Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35 results about "Heparan sulphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glycosaminoglycans

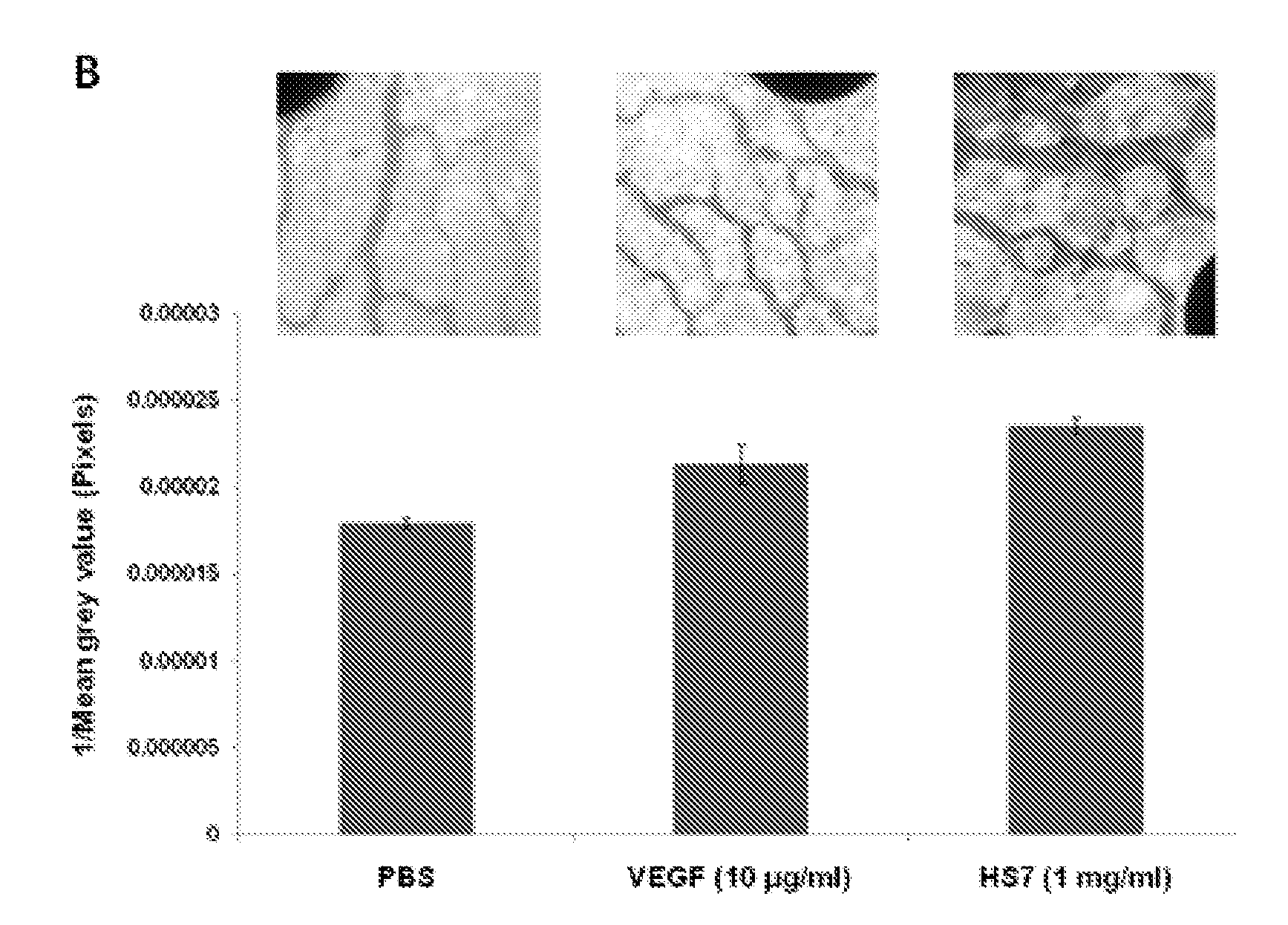

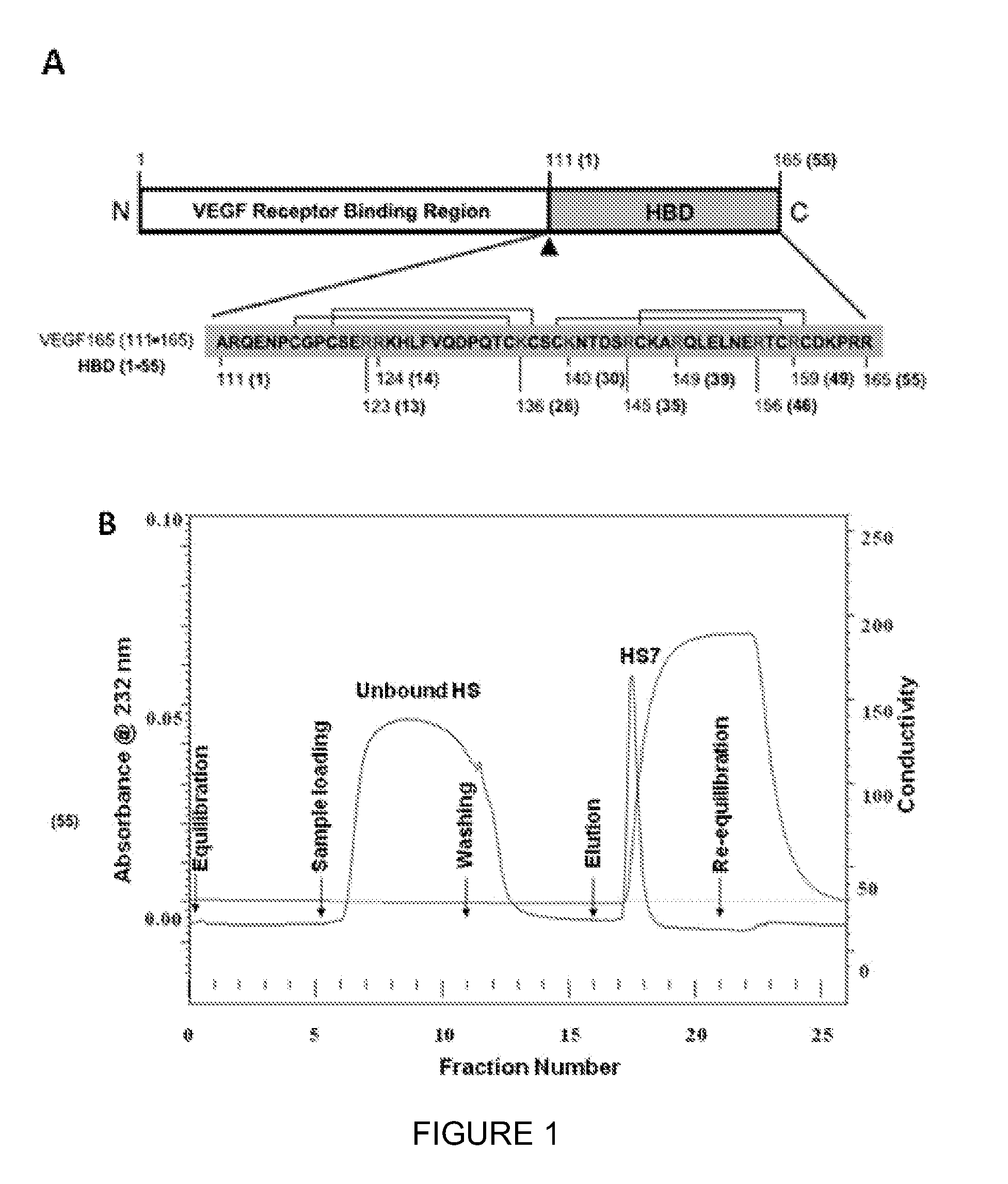

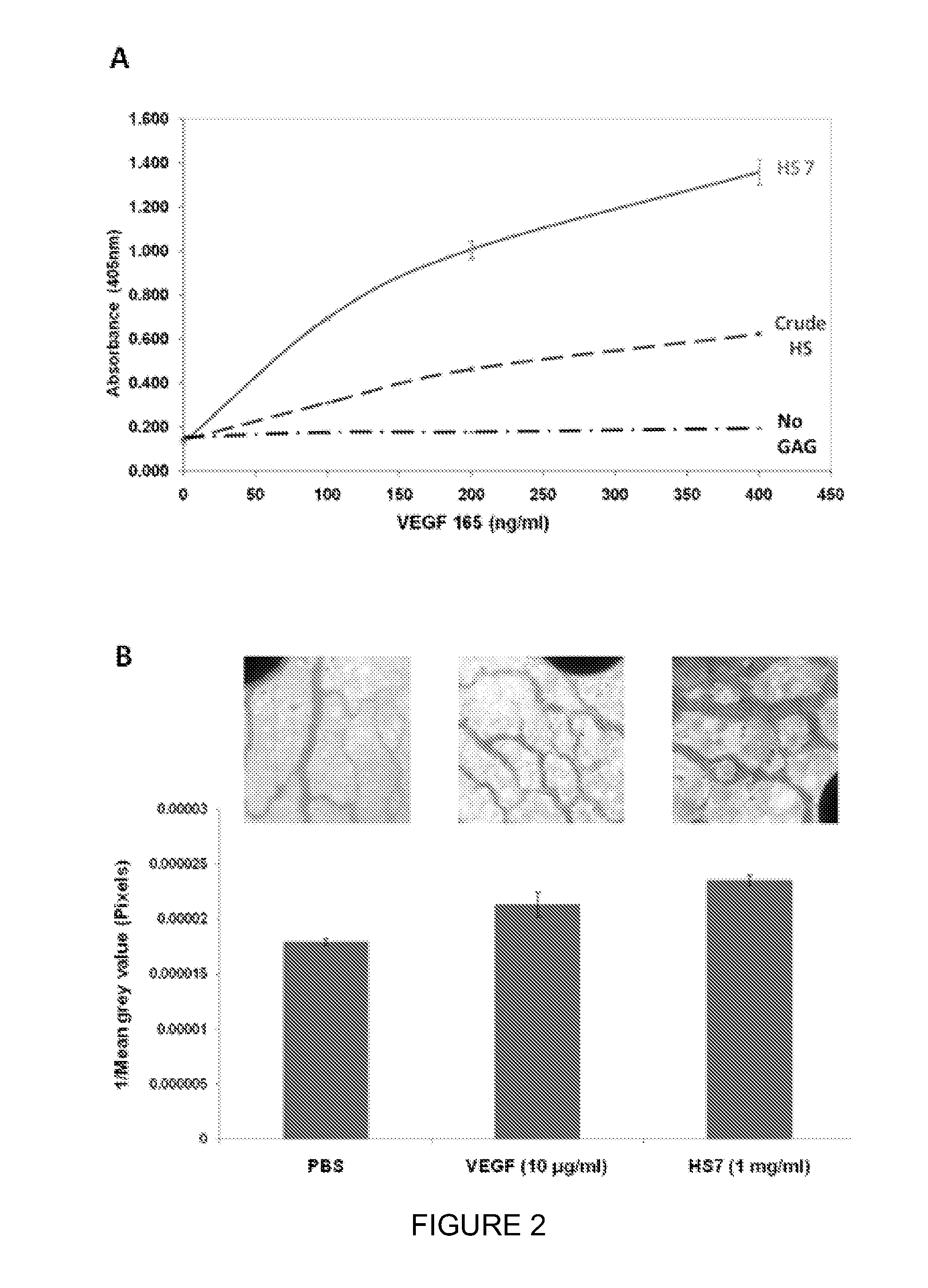

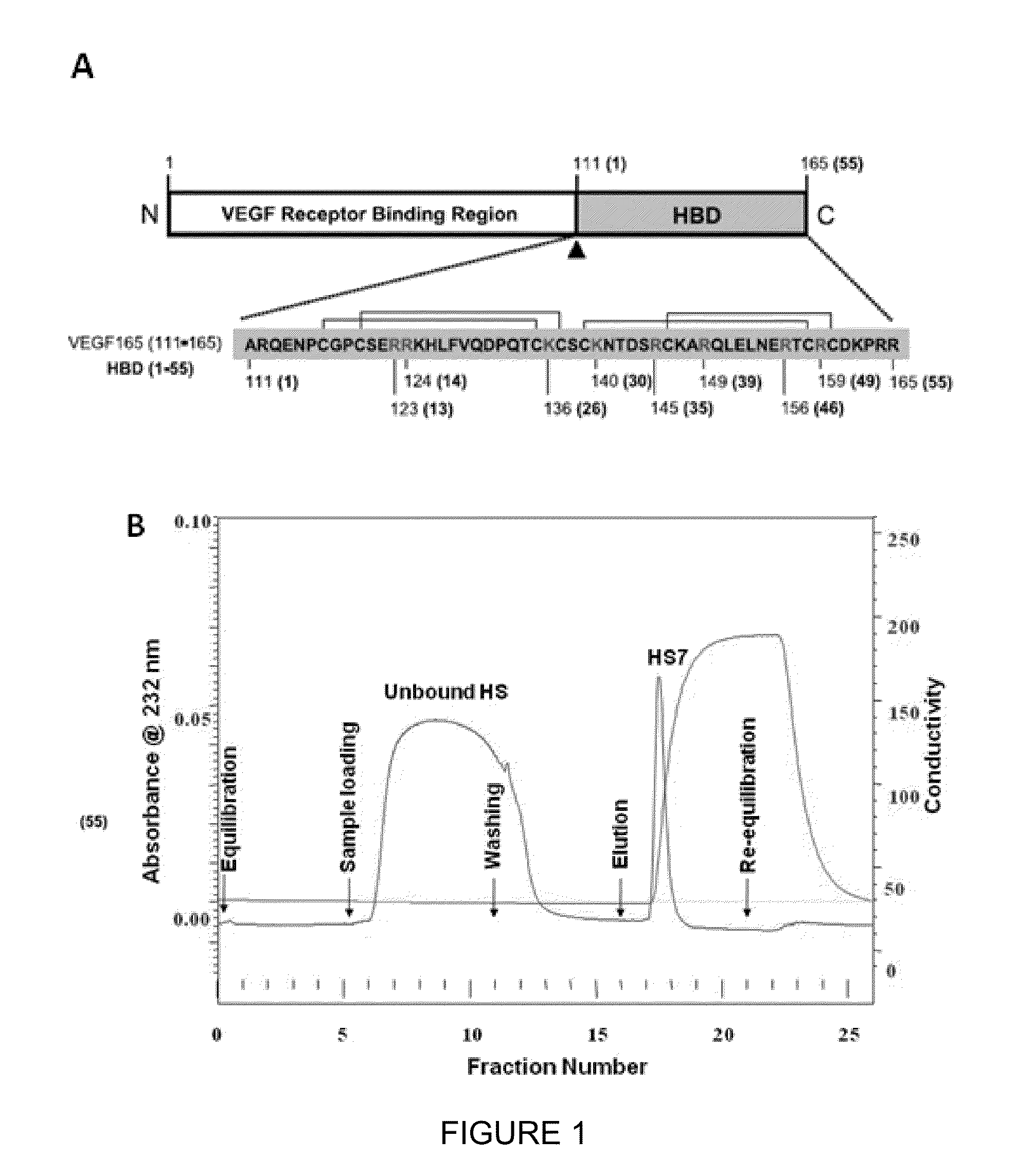

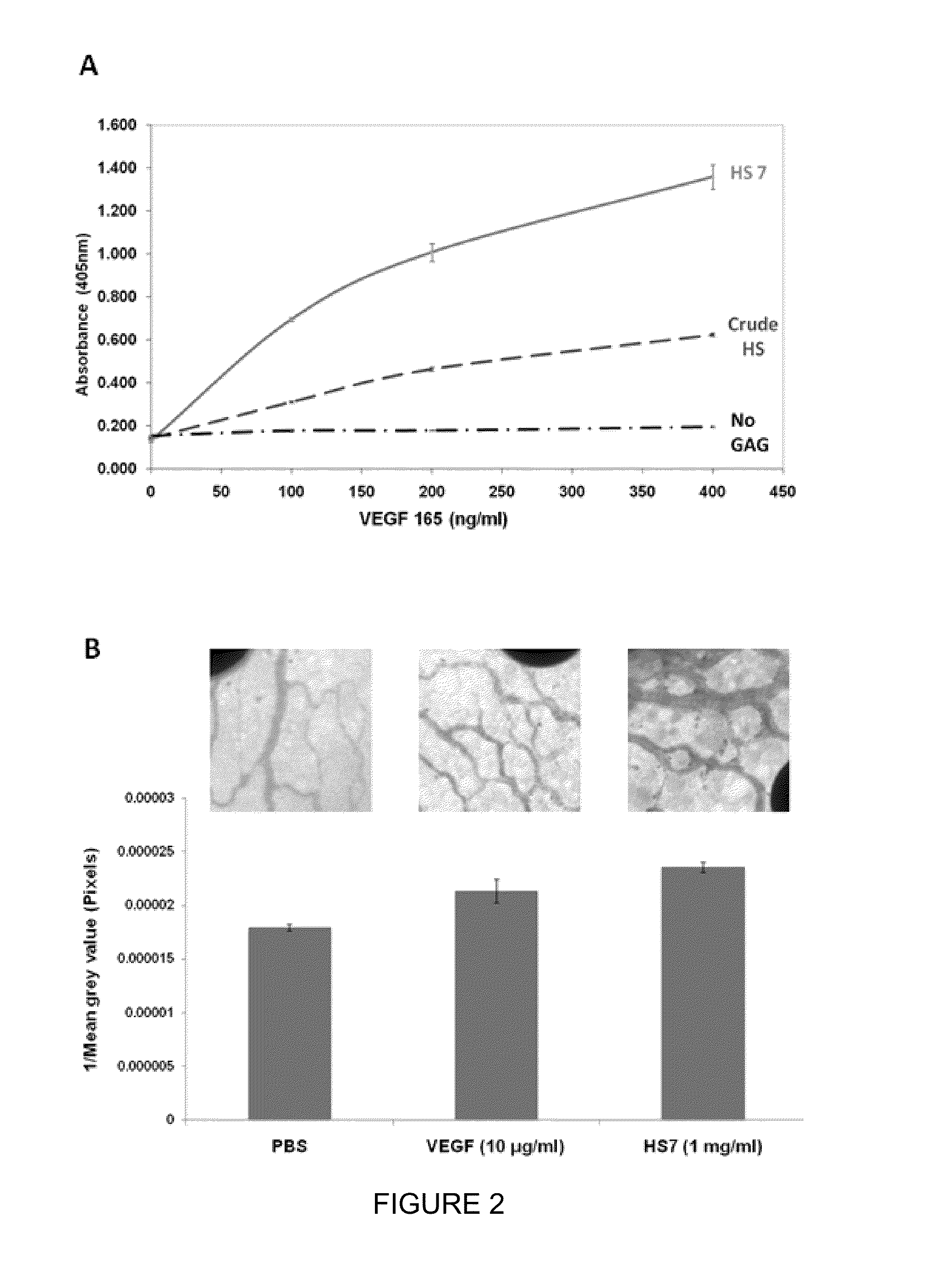

Heparan sulphate HS7 is disclosed, together with the use of HS7 in the growth and / or development and / or regeneration of tissue.

Owner:AGENCY FOR SCI TECH & RES

Composition for stimulating bone growth and differentiation and method for isolating same

InactiveUS20050288252A1Useful propertyPromote cell growthOrganic active ingredientsSkeletal disorderDamages tissueBone tissue

