Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

136 results about "Sequence planning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and Method for Re-home Sequencing Optimization

InactiveUS20100017247A1Optimizes sequencingOptimization orderMultiplex system selection arrangementsData processing applicationsSequence planningTelecommunications network

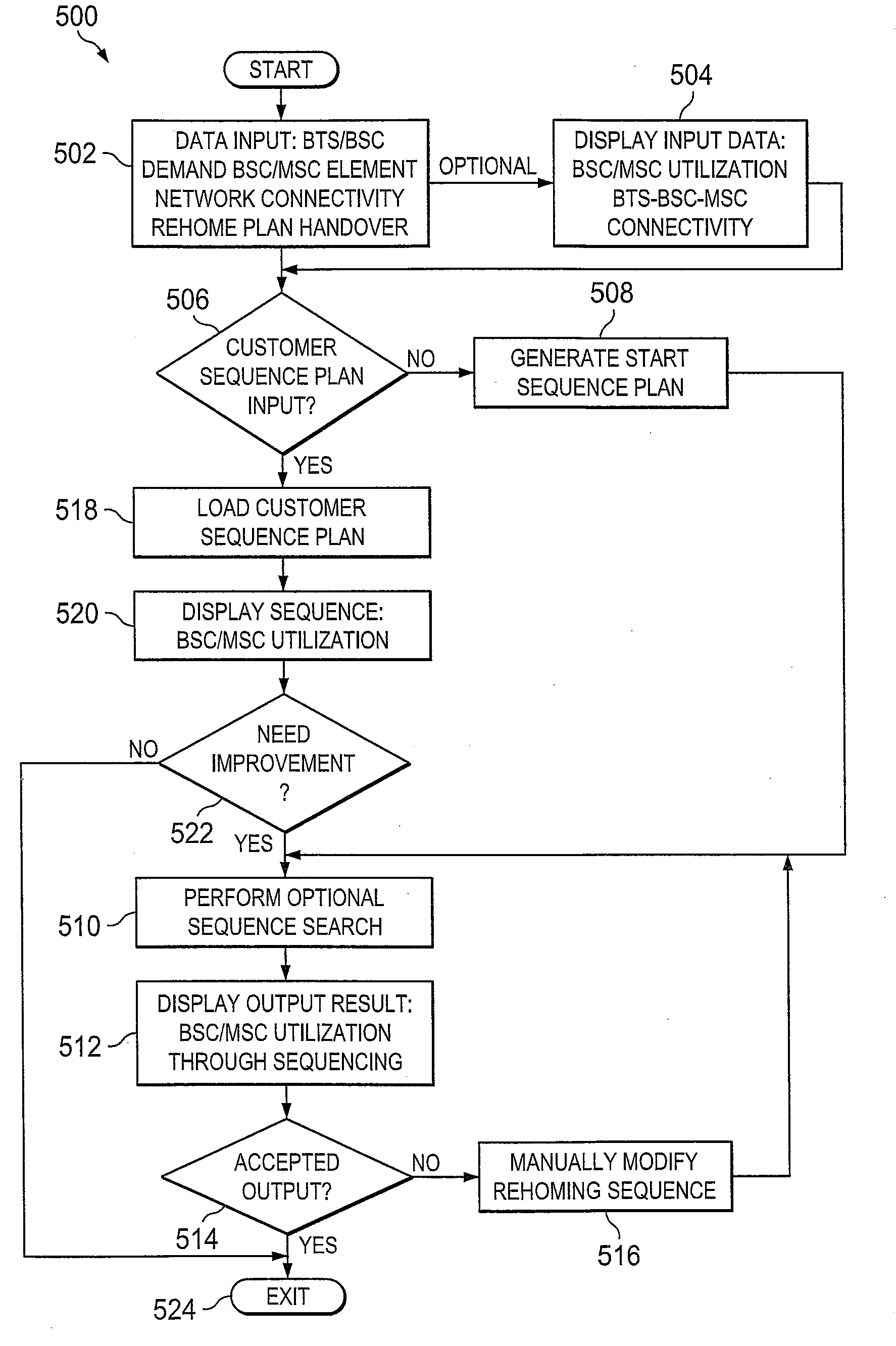

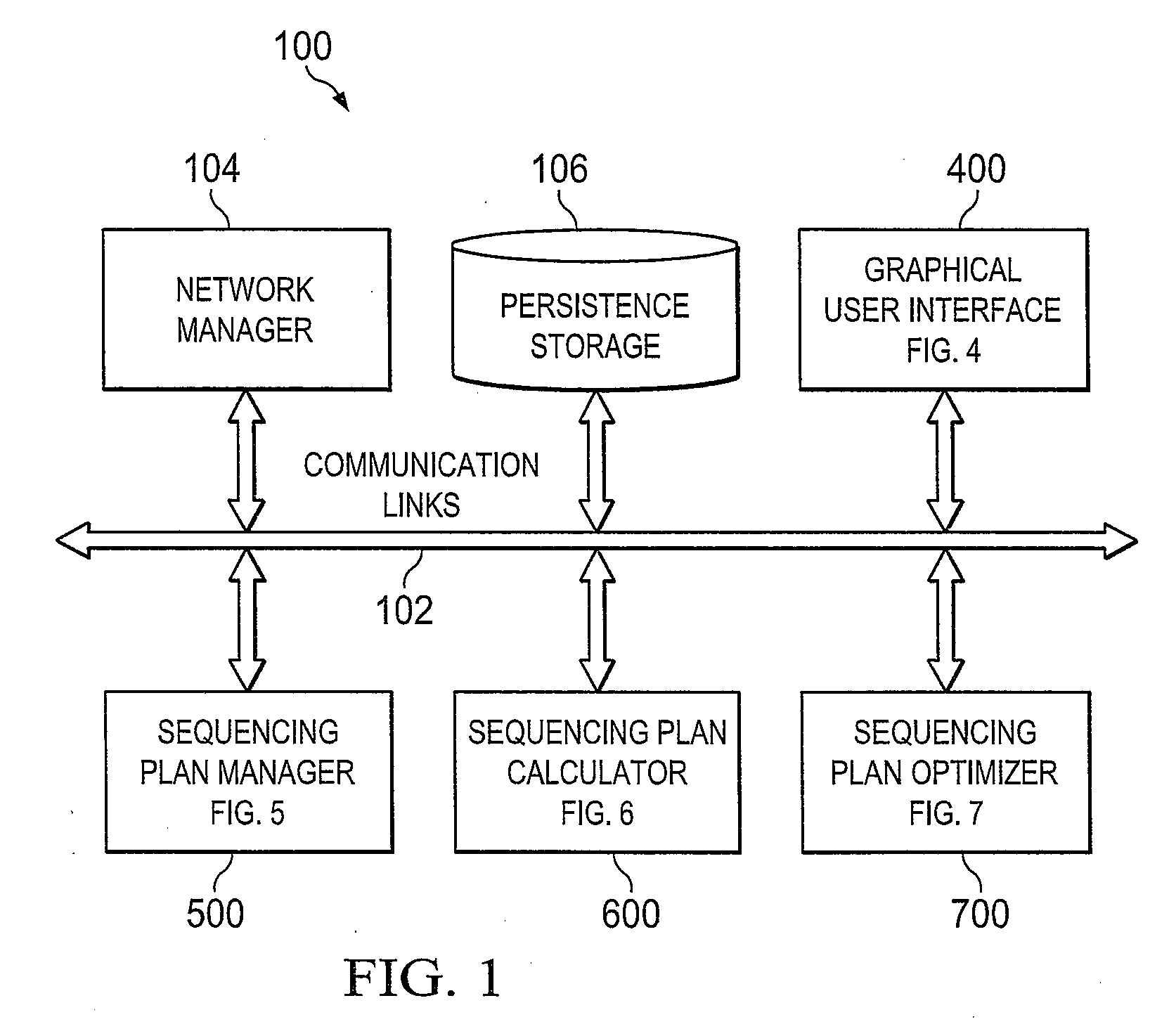

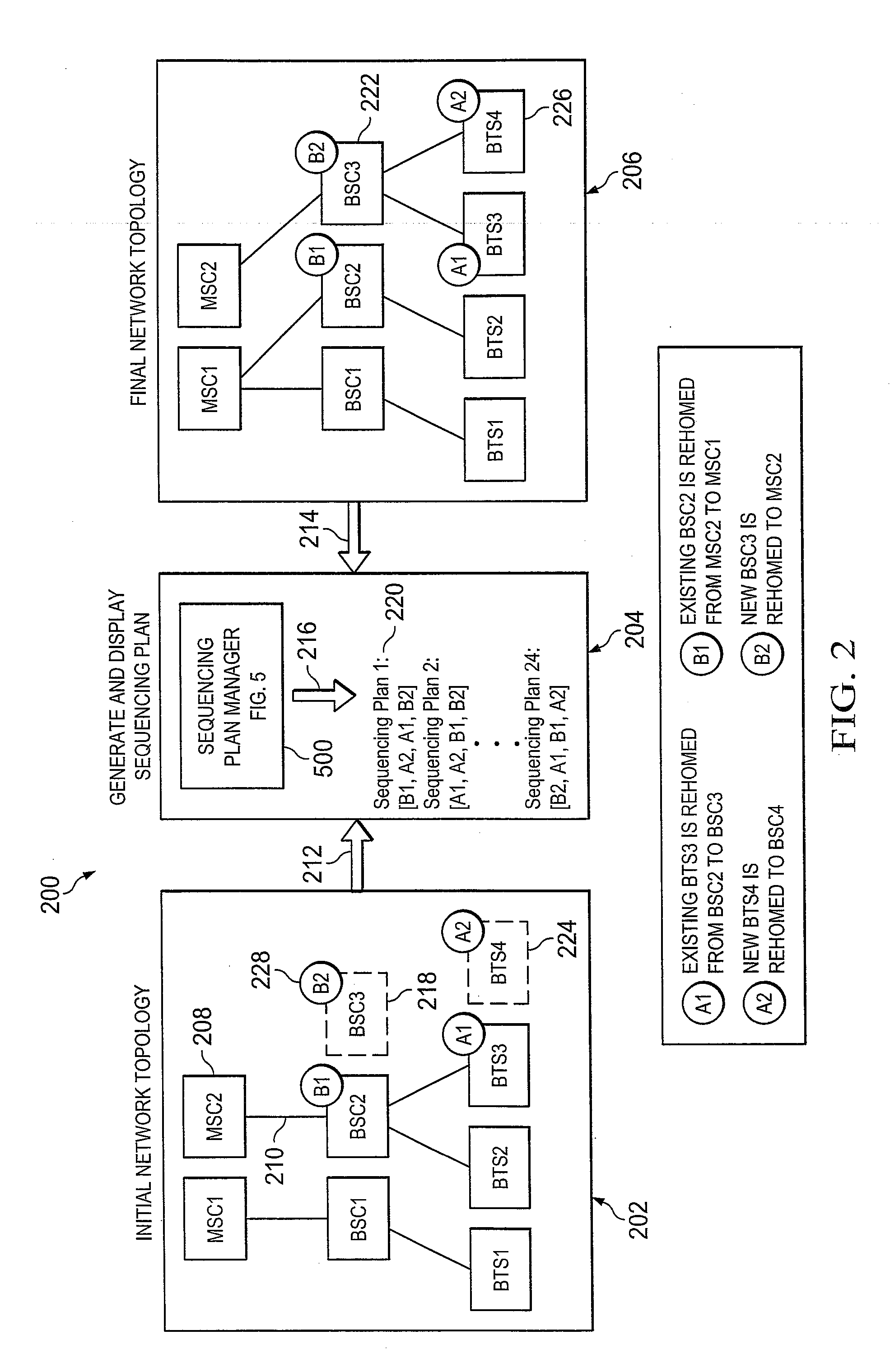

A system and method for rehome sequencing optimization of a telecommunications network. In a preferred embodiment, a practicable optimized rehome sequencing plan is determined for a rehome plan in order to migrate the network topology from an initial state to a final state while minimizing the costs incurred during the network state transitions across multiple time periods. Constraints that may be considered include specific market restrictions such as the limit on the number of network elements in a cluster, the limit on the number of clusters in a sequencing step, the limit on the number of sequencing steps, and the immobility limit on the network elements. Constraints also may include cost restrictions incurred during network transitions, such as individual cost limits during each network transition state and an overall cost limit of network transitions from the initial state to the final state.

Owner:CERION OPTIMIZATION SERVICES

Route planning method for moving carrier

InactiveCN108896048AAccurate divisionImprove work efficiencyNavigational calculation instrumentsSpecial data processing applicationsSequence planningSimulation

The invention provides a route planning method for a moving carrier and belongs to the field of navigation. The method comprises the following steps: taking a grid as a minimal unit for performing partitioning treatment on an operation area of the moving carrier, thereby acquiring operation blocks; performing reciprocating operation in each operation block in an ergodic manner; performing trans-block operation after the moving carrier finishes the operation in each operation block, and performing reciprocating operation in another operation block in the same ergodic manner. The moving carrieris capable of acquiring a plurality of operation blocks through a block cutting algorithm on the basis of an electronic grid map of the known information and the operation routes in the blocks are planned in each operation block through a reciprocating traversing route planning algorithm; the cutting sequence between the blocks is planned through a trans-block operation sequence planning algorithmafter the operation is finished in the present block; various algorithms are utilized to accurately divide the routes in the operation area and the working efficiency can be finally promoted.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD +1

