Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35 results about "Material Description" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The textual representation of the material.

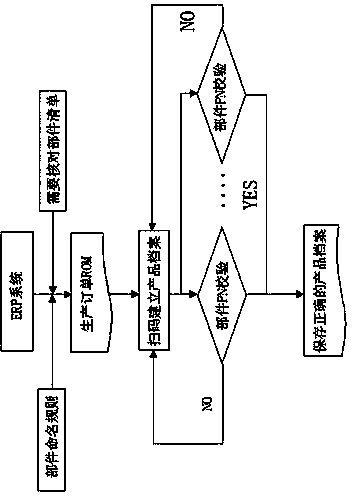

Automatic calibrating method of make-to-order production materials by server

InactiveCN103971223AImprove controlVersatileLogisticsSpecific program execution arrangementsMaterial DescriptionEnterprise resource planning

The invention discloses an automatic calibrating method of make-to-order production materials by a server. The method comprises the following steps: each machine automatically generates an SN (Serial Number) number according to a production order BOM (Bill of Materiel) established in ERP (Enterprise Resource Planning), wherein the SN number is associated with the production order number and the production order BOM comprises PN (Part Number) codes of all materials, material description, standard quantity of the materials, make-to-order number and the production order number; quality guarantee bar codes are adhered to all materials, wherein each quality guarantee bar code comprises two pieces of association information: PN code and QN (Quality Notification) code; based on existing file code scanning program, an automatic calibrating script program is compiled; after wall parts are code-scanned, the save button is clicked, thus, a background calibrating program further checks the PN, quantity and BOM of all code-scanning parts; when the result is inconsistent, mistaken material rows are prompted; and if no mistakes are found, the product record is successfully stored. By adopting the technology provided by the invention, under a mode of customerized production of a server product, manual checking work can be completed by system and program.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

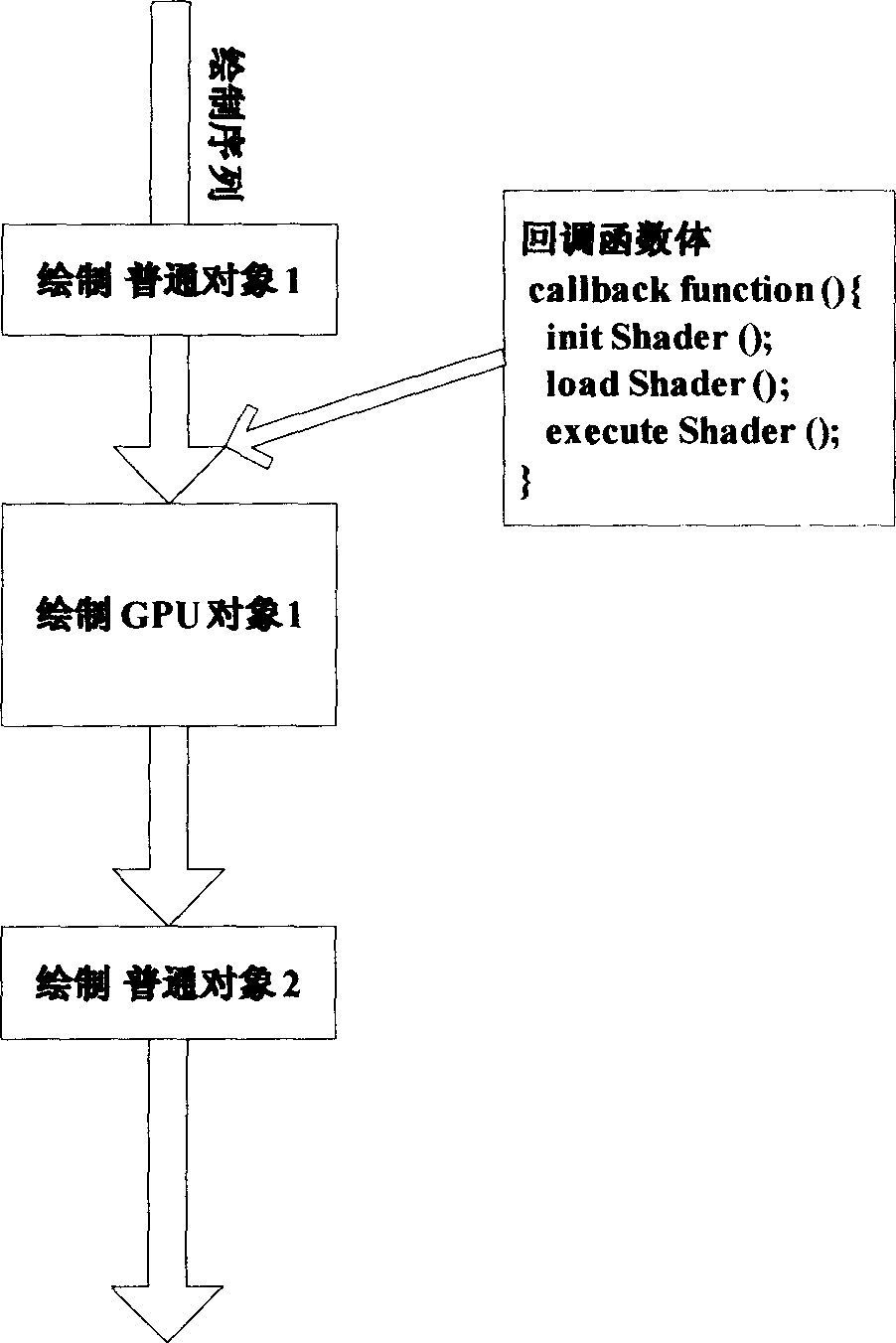

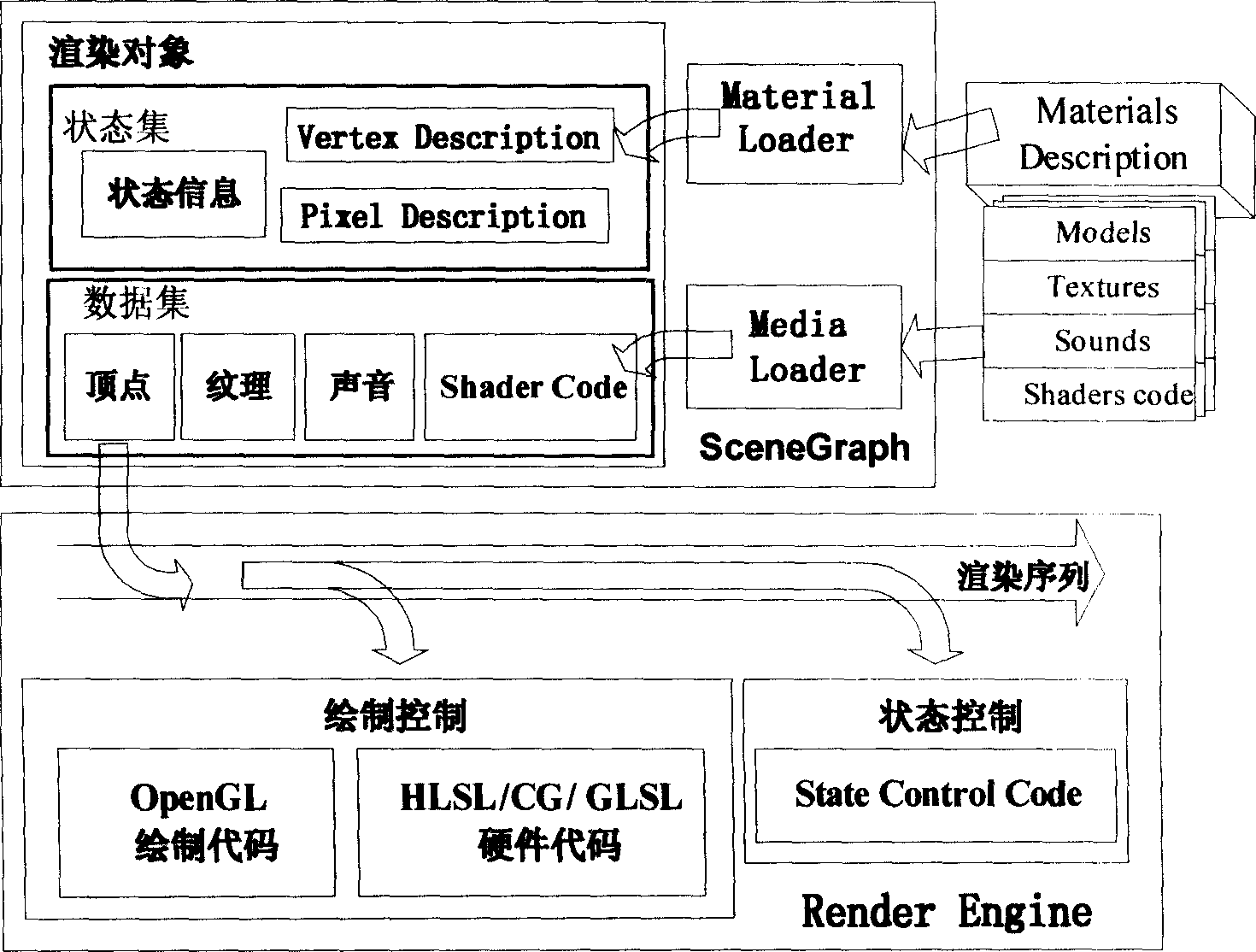

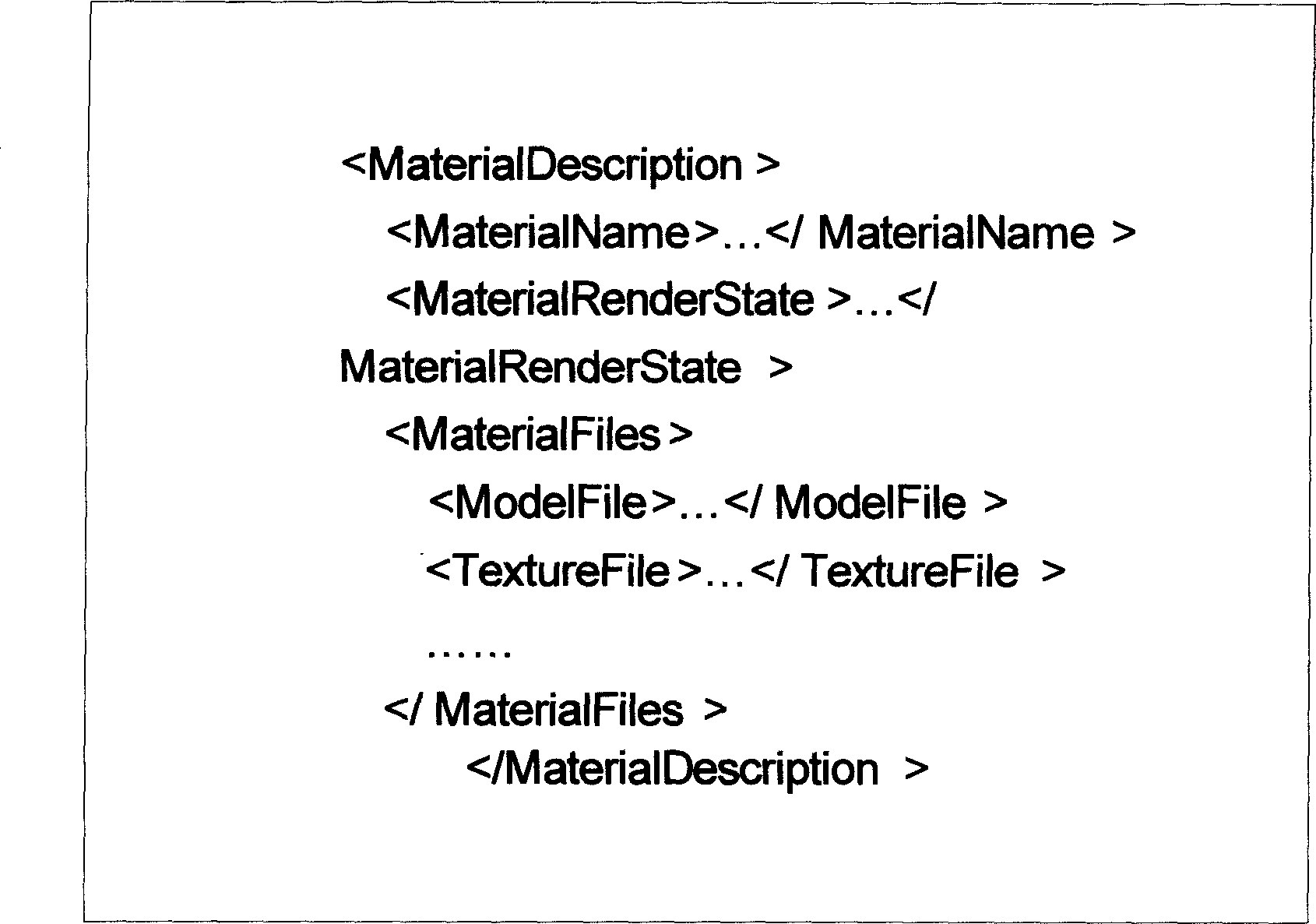

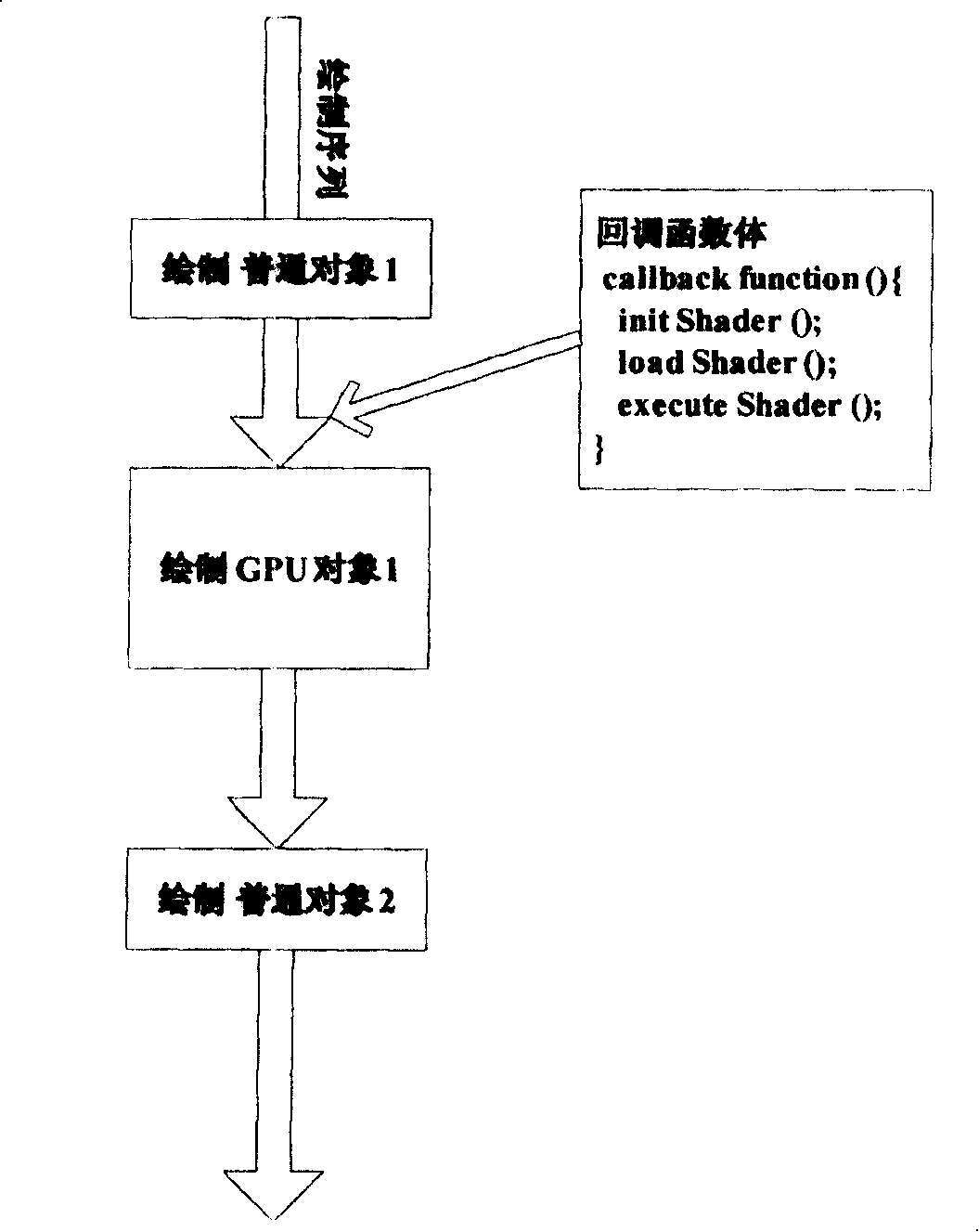

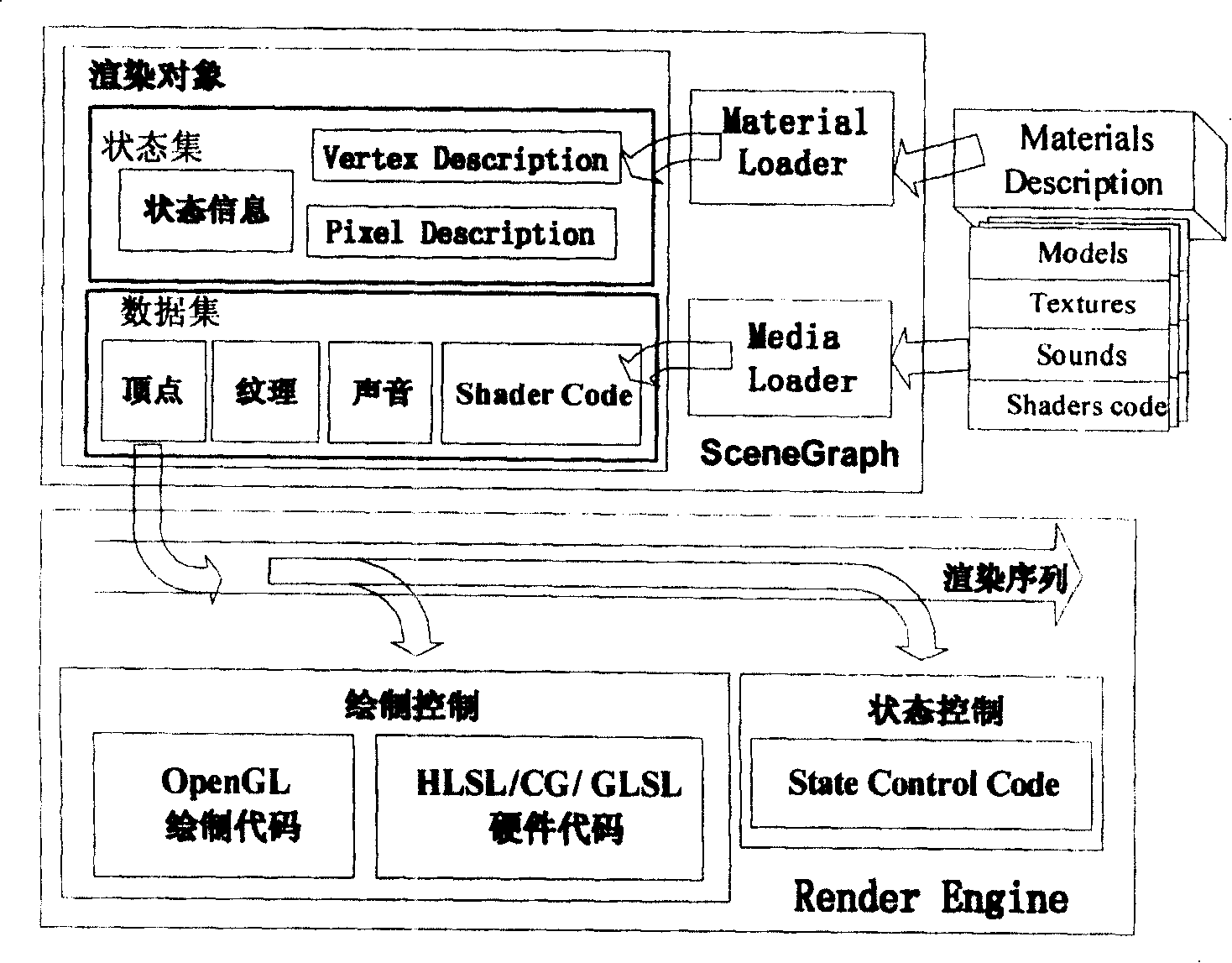

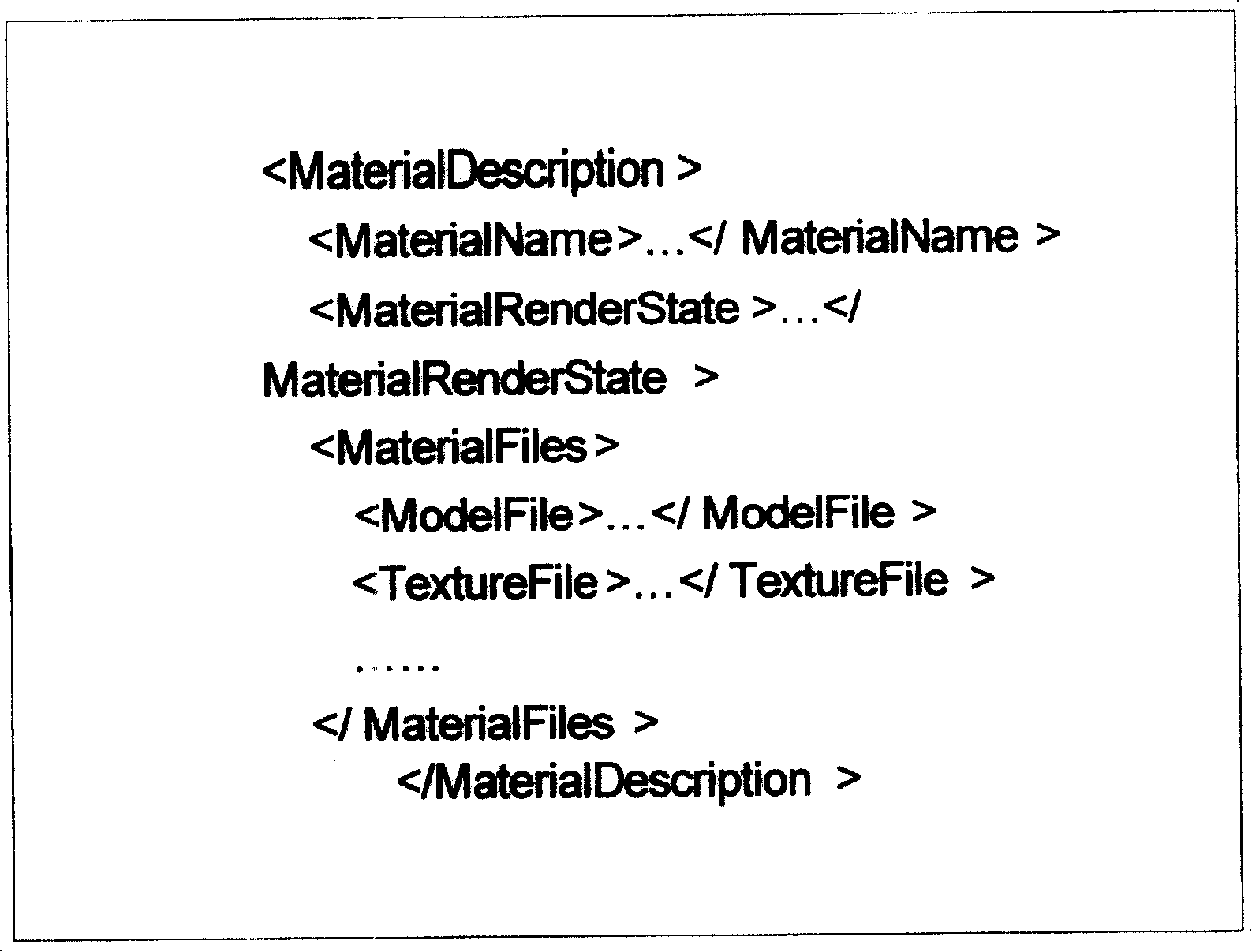

State set based shader three-dimensional graph drawing frame and drawing method

InactiveCN1851753AImprove integrityImprove acceleration performance3D-image renderingDynamical optimizationMaterial Description

The present invention uniformly package and descript the drawing object model information, texture information, voice message relevant Shader code in Materials Description file before tuning in scene chart, and tuning in shown off object through Material Loader and Media Loader in scene chart data store organization, also according to Shader information sorting and to proceed static and dynamic optimization, then using optimized drawing status information loading to engine to proceed drawing, drawing engine consisting of drawing control and state control, both combined to complete one drawing object drawing process. The present invention makes effective management to Vertex Shader and Pixel Shader, fully utilizing state package and sorting function, simplifying interface calling.