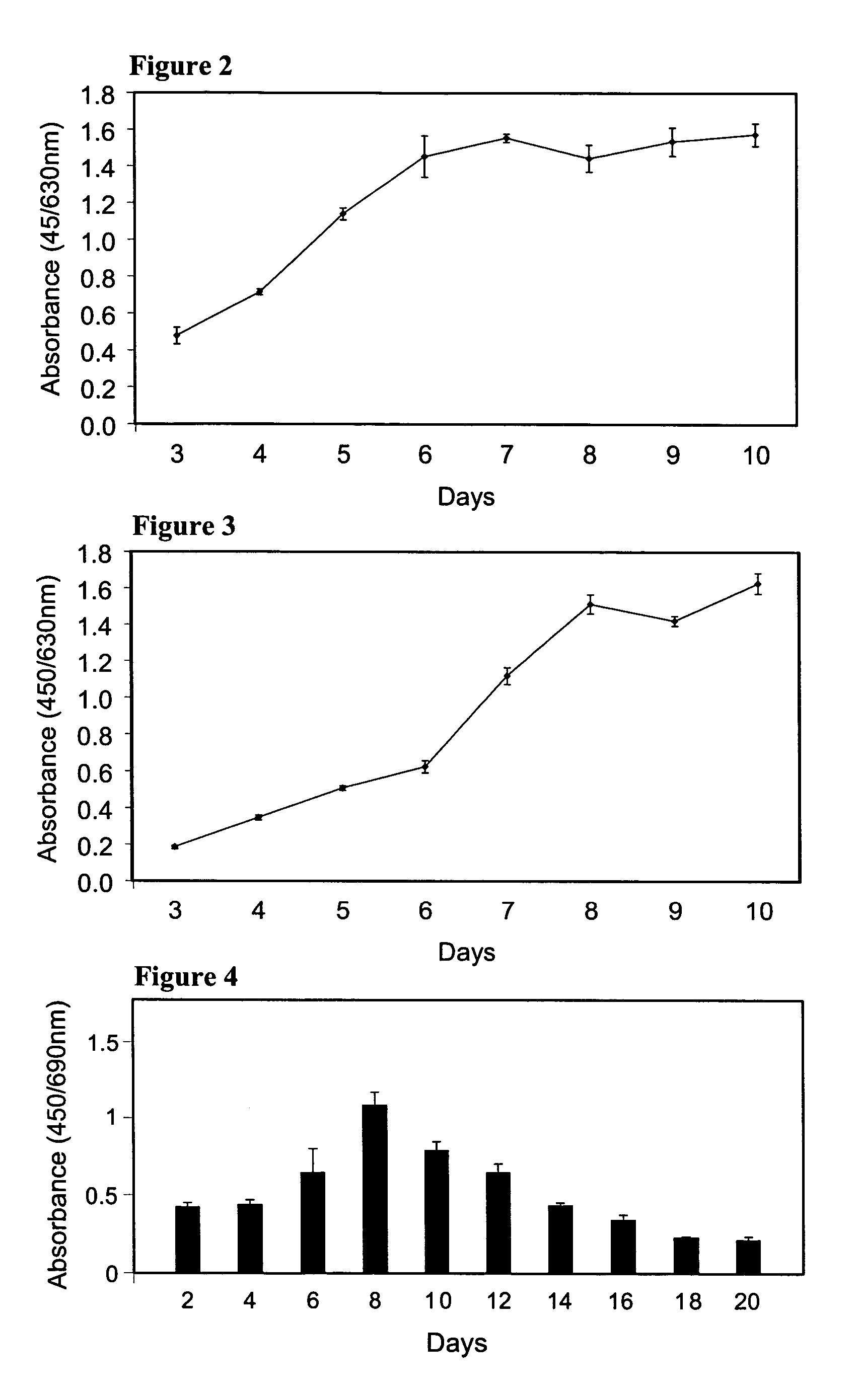

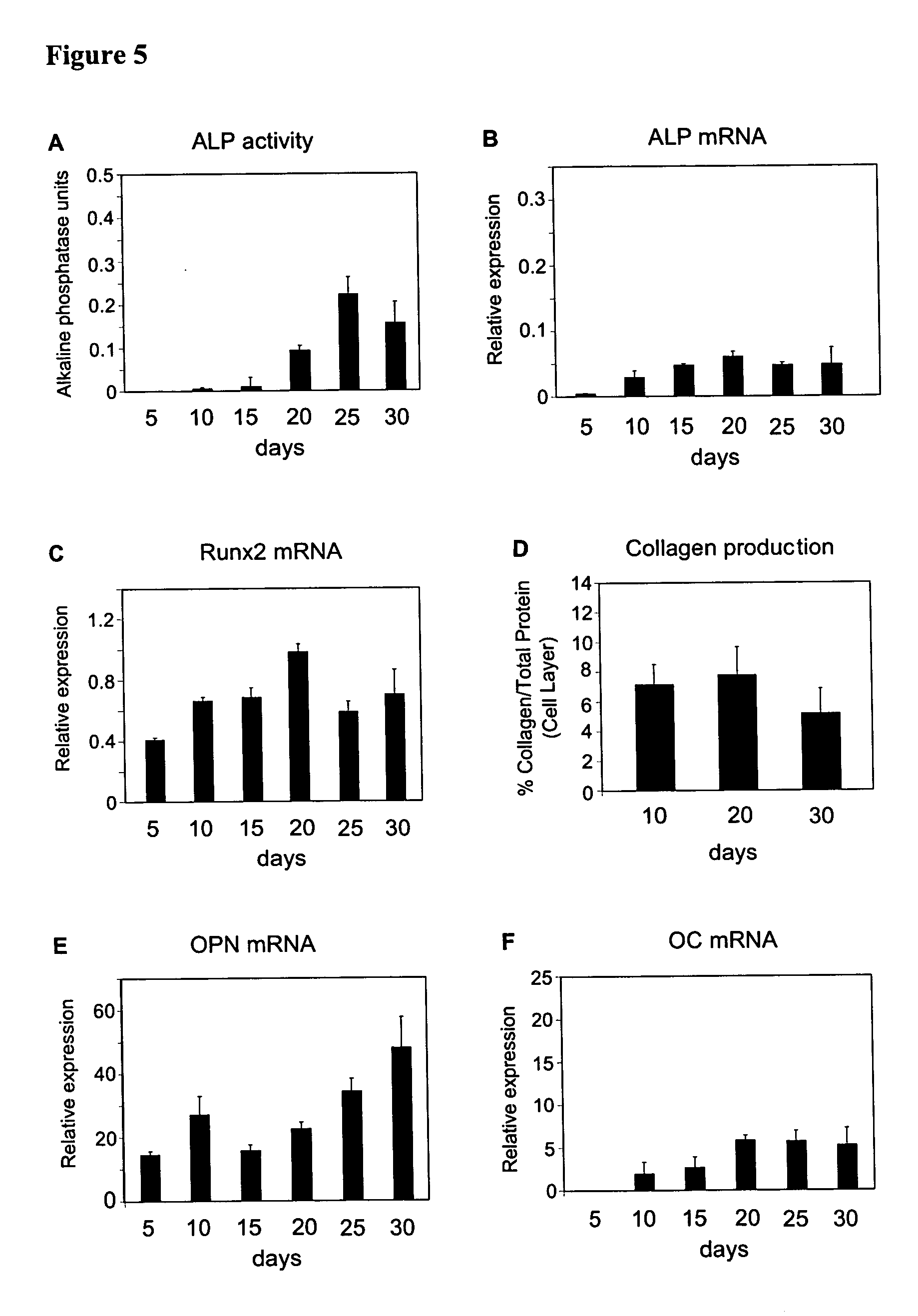

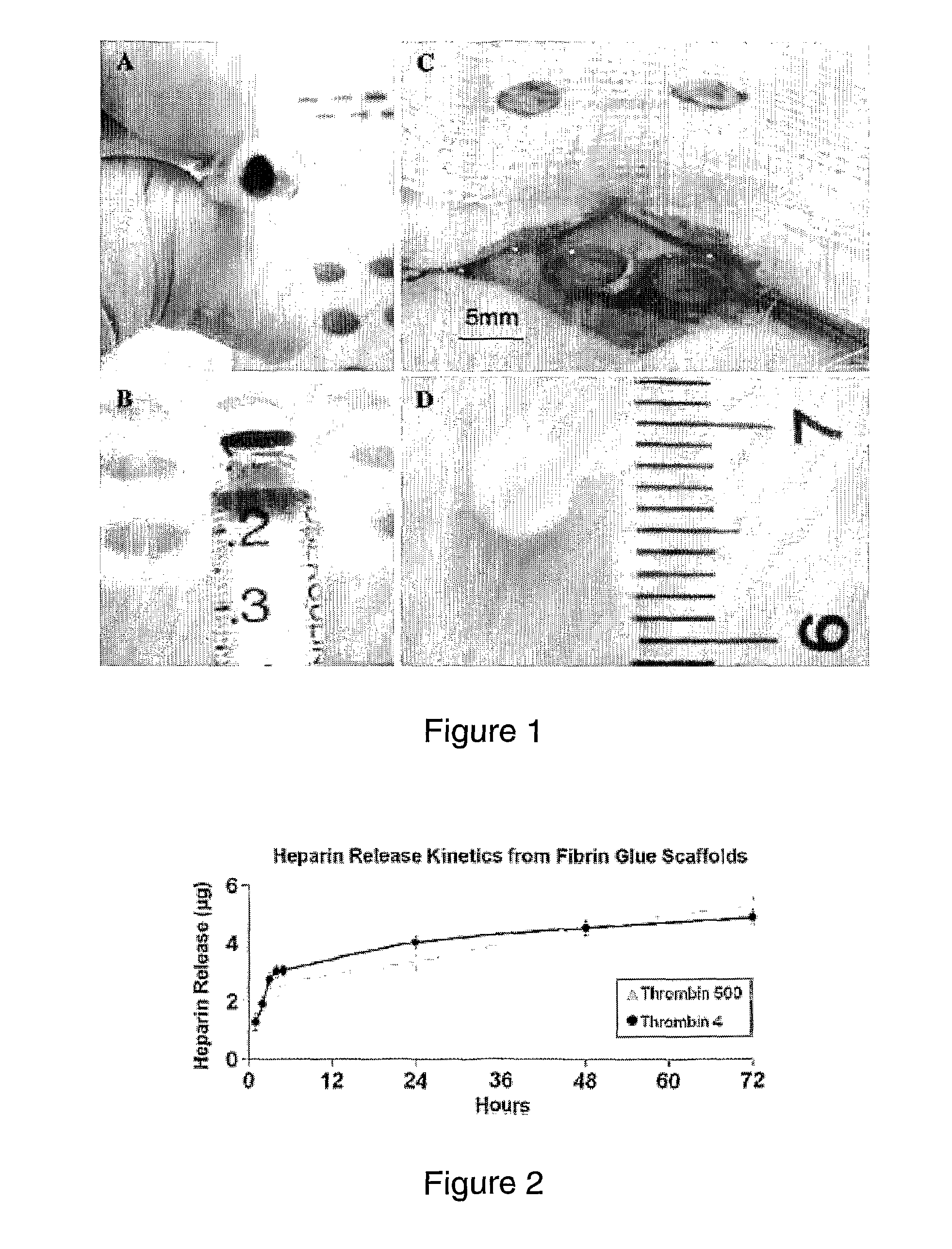

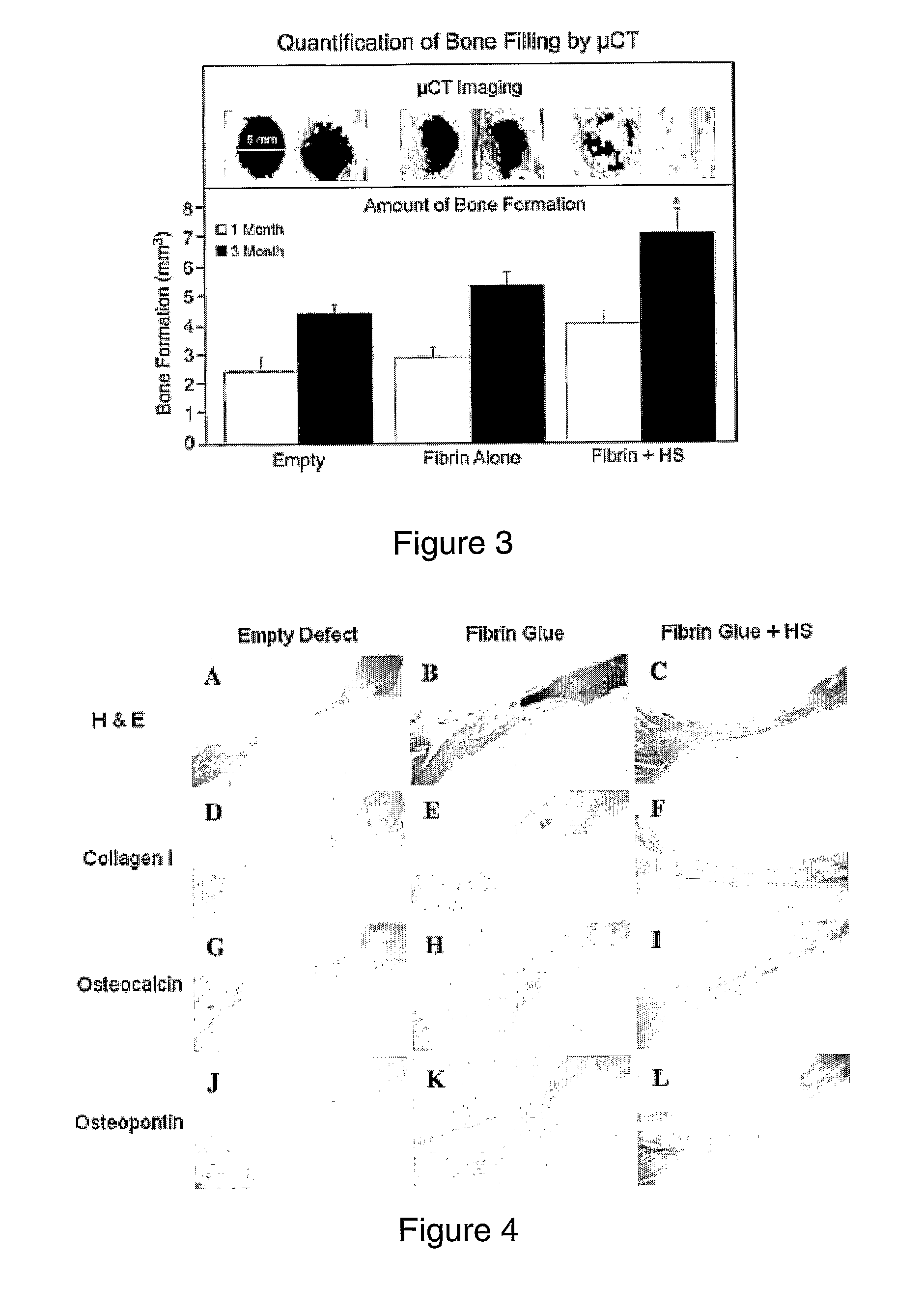

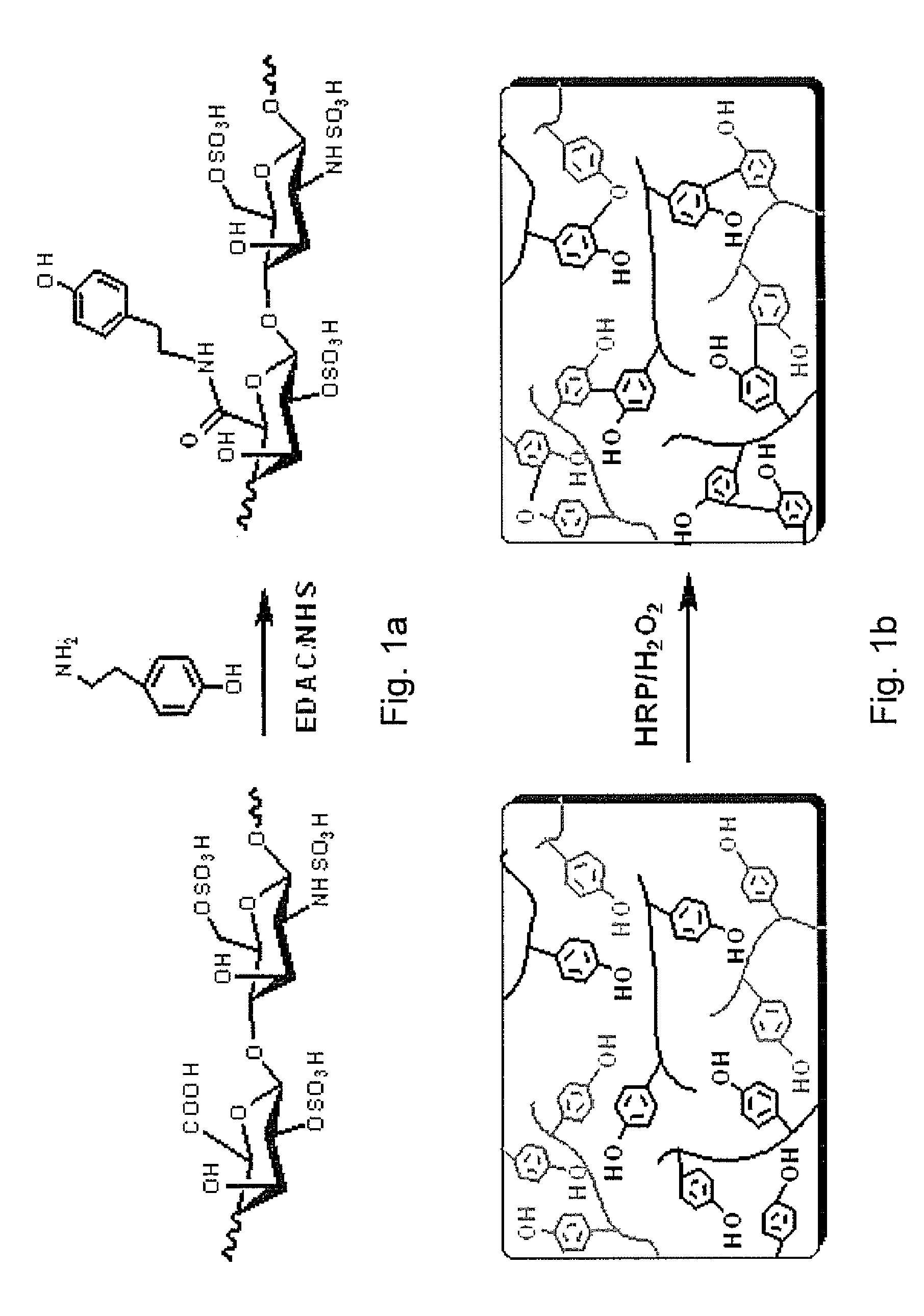

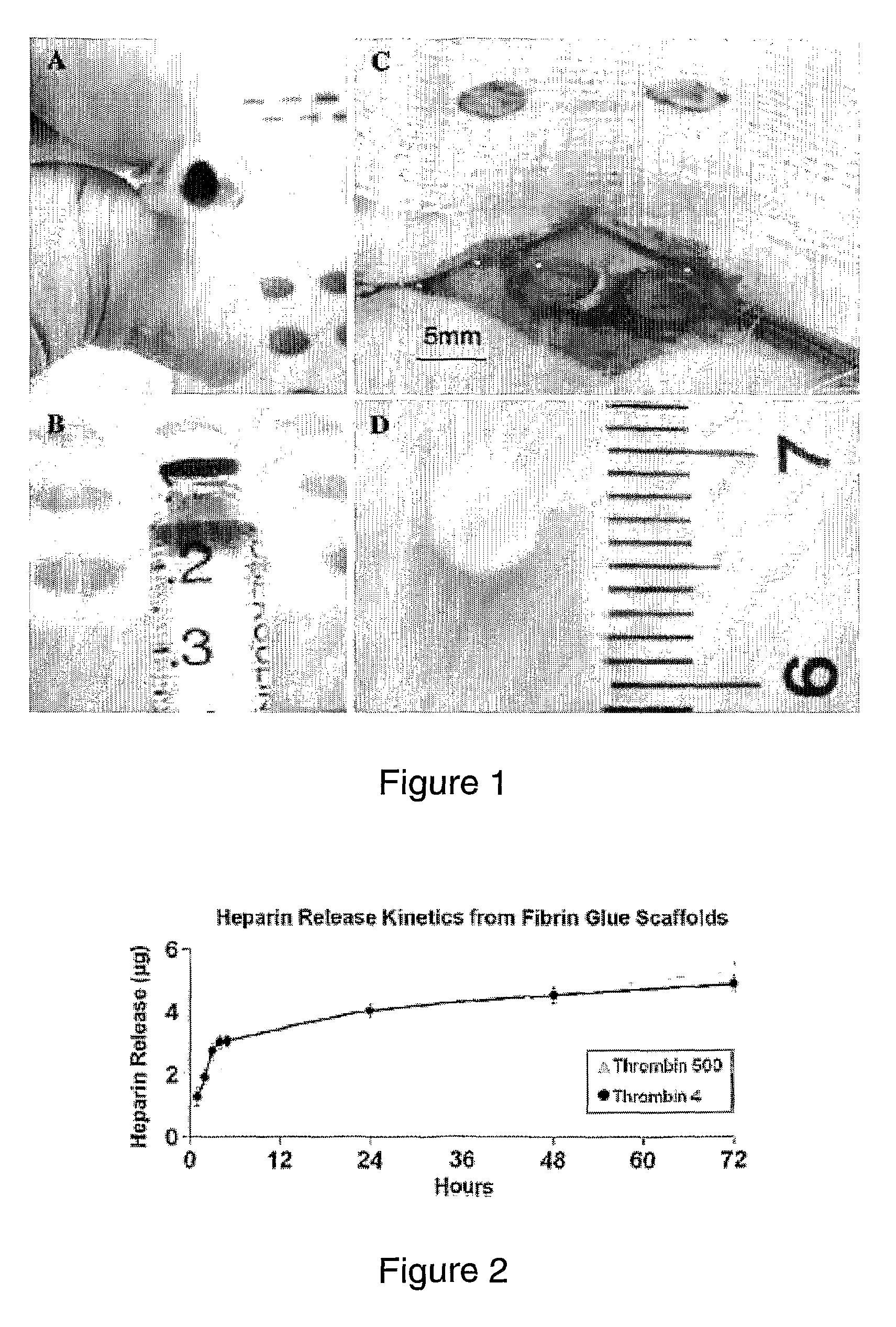

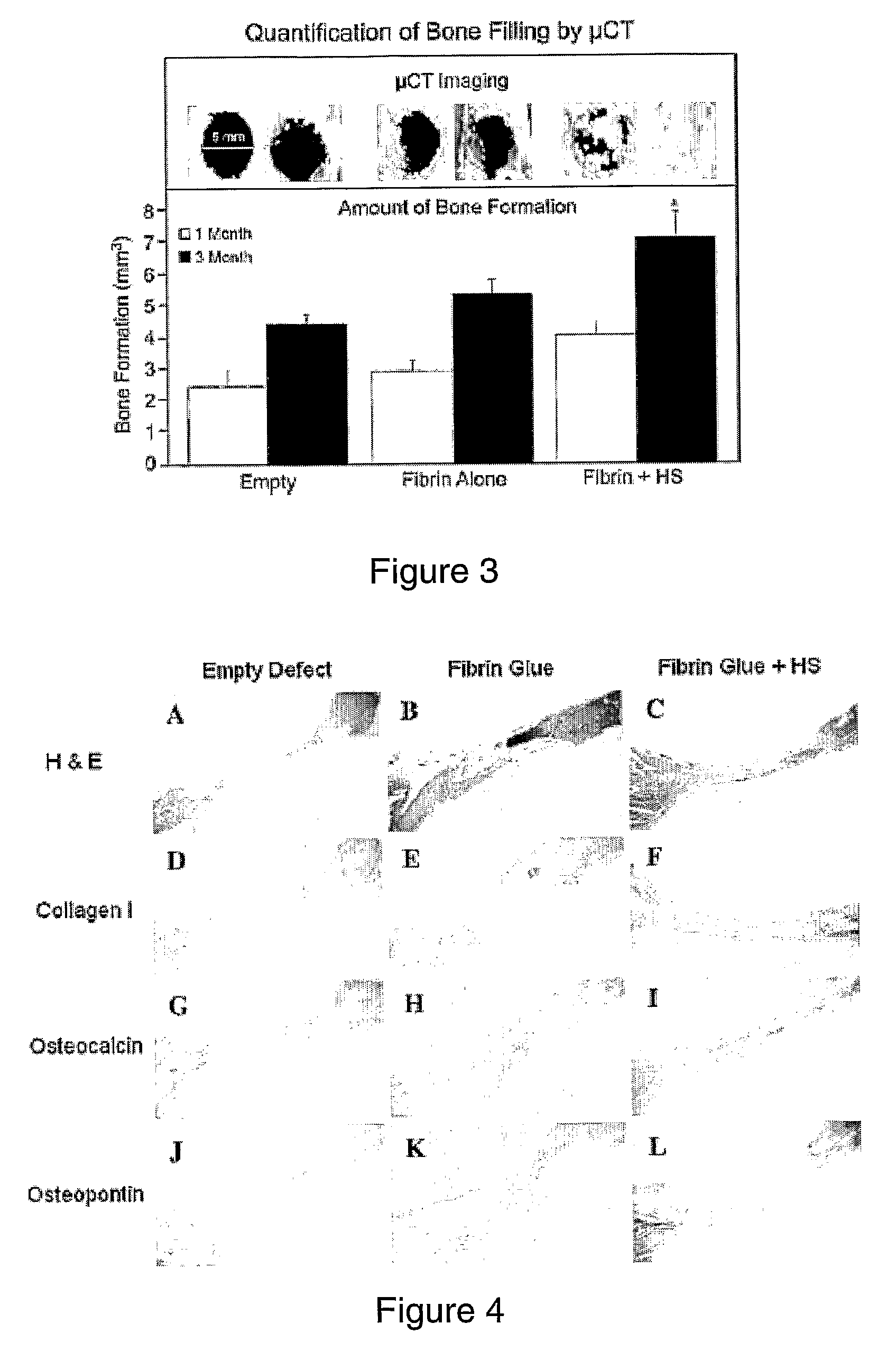

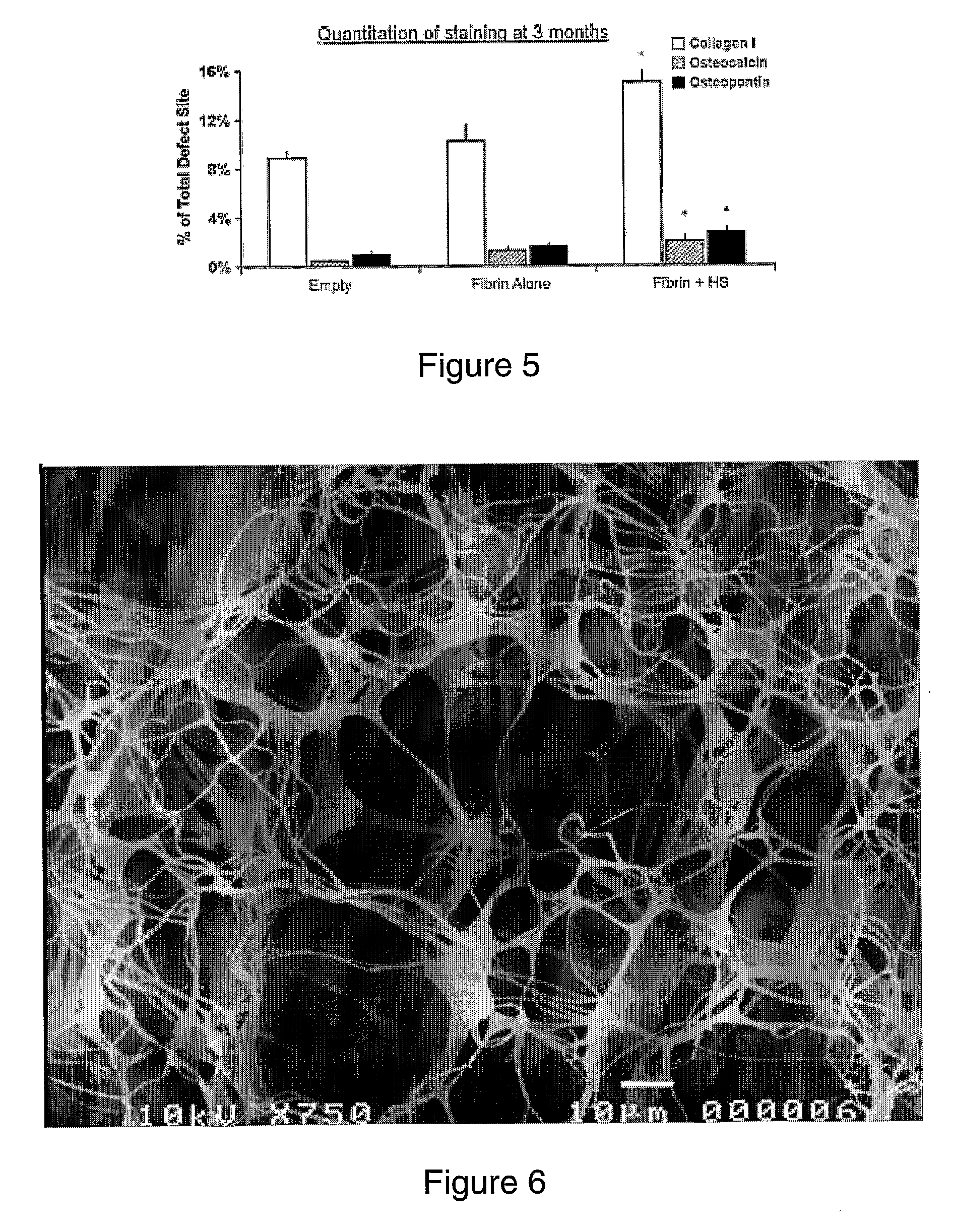

This invention relates to isolated heparan sulphate and use thereof to stimulate bone cell growth and differentiation. The invention also relates to use of heparan sulphate with implants, prosthesis and bioscaffolds to repair and regenerate bone. Such use may be for repair of damaged tissue including bone tissue, for example damage resulting from injury or defect.