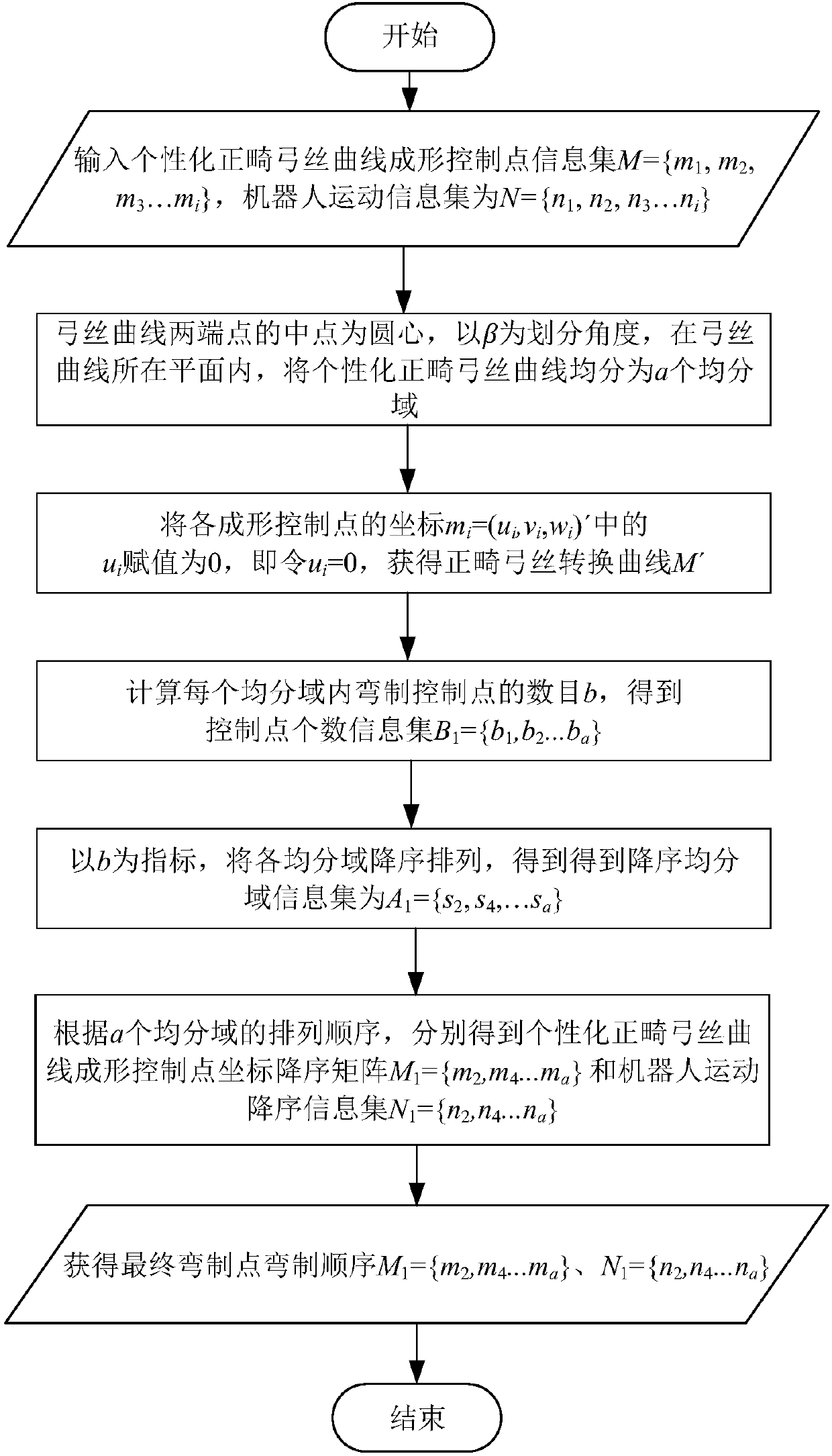

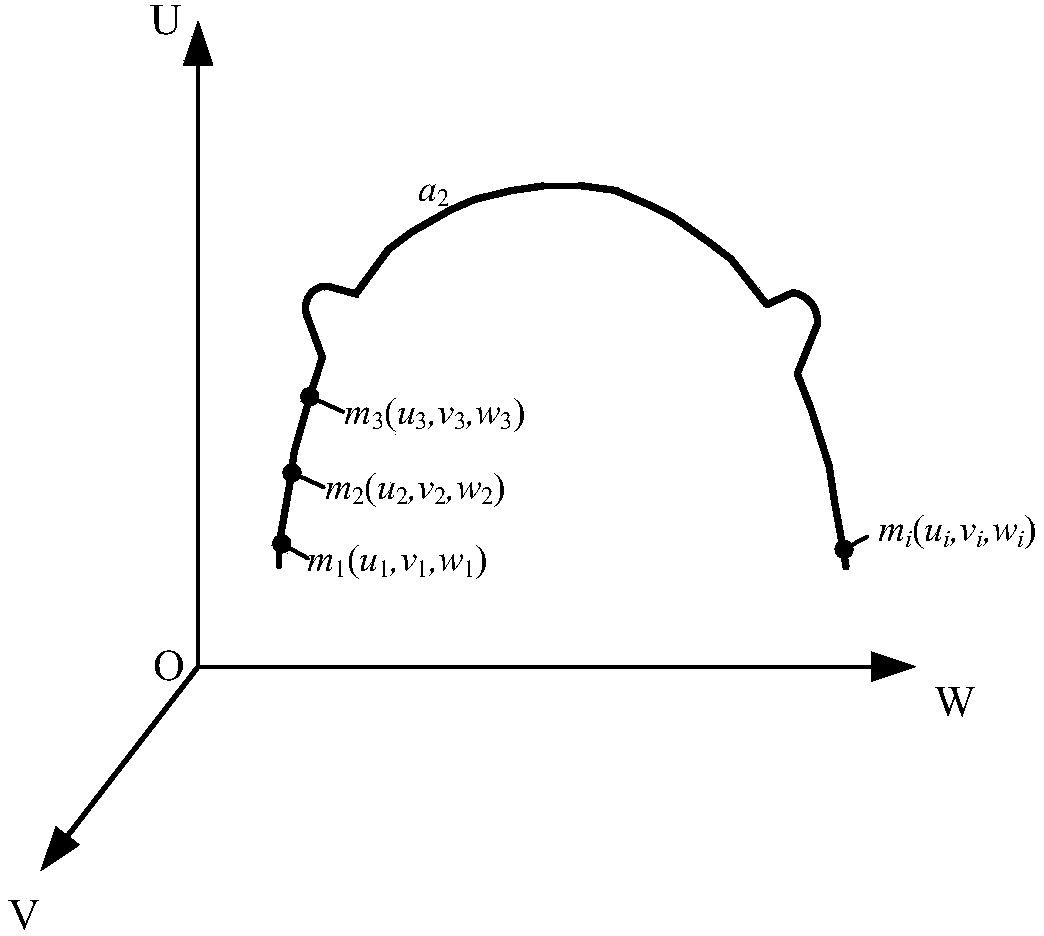

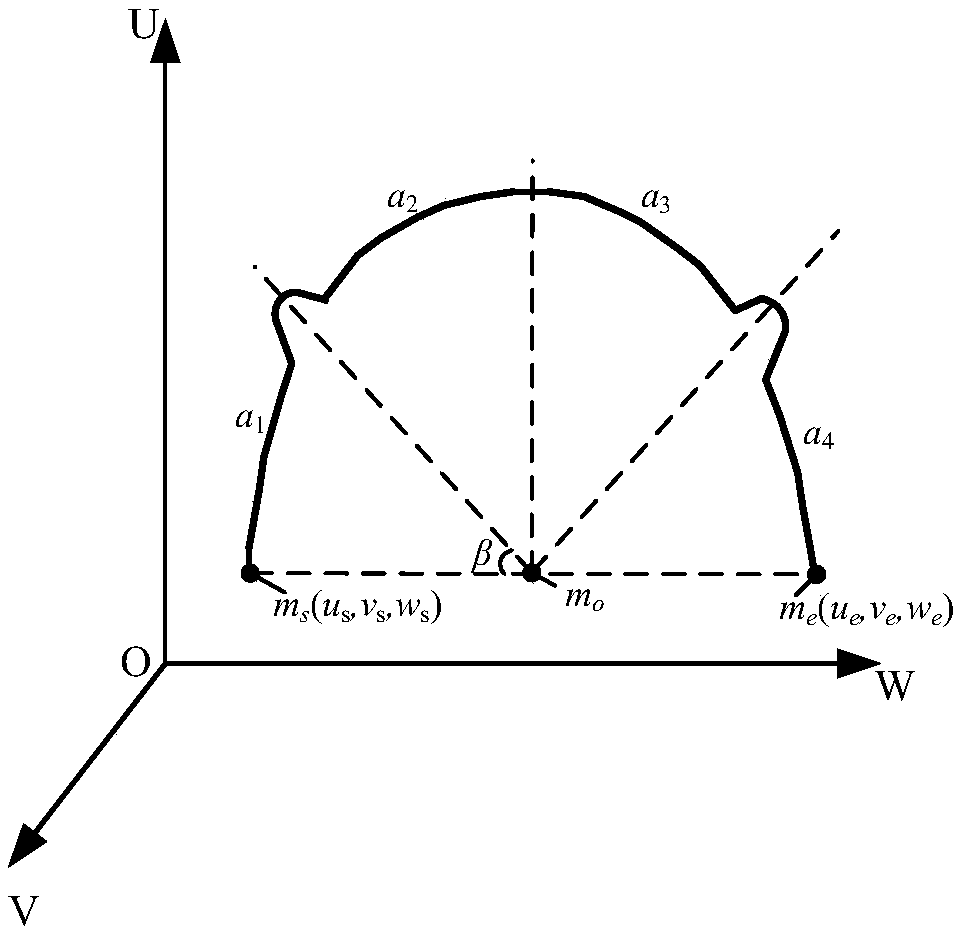

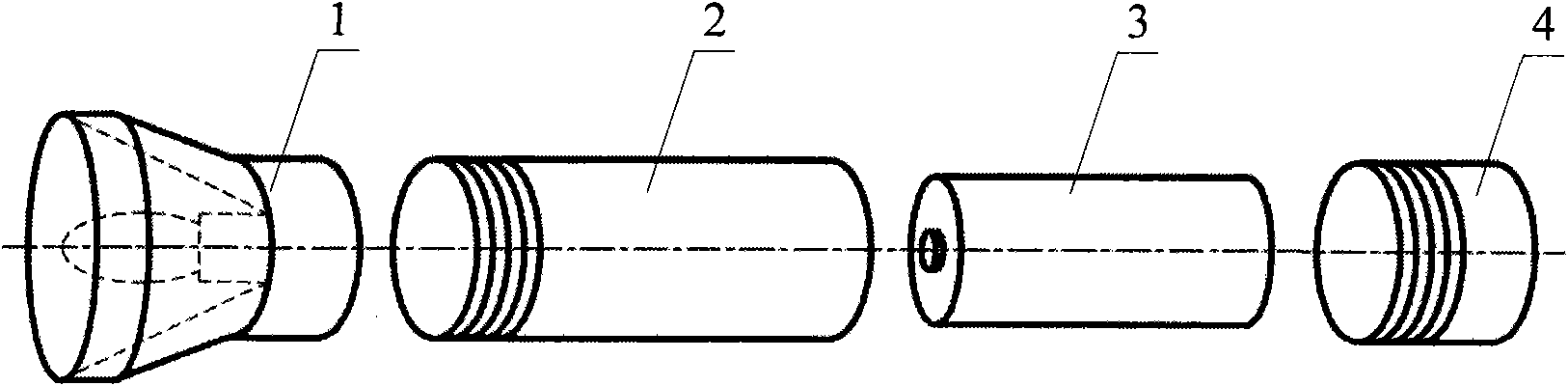

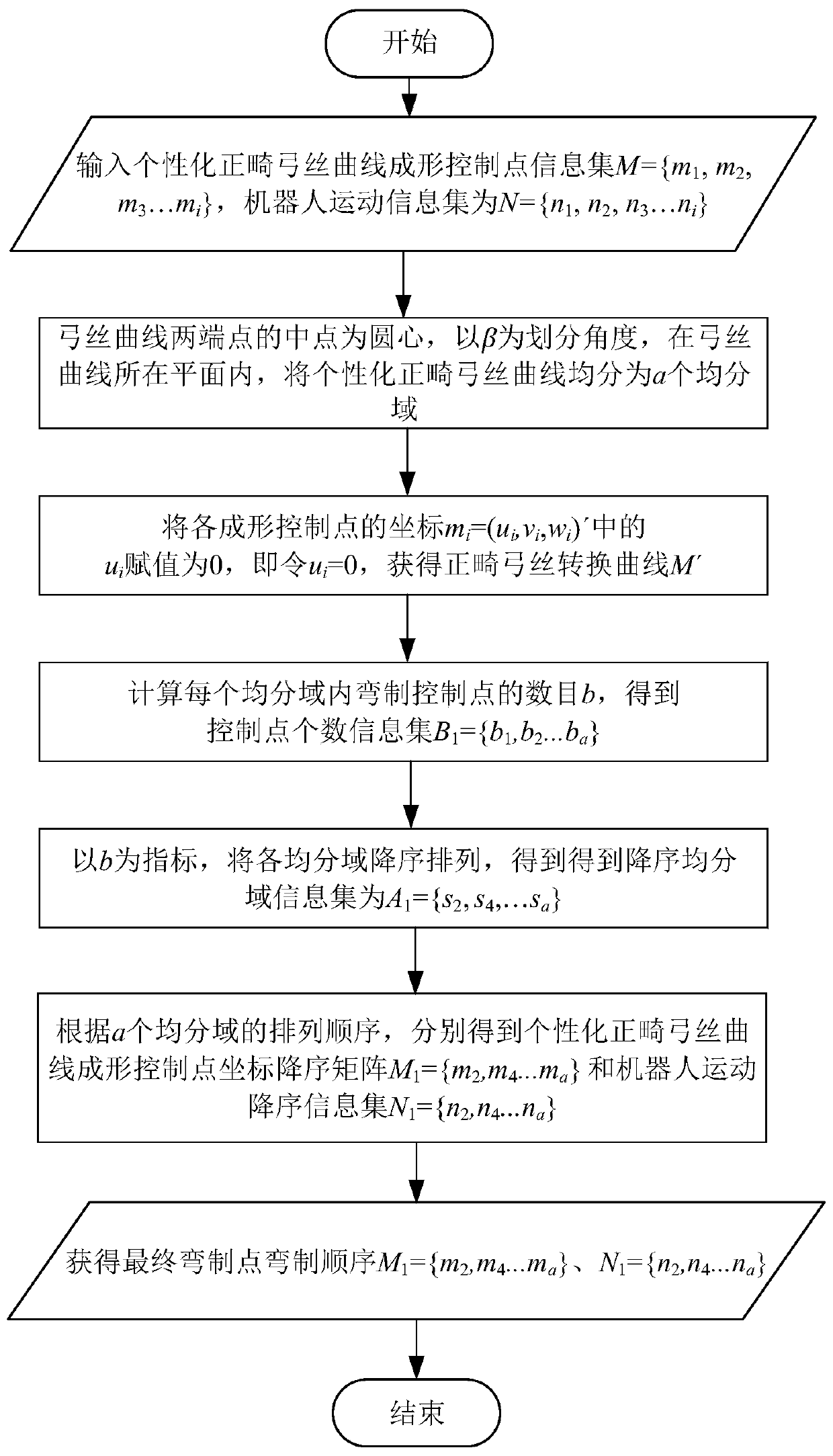

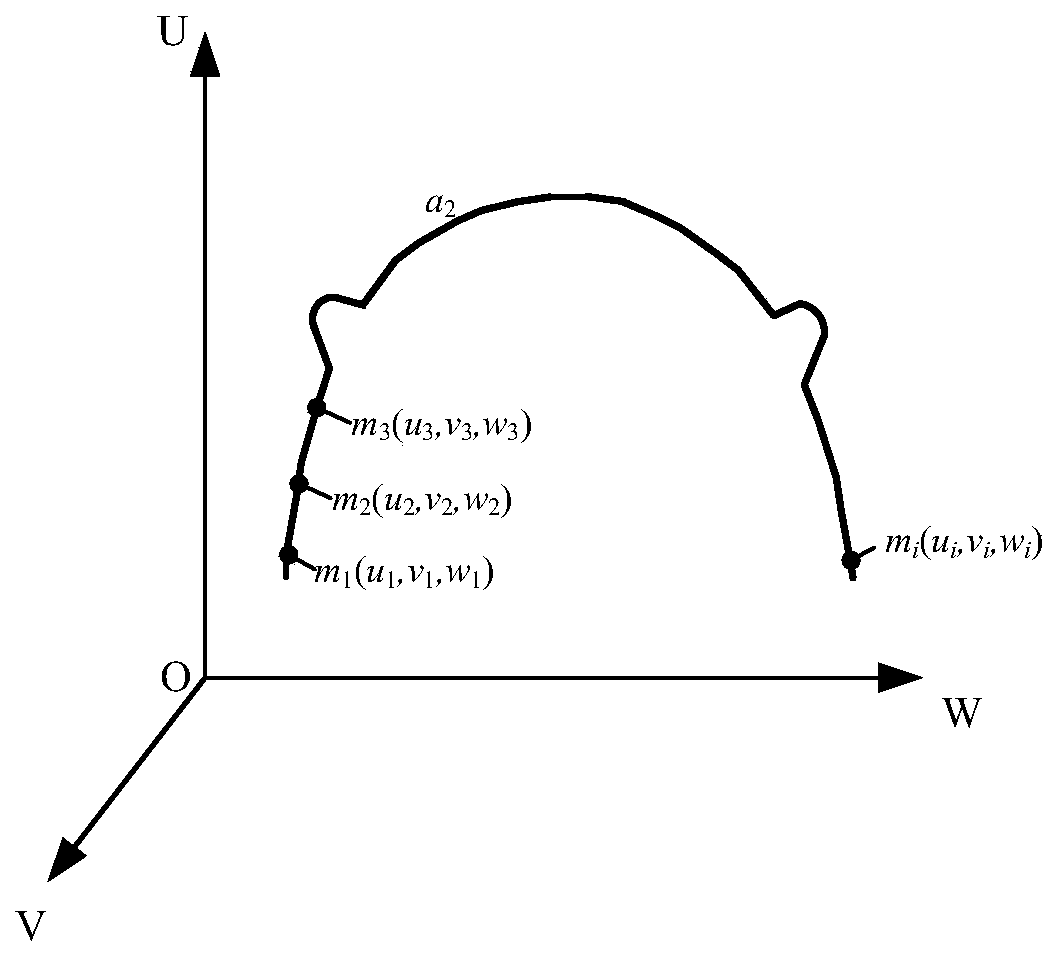

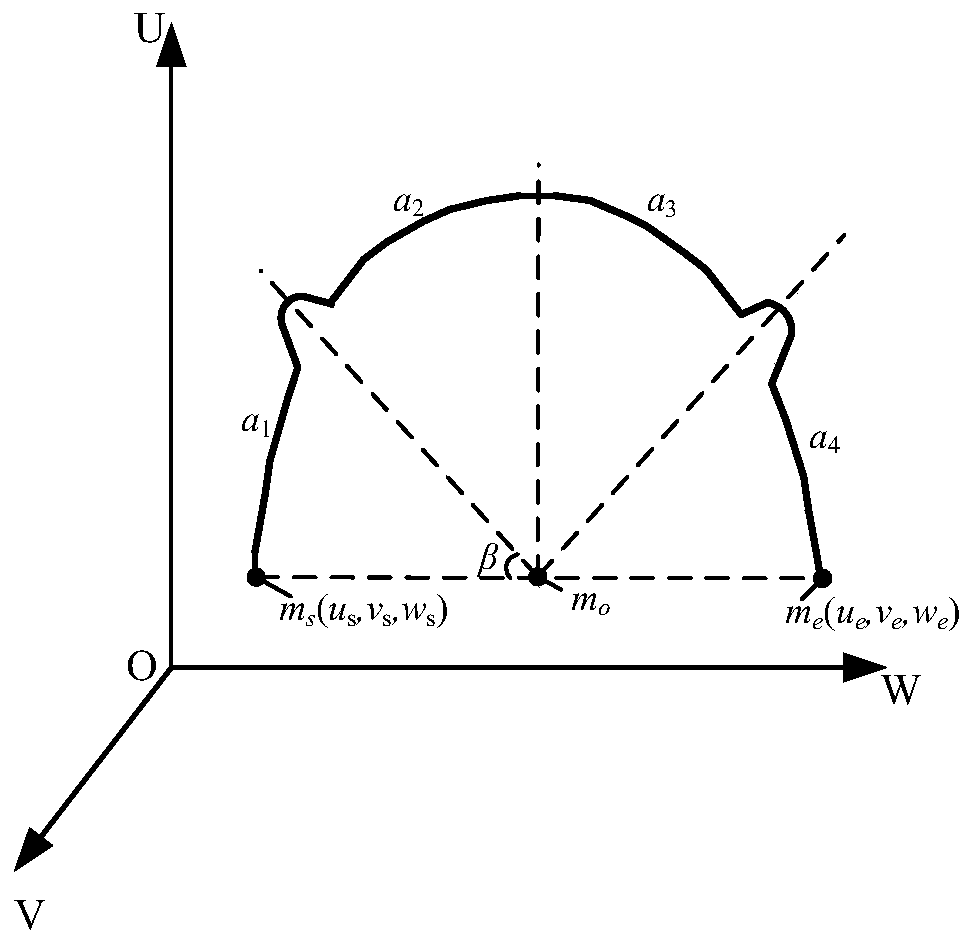

Uniform angle division orthodontic arch wire bending sequence planning method

The invention discloses a uniform angle division orthodontic arch wire bending sequence planning method and relates to the technical field of orthodontic arch wire bending techniques. The uniform angle division orthodontic arch wire bending sequence planning method is provided according to individual orthodontic arch wire curves of patients, on the basis of an orthodontic arch wire curve formationcontrol point information set and a robot movement information set of formation control points and with the combination of characteristic that an orthodontic arch wire is bent by using a robot. The method is technically characterized by comprising the following steps: according to the individual orthodontic arch wire curves of patients, inputting the orthodontic arch wire curve formation controlpoint information set M and the robot movement information set N of the formation control points into an orthodontic arch wire bending system; dividing the individual orthodontic arch wire curves; andsequencing divided uniform division domains.

Owner:HARBIN UNIV OF SCI & TECH

Assembly sequence planning method

The invention relates to an assembly sequence planning method. According to the method, a general assembly body model is disassembled to sub assembly components; the sub assembly components are assembled into a general assembly body model; an optimal assembly sequence can be obtained based on the connection of the general assembly body model; the sub assembly components are disassembled into sub assembly parts; the sub assembly parts are assembled into sub assembly components; a disassembly sequence can be obtained through the sub assembly parts; algorithm optimization and evaluation are carried out through the disassembly sequence; an optimal disassembly sequence is selected through the algorithm optimization and evaluation; and the sub assembly parts can be obtained through selecting the optimal disassembly sequence.

Owner:XIAN TECHNOLOGICAL UNIV

Three-dimensional flight track planning method for electric transmission line inspection unmanned aerial vehicle

ActiveCN106403948AImprove track planning efficiencyReduce 3D trajectory planning timeNavigational calculation instrumentsSequence planningPlanning approach

The present invention relates to a three-dimensional flight track planning method for an electric transmission line inspection unmanned aerial vehicle. The three-dimensional flight track planning method comprises: 1, establishing the models of obstacles, setting cylindrical models for wrapping each obstacle in the map of an unmanned aerial vehicle onboard computer, and obtaining the plane projection equation of the smallest cylinder capable of wrapping the obstacle; and 2, according to the detected flight environment information, carrying out unmanned aerial vehicle overall-situation flight track planning by using a BP neural network algorithm, and obtaining a reference flight track. According to the present invention, the electric transmission line inspection unmanned aerial vehicle flight track planning method is researched, and the reference flight track is planned by using the BP neural network algorithm based on the sequence planning idea, such that the flight track planning efficiency is improved, and the three-dimensional flight track planning time of the electric transmission line inspection of the unmanned aerial vehicle is reduced.

Owner:STATE GRID CORP OF CHINA +2

Service robot controller and control method thereof

InactiveCN105500371AFunction increaseFirmly connectedProgramme-controlled manipulatorHuman–machine interfaceOpen architecture

The invention discloses a service robot controller and a control method thereof. The service robot controller adopts an open type secondary layered architecture and comprises a task planning layer and a motion control layer which are connected by virtue of a communication interface, wherein the task planning layer accepts tasks by virtue of a human-machine interface, carries out task planning and action sequence planning and adjusts an action sequence according to visual, hearing and proximity sense information obtained by a vision sensor and a hearing sensor; and the motion control layer carries out corresponding motion control according to a motion trail planned by the task planning layer and adjusts a motion control process in real time according to touch information obtained by a touch sensor. The service robot controller adopts an open architecture and provides a platform which flexibly defines and develops different function of the service robot. A layered open software-hardware platform can provide openness at different levels according to different requirements, and application requirements of the service robot on task reconfiguration and functional reconstruction can be met.

Owner:SHANDONG YOUBAOTE INTELLIGENT ROBOTICS CO LTD

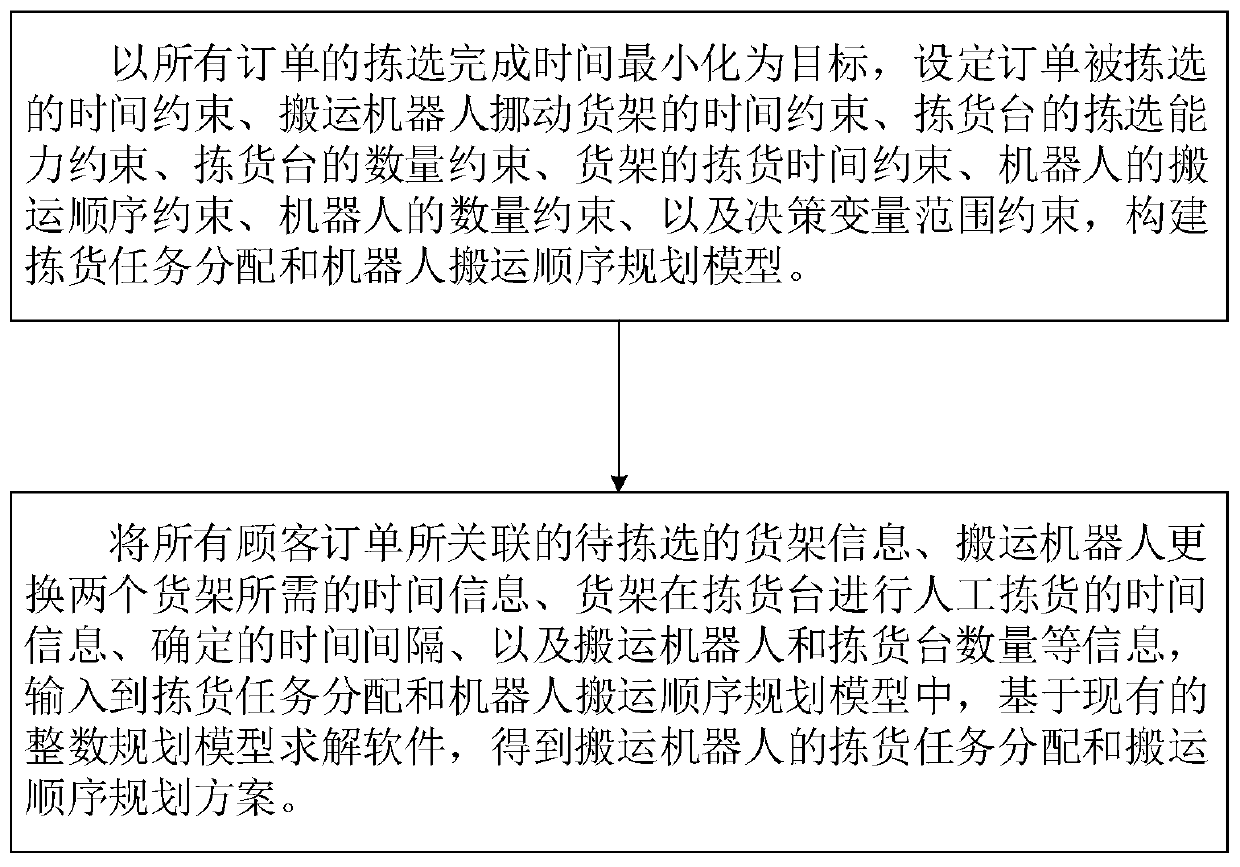

Transfer robot picking task scheduling method for movable goods shelf warehousing system

ActiveCN111409997ASave driving distanceSave travel timeStorage devicesTime informationSequence planning

The invention discloses a transfer robot picking task scheduling method for a movable goods shelf warehousing system, and belongs to the field of electronic commerce. The method comprises the following steps of constructing a picking task allocation and robot transfer sequence planning model with the minimum picking completion time of all orders as a target; and inputting information such as to-be-picked goods shelf information associated with all customer orders, time information about time required for replacing two goods shelves by a transfer robot, time information for manual picking of the goods shelves on a picking table, a determined time interval, and the number of the transfer robots and the picking tables into the picking task allocation and robot transfer sequence planning model, and obtaining a picking task allocation and transfer sequence planning scheme of the transfer robot based on existing integer programming model solution software. According to the method, the technical scheme is simultaneously provided for the picking task allocation and service sequences of the transfer robot, the walking distance of the transfer robot is reduced, the total picking time is reduced, the optimization effect is achieved, and the working efficiency of the movable goods shelf warehousing system is improved.