Owner:BEIHANG UNIV

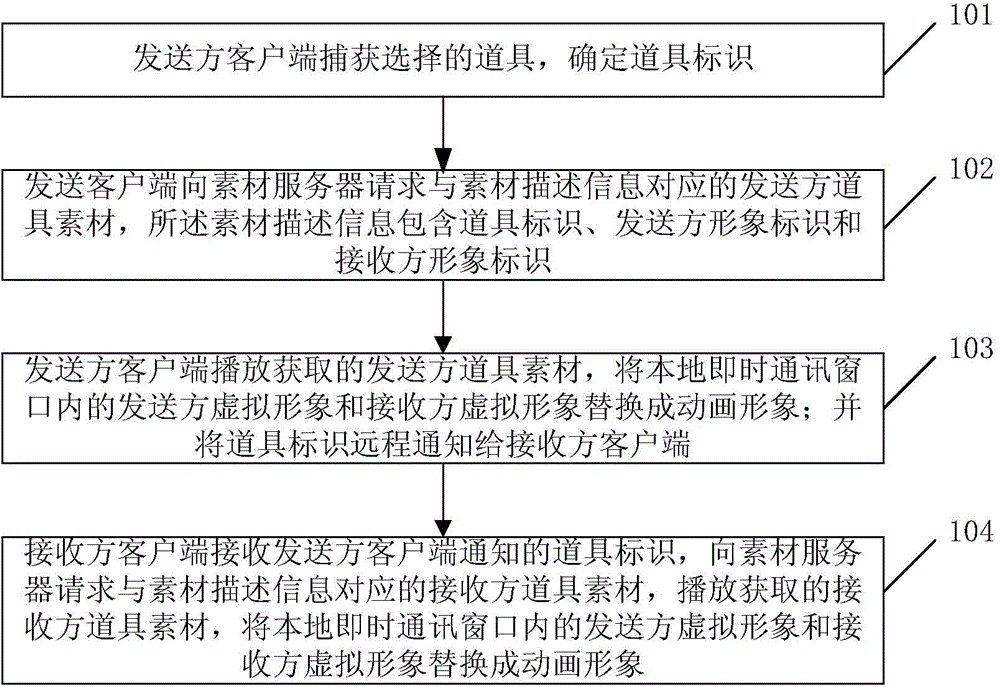

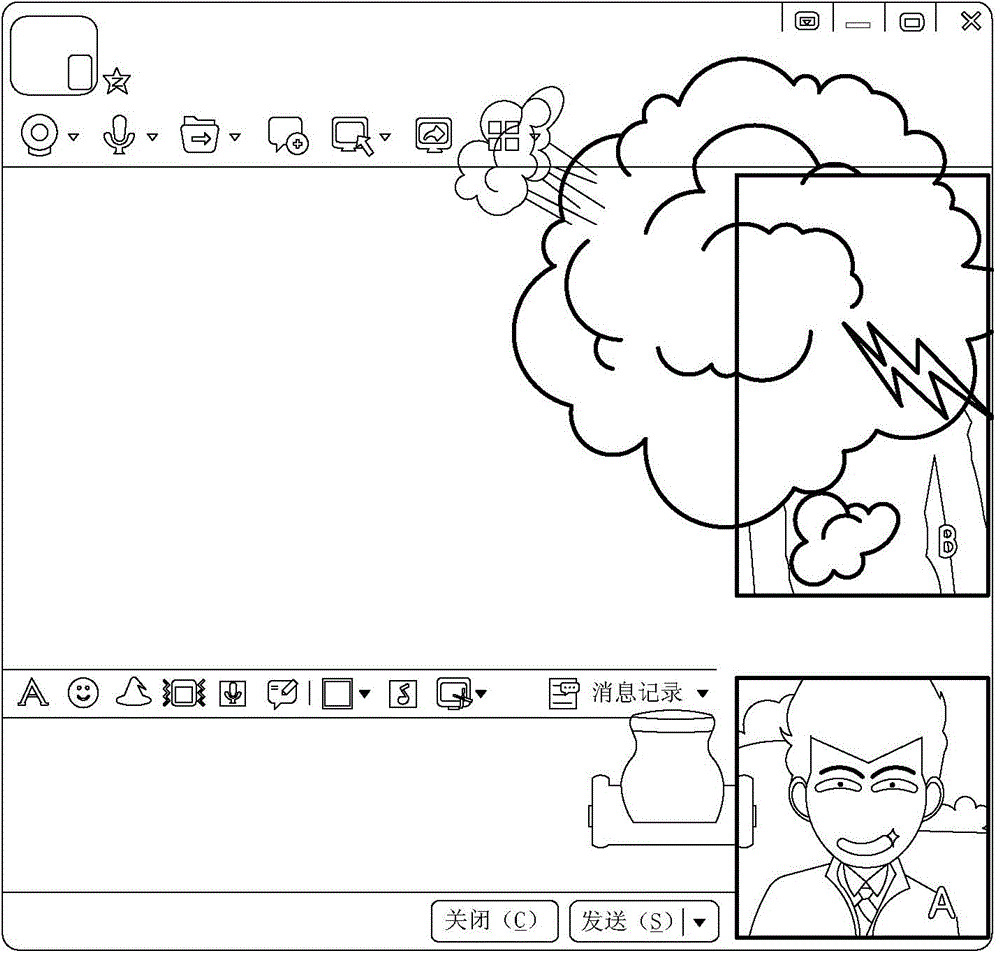

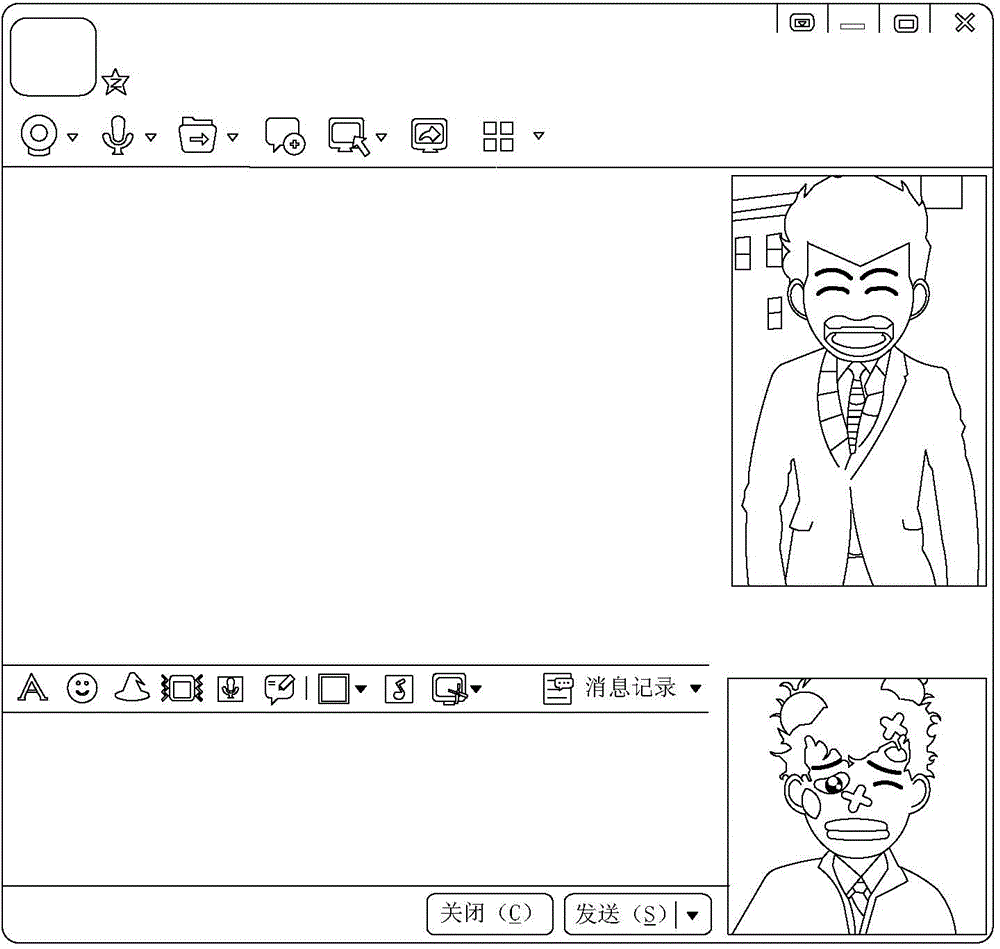

Method and system for performing real-time interaction in instant messaging and client

ActiveCN105099860AEnable real-time interactionMeet needsData switching networksMaterial DescriptionAnimation

The invention discloses a method and system for performing real-time interaction in instant messaging and a client. The method includes the following steps: a sender client captures a selected prop and determines a prop identifier; a sender prop material corresponding to material description information are requested from a material server, and the material description information includes the prop identifier, a sender image identifier and a receiver image identifier; the prop identifier is remotely notified to a receiver client; the sender client plays the sender prop material that is obtained; and the receiver client receives the prop identifier notified by the sender client, requests a receiver prop material corresponding to material description information from the material server, plays the receiver prop material that is obtained, and replaces a sender virtual image and a receiver virtual image in a local instant messaging window with cartoon images. The scheme of the method provided by the invention can realize real-time interaction of the vertical images in instant messaging.

Owner:TENCENT TECH (SHENZHEN) CO LTD

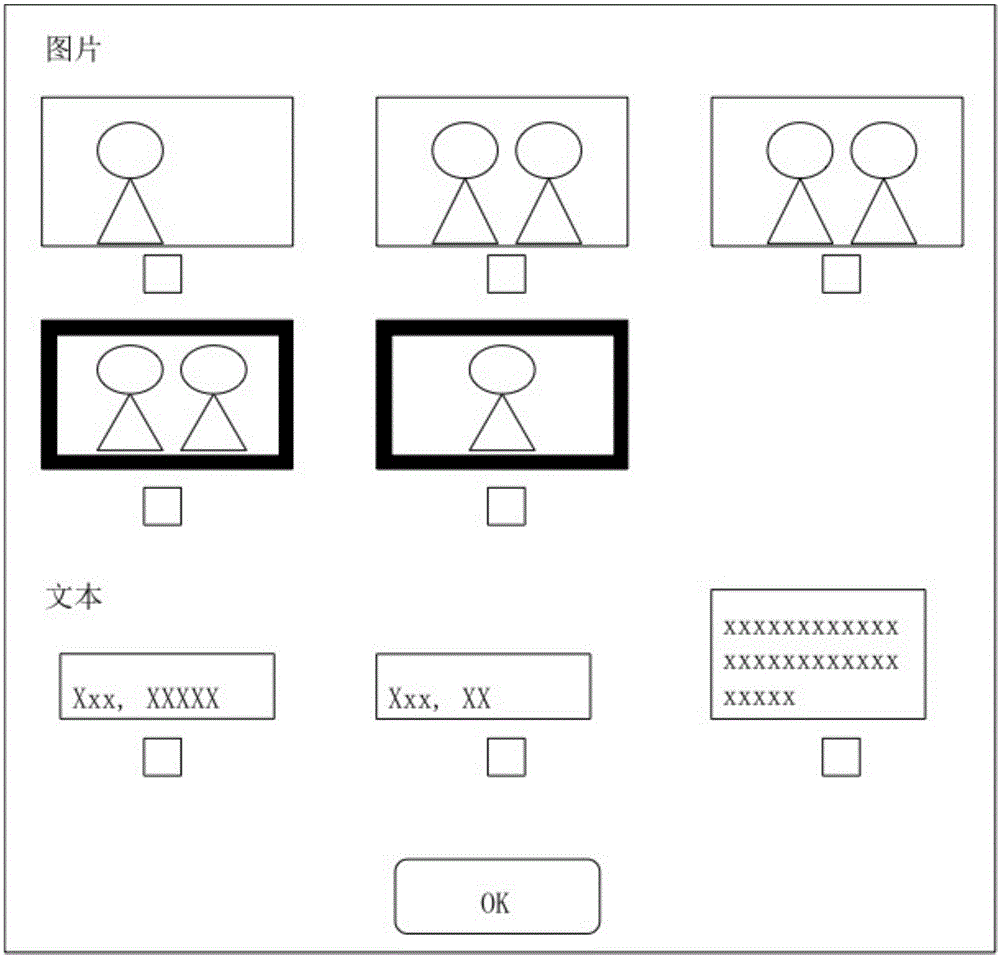

Printed matter on-line design service cloud platform and on-line design method thereof

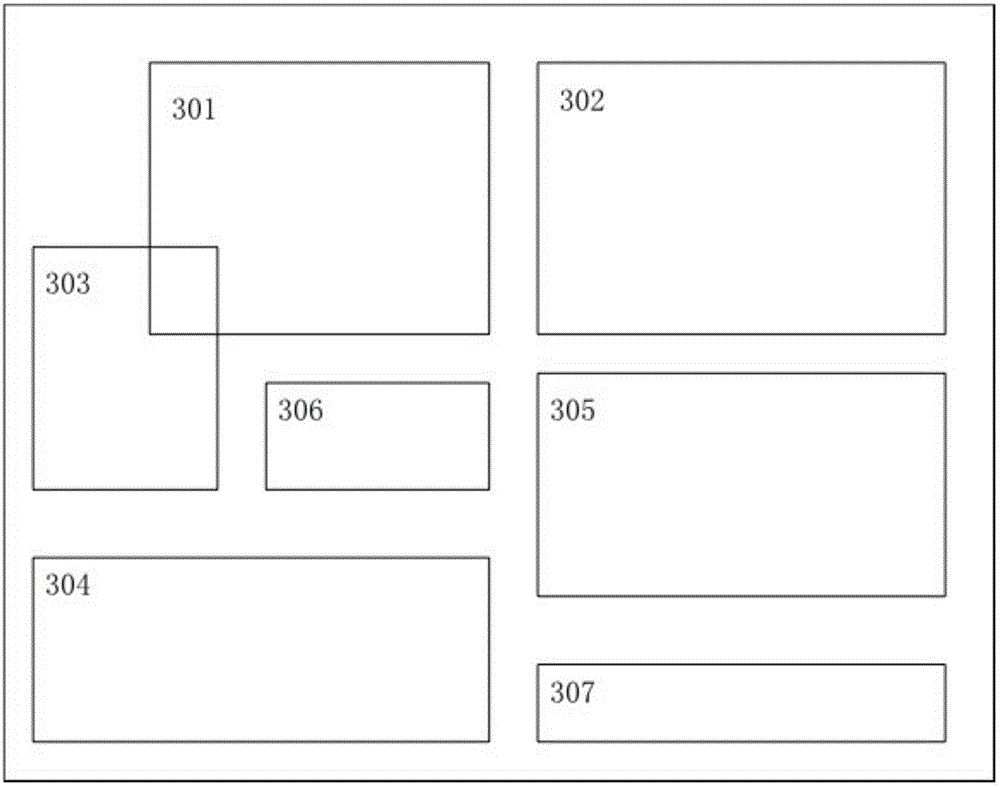

The invention provides a printed matter on-line design service cloud platform and an on-line design method thereof. On one hand, mass standardized templates are aggregated, and analysis is conducted on the standardized templates to form adaptability condition parameters; on the other hand, the mode that a user selects a template and then fills the template with materials during printed matter layout on-line design is changed into the mode that the user provides the materials, material description information is generated according to the materials, the standardized templates with the adaptability condition parameters meeting the requirements are screened out through template retrieval operation with the material description information as the condition, the matching degree sequence is generated, and the standard templates are recommended to the user according to the sequence. By means of the printed matter on-line design service cloud platform and the on-line design method, the templates satisfying the requirements and materials of the user are pushed to the user from mass-grade standardized template resources of a template library, time consumed when the user browses a large amount of template resources is saved, and difficulty caused to the printed matter layout design when the matching degree of the selected templates and the materials is not high is avoided.

Owner:武汉改图网技术有限公司

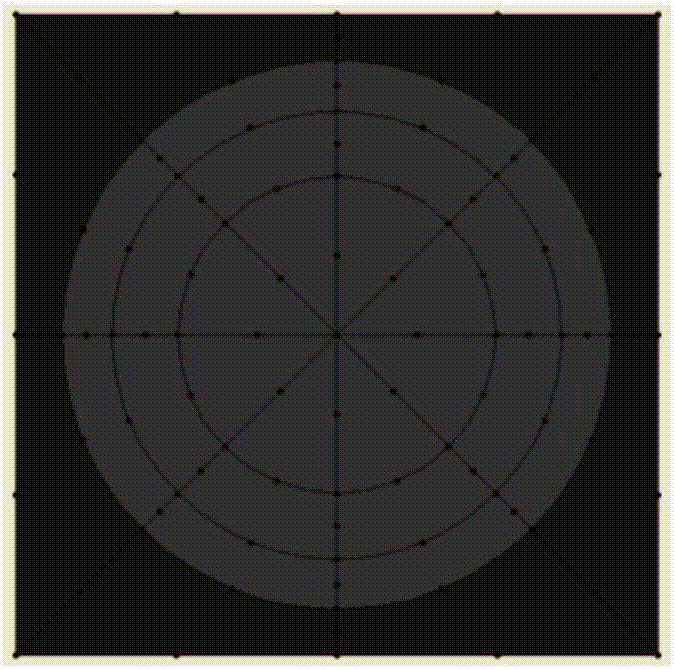

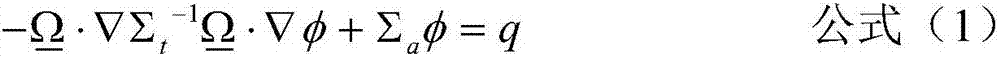

Non-uniform geometrical variational nodal method aiming at reactor neutron diffusion equation

ActiveCN107145657AUniform description abilityThe description is validDesign optimisation/simulationSpecial data processing applicationsNODALNuclear reactor

The invention discloses a non-uniform geometrical variational nodal method aiming at a reactor neutron diffusion equation. The method comprises the following steps: 1, establishing a functional containing a neutron conservation relationship inside the nodal block and flow continuity conditions on the nodal surface; 2, performing nodal discrete disposal by utilizing a finite element shape function in the x-y direction and a chip constant polynomial, and realizing non-uniform nodal geometrical and material description functions; 3, deducing to obtain a response matrix equation; and 4, solving the response matrix equation by utilizing a red-black scanning manner, and finally obtaining the neutron-flux density distribution in the whole non-uniform solving area. According to the method disclosed by the invention, the non-uniform lattice-cell structure of a nuclear reactor can be finely described; and according to the method, the nodal internal fine geometrical structure is processed based on the variational nodal method by adopting an isoparametric finite element, and then the non-uniform geometrical neutron diffusion equation is solved.

Owner:XI AN JIAOTONG UNIV

Core material for vacuum heat insulation material, and vacuum heat insulation material

InactiveUS20030175493A1Excellent in heat insulating propertyHigh compressive strengthThermal insulationSynthetic resin layered productsMaterial DescriptionPolystyrene

Description is made of an open cell polystyrene resin foam having a content of organic volatile matters of less than 100 ppm. The open cell foam is suitable as a core material for a sound insulating material or a vacuum heat insulating material. The open cell foam can be produced by melt-kneading a polystyrene resin having a content of organic volatile matters of 100 ppm or higher together with water in an extruder, sucking out the organic volatile matters as an azeotrope with water through a vent, injecting a blowing agent and kneading the injected mixture, and extruding the mixture into a lower pressure area to cause the resin to foam.

