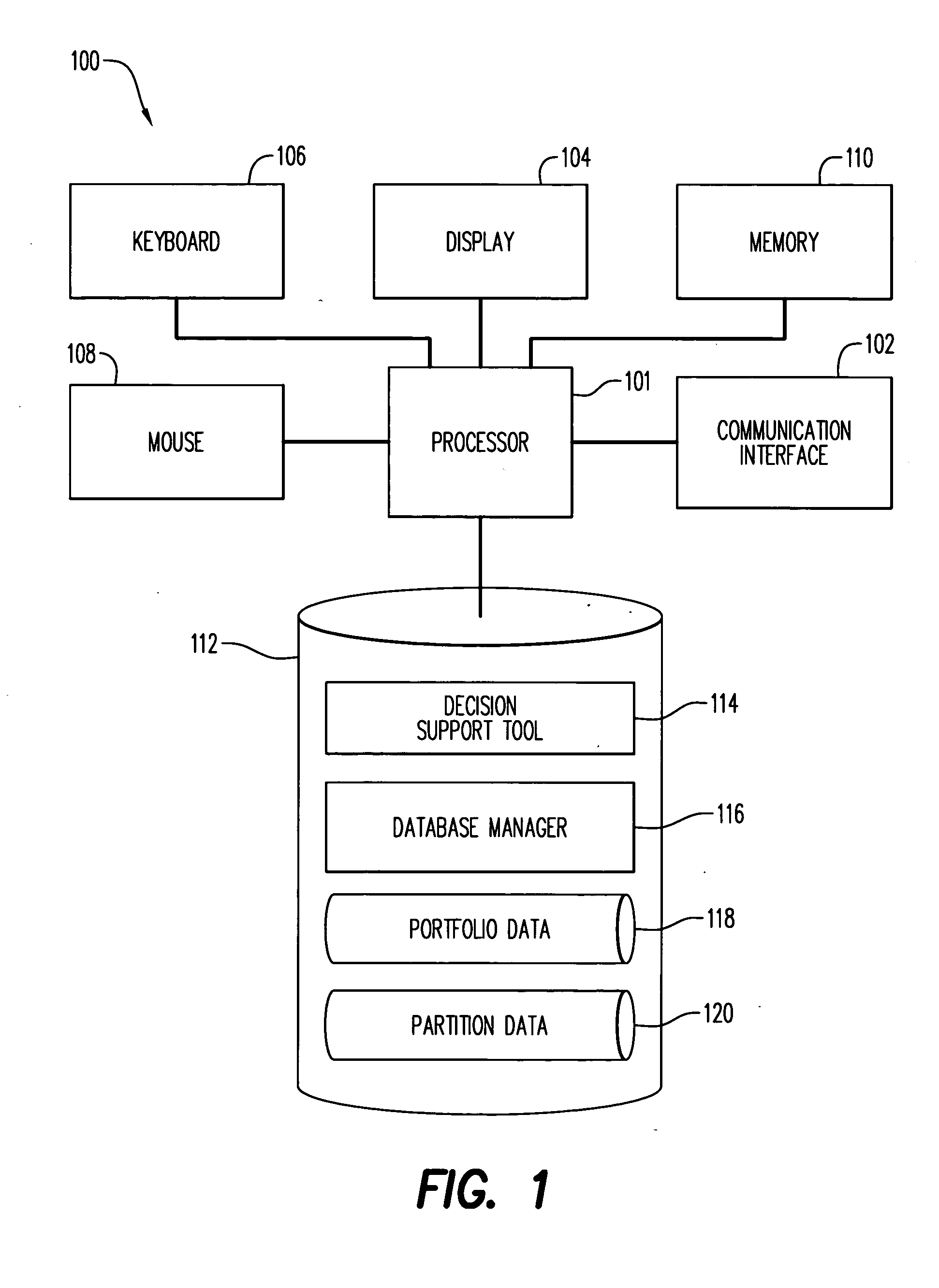

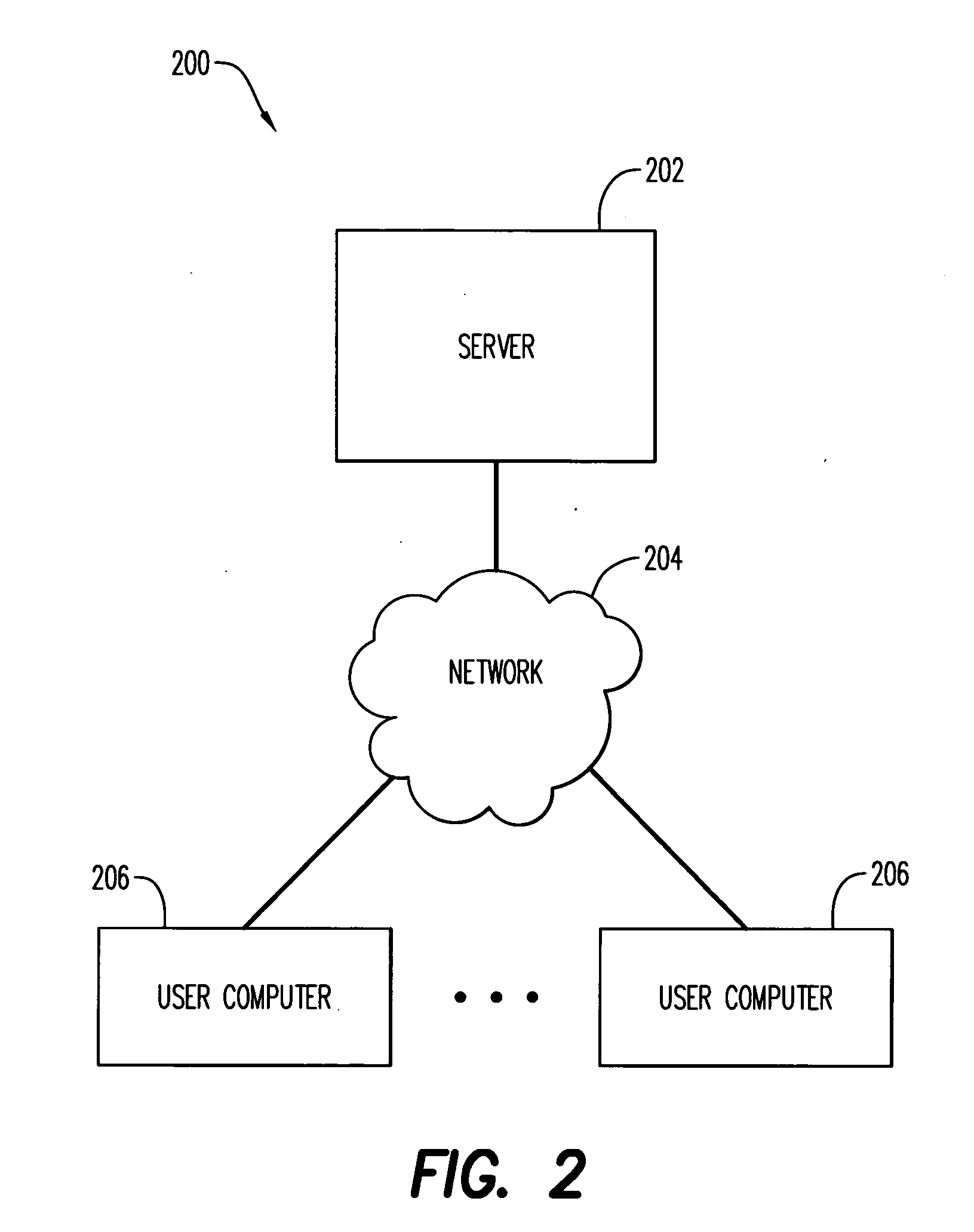

Multi-criteria decision support tool interface, methods and apparatus

InactiveUS20080163085A1Execution for user interfacesInput/output processes for data processingEngineeringDecision taking

A visual interactive multi-criteria decision-making method and computer-based apparatus for portfolio management. The method / apparatus supports partitioning of a portfolio of physical or other assets into two mutually exclusive categories, such as assets recommended for sale and assets recommended for retention. The method / apparatus utilizes one or more coupled 2-D projections of the portfolio in criteria space. The user interacts with the projections to express and record preferences.

Owner:GEN ELECTRIC CAPITAL

Systems, Computer-Implemented Methods and Computer-Readable Media to Provide Multi-Criteria Decision-Making Model for Outsourcing

InactiveUS20130166346A1Reduce subjectivityDifferent profileFinanceResourcesGraphicsMulticriteria decision

Embodiments including systems, computer-implemented methods, and computer-readable media can generate an outsourcing questionnaire interface to be displayed at a display. The outsourcing questionnaire interface can include a plurality of questions, relating to a plurality of outsourcing dimensions, and a corresponding plurality of response fields for users to respond with respect to a business process. Embodiments can further determine a plurality of dimensional scores for the business process responsive to a plurality of user-selected responses received at the plurality of response fields. Embodiments can further generate an outsourcing recommendation interface, to be displayed at the display, that is a graphical chart including a process-recommendation bubble, for the business process, which can be displayed having a position and size in the graphical chart determined responsive to one or more of the plurality of dimensional scores.

Owner:SAUDI ARABIAN OIL CO

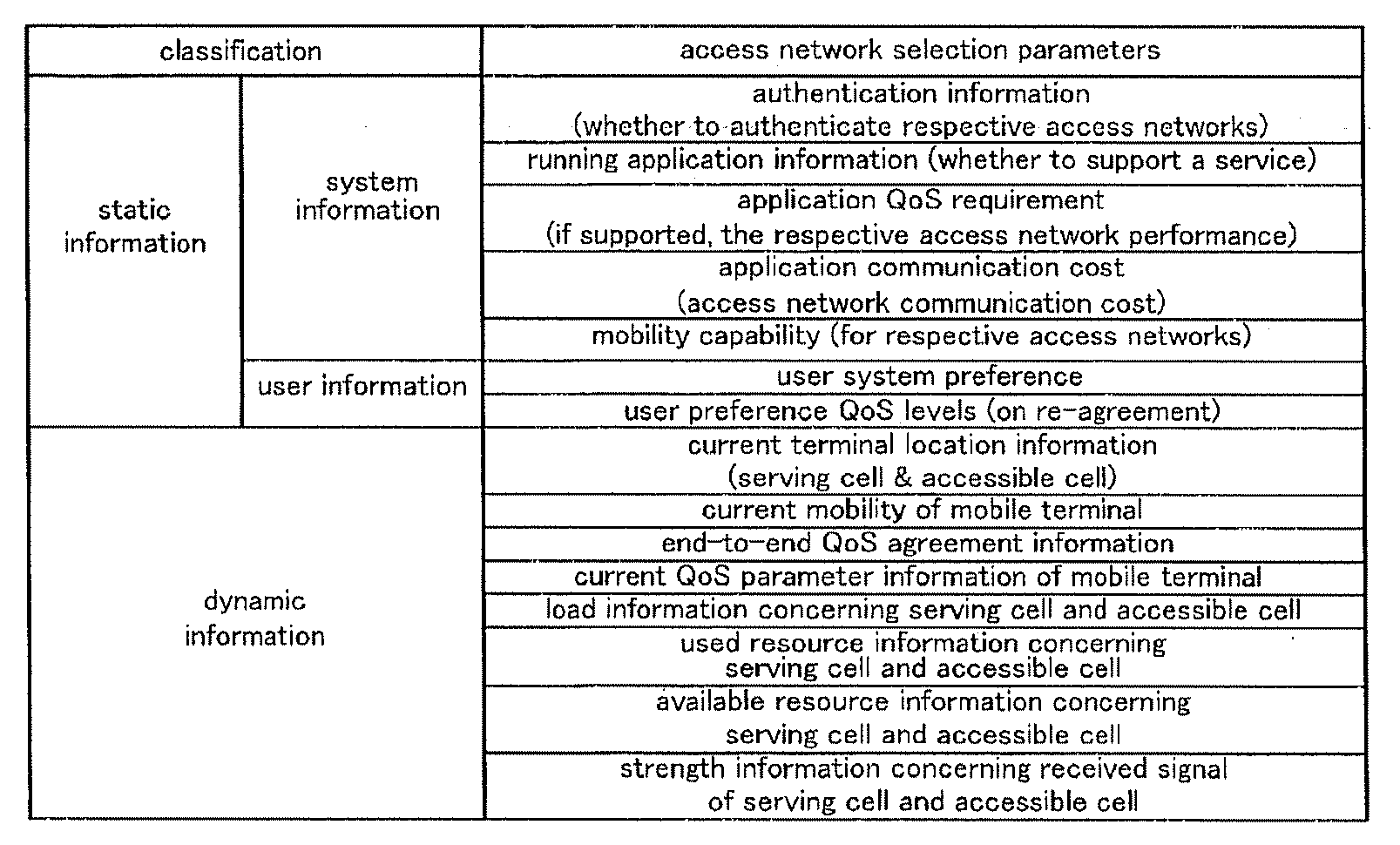

Acess Network Selection Method Using Multi-Criteria Decision Making In Mobile Heterogeneous Network

InactiveUS20080130558A1Quality improvementEfficient managementAssess restrictionRadio/inductive link selection arrangementsAccess networkMulticriteria decision

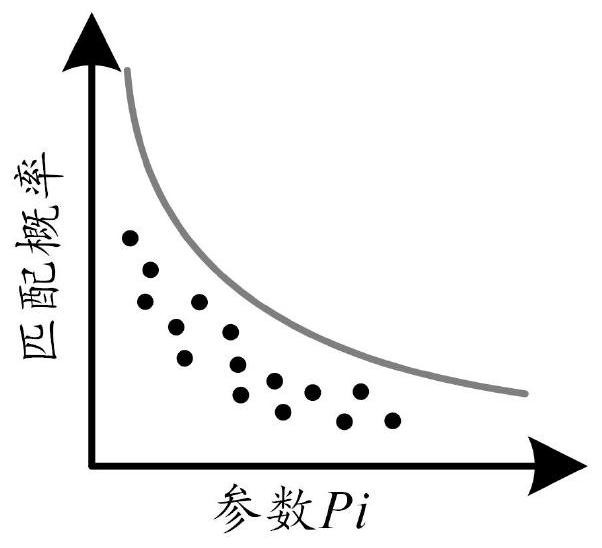

An access network selection system and method using a fuzzy multi-criteria decision making method under a heterogeneous network system are provided. With such a system and method, a subscriber selectively accesses an access network having advantageous communication quality and cost according to transmission environment and service characteristics so that mobility capability is increased due to effective utilization of radio resources and traffic division of heterogeneous access networks. In addition, an optimum access network can be selected using a membership function and a decision making function evaluating access network selection parameters for multi criteria decision-making. Therefore, the access network selection method using fuzzy multi-criteria decision making can ensure mobility and access network options for a subscriber and ensure effective management of a wireless infrastructure resource to a provider under a heterogeneous network environment.

