Automatic calibrating method of make-to-order production materials by server

An automatic verification and server technology, applied in the direction of logistics, data processing applications, program control devices, etc., can solve the problems of manual verification, mixing of materials, and difficulty in ensuring the accuracy of manual verification in the system, and achieve the goal of improving control capabilities and enriching functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

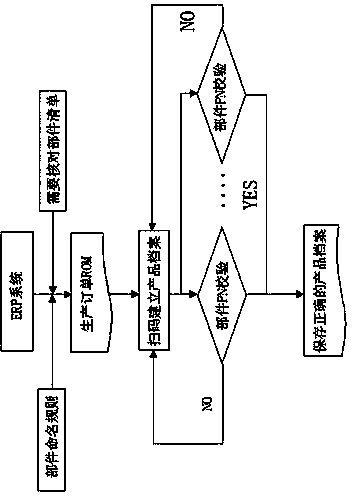

[0019] Below with reference to accompanying drawing, the present invention is further described by specific embodiment:

[0020] First of all, the production order BOM is the basis in the ERP system, and the production order number is associated with the SN number. The production order BOM includes: PN codes of all components, and material descriptions (conforming to the component naming rules).

[0021] The materials (components) that need to be verified must be clearly defined, generally electronic components, generally including: CPU, memory, hard disk, power supply, motherboard, hard disk backplane, RAID card, SAS card, network card, optical drive, etc.

[0022] The product file scanning code program calls the verification program through the background to realize the verification process of all components and realize the purpose of automatic material verification.

[0023] Among them, the system scans the QN code of the part when creating the product file, and the backgro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com