Owner:DALIAN MARITIME UNIVERSITY

Assembly sequence planning method and assembly sequence planning system

InactiveCN104504471AReduce difficultyDegree of reductionForecastingManufacturing computing systemsSequence planningLocal optimum

The invention provides an assembly sequence planning method and an assembly sequence planning system. The method includes the following steps: A. determining assembly sequence qualitative constraint and assembly sequence quantitative constraint; B. selecting a basic part, and determining parts meeting an assembly precedence relation with the basic part according to the assembly sequence qualitative constraint; C. obtaining assembly priorities of the parts meeting the assembly precedence relation according to the assembly sequence quantitative constraint, assembling the part with the highest assembly priority onto the basic part, taking the assembled parts as a new basic part, and updating the assembly sequence qualitative constraint; D. circularly executing the steps B and C until all the parts are assembled; E. outputting an assembly sequence. By utilizing the assembly sequence planning method and the assembly sequence planning system provided by the invention, local heuristic method information can be utilized to generate a local optimal assembly sequence segment and an optimal assembly sequence , so that the difficulty of assembly sequence planning is decreased.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

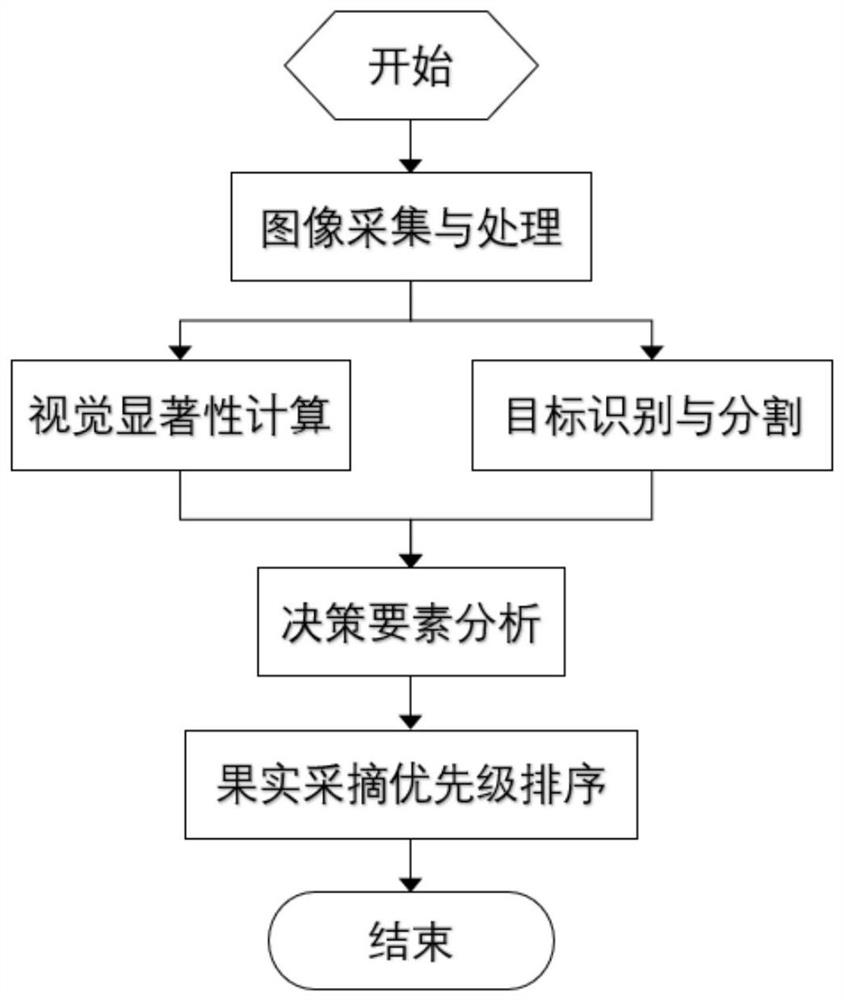

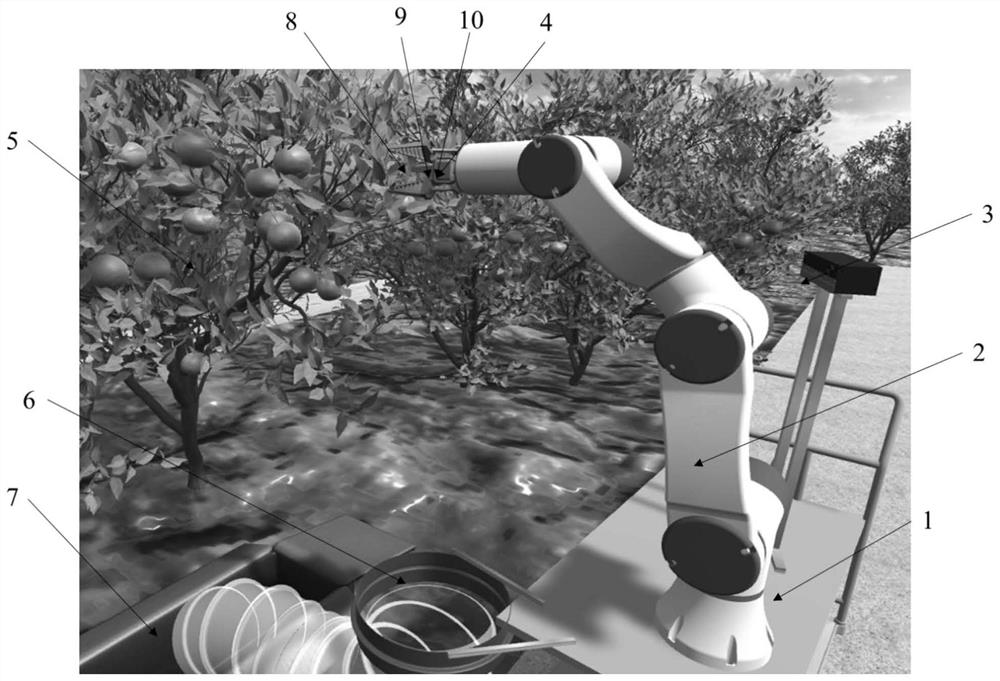

Fruit picking sequence planning method based on visual selection attention mechanism

ActiveCN112136505AQuality improvementPromote production and incomeImage enhancementImage analysisSequence planningVisual saliency

The invention discloses a fruit picking sequence planning method based on a visual selection attention mechanism. The method comprises the steps that a fruit image is collected and registered, fruit visual saliency is calculated, a fruit target is recognized and segmented, fruit picking decision attribute is analyzed, then the average saliency, the central depth value and the shielding coefficientof each fruit are taken as three decision elements for picking priority ranking, the decision element attribute value of each fruit is comprehensively evaluated by adopting a fruit picking priority ranking method, and the picking priority sequence of each fruit in the current scene is determined; and according to the picking priority sequence of each fruit, the three-dimensional coordinates of each fruit are sequentially sent to a fruit robot, and the fruit robot is driven to perform continuous picking. The fruit picking sequence planning method can pick the higher-quality fruits under the condition that energy consumption is relatively low, and has practical significance for promoting production and income increase of the fruit industry in China and intellectualization of automatic picking equipment.

Owner:SOUTH CHINA AGRI UNIV

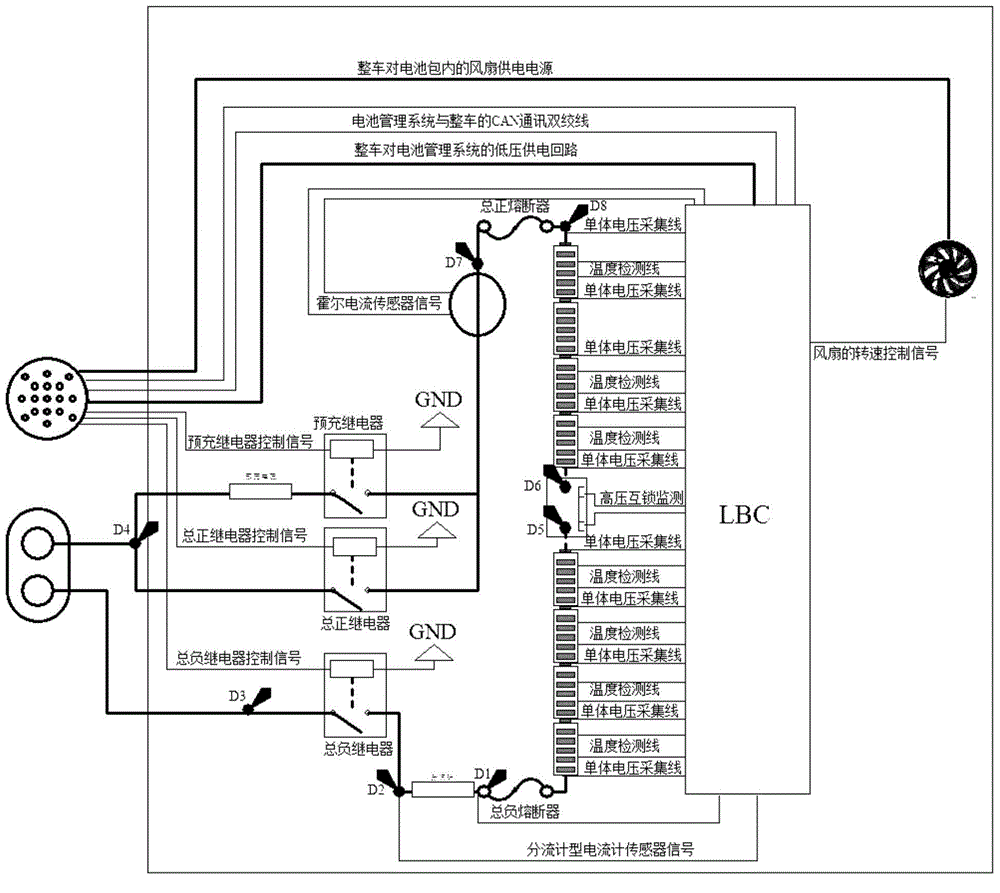

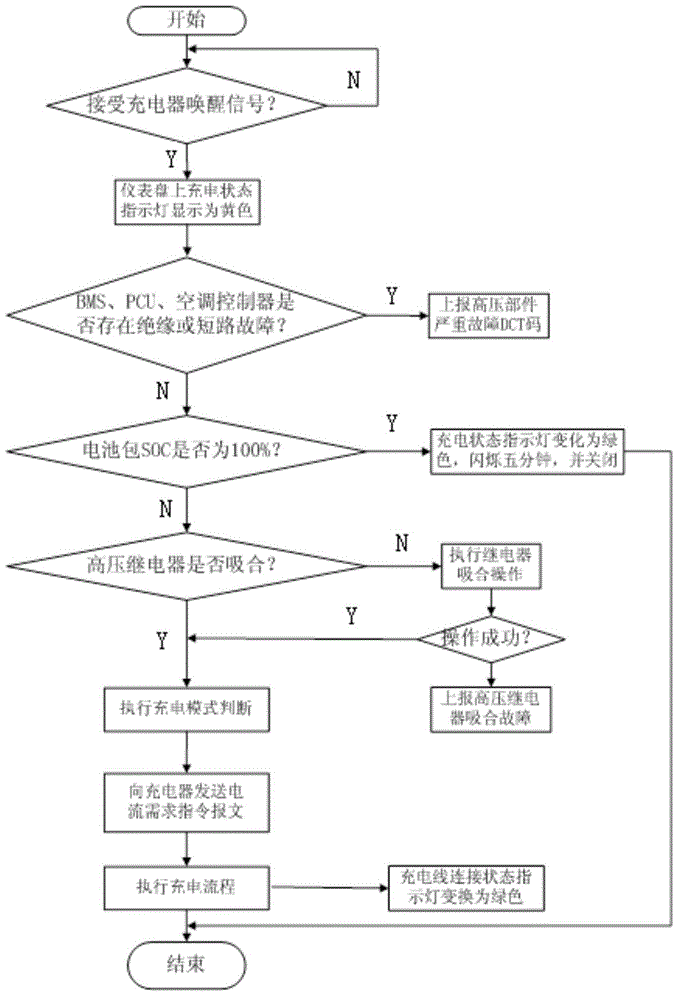

Charging power-on control method based on battery electric vehicle

ActiveCN104648178ANormal operating procedureImprove securityElectric vehicle charging technologyElectric propulsionArea networkElectrical battery

The invention relates to a charging power-on control method based on a battery electric vehicle. The method comprises the following steps that after receiving an externally-connected high-voltage alternating current, a charger sends a charging awakening signal to a vehicle control unit; the vehicle control unit sends remote frame messages to high-voltage components of a vehicle CAN (Controller Area Network) communication network by virtue of a vehicle network and requests each high-voltage component to supply a feedback signal of whether a severe fault exists; if the feedback signal refers to no fault, the electric quantity of a battery pack is determined to be not full; the charger judges whether a main negative relay and a main positive relay are sucked or not; the vehicle control unit controls the main negative relay and the main positive relay to perform charging control. Charging power-on process time sequence planning is performed on an electric vehicle structure state based on the scheme, so that the whole vehicle can perform a normal operation process.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

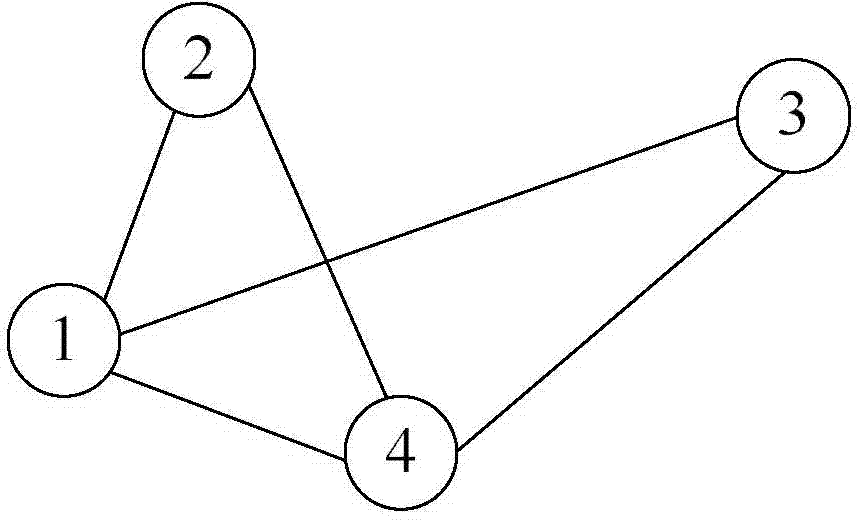

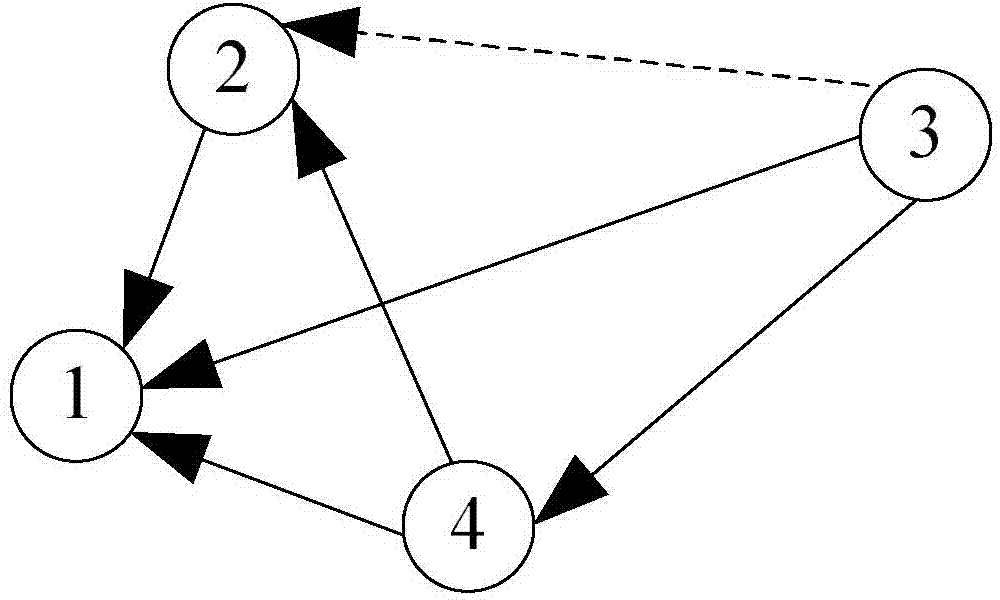

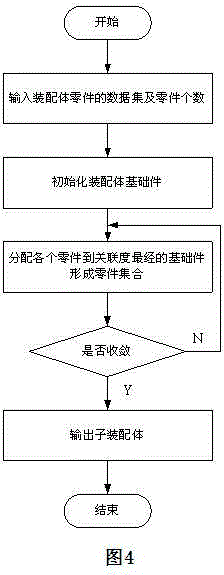

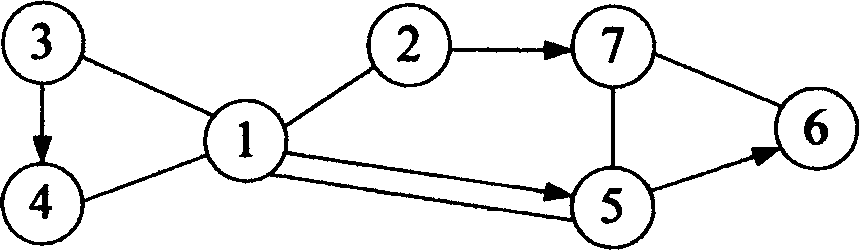

Recognition method for subassembly in assembly sequence planning

InactiveCN104573194AReduce planning timeReduce the difficulty of assemblySpecial data processing applicationsSequence planningAlgorithm

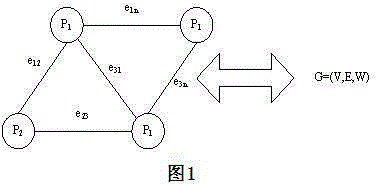

The invention discloses a recognition method for a subassembly in assembly sequence planning. The recognition method comprises the steps of building a weighted non-vector connection diagram through a relationship between assemblies, and then determining basic parts; judging the subassembly according to the definition and the association degree of parts; finally, realizing a subassembly recognition algorithm through designing and compiling under a Matlab (matrix laboratory) environment. According to the recognition method disclosed by the invention, an algorithm instance verifies that a great significance in realizing assembly sequence optimization and shortening assembly sequence planning time is obtained by applying the subassembly recognition to the assembly sequence planning, an assembly sequence is simplified, and the assembly difficulty and the assembly cost are reduced.

Owner:XIAN TECHNOLOGICAL UNIV

Product assembly representation method based on engineering connection relationship

InactiveCN102129494AAssembly Design Solver ValidAvoid Combinatorial Explosion SituationsSpecial data processing applicationsSystems designComputer-aided

The invention discloses a product assembly representation method based on engineering connection relationship, i.e. a product assembly modeling method which is applied to the development of a computer aided assembly design system, especially applied to the development of to a CAD (Computer Aided Design) system. In the method, the engineering connection relationship serves as a principal line represented by assembly knowledge and assembly models; a product and parts are represented by a generalized ring method according to the engineering connection relationship to form an engineering connection drawing, namely a product assembly model, thus, the connection composition relationship of the product is represented on an engineering connection level; and meanwhile, geometry information or other non-geometry information can be represented on a lower level because information is added on a related knot, thereby expressing production assembly information more integrally. The method can be suitable for the requirements of assembly design, such as product assembly structure design, assembly sequence planning, assembly system design and the like, so that the assembly design can be solved more effectively, and especially, the phenomenon of combinatorial explosion can be effectively avoided during assembly sequence planning.

Owner:HUAZHONG UNIV OF SCI & TECH

An Orthodontic Archwire Bending Sequence Planning Method Based on Equiangular Partitioning

The invention discloses a uniform angle division orthodontic arch wire bending sequence planning method and relates to the technical field of orthodontic arch wire bending techniques. The uniform angle division orthodontic arch wire bending sequence planning method is provided according to individual orthodontic arch wire curves of patients, on the basis of an orthodontic arch wire curve formationcontrol point information set and a robot movement information set of formation control points and with the combination of characteristic that an orthodontic arch wire is bent by using a robot. The method is technically characterized by comprising the following steps: according to the individual orthodontic arch wire curves of patients, inputting the orthodontic arch wire curve formation controlpoint information set M and the robot movement information set N of the formation control points into an orthodontic arch wire bending system; dividing the individual orthodontic arch wire curves; andsequencing divided uniform division domains.

Owner:HARBIN UNIV OF SCI & TECH

Assembly sequence planning method

ActiveCN104616084AExpand the search spaceIncrease the number ofForecastingManufacturing computing systemsSequence planningAlgorithm

The invention discloses an assembly sequence planning method. The method can be divided into three stages, wherein at the first stage, assembly information is collected and a fitness function is established; at the second stage, the assembly sequence is found through the chaotic mixing algorithm; at the third stage, the fitness value is calculated, the scales of species are dynamically renewed, and route pheromones are renewed. The chaotic algorithm is added on the basis of the ant genetic algorithm, the chaotic algorithm search is introduced after the ant algorithm search is conducted so that the local search capacity of the algorithms is enhanced, feasible solutions fond through the two algorithms serve as initial species of the genetic algorithm, and the overall search capacity of the genetic algorithm is guided. Due to the fact that the initial species are enriched, the overall search capacity of the genetic algorithm is enhanced, and the search space is enlarged.