Owner:ELECTRONICS & TELECOMM RES INST

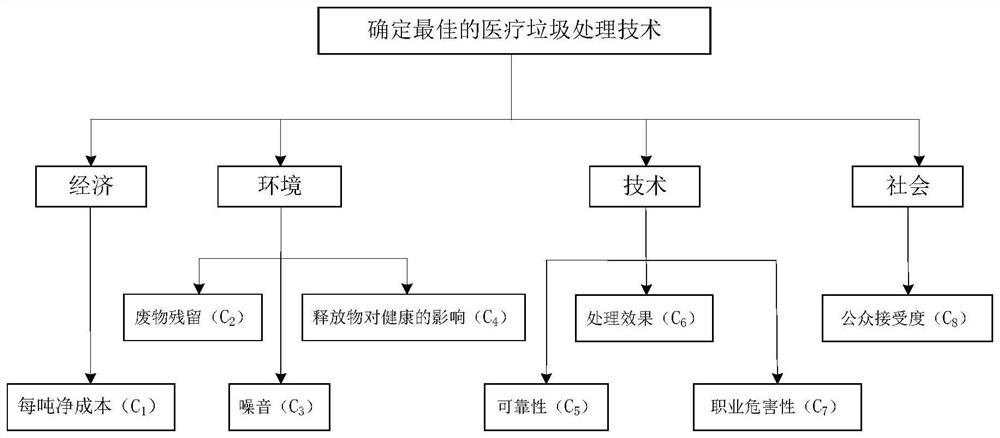

An improved FMEA method based on interval intuitionistic fuzzy set and hybrid multi-criteria decision model

InactiveCN108985554AEvaluation is convenient and trueReduce the impact of the final risk ranking resultResourcesTotal riskGuideline

The invention discloses an improved FMEA method based on an interval intuitionistic fuzzy set and a mixed multi-criterion decision model. In the first stage, an interval intuitionistic fuzzy network analysis method is used to determine the weight of risk factors, firstly, the network structure diagram of risk factors and sub-risk factors is formed, the interval intuitionistic fuzzy pair comparisonmatrix is constructed and the aggregation degree is calculated, then the local ranking vector is calculated to obtain the initial super-matrix and weighted super-matrix, and finally the weights of all sub-risk factors are determined. In the second stage, an interval intuitionistic fuzzy comprehensive proportional evaluation method is utilized to determine the risk order of all failure modes, theset interval intuitionistic fuzzy risk assessment matrix is constructed for the first time, then the matrix is standardized and weighted to calculate the total risk and risk degree of each failure mode, and finally the ranking of all failure modes is determined. The fuzziness and uncertainty of expert language evaluation is overcome effectively. the hierarchy and interrelation of risk factors areconsidered. Thus, the risk ranking of failure modes is more accurate.

Owner:SHANGHAI UNIV

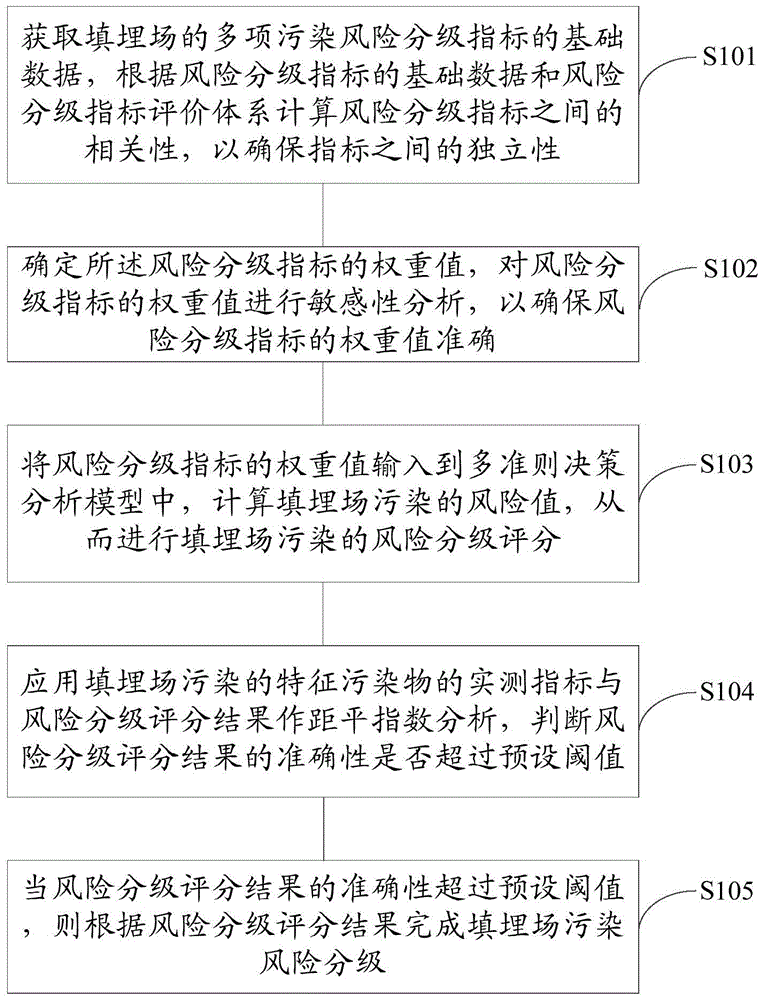

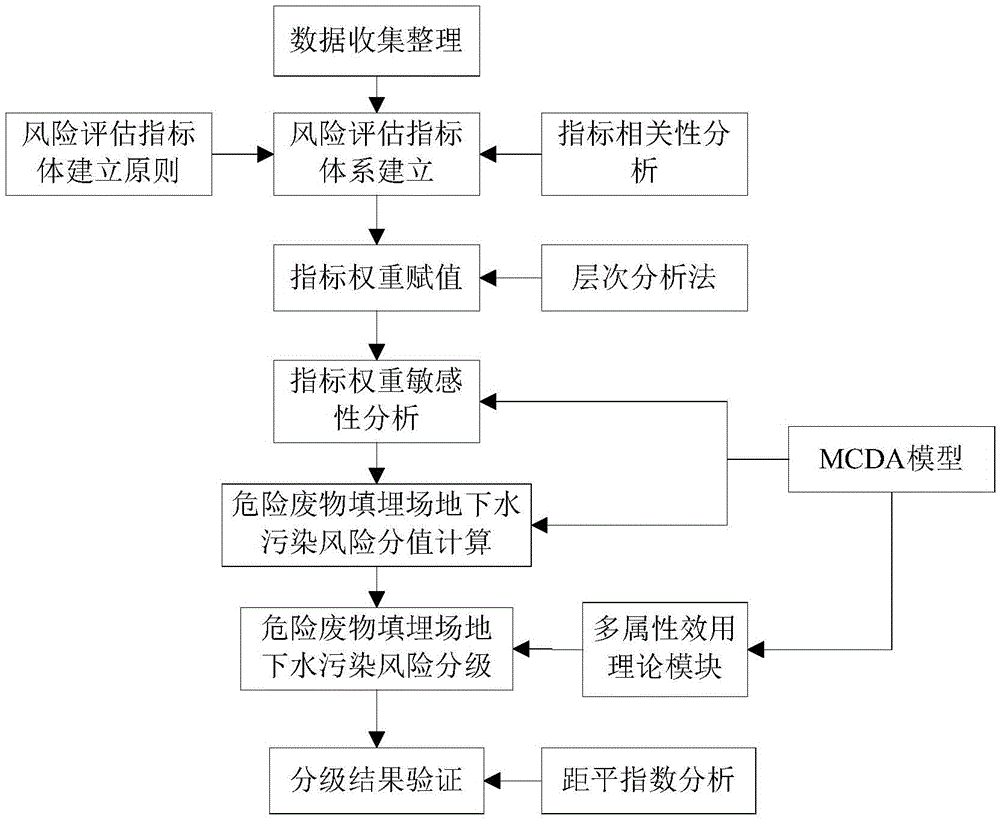

Pollution risk grading method and apparatus for landfill site

InactiveCN105550817AStrong independenceMany risk rating indicatorsResourcesSensitive analysisDecision taking

An embodiment of the invention provides a pollution risk grading method for a landfill site. The pollution risk grading method for the landfill site comprises the steps of obtaining basic data of multiple pollution risk grading indexes of the landfill site and calculating the correlation among the risk grading indexes according to the basic data of the risk grading indexes and a risk grading index evaluation system to ensure the independence of the indexes; determining weight values of the risk grading indexes and performing sensitive analysis on the weight values of the risk grading indexes to ensure that the weight values of the risk grading indexes are accurate; and inputting the weight values of the risk grading indexes into a multi-criteria decision analysis model to calculate a risk value of landfill site pollution so as to perform risk grading scoring of landfill site pollution. Correspondingly, an embodiment of the invention furthermore provides a pollution risk grading apparatus for the landfill site. According to the technical scheme provided by the embodiments of the invention, the groundwater pollution risk of a hazardous waste landfill site can be subjected to grading evaluation quickly and accurately, so that a risk grading result is more scientific.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

