Computer-implemented squeak detection method and system

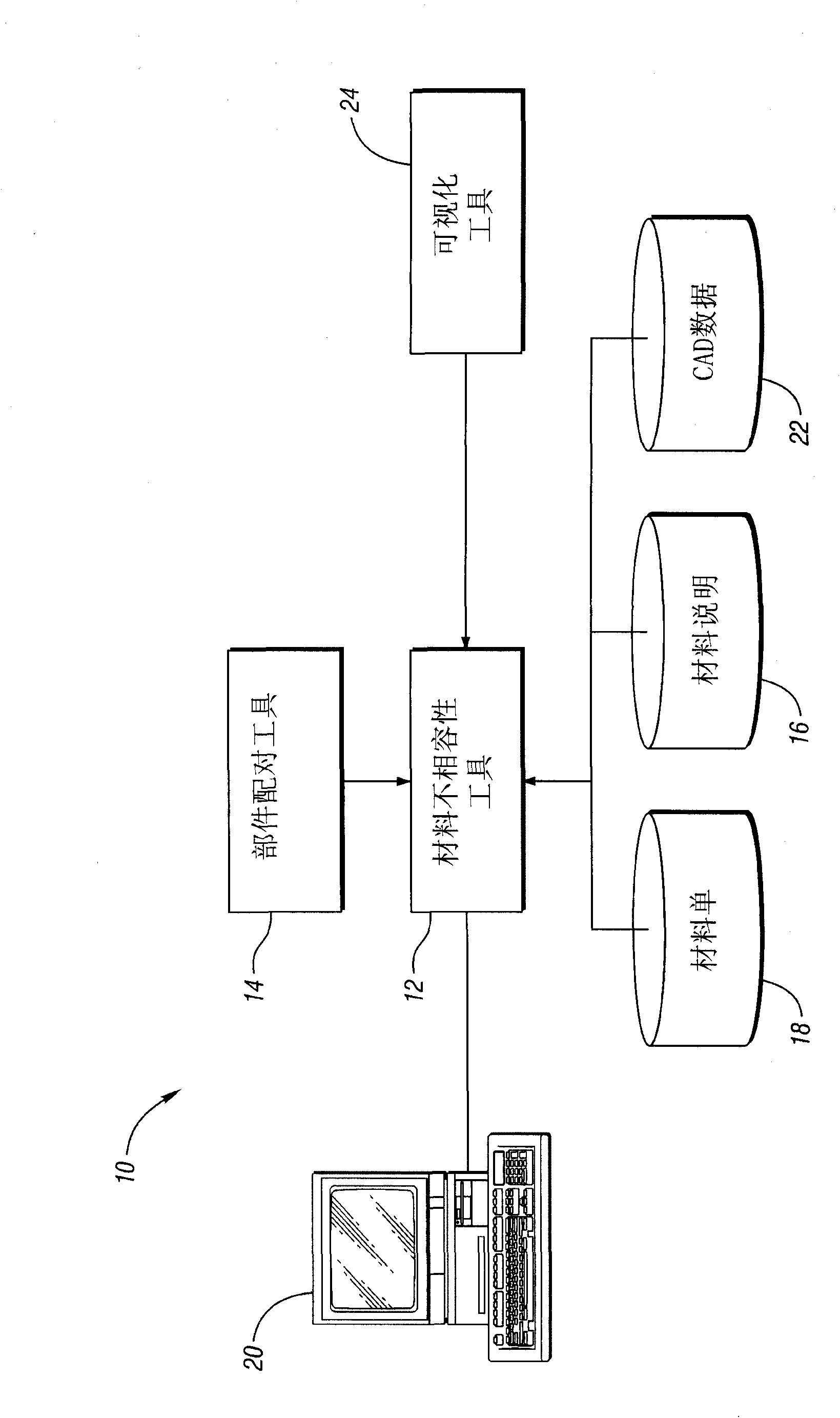

A computer, computer-aided technique used in machine/structural component testing, vehicle testing, measuring devices, etc., to solve problems such as noise detection that do not show incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