Owner:GUILIN UNIV OF ELECTRONIC TECH

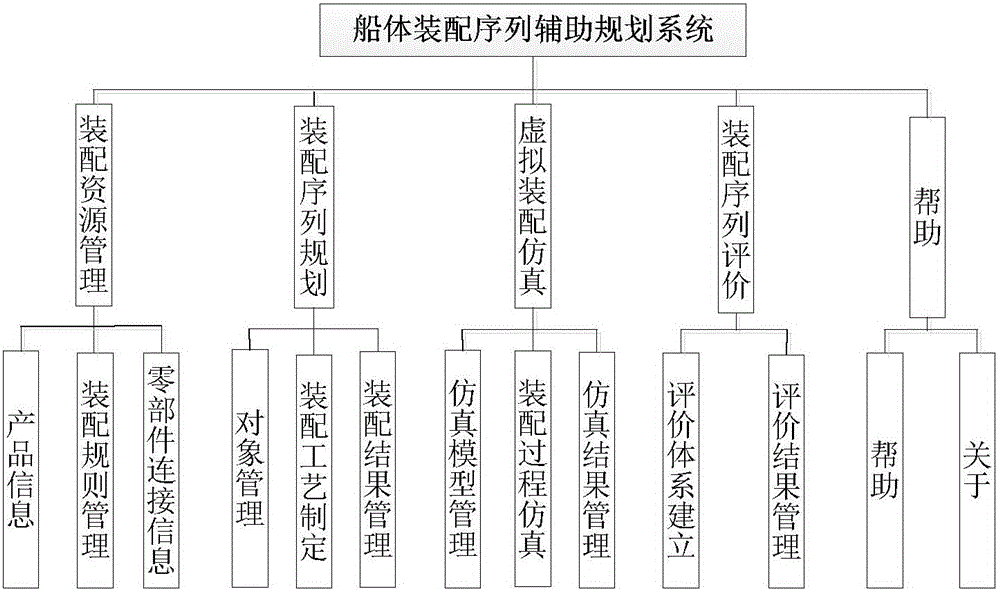

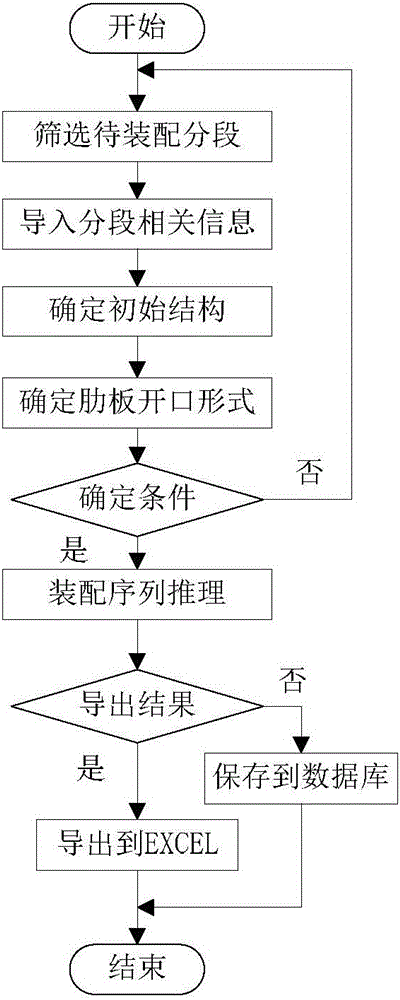

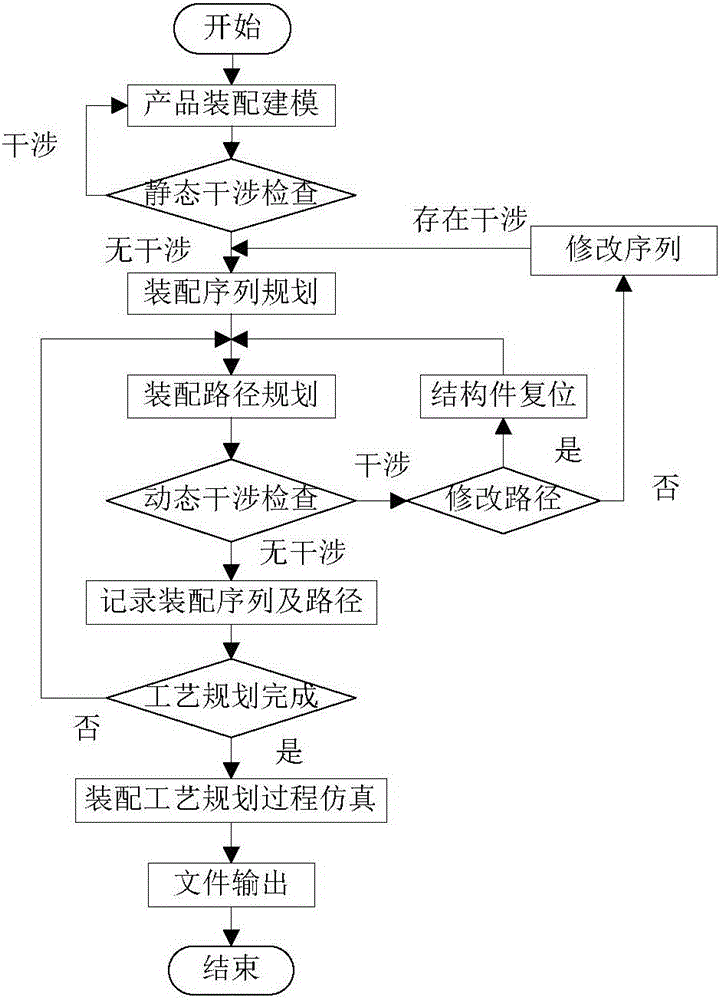

Hull block assembly sequence planning system and planning method

InactiveCN106294965AEfficient and intelligent managementSimple methodDesign optimisation/simulationSpecial data processing applicationsSequence planningComputer module

The invention discloses a hull block assembly sequence planning system and planning method. The system comprises an assembly resource management module, an assembly sequence planning module, an assembly sequence simulation module and an assembly sequence evaluation module; the method comprises the steps that the assembly resource management module completes block related information entry and assembly related rule compiling; the assembly sequence planning module conducts assembly sequence reasoning by importing the block information and determining initial assembly conditions; the assembly sequence simulation module simulates the assembly process by planning the assembly path according to the reasoning result of the assembly sequence planning module; the assembly sequence evaluation module conducts fuzzy comprehensive evaluation on an assembly sequence to be evaluated. According to the hull block assembly sequence planning system and planning method, an efficient, accurate and intelligent solution can be provided for hull block assembly technological design and simulation verification and evaluation and optimization in the whole technological process for assembly technologists, and great significance is achieved for improving the technological compilation efficiency and shortening the block construction period.

Owner:JIANGSU UNIV OF SCI & TECH

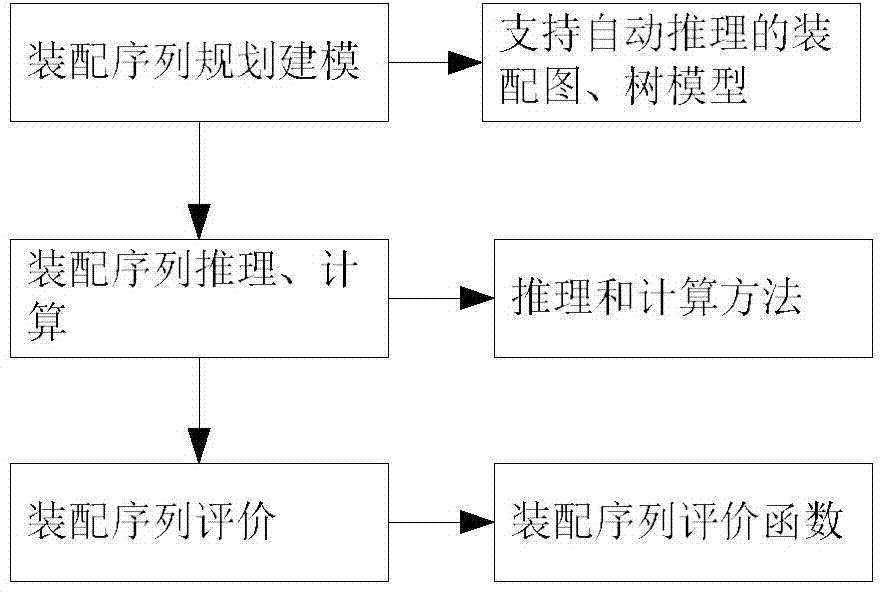

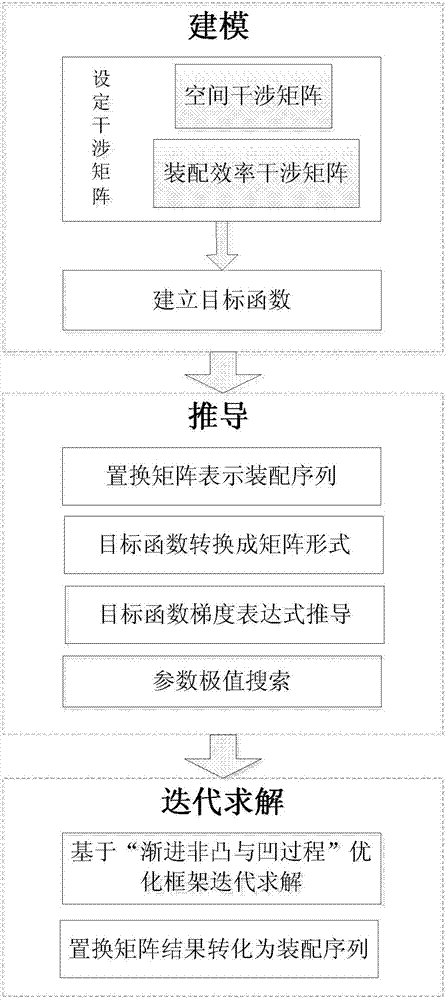

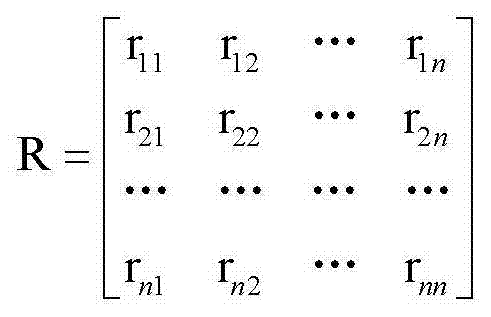

Intelligent assembly sequence planning method

The invention discloses an intelligent assembly sequence planning method. The intelligent assembly sequence planning method includes the following steps of modeling an assembly relationship among sub-parts of assembly bodies by means of an interference matrix manner, evaluating an assembly sequence by means of an objective function, expressing the assembly sequence by means of a permutation matrix manner, converting the objective function into a matrix manner, subjecting an assembly sequence planning problem to iteration solving by means of a progressive non-convex and concave progress optimizing framework, converting the solved permutation matrix into a part number sequence which is a result of assembly body assembly sequence planning. Compared with traditional assembly sequence planning methods, the intelligent assembly sequence planning method has the advantages that under the condition that effectiveness of the assembly sequence planning result is guaranteed, solving speeds are greatly accelerated.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

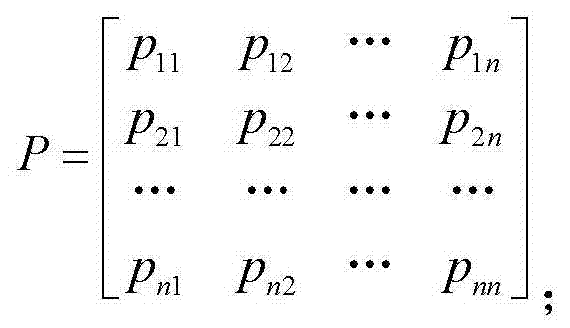

Assembly sequence planning method and device based on dynamic programming and genetic algorithm

ActiveCN103870658ASolve hard-to-solve defectsStrong limitationsGenetic modelsSpecial data processing applicationsSequence planningGenetic algorithm

The invention discloses an assembly sequence planning method and device based on dynamic programming and a genetic algorithm. The method comprises the steps that an object to be assembled is decomposed into a plurality of sub-modules according to the assembly relations between all sub-parts; a first space interference matrix and a first assembly efficiency relation interference matrix are established according to the module-level interference relations between all the sub-parts; the relative assembly sequences between all the sub-modules are found by using a dynamic programming algorithm according to the first space interference matrix and the first assembly efficiency relation interference matrix; a second space interference matrix and a second assembly efficiency relation interference matrix are established according to the interference relations between all the parts in all the sub-modules; the relative assembly sequences between all the parts in all the sub-modules are found by using the genetic algorithm according to the second space interference matrix and the second assembly efficiency relation interference matrix; the relative assembly sequences between all the sub-modules and the relative assembly sequences in all the modules are integrated to obtain the overall assembly sequence of the object to be assembled.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

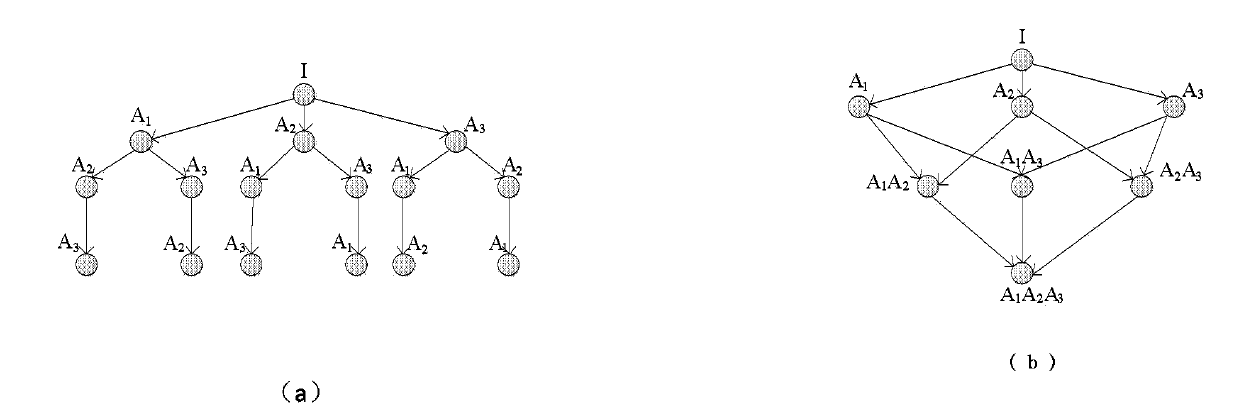

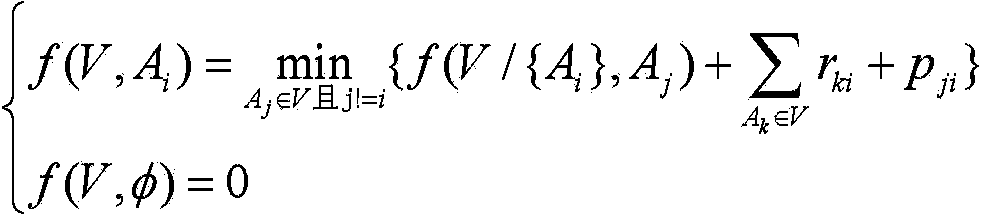

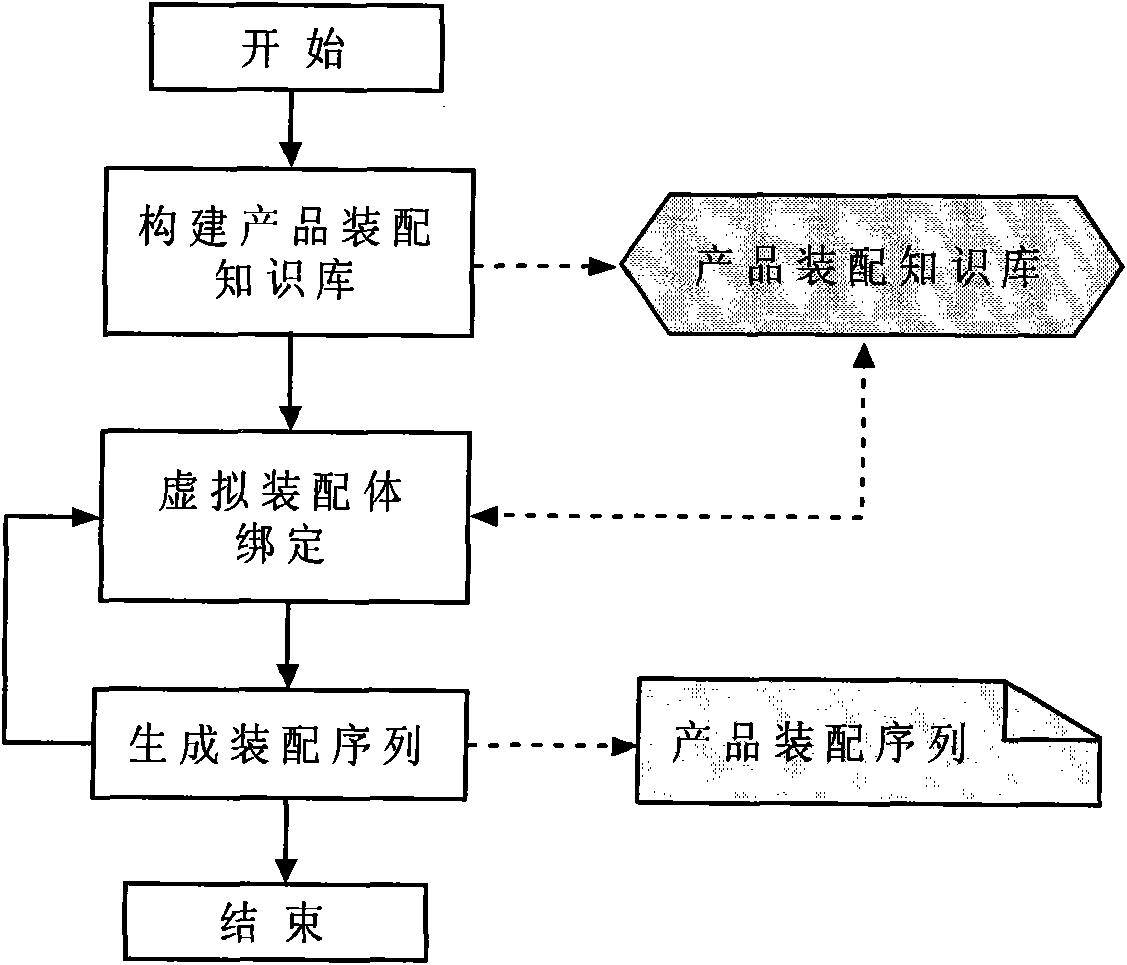

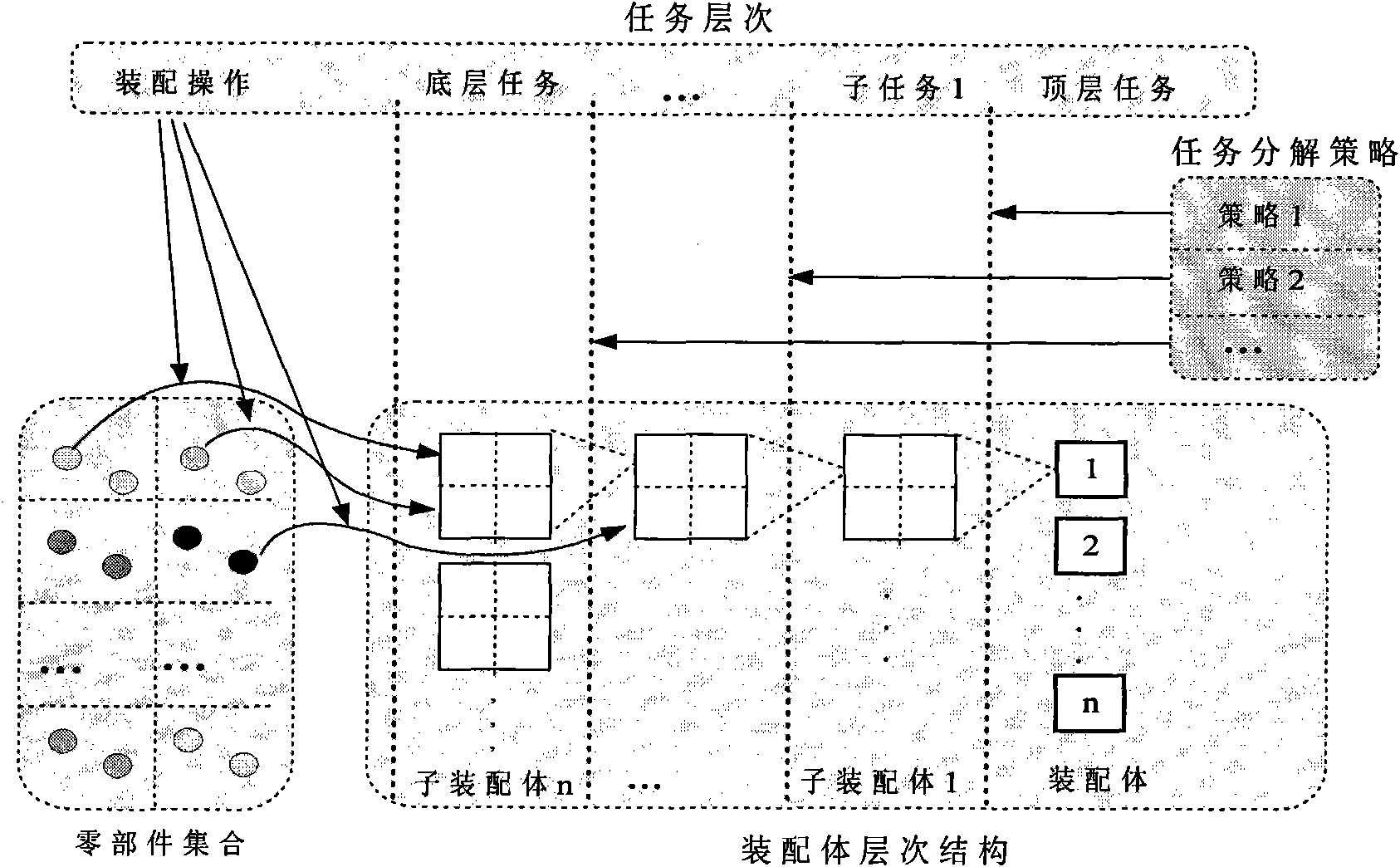

Computer subsidiary product assembling sequence generation method

InactiveCN101645102AClear structureEasy to understandSpecial data processing applicationsSequence planningDecomposition

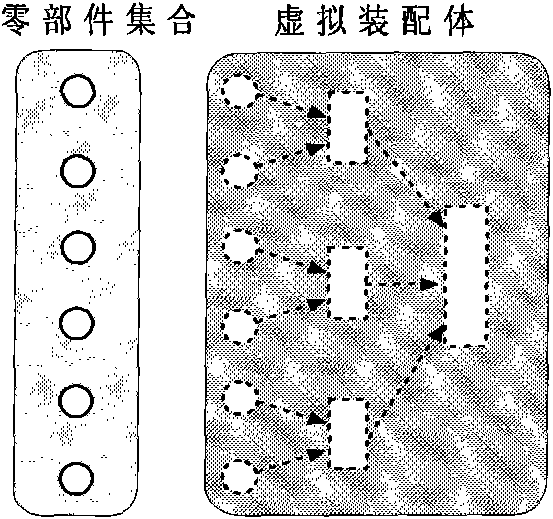

The invention discloses a computer subsidiary product assembling sequence generation method, belonging to the computer aided manufacturing technical field; the method comprises the following steps: firstly based on a layering task net programming method, building a product assembling knowledge base structure; secondly, virtual assembling body binding process, namely, using the layering structure of the virtual assembling body and the connecting structure of components and parts as a guide, binding the real components and parts to the corresponding virtual components and parts of the virtual assembling body; and finally generating the bound product assembling sequence based on the virtual assembling body; wherein the product assembling knowledge base structure comprises four knowledge modules which are of components and parts collection, assembling body layering structure, task layering and task decomposition strategy. The generation method can cause the structure of the product assembling sequence planning knowledge base to become clearer and be easily understood, the layering design of the task and the decision of decomposition tragedy to be more methodic and pertinence, thus increasing the generative flexibility and efficiency of the product assembling sequence and promoting the application of the computer subsidiary product assembling sequence in the intelligent manufacturing field.