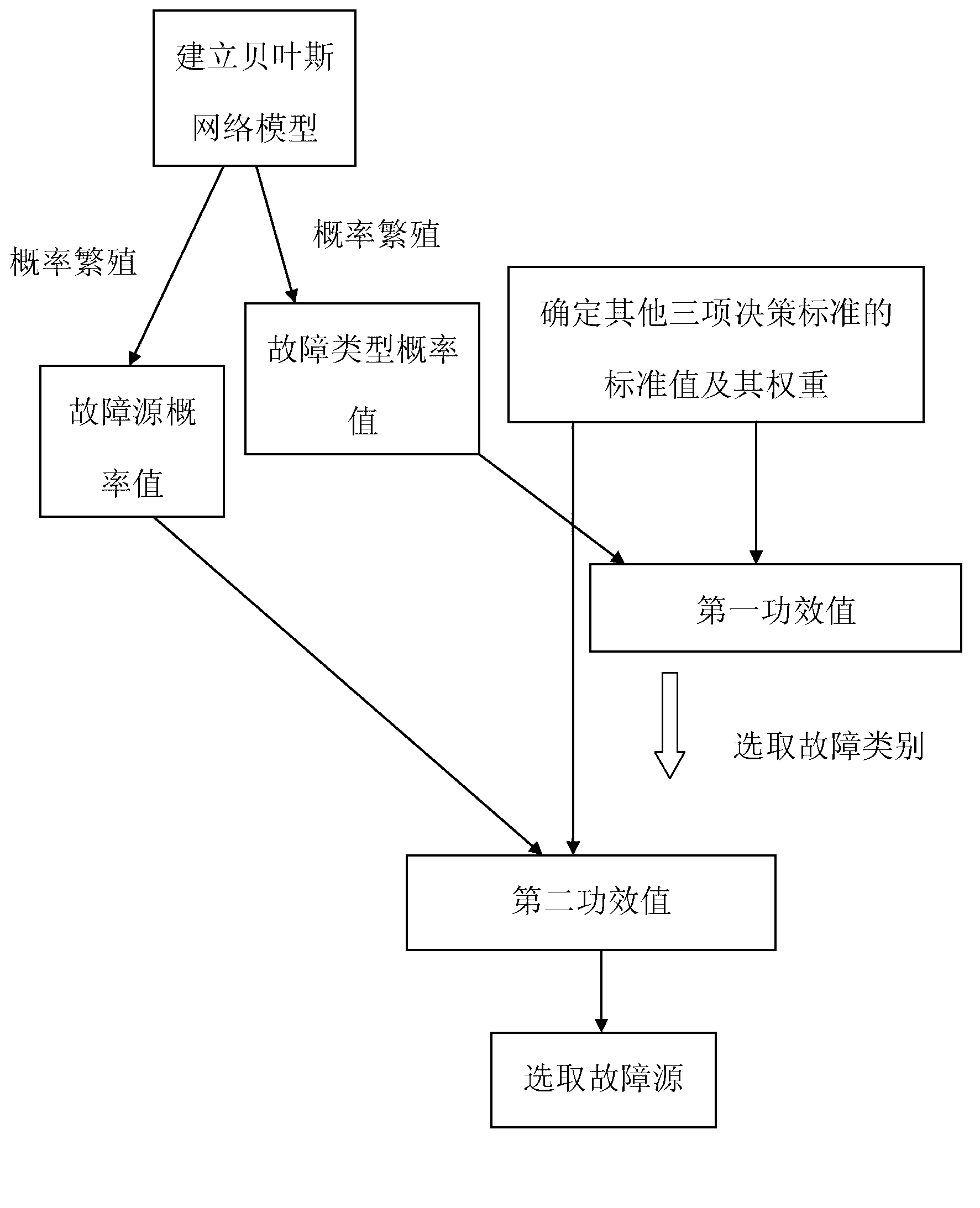

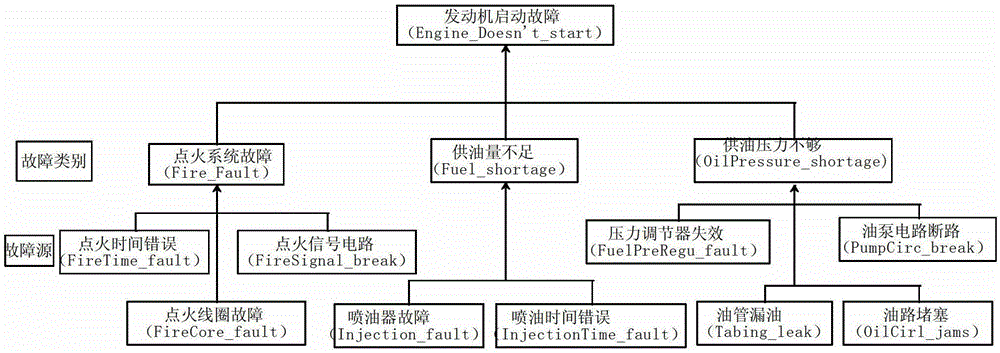

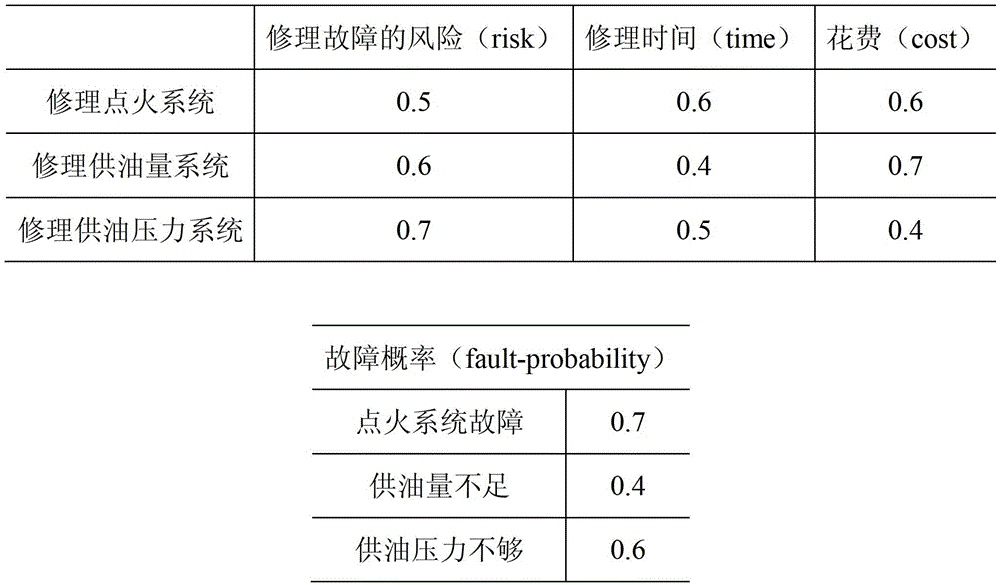

Automobile engine fault maintenance method based on Bayesian network models and multi-criteria decision analysis

An automobile engine fault maintenance method based on Bayesian network models and multi-criteria decision analysis includes: using each fault category and each fault source under each fault category, which affect an automobile engine, to build Bayesian network models so as to obtain a first probability value of each fault category and a second probability value of each fault source; respectively determining standardized weight of each decision criterion through multi-criteria decision analysis according to the decision criteria; obtaining a first effect value of each fault category according to each decision criterion, the standardized weight and the first probability value, selecting the fault category with the highest first effect value, obtaining a second effect value of each fault source under the fault category with the highest first effect value, and selecting the fault source with the highest effect value in the second effect values to serve as the maintenance judging results.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Quantitative assessment tool

A mathematically rigorous process for evaluating and prioritizing decision alternatives in an operational management or fiscal decision environment using a quantitative assessment tool (QAT). It employs current multi-criteria decision-theoretic methodologies and standard life cycle cost and statistical analysis techniques to provide decision makers with visual measures of the relative effectiveness and cost-effectiveness of the decision alternatives and a statistical curve which identifies areas of minimal or optimal funding, enabling decision makers to efficiently manage resources. The QAT is traceable and auditable, providing credibility and defensibility to decisions made with the tool.

Owner:RIGGS JEFFREY L +2

Multi-candidate, multi-criteria decision-making method

InactiveUS20080016058A1Simple methodReduce amountVoting arrangementDrawing from basic elementsAlgorithmDecision taking

Owner:DECISION HELP

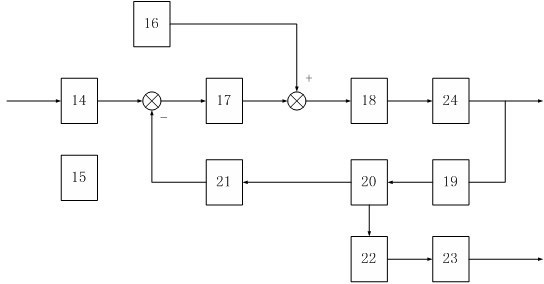

Intelligent jamming and chucking detection controller for hydraulic valve

InactiveCN102620047AGuaranteed monotonicityGuaranteed validityOperating means/releasing devices for valvesControl signalRegulated power supply

The invention relates to an intelligent jamming and chucking detection controller for a hydraulic valve. The intelligent jamming and chucking detection controller is electrically connected with an electro-hydraulic proportional valve provided with a proportional electromagnet and a valve element, and comprises a flutter signal generation module (16), a system control signal module (14), a stabilized power module (15), a proportion integration differentiation (PID) control module (17), a power amplification module (18), a sampling module (19), a signal processing module (20), a negative feedback module (21) and a jamming and chucking decision-making module (22), wherein the jamming and chucking decision-making module (22) makes jamming and chucking membership decision by a fuzzy multi-criteria decision-making method. By the controller, a jamming and chucking failure of a valve element of a sliding valve can be detected and judged in real time; and the controller is high in sensitivity and accuracy, simple in structure and low in cost.