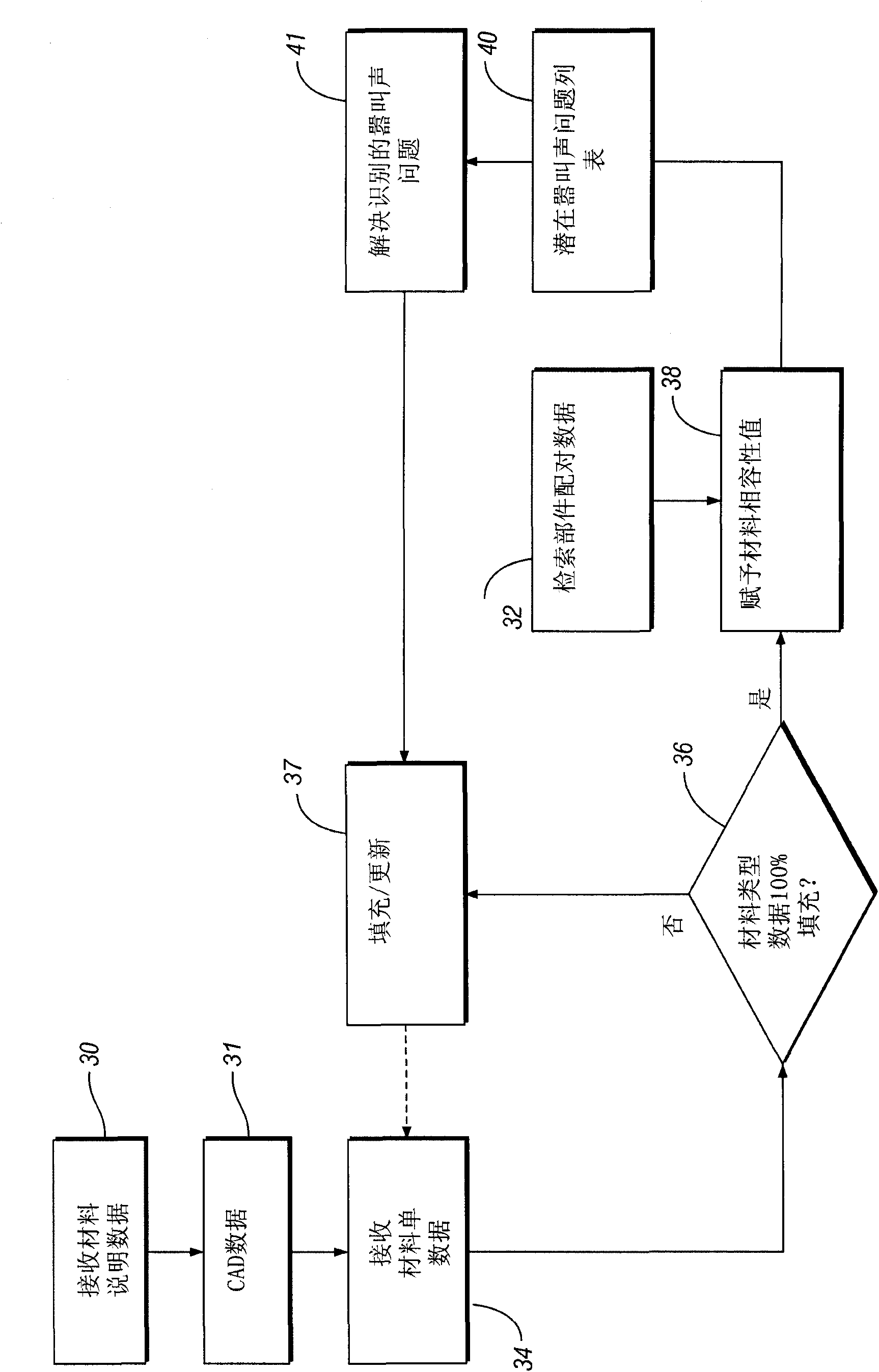

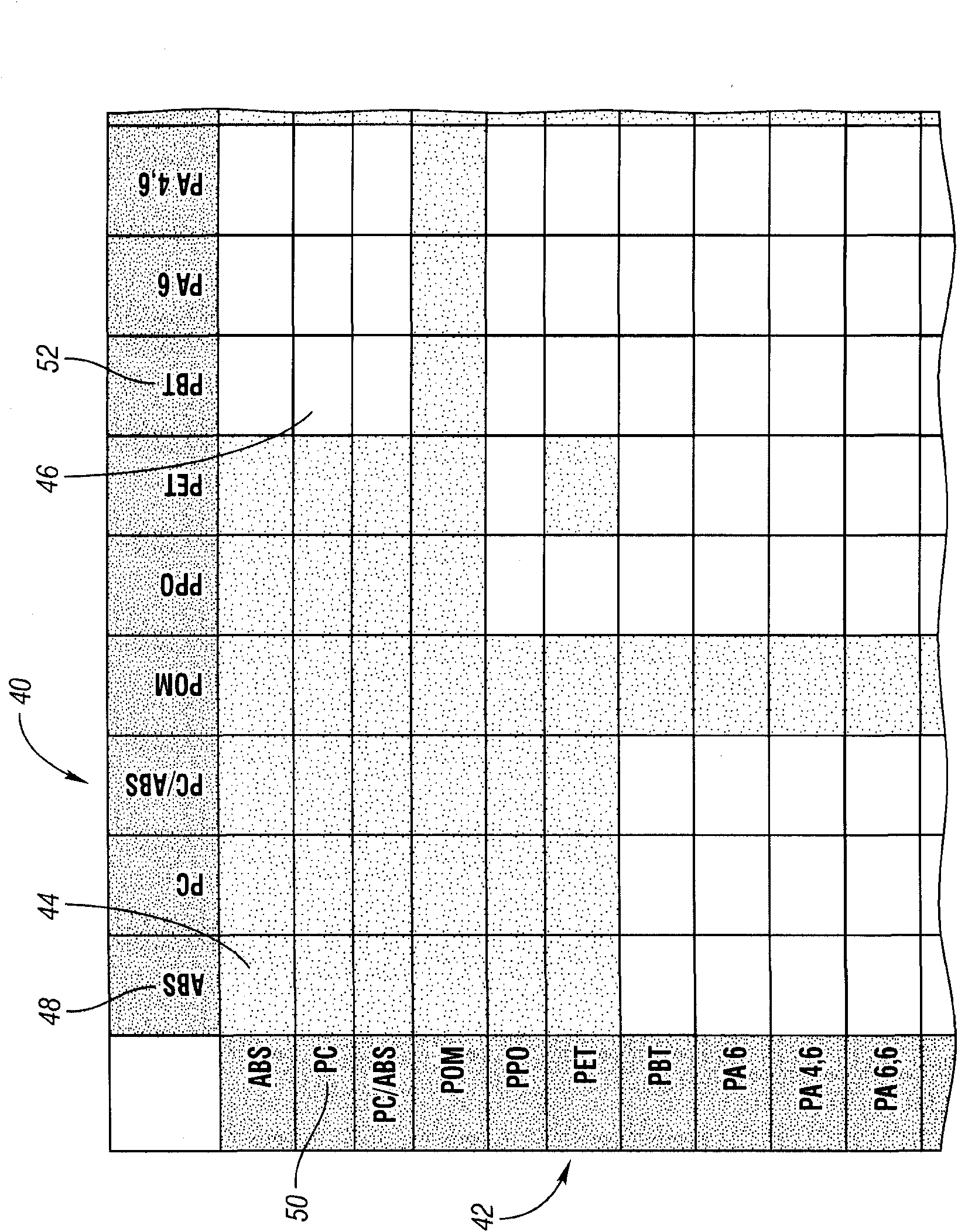

Embodiment Construction

[0033] The novel features of the invention are disclosed with particularity in the claims. The composition and mode of operation of the present invention, together with further objects and advantages thereof, will become apparent from the following description taken in conjunction with the accompanying drawings.

[0034] As required, specific embodiments of the invention are disclosed in this specification. It is to be understood, however, that the disclosed embodiments are merely exemplary of the invention, which may be embodied in various and alternative forms. Therefore, specific functional details disclosed in this specification are not to be interpreted as limiting, but merely as a representative basis for the claims or as a representative basis for teaching one skilled in the art to variously employ the present invention.

[0035]A typical design and engineering process includes the steps of manufacturing the various automotive components included in a vehicle. Modern ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com