Owner:THE UNIV OF QUEENSLAND

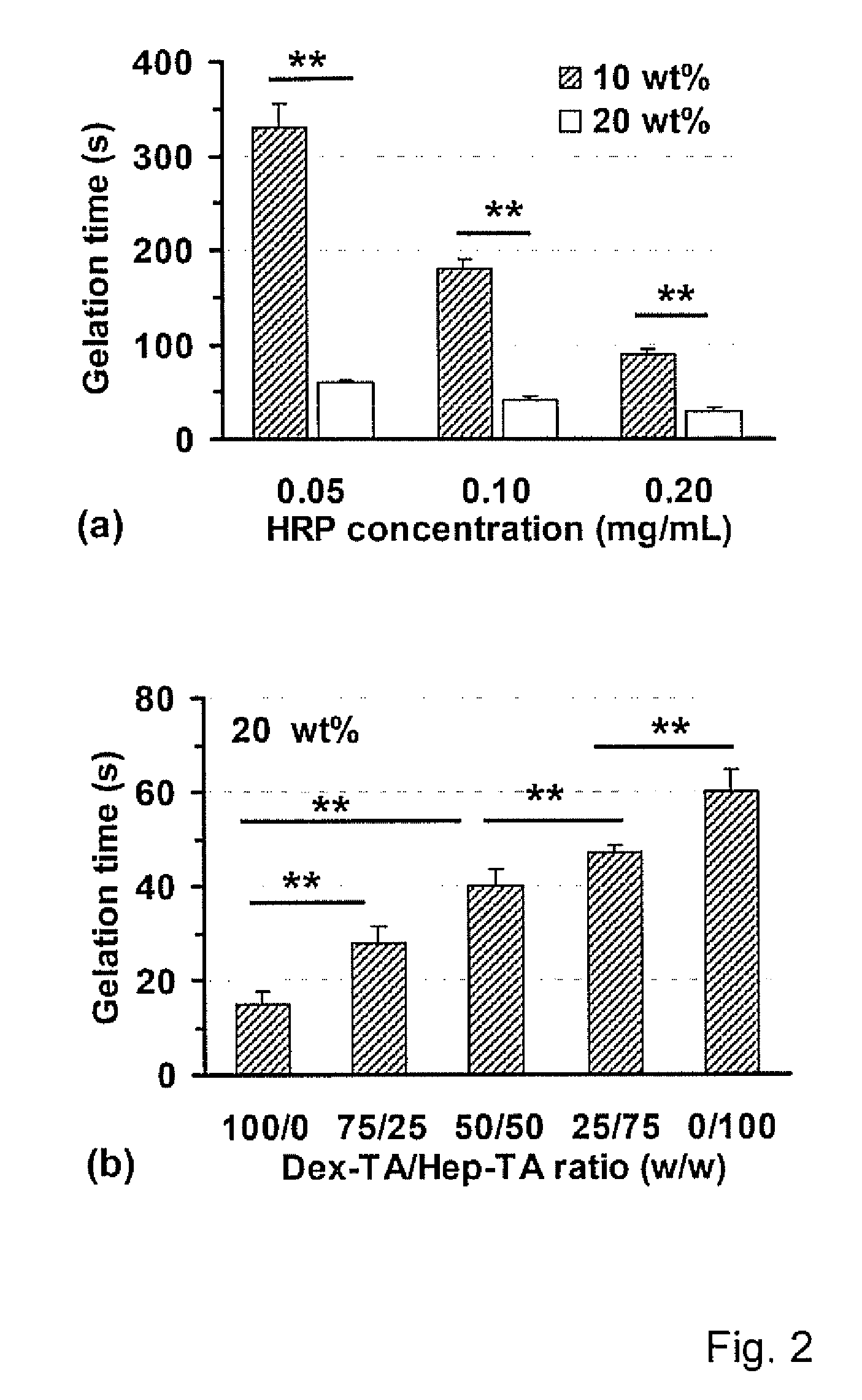

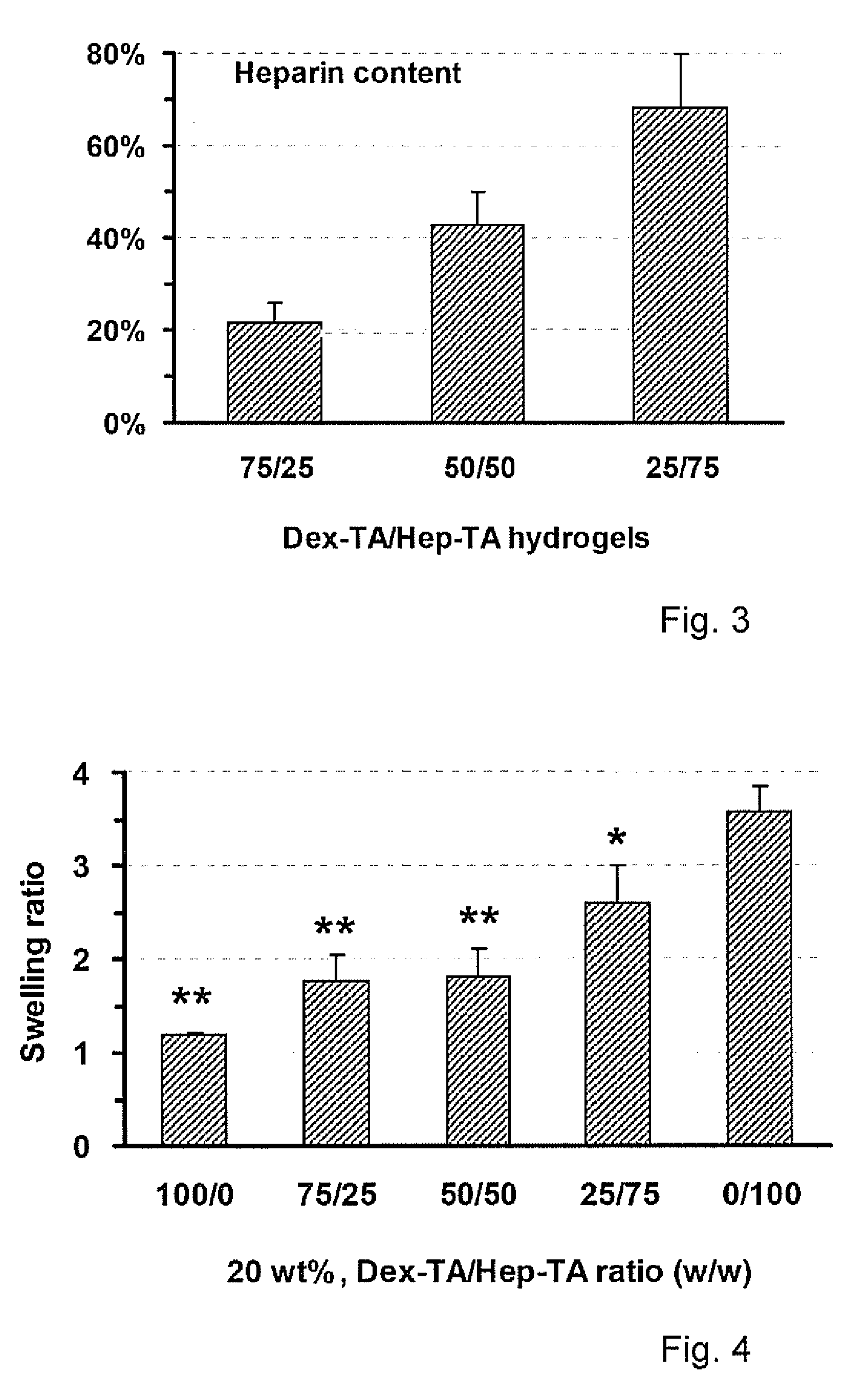

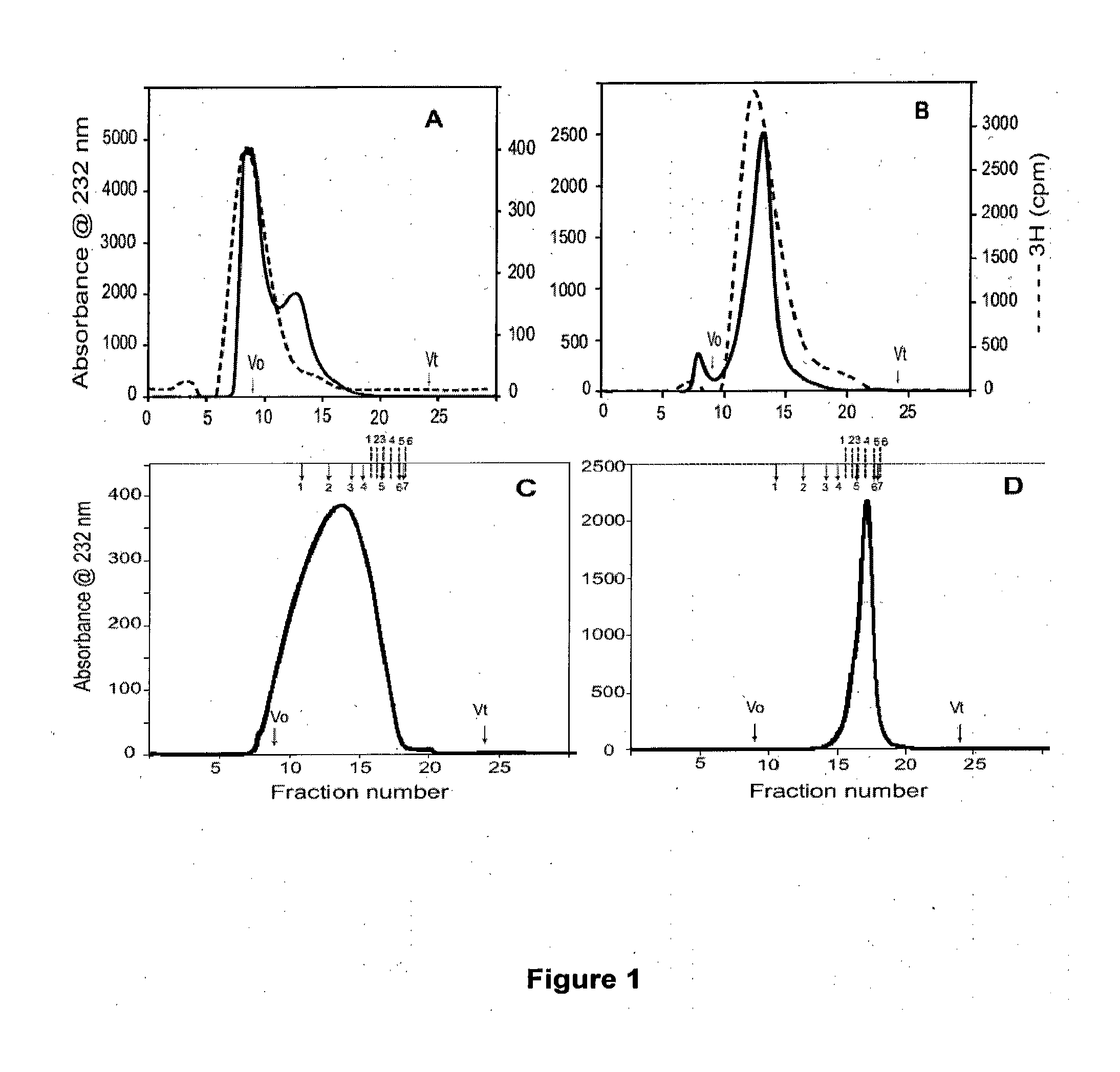

Hydrogels based on polymers of dextran tyramine and tyramine conjugates of natural polymers

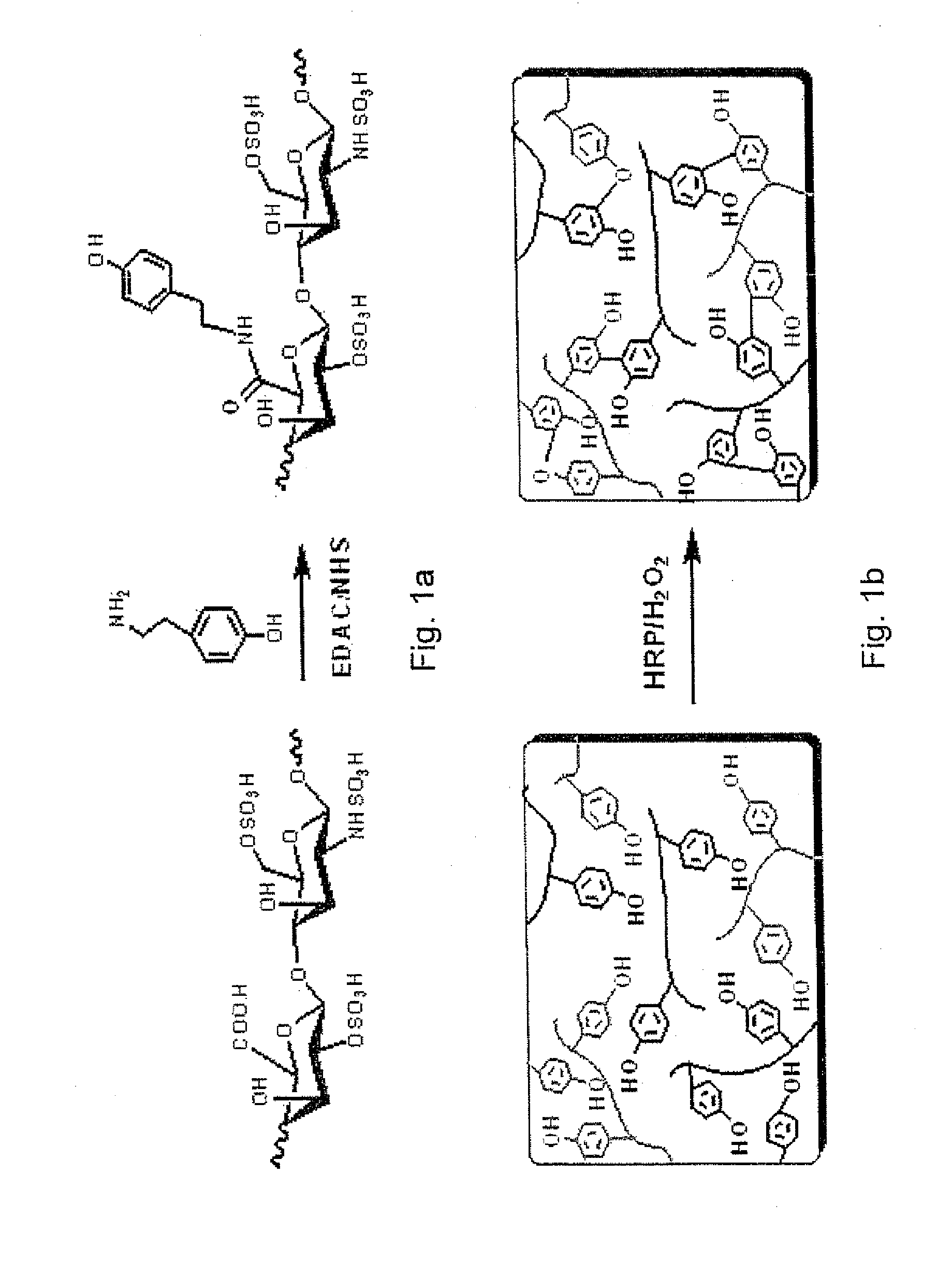

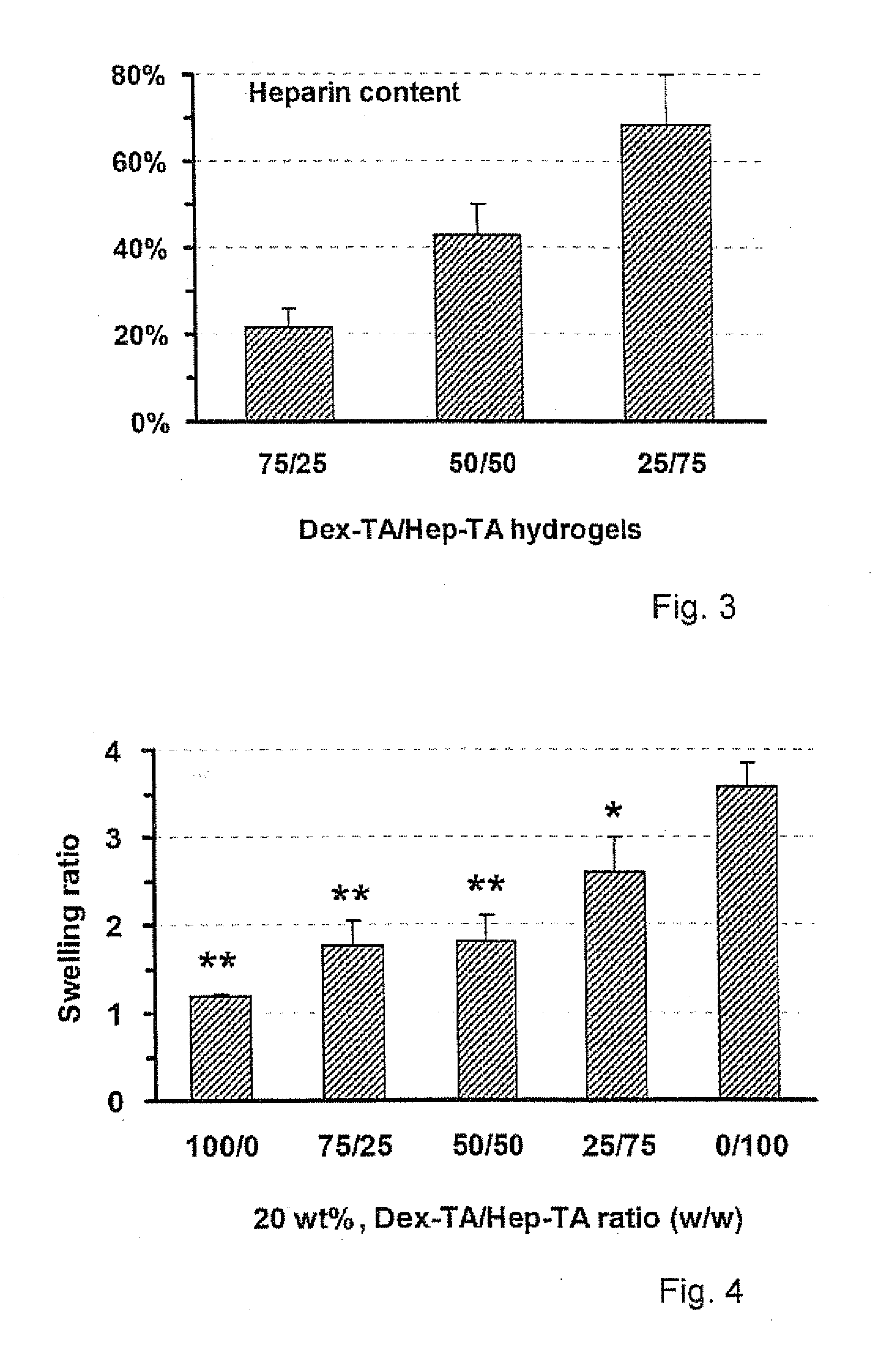

The invention relates to composition comprising a dextran-tyramine conjugate and a conjugate selected from the group consisting of chondroitin sulphate-tyramine, collagen-tyramine, chitosan-tyramine, chitosan-phloretic acid, gelatine-tyramine, heparan sulphate-tyramine, keratin sulphate-tyramine, hyaluronic acid-tyramine and heparin-tyramine.

Owner:HY2CARE BV

Glycosaminoglycans

Owner:AGENCY FOR SCI TECH & RES

Therapeutic Bone Growth and Regeneration

InactiveUS20110165218A1Improve the quality of lifeProlong lifeOrganic active ingredientsPretreated surfacesEmbryoHeparan sulphate

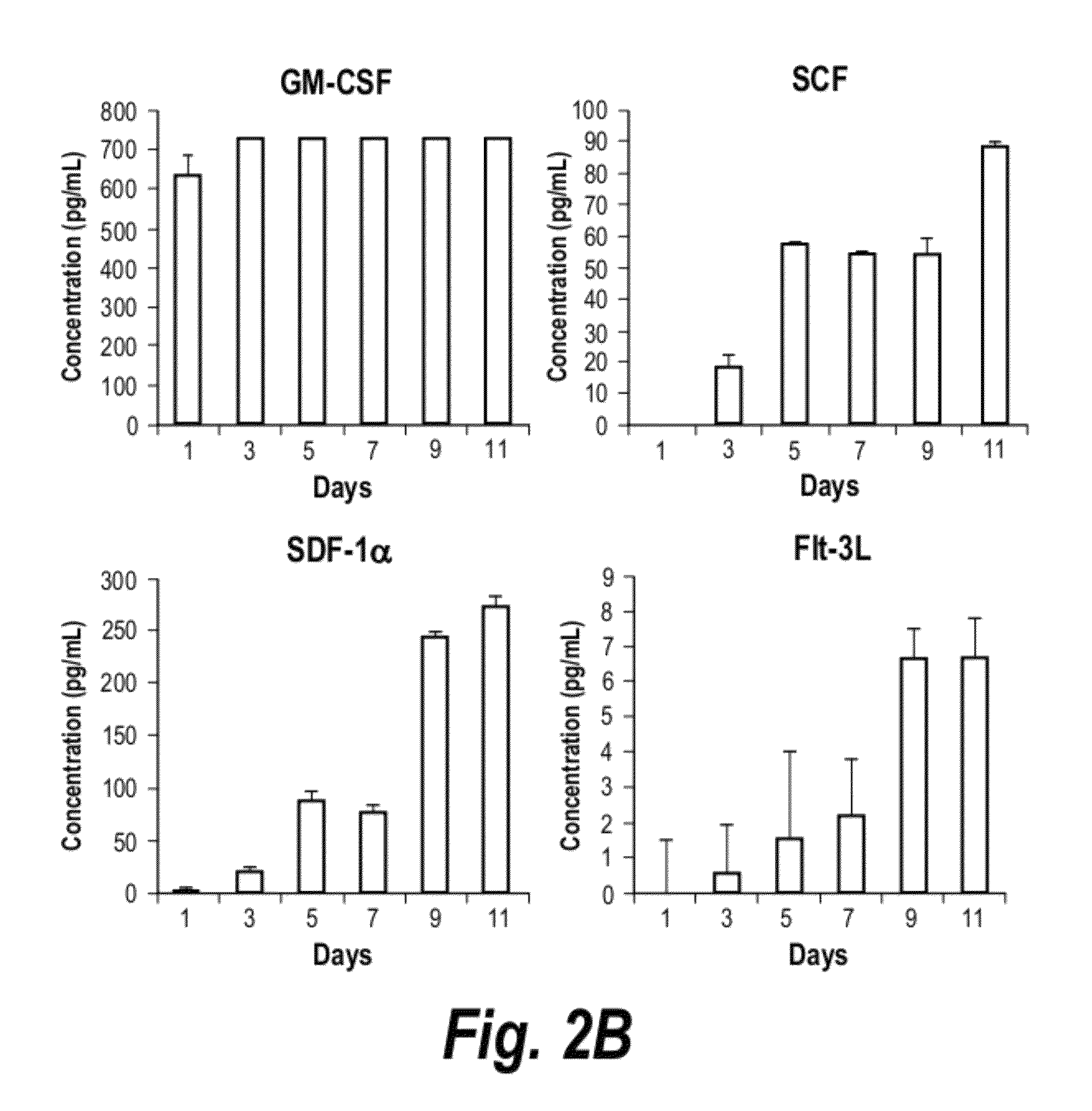

The use of Herapan Sulphate 2 (HS-2) in therapeutic bone growth and regeneration is described. Herapan Sulphate 2 was identified as a variant of Heparan Sulphate purified from embryonic day (E10) of murine neuroepithelia.

Owner:AGENCY FOR SCI TECH & RES

Hydrogels based on polymers of dextran tyramine and tyramine conjugates of natural polymers

The invention relates to composition comprising a dextran-tyramine conjugate and a conjugate selected from the group consisting of chondroitin sulphate-tyramine, collagen-tyramine, chitosan-tyramine, chitosan-phloretic acid, gelatine-tyramine, heparan sulphate-tyramine, keratin sulphate-tyramine, hyaluronic acid-tyramine and heparin-tyramine.

Owner:HY2CARE BV

The isolation and characterisation of heparan sulphates and their use in pharmaceutical compositions, methods of treatment and stem cell culture media suitable for conditions associated with bone repair

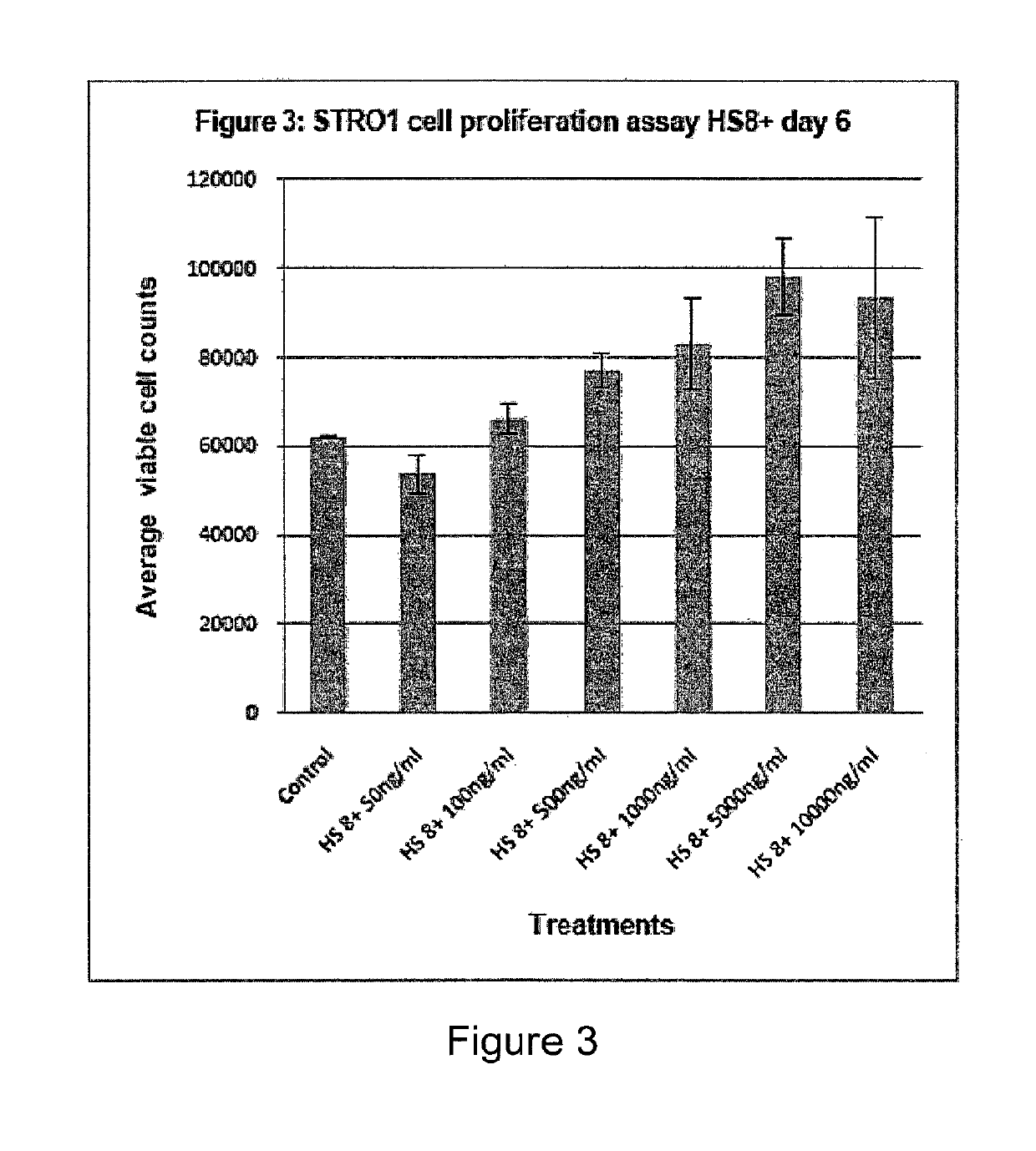

InactiveUS20120230964A1Increased proliferationIncrease differentiationBiocideOrganic active ingredientsMurine liverHeparan sulphate

Heparan sulphates isolated from male and female murine liver, their characterisation and use in pharmaceutical compositions, methods of treatment and in stem cell culture media suitable for conditions associated with bone repair.