Owner:BEIJING JIAOTONG UNIV

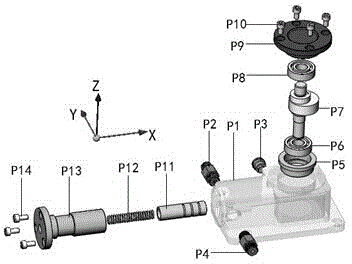

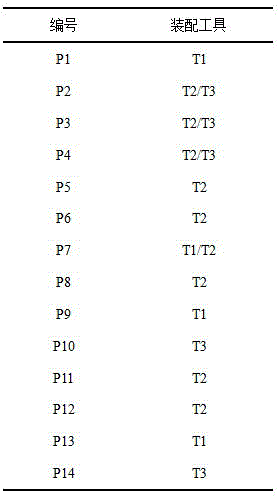

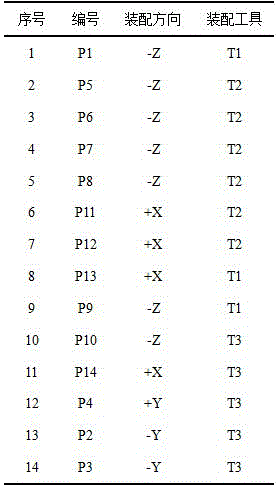

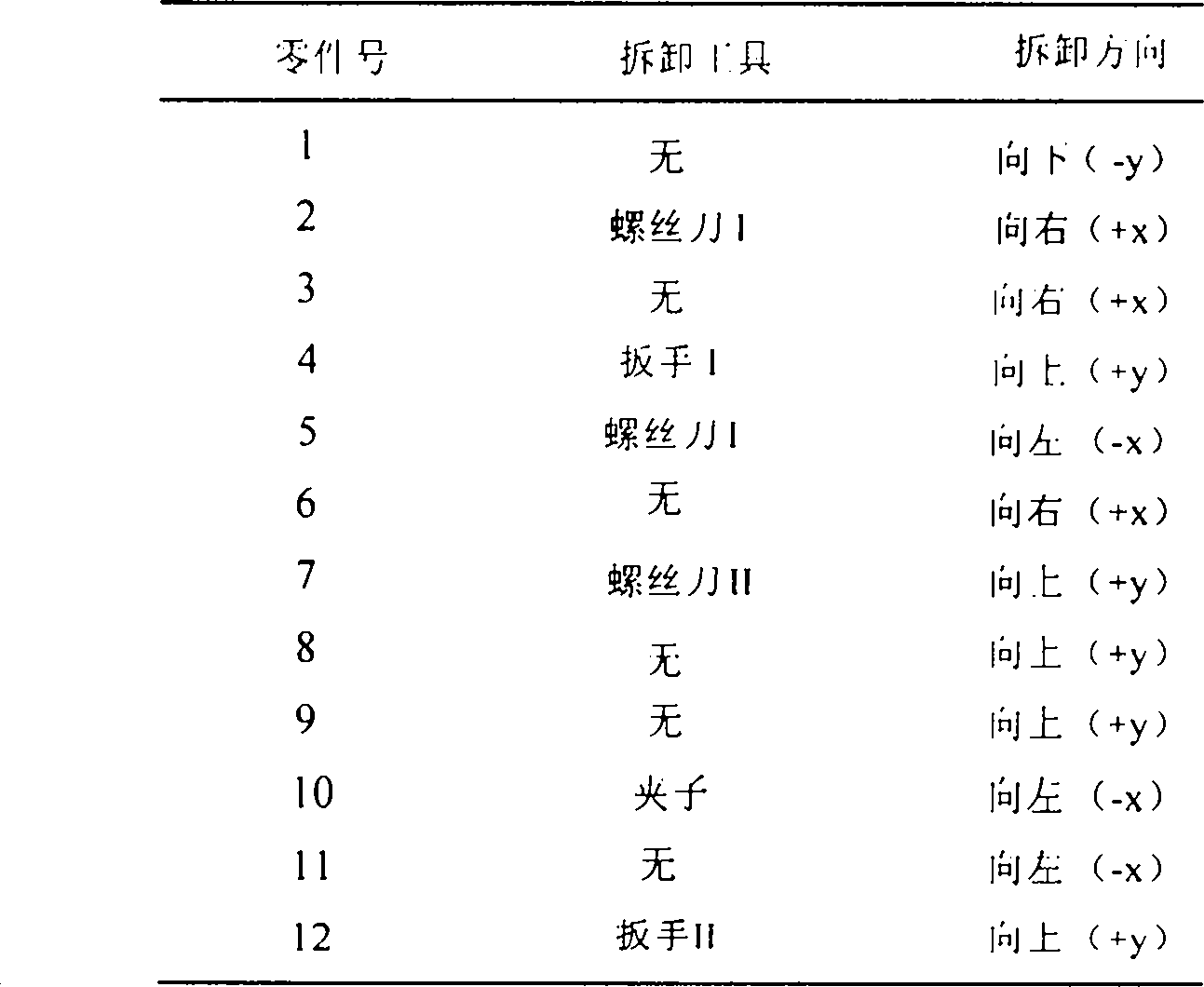

Method for achieving remote control and maintenance assembly sequence planning of parts in radiation environment

InactiveCN104376227AImproved premature convergenceImprove efficiencySpecial data processing applicationsSequence planningSupport matrix

The invention relates to an assembly sequence planning method based on the particle swarm optimization algorithm, in particular to a method for achieving remote control and maintenance assembly sequence planning of parts in a radiation environment. The method is implemented based on the adaptive mutation particle swarm optimization algorithm and improves the algorithm. The method for achieving assembly sequence planning mainly comprises the steps: (1) establishing an interference matrix and then establishing an enhanced adjacency matrix and an enhanced support matrix of the parts; (2) establishing the assembly sequence of an assembly tool set; (3) determining the feasible assembly direction according to the geometric feasibility of the assembly sequence; (4) establishing an objective function based on evaluation indexes established in the previous three steps; (5) redefining the positions and the speeds of particles and an algorithm for updating operation of the positions and the speeds; (6) carrying out assembly sequence planning. The method overcomes the defects of the particle swarm optimization algorithm in assembly sequence planning, and by redefining the positions and the speeds of the particles according to the dispersion characteristic of assembly sequence planning, the efficiency and quality of assembly sequence planning can be effectively improved.

Owner:DONGGUAN UNIV OF TECH

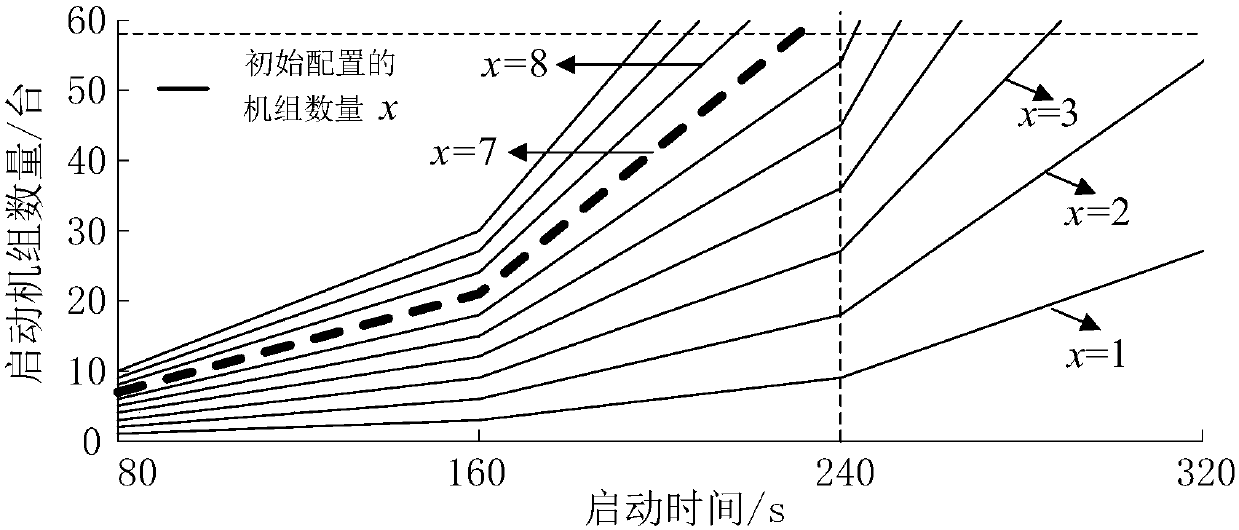

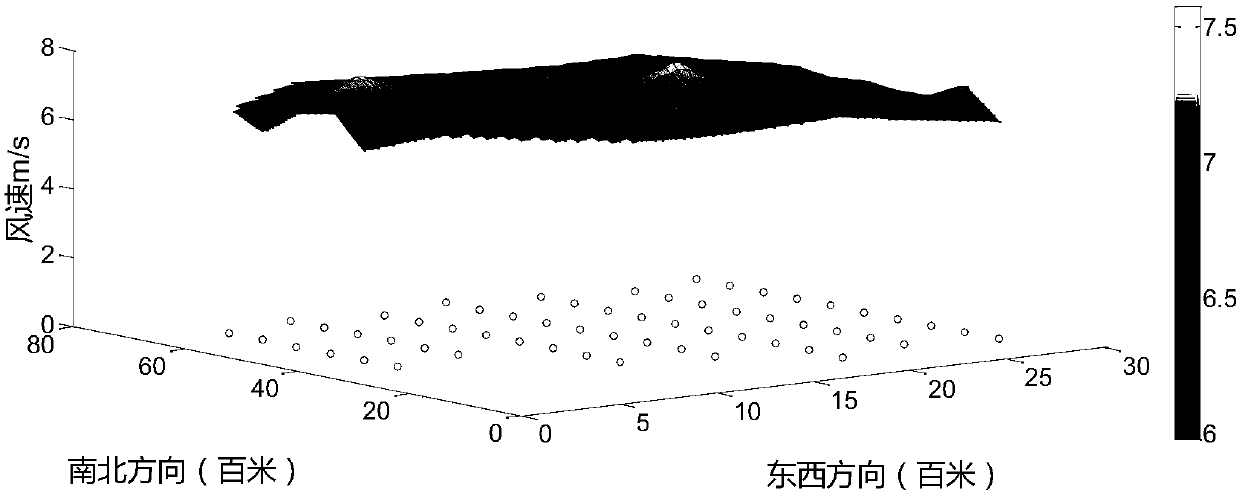

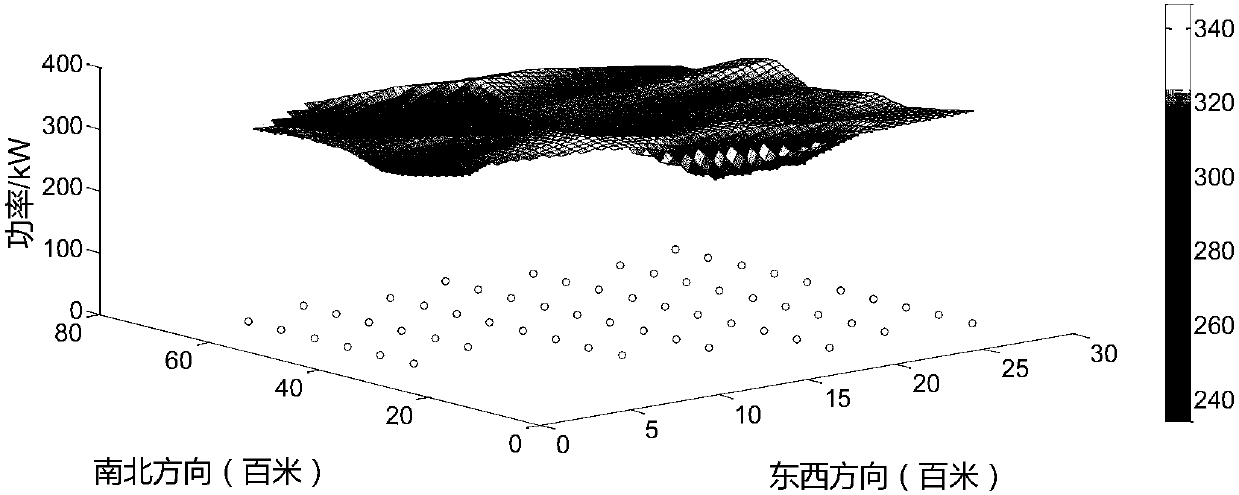

Wind energy storage generating black-start system and energy storage configuration method of the same

ActiveCN107294130ASimple structureImprove reliabilitySingle network parallel feeding arrangementsWind energy generationElectricitySequence planning

The invention provides a wind energy storage generating system. The wind energy storage generating system is characterized in that an energy storage cabinet is connected with the high voltage side of a house transformer of a set wind turbine generator; when black-start occurs, the energy storage cabinet supplies power for the house power supply system of the set wind turbine generator; and black-start of the whole wind power plant can be completed depending on the small capacity of energy storage. The energy storage configuration method of the wind energy storage generating system includes the steps: establishing a wind turbine generator starting sequence planning model and a generator starting sequence, establishing an energy storage configuration capacity model, and establishing an energy storage configuration layout model. The wind energy storage generating black-start system has the advantages of simple structure and high reliability. The energy storage configuration method of the wind energy storage generating black-start system is scientific and reasonable, is high in applicability and has good effect.

Owner:NORTHEAST DIANLI UNIVERSITY +1

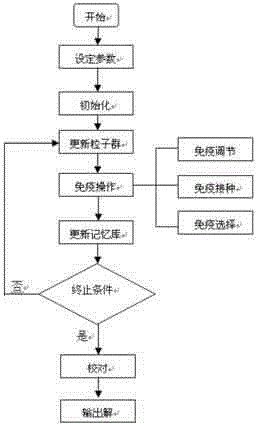

Method for solving product assembly sequence planning problem on the basis of immune particle swarm algorithm

InactiveCN105022852ABiological modelsSpecial data processing applicationsSequence planningElectrical battery

The invention discloses a method for solving a product assembly sequence planning problem on the basis of an immune particle swarm algorithm. The method comprises the setting of the naming rules and algorithms of parts and specifically comprises the following steps: firstly, setting the naming rule of each part, and then, combining an immune algorithm with particle swarm optimization through two self-defining functions to solve a product assembly sequence problem. The method carries out serial mixing on two algorithms including the artificial immune algorithm and the particle swarm optimization, establishes a novel mixed algorithm which can combine the advantages of the two algorithms and overcome the respective defects of the two algorithms and can be used for solving the product assembly sequence planning problem. For example, the method can be used for solving the assembly sequence planning problem of lithium ion batteries.

Owner:TONGJI UNIV

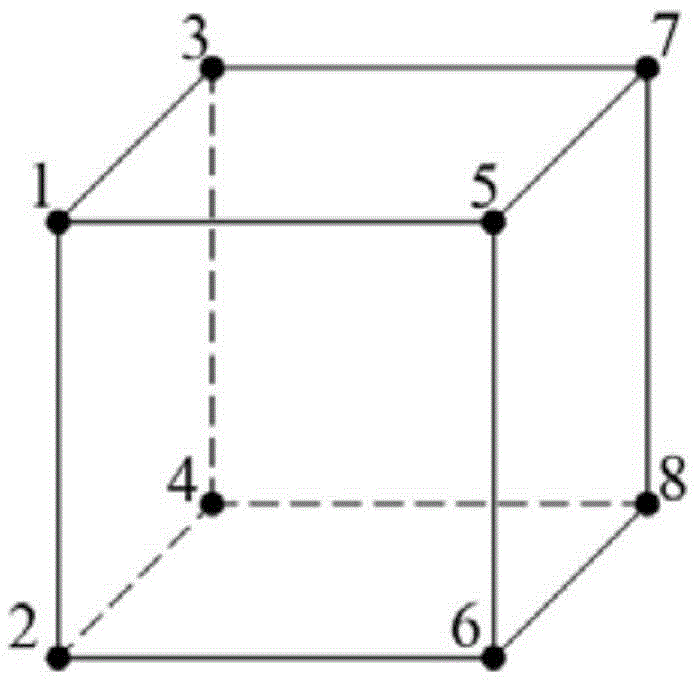

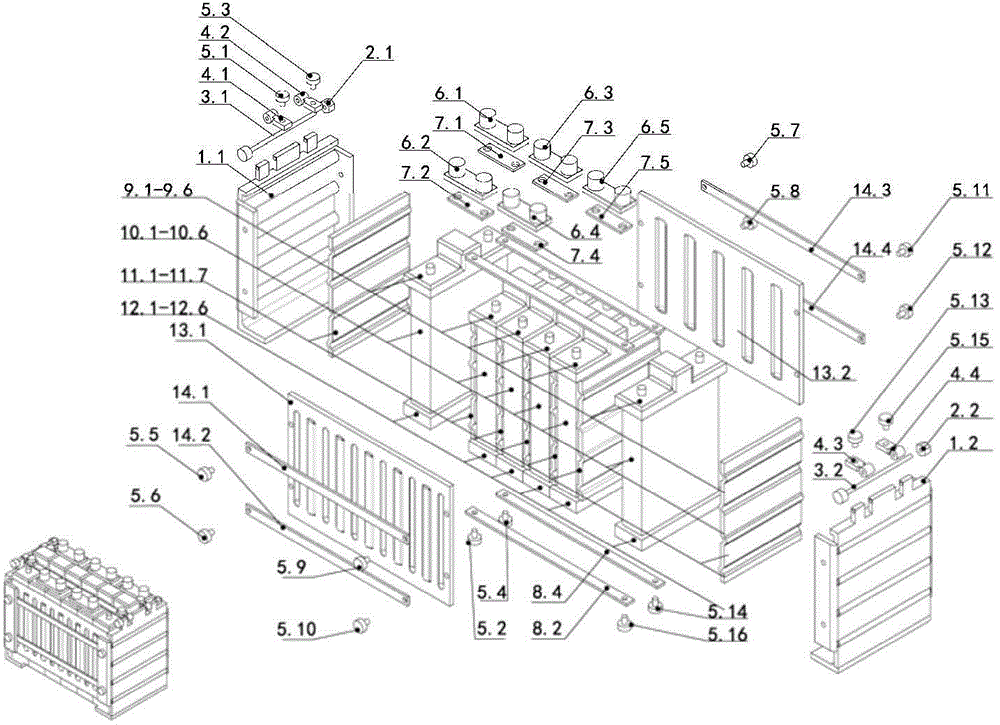

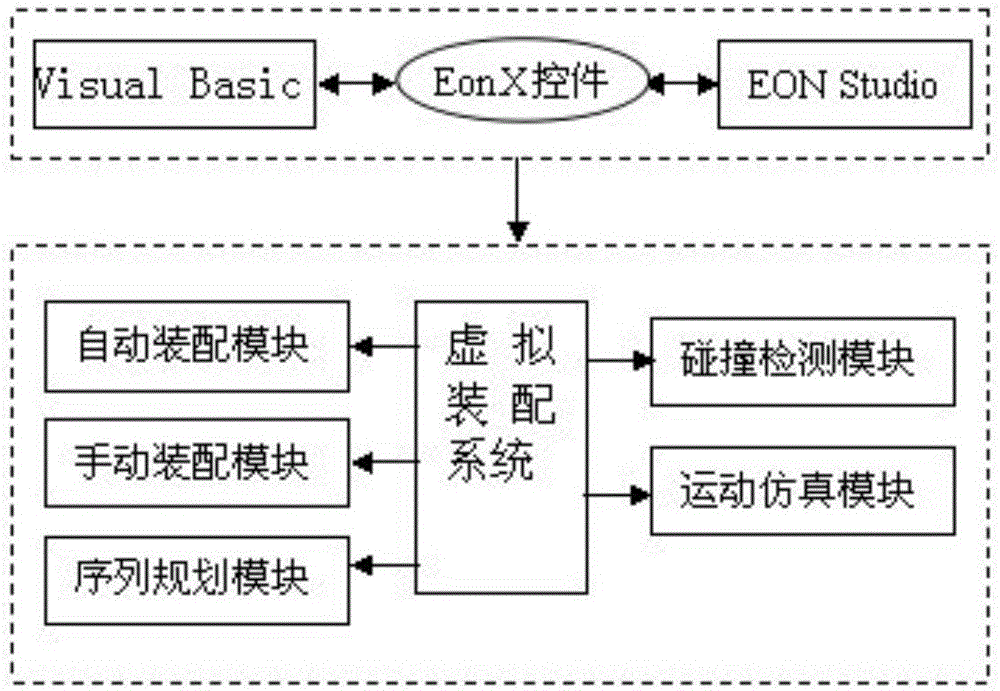

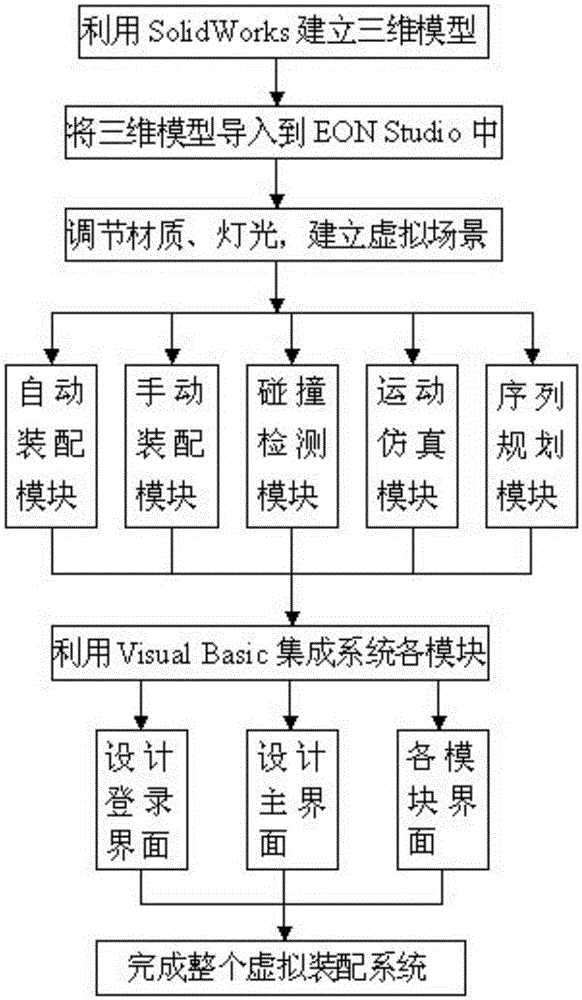

Virtual assembly system based on Visual Basic and EON Studio

ActiveCN105138315ALess programming experienceEasy to masterSpecial data processing applicationsSpecific program execution arrangementsVisual BasicSequence planning

The invention provides a virtual assembly system based on Visual Basic and EON Studio. The virtual assembly system comprises an automatic assembly module, a manual assembly module, a motion simulation module, a collision detection module and an assembly sequence planning module, wherein the five function modules are all integrated in a Visual Basic integrated development tool; the Visual Basic integrated development tool builds the connection with an EON Studio simulation platform through an EonX control; the man-computer interaction can be realized through a mouse and a keyboard; the manual assembly process of a virtual mechanical product is completed; the moving and work process of the mechanical product and the motion transmission mode among all components are simulated; the collision response is made on the part collision in the simulation process; the virtual assembly system can be applied to enterprise mechanical product assembly link development, staff training and mechanical university practice teaching links; and the programming amount is reduced. Meanwhile, the virtual assembly system has the characteristics that the operation is simple; the manufacturing cost is low; and the man-machine interaction performance is high.