Owner:SHAOXING UNIVERSITY

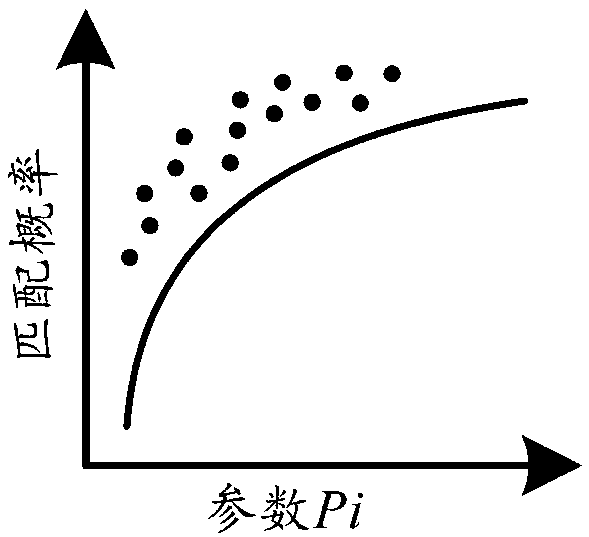

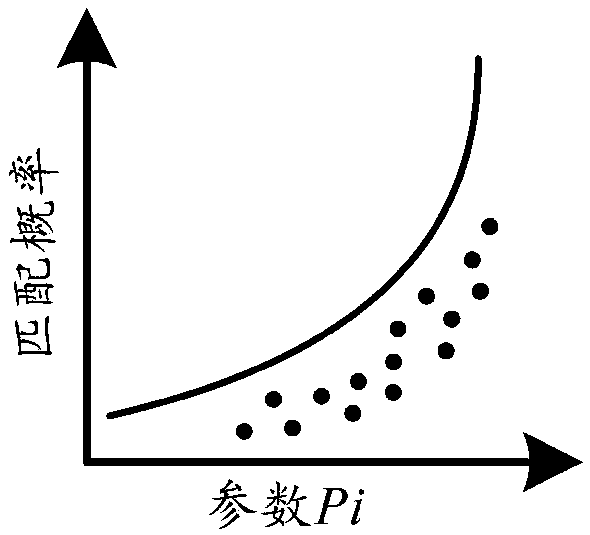

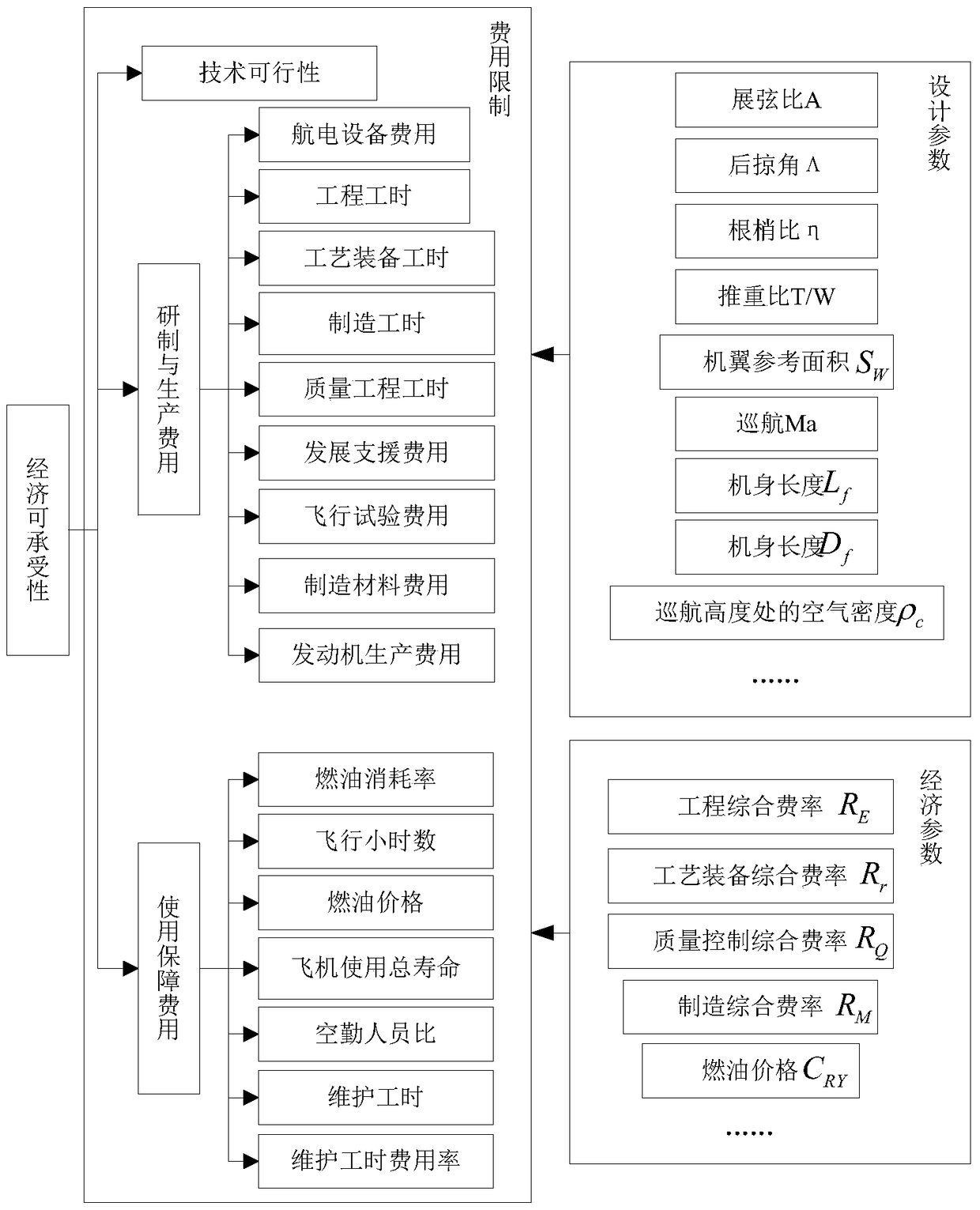

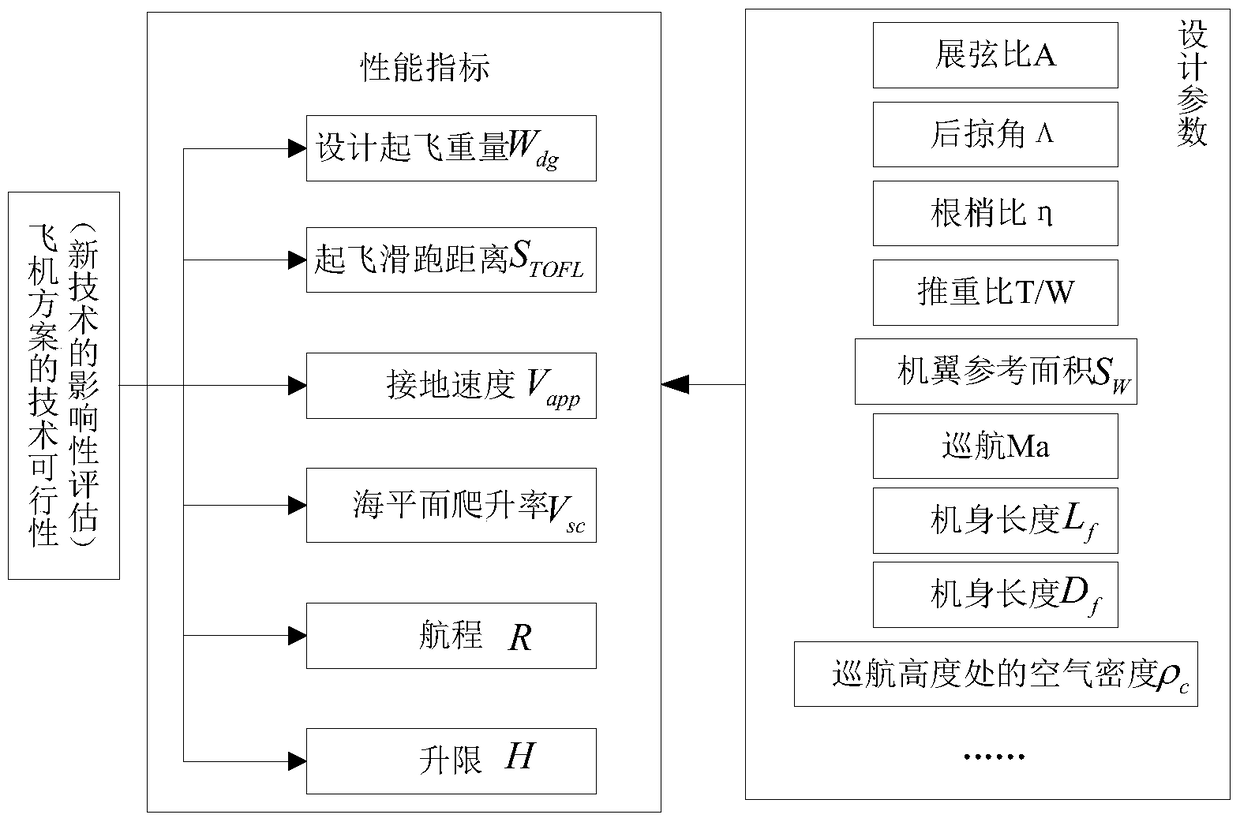

Multi-criteria decision making method for airplane design economic affordability evaluation process

A multi-criteria decision making method for an airplane design economic affordability evaluation process includes step 1, determining design variables and fixed parameters of airplane design, and optionally distributing the design variables to reflect indeterminacy of a design stage; step 2, taking main design parameters as analytic objects, and checking the probability of technological feasibility of a design scheme; step3, on the basis of a technological feasibility analysis result, checking the probability of expense affordability of the design scheme; step 4, if the design scheme is feasible in terms of airplane design technology and is receptible in terms of economic affordability, determining that the design scheme is receptible. Fuzzy interval number and RD (robust design) are combined organically on the basis of probability technology to create the probability multi-criteria decision making method based on the fuzzy interval number and the RD.

Owner:BEIHANG UNIV

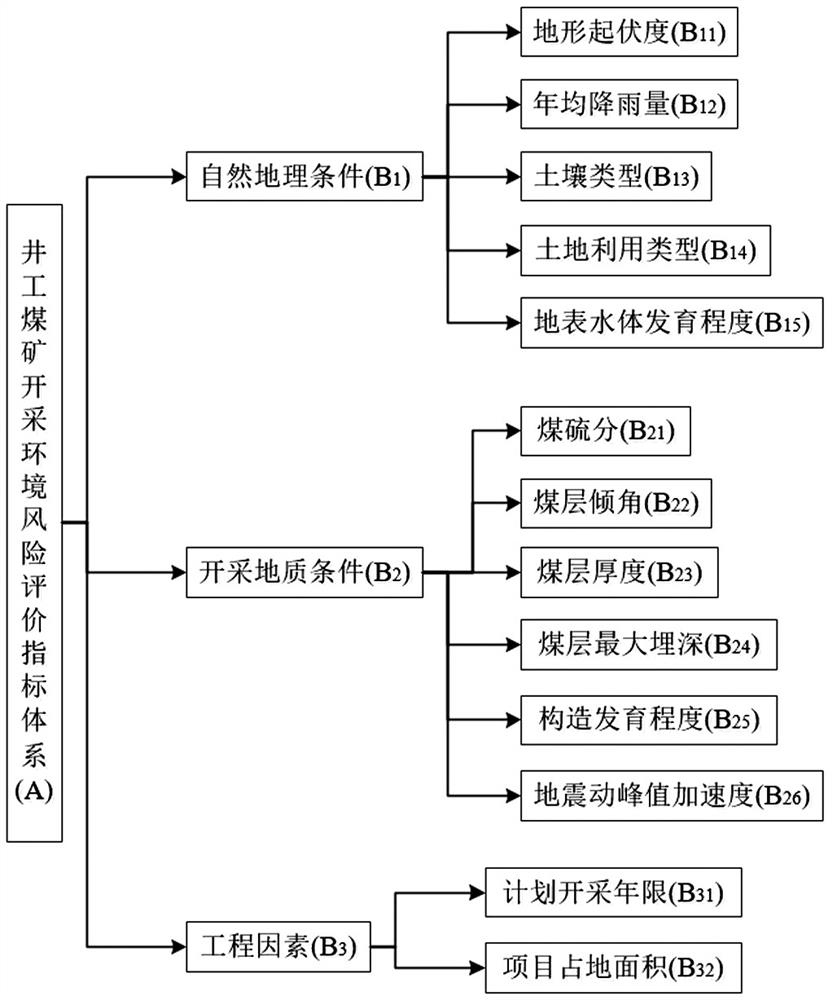

Underground coal mining environment risk prediction grading method

ActiveCN111815063AClear mechanismGood for distinguishing the size of influenceForecastingResourcesIndex systemData mining

The invention discloses an underground coal mining environment risk prediction grading method. The method comprises the following specific steps: step 1, identifying a main underground coal mining environment risk problem; 2, analyzing a main underground coal mining environment risk problem; 3, constructing an underground coal mine environment risk evaluation index system; 4, performing correlation discussion on each index in the index system; 5, determining main evaluation indexes influencing the environmental risk; step 6, carrying out weight sensitivity analysis on each index in the index system; and step 7, predicting and grading the mining environment risk of the underground coal mine area. According to the invention, the existing environmental risk problems can be comprehensively researched in a classified manner, and a corresponding index system is constructed; the influence of different influence indexes can be distinguished, so that key response is realized; by comparing the correlation among the indexes, an index library is optimized; through index grading and a multi-criterion decision-making model, key prevention and treatment measures are facilitated to be implemented.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

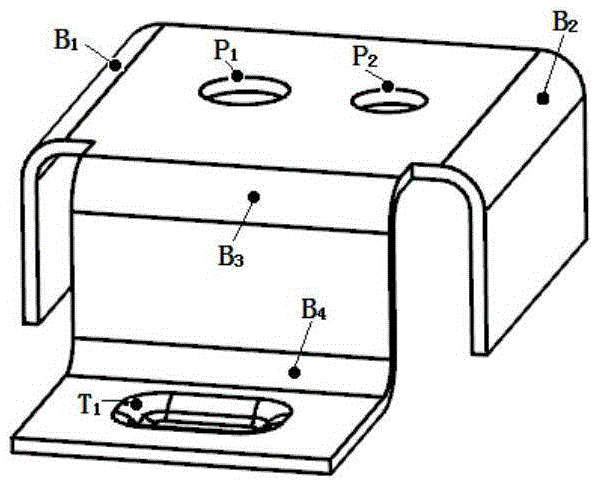

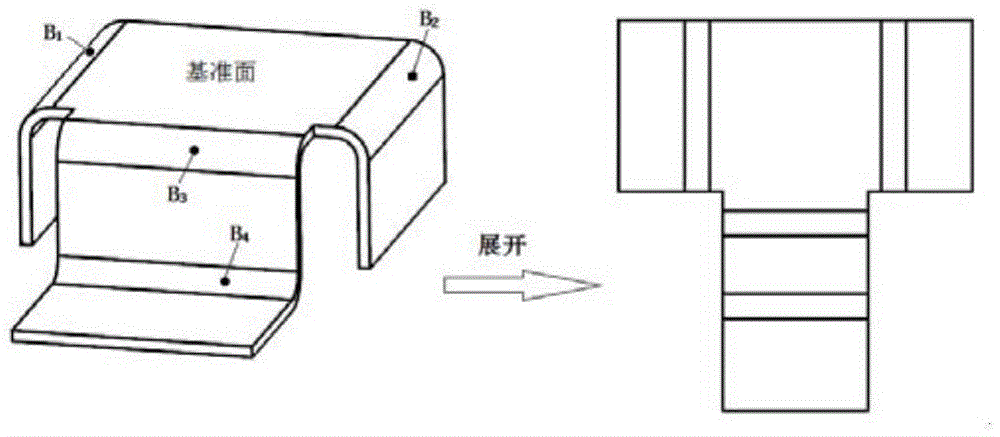

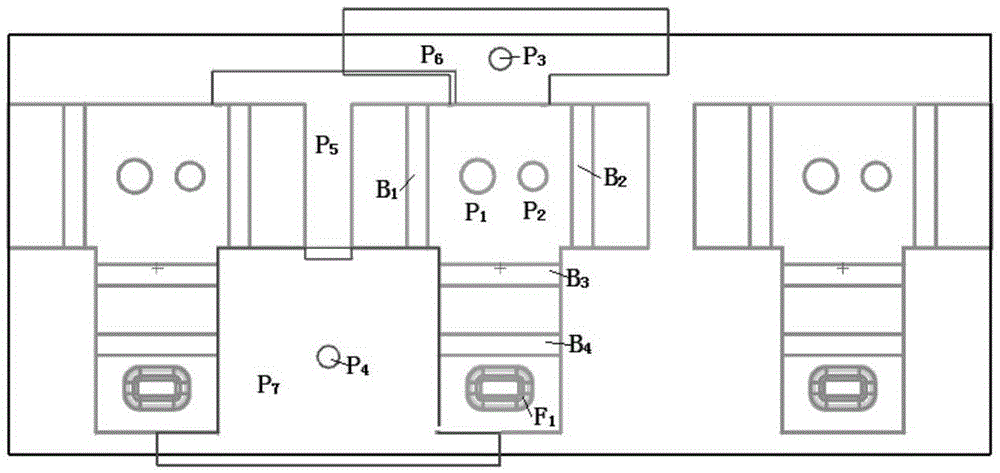

Progressive die complex metal plate member stamping process sequence planning method

ActiveCN105487488ASimple methodEnable smart designProgramme controlComputer controlSequence planningLayout

The invention discloses a progressive die complex metal sheet member stamping process sequence planning method, comprising steps of performing metal plate characteristic identification, bending and expanding, generating a stock layout characteristic, and formulating a stock layout rule, listing all possible layout schemes by adopting a sequencing planning matrix, a synchronization sequence planning matrix, and an idle station planning matrix, listing all possible stock layout schemes, establishing an influence factor set U=[u1,u2,u3... un] and a corresponding weight set A=[w1,w2,w3, ...,wn], wherein w1+w2+w3+...+wn=1 and 0<=w1,w2,w3, ...,wn<=1, and calculating the multi-norm decision total score Ev sigma(j=i)<n>wjuj=w1*u1+w2*u2+w3*u3...wn*un according to the influence factor and the corresponding weight, wherein when the Ev value is the maximum, the scheme is optimal. The invention is simple and can obtain the optimal scheme through the data, can manufacture the correct working station stock layout without the stamping and processing knowledge and experience of the design personnel, gets rid of the designer, realizes the intelligent designing in a real meaning, and realizes the processing of the standardization production.

