Sequence planning method of mixed processing of material increasing and decreasing of five shafts of composite structure

A technology of processing sequence and complex structure, applied in the direction of program control, instrument, computer control, etc., can solve the problems such as affecting the overall processing efficiency of mixed processing, many alternations of adding and subtracting materials, and low mixing processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0082] Such as Figure 1-9 shown.

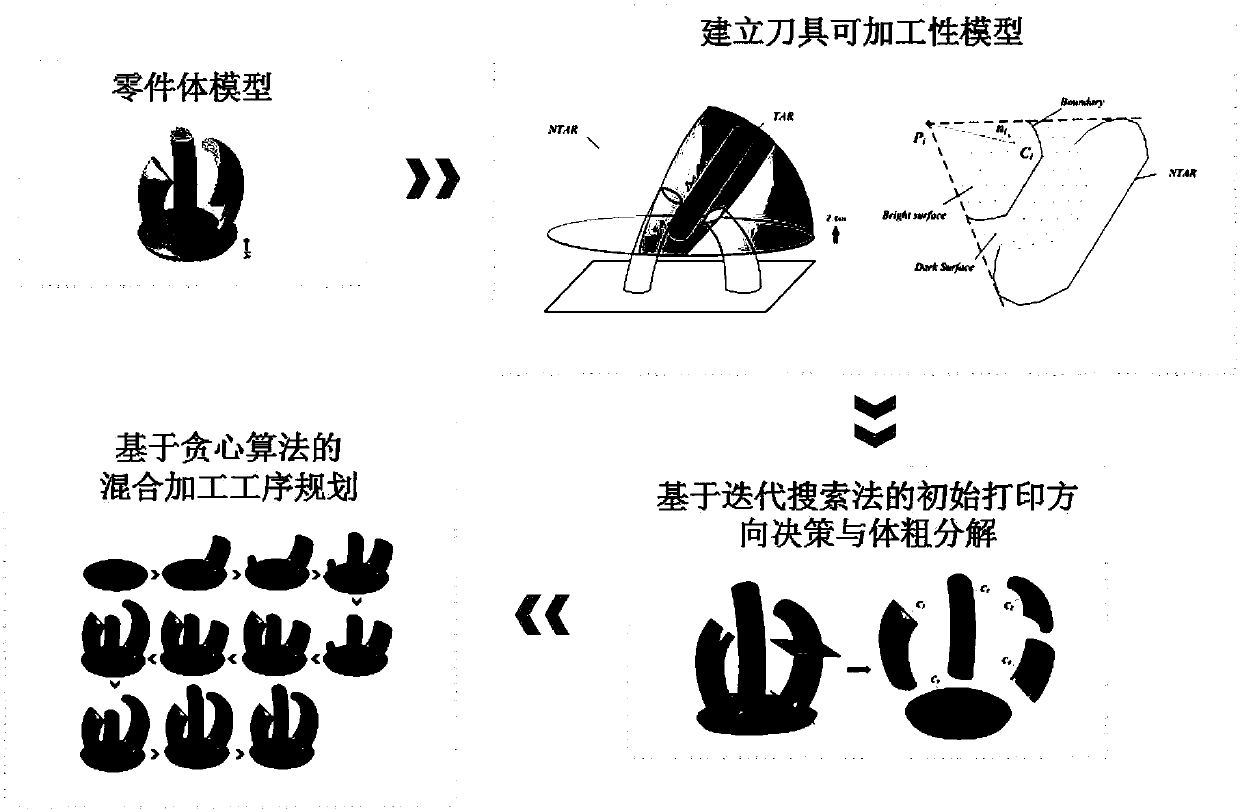

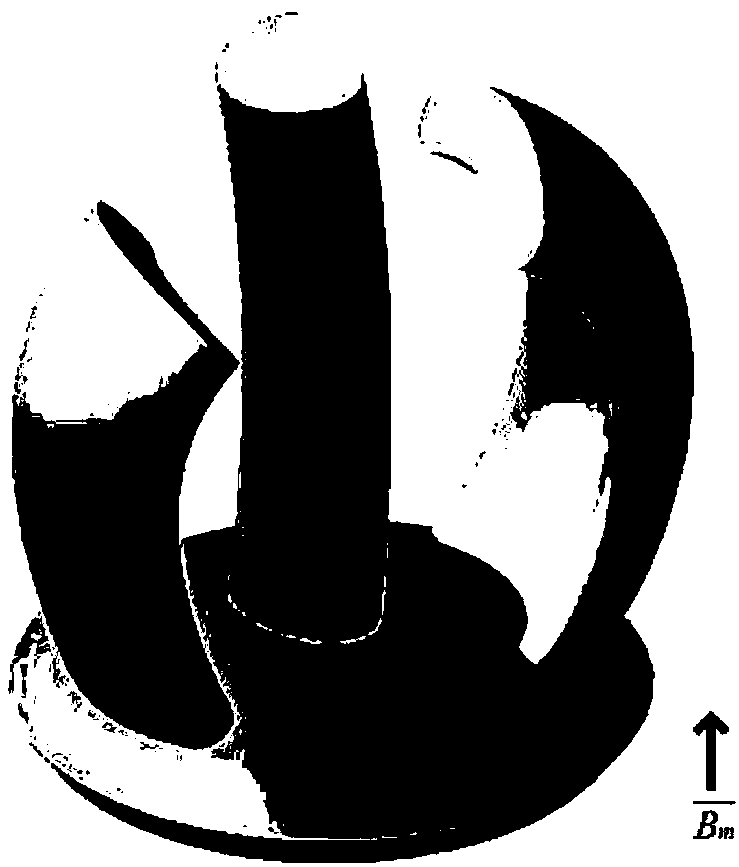

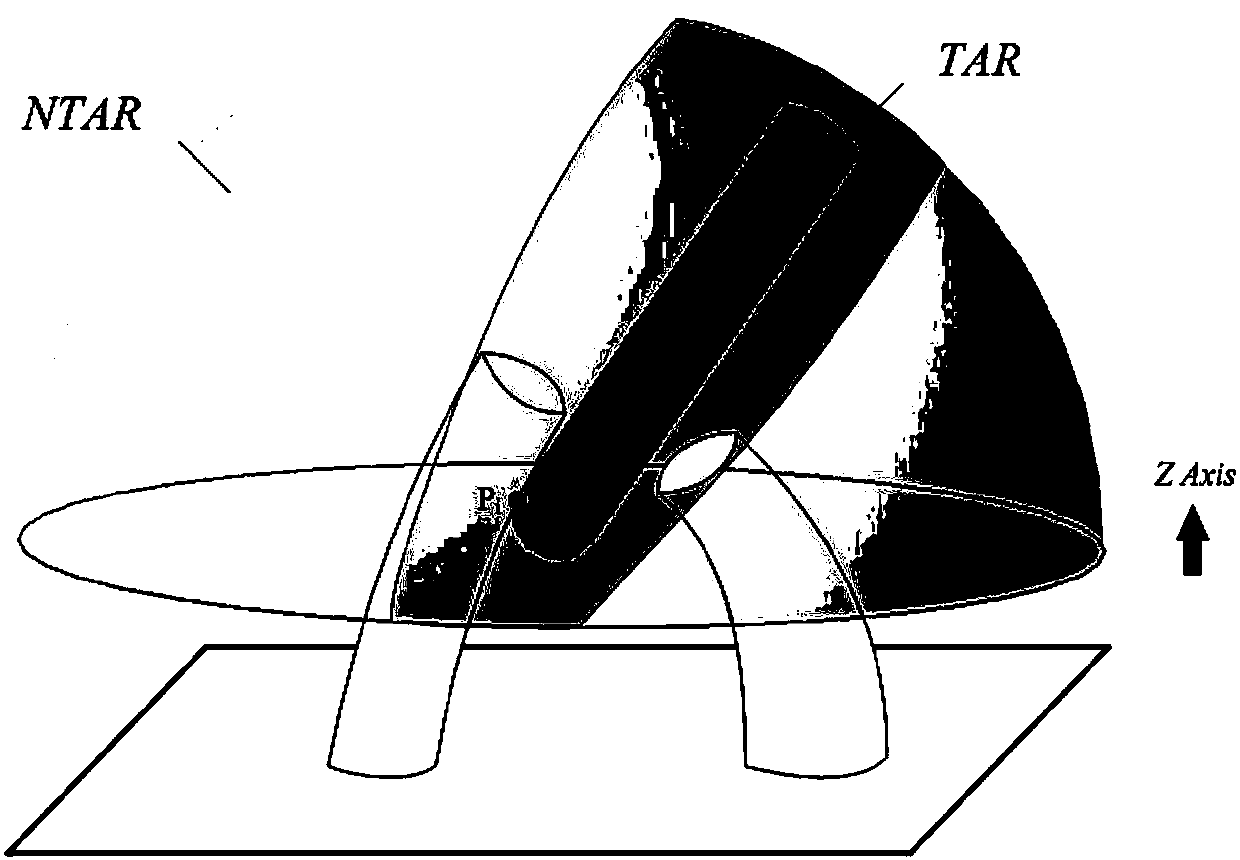

[0083] A sequence planning method for five-axis mixed machining of complex structural parts with adding and subtracting materials. This method aims at the problems of printability and machinability caused by the change of printing direction under the mixed machining mode of five-axis linkage adding and subtracting materials. The machinability of the tool is defined, and the machinability of the tool is analyzed and calculated based on the light projection method. Orientation decision-making and machinability calculation are a pair of coupling problems. Based on the iterative search method, the initial printing direction decision of the part is made, and the part body is roughly decomposed to construct the initial mixed processing sequence. Then, under the constraint of tool machinability, based on The greed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com