Owner:SHAANXI UNIV OF SCI & TECH

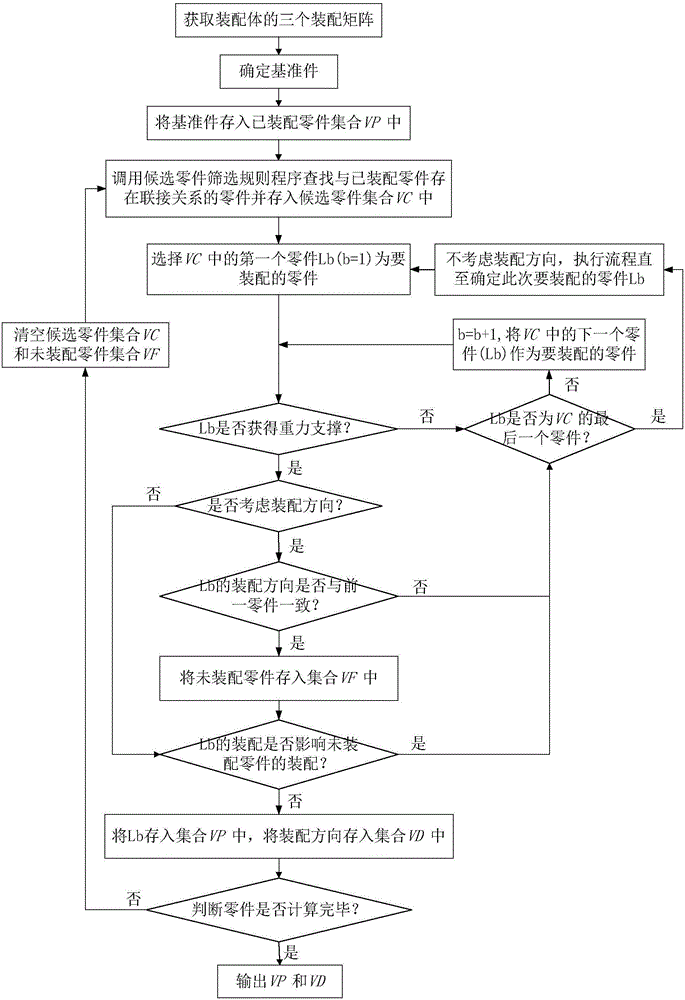

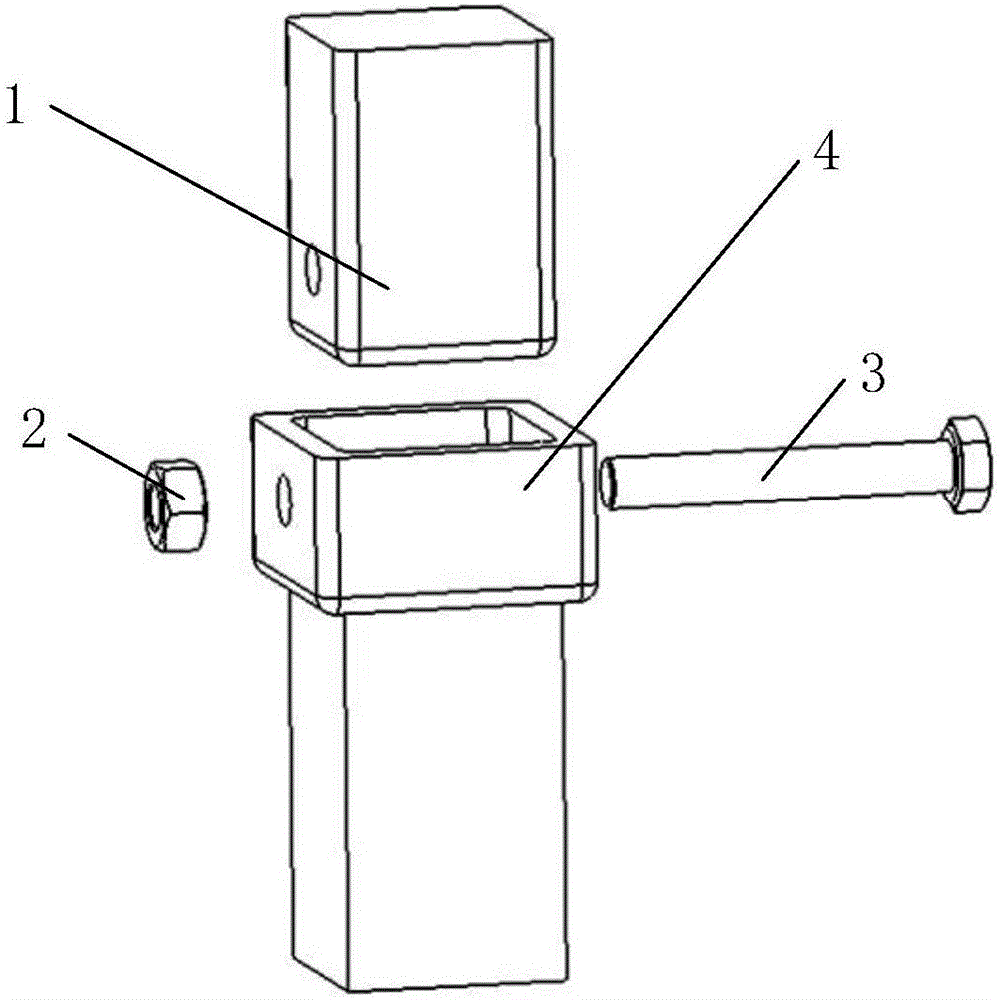

Assembly sequence planning method of complex assembly on the basis of assembly matrix

ActiveCN106372393AIncrease the level of automationImprove planning efficiencyInformaticsSpecial data processing applicationsProduction lineSequence planning

The invention discloses an assembly sequence planning method of a complex assembly on the basis of an assembly matrix in the field of the automatic assembly sequence planning of products. A general generation method of the assembly matrix is used for obtaining an assembly connection matrix, an assembly supporting matrix and an assembly interference integration matrix; and through the assembly supporting matrix, a reference element is determined and is stored into a set where an assembled part is stored, a candidate part is determined and is stored into the set where the candidate part is stored, a gravity supporting part is obtained through the assembly supporting matrix, and an assembly direction is determined through the assembly interference integration matrix. Through the classification of the assembly direction, a product assembly sequence which can be used for an automatic production line is directly obtained, the automation level of the production line can be improved, efficiency on the assembly sequence planning of the complex assembly is improved, an error ratio is lowered, assembly cost is lowered, and a production period is shortened.

Owner:CHANGSHU ZHAOSHI HUADA DYEING & FINISHING

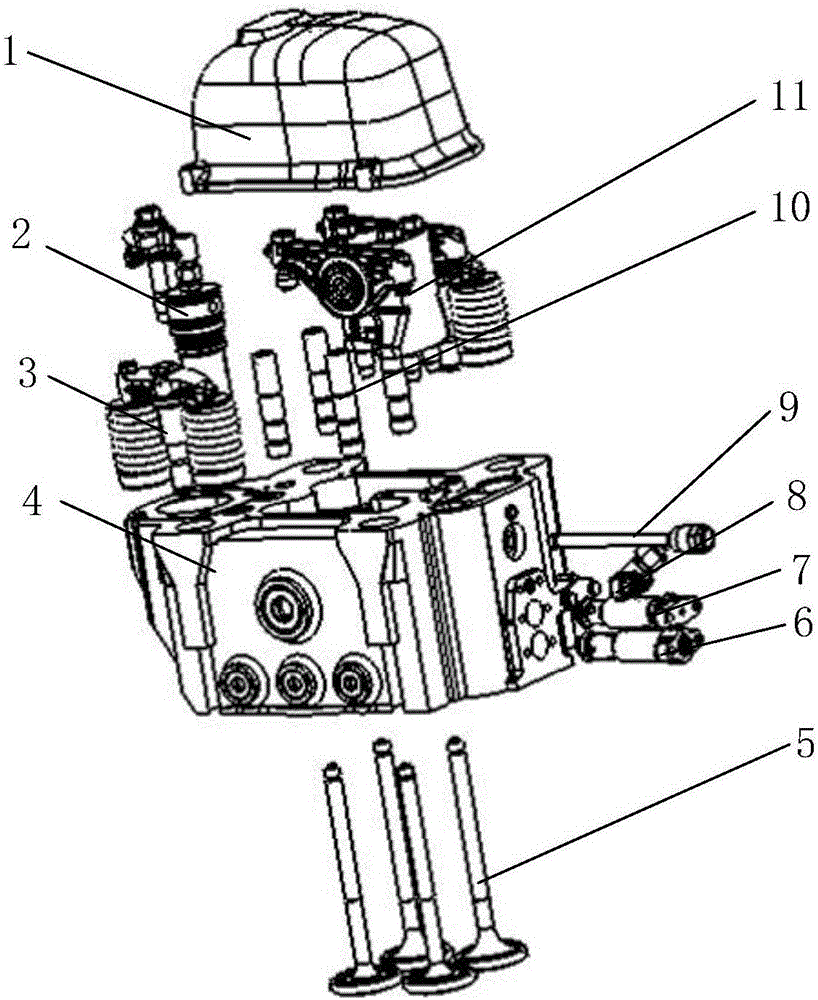

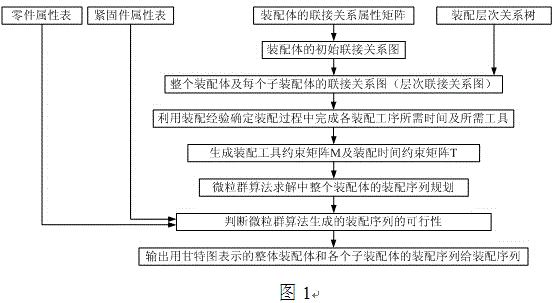

Fixture assembly sequence planning method based on particle swarm optimization algorithm

InactiveCN104462705AAvoid complex genetic manipulationsImprove robustnessSpecial data processing applicationsRelation graphSequence planning

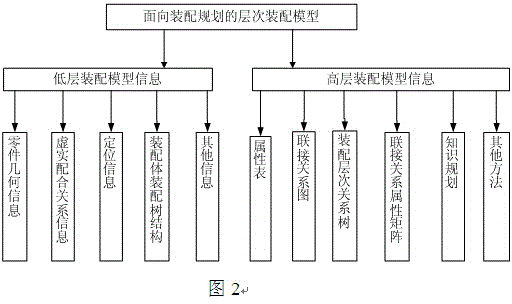

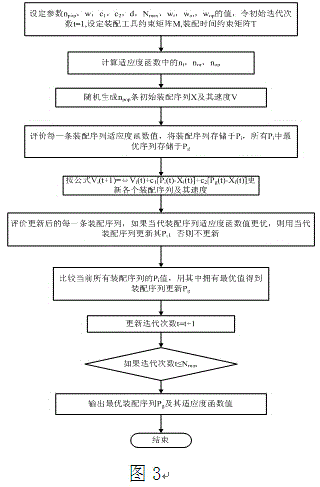

Provided is a fixture assembly sequence planning method based on a particle swarm optimization algorithm. The method includes the steps that information in a connection relation attribute list in a hierarchical assembly model orientated to assembly planning is utilized to generate an initial connection relation graph of an assembly body; a connection relation graph corresponding to the whole assembly body and a connection relation graph corresponding to each sub-assembly body are constructed according to hierarchy inclusion relations among components and parts in the connection relation graph and an assembly hierarchy relation ship; tools needed in an assembling process are determined according to the assembly connection relation graph, and an assembly tool constraint matrix M is constructed; time required by each procedure in the assembling process is determined, and finally a time constraint matrix T is generated; a feasible assembly sequence plan is generated by the adoption of the particle swarm optimization algorithm; the correctness of a generated assembly sequence is judged; an overall assembly sequence plan result represented by a Gantt diagram is output. According to the method, products designed under the conditions that production technologies and use reliability and safety are satisfied, the cost is reduced as much as possible and errors are the smallest are good in performance.

Owner:XIAN TECHNOLOGICAL UNIV

Child day planner and sub-task sequence planner

InactiveUS7896652B1Relieve frustrationRelieving their anxiety-somethingTeaching apparatusMechanical appliancesComputer scienceVisual perception

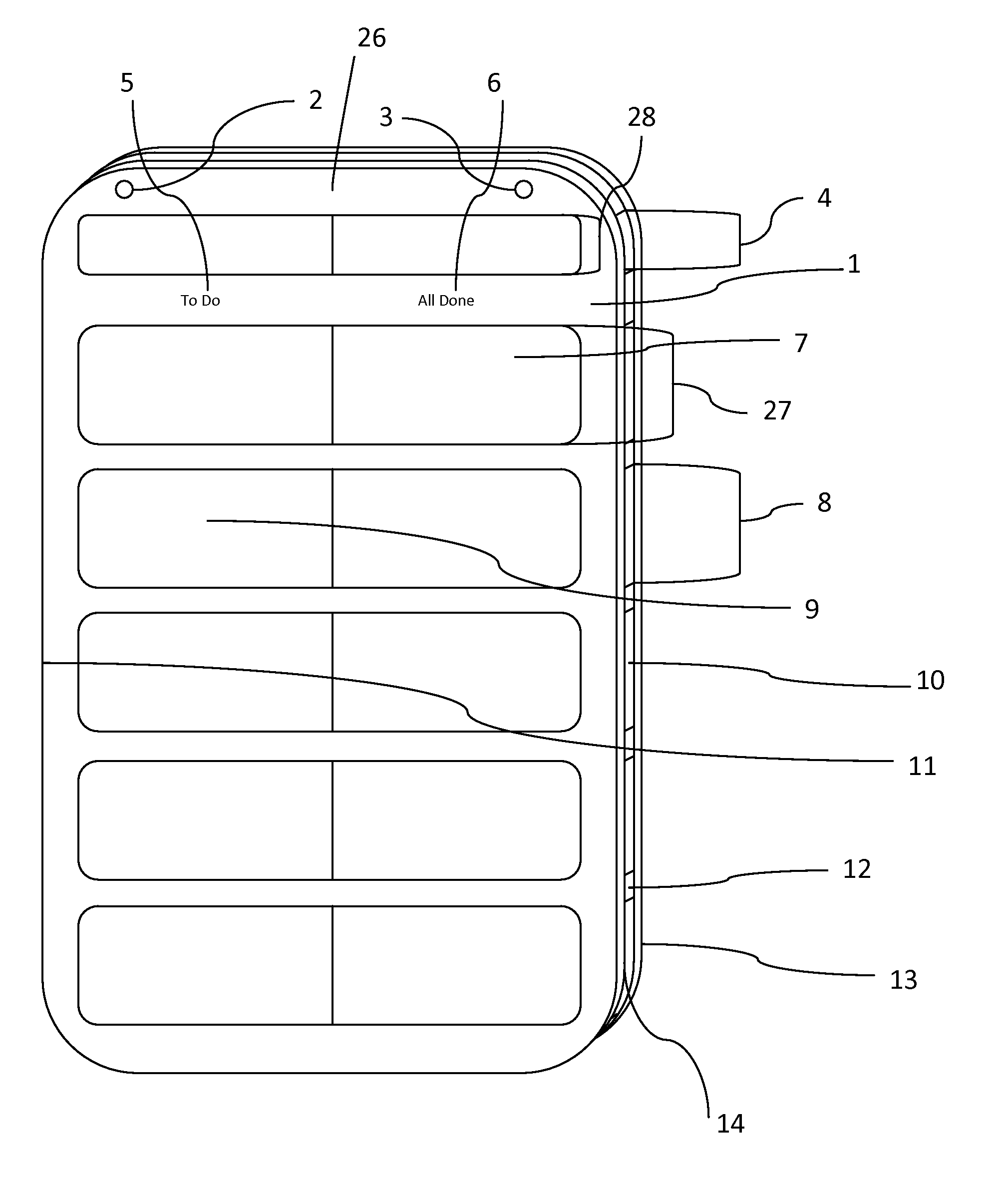

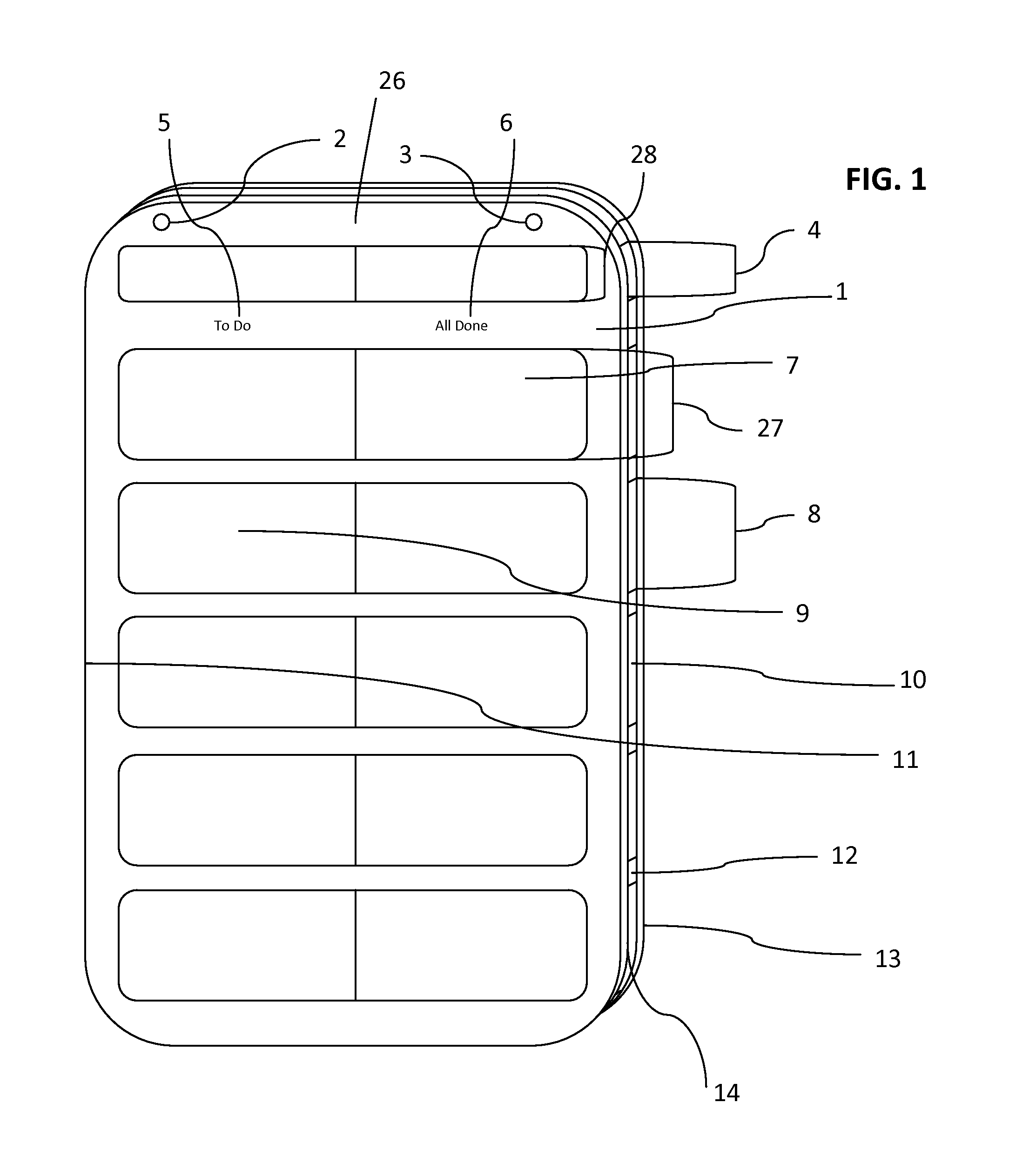

One embodiment of a device that provides a means of displaying pictures that represent activities, or steps within an activity, for the purpose of teaching a sequence, displaying expectations, and encouraging participation in new or existing routines. The device is comprised of a board (FIG. 1) that is capable of displaying visual cues in the form of picture cards (FIG. 4A / B / C) in a plurality of interior channels. The pictures can be viewed from the front of the board (FIG. 1) and are moved from a ‘To Do’ column (9) to an ‘All Done’ column (7) as tasks or steps within a sequence are completed. The board (FIG. 1) is constructed in such a fashion as to create interior channels that allow the unimpeded passage of picture cards (FIG. 4A / B / C) through the entire interior of the board (FIG. 1). The picture cards (FIG. 4A / B / C) that pass through the channels are of a size that is slightly smaller than the interior dimensions to allow them to be inserted, slid across, and removed from the board (FIG. 1). The frontal area of the board (FIG. 1) incorporates ‘frame like’ openings that allow the picture cards (FIG. 4A / B / C) to be slid across by using a finger pressed upon the surface of the card and applying slight pressure to move it across. The device is designed to be vastly versatile and capable of being used by many age groups and in many situations.