Owner:JSP CORP

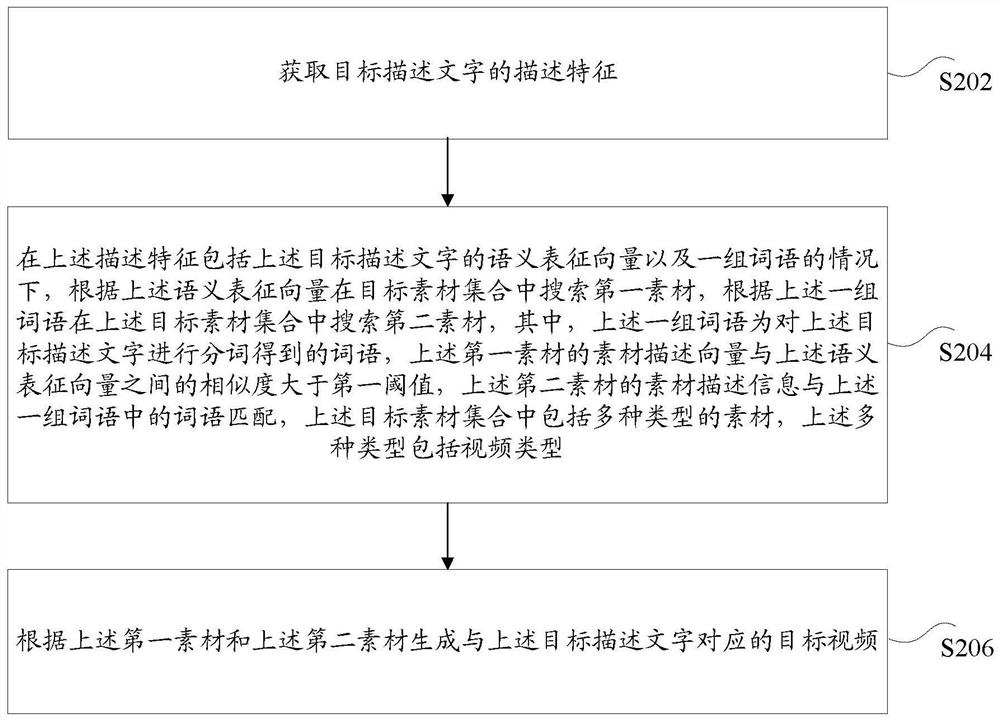

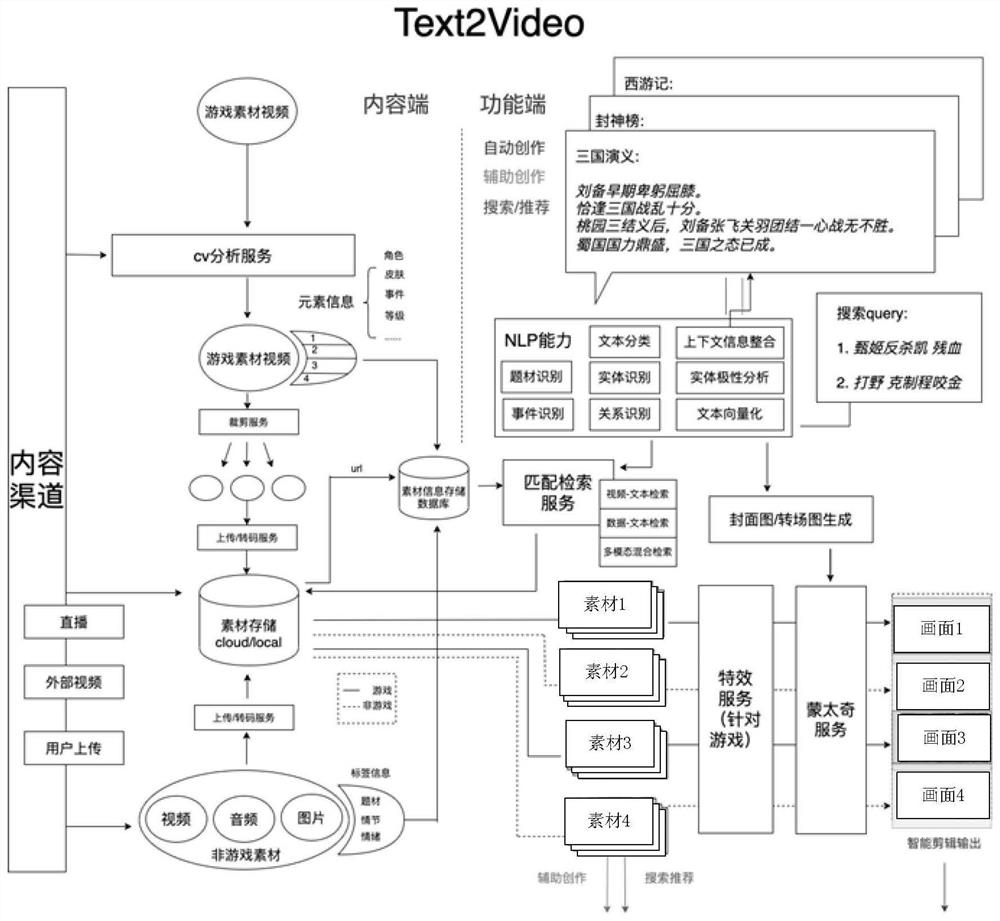

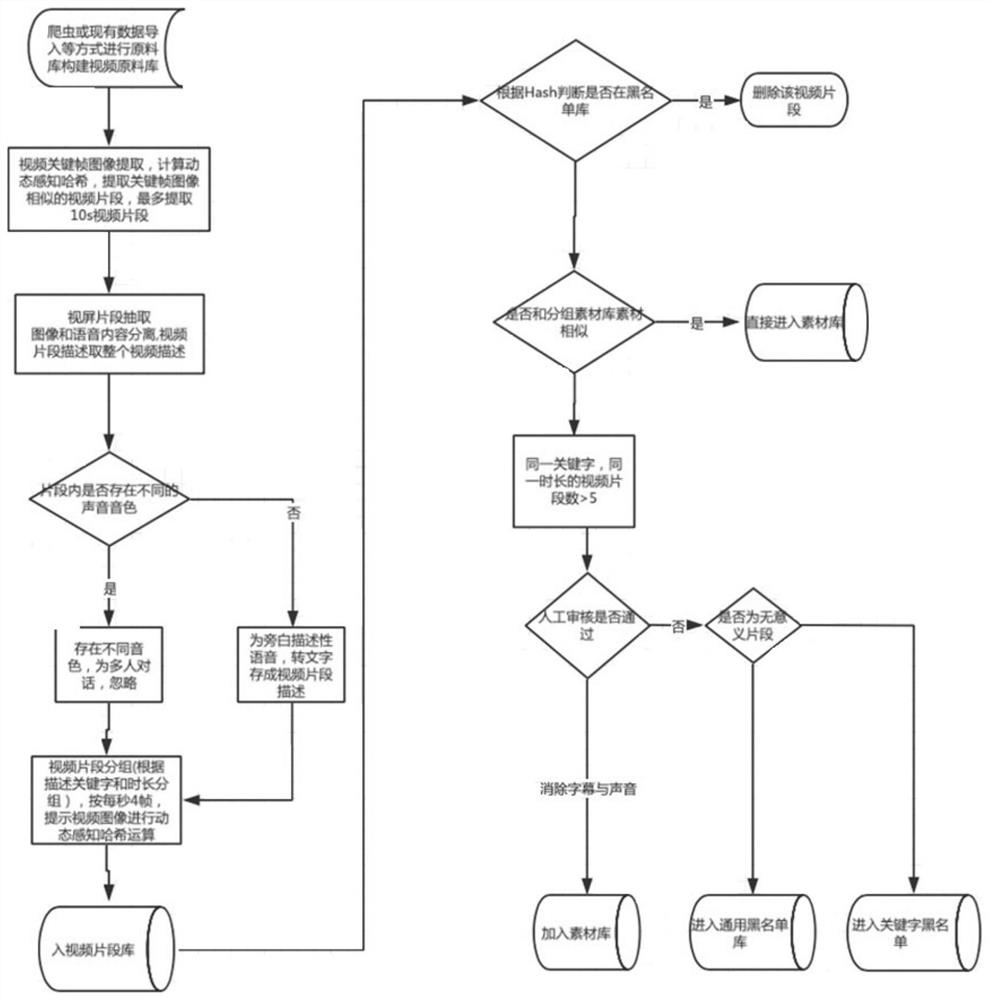

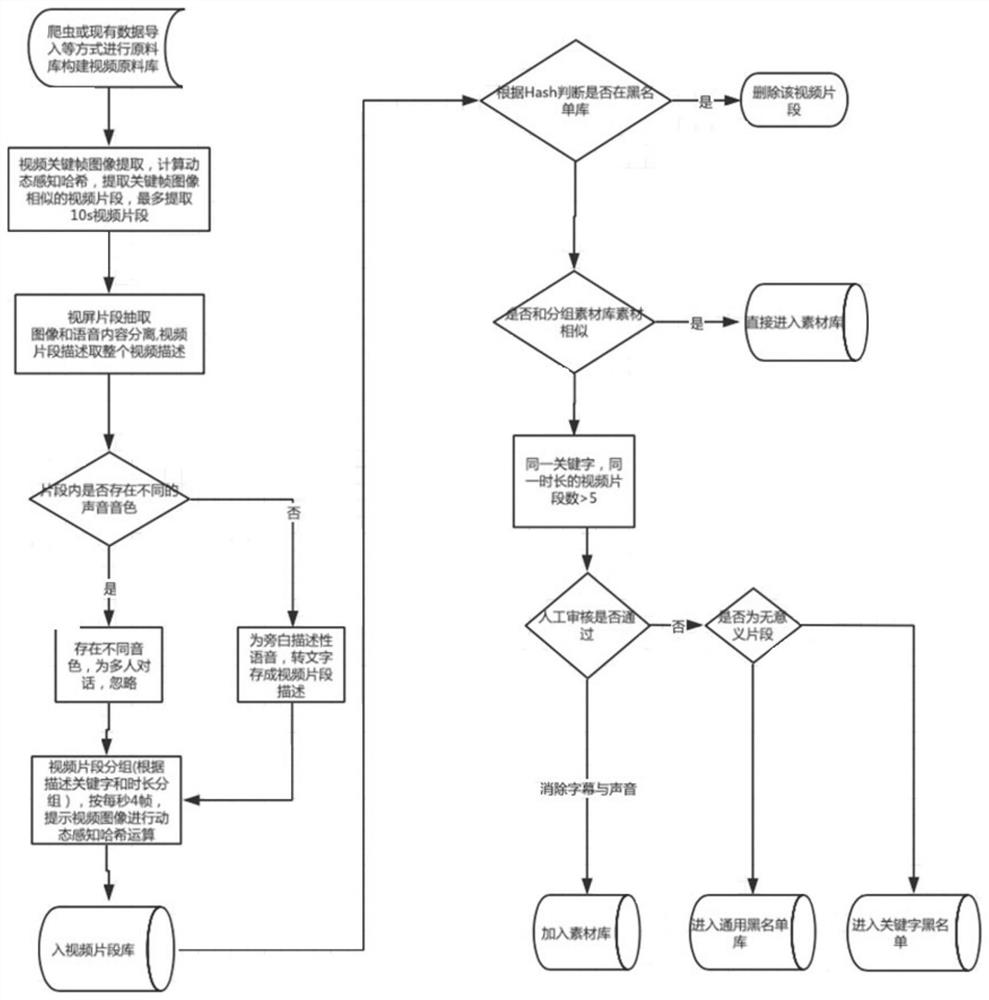

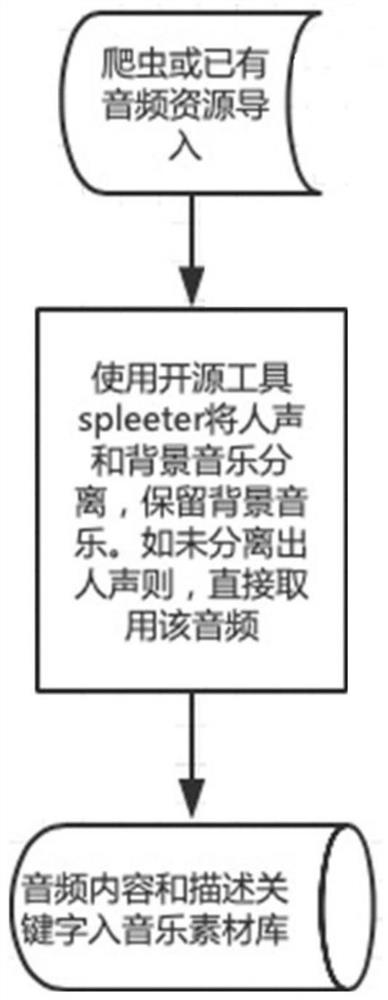

Video generation method and device, storage medium and electronic equipment

ActiveCN112015949AQuality improvementGood effectVideo data indexingSemantic analysisSemantic representationMaterial Description

The invention discloses a video generation method and device, a storage medium and electronic equipment. The method comprises the steps of obtaining description features of target description characters; when the description feature comprises a semantic representation vector of the target description character and a group of words, searching a first material in a target material set according to the semantic representation vector, searching a second material in the target material set according to the group of words, wherein the set of words is obtained by performing word segmentation on the target description text, the similarity between the material description vector of the first material and the semantic representation vector is greater than a first threshold, the material descriptioninformation of the second material is matched with the words in the set of words, the target material set comprises multiple types of materials, and the multiple types comprise video types; and generating a target video corresponding to the target description text according to the first material and the second material. By adoption of the technical scheme, the problem of low quality of the generated video when the video is generated based on the characters in the related art is solved.

Owner:TENCENT TECH SHANGHAI

Method for assistance with the construction and validation of an avionics platform

InactiveUS20100292979A1Geometric CADAnalogue computers for electric apparatusAviationMaterial Description

The invention concerns a method for assisting the construction and validation of an avionics platform. It uses, on the one hand, a functional description of the platform using avionics functions, software modules suitable for executing these functions, and functional link occurrences between these modules and, on the other hand, a material description of this platform using calculation or communication items of equipment and physical links between these equipment. The method according to the invention enables to generate paths between the various items of equipment by using direct physical links and / or physical links belonging to one or more network(s), and subsequently to associate at least one such path to be each functional link occurrence. It also enables to associate to each software module an item of equipment adapted to host it.

Owner:AIRBUS OPERATIONS (SAS)

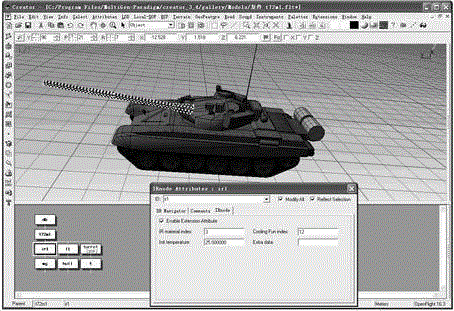

Real-time infrared simulation method based on thermal model

ActiveCN106372268ASimplify the development processSimplify workSpecial data processing applicationsMaterial DescriptionRadiance

The invention discloses a real-time infrared simulation method based on a thermal model. The method comprises the steps that an infrared material library is modeled, wherein a material temperature and an output level value of an infrared imaging system are measured, atmospheric radiation inversion and imaging effect inversion are carried out, and a corresponding relation between intrinsic radiance and the output level value of the infrared imaging system is established; a cooling function of a material is established, so that an infrared material description model of the material can be established; the infrared material library is established through testing and analysis of a series of materials; a storage format of an infrared thermal model is defined, wherein infrared characteristic parameters are stored in a geometric model through expansion of a storage format of the geometric model; and infrared effects are rendered, wherein the infrared characteristic parameters are read in synchronously during reading of the geometric model, thermal transmission effects, natural cooling courses and atmospheric transmission effects are simulated, and color control of the geometric model is achieved by fragment shader programming of GPU, so that verisimilar infrared simulation effects could be achieved finally.