Owner:AGENCY FOR SCI TECH & RES

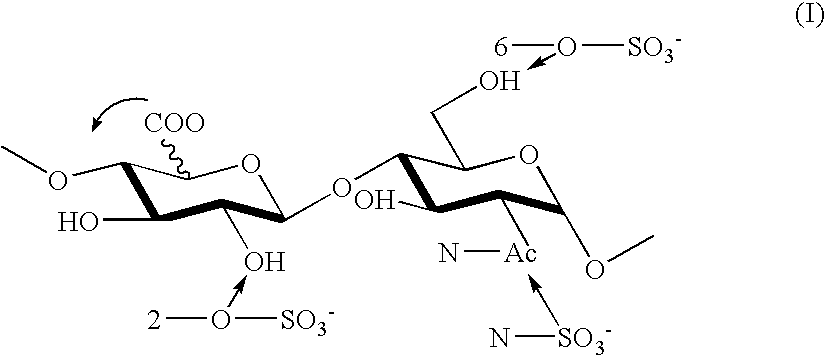

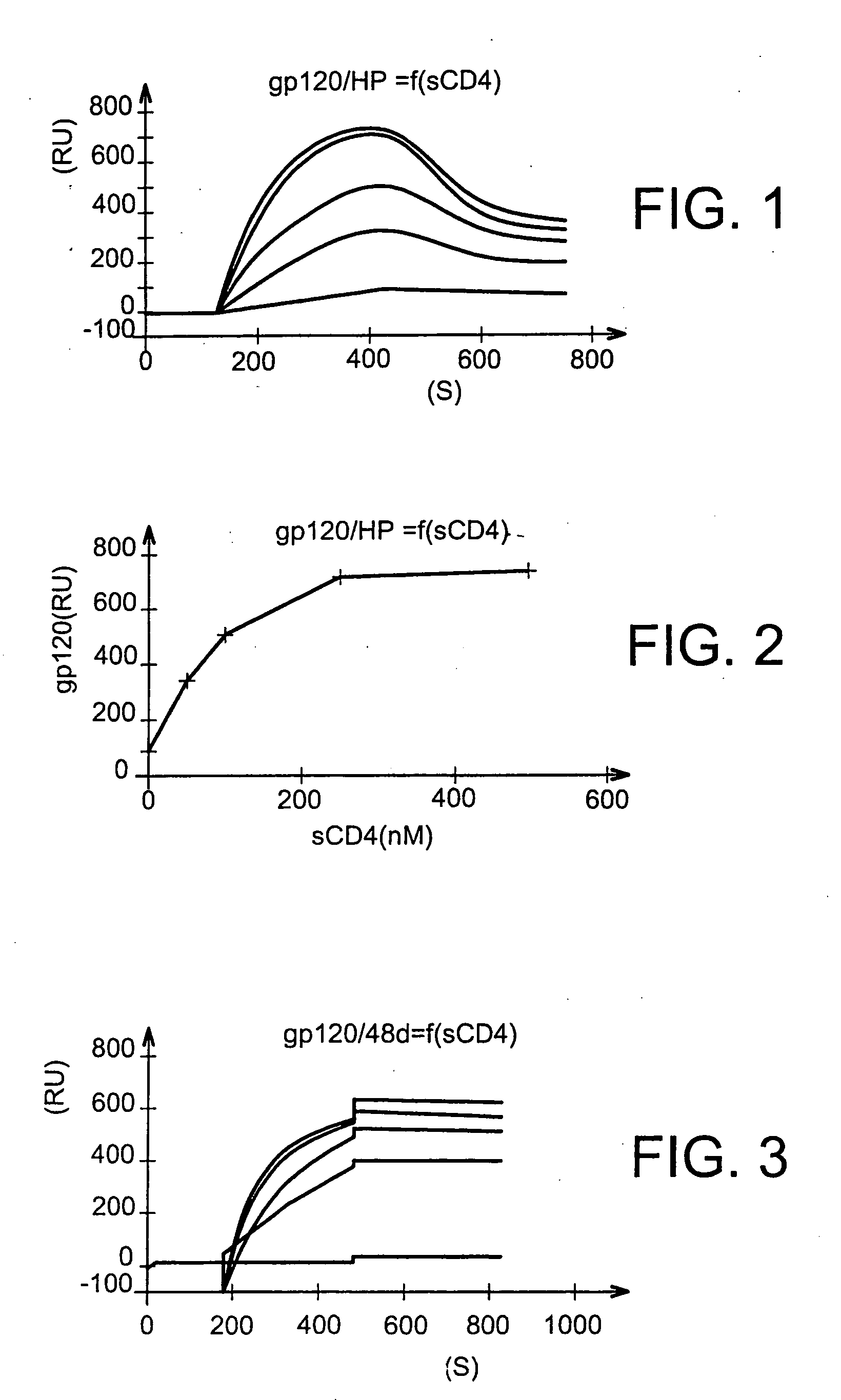

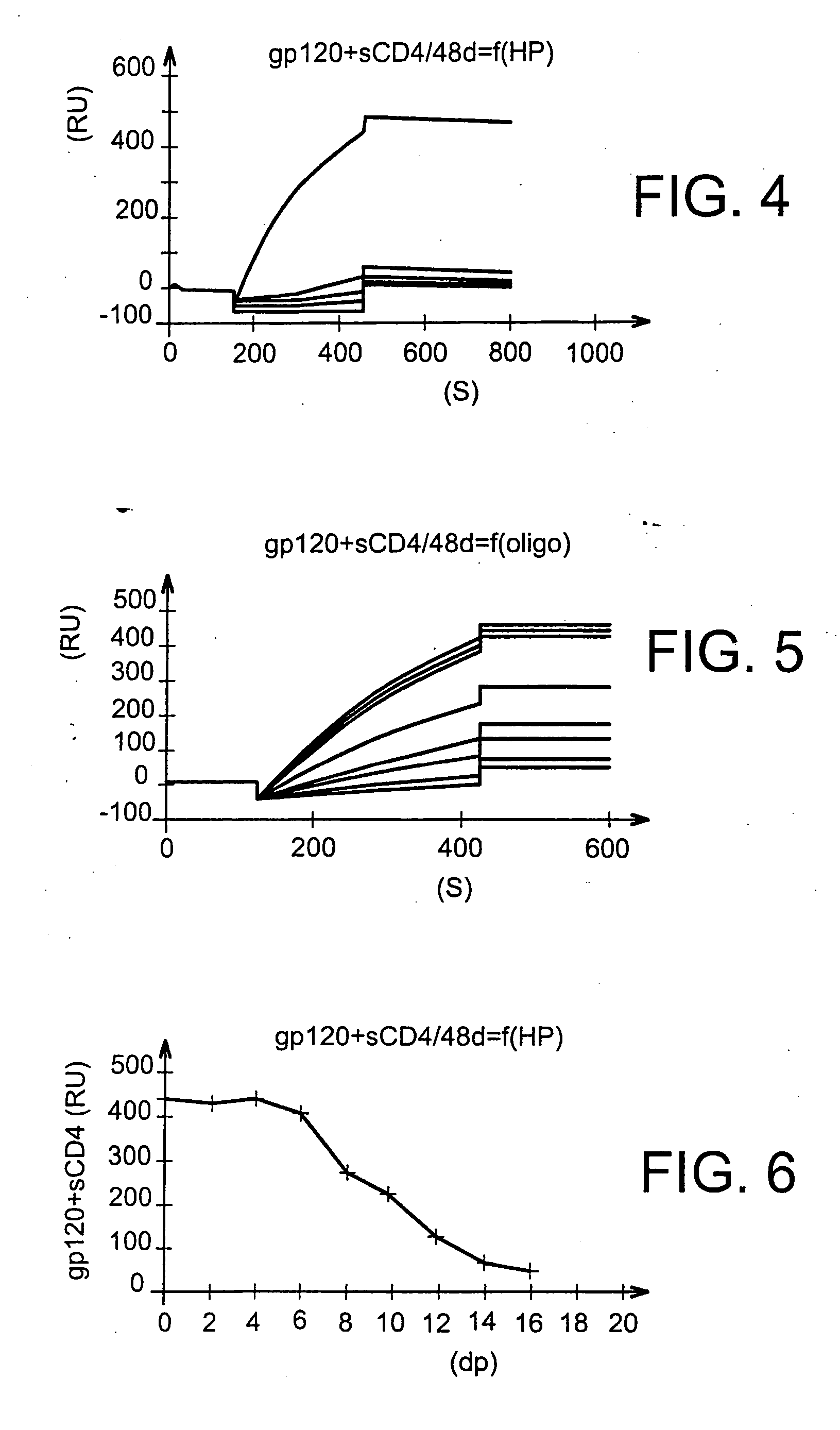

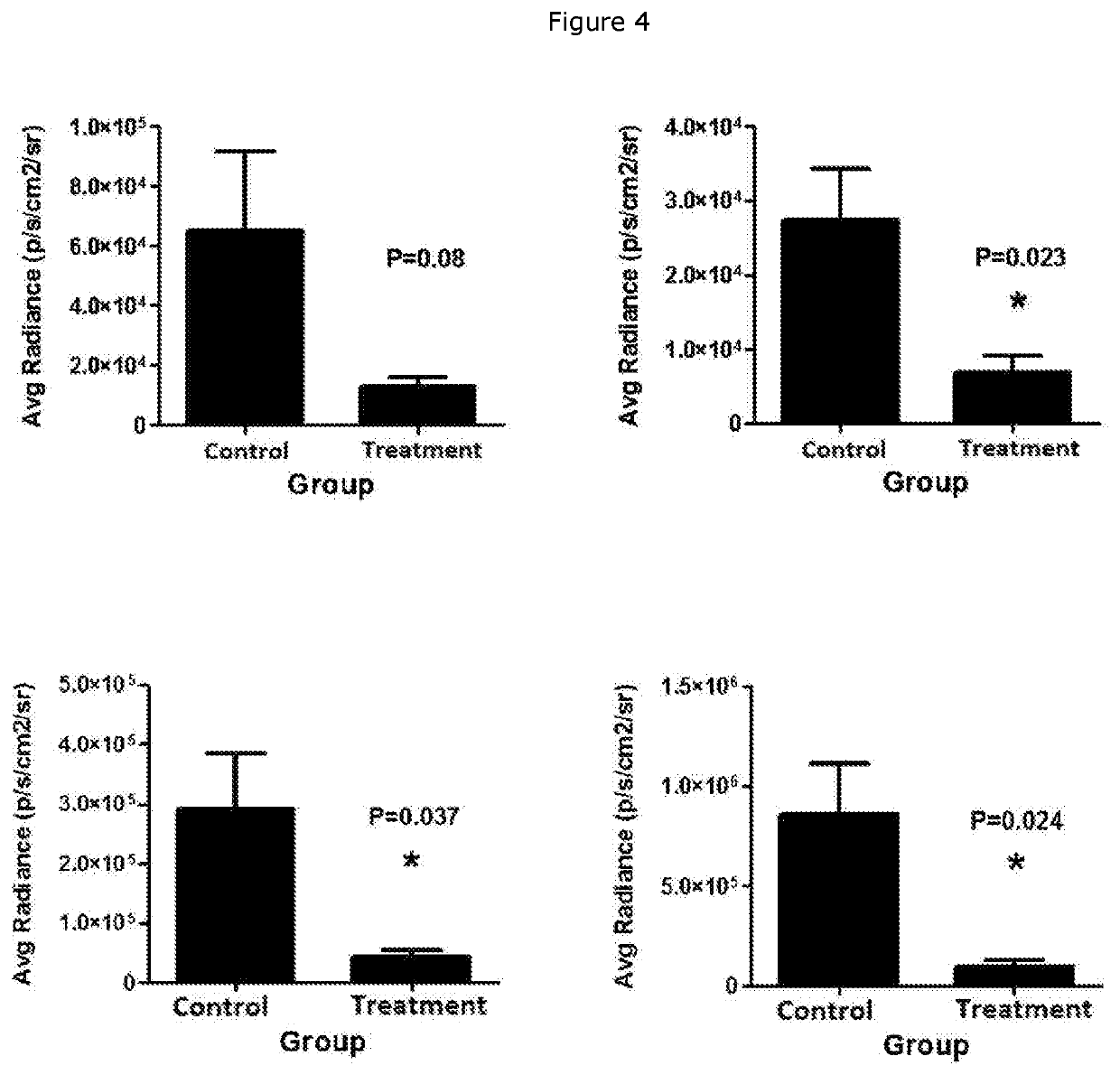

Anti-hiv composition, production method thereof and medicament

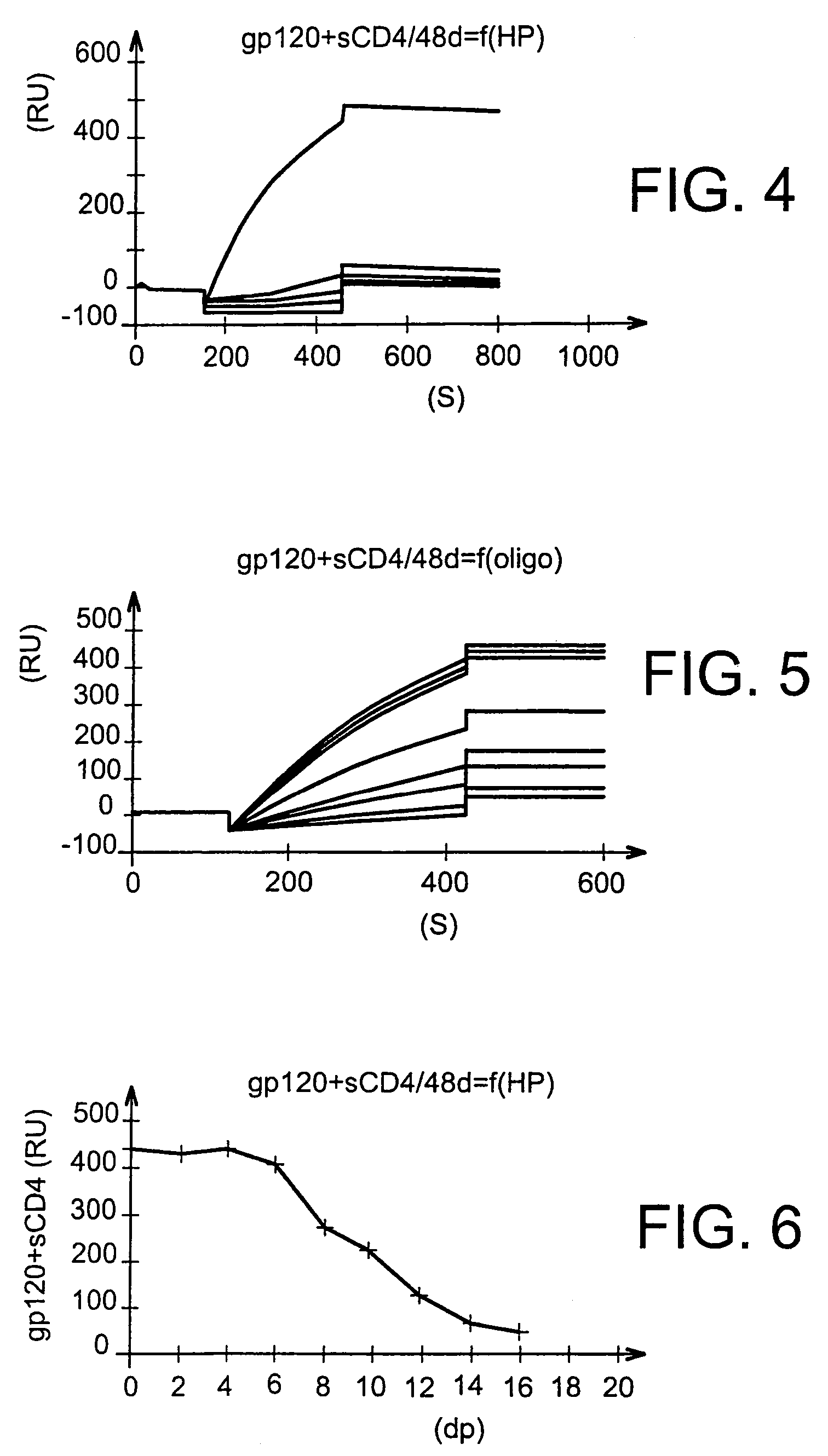

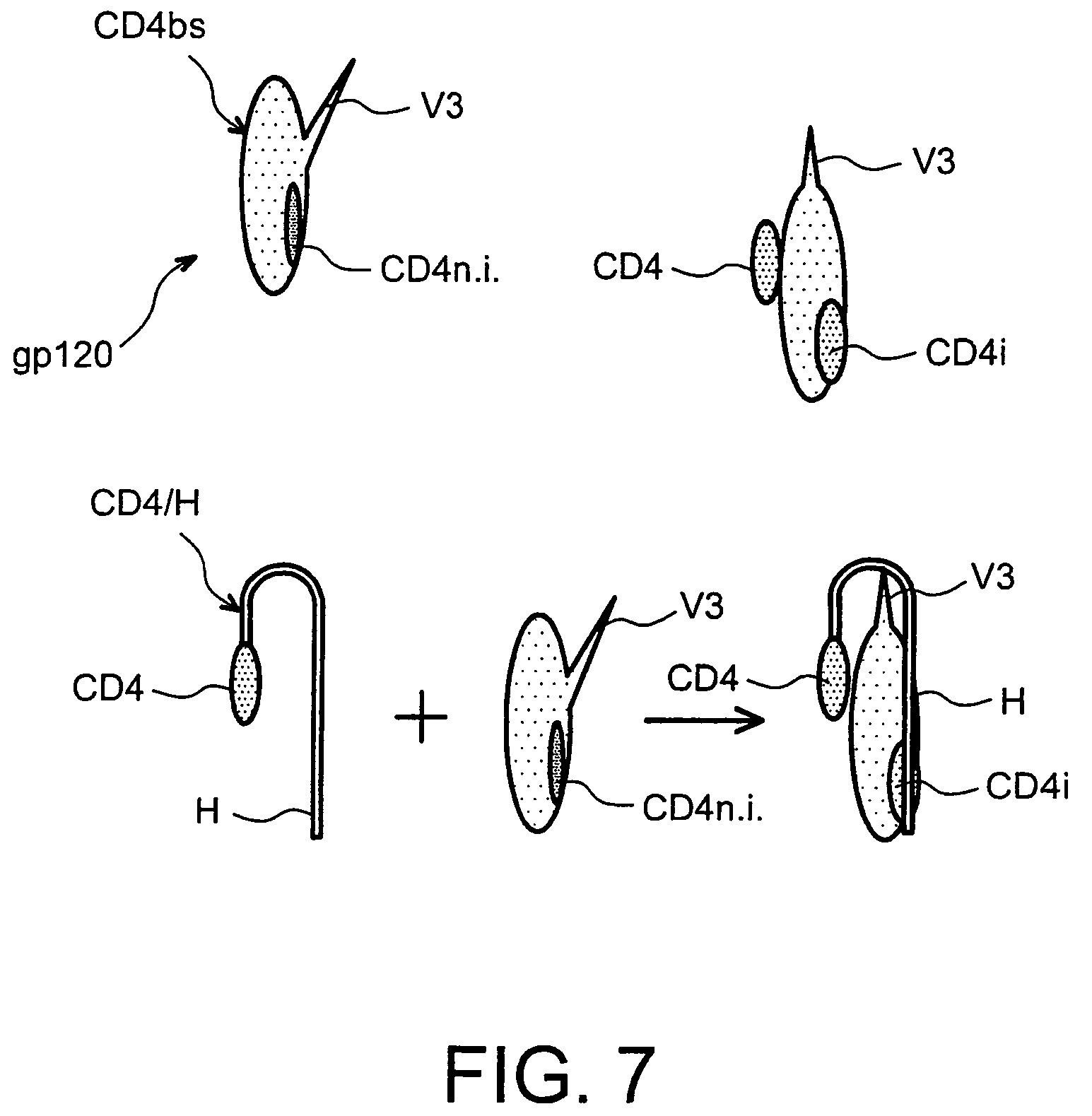

InactiveUS20060084593A1Inhibits gp120/48dIncrease infectivityBiocideOrganic active ingredientsEpitopePharmacy medicine

The present invention relates to an anti-HIV composition and to the method for producing it. The composition of the present invention comprises a polyanion and a molecule capable of inducing the exposure of the CD4i epitope of the gp120 viral protein. The polyanion may be chosen, for example, from the group consisting of heparin, heparan sulphate, and a polyanion equivalent to heparin or to heparan sulphate. The molecule capable of inducing the exposure of the CD4i epitope of the gp120 viral protein is a CD4 peptide or a derivative thereof. The present invention also relates to the use of said composition for producing a medicinal product, in particular a medicinal product intended for the treatment of AIDS.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