Owner:VAN BALVEREN KIM GALLO +1

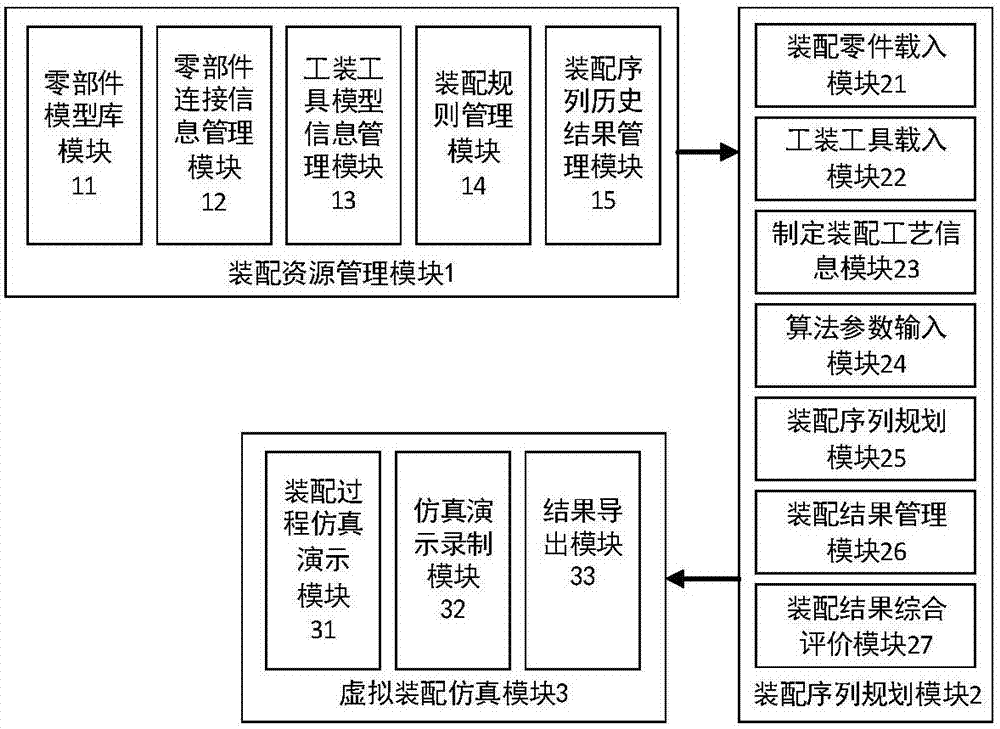

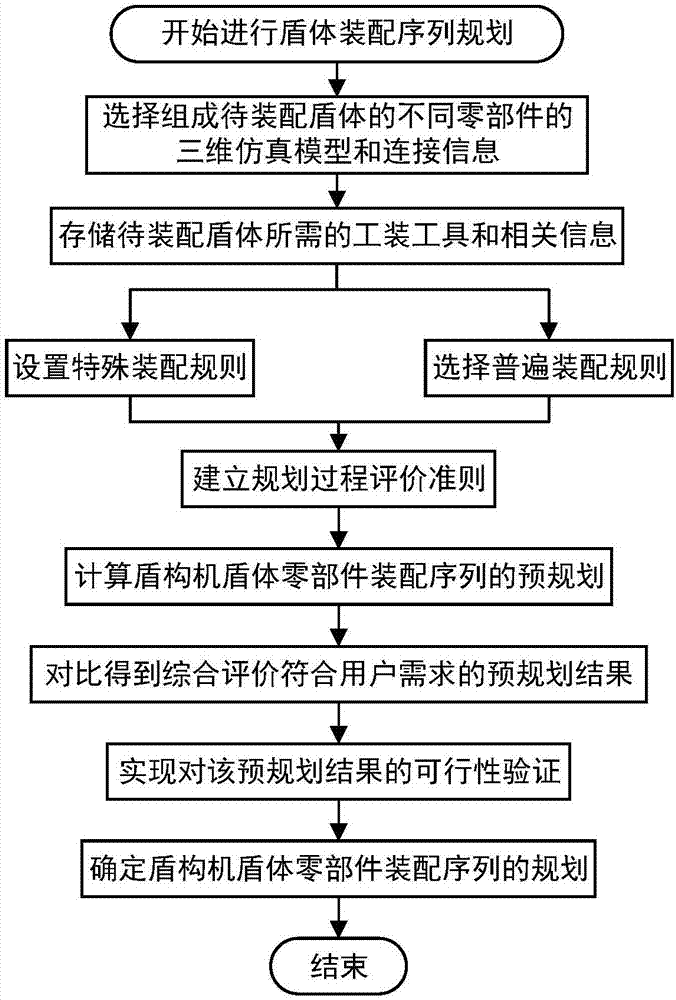

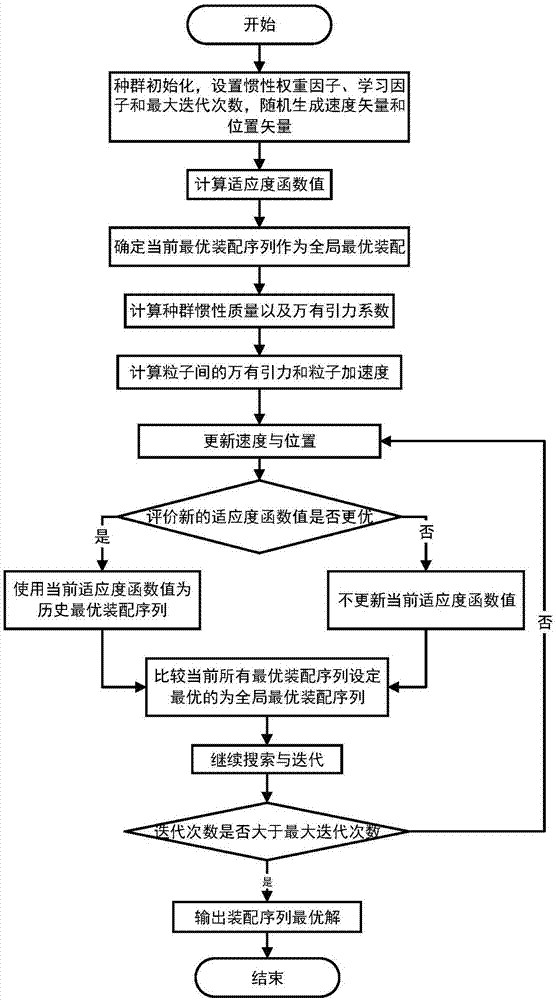

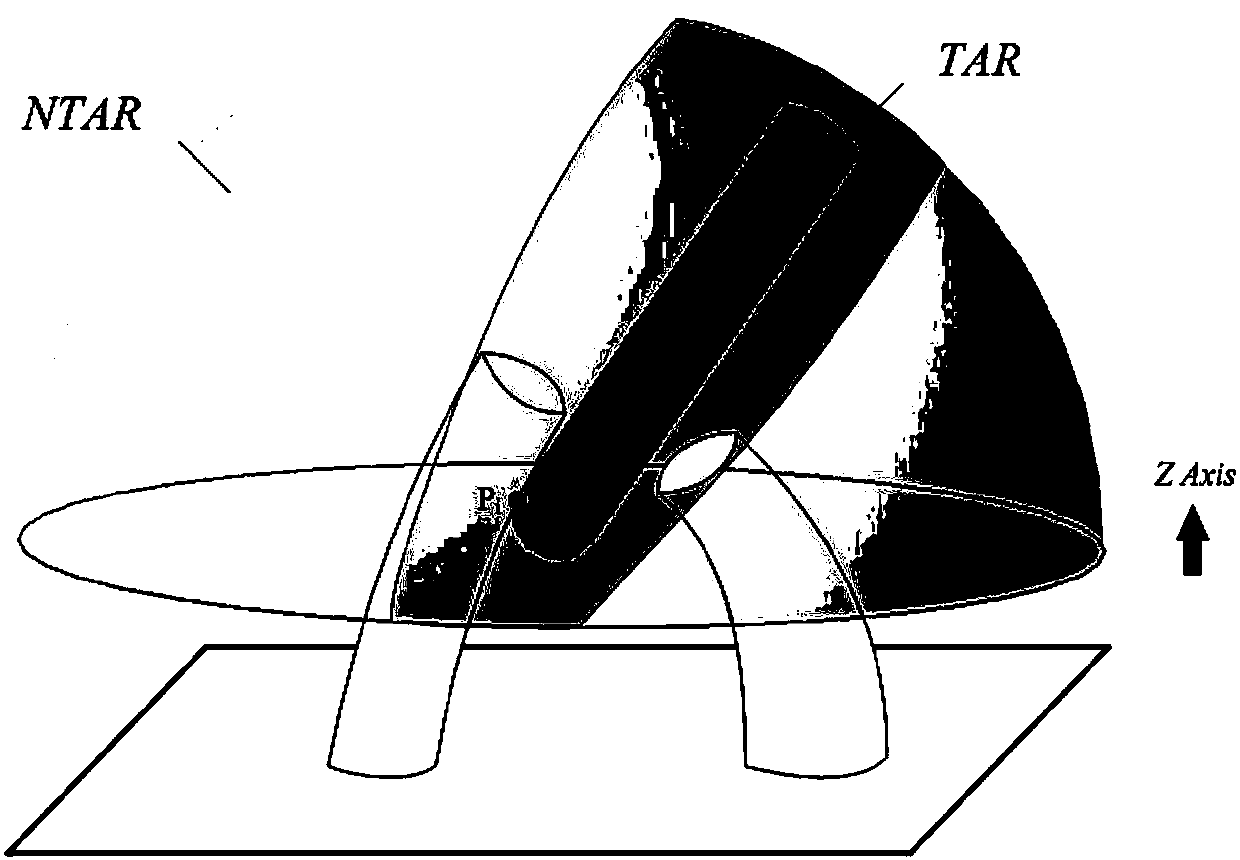

Planning system and method for shield body assembly sequence of shield machine

InactiveCN107273588AMeet needsFlexible settingsForecastingDesign optimisation/simulationSequence planningResource management

The invention provides a planning system and method for a shield body assembly sequence of a shield machine, and aims to lower the complexity of planning the shield body assembly sequence of the shield machine and obtain the assembly sequence meeting user demands to the maximum extent. The system comprises an assembly resource management module connected with a database, an assembly sequence planning module and a virtual assembly simulation module, wherein the assembly resource management module stores resources required for planning the shield body assembly sequence of the shield machine; the assembly sequence planning module stores various information required for planning a to-be-assembled shield body assembly sequence of the shield machine, and calculates and selects a pre-planning result of a shield body part assembly sequence of the shield machine by utilizing a discrete particle swarm universal gravitation search algorithm; and the virtual assembly simulation module performs verification on the feasibility of the pre-planning result, and determines and outputs a plan of the to-be-assembled shield body part assembly sequence of the shield machine. The planning system is flexible and low in assembly sequence planning complexity.

Owner:XIDIAN UNIV

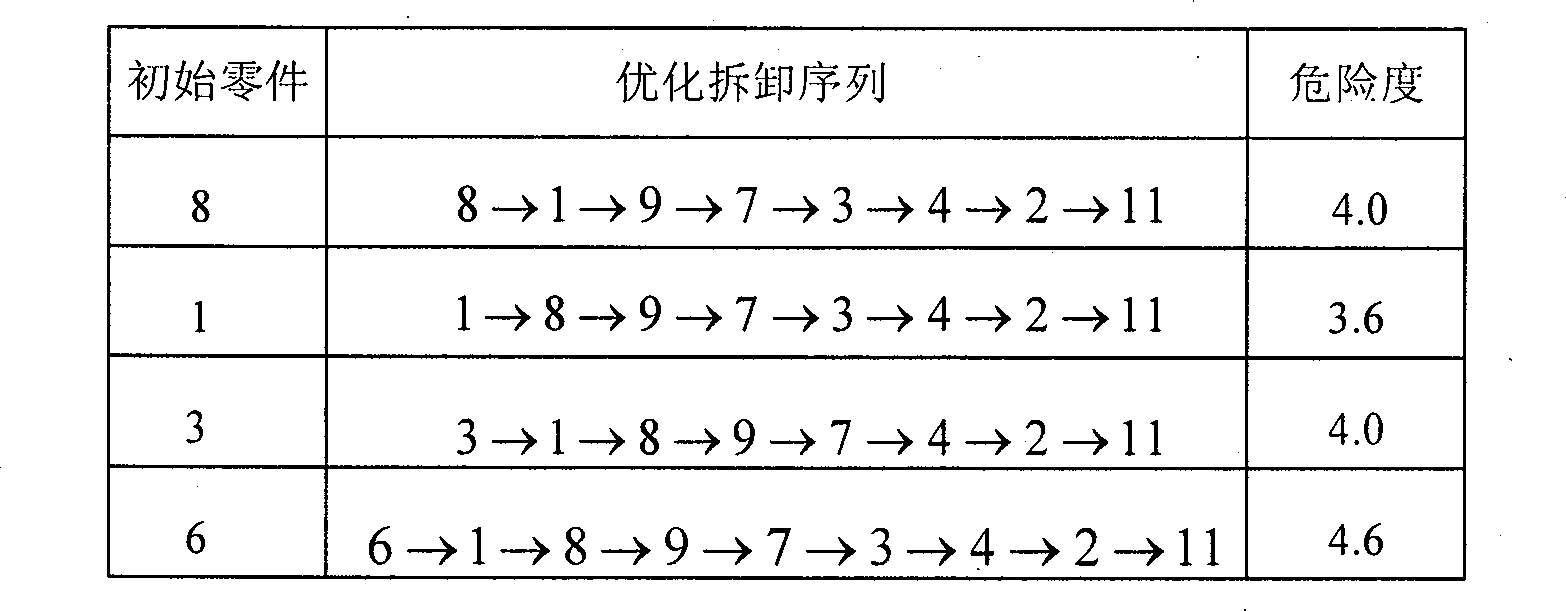

Virtual prototype disassembly sequence planning method

InactiveCN103164550ASolve the problem of unreasonable disassemblyOptimizing the disassembly sequenceSpecial data processing applicationsSequence planningComputer science

The invention relates to virtual prototype disassembly sequence planning technology and provides a virtual prototype disassembly sequence planning method which mainly aims at solving the problem that high arbitrariness exists in a starting point and a stopping point of disassembly and removal of disassembly restriction in the process of practical maintenance disassembly of a guided missile device due to different disassembly missions. Due to lack of scientific judgment on a feasible disassembly sequence of the device, particular of a guided missile weaponry device, the guided missile weaponry device is complex in assembly structure and large in maintenance operation difficulty, wrong disassembly operation and procedure usually lead to damage of the device and danger is brought to an operator. According to disassembly characteristics of the guided missile device, a disassembly risk factor serves as a cost function, based on the foundation that disassembly safety is considered, a selective disassembly sequence optimized model based on mutual restriction relationship of parts is established, a selective disassembly sequence optimized algorithm based on an ant colony algorithm is designed and the optimal selective disassembly sequence or the selective disassembly sequence close to optimization is searched from all the feasible sequences. The virtual prototype disassembly sequence planning method can guide practical assembly and maintenance operation, effectively reduce maintenance and training expense and improve maintenance accuracy and safety.