Owner:盐城市金德模具制造有限公司

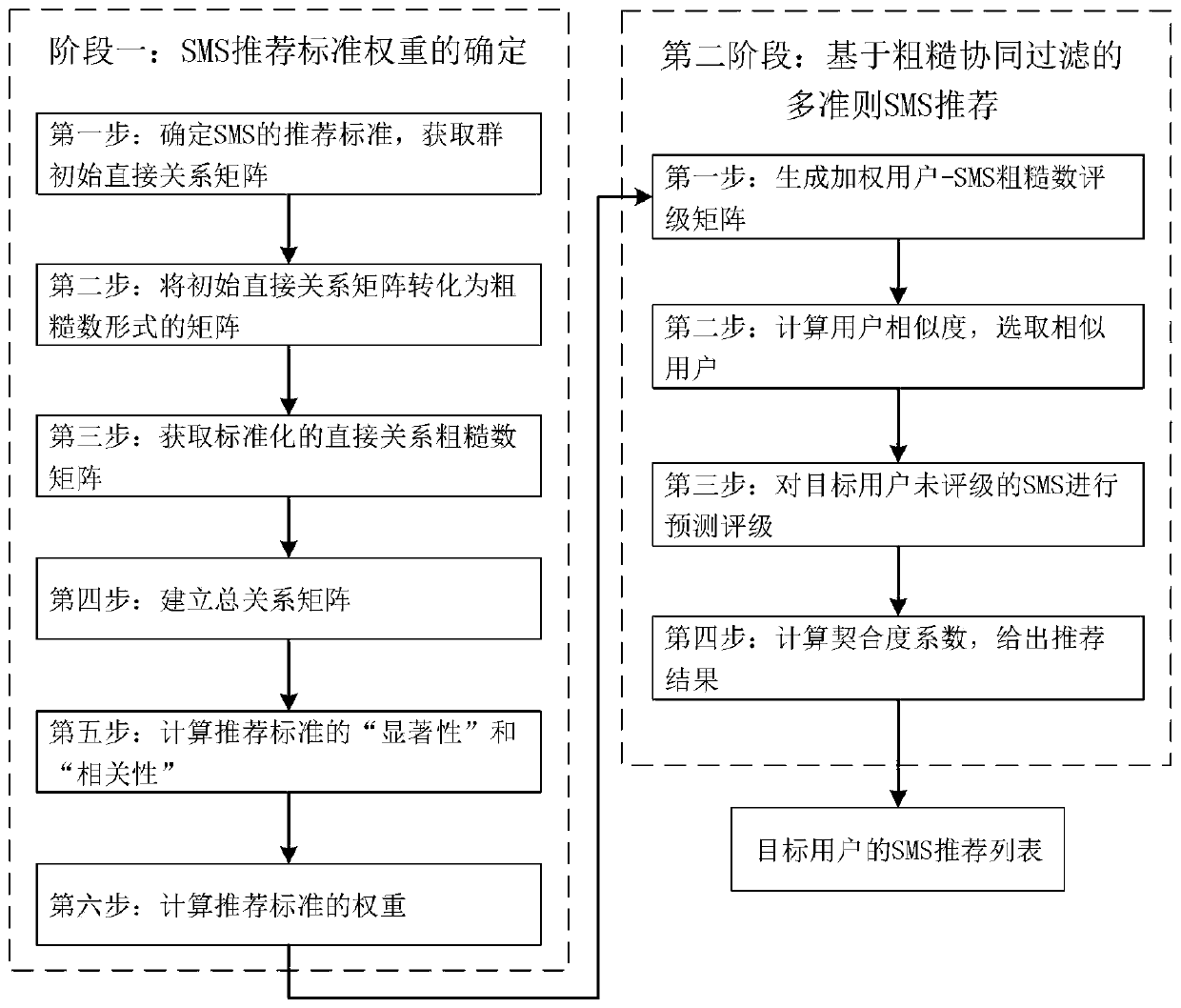

Smart manufacturing service (SMS)-oriented precise pushing method

InactiveCN109857939ASave time and costReduce the possibility of error-proneData processing applicationsDigital data information retrievalUser needsGuideline

The invention relates to a smart manufacturing service (SMS)-oriented precise pushing method in the technical field of internet information interaction. The smart manufacturing service (SMS)-orientedprecise pushing method comprises a step 1 and a step 2. The method comprises the following steps of: step 1, calculating the weight of a recommendation standard by using a rough decision test and an evaluation experiment method; and step 2, using a rough collaborative filtering method to complete SMS module recommendation based on multi-criterion decision. According to the smart manufacturing service (SMS)-oriented precise pushing method, the time cost for the user to obtain the target intelligent manufacturing service can be reduced, the possibility of errors caused by manual subjective selection of the intelligent manufacturing service is reduced, and an enterprise is helped to intelligently and actively respond to user requirements. According to the method, the problems of interaction among recommendation standards, importance influence of the recommendation standards, subjectivity of user evaluation and the like are comprehensively considered, and objective distribution of the userevaluation is considered by using the rough number, so that a recommendation result is ensured to be more accurate.

Owner:BEIHANG UNIV

Terrain adaptive area selecting scheme based on hierarchical decision making

ActiveCN108416168AHigh precisionReduce riskDesign optimisation/simulationSpecial data processing applicationsTerrainApplicability domain

The invention provides a terrain adaptive area selecting scheme based on hierarchical decision making, and belongs to the field of terrain assisting navigation. The terrain adaptive area selecting scheme involves a threshold value judgment model and a multi-criterion decision making model, wherein 1, the terrain adaptability is described by terrain characteristic parameters; 2, the threshold valuejudgment model comprises necessary conditions and sufficient conditions of an adaptive terrain, and the necessary conditions and the sufficient conditions are used for detecting an obvious inadaptiveterrain and an obvious adaptive terrain with high accuracy separately and transmitting a to-be-determined area to the multi-criterion decision making model; 3, according to the difficulty of modelingthe to-be-determined area, the multi-criterion decision making model builds one or more classifier models through a mode recognition method, and through decision making or merging decision making, anadaptive judgment result of the to-be-determined area is given. By the adoption of a hierarchical decision making scheme, by reducing the model adaptive range, the decision making efficiency and thedecision making reliability are effectively improved.

Owner:BEIHANG UNIV

Simulation medical teaching system for marking system based on multi-criterion decision weight analysis math model

InactiveCN102708720AImprove medical educationCosmonautic condition simulationsSimulatorsSimulationMedical treatment

The invention provides a solution of a simulation medical teaching system for a marking system based on a multi-criterion decision weight analysis math model. An algorithm of the marking system based on the multi-criterion decision weight analysis math model is implemented in a human-machine interaction system; the human-machine interaction system is connected with an embedded control system; the embedded system is connected with a simulator; the simulator is connected with a simulation medical operation device, acquires medical operation corresponding to a user and transmits the medical operation to the human-machine interaction system; the medical operation is used as a marking basis; the human-machine interaction system integrates solutions provided by professionals and performs comprehensive coordination according to index criterions such as the optimal treatment time, the effect, the cost and the reliability; and a priority sequence relation of the treatment solutions is obtained through a multi-criterion decision weight analysis algorithm, so that the operation of a student can be marked rationally. The marking decision comprises the following steps of: 1, building a hierarchical layer structure; 2, constructing pairwise comparative judgment matrixes; and 3, calculating a relevant weight of each element under the single criterion, and finally obtaining a marking result.

Owner:GUANGXI NANNING HENGSHENG TAIJUHUI ELECTRONICS TECH

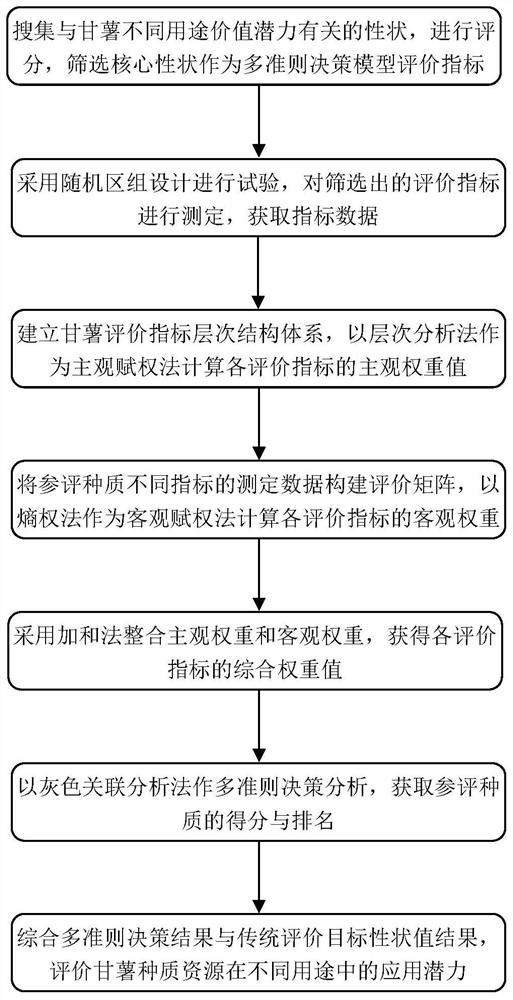

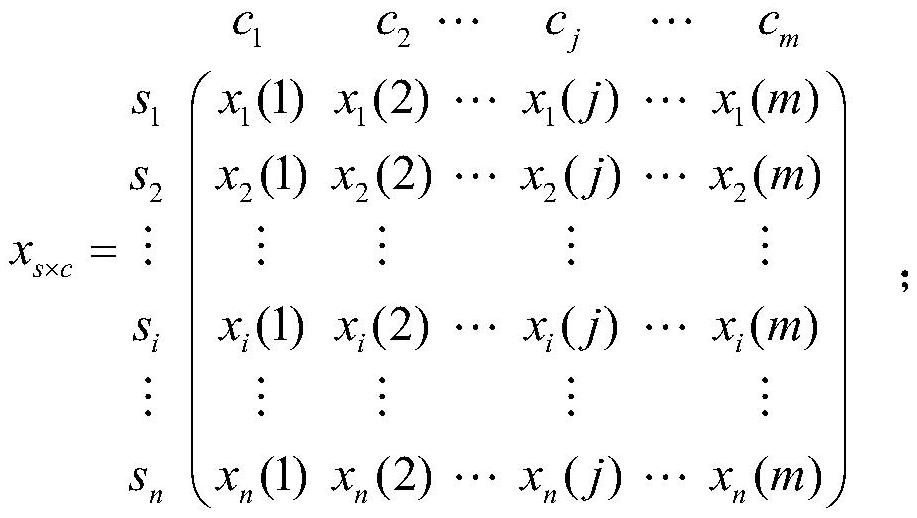

Sweet potato germplasm resource evaluation method based on multi-criterion decision

The invention relates to a sweet potato germplasm resource evaluation method based on multi-criterion decision, which comprises the following steps: screening sweet potato agronomic and quality related traits through a literature method, a research method, an expert consultation method and the like, and determining core traits, namely evaluation indexes; calculating a weight value of the evaluation index through a comprehensive weighting method in combination with a subjective weighting method and an objective weighting method; and finally, calculating evaluation index data through multi-criterion decision analysis to obtain scores and rankings of the evaluated germplasm. The invention has the advantages that the method is high in reliability, deep in mathematical background and suitable for comprehensive analysis and processing of large-batch sample data, the value potential of sweet potato germplasm in different purposes can be analyzed at the same time, the situation that sweet potato breeding workers neglect and omit some excellent genotypes due to decision fatigue can be avoided, and the germplasm evaluation efficiency is greatly improved. By adopting the method disclosed by the invention, excellent germplasm screening, cross parent selection, filial generation screening and the like of the sweet potatoes can be effectively guided, and a scientific and efficient evaluation model is provided for creation of special sweet potato varieties.