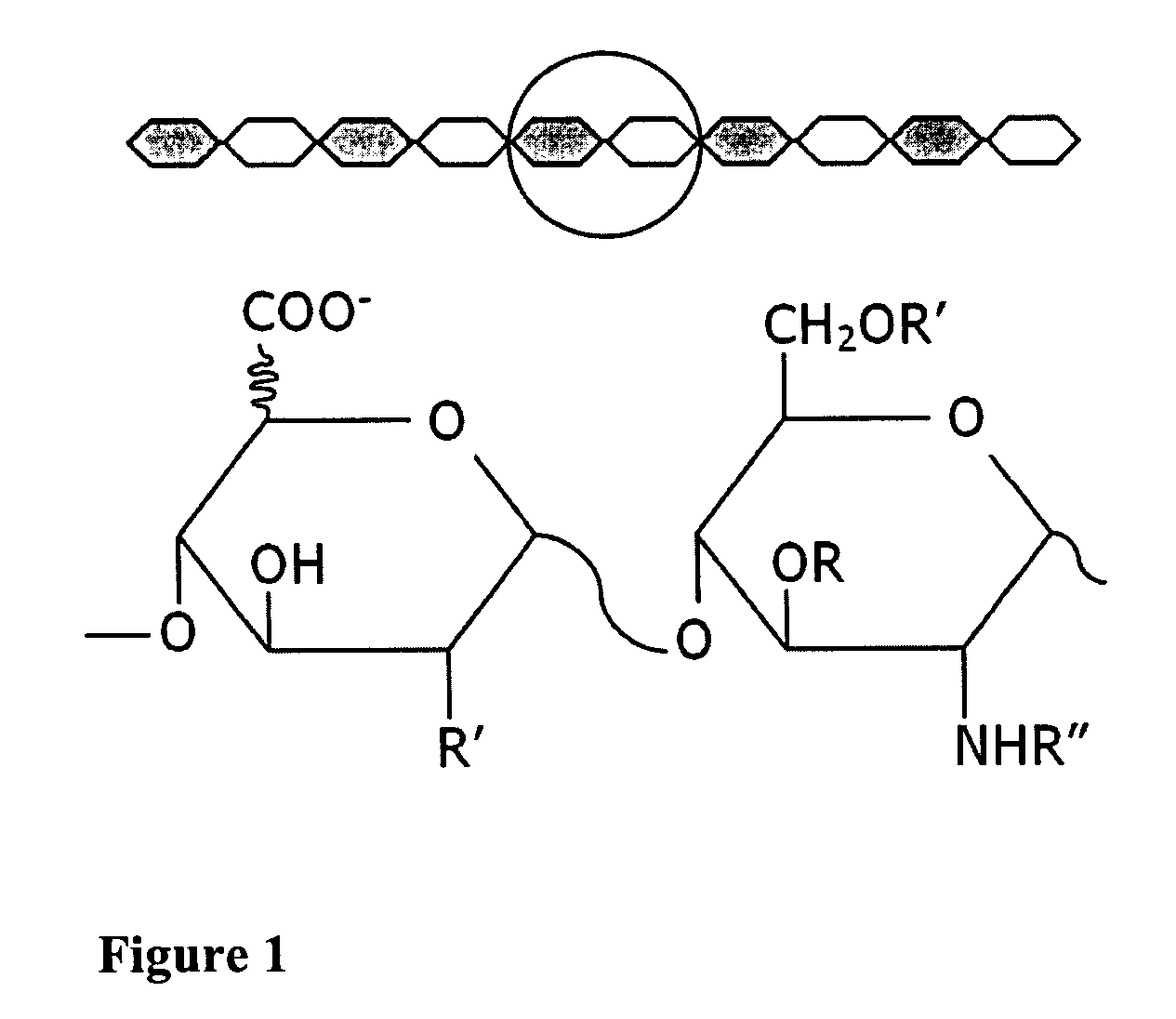

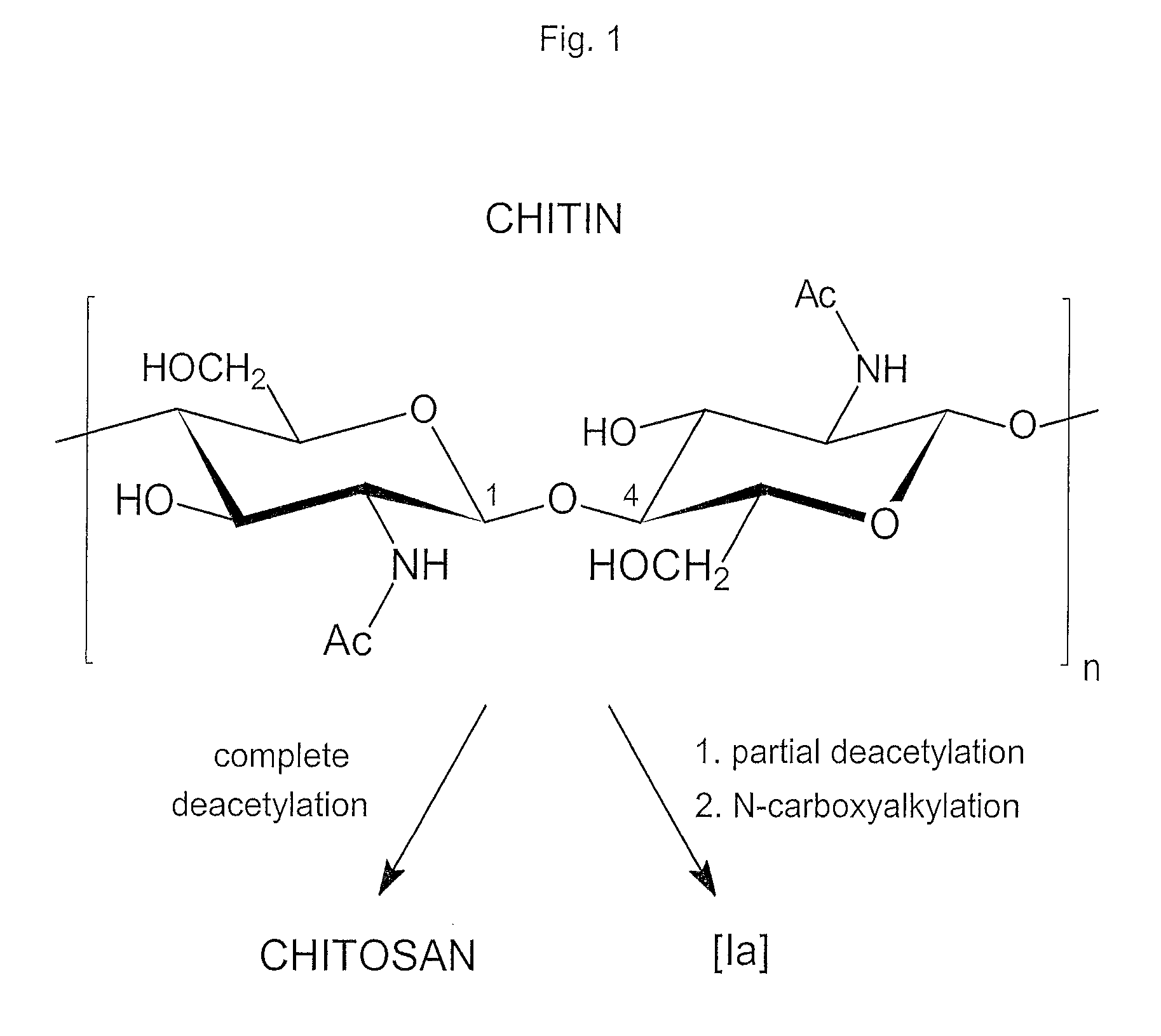

Compounds and method for coating surfaces in a hemocompatible manner

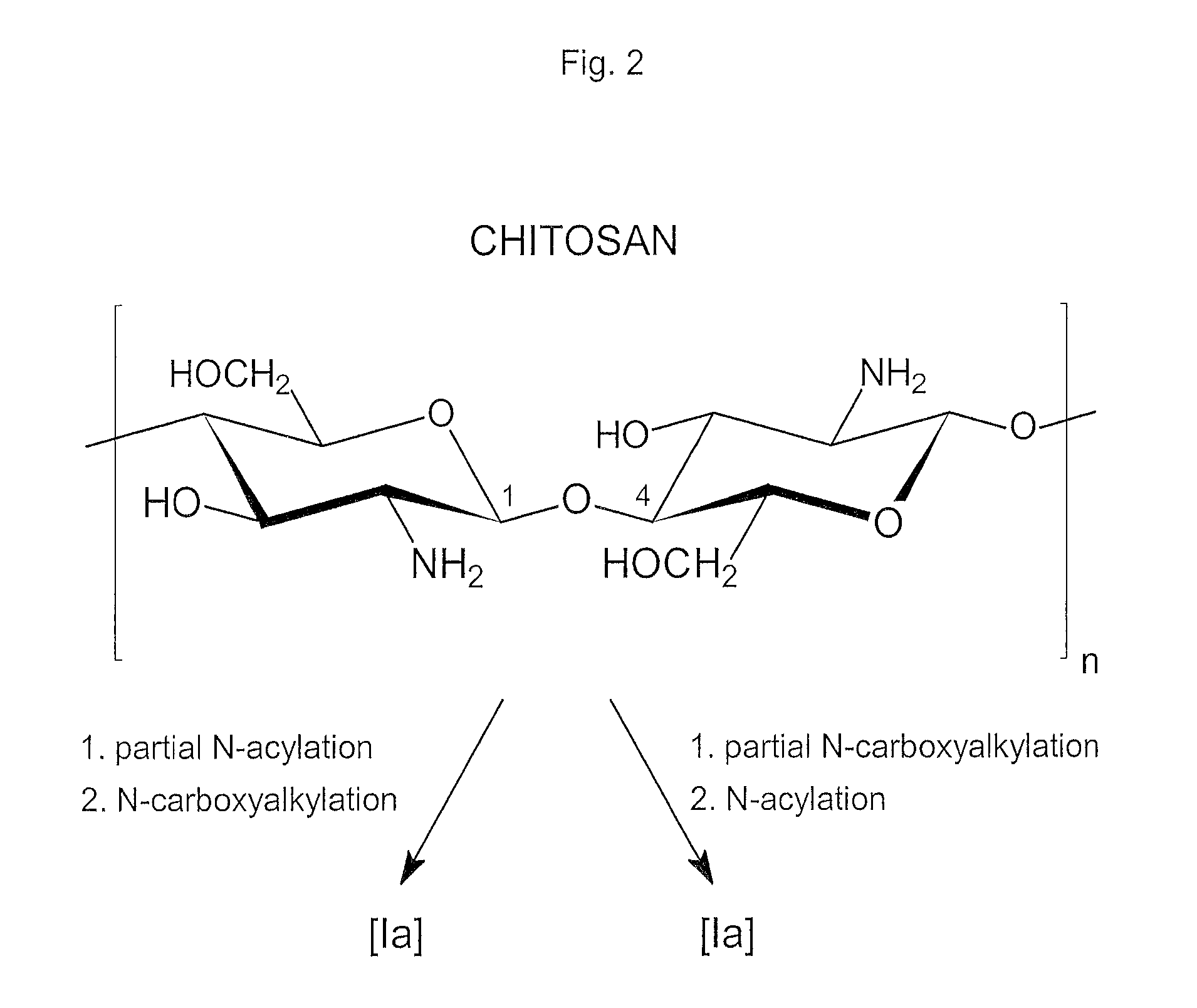

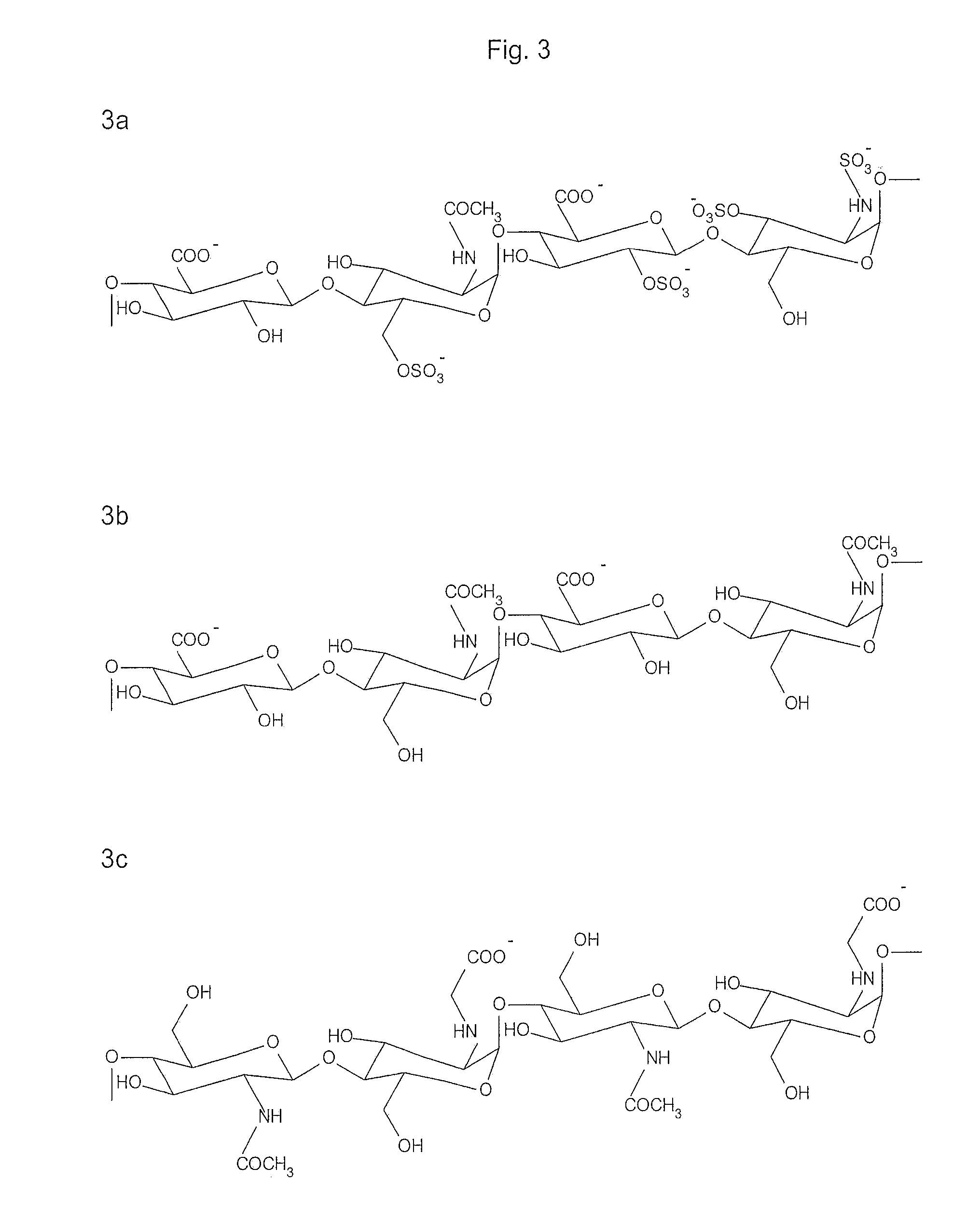

InactiveUS8784862B2Prevention and reduction of undesired reactionSuppression problemOrganic active ingredientsPeptide/protein ingredientsRestenosisActive agent

The invention concerns oligosaccharides and polysaccharides as well as the use of these oligosaccharides and / or polysaccharides, which contain the sugar unit N-acylglucosamine or N-acylgalactosamine for the production of hemocompatible surfaces as well as methods for the hemocompatible coating of surfaces with said oligosaccharides and / or polysaccharides, which imitate the common biosynthetic precursor substance of heparin, heparan sulphates and chitosan. The invention further describes methods for producing said oligosaccharides and / or polysaccharides and discloses various possibilities of using hemocompatibly coated surfaces. The invention relates particularly to the use of said oligosaccharides and / or polysaccharides on stents with at least one according to invention deposited hemocompatible coating, which contains an antiproliferative, antiinflammatory and / or antithrombotic active agent, methods for the preparation of said stents as well as the use of said stents for the prevention of restenosis.

Owner:HEMOTEQ AG

Heparan sulphates

ActiveUS10266612B2Increased proliferationFacilitated DiffusionOrganic active ingredientsPeptide/protein ingredientsHeparan sulphateBiology