Owner:中国人民解放军92728部队 +1

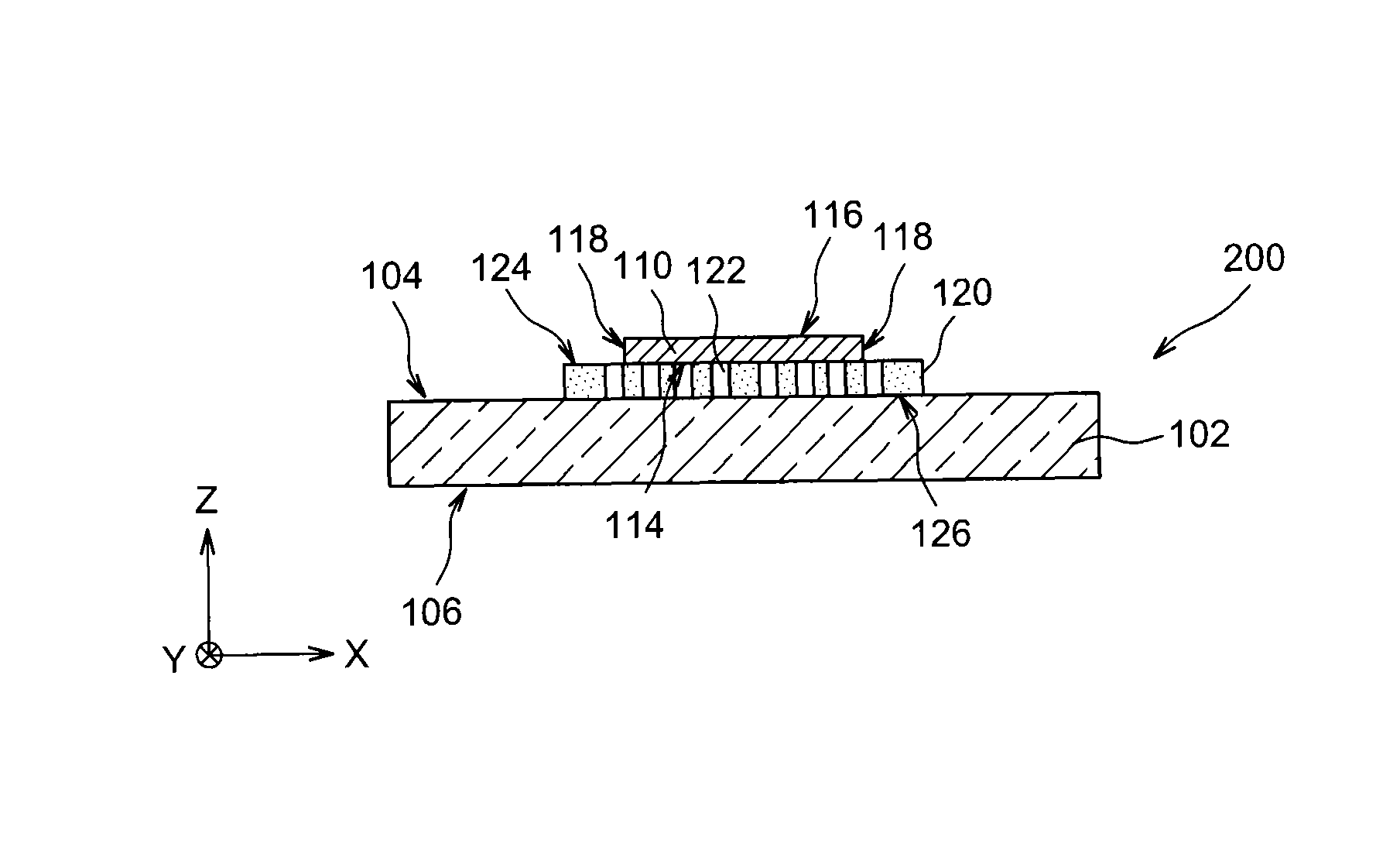

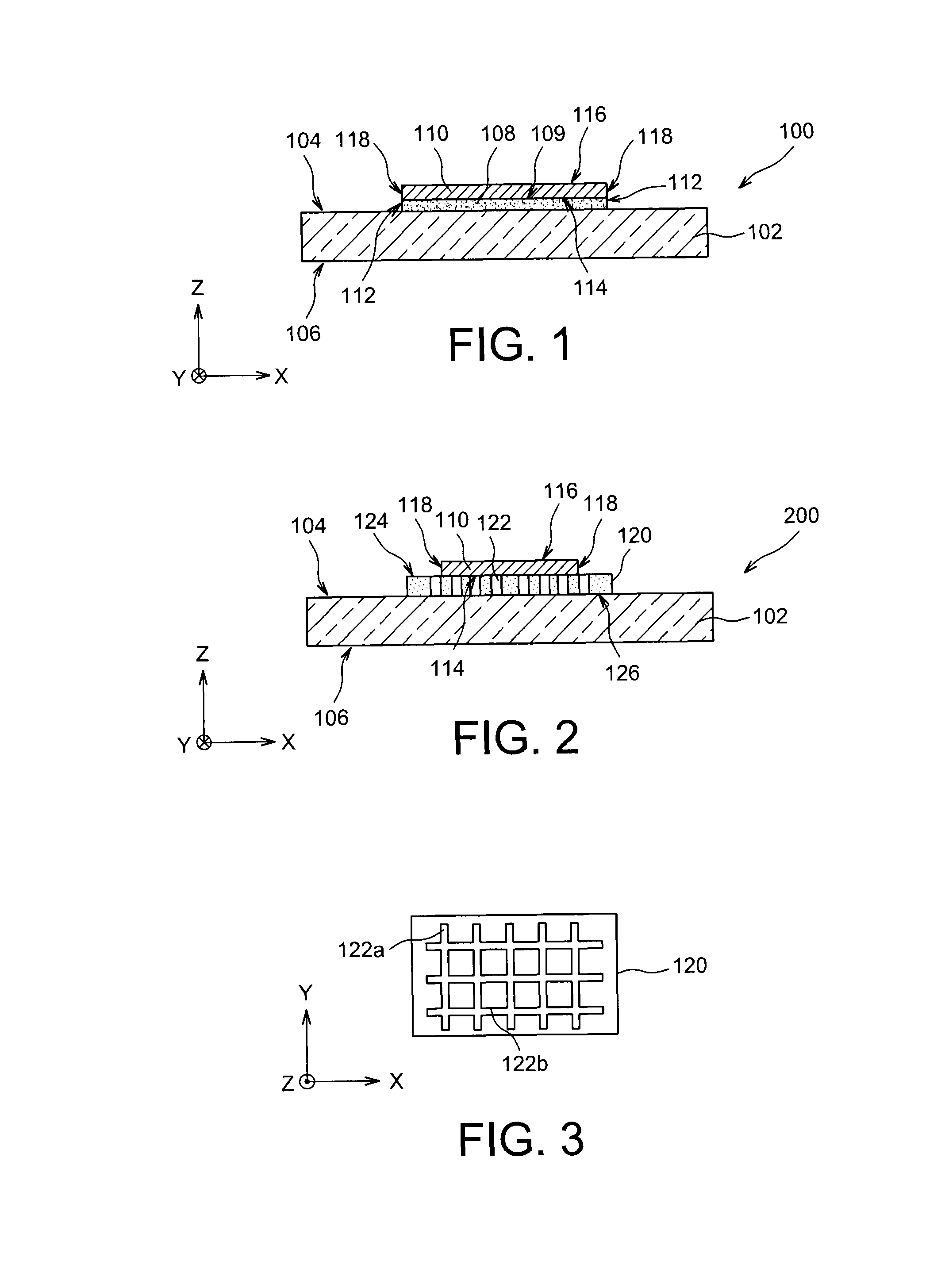

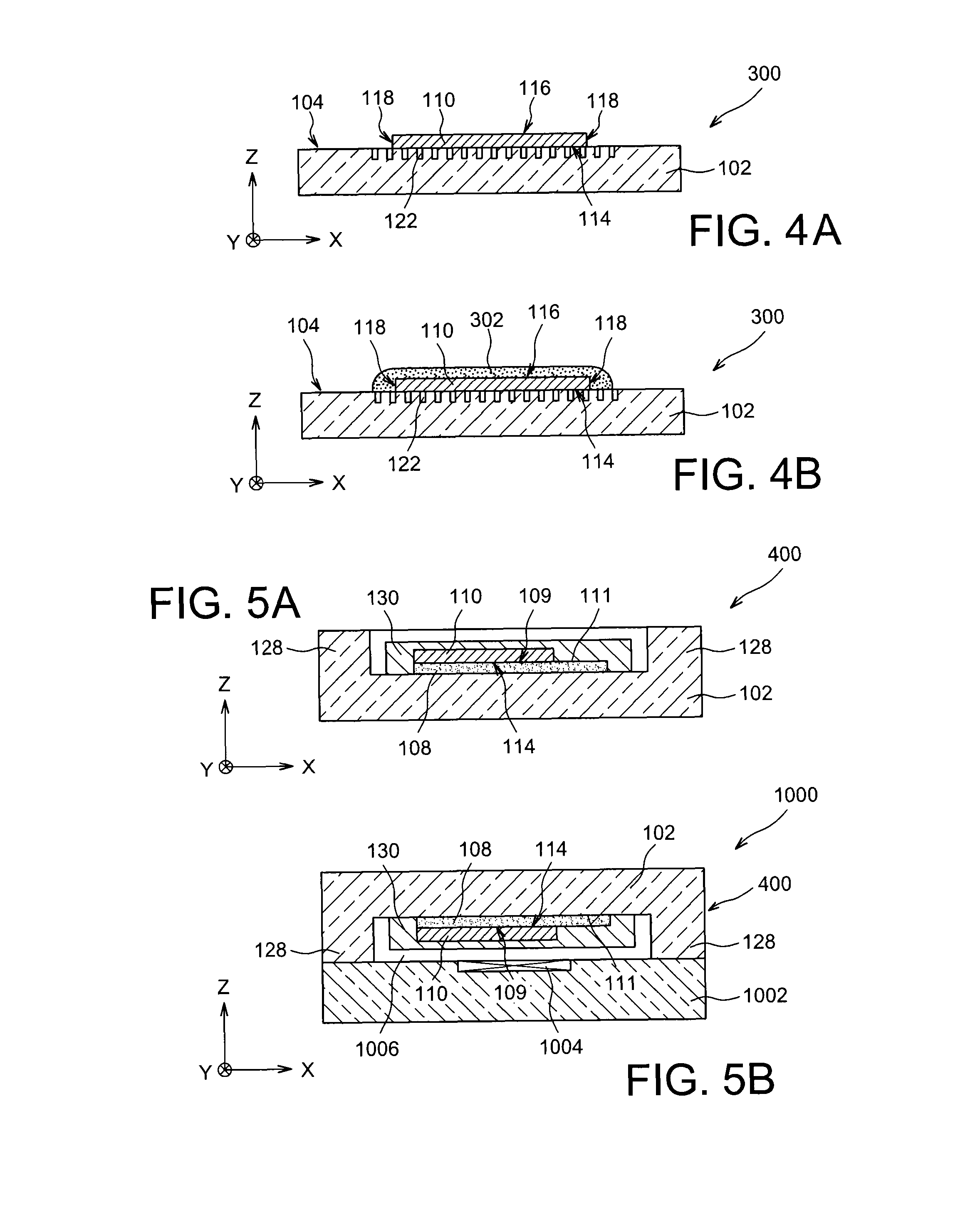

Getter structure including a gas-permeable material description

A getter structure including at least one portion of getter material at least one face of which is positioned against at least one portion of gas-permeable material such that said portion of getter material is able to achieve a gaseous absorption and / or adsorption at least by said face through at least said portion of gas-permeable material, and in which the portion of gas-permeable material includes one or more channels made at the level of a face of said portion of gas-permeable material which is in contact with the portion of getter material, where the portion of getter material is able to achieve a gaseous absorption, or a gaseous adsorption, or both a gaseous absorption and a gaseous adsorption, via the channel or channels.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

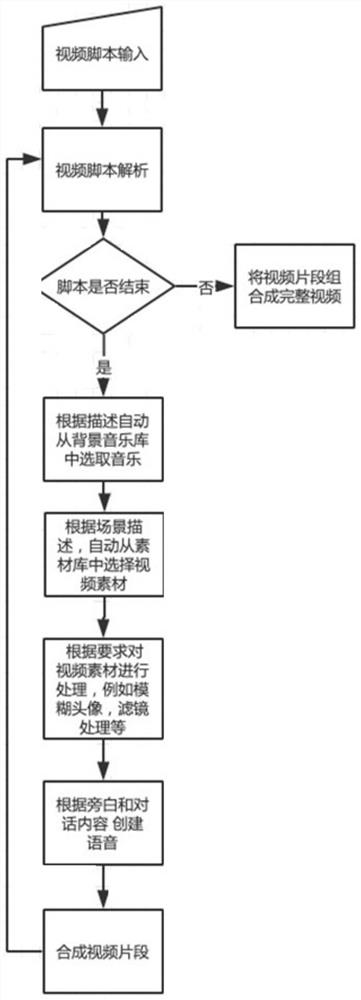

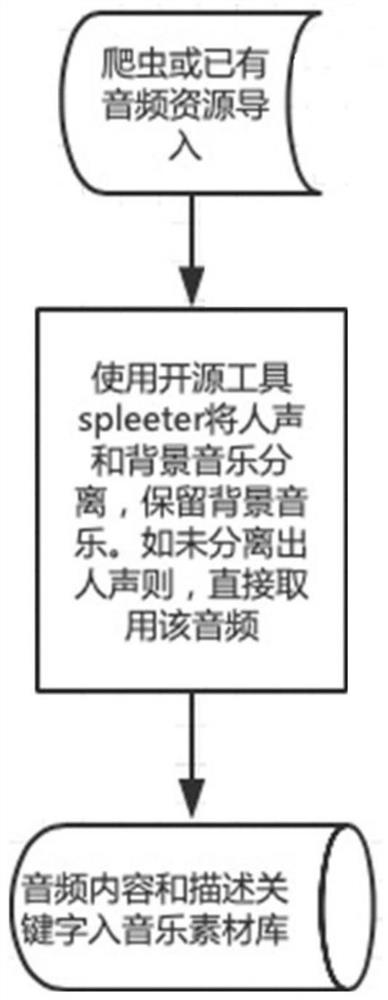

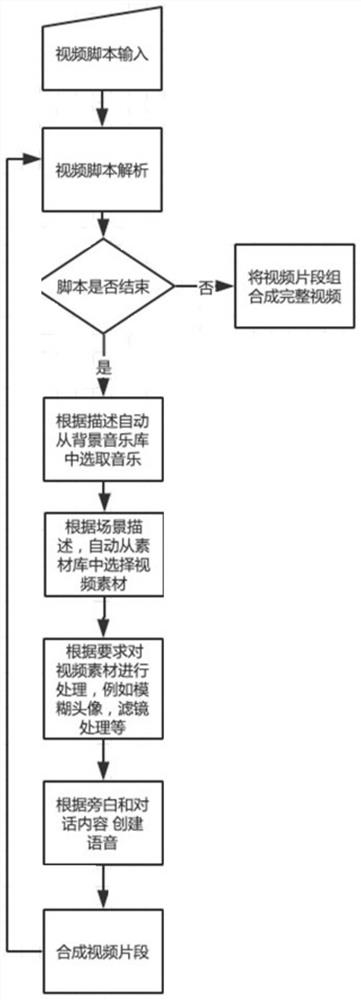

Video production method and device based on video script semantic recognition

ActiveCN112632326AInsightVideo data browsing/visualisationSpecial data processing applicationsMaterial typeMaterial Description

The invention provides a video production method and device based on video script semantic recognition, and the method comprises the steps: obtaining a video production script given by a user, the video production script carrying a plurality of video production statements, and each video production statement comprising a material type recognition label and a material attribute label, wherein the material attribute label comprises a material description and / or a material display form; and determining a material library for material selection according to the material type identification tag, determining materials and / or determining an operation mode of the materials according to the material attribute tag in the material library, and generating videos from the materials according to a sequence of video production statements in the video production script. Through the method or the device, massive video materials can be intelligently analyzed, and the short video is automatically generated by combining the semantic comprehension video script.

Owner:北京风平科技有限公司

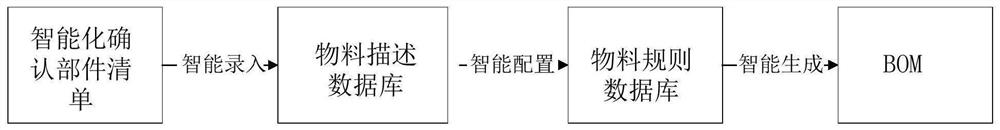

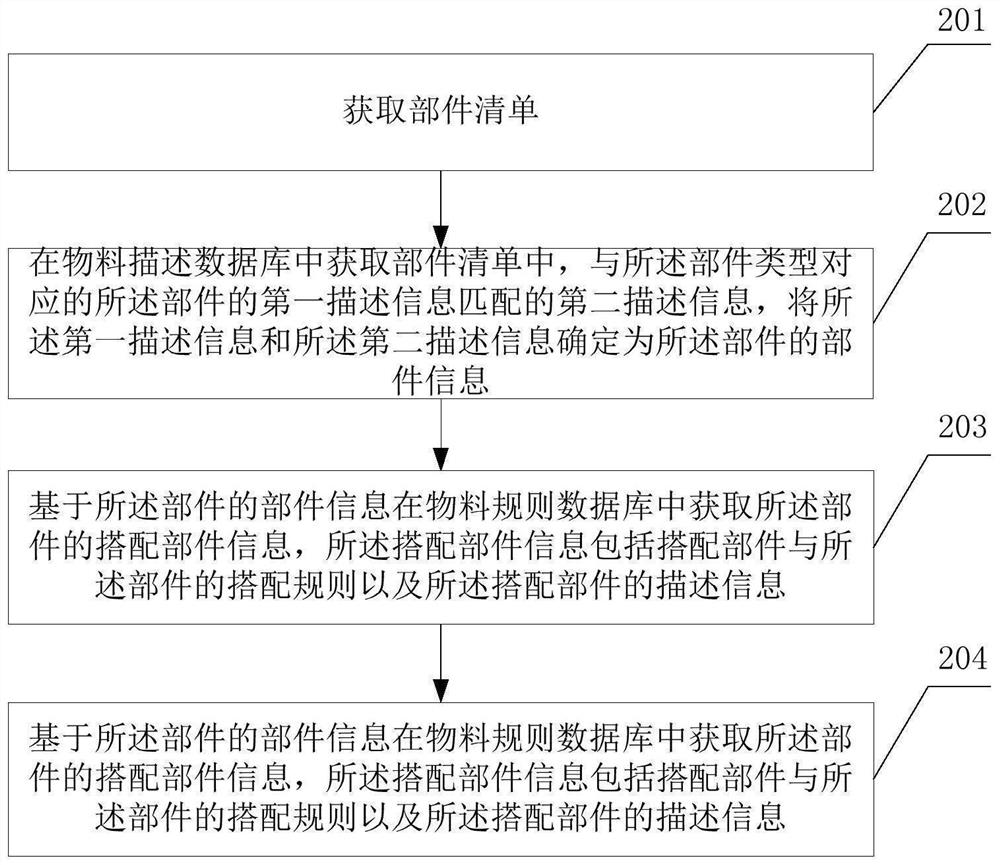

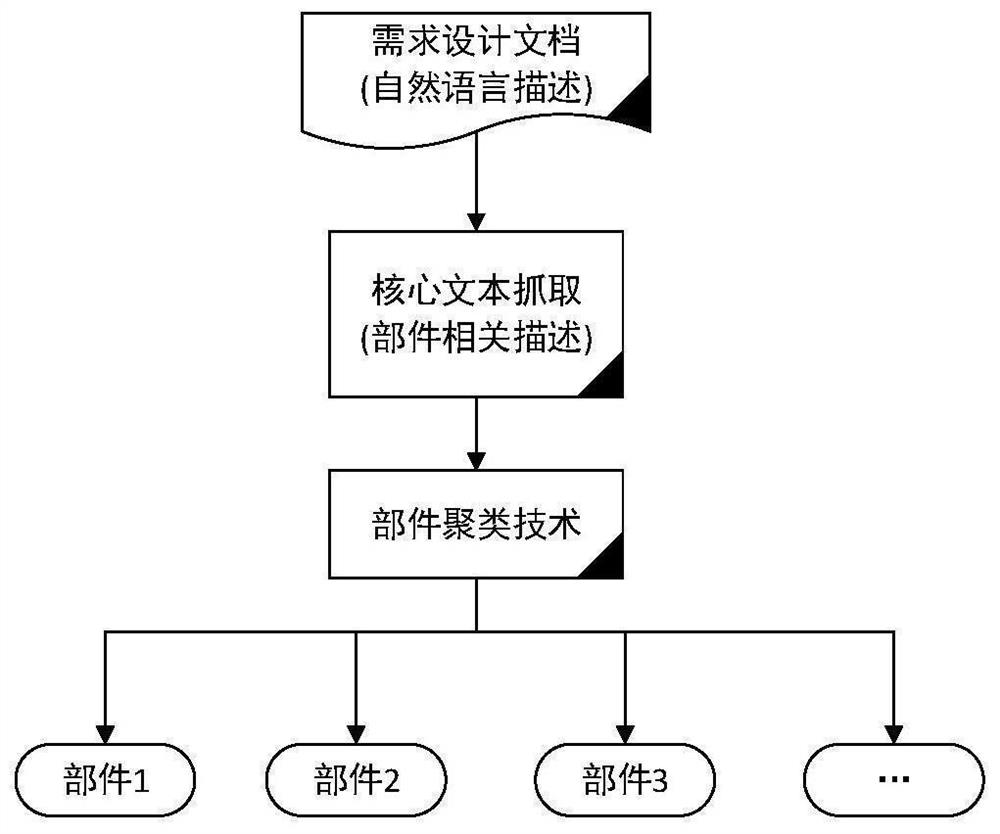

Bill of materials generation method and electronic equipment

PendingCN111611284ARealize automatic generationIntegrity guaranteedDatabase updatingSpecial data processing applicationsMaterial DescriptionBill of materials

The invention provides a bill of materials generation method and electronic equipment, and the method comprises the steps: obtaining a part list which comprises at least one part type, and enabling each part type to correspond to the first description information of at least one part; obtaining second description information, matched with the first description information of the part correspondingto the part type, in the part list from a material description database, and determining the first description information and the second description information as part information of the part; based on the component information of the components, acquiring matching component information of the components in a material rule database, wherein the matching component information comprises matchingrules of the matching components and the components and description information of the matching components; and generating the bill of materials based on the component information of the components and the matching component information. According to the bill of materials generating method, automatic generation of the bill of materials is achieved, and generation integrity of the bill of materialsis guaranteed.

Owner:LENOVO (BEIJING) CO LTD

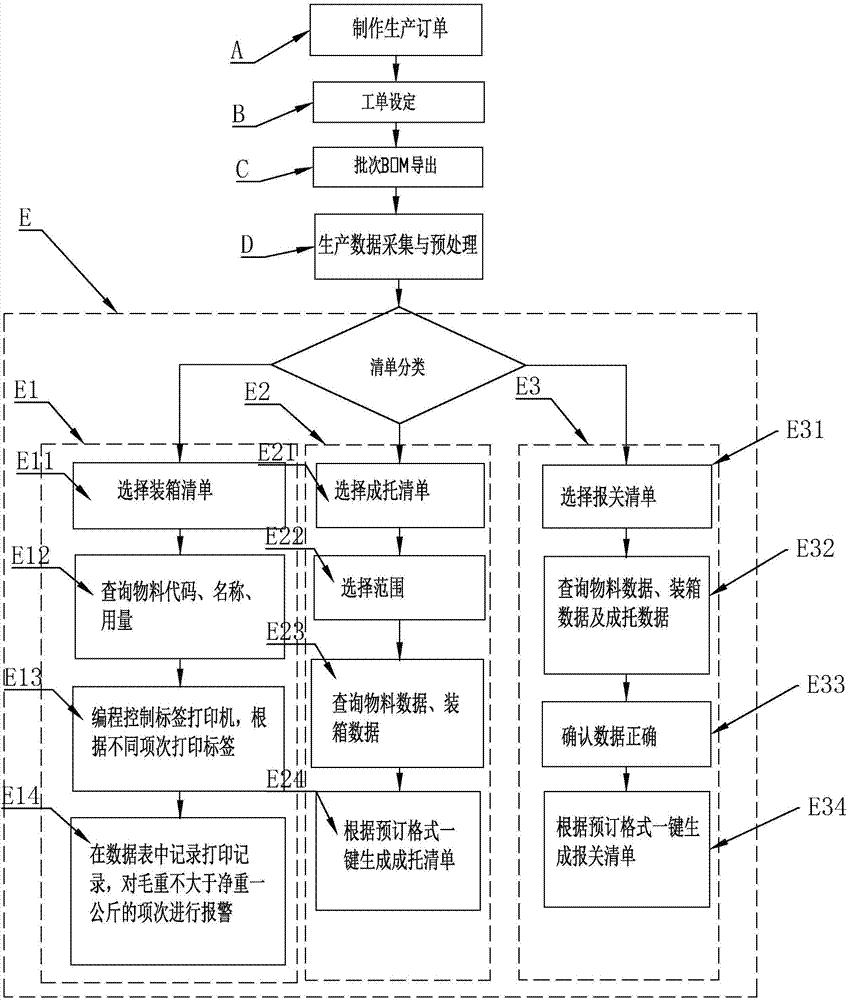

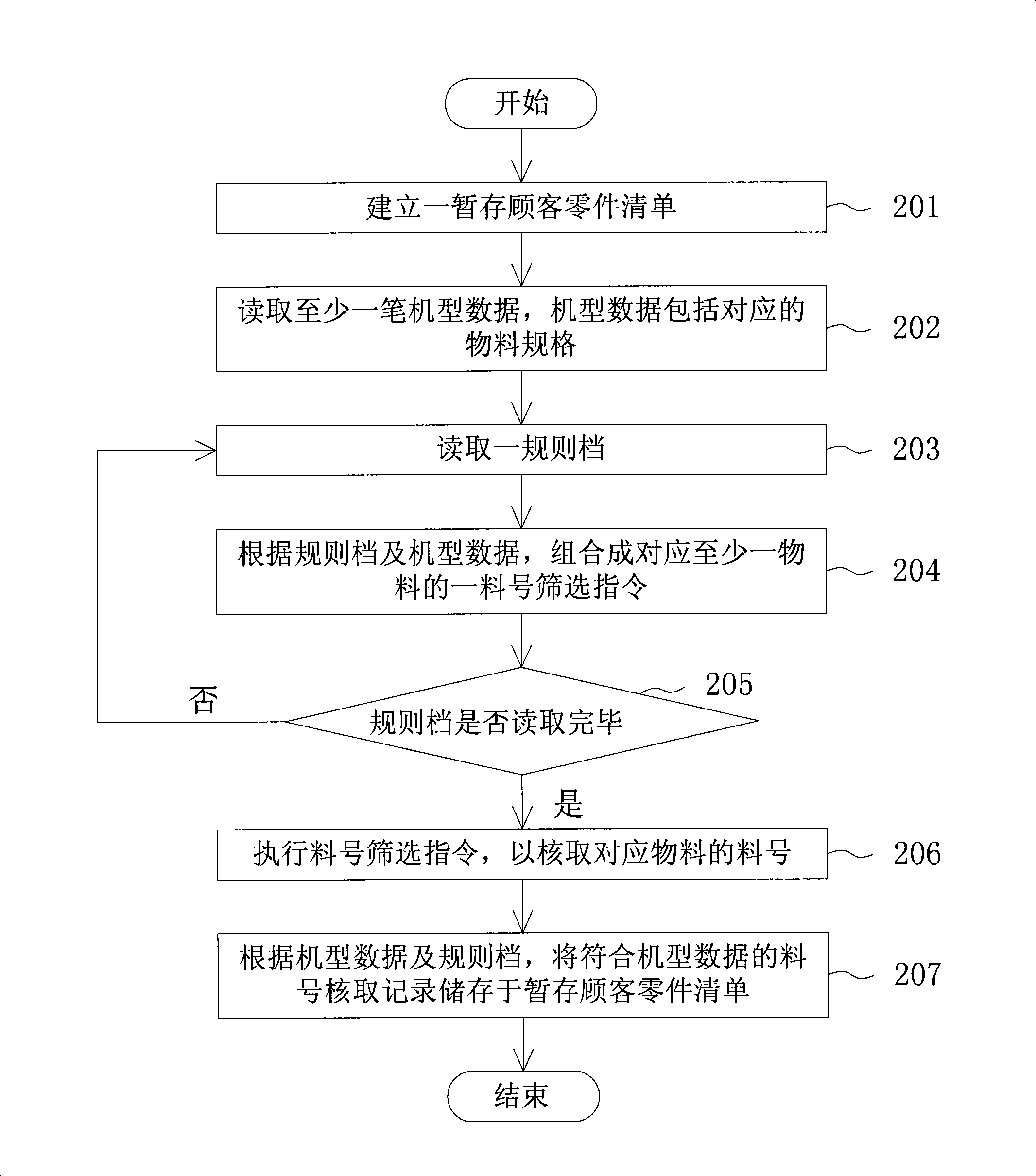

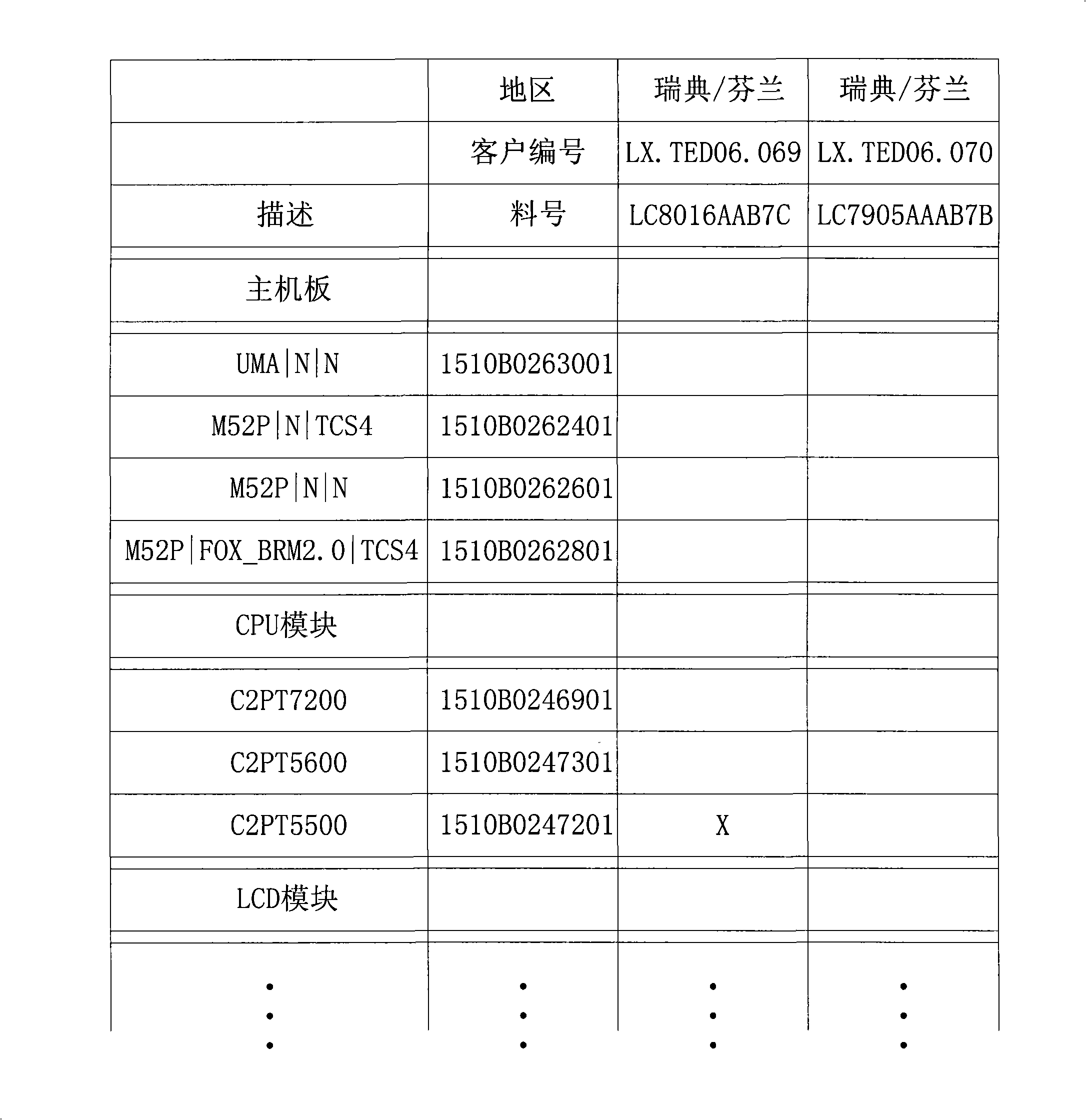

Automatic CKD (completely knock down)/SKD (semi knock down) inventory generation method

InactiveCN103699605AAvoid customer complaintsData processing applicationsSpecial data processing applicationsMaterial DescriptionOriginal data

The invention discloses an automatic CKD (completely knock down) / SKD (semi knock down) inventory generation method which is based on a database of production materials. The database comprises corresponding relations between various materials and material parameters. The method comprises the following steps of A, making a production order; B, setting a work order according to the production order, wherein the work order comprises at least one batch of material inventories; C, leading out all the material inventories comprised in the work order; D, acquiring and preprocessing production data, namely performing sequencing, counting and material description translation on the material inventories; E, determining the types of the material inventories and printing the material inventories. According to the automatic CKD / SKD inventory generation method disclosed by the invention, original data are recorded into a standard database; due to computer programming application, the relevant data are respectively called; a label printer is driven to generate different labels or all versions of inventories through sequencing, counting and material description translation according to conditions as well as according to requirements on different items, and the printing operation can be finished by one click; therefore, the phenomenon of customer complaints caused by low efficiency and mis-operation of manual modification is avoided.