Owner:湖南省作物研究所

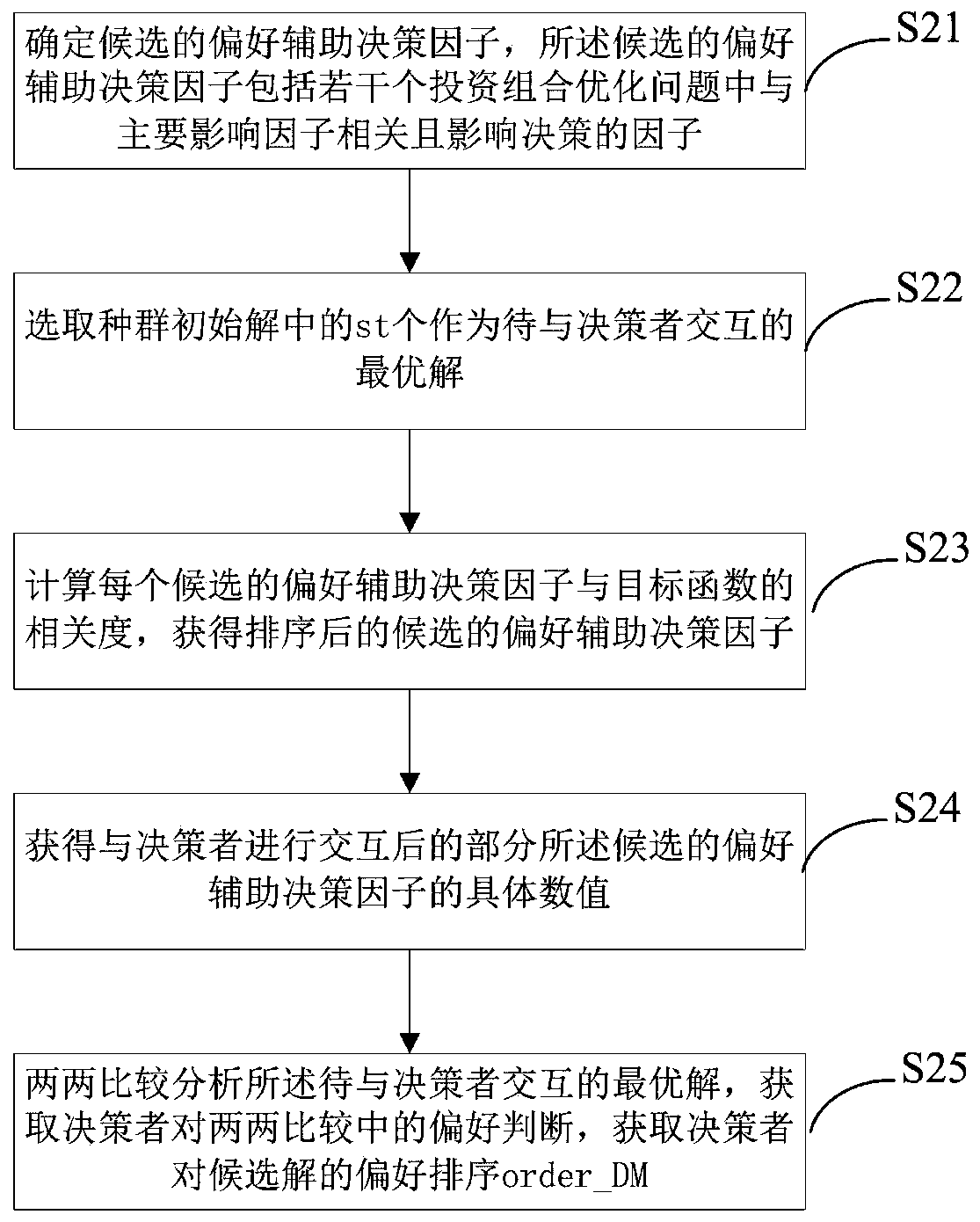

Interactive multi-criterion decision-making method and device including preference aid decision factor optimization and computer equipment

ActiveCN111080160APredict Preference Propensity CorrectlyHigh Average Prediction AccuracyFinanceCharacter and pattern recognitionDecision makerClassification rule

The invention discloses an interactive multi-criterion decision-making method containing preference auxiliary decision-making factor optimization, and the method comprises the following steps: settingthe number of interactive iterations based on the operation of an evolutionary multi-objective optimization algorithm, and obtaining a population initial solution of investment portfolio double problems; making an interactive preference feedback mode algorithm based on a preference auxiliary decision factor interact with a decision maker to obtain decision maker preference feedback; establishinga preference model based on the decision tree of the classification rule, and obtaining model preference feedback by utilizing the preference model; calculating an evaluation preference model by utilizing decision maker preference feedback and model preference feedback; and training and updating the preference model until a training termination condition is satisfied. The invention further discloses an interactive multi-criterion decision-making device containing preference auxiliary decision-making factor optimization, and the interactive multi-criterion decision-making device can obtain higher average prediction accuracy and can obtain a satisfactory solution with more centralized distribution.

Owner:HARBIN INST OF TECH AT WEIHAI

Wireless Mesh network trust measurement system based on multi-criteria decision making

The invention relates to a wireless Mesh network trust measurement system based on multi-criteria decision making. The wireless Mesh network trust measurement system comprises a direct trust generation module, a recommendation trust generation module and a total trust computation module, wherein the direct trust generation module comprises a monitoring unit, a quantification unit and a direct trust computation unit; the recommendation trust generation module comprises a temporary trust table unit and a recommendation trust computation unit; and the total trust computation module comprises a total trust value computation unit and a trust table unit. In the wireless Mesh network trust measurement system based on multi-criteria decision making provided by the invention, a low-overhead misbehavior node detection method is adopted. The system can be suitable for safe path computation of various routing protocols, and has general applicability.

Owner:FUJIAN NORMAL UNIV

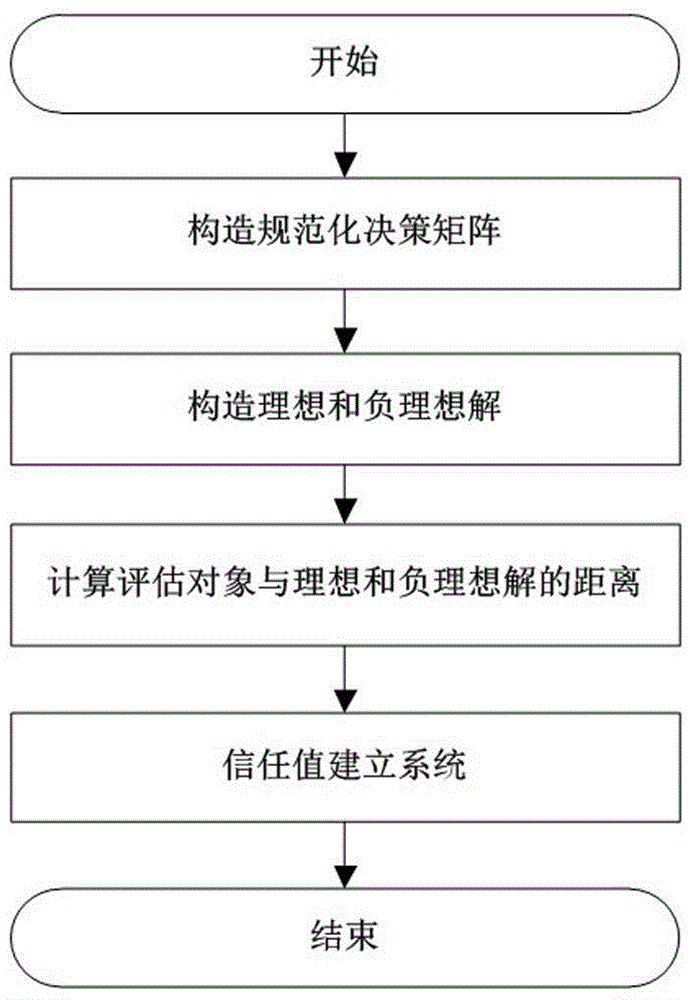

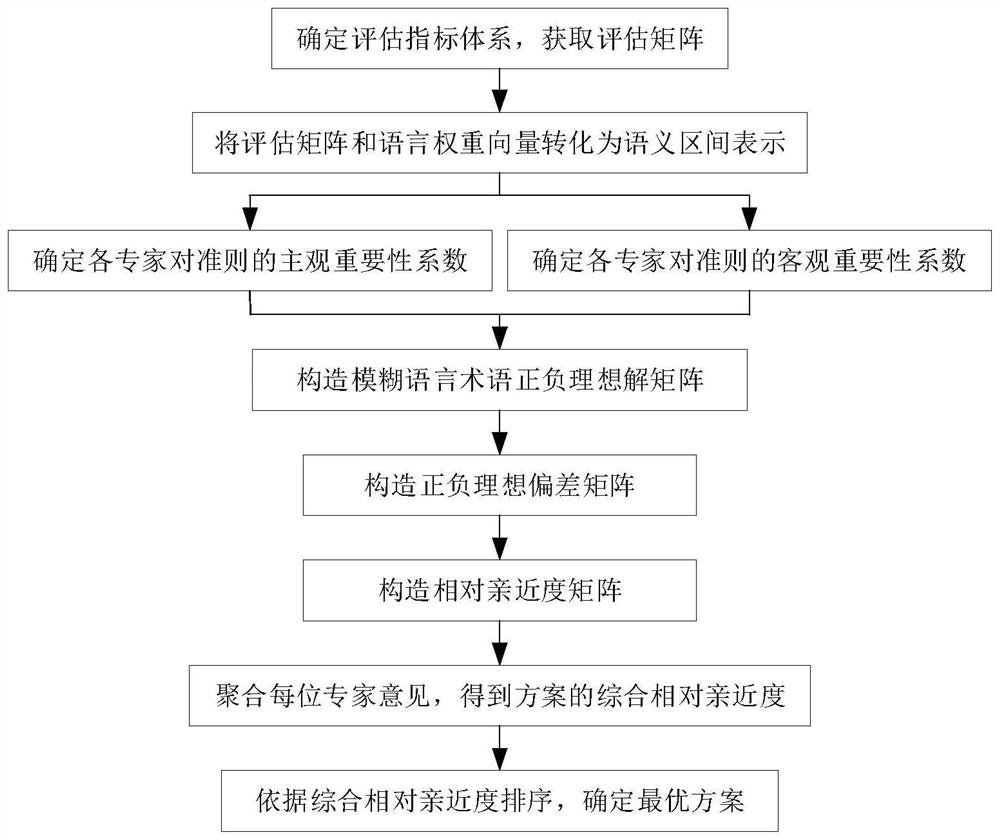

Multi-criterion decision-making method for hesitant fuzzy language term set

PendingCN114218959ACalculations are reasonableOvercoming the Insufficiency of Distance MetricsSemantic analysisComplex mathematical operationsGranularityIndex system

The invention discloses a hesitant fuzzy language term set multi-criterion decision-making method, which comprises the steps of determining an evaluation index system and obtaining an evaluation matrix; converting the evaluation matrix Xk and the language weight vector Wk into semantic interval representation; determining a subjective importance coefficient of each expert to the criterion; determining an objective importance coefficient of each expert to the criterion; constructing positive and negative ideal solution matrixes S + and S-of fuzzy language terms; constructing positive and negative ideal deviation matrixes D + and D-; constructing a relative proximity matrix Rc; aggregating the opinions of each expert to obtain the comprehensive relative proximity of the scheme; and according to the comprehensive relative closeness ranking, determining an optimal scheme. The method can be effectively applied under the condition of multi-granularity imbalance. The method is simple and easy to implement, subjective and objective importance coefficients of evaluation criteria are integrated, the decision making process is more practical, and therefore a more reasonable decision making result is obtained.

Owner:HARBIN ENG UNIV

Selection Scheme of Terrain Adaptation Area Based on Hierarchical Decision-Making

ActiveCN108416168BHigh precisionReduce riskDesign optimisation/simulationSpecial data processing applicationsTerrainDiscriminant model

The invention provides a terrain adaptation area selection scheme based on hierarchical decision-making, which belongs to the field of terrain-assisted navigation, including a threshold discrimination model and a multi-criteria decision-making model: (1) terrain adaptability is described by terrain characteristic parameters; (2) The threshold discriminant model includes necessary and sufficient conditions for adaptive terrain, which are used to detect significantly unsuitable terrain and significantly adapted terrain with high accuracy, and transfer the undetermined area to the multi-criteria decision-making model; (3) Multi-criteria decision-making model According to the difficulty of modeling the undetermined area, one or more classifier models are established by using the pattern recognition method, and the suitability judgment result of the undetermined area is given through decision-making or fusion decision-making. The invention adopts a layered decision-making scheme, and effectively improves decision-making efficiency and decision-making reliability by narrowing the applicable range of the model.