Owner:AGENCY FOR SCI TECH & RES

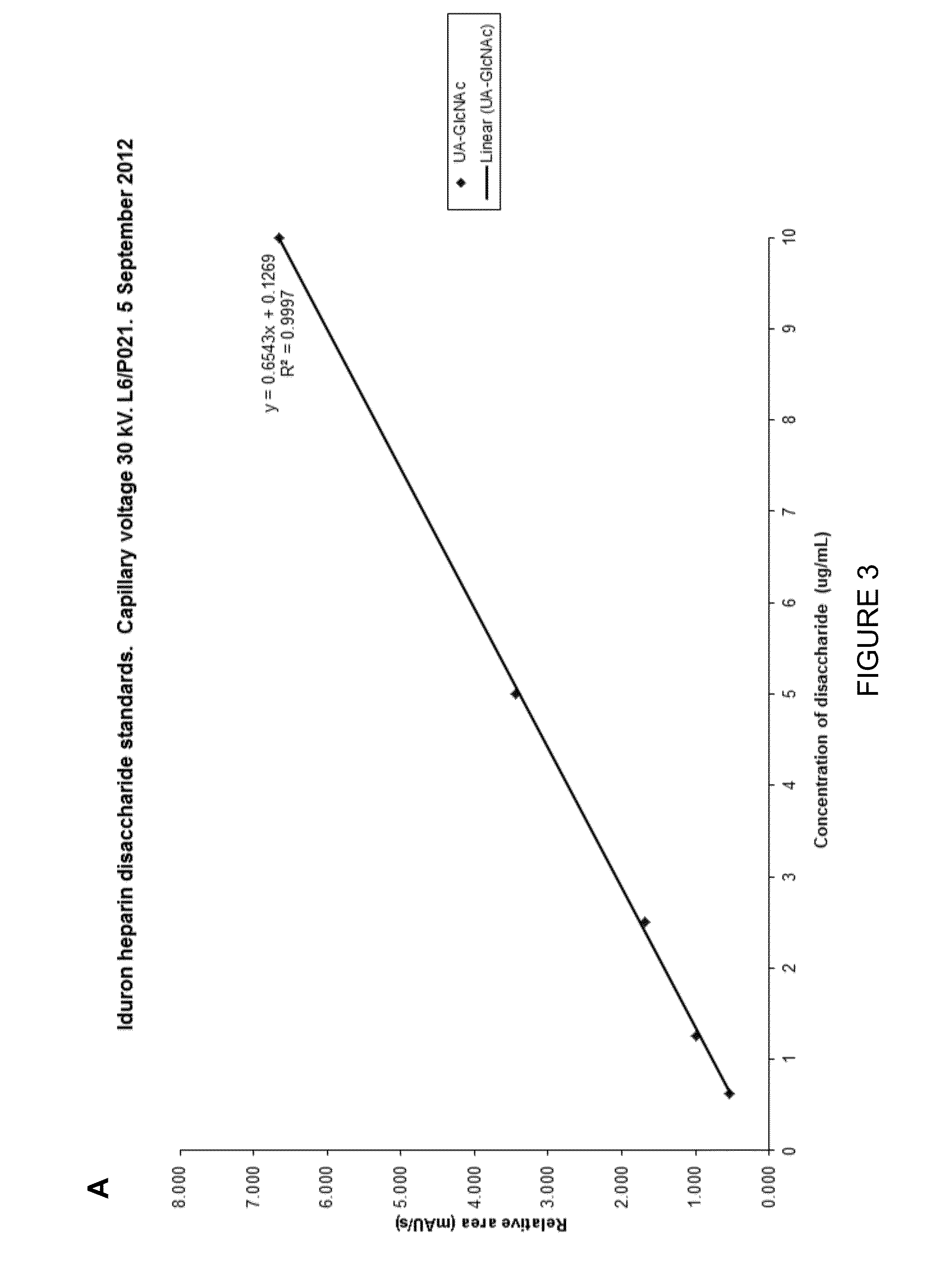

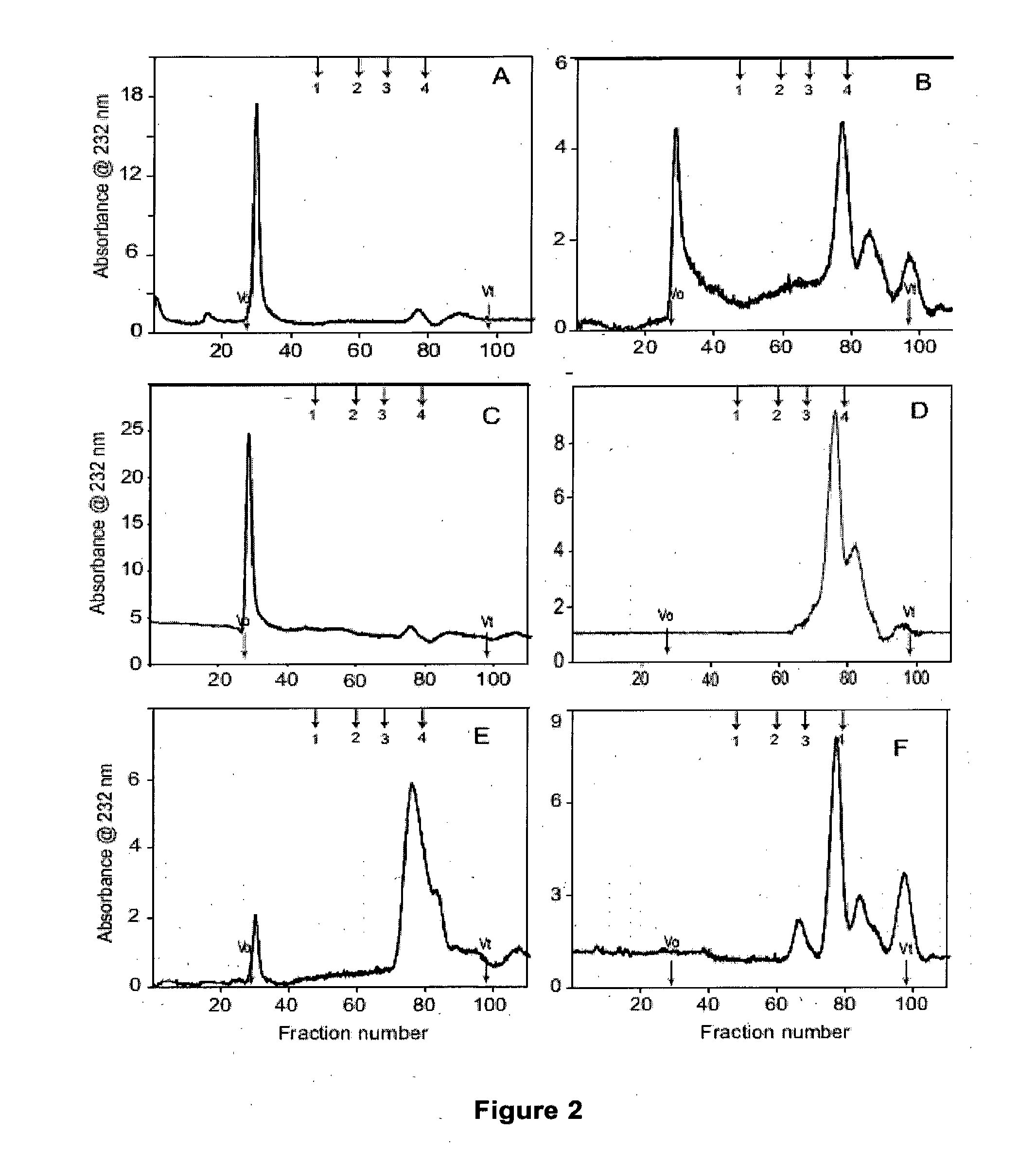

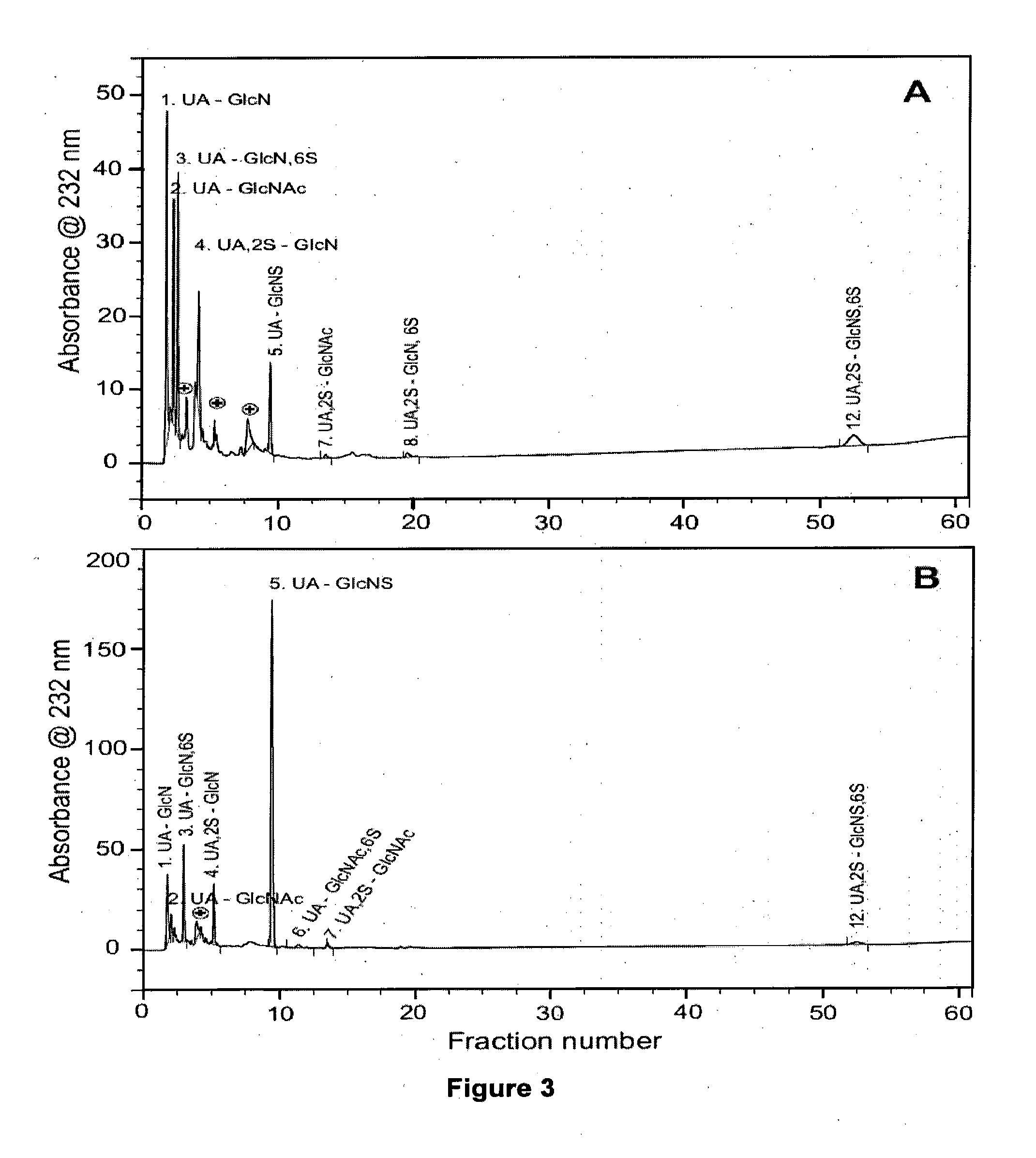

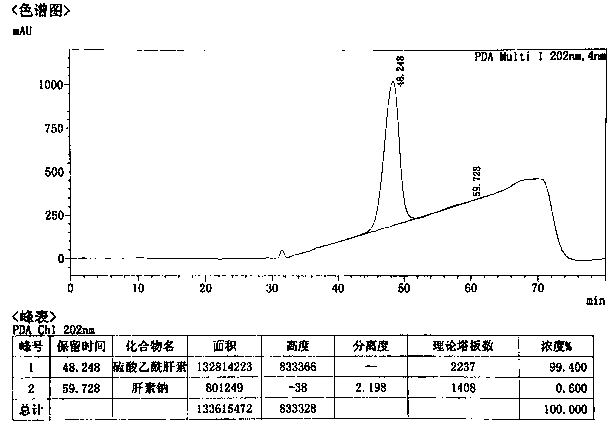

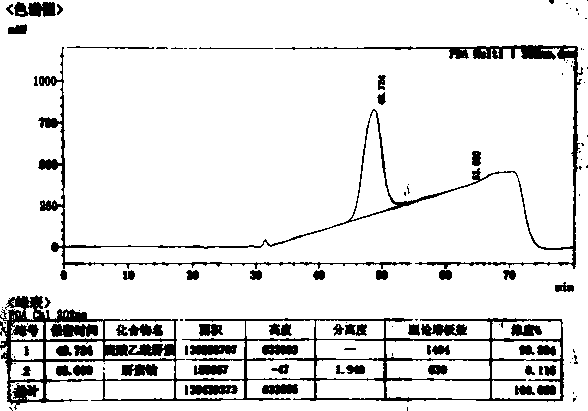

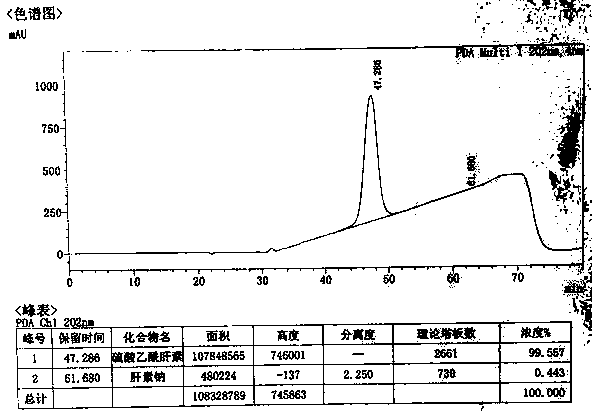

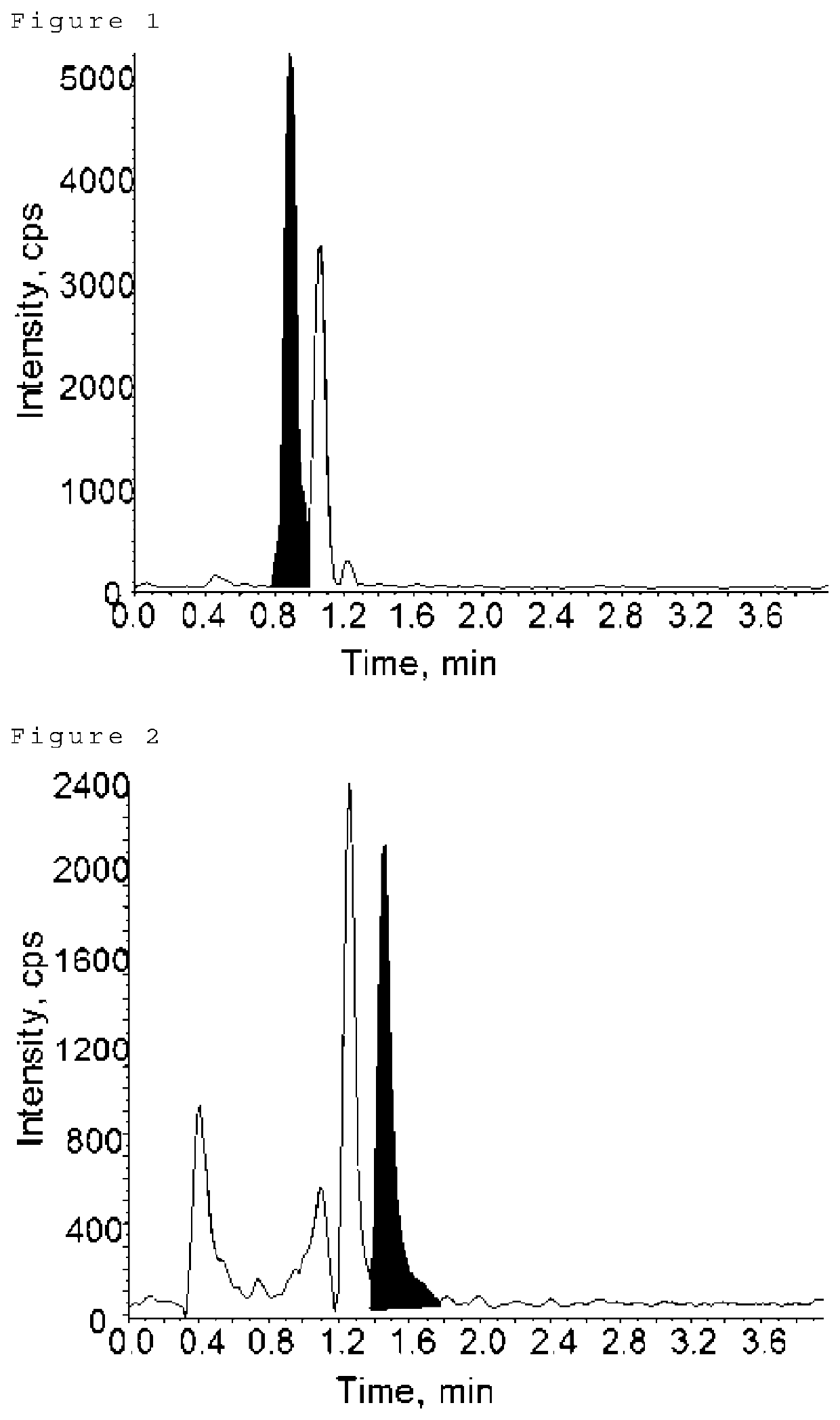

Identification method and application of heparin and heparan sulfate

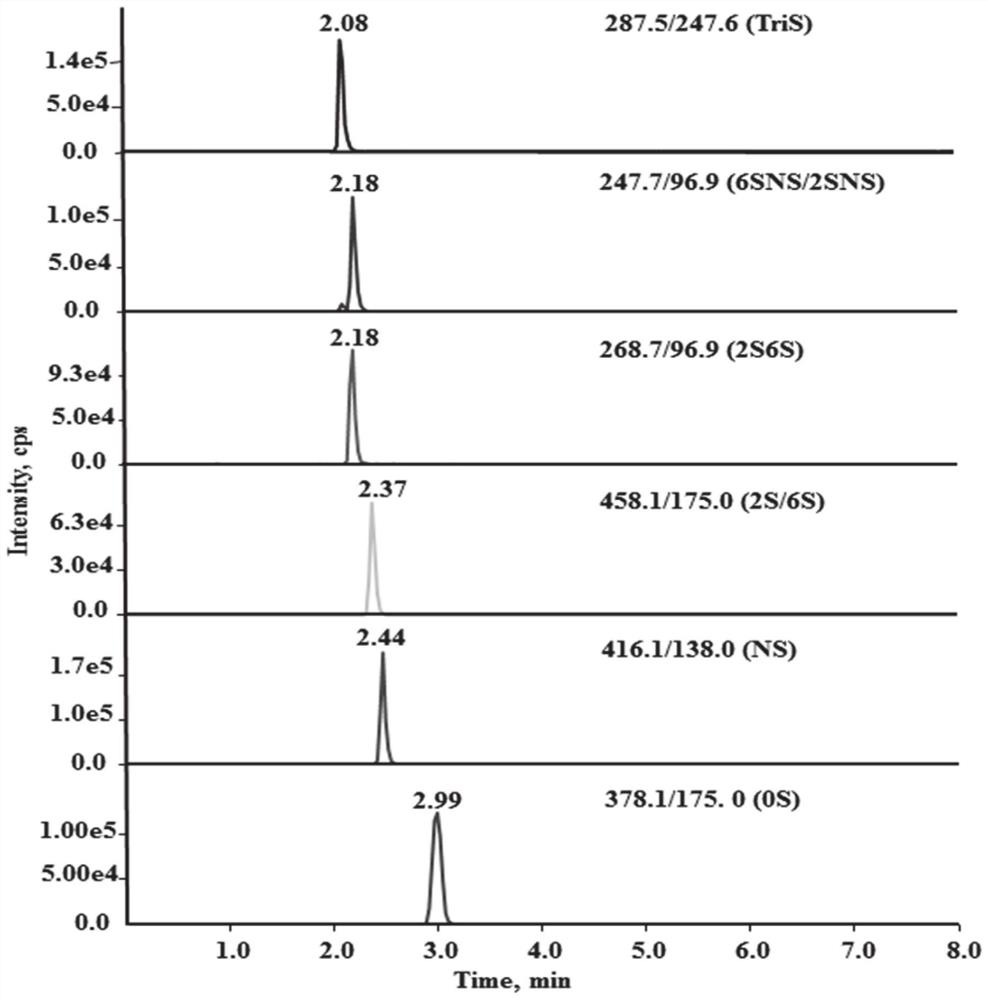

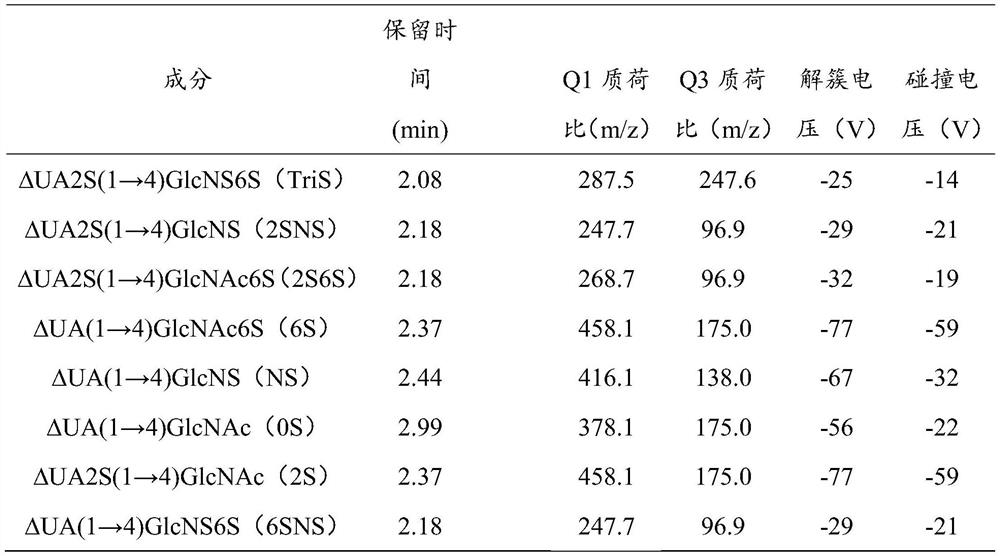

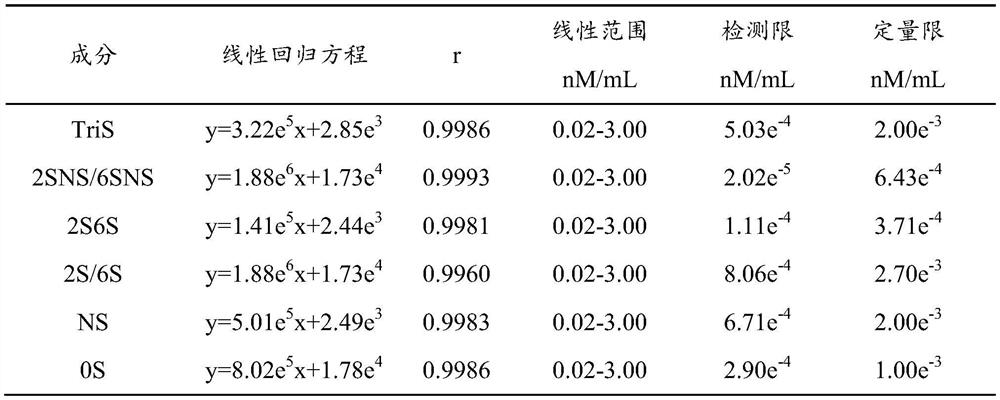

ActiveCN111721872ASimple methodFast wayComponent separationMass Spectrometry-Mass SpectrometryHeparan sulphate

The invention provides an identification method and application of heparin and heparan sulfate, and belongs to the technical field of medicine detection. Research finds that eight disaccharide components of 0S, NS, 6S, 2S, 2SNS, 6SNS, 2S6S and TriS are rich in heparin drugs, and can be well used for identifying heparin and heparan sulfate as a mixed standard substance. Therefore, a set of quantitative detection method based on hydrophilic interaction chromatography-mass spectrometry is established for the eight components, and the method has the advantages of being easy and convenient to operate, short in consumed time, high in selectivity, high in sensitivity, good in specificity, good in repeatability and the like. The method can be used for simply, conveniently and accurately identifying heparin and heparan sulfate, a method and data reference are provided for constructing a more complete quality control standard system of glycosaminoglycan drugs, so that the method has good practical application value.

Owner:SHANDONG UNIV

Therapeutic bone growth and regeneration

InactiveUS9205106B2Promote wound healingPromote bone regenerationOrganic active ingredientsMedical devicesSulphate IonHeparan sulphate

The use of Herapan Sulphate 2 (HS-2) in therapeutic bone growth and regeneration is described. Herapan Sulphate 2 was identified as a variant of Heparan Sulphate purified from embryonic day (E10) of murine neuroepithelia.