Owner:GUANGDONG CHANGHONG ELECTRONICS

Method for manufacturing of optoelectronic devices based on thin-film, intermediate-band materials description

InactiveUS20110143475A1Final product manufactureSemiconductor/solid-state device manufacturingMaterial DescriptionSecondary stage

Method for manufacturing of optoelectronic devices based on thin-film, intermediate band materials, characterized in that it comprises, at least, the following steps:a first stage wherein a substrate (1) is coated with a metal layer acting as electrode (2);a second stage, whereby atop the metal layer (2) a p-type semiconductor (3) is deposited; anda third stage, whereby the intermediate band material is processed;and wherein such an intermediate band material comprises nanoscopic structures (4) of multinary material of the type (Cu,Ag)(Al,Ga,In)(S,Se,Te)2 embedded in a matrix (5) of a similar composition, except for the absence of, at least, one cationic species present in the nanostructure.

Owner:UNIV MADRID POLITECNICA

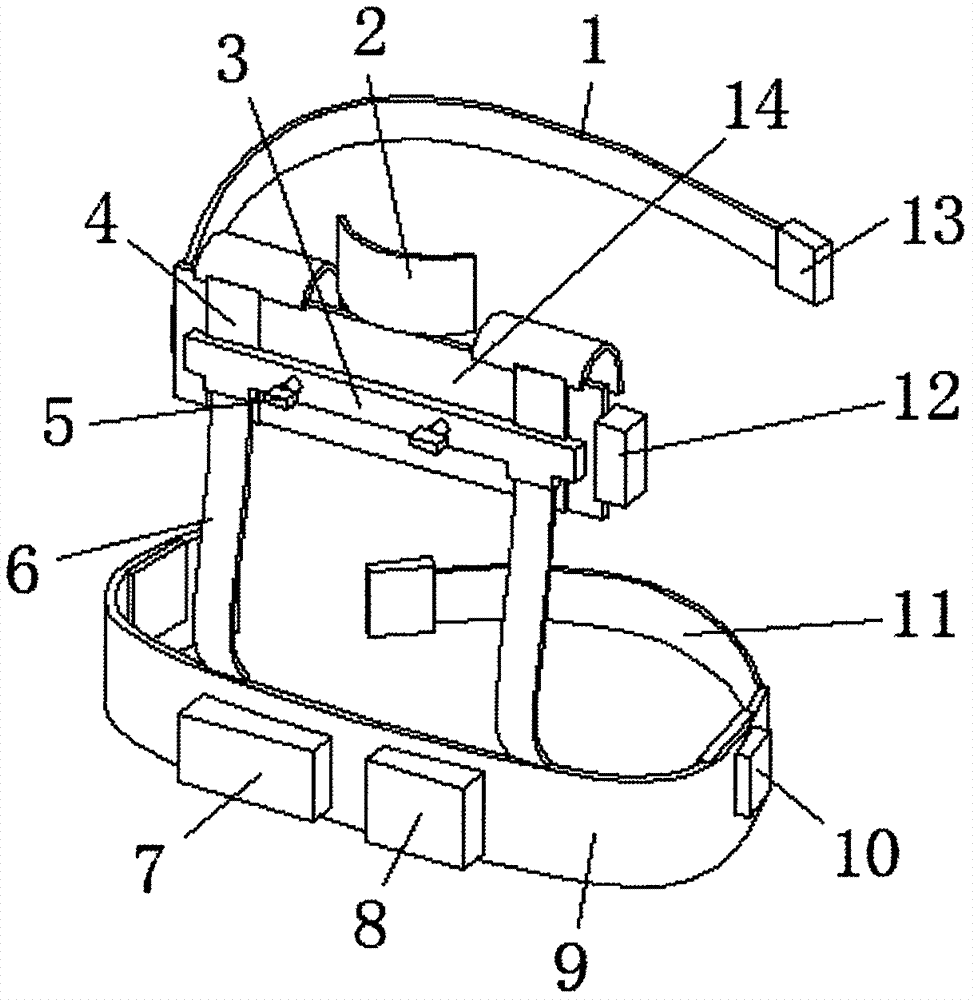

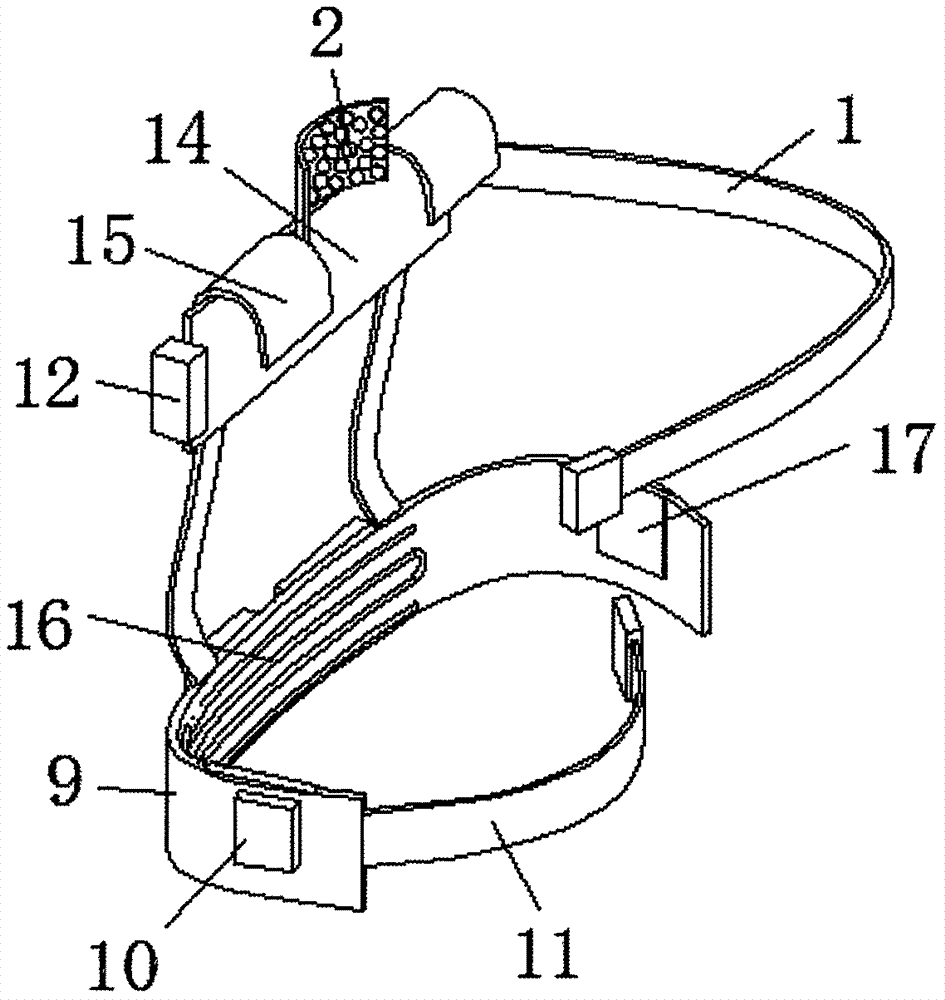

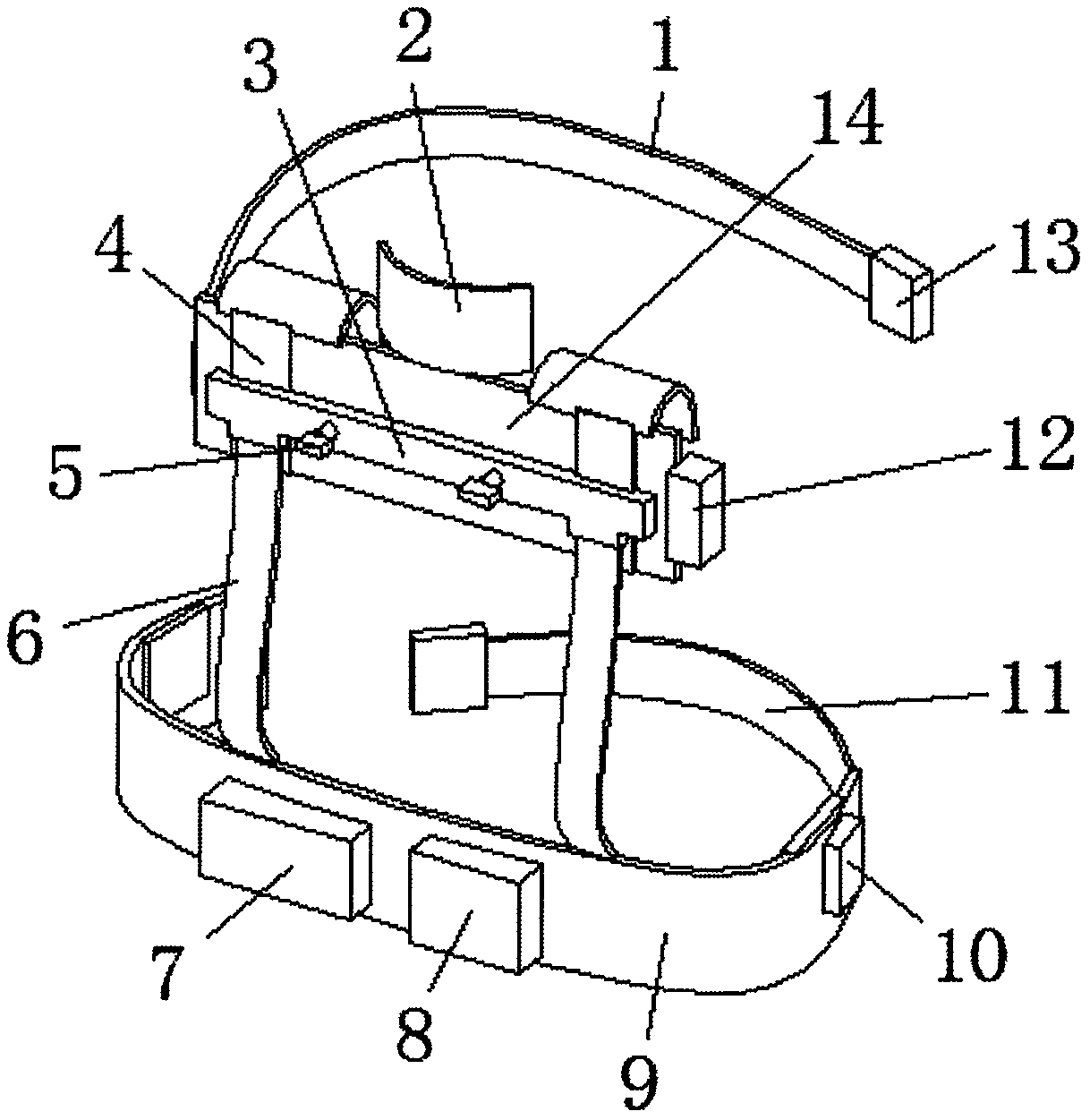

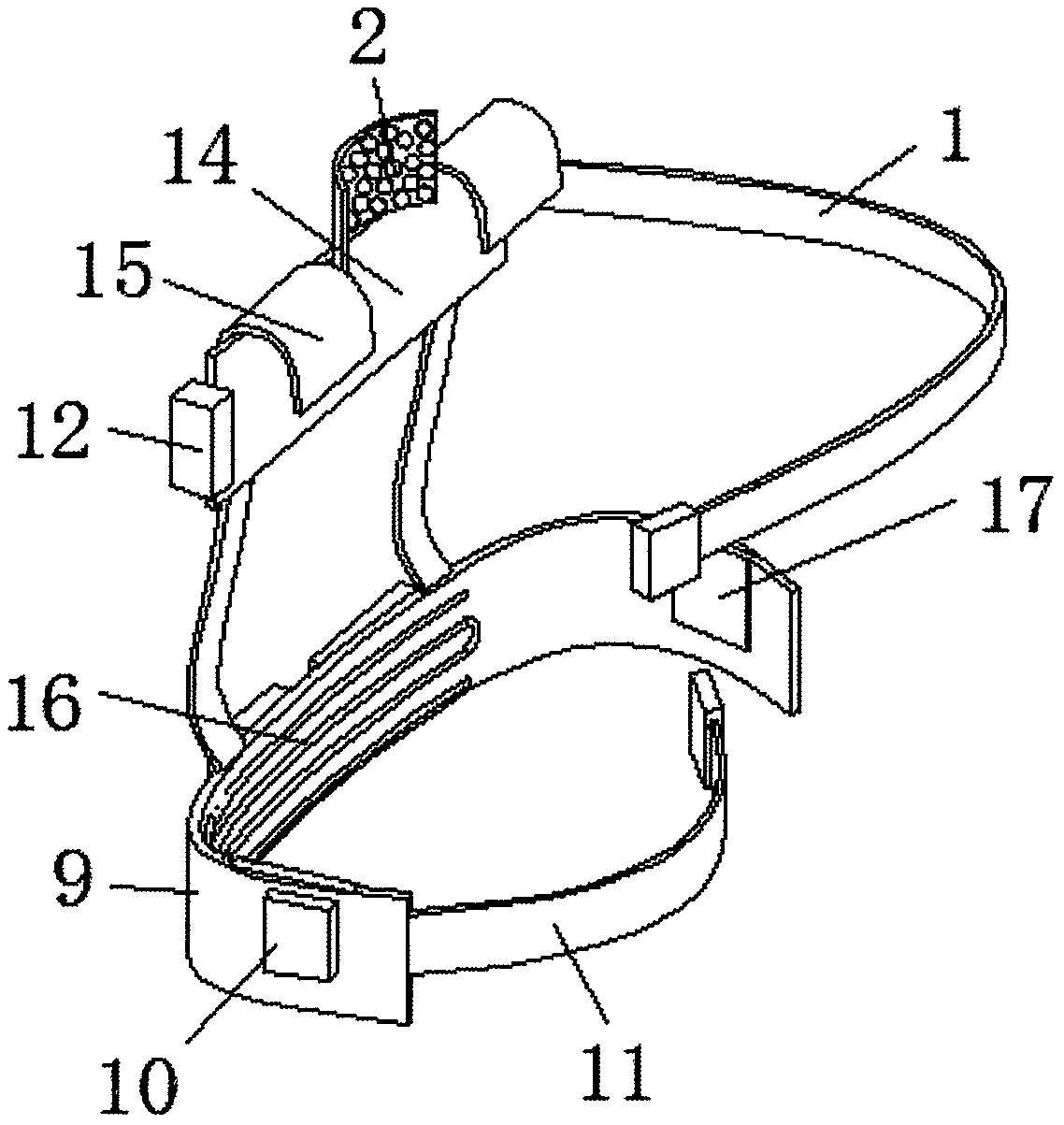

Neck, shoulder and waist personal protecting tool for oilfield well repairing workers

ActiveCN107173875AAvoid injuryAvoid coldDevices for heating/cooling reflex pointsMagnetotherapy using coils/electromagnetsMaterial DescriptionEngineering

The invention discloses a neck, shoulder and waist personal protecting tool for oilfield well repairing workers. The tool comprises a support plate, wherein a neck protecting plate is arranged at the center of the upper end of the support plate; a shoulder protecting plate is welded at the upper end of one side of the support plate; two sliding tracks are arranged at the other side of the support plate; and a sliding connection plate is in sliding connection on the sliding tracks. Necks of the workers can be protected through the neck protecting plate; waists of the workers can be protected through a waist protecting belt; the waists of the workers can be heated through heating wires; and magnetic therapy is carried out on the waists of the workers through electromagnetic release plates so as to promote the blood circulation of the waists. The neck, shoulder and waist personal protecting tool for the oilfield well repairing workers has the characteristics of being safe, portable, comfortable, convenient and the like, and is capable of effectively protecting the necks, shoulders and waists of the workers during the well repairing operation; the characteristics of being portable and comfortable are not realized through simple material descriptions but realized through simple structure and wearing convenience; and aiming at the problem that heating is not needed in summer, the tool is provided with a switch for controlling electromagnetic release, and heating can be controlled as needed.

Owner:山东省职业卫生与职业病防治研究院

State set based shader three-dimensional graph drawing frame and drawing method

InactiveCN100388318CImprove integrityImprove acceleration performance3D-image renderingDynamical optimizationMaterial Description

The present invention uniformly package and descript the drawing object model information, texture information, voice message relevant Shader code in Materials Description file before tuning in scene chart, and tuning in shown off object through Material Loader and Media Loader in scene chart data store organization, also according to Shader information sorting and to proceed static and dynamic optimization, then using optimized drawing status information loading to engine to proceed drawing, drawing engine consisting of drawing control and state control, both combined to complete one drawing object drawing process. The present invention makes effective management to Vertex Shader and Pixel Shader, fully utilizing state package and sorting function, simplifying interface calling.

Owner:BEIHANG UNIV

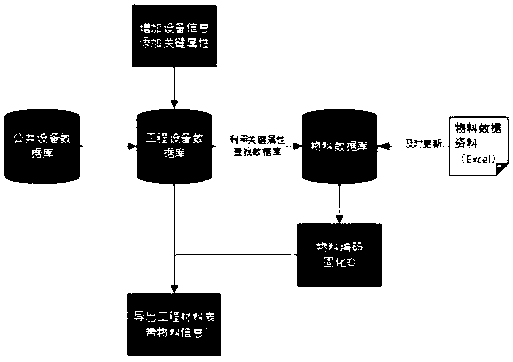

Transformer substation equipment material summary sheet making method based on three-dimensional design software

PendingCN110096687AHigh degree of automationAvoid mistakesData processing applicationsDatabase management systemsRelevant informationMaterial Description

The invention relates to a transformer substation equipment material summary sheet making method based on three-dimensional design software, which comprises the following steps: 1) constructing a material data collecting material data, defining the meaning of each piece of information, and importing and updating the data; 2) defining key fields of the engineering equipment data adding key fields for defining corresponding equipment in the engineering equipment database in the power transformation three-dimensional design software in the material database; step 3) searching material data; step 4) making an equipment material summary sheet: after the equipment in the engineering equipment library is used in engineering, recording relevant information of the equipment by the platform, finally exporting the equipment material summary sheet, and displaying the material code, the solidification ID and the complete material description of the equipment by the material sheet according to a result of searching the material data. The method has the beneficial effects that the advantages of three-dimensional design software are fully utilized, the automation degree is high, errors and omissions possibly caused by manual judgment in a conventional design mode are avoided, and the design efficiency and the design quality are effectively improved.