Owner:BEIHANG UNIV

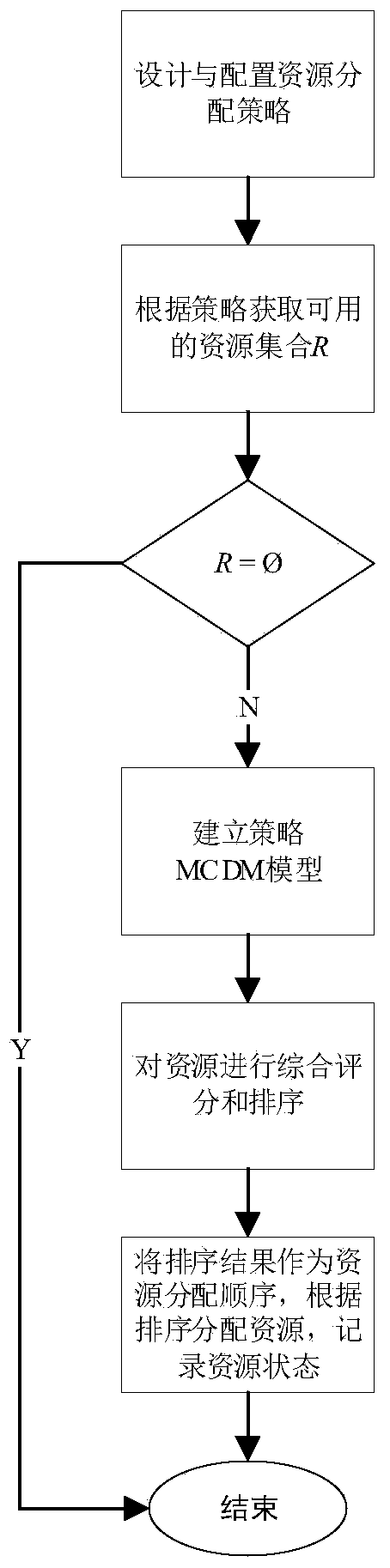

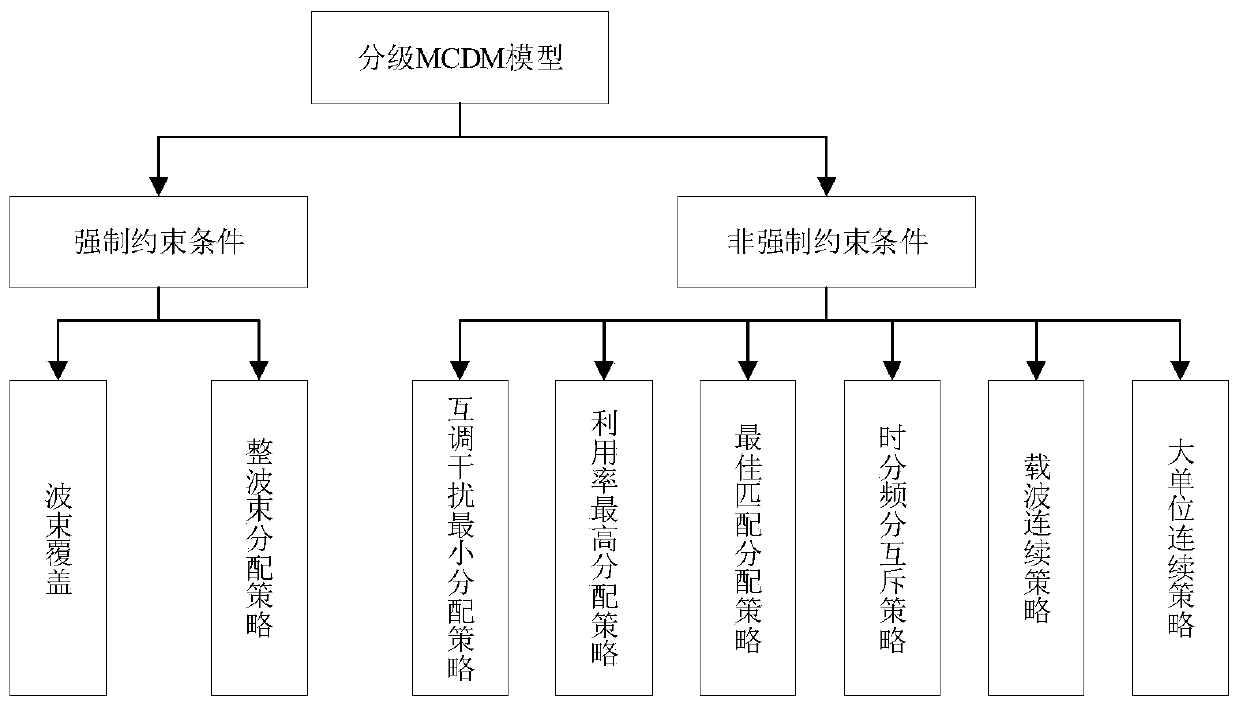

A method for allocating satellite communication channel resources

ActiveCN111294109BResource optimizationConvenience needsNetwork traffic/resource managementRadio transmissionResource assignmentResource Management System

The invention discloses a satellite communication channel resource allocation method based on multi-criterion decision making (MCDM). The method comprises the steps of: designing and configuring a satellite communication channel resource allocation strategy; establishing hierarchical MCDM model, screening the obtained available resources through a forced constraint condition; enabling resources meeting the mandatory constraint conditions to be subjected to resource allocation; according to the strategy requirements of the satellite communication resource management system in different scenes,giving different weights to all the non-forced constraint condition indexes, comprehensively sorting available satellite communication resources, wherein a sorting result serves as available resourcecandidate sorting, and therefore reasonable assessment of the available resources is achieved, and reasonable allocation of the resources is completed.

Owner:军事科学院系统工程研究院网络信息研究所

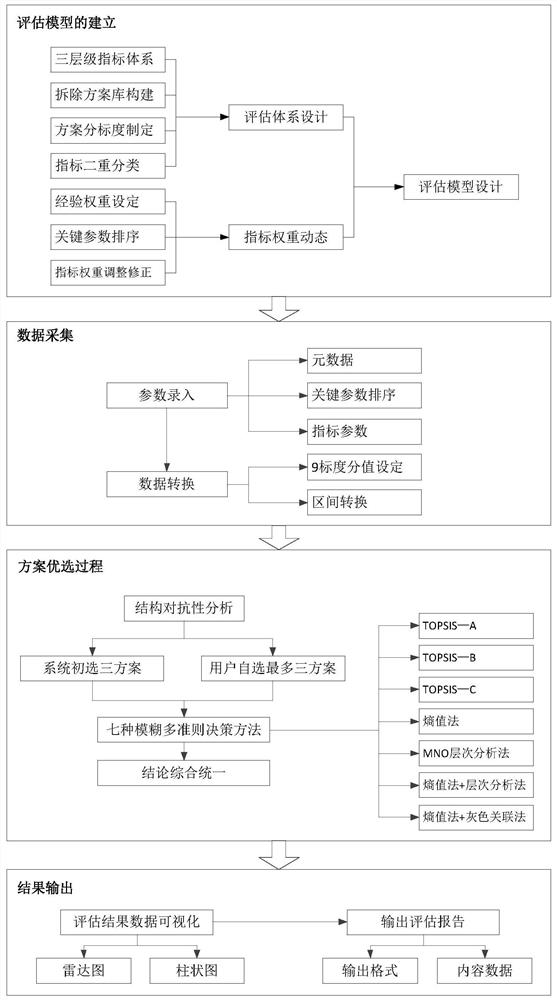

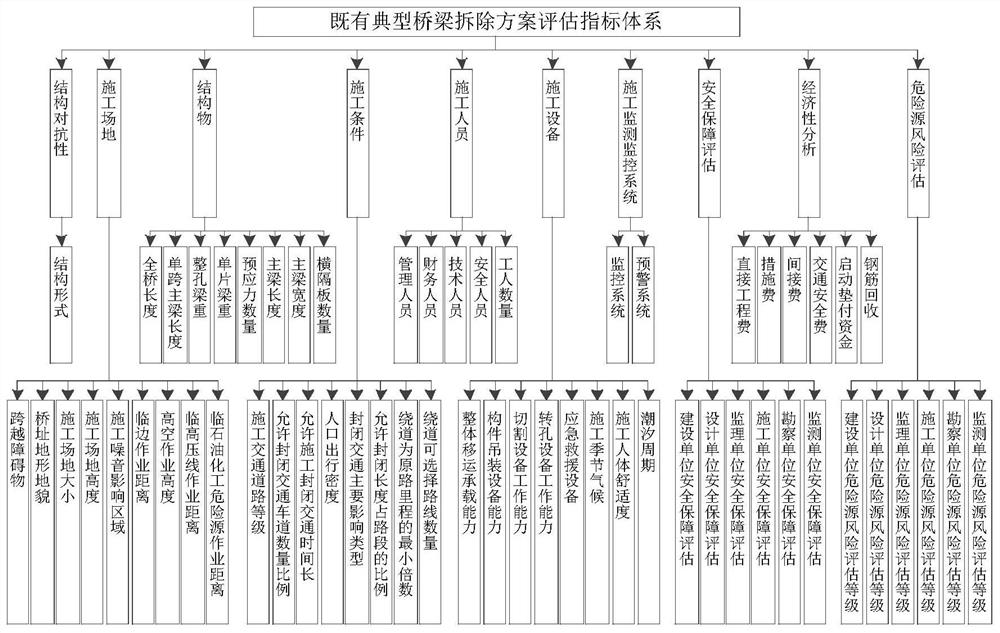

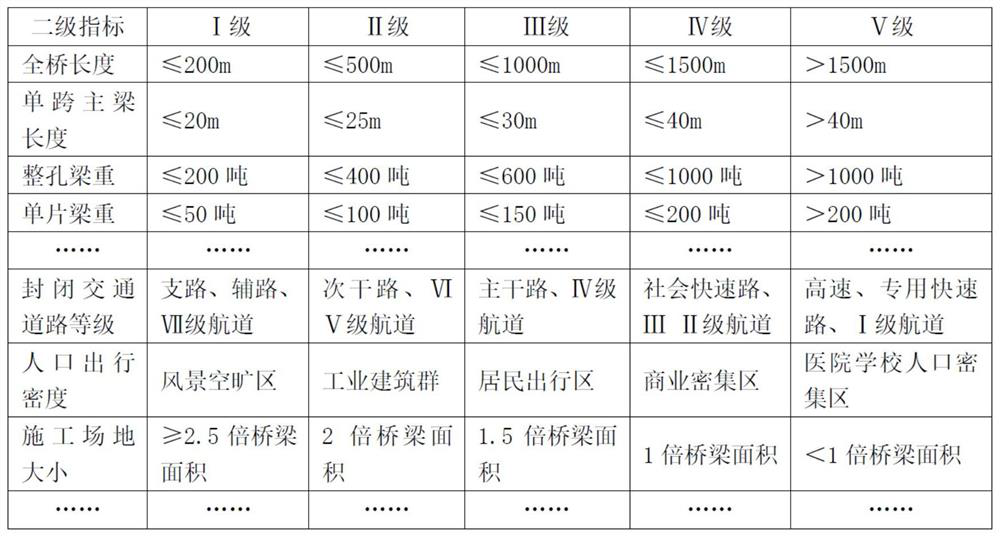

Urban typical bridge quick demolition scheme decision-making software system

PendingCN111640045AReasonable structureEconomically reasonableBuilding repairsResourcesDecision makerDecision-making software

The invention provides a decision-making software system for a quick demolition scheme of an urban typical bridge. The decision-making software system is characterized by comprising an evaluation model establishment module, a data collection module and a scheme optimization module, wherein the evaluation model establishing module is used for setting a scheme database, an index system and corresponding index weights; the data collection module is used for receiving the parameters of the bridge to be dismantled and quantifying the input parameters according to the index system and the corresponding index weights; and the scheme optimization module brings the quantified parameters into alternative schemes in a scheme database, performs single-method decision making on the alternative schemesthrough multiple multi-criterion decision making methods, performs unified processing on multiple decision making results, completes comprehensive decision sorting and outputs an optimal quick dismantling scheme. According to the method, the demolition efficiency is improved, the decision risk and the construction risk are reduced, and a decision maker is assisted to improve the decision efficiency and select a reasonable quick demolition scheme.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

A multi-criteria decision-making method for the evaluation process of aircraft design economic affordability

A multi-criteria decision making method for an airplane design economic affordability evaluation process includes step 1, determining design variables and fixed parameters of airplane design, and optionally distributing the design variables to reflect indeterminacy of a design stage; step 2, taking main design parameters as analytic objects, and checking the probability of technological feasibility of a design scheme; step3, on the basis of a technological feasibility analysis result, checking the probability of expense affordability of the design scheme; step 4, if the design scheme is feasible in terms of airplane design technology and is receptible in terms of economic affordability, determining that the design scheme is receptible. Fuzzy interval number and RD (robust design) are combined organically on the basis of probability technology to create the probability multi-criteria decision making method based on the fuzzy interval number and the RD.

Owner:BEIHANG UNIV

Automobile engine fault maintenance method based on Bayesian network models and multi-criteria decision analysis

InactiveCN103308314BReduce wasteShorten the timeEngine testingGaussian network modelBayesian network

An automobile engine fault maintenance method based on Bayesian network models and multi-criteria decision analysis includes: using each fault category and each fault source under each fault category, which affect an automobile engine, to build Bayesian network models so as to obtain a first probability value of each fault category and a second probability value of each fault source; respectively determining standardized weight of each decision criterion through multi-criteria decision analysis according to the decision criteria; obtaining a first effect value of each fault category according to each decision criterion, the standardized weight and the first probability value, selecting the fault category with the highest first effect value, obtaining a second effect value of each fault source under the fault category with the highest first effect value, and selecting the fault source with the highest effect value in the second effect values to serve as the maintenance judging results.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