Owner:AGENCY FOR SCI TECH & RES

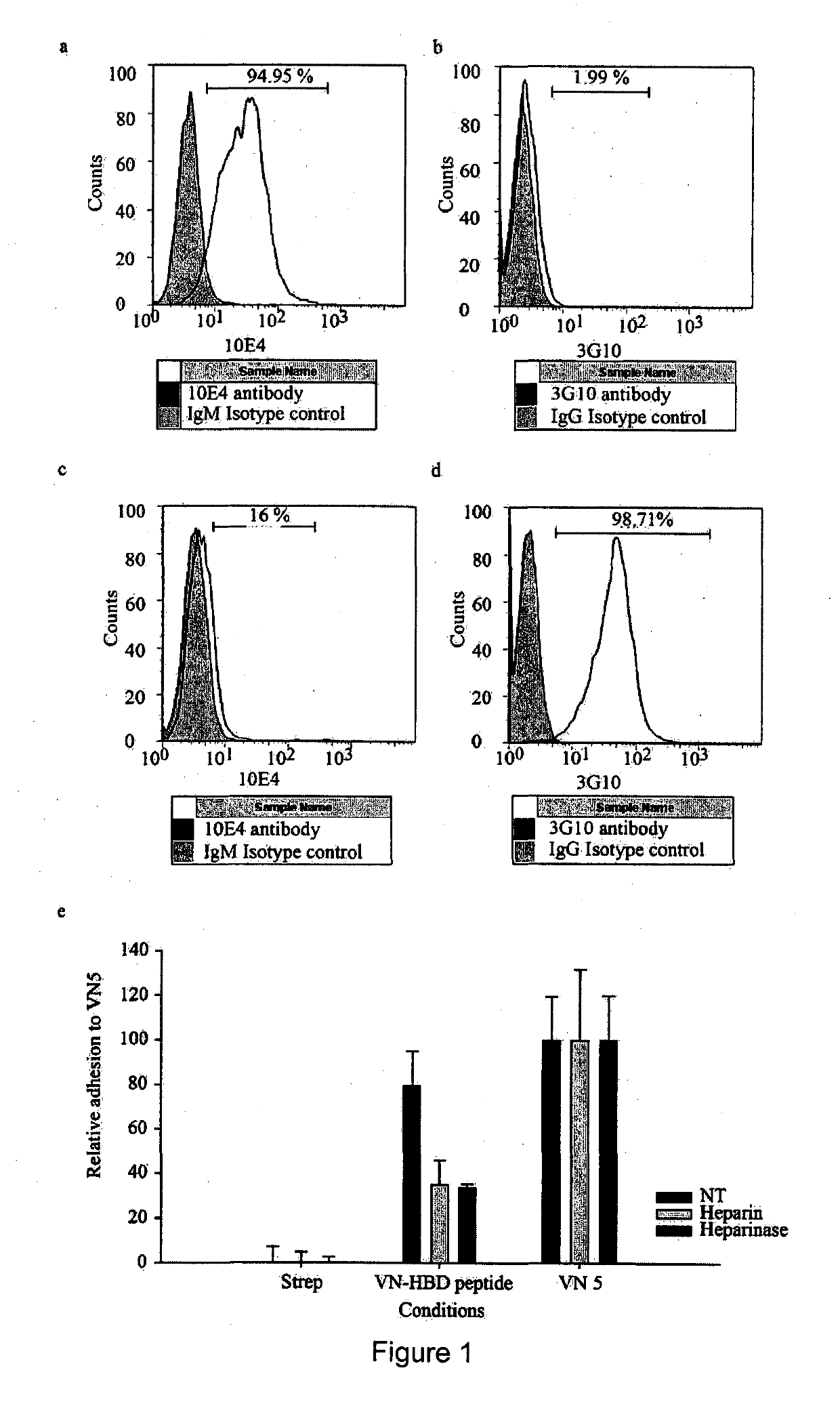

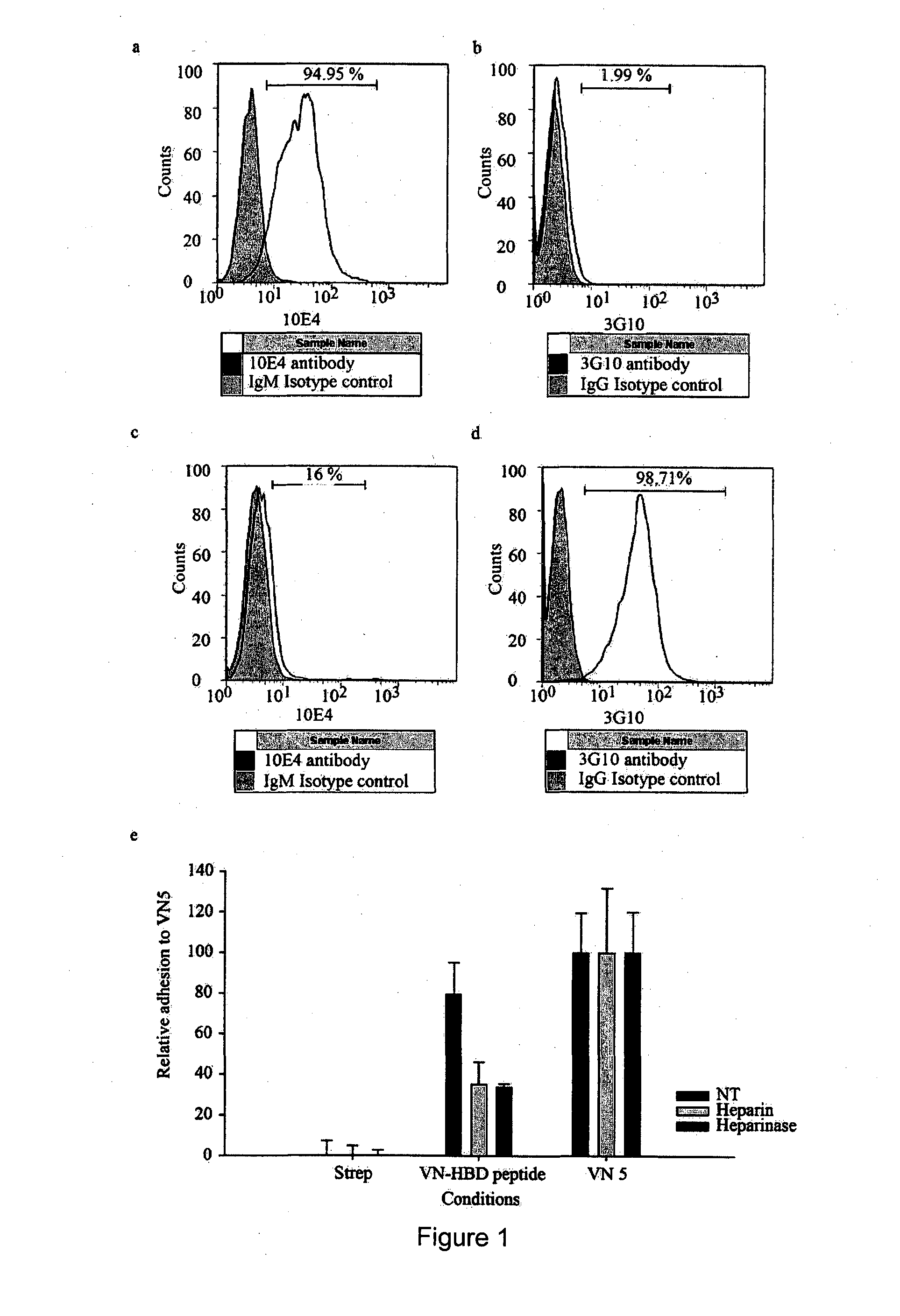

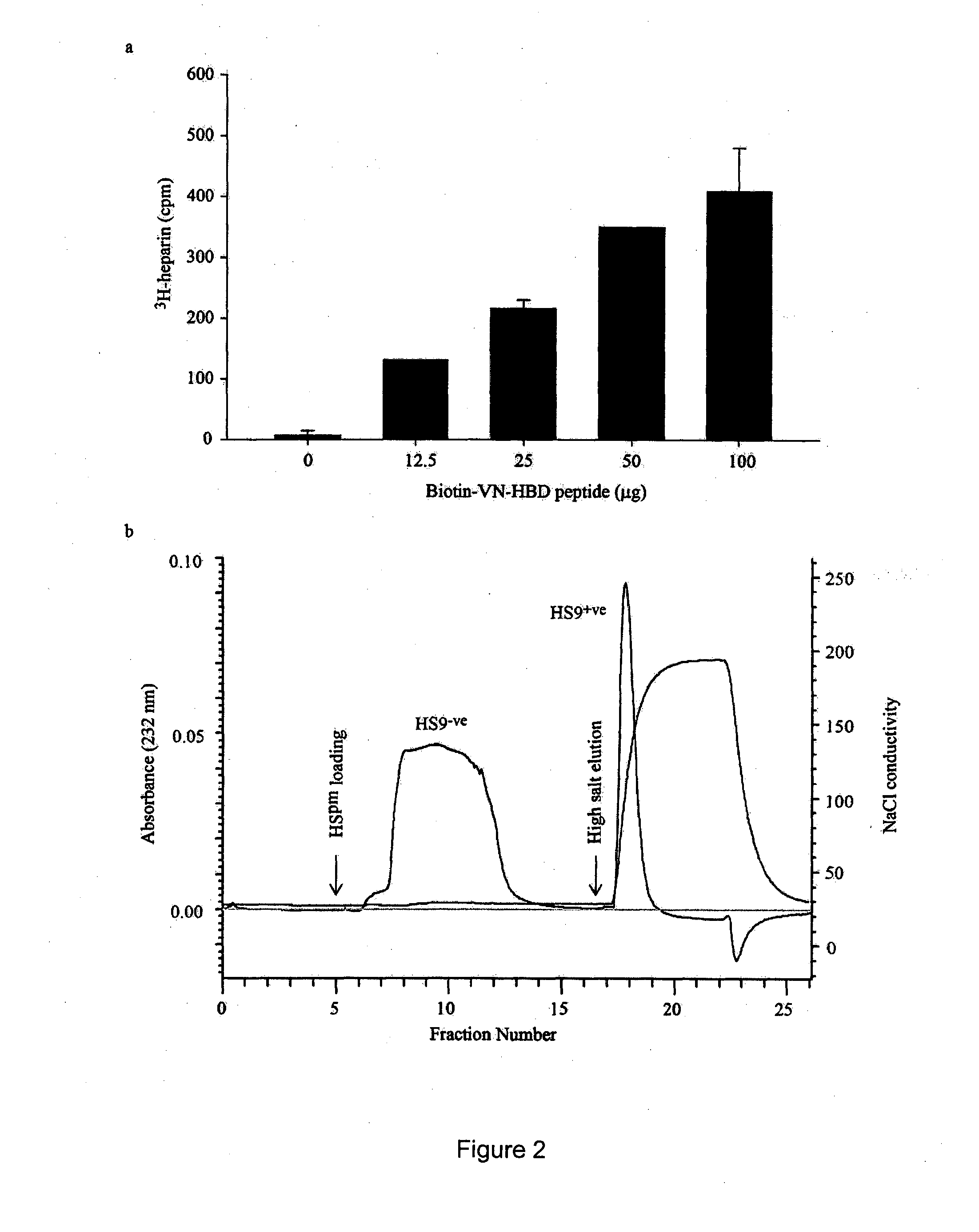

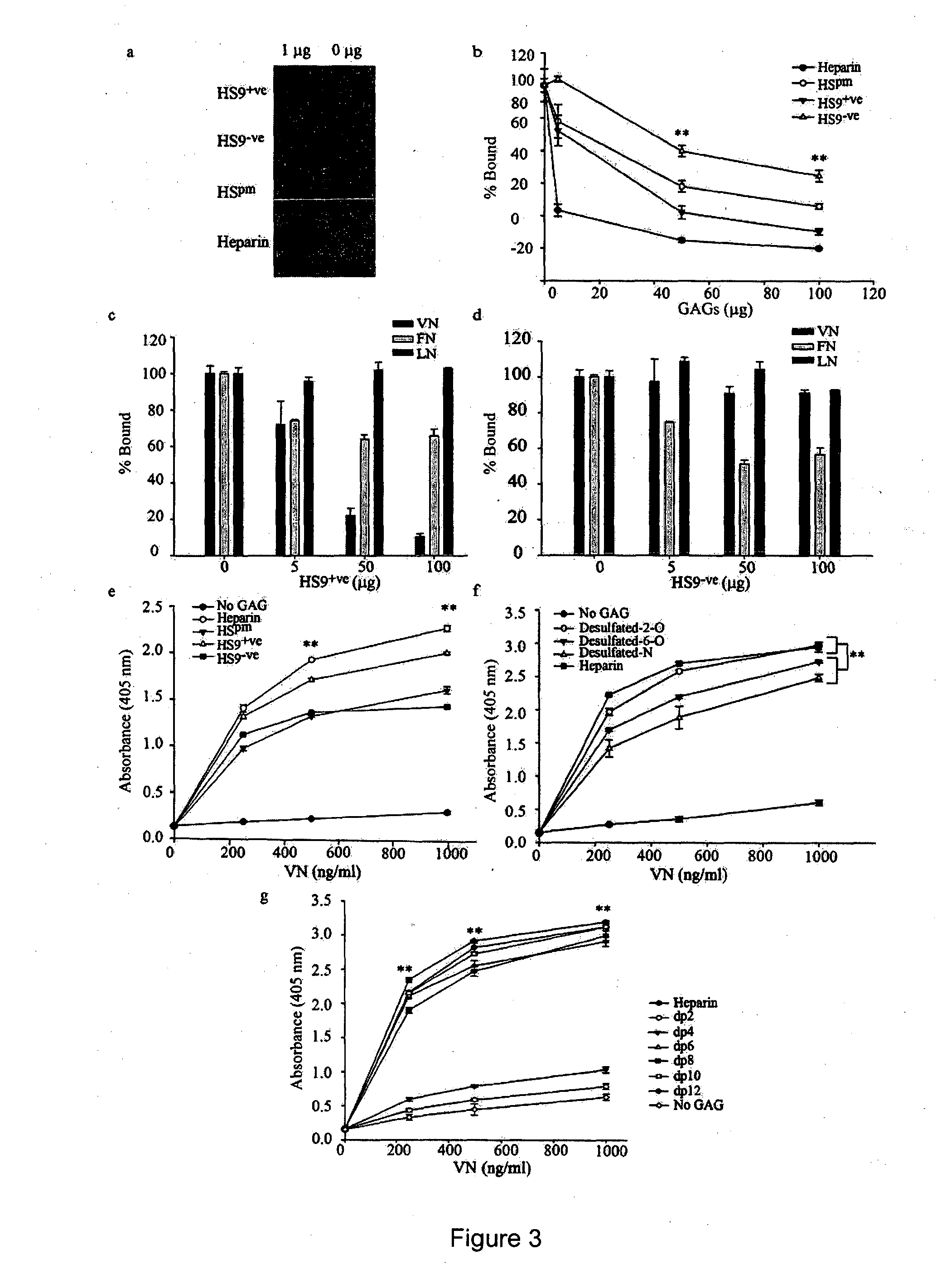

Heparan sulphate

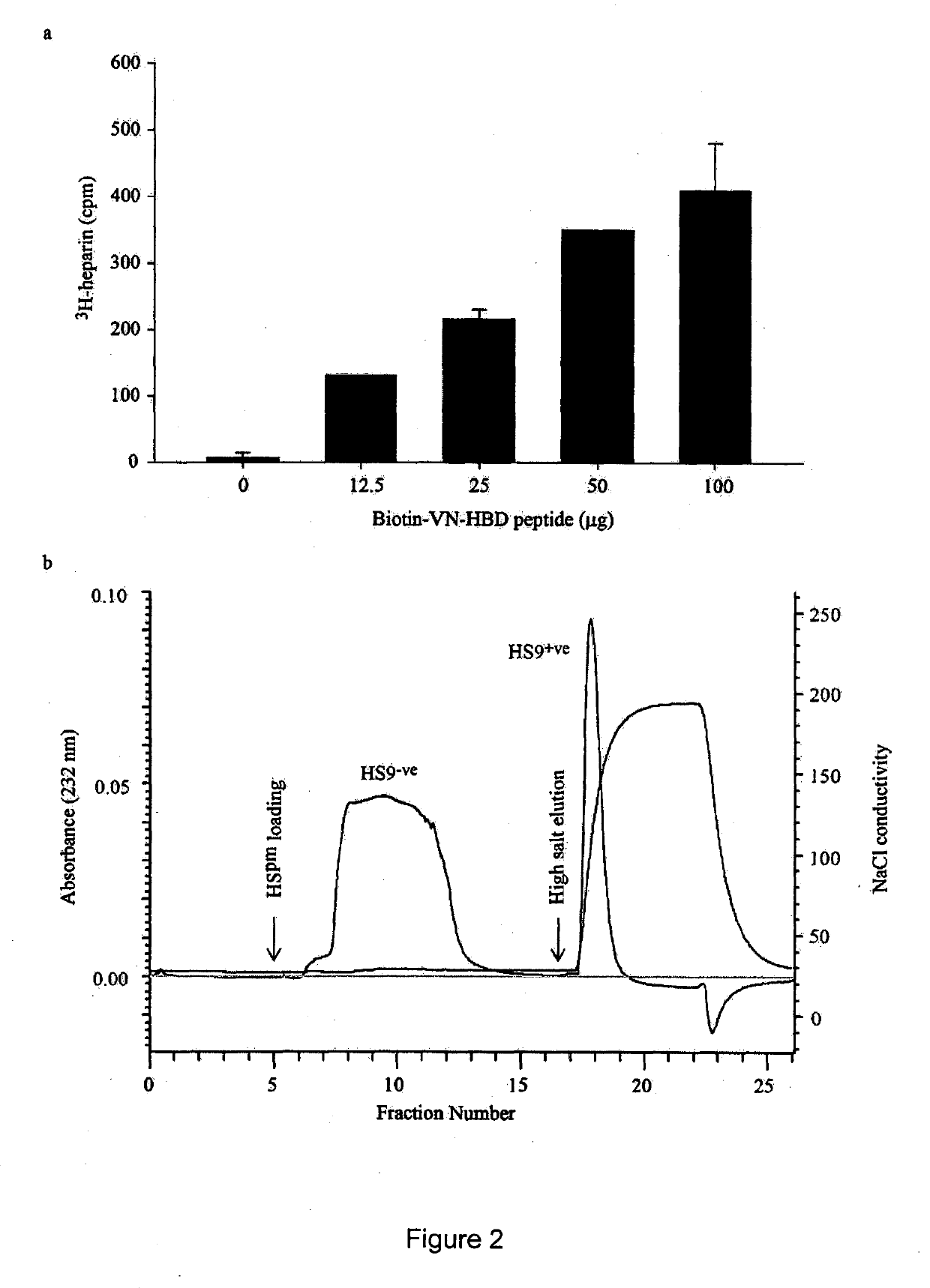

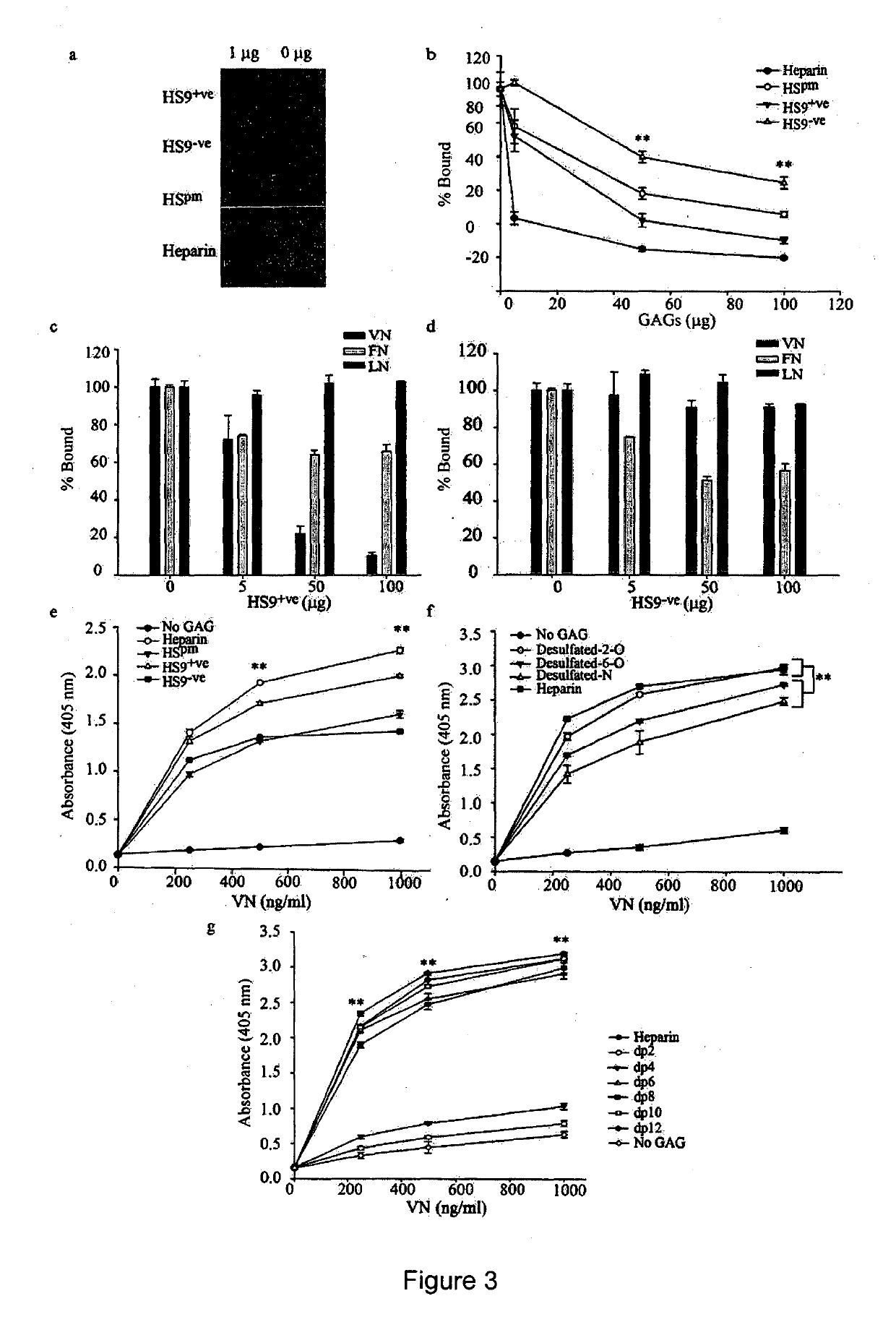

InactiveUS20190135949A1Reduced surface densityHigh degree of structural characterisationOrganic active ingredientsPeptide/protein ingredientsVitronectinHeparan sulphate

Owner:AGENCY FOR SCI TECH & RES

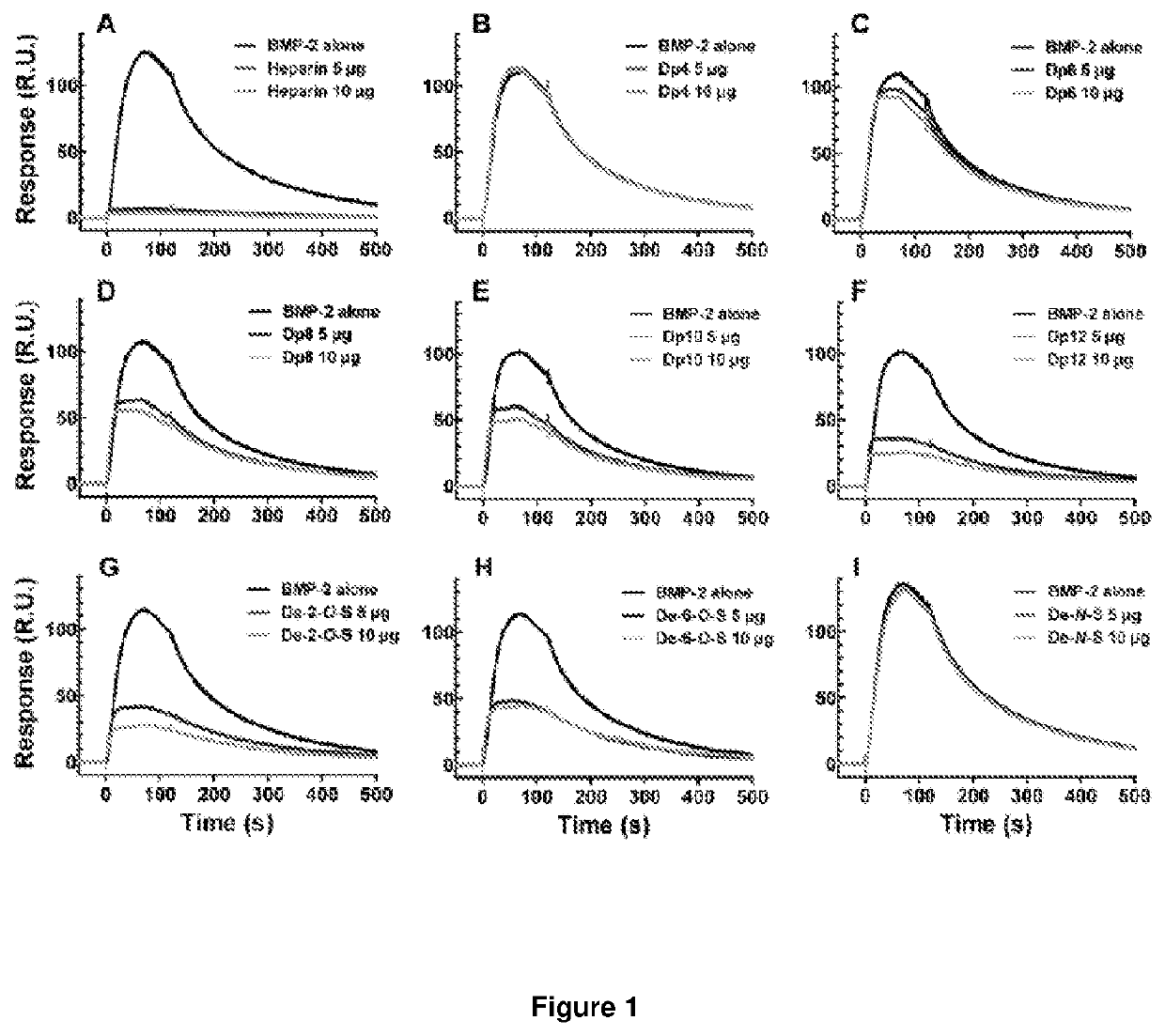

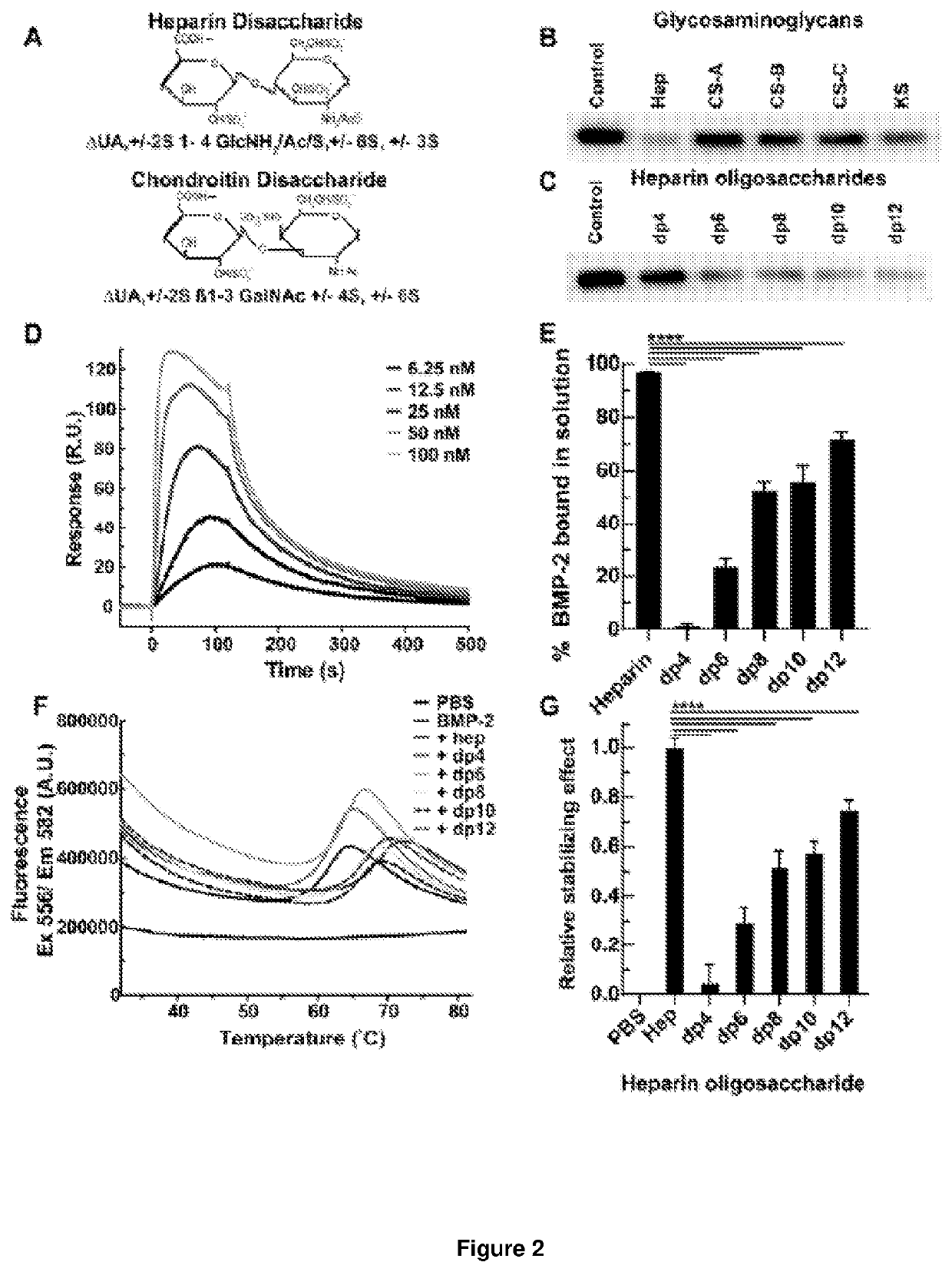

Heparin and heparan sulphate oligosaccharides

ActiveUS11331337B2High activityPromote repairOrganic active ingredientsSkeletal disorderConnective tissue fiberPharmaceutical drug

Owner:AGENCY FOR SCI TECH & RES

Heparan sulphate

InactiveUS20160215072A1Maintaining sternnessReduced surface densityOrganic active ingredientsPeptide/protein ingredientsVitronectinHeparan sulphate