Owner:STATE GRID JIANGSU ECONOMIC RES INST +3

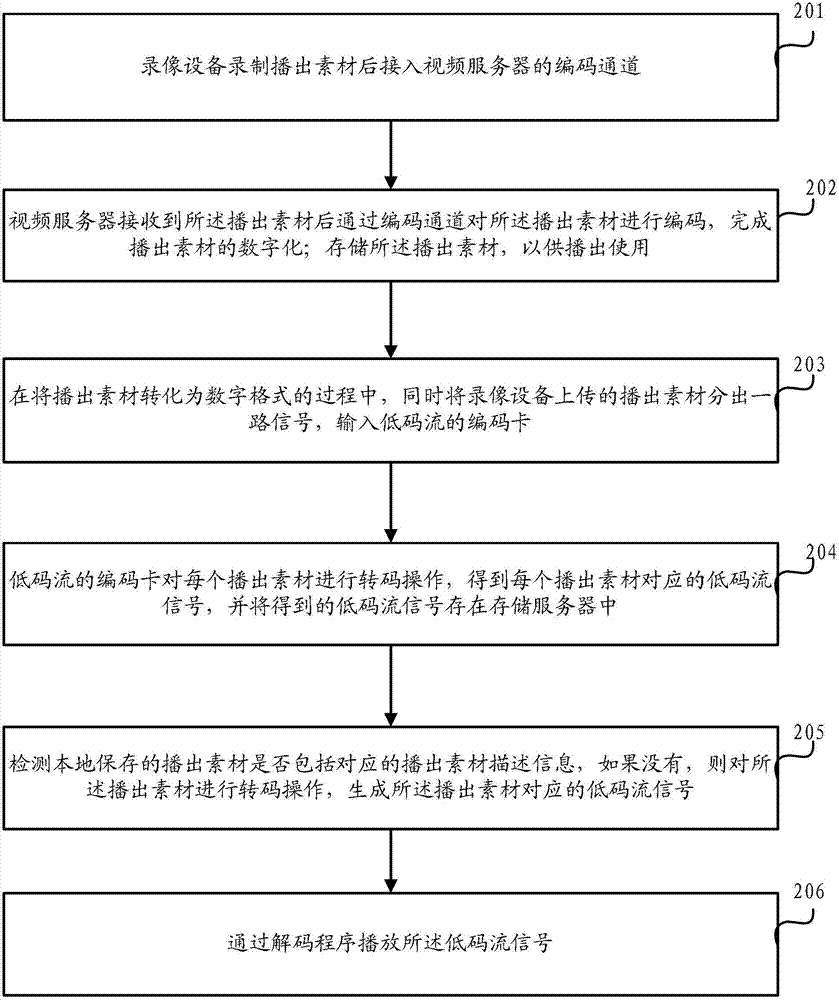

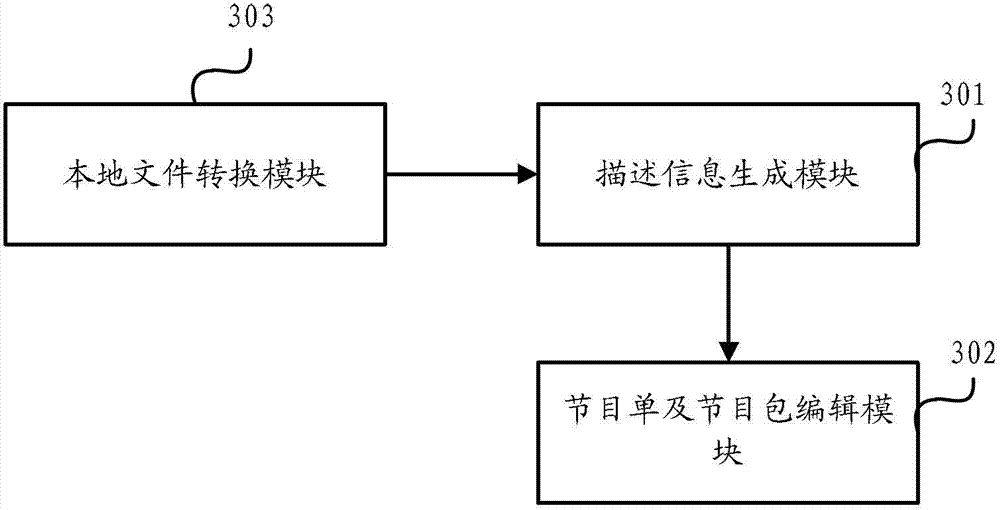

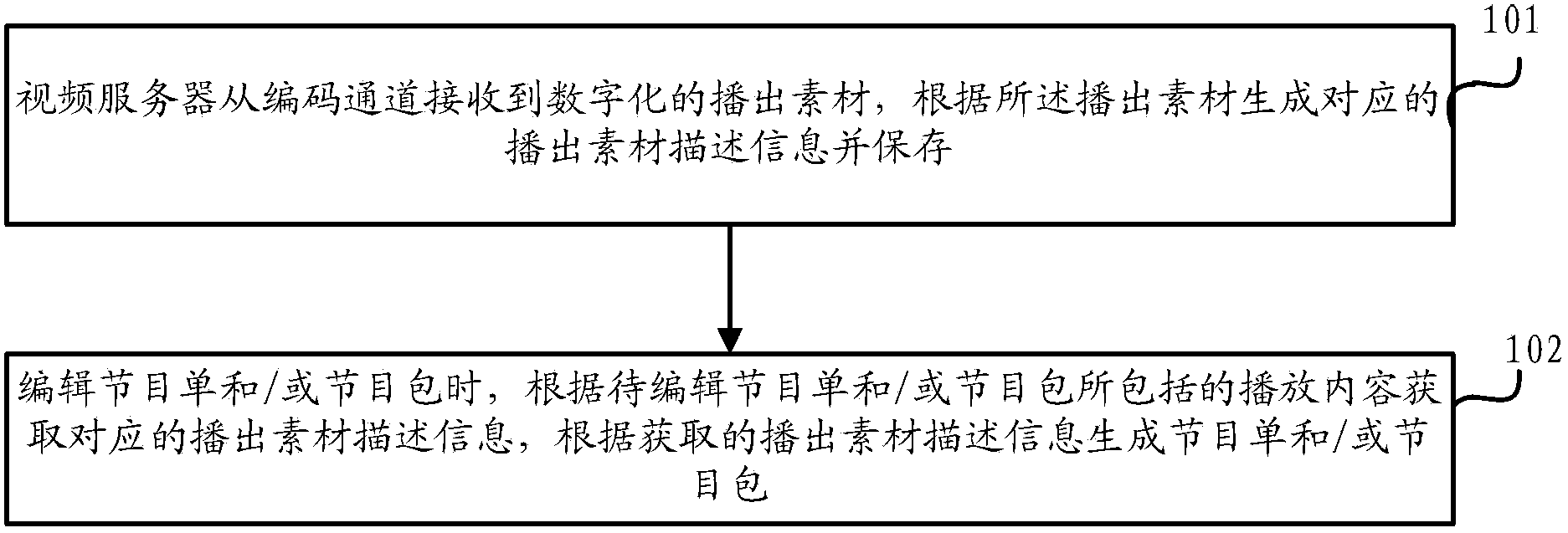

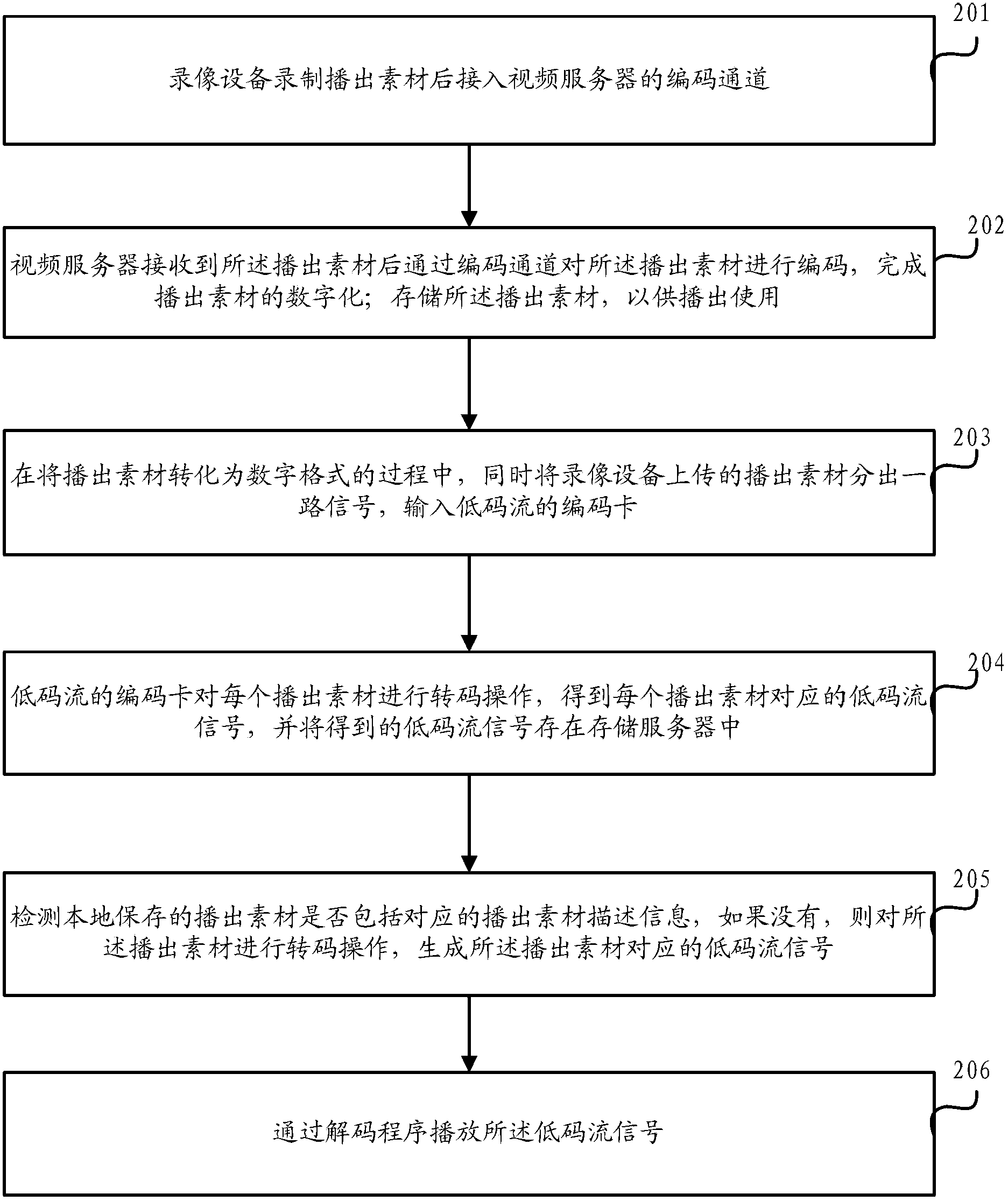

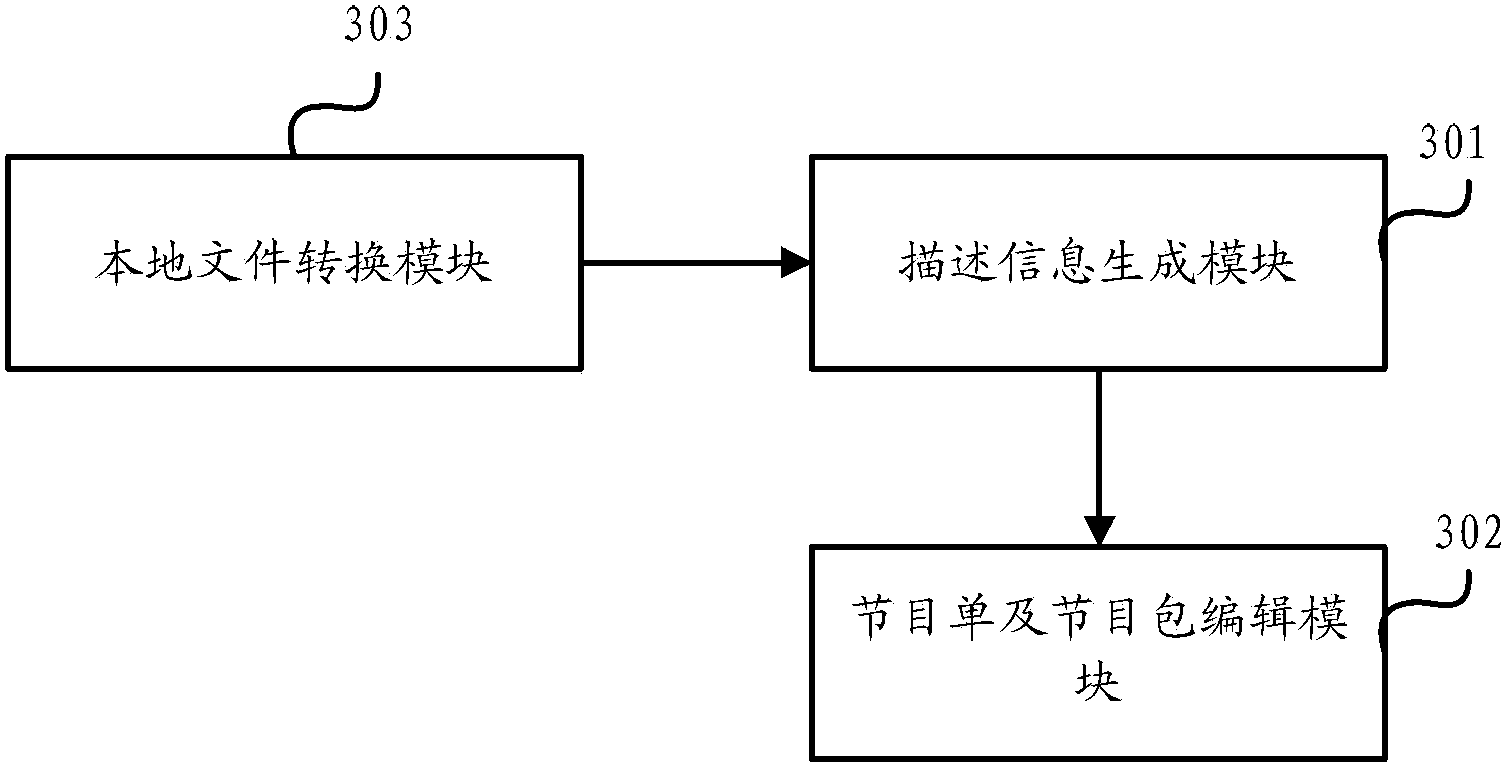

Method and device for generating audio and video program list and program package

InactiveCN103475903BReduce waste of resourcesReduce wasteSelective content distributionMaterial DescriptionDigitization

The present invention discloses a audio and video program and the generation method and device of the program package. This method includes: the video server receives digital broadcast materials from the encoding channel, and the corresponding broadcast material description information is generated according to the broadcast material generated by the broadcast material and the corresponding broadcast material is described and information is described and information is described and information is described and information is described and the information is generated.Save; when editing program lists and / or program packages, the corresponding broadcast material description information is obtained according to the content of the program list and / or the show package, and the program list and / or / or / or / or or / or or / or or / or / or or / or / or or / or / or or / or / or or / or / or / or available broadcast materials are available.Program package.The accuracy of the program list and / or program packaging has been added, and the waste of resource resources is reduced.

Owner:CHINA DIGITAL VIDEO BEIJING

A video production method and device based on video script semantic recognition

ActiveCN112632326BInsightVideo data browsing/visualisationSpecial data processing applicationsMaterial typeMaterial Description

The present application provides a video production method and device based on semantic recognition of video scripts. The method includes obtaining a video production script given by the user. The video production script carries a plurality of video production sentences, and each video production sentence Including a material type identification tag and a material attribute tag, the material attribute tag includes a material description and / or a material display form; the material library for material selection is determined according to the material type identification tag, and in the material library, according to the The material attribute tag determines the material and / or determines the operation mode of the material, and generates a video from the material according to the order of the video production statements in the video production script. Through the above method or device, the present application can intelligently analyze massive video materials, combine semantic understanding of video scripts, and automatically generate short videos.

Owner:北京风平科技有限公司

Inhomogeneous geometric variational nodal method for reactor neutron diffusion equation

ActiveCN107145657BUniform description abilityThe description is validDesign optimisation/simulationSpecial data processing applicationsMaterial DescriptionNuclear reactor

The invention discloses a non-uniform geometrical variational nodal method aiming at a reactor neutron diffusion equation. The method comprises the following steps: 1, establishing a functional containing a neutron conservation relationship inside the nodal block and flow continuity conditions on the nodal surface; 2, performing nodal discrete disposal by utilizing a finite element shape function in the x-y direction and a chip constant polynomial, and realizing non-uniform nodal geometrical and material description functions; 3, deducing to obtain a response matrix equation; and 4, solving the response matrix equation by utilizing a red-black scanning manner, and finally obtaining the neutron-flux density distribution in the whole non-uniform solving area. According to the method disclosed by the invention, the non-uniform lattice-cell structure of a nuclear reactor can be finely described; and according to the method, the nodal internal fine geometrical structure is processed based on the variational nodal method by adopting an isoparametric finite element, and then the non-uniform geometrical neutron diffusion equation is solved.