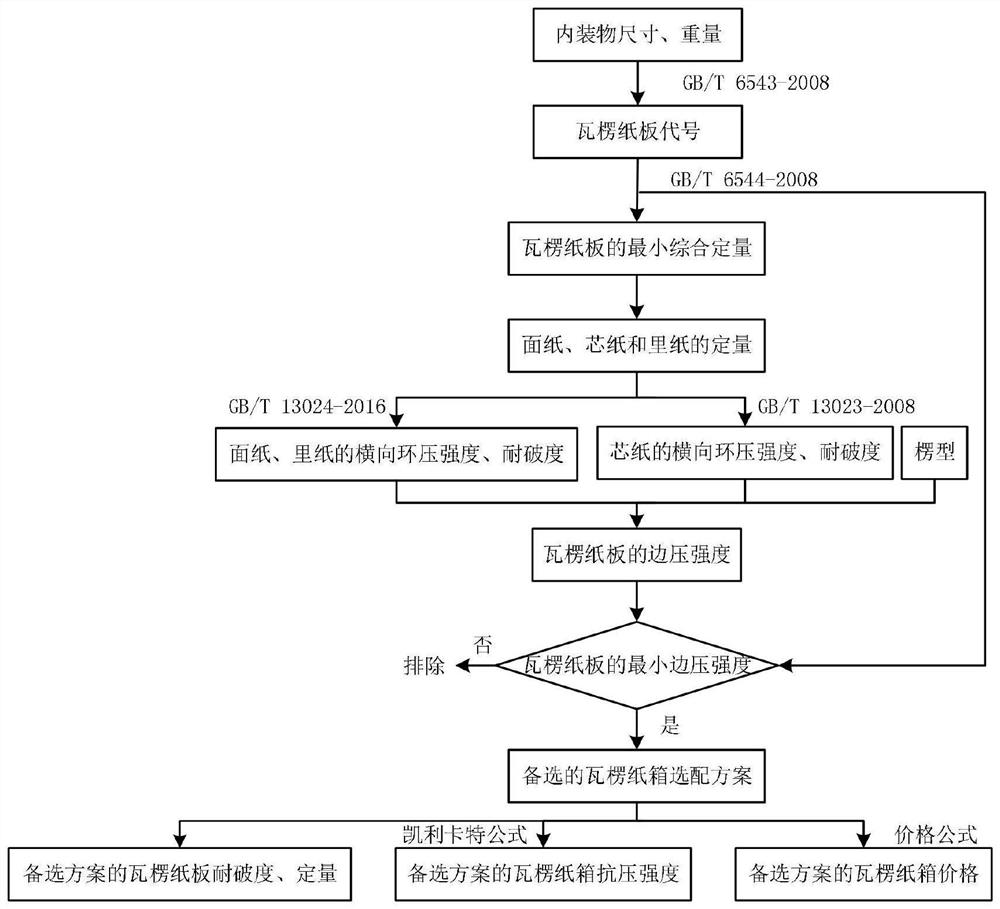

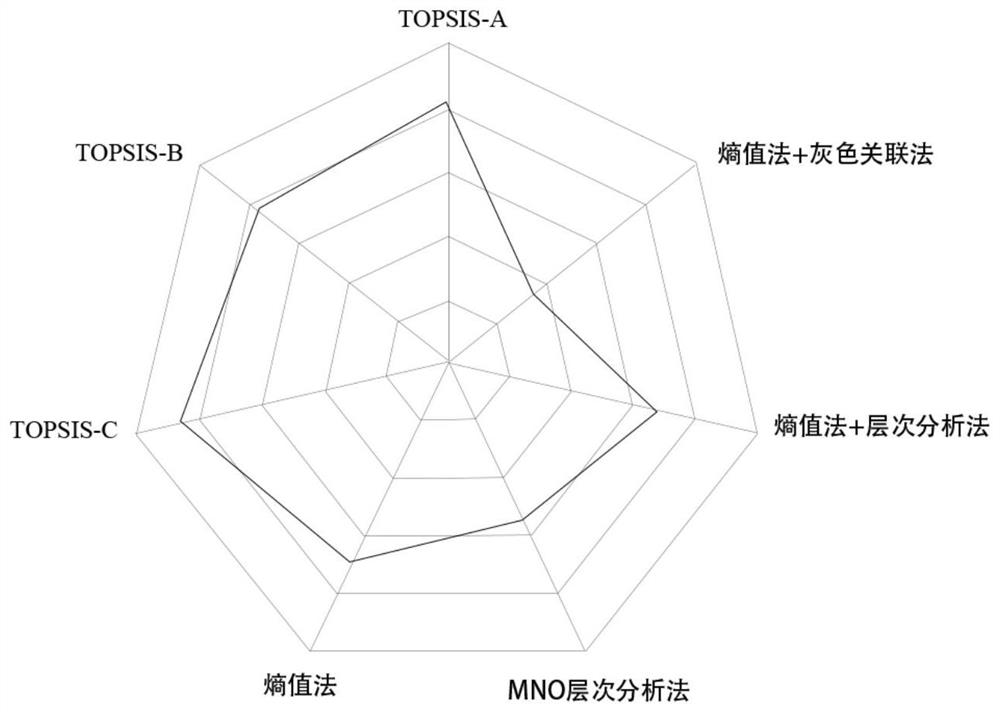

Corrugated carton paper distribution and material selection optimization method based on mixed mathematical model analysis

A corrugated carton paper distribution and material selection optimization method based on mixed mathematical model analysis is characterized in that a combined mixed mathematical model is formed on the basis of mathematical models of a data envelopment analysis method (DEA) and an entropy weight method (EWM) and in combination with a mathematical model of a superior and inferior solution distance method (TOPSIS), and according to the principle of a multi-criterion decision model material selection method, based on the mixed mathematical model, paper distribution and material selection of a corrugated carton are optimized. And carrying out material selection on the corrugated carton paper distribution by adopting cross efficiency combination model analysis. According to the method, the evaluation index data for evaluating the corrugated carton can be obtained only by determining the size and the weight of the content and by means of cross efficiency calculation and analysis; and calculating the closeness and ranking of each candidate paper matching scheme by utilizing the constructed mathematical model to obtain the optimal material and configuration scheme of the corrugated carton. In addition, the coupling effect of various variable factors is considered, overall optimization is taken as a target, a scientific and effective method is provided for selection and decision-making of corrugated carton materials, and the uncertainty of material selection and matching in the corrugated carton design stage is reduced.

Owner:HUNAN UNIV OF TECH

Detection restorative method of hydraulic valve jamming and chucking faults

InactiveCN102606800BGuaranteed monotonicityGuaranteed validityValve arrangementsCleaning using liquidsElectricityControl signal

Owner:SHAOXING UNIVERSITY

Decision-making method for rapid demolition scheme of urban typical bridge

PendingCN111667174AHigh precisionImprove reliabilityResourcesIndustrial engineeringMulti criteria decision

The invention provides a decision-making method for a rapid demolition scheme of an urban typical bridge. The decision-making method is characterized by comprising the following steps: a, acquiring related index parameters of a to-be-demolished bridge; b, obtaining a selectable dismantling scheme; c, calculating the resistance scores of all the demolition schemes based on the related index parameters of the to-be-demolished bridge, and selecting a plurality of demolition schemes with weaker resistance as an alternative scheme set; d, performing single-method decision making on all the alternative schemes through multiple multi-criterion decision making methods; and e, performing unified processing on a plurality of decision results and finishing comprehensive decision sorting, wherein thedecision result with the highest sorting is the optimal quick dismantling scheme. Aiming at the defects in the prior art, the invention provides the decision-making method for the rapid removal schemeof the urban typical bridge, and the most suitable bridge removal method is effectively selected.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

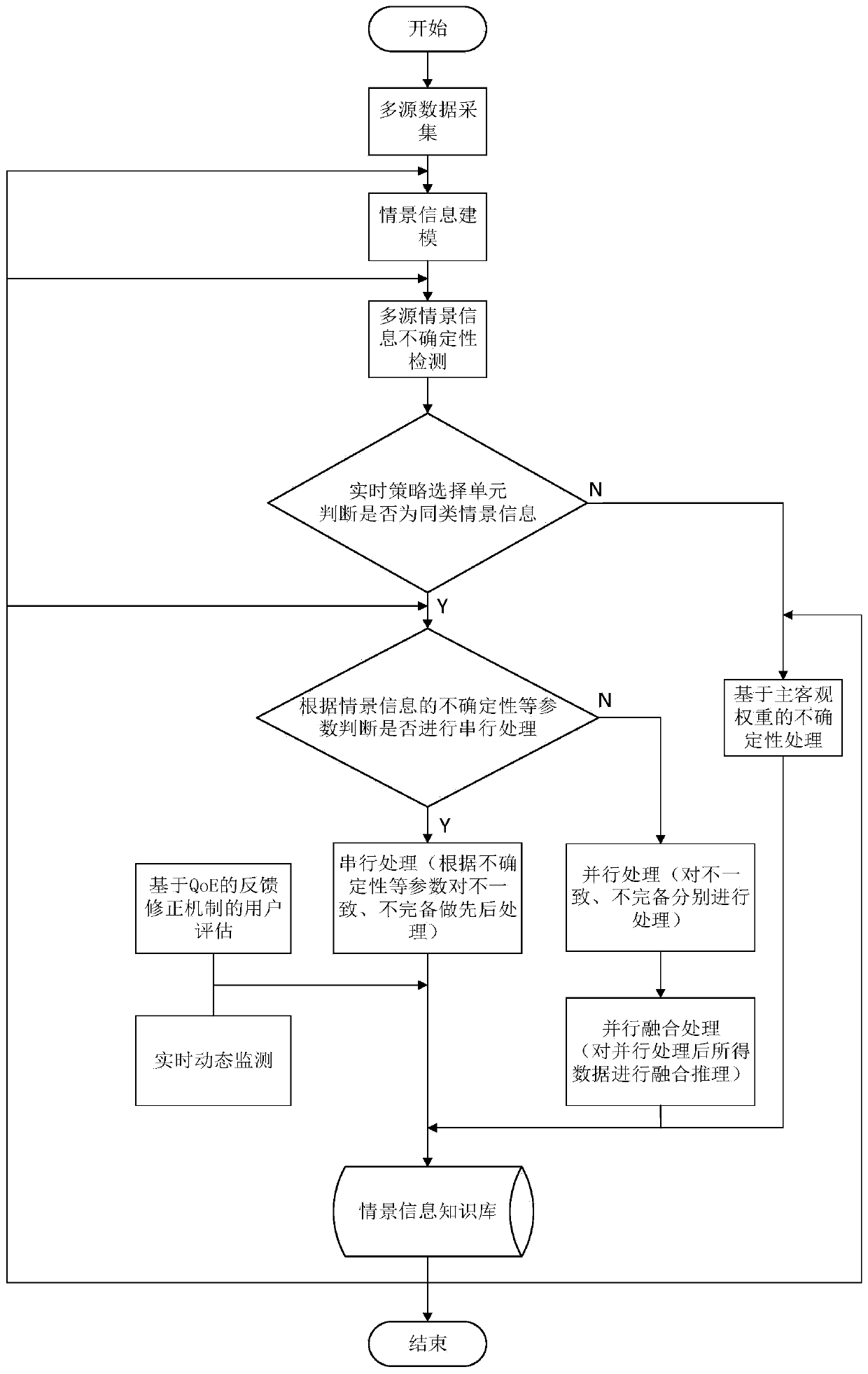

Multi-criterion decision-making-based multi-modal scene information uncertainty processing method and system

ActiveCN111062427AImprove integrityIncrease diversityCharacter and pattern recognitionNeural learning methodsInformation typeEngineering

The invention provides a multi-criterion decision-making-based multi-modal scene information uncertainty processing method and system. The method comprises the following steps: receiving multi-sourcescene information, and modeling the multi-source scene information based on a concept lattice; detecting uncertainty of the multi-source scene information after modeling according to preset thresholdinformation of a scene information knowledge base to obtain the multi-source scene information meeting preset requirements; based on a real-time strategy of multi-mode control, judging whether the scene information is the same type or not according to attributes related to the scene information type in the scene modeling information, and then selecting an uncertainty processing mode according to the type of the scene information; dynamically monitoring processing results of the same kind of scene information in real time; evaluating user satisfaction degree of processing results of the same kind of scene information based on a feedback correction mechanism of QoE. Feedback information of uncertainty processing is continuously obtained through the real-time feedback mechanism, and then real-time closed-loop adjustment is conducted on threshold value information, expert experience and weight parameters in the scene information knowledge base through the feedback information.

Owner:SHANDONG UNIV

Satellite communication channel resource allocation method

ActiveCN111294109AResource optimizationConvenience needsNetwork traffic/resource managementRadio transmissionResource assignmentResource Management System

The invention discloses a satellite communication channel resource allocation method based on multi-criterion decision making (MCDM). The method comprises the steps of: designing and configuring a satellite communication channel resource allocation strategy; establishing hierarchical MCDM model, screening the obtained available resources through a forced constraint condition; enabling resources meeting the mandatory constraint conditions to be subjected to resource allocation; according to the strategy requirements of the satellite communication resource management system in different scenes,giving different weights to all the non-forced constraint condition indexes, comprehensively sorting available satellite communication resources, wherein a sorting result serves as available resourcecandidate sorting, and therefore reasonable assessment of the available resources is achieved, and reasonable allocation of the resources is completed.

Owner:军事科学院系统工程研究院网络信息研究所

A Stamping Process Sequence Planning Method for Complex Sheet Metal Parts with Progressive Die

ActiveCN105487488BSimple methodEnable smart designProgramme controlComputer controlIntelligent designSequence planning

The invention discloses a progressive die complex metal sheet member stamping process sequence planning method, comprising steps of performing metal plate characteristic identification, bending and expanding, generating a stock layout characteristic, and formulating a stock layout rule, listing all possible layout schemes by adopting a sequencing planning matrix, a synchronization sequence planning matrix, and an idle station planning matrix, listing all possible stock layout schemes, establishing an influence factor set U=[u1,u2,u3... un] and a corresponding weight set A=[w1,w2,w3, ...,wn], wherein w1+w2+w3+...+wn=1 and 0<=w1,w2,w3, ...,wn<=1, and calculating the multi-norm decision total score Ev sigma(j=i)<n>wjuj=w1*u1+w2*u2+w3*u3...wn*un according to the influence factor and the corresponding weight, wherein when the Ev value is the maximum, the scheme is optimal. The invention is simple and can obtain the optimal scheme through the data, can manufacture the correct working station stock layout without the stamping and processing knowledge and experience of the design personnel, gets rid of the designer, realizes the intelligent designing in a real meaning, and realizes the processing of the standardization production.

Owner:盐城市金德模具制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com