Owner:PLA SECOND ARTILLERY ENGINEERING UNIVERSITY

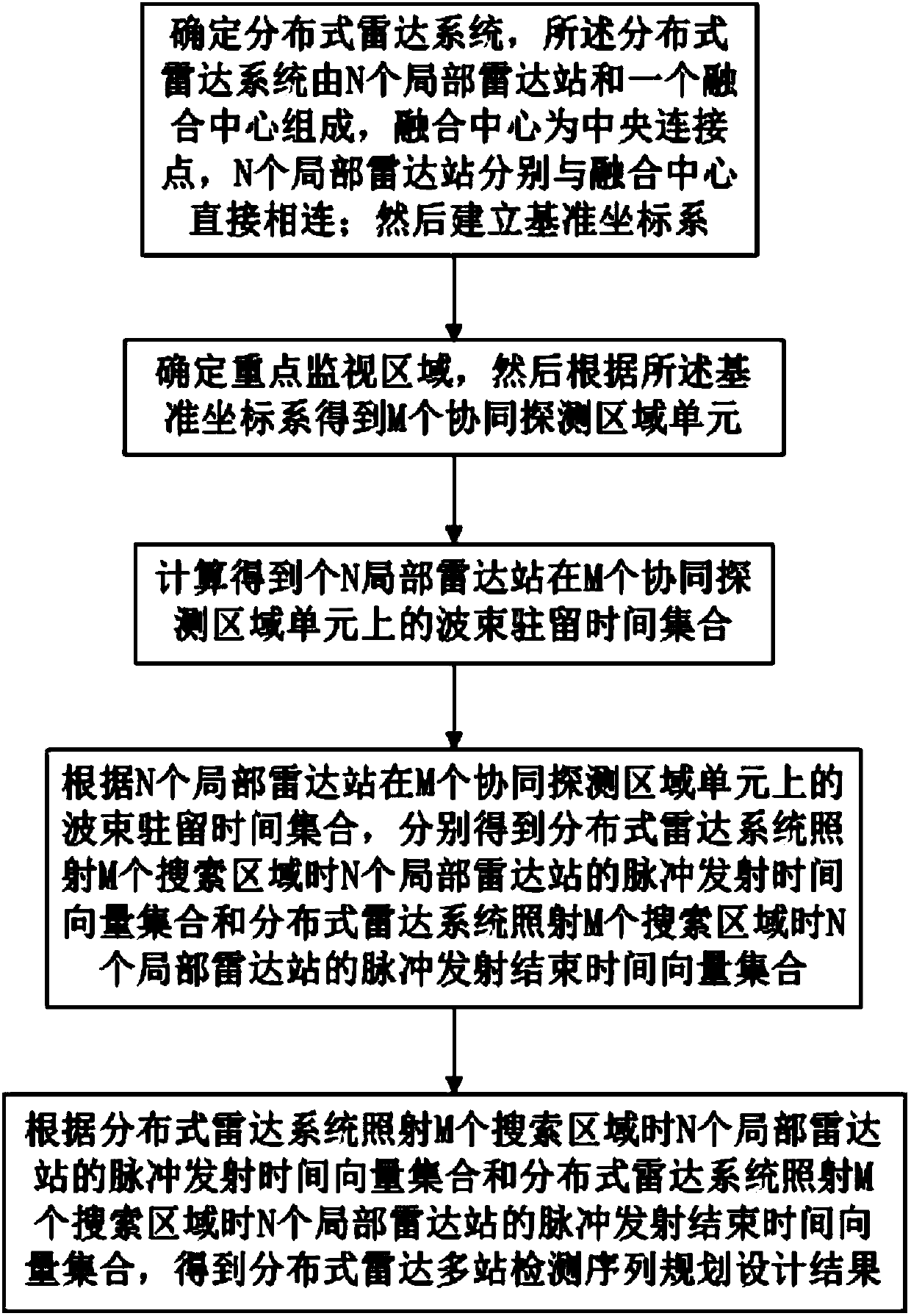

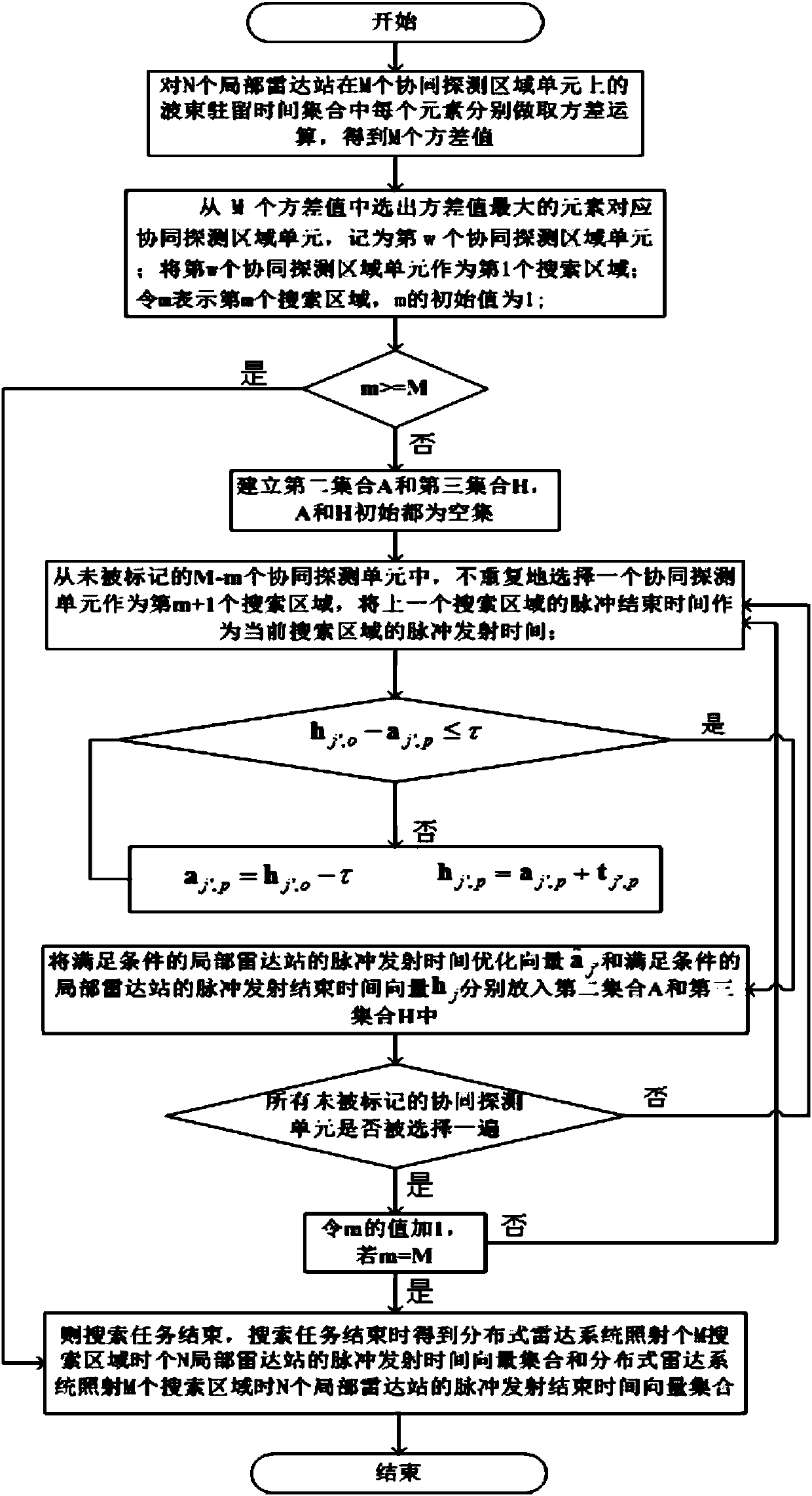

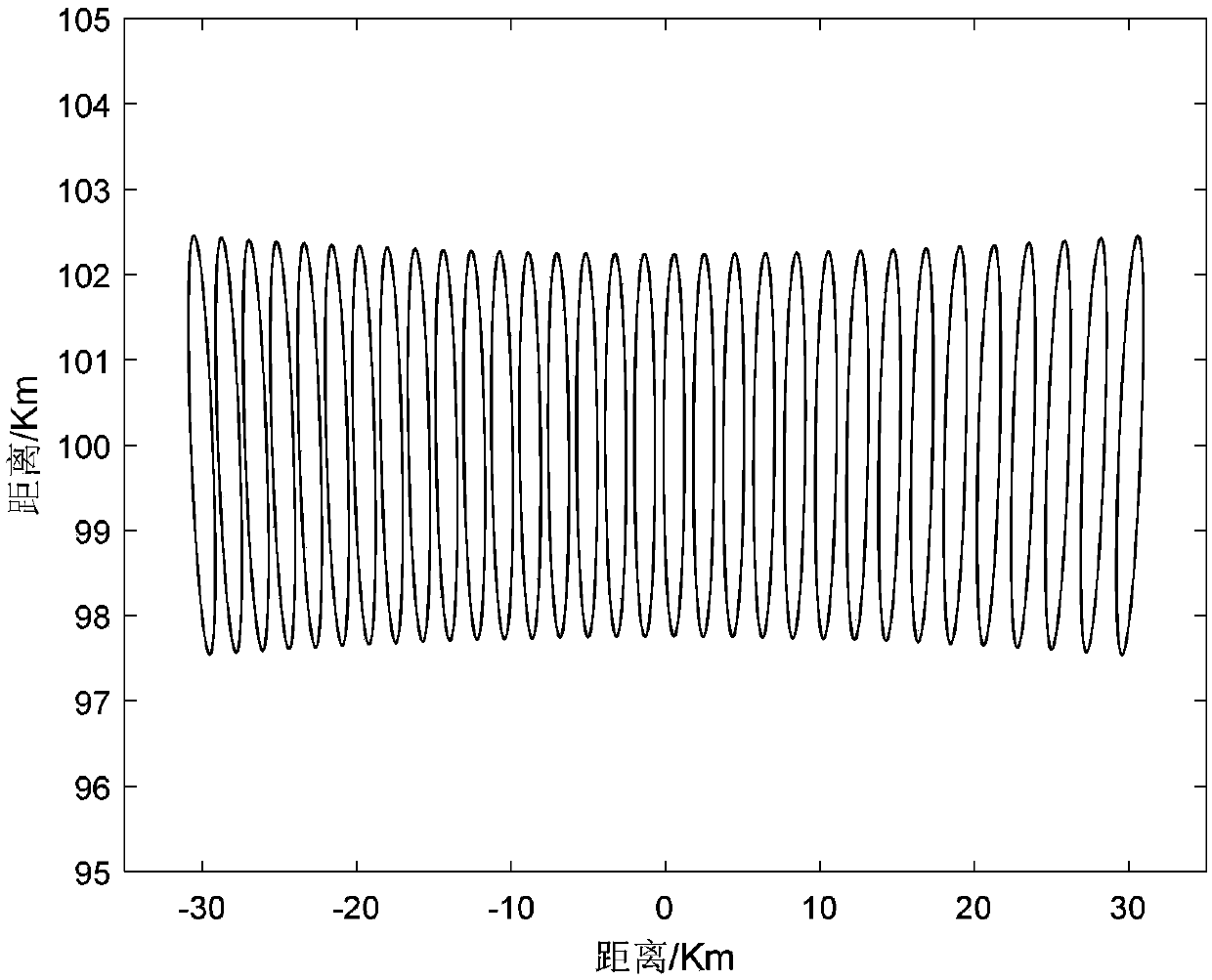

Distributed radar multi-station detection sequence planning design method

ActiveCN108594203AAchieve seamless coverageOrderly irradiationRadio wave reradiation/reflectionSequence planningRadar systems

The invention discloses a distributed radar multi-station detection sequence planning design method. The method comprises the steps that a distributed radar system is determined, and a reference coordinate system is established; a key monitoring area is determined to obtain M collaborative detection area units; a wave beam residence time set of N local radar stations on the M collaborative detection area units is calculated; according to the wave beam residence time set of the N local radar stations on the M collaborative detection area units, a pulse emission time vector set and a pulse emission end time vector set of the N local radar stations when a distributed radar system irradiates M search areas are obtained respectively; according to the pulse emission time vector set and the pulseemission end time vector set, obtained when the distributed radar system irradiates the M search areas, of the N local radar stations, a distributed radar multi-station detection sequence planning design result is obtained.

Owner:XIDIAN UNIV +1

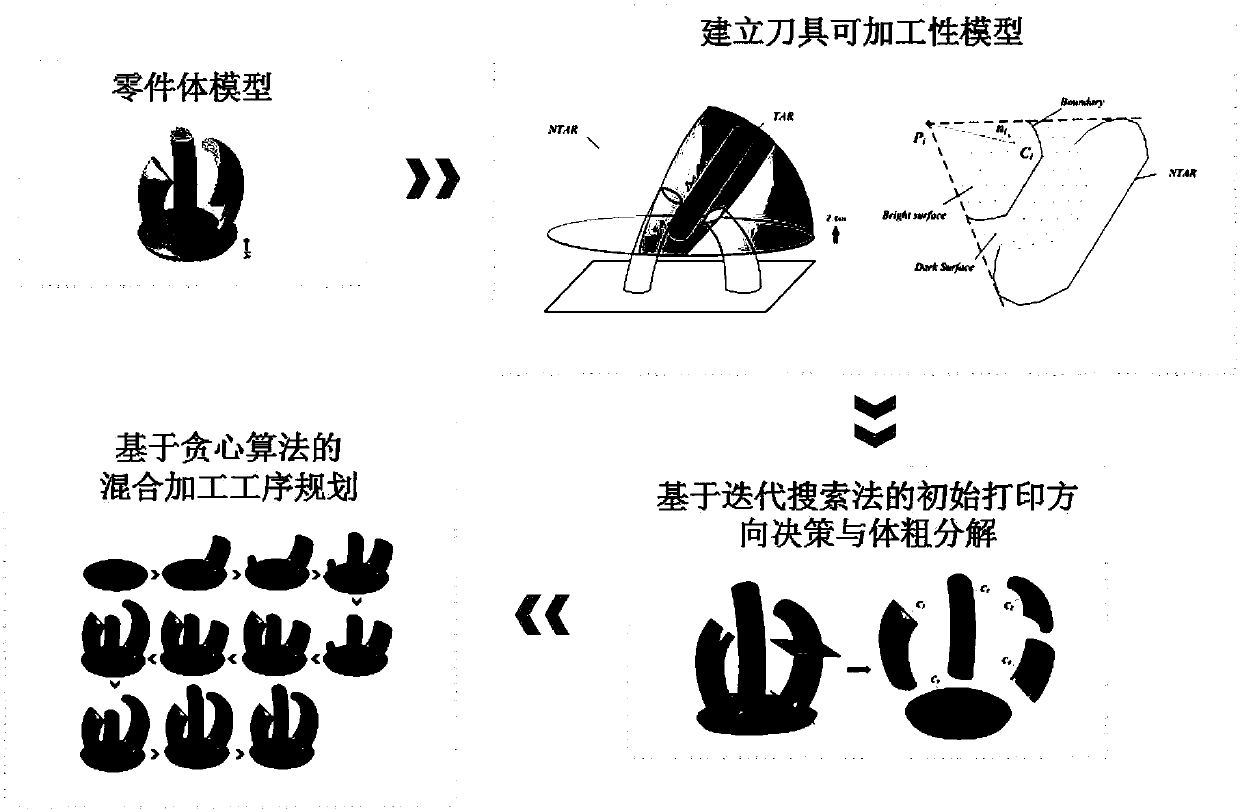

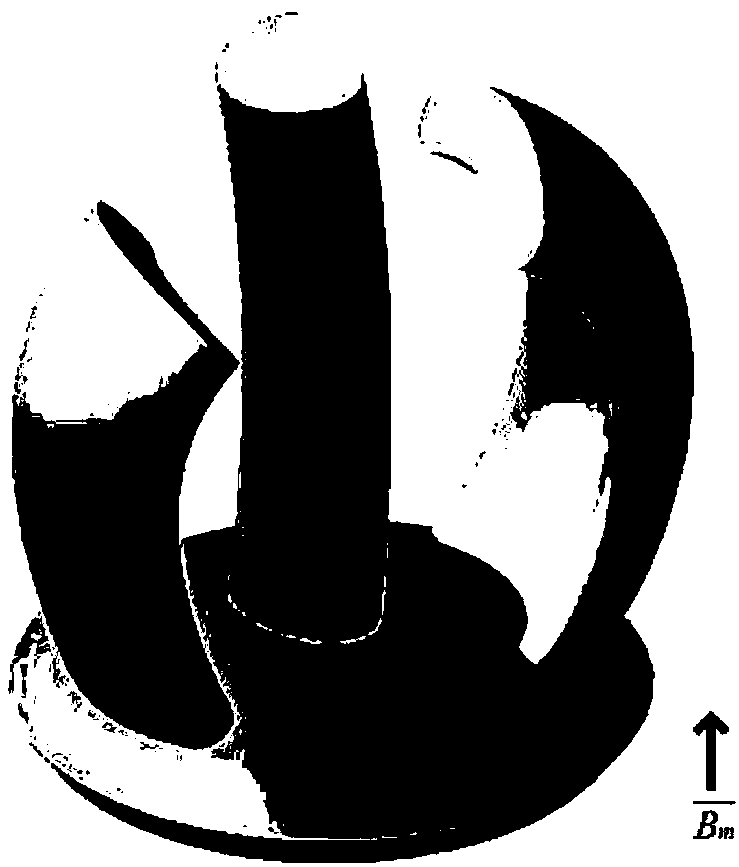

Sequence planning method of mixed processing of material increasing and decreasing of five shafts of composite structure

The invention provides a sequence planning method of mixed processing of material increasing and decreasing of five shafts of a composite structure. The method is characterized by comprising steps offirstly, defining the machinability of a knife based on a Gauss ball; based on a light protection method, carrying out analysis and calculation on the machinability of the knife; establishing a knifemachinability model under a five-shaft linkage material increasing and decreasing mixed processing mode; meanwhile, in a sequence planning process, for the coupling problem of printing direction decision making and the machinability calculation, based on an iteration searching method, carrying out initial printing method decision making on parts; carrying out coarse decomposition on part bodies; constructing an initial mixed processing sequences; and under the constraint of the knife machinability, based on a greedy algorithm, achieving the whole planning of the mixed processing sequences. According to the invention, optimization of material increasing and decreasing alternative time sequences in the mixed processing process is achieved; knife changing frequency is greatly reduced and thefoundation is laid for achieving of highly-efficient mixed processing.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

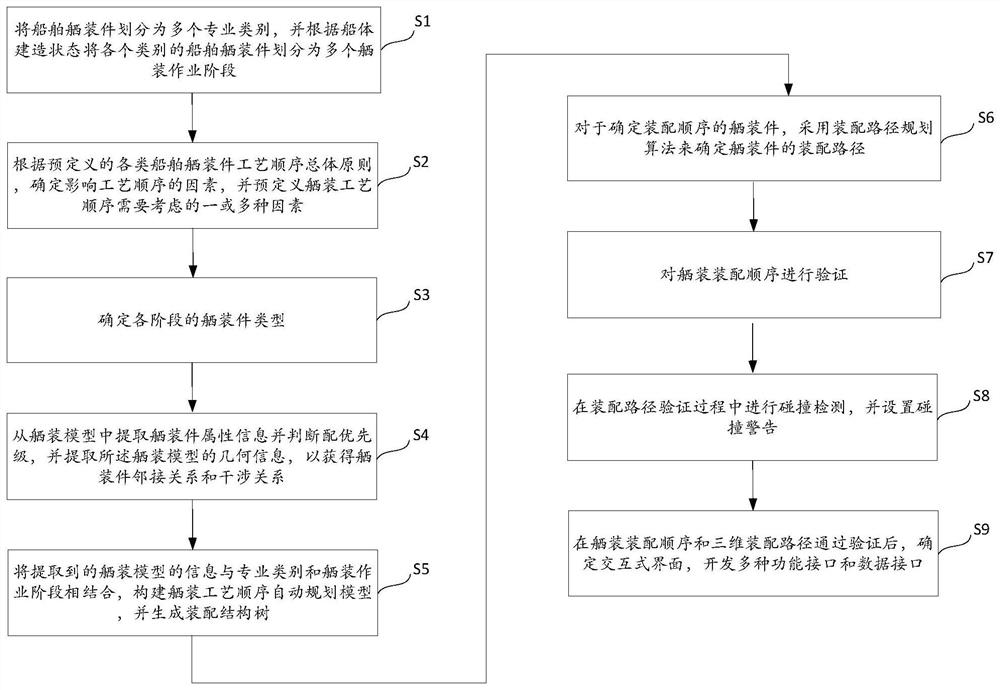

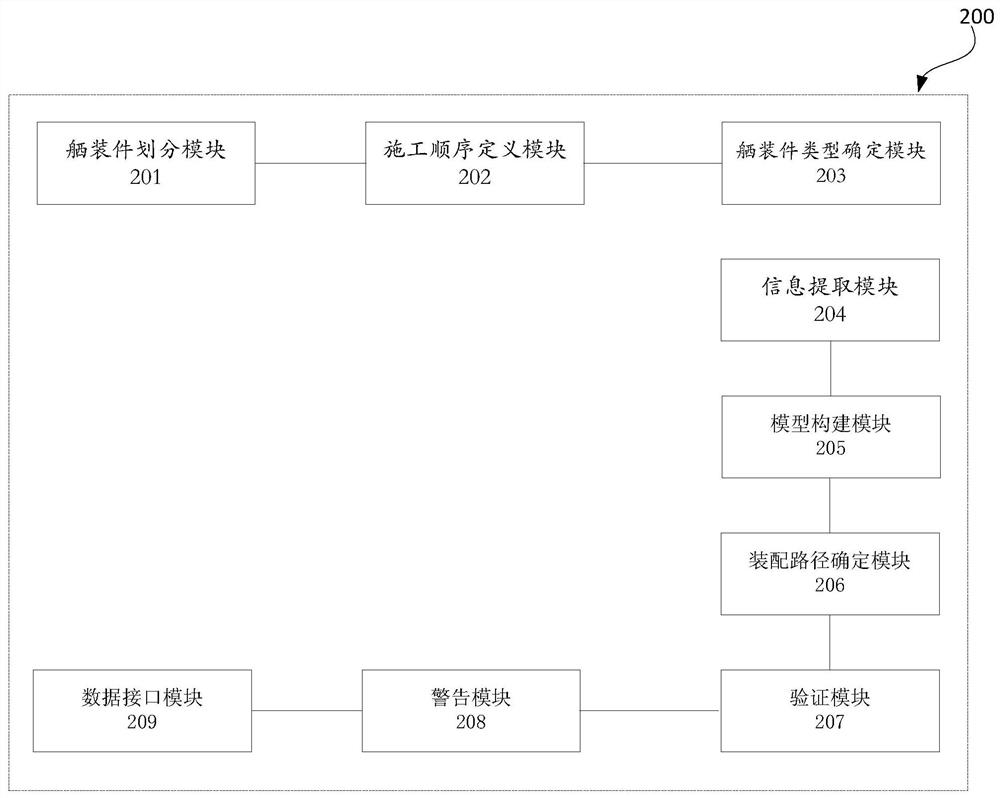

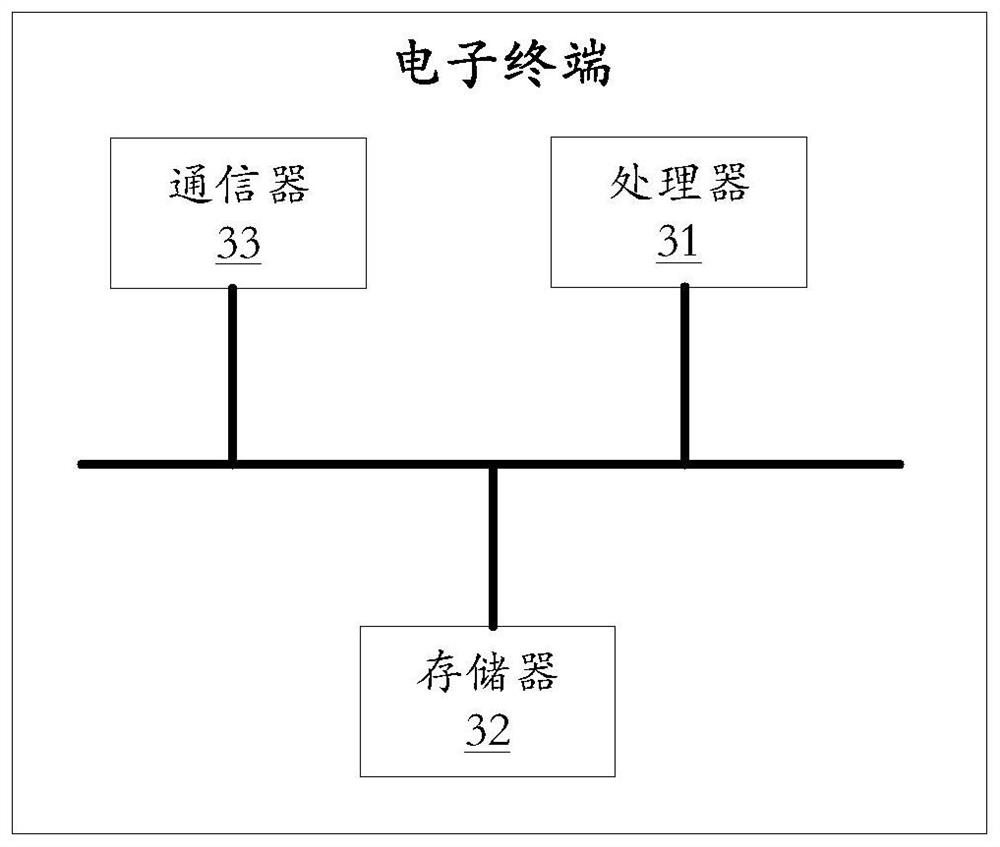

Ship outfitting process sequence automatic planning method and device, terminal and storage medium

PendingCN112036760AImprove accuracyRaise the level of digitizationResourcesManufacturing computing systemsSequence planningSequence design

The invention provides a ship fitting-out process sequence automatic planning method and device, a terminal and a storage medium, and solves the problems of unreasonable sequence, high construction difficulty, low design efficiency, frequent rework and the like in the existing ship fitting-out process sequence planning process, thereby achieving reasonability and standardization of ship fitting-out process sequence design, and improving the efficiency of ship fitting-out process sequence planning. Through the automatic planning function of the outfitting assembly sequence, the accuracy of theconstruction process is improved, the rework phenomenon is reduced, the dock or berth period is shortened, the production cost is reduced, through the automatic planning function of the ship outfitting three-dimensional assembly path, interference and collision are avoided, field assembly operation is guided, and the digital level of the outfitting construction process is improved; and the assembly efficiency is improved.

Owner:JIANGNAN SHIPYARD GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com