Owner:XI AN JIAOTONG UNIV

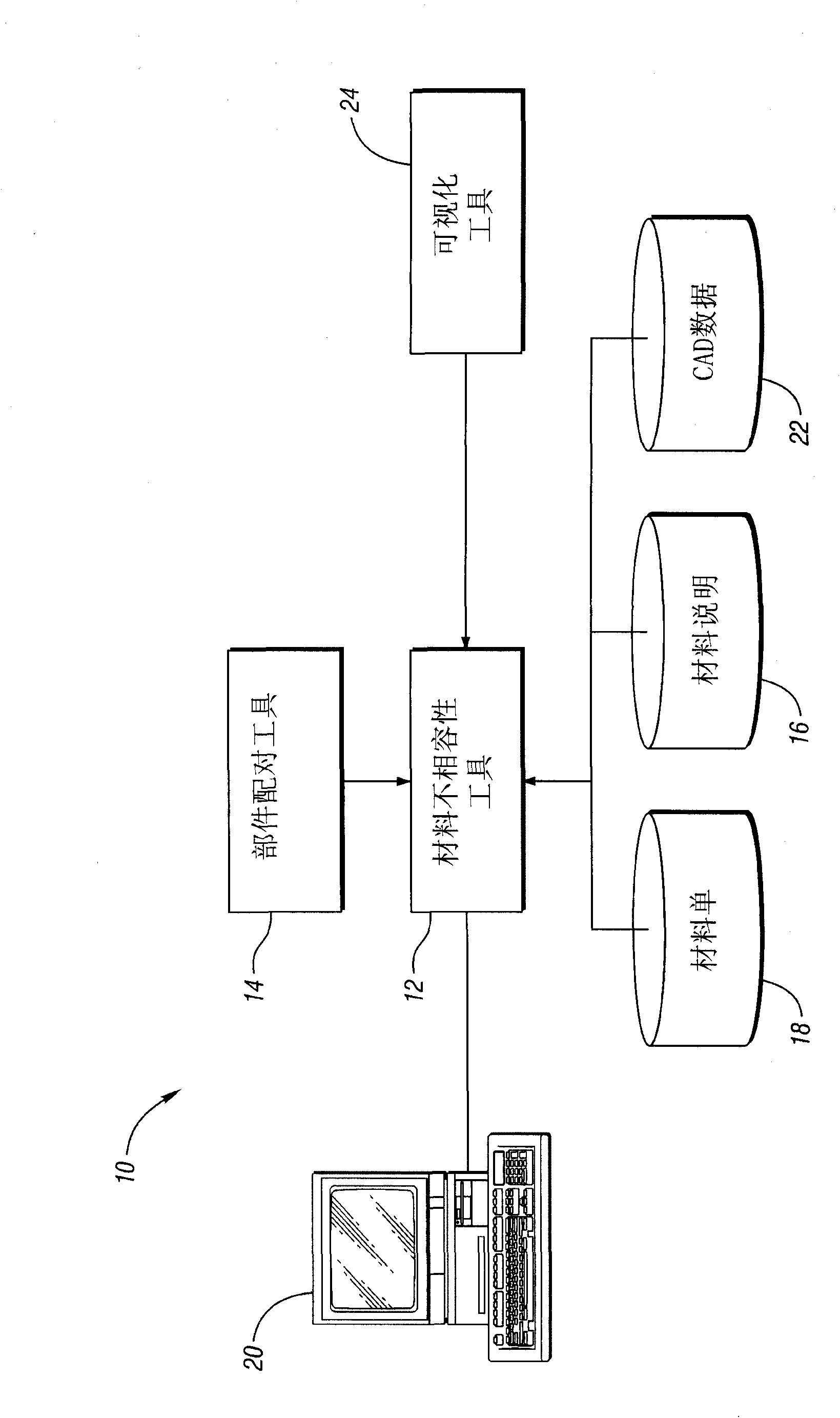

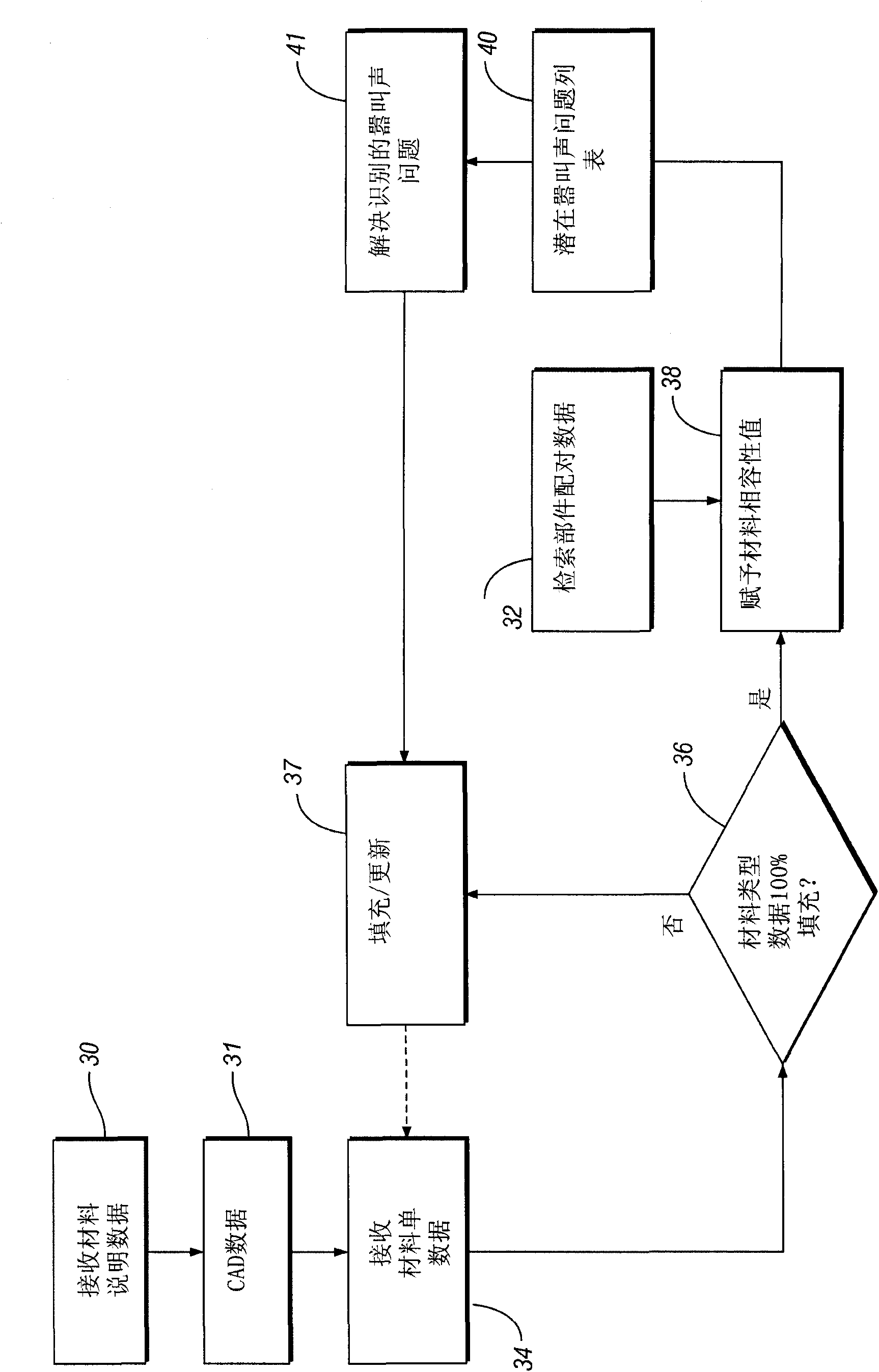

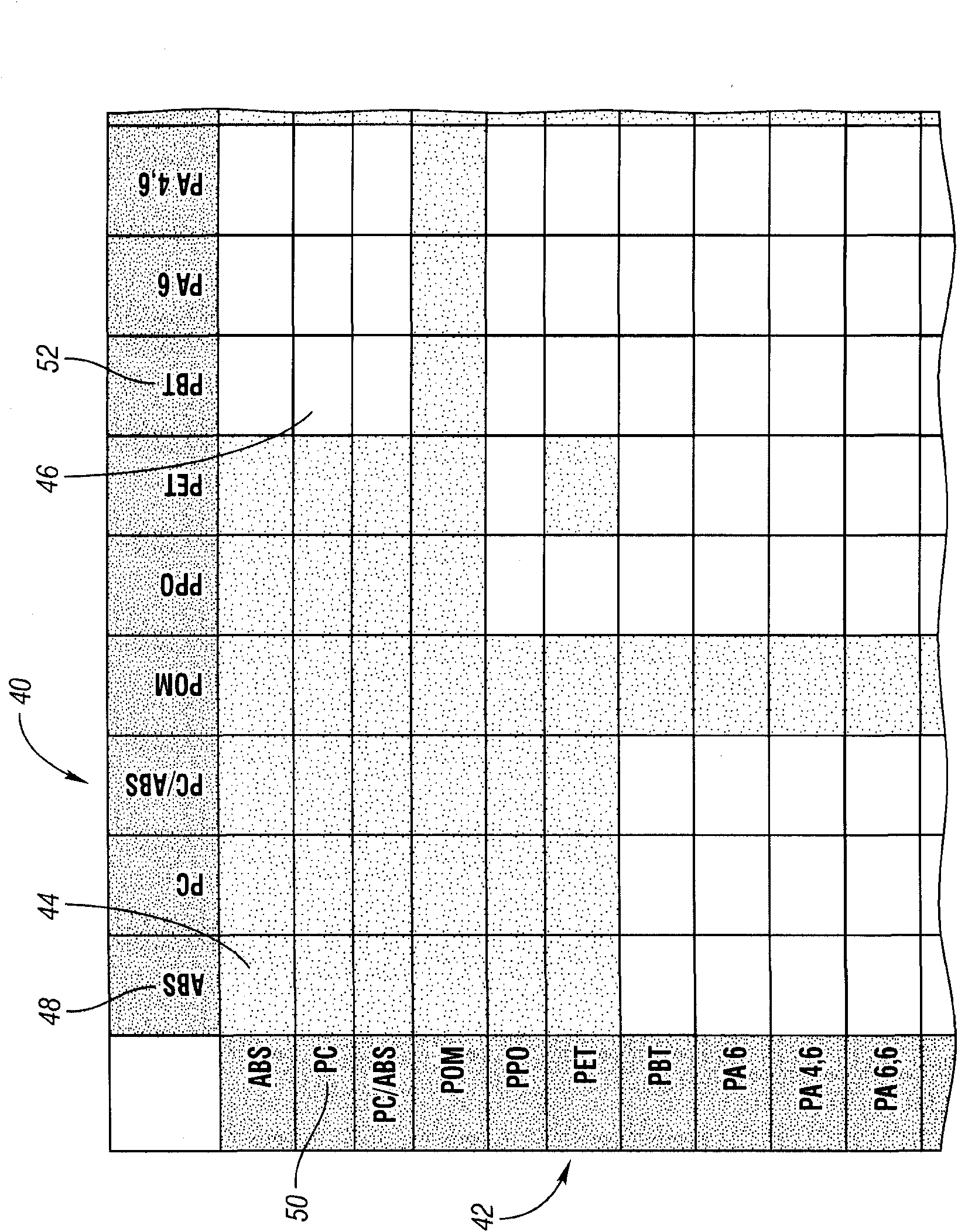

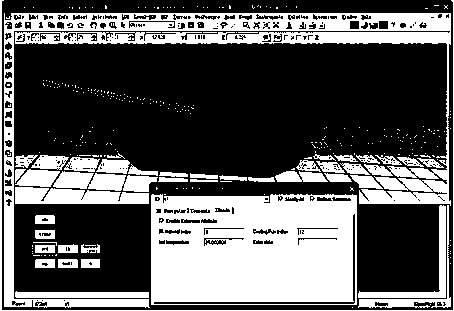

Computer-implemented squeak detection method and system

InactiveCN101839808AVehicle testingSubsonic/sonic/ultrasonic wave measurementMaterial DescriptionComputer science

The present invention discloses a computer-implemented systerm for identifying potential squeak concerns between a pair of vehicle components. The computer implemented system comprises at least one computer, which is used for receiving CAD data, identifying a plurality of vehicle component pairs within a predetermined tolerance of each other, assigning a material description and material compatibility value to each of the pairs in each of the number of vehicle component pairs, and outputting the material compatibility values for each of the vehicle component pairs for use in identifying squeak concerns. Therefore, the system disclosed by the invention can at a minimum provide for less or no noise in the final product and, accordingly, reduce the customer dissatisfaction associated with vehicle use due to these persistent noises generated by their vehicle.

Owner:FORD GLOBAL TECH LLC

Real-time infrared simulation method based on thermal model

ActiveCN106372268BSimplify the development processSimplify workSpecial data processing applicationsMaterial DescriptionRadiance

The invention discloses a real-time infrared simulation method based on a thermal model. The method comprises the steps that an infrared material library is modeled, wherein a material temperature and an output level value of an infrared imaging system are measured, atmospheric radiation inversion and imaging effect inversion are carried out, and a corresponding relation between intrinsic radiance and the output level value of the infrared imaging system is established; a cooling function of a material is established, so that an infrared material description model of the material can be established; the infrared material library is established through testing and analysis of a series of materials; a storage format of an infrared thermal model is defined, wherein infrared characteristic parameters are stored in a geometric model through expansion of a storage format of the geometric model; and infrared effects are rendered, wherein the infrared characteristic parameters are read in synchronously during reading of the geometric model, thermal transmission effects, natural cooling courses and atmospheric transmission effects are simulated, and color control of the geometric model is achieved by fragment shader programming of GPU, so that verisimilar infrared simulation effects could be achieved finally.

Owner:中国人民解放军92728部队 +1

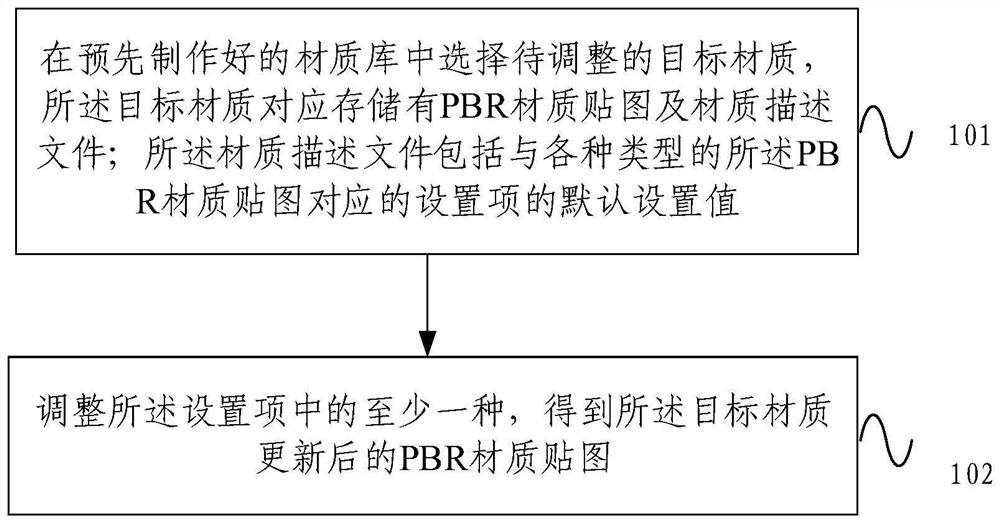

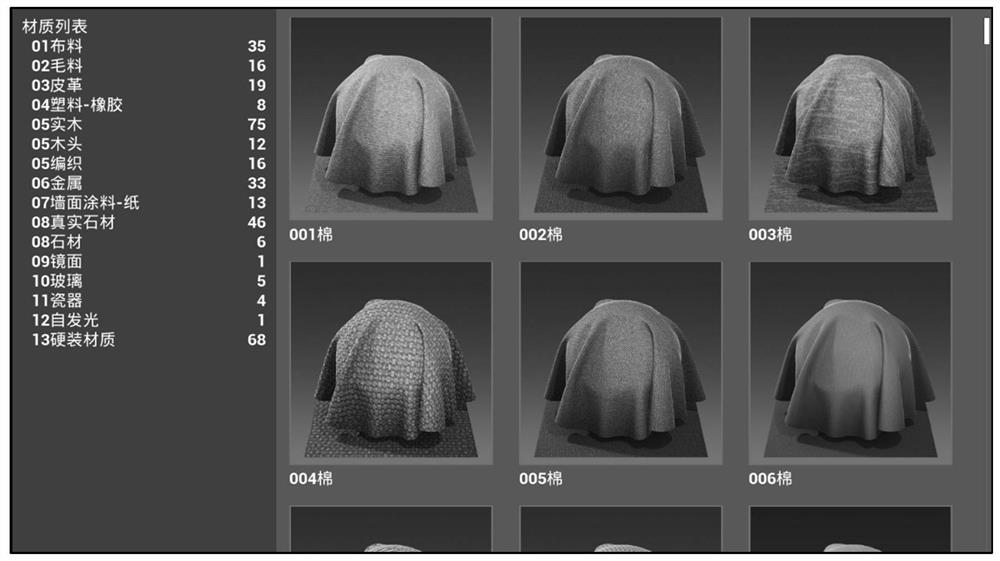

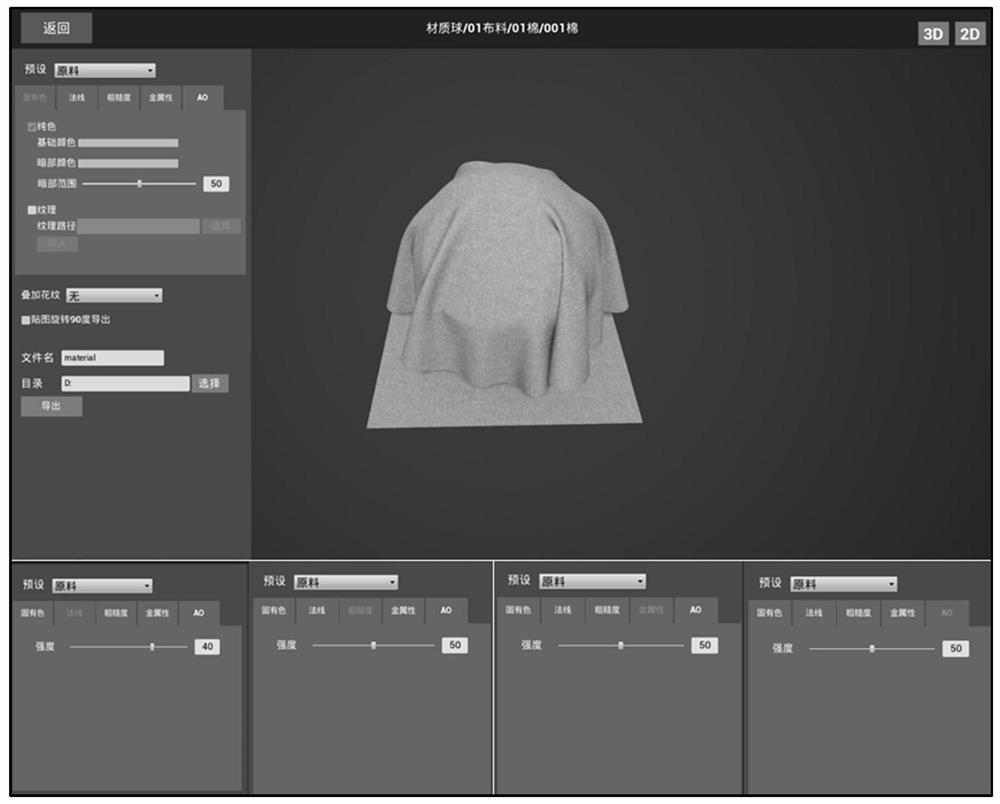

PBR material map generation method and device

ActiveCN112562053APromote generationQuick buildImage renderingFilling planer surface with attributesMaterial DescriptionManufactured material

The embodiment of the invention provides a PBR material map generation method and device, and the method comprises the steps: selecting a to-be-adjusted target material from a pre-manufactured material library, wherein the target material correspondingly stores a PBR material map and a material description file, and the material description file comprises default setting values of setting items corresponding to the various types of PBR material maps; and adjusting at least one of the setting items to obtain a PBR material map after the target material is updated. According to the embodiment ofthe invention, a set of PBR material map library commonly used for current modeling is designed in advance, a set of high-quality PBR maps can be generated through simple interface click operation, maps in the material map library can be conveniently modified and subjected to detail adjustment, operation can be performed without professional knowledge, and the PBR material map can be generated quickly, efficiently and conveniently.

Owner:BEIKE TECH CO LTD

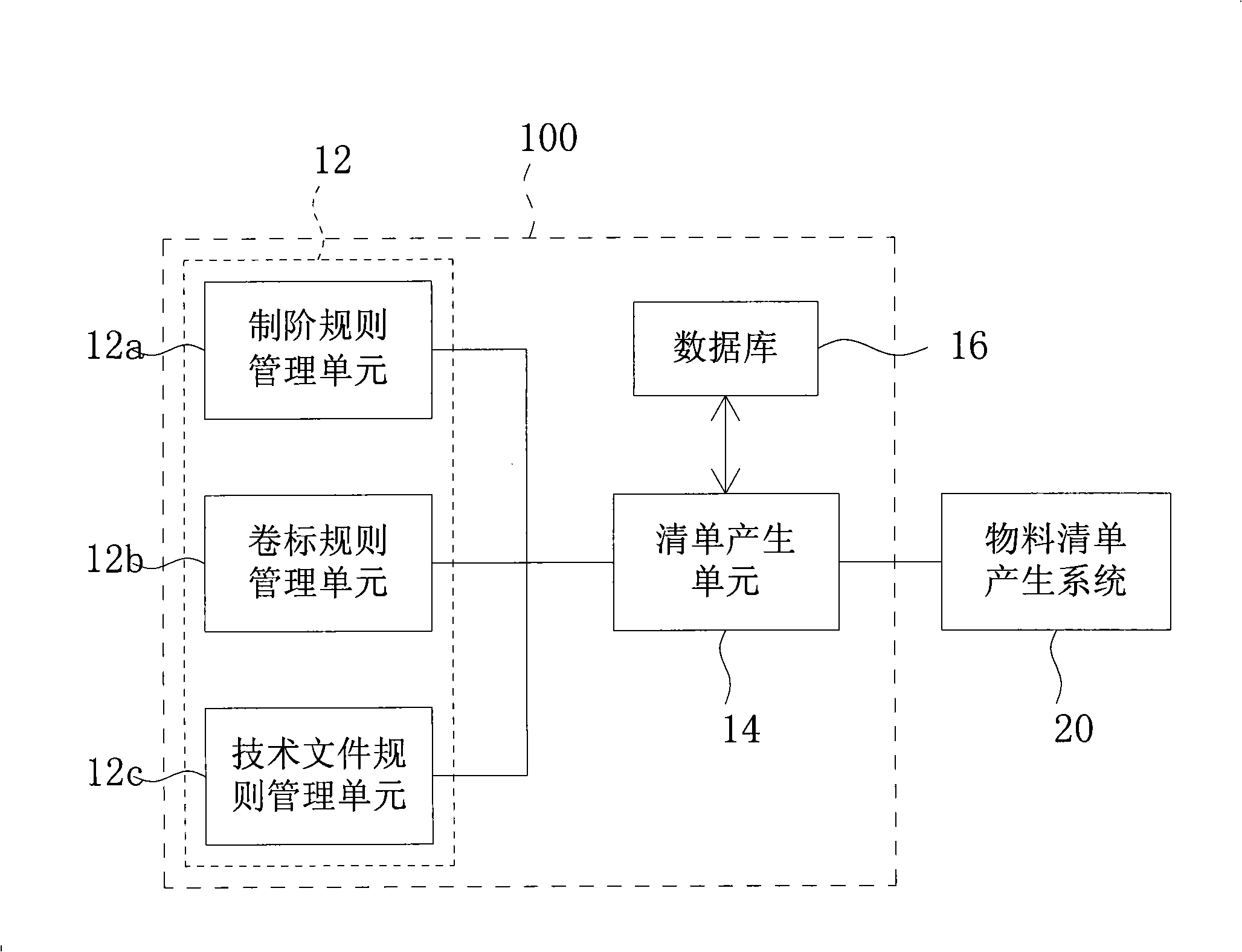

Client part bill material establishment method and computer readable medium for storing same

The invention relates to a computer readable media which is provided with a plurality of instructions executable to a computer, to execute a method to create materials of a customer part list. The method consists of the following steps: first, at least one machine type data is read, and the machine type data comprises the specification for the relevant materials; then a temporal customer part list is created to store the material description of the material specification for the relevant machine type data. Later, the material of the material description of the material specification for the relevant machine type data is created and stored in the temporal customer part list.

Owner:INVENTEC CORP

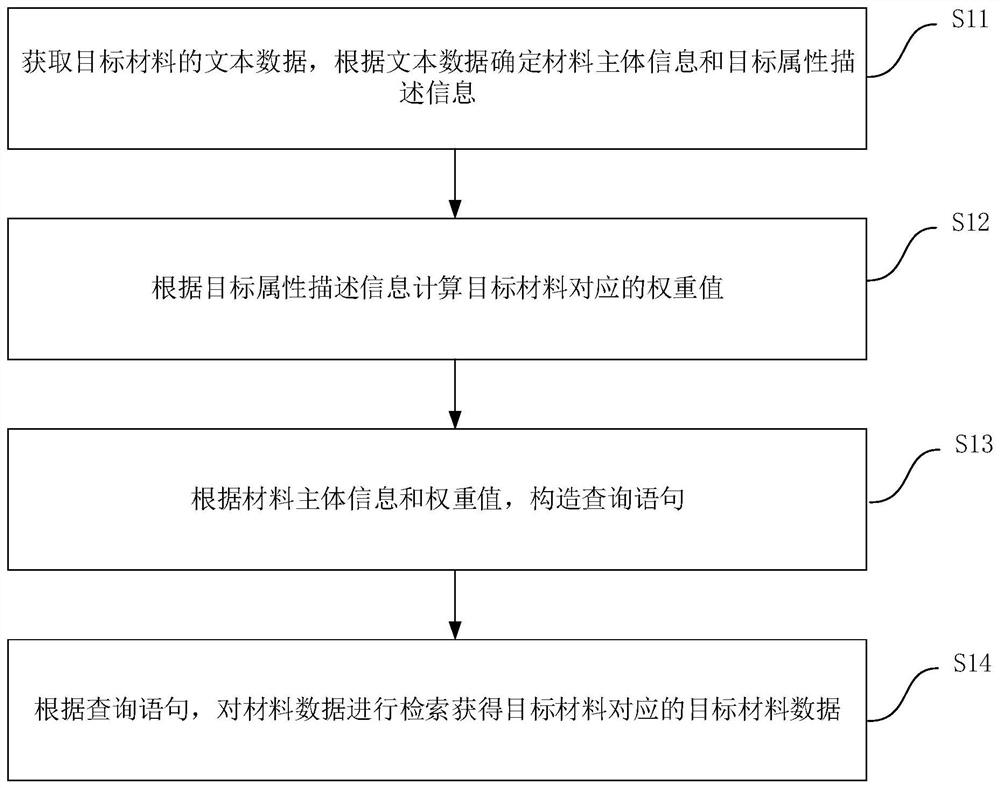

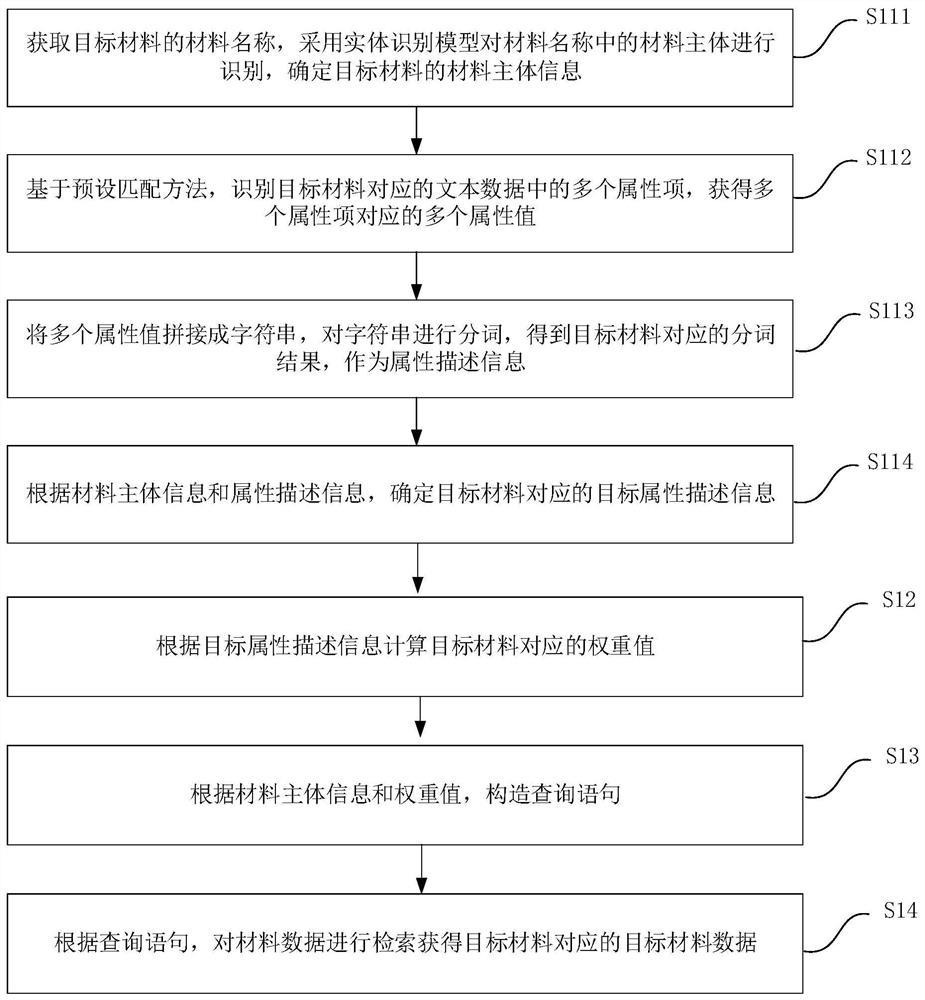

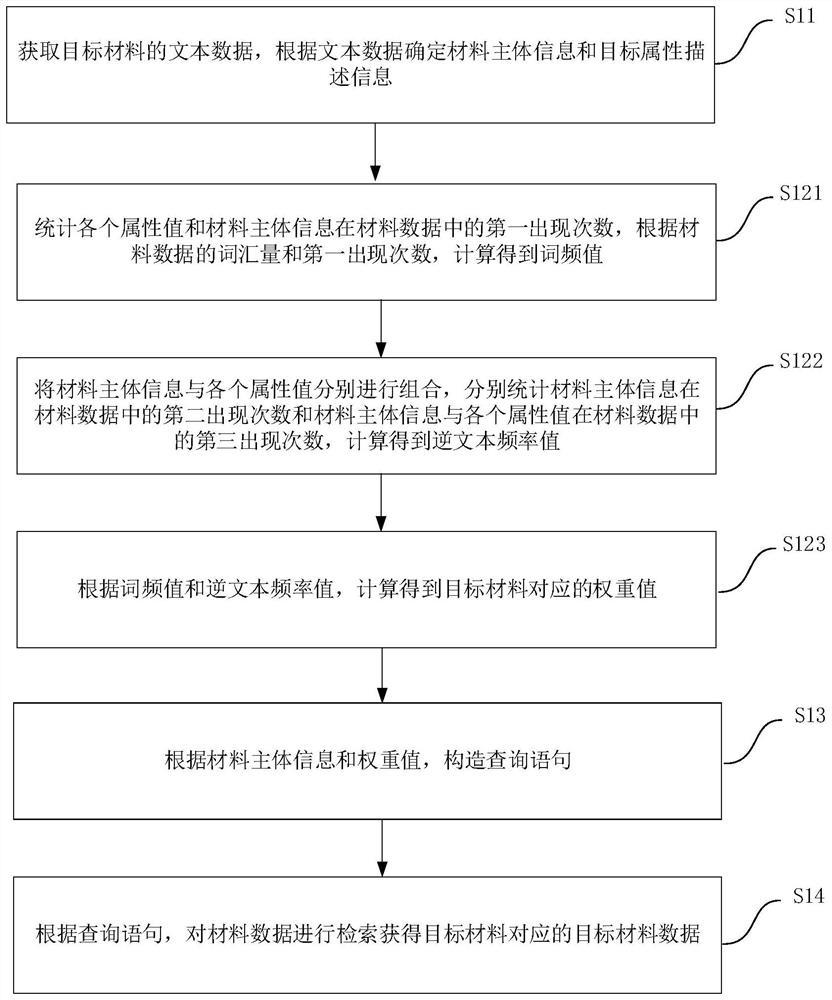

Target material matching method, device and apparatus, and readable storage medium

PendingCN111737428AImprove matching accuracyMeet matching needsDigital data information retrievalNatural language data processingMaterial DescriptionEngineering

The invention discloses a target material matching method, device and apparatus and a readable storage medium, and the method comprises: obtaining the text data of a target material, and determining the material main body information and target attribute description information according to the text data; calculating a weight value corresponding to the target material according to the target attribute description information; constructing a query statement according to the material main body information and the weight value; and according to the query statement, retrieving the material data toobtain target material data corresponding to the target material. By implementing the nvention, the matching difference caused by non-uniform target material description is avoided, the matching requirements of users on different target materials are met, and the matching accuracy of the target materials is improved.

Owner:GLODON CO LTD

A protective device for the neck, shoulders and waist of oil field workover workers

ActiveCN107173875BEffective protectionSimple structureDevices for heating/cooling reflex pointsMagnetotherapy using coils/electromagnetsMaterial DescriptionEngineering

The invention discloses a neck, shoulder and waist personal protecting tool for oilfield well repairing workers. The tool comprises a support plate, wherein a neck protecting plate is arranged at the center of the upper end of the support plate; a shoulder protecting plate is welded at the upper end of one side of the support plate; two sliding tracks are arranged at the other side of the support plate; and a sliding connection plate is in sliding connection on the sliding tracks. Necks of the workers can be protected through the neck protecting plate; waists of the workers can be protected through a waist protecting belt; the waists of the workers can be heated through heating wires; and magnetic therapy is carried out on the waists of the workers through electromagnetic release plates so as to promote the blood circulation of the waists. The neck, shoulder and waist personal protecting tool for the oilfield well repairing workers has the characteristics of being safe, portable, comfortable, convenient and the like, and is capable of effectively protecting the necks, shoulders and waists of the workers during the well repairing operation; the characteristics of being portable and comfortable are not realized through simple material descriptions but realized through simple structure and wearing convenience; and aiming at the problem that heating is not needed in summer, the tool is provided with a switch for controlling electromagnetic release, and heating can be controlled as needed.

Owner:山东省职业卫生与职业病防治研究院

Method and device for generating audio-video program list and program package

InactiveCN103475903AReduce waste of resourcesReduce wasteSelective content distributionMaterial DescriptionDigitization

The invention discloses a method and a device for generating an audio-video program list and a program package. The method comprises the following steps: a video server receives a digital broadcast material from a coding channel, generates corresponding broadcast material description information according to the broadcast material and stores the broadcast material description information; and when editing a program list and / or a program package, the video server acquires corresponding broadcast material description information according to broadcast content included in a to-be-edited program list and / or program package and generates a program list and / or a program package according to the acquired broadcast material description information. The accuracy of program list and / or program package generation is increased, and waste of resources caused by repeated work is reduced.

Owner:CHINA DIGITAL VIDEO BEIJING

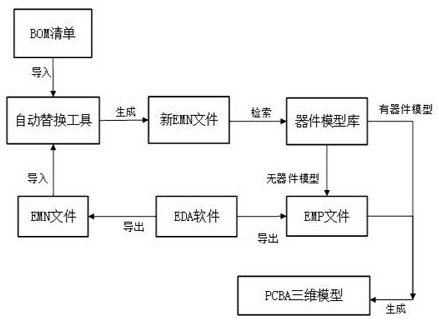

A method for automatic generation of precise 3D model of PCBA based on ecad interface

ActiveCN111739162BRealize automatic generationImprove design accuracyRelational databasesSpecial data processing applicationsMaterial DescriptionTheoretical computer science

The invention discloses a PCBA accurate three-dimensional model automatic generation method based on an ECAD interface, and relates to the technical field of three-dimensional model automatic generation methods, including an EMN file and a BOM list. The EMN file is used for recording geometric coordinate information of the PCB and packaging names, bit numbers and coordinate information of all devices on the board; the BOM list is used for reflecting information of material codes, material description, specifications and models, quantity and bit numbers; the beneficial effects of the inventionare that a device bit number in the EMN file is exported through EDA software and associated with the device bit number with device information in the BOM list, and a packaging name in the EMN file is replaced with a device code; the uniqueness of the device corresponding to the EMN file information is ensured, so that the device model library can be retrieved through the device code, the devicemodel can be accurately called, the PCBA accurate three-dimensional model based on the ECAD interface can be automatically generated, and the design accuracy and the evaluation efficiency of a high-density electronic product can be greatly improved.

Owner:CHENGDU ZHIMINGDA DIGITAL EQUIP

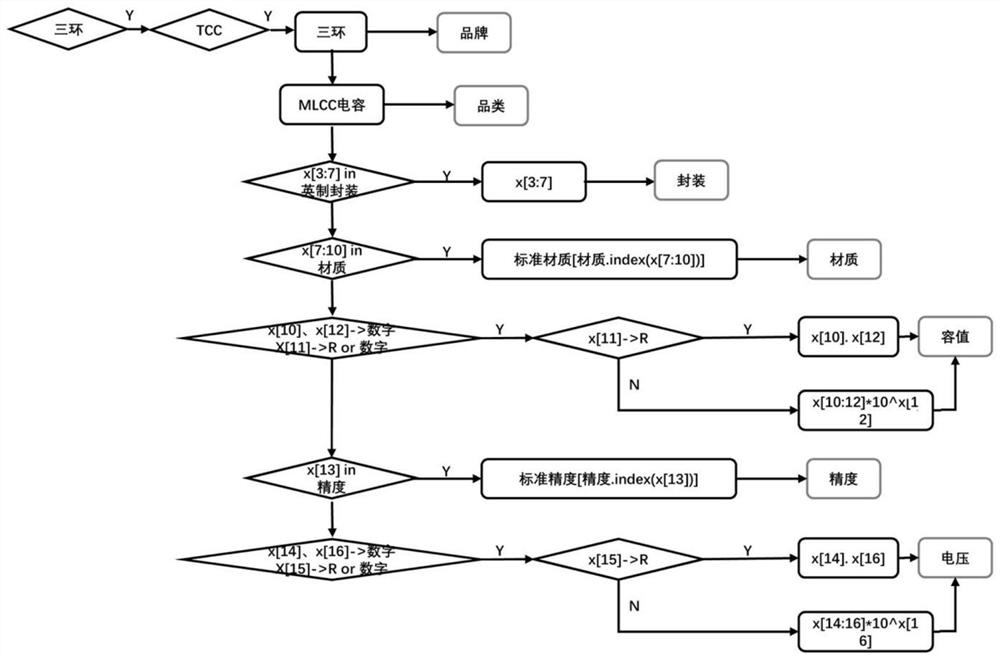

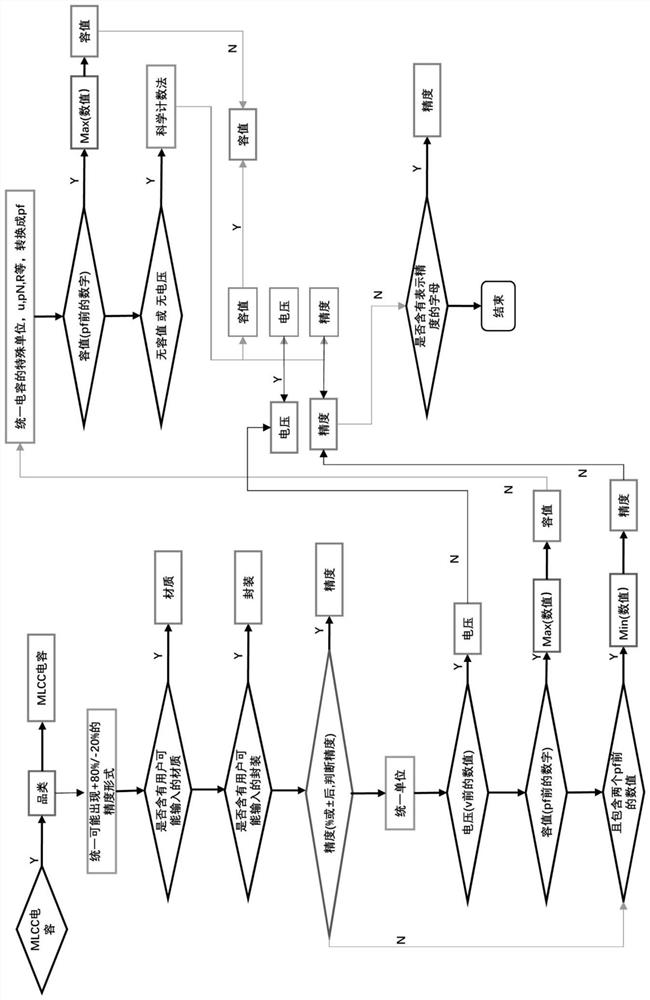

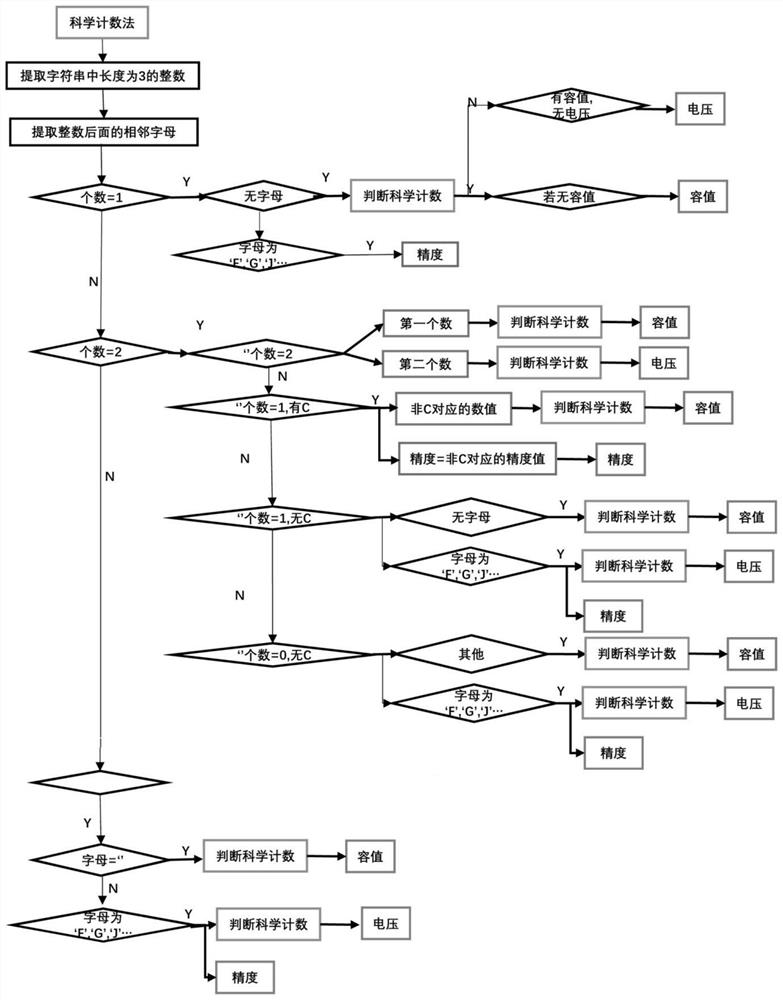

MLCC capacitance parameter matching method

ActiveCN112580685AImprove efficiencyHigh precisionDigital data information retrievalCharacter and pattern recognitionCapacitanceMaterial Description

The invention belongs to the technical field of artificial intelligence and electric devices, and provides an MLCC capacitance parameter matching method. The method comprises the following steps: S1,collecting material description content input by a user, and judging whether the material description has a brand and an original factory model or not; S2, carrying out the segmented extraction on thesubstrings corresponding to the original factory model, obtaining parameters of the MLCC capacitor, and obtaining a corresponding product and a replaceable product through matching; S3, performing parameter extraction on the pure material description, and matching a corresponding product and an alternative product; S4, calculating the scores of the matched corresponding products and the alternative products thereof; S5, taking each score of each product as the input of the product, calculating the probability that the user may purchase the product by using a naive Bayesian algorithm, sortingthe products with the attributes being purchased according to the probability, and generating a recommendation sequence. According to the invention, the MLCC capacitance matching efficiency and precision are greatly improved.

Owner:青岛檬豆网络科技有限公司

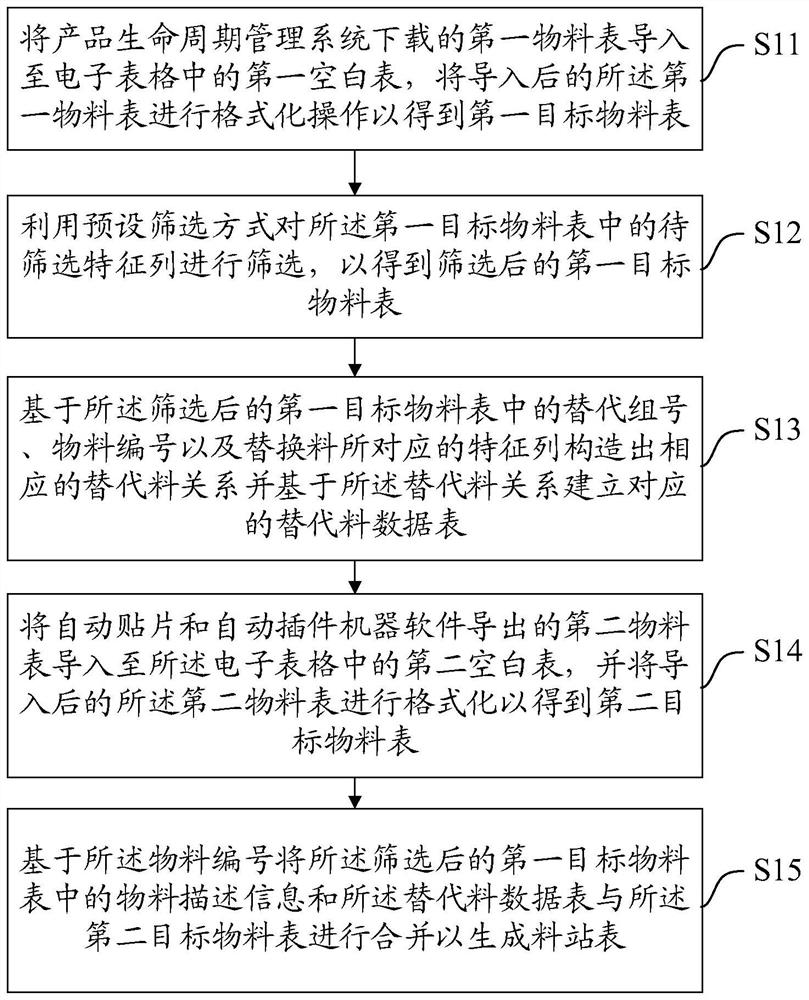

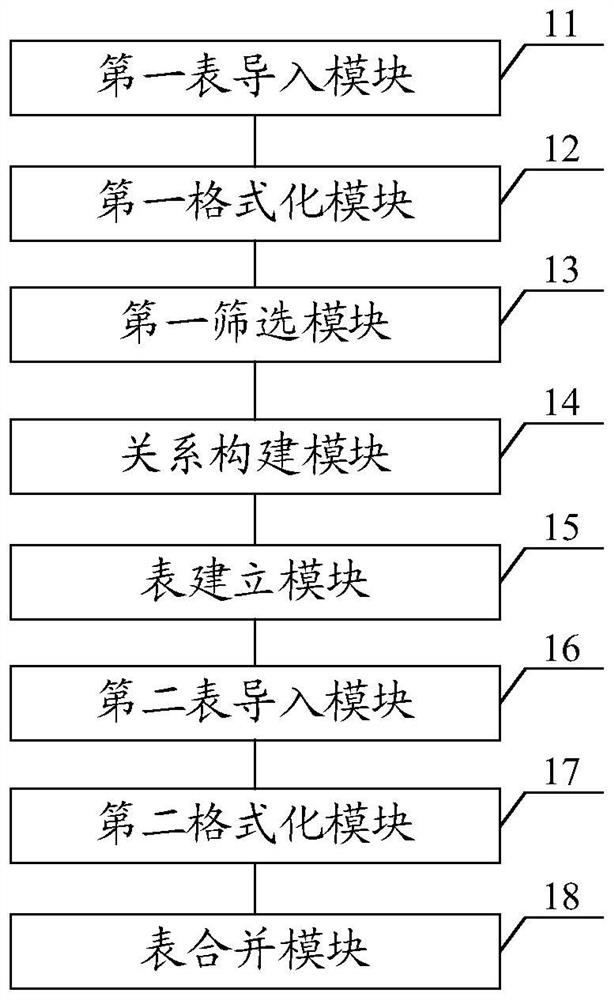

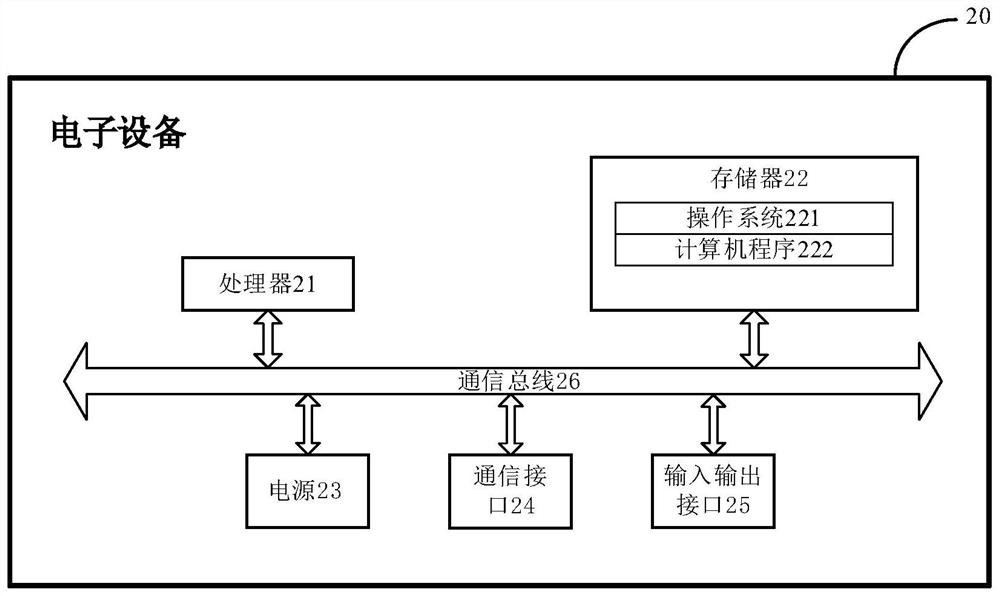

Material station table synthesis method, system and equipment and storage medium

PendingCN114565355AReduce the burden onAvoid missing partsOffice automationLogisticsDatasheetMaterial Description

The invention discloses a material station table synthesis method, system and device and a storage medium, and the method comprises the steps: importing a first material table into a first blank table in a spreadsheet, and carrying out the formatting operation to obtain a first target material table, constructing a substitute material relationship and establishing a substitute material data table based on the substitute group number, the material number and the feature column corresponding to the substitute material in the screened first target material table; importing a second material table exported by automatic surface mounting and automatic plug-in machine software into a second blank table, and formatting to obtain a second target material table; and combining the substitute material data table and the material description information in the screened first target material table with the second target material table based on the material number to generate a material station table. According to the method, the legal compliant material station table is automatically generated based on the first material table and the second material table, manual operation is replaced, missing, excessive and wrong parts in electronic product manufacturing are avoided, the burden of technicians is relieved, and the production efficiency is improved.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com