Owner:AGENCY FOR SCI TECH & RES

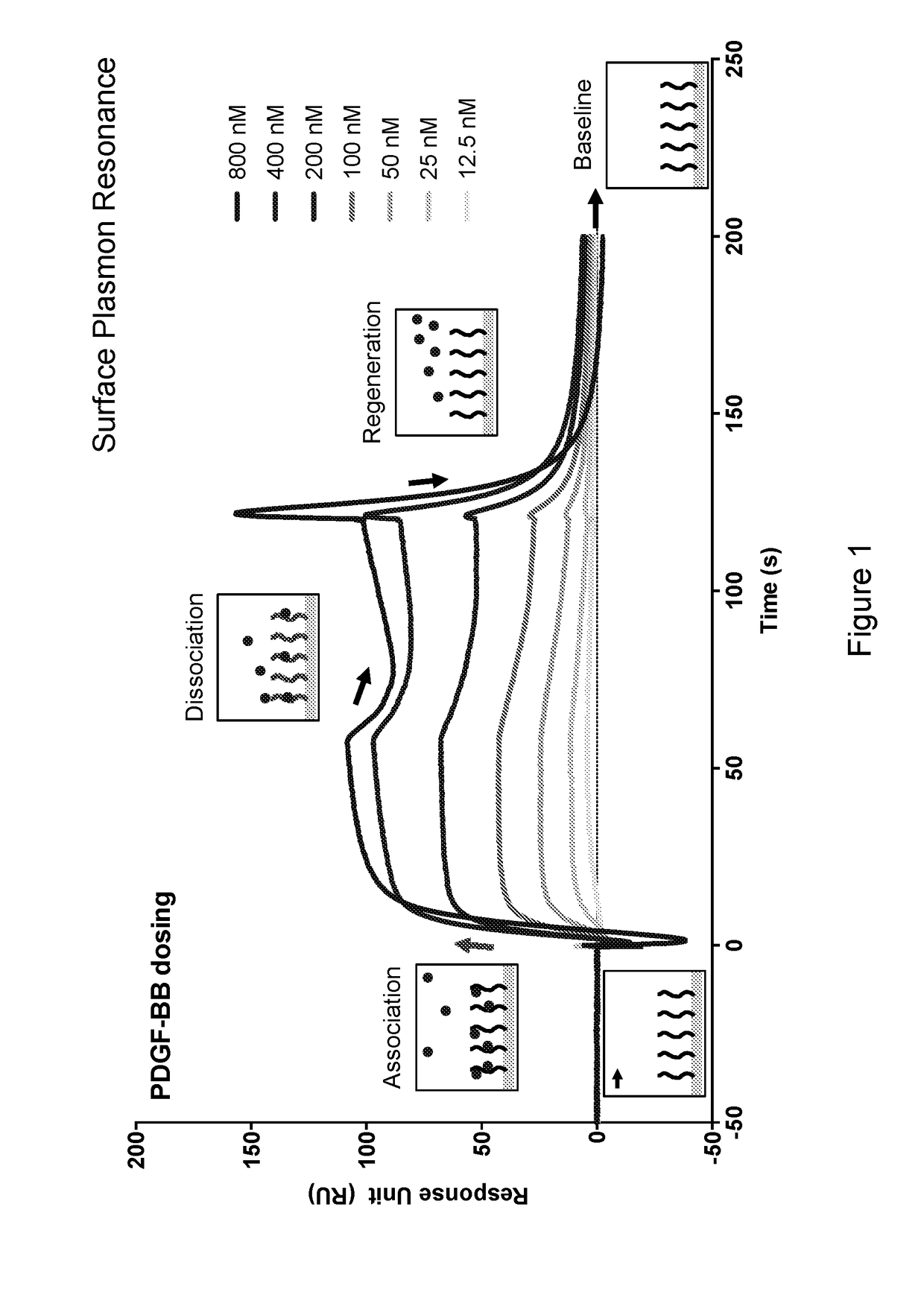

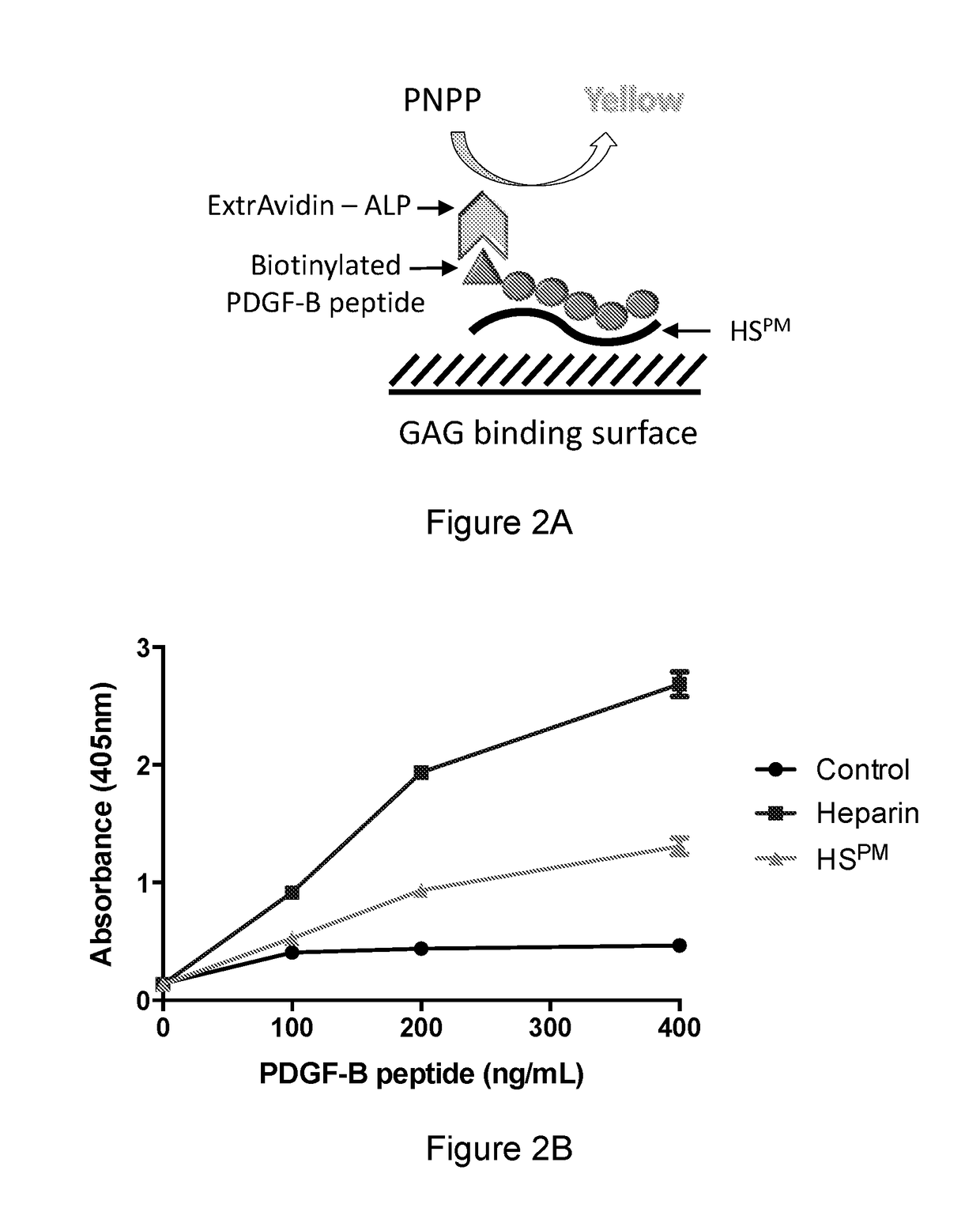

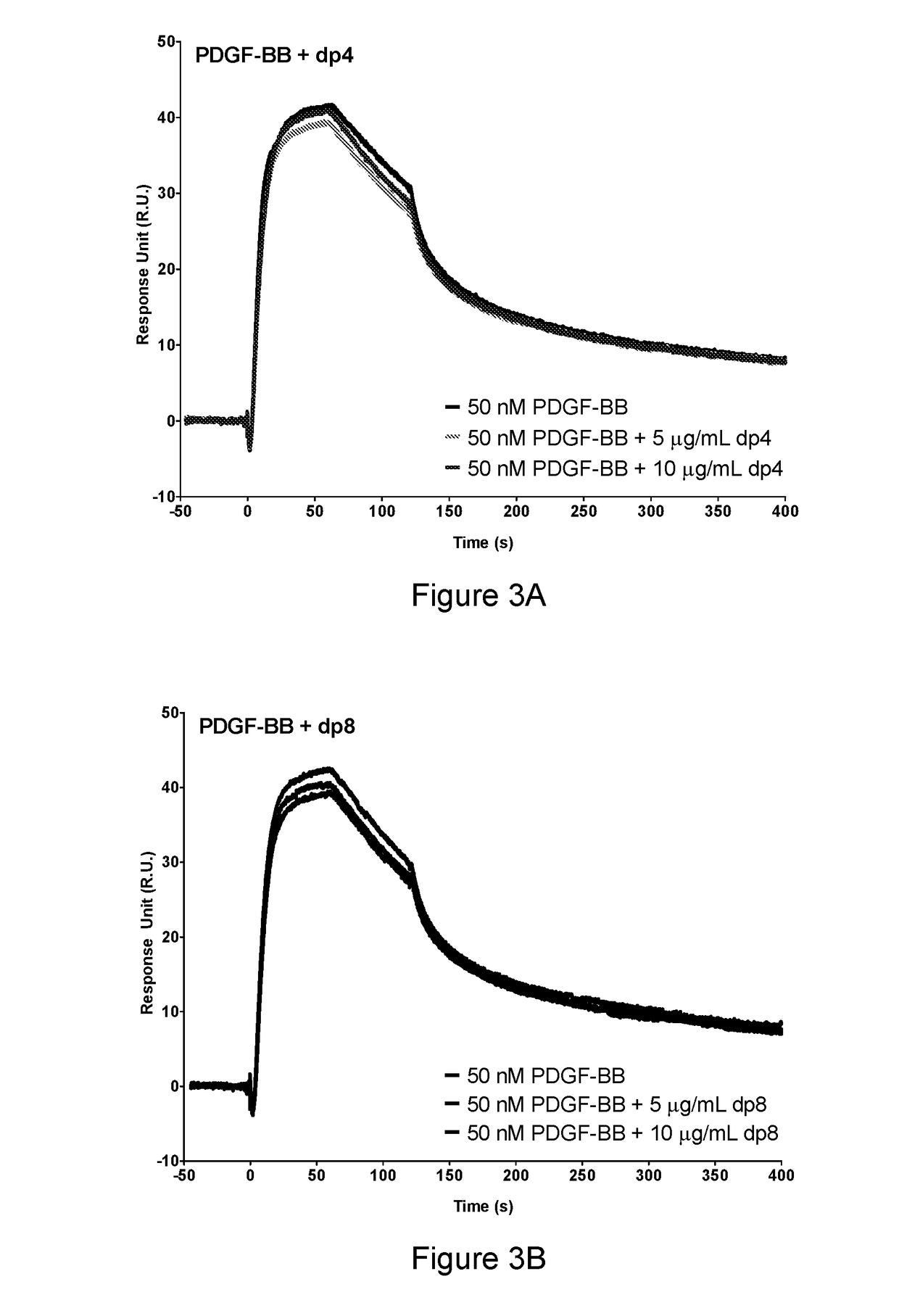

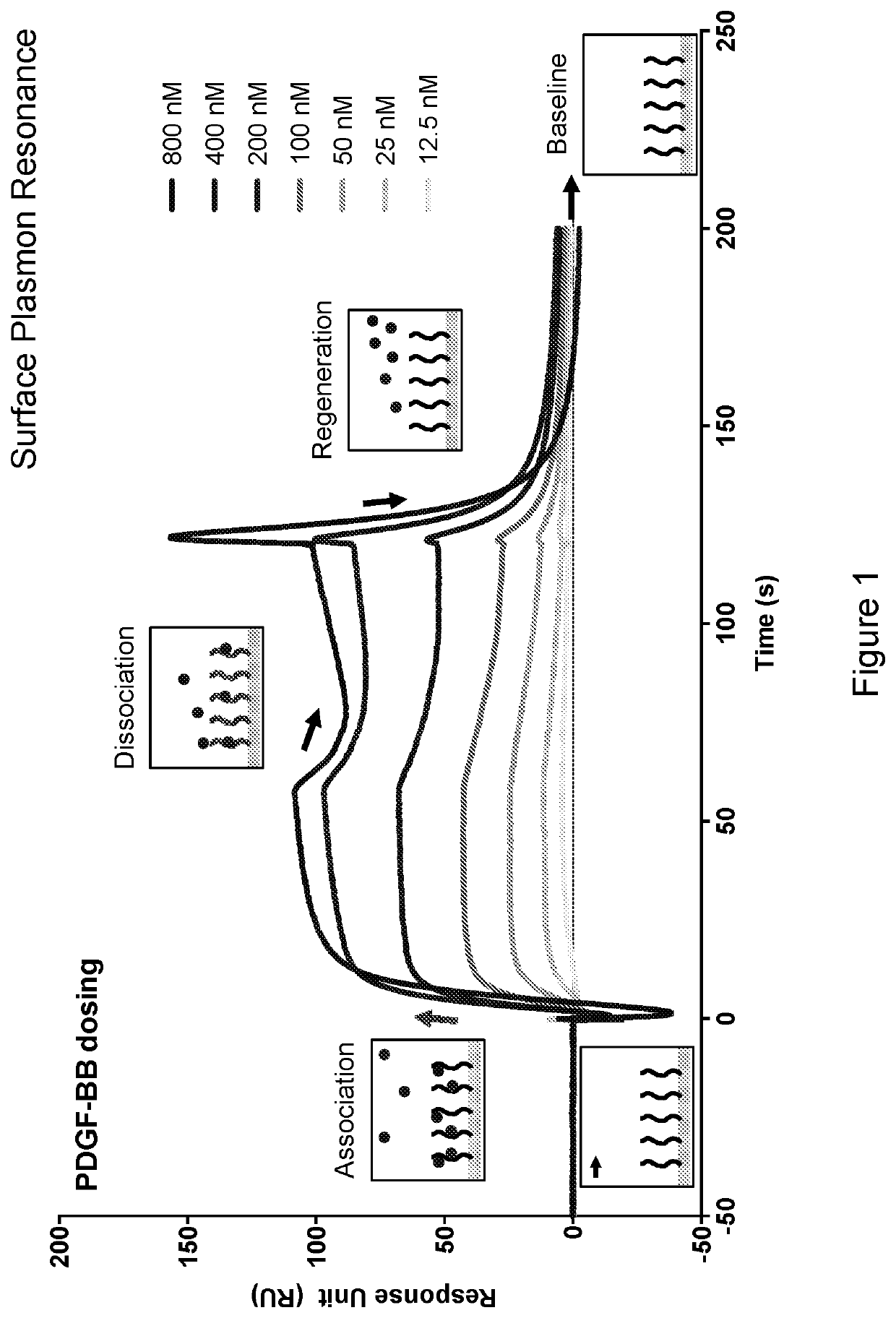

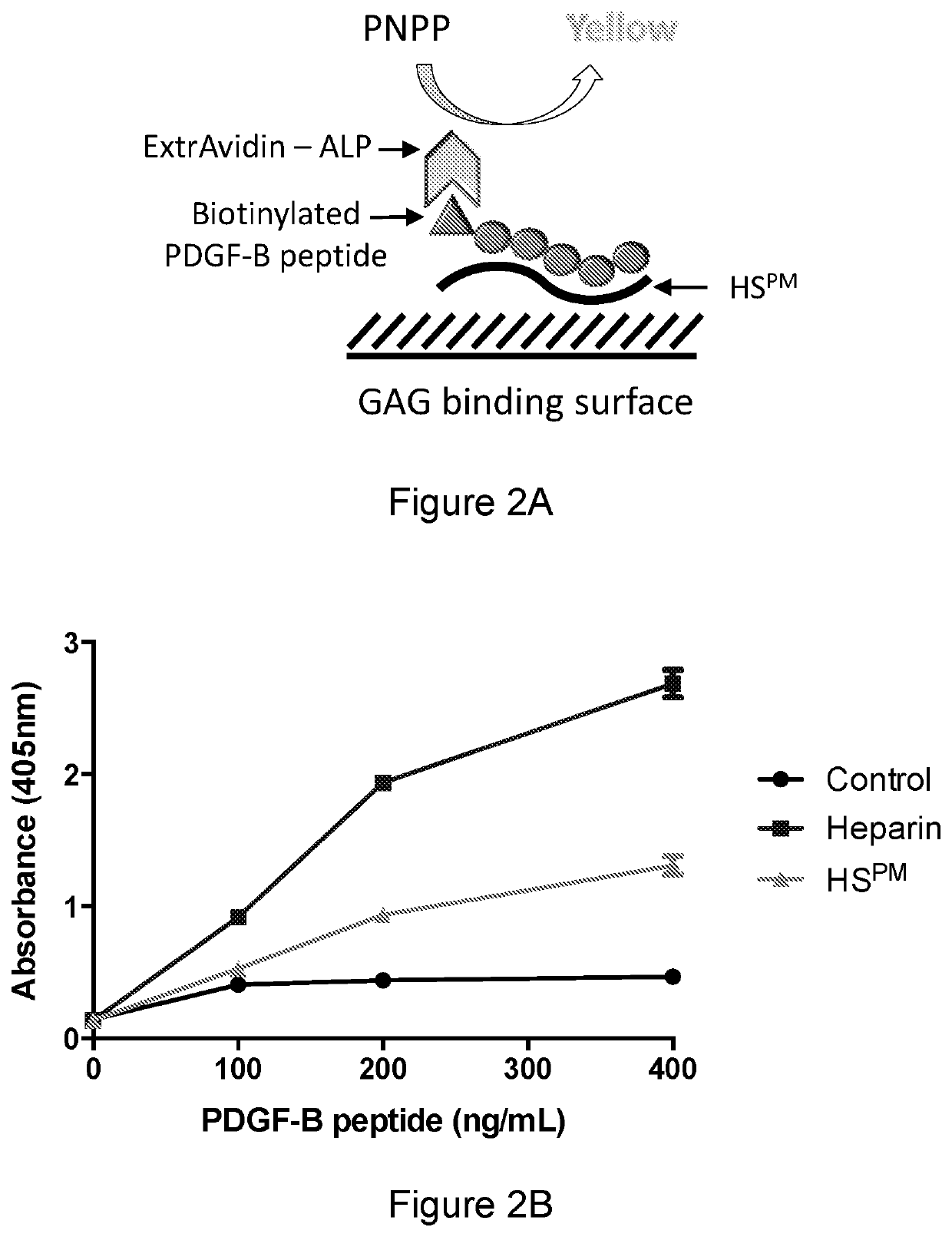

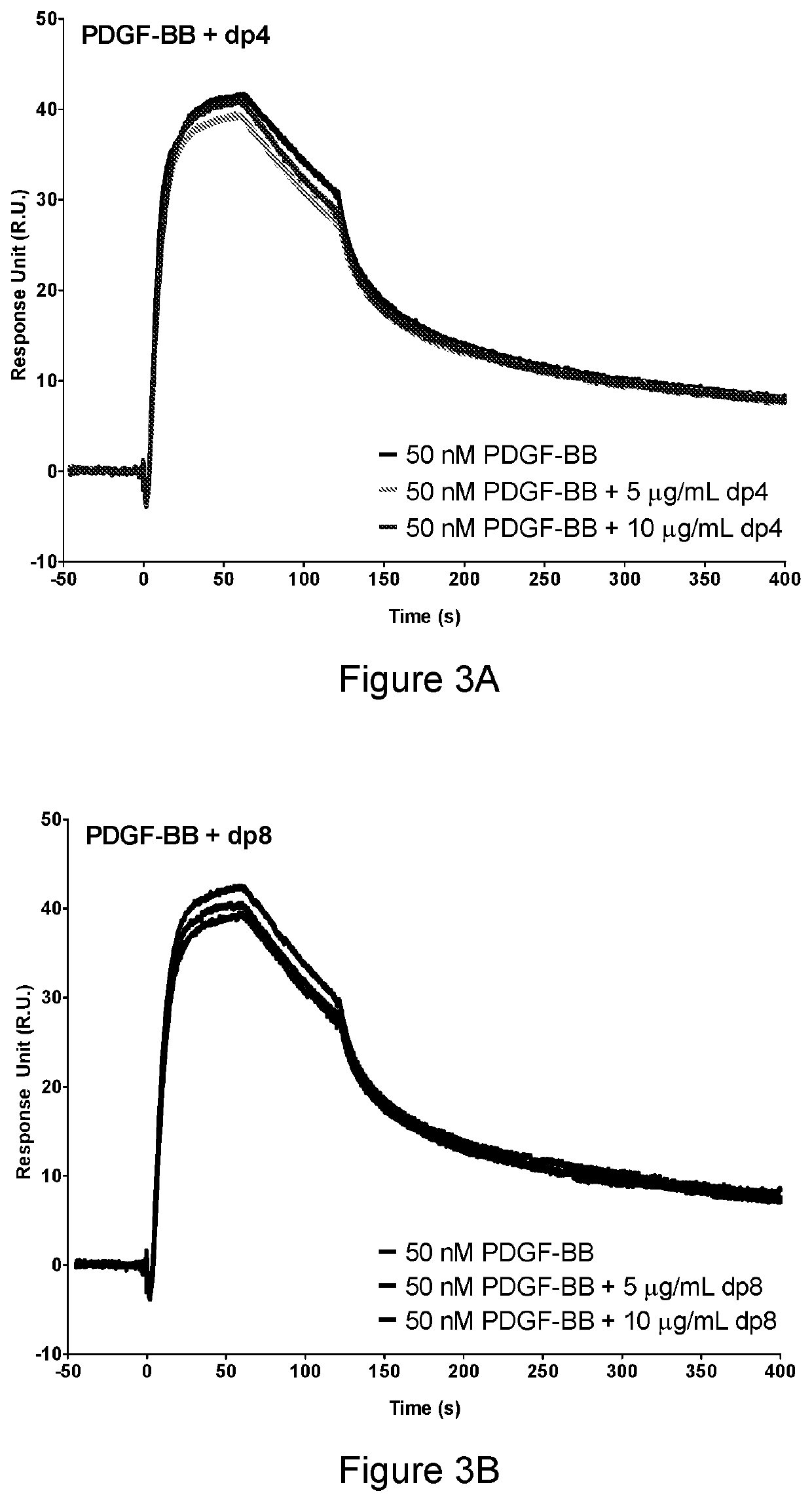

Pdgf-b /pdgf-bb binding variants of heparan sulfates

ActiveUS20180258193A1Improve growth stabilityIncreased proliferationOrganic active ingredientsPeptide/protein ingredientsSkin InjuryPlatelet

Affinity purification of platelet-derived growth factor-binding heparan sulphate from porcine mucosa (HS6) is disclosed. Also disclosed is the use of HS6 in repair and regeneration of the skin for treating wounds, burns, ulcers and other skin injuries.

Owner:AGENCY FOR SCI TECH & RES

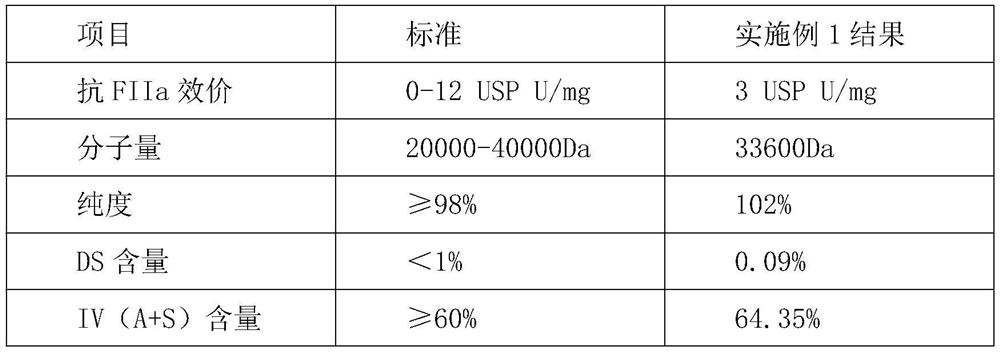

A method for separating and purifying sulodexide bulk drug from heparin by-products

The invention discloses a method for separating and purifying sulodexide raw materials from heparin by-products. After dissolving the heparin by-products, high-temperature precipitation is adopted to separate the crude heparan sulfate and dermatan sulfate; then the crude product solution is passed through hydrogen peroxide -Sulodexide is prepared by oxidative precipitation and drying in an ozone system, and the invention relates to the technical field of medicine. In the method for separating and purifying the raw material drug of sulodexide from the by-product of heparin, the hydrogen peroxide-ozone system is adopted in the oxidation, which can improve the oxidation effect and effectively remove the pigment protein and impurities. The high-temperature precipitation method during precipitation increases the titer recovery rate by 10% compared with the traditional low-temperature precipitation method, and also reduces the use of centrifuges and ion exchange resins, saves 60% of the time compared to simple hydrogen peroxide treatment, and improves product quality. and production efficiency, suitable for large-scale industrial production, short cycle, low cost, full and effective utilization of heparin by-products, high product purity and strong stability.

Owner:HUBEI YINUORUI BIOLOGICAL PHARMA

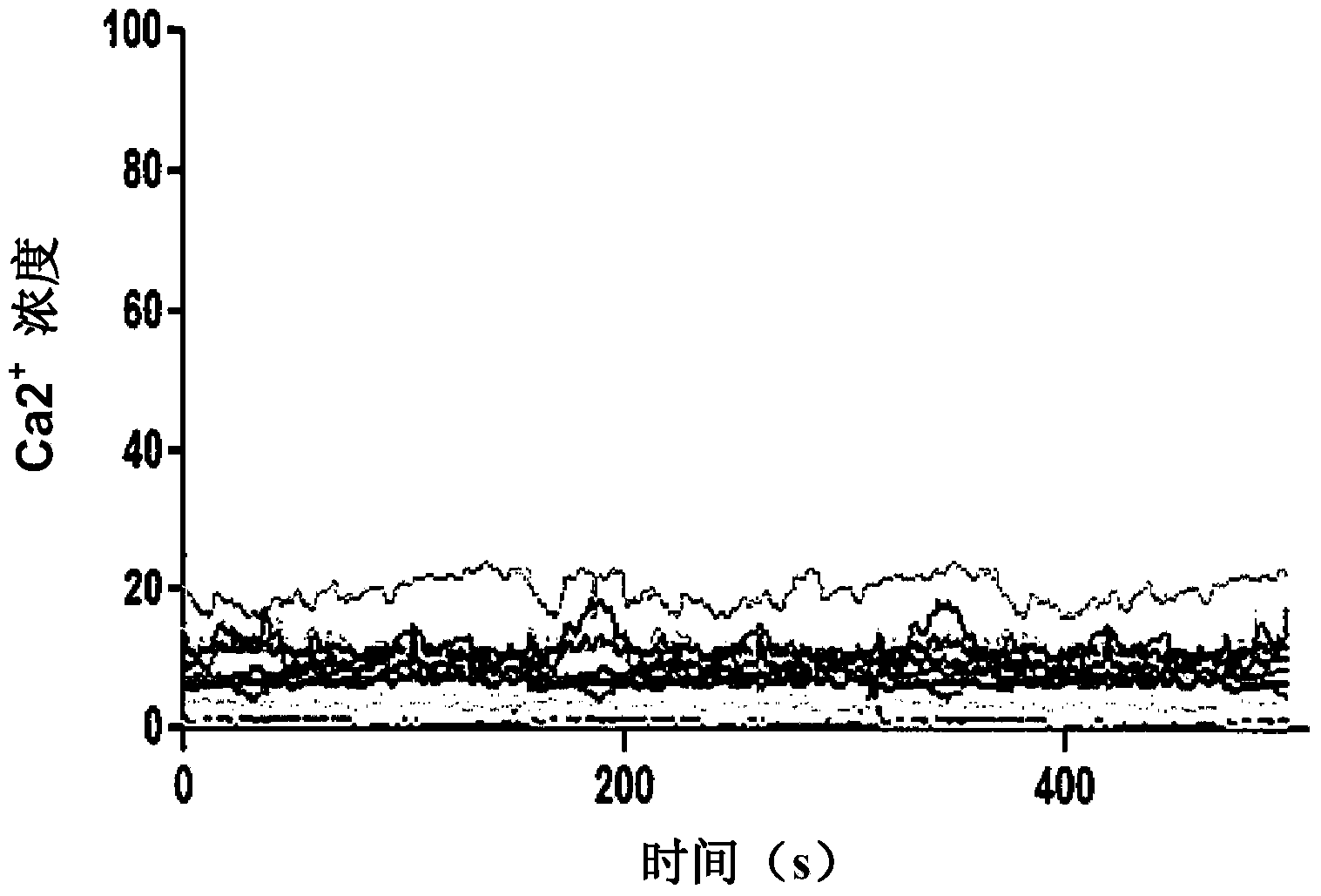

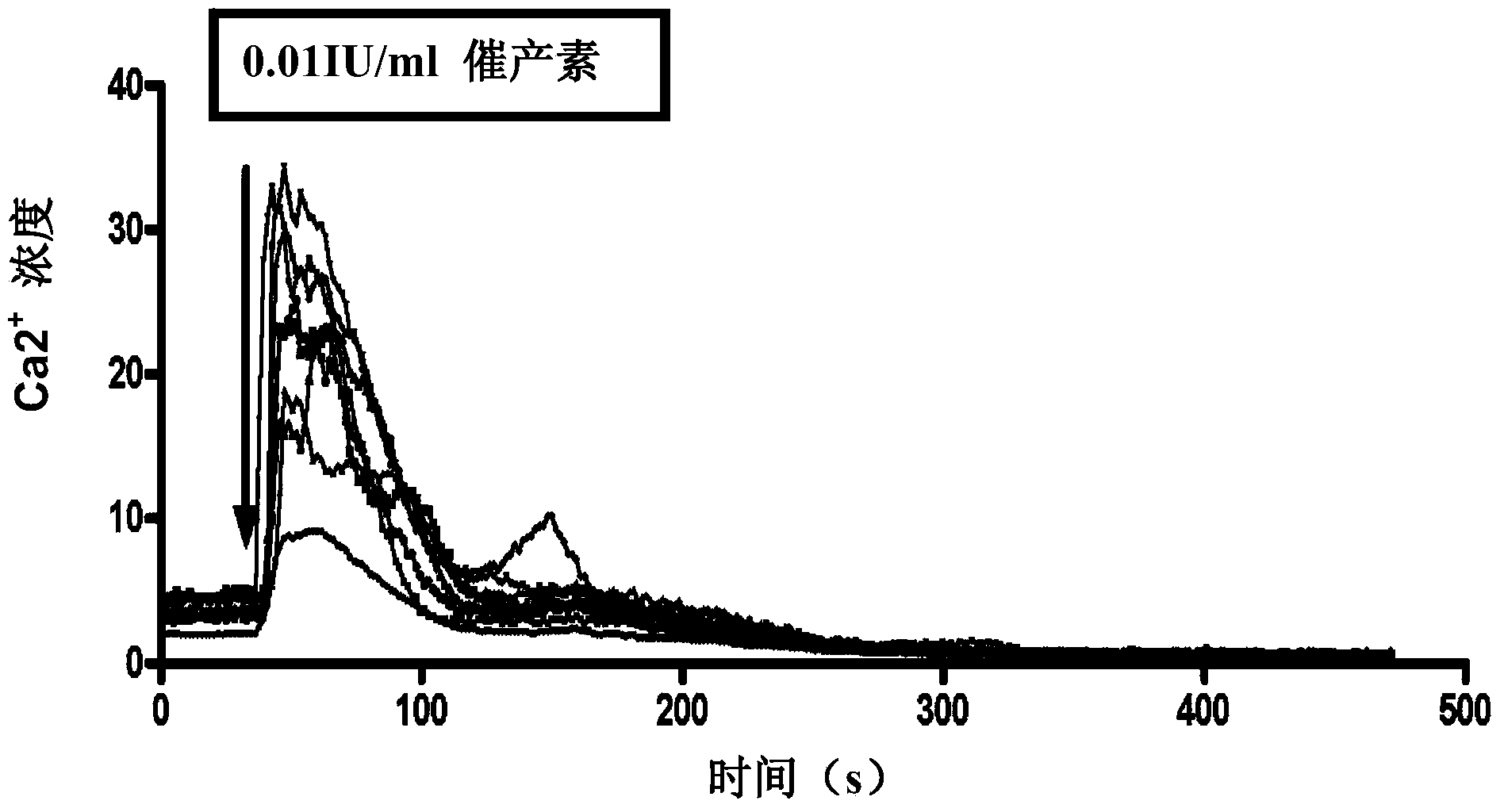

Treatment of postpartum haemorrhage with chemically modified heparin or heparan sulphate and a uterotonic agent

InactiveCN104284667AHas anti-factor IIa activityEasy to shrinkPeptide/protein ingredientsSexual disorderSulfationPostpartum haemorrhage

The present invention refers to the use of certain sulfated glycosaminoglycans for treatment or prevention of postpartum haemorrhage. The sulfated glycosaminoglycans have a reduced anticoagulant activity and are administered in combination with at least one uterotonic agent capable of promoting myometrial contractions of the uterus and thereby compress the vessels and cease the bleeding.

Owner:DILAFOR

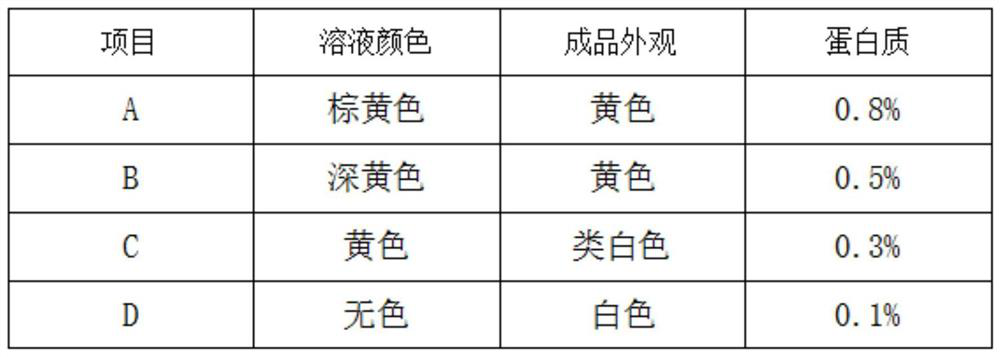

Preparation method of ultra-high purity heparan sulfate

InactiveCN111154012AOvercoming difficult separationHigh purityHeparan sulphateDissolution precipitation

The invention discloses a preparation method of ultrahigh-purity heparan sulfate. The preparation method comprises the following steps: dissolving and precipitating a heparin sodium byproduct to obtain a heparan sulfate crude product; and carrying out secondary dissolution, oxidation and cold precipitation on the heparan sulfate crude product to obtain supernatant, precipitating again, re-dissolving, adsorbing, eluting and precipitating to finally obtain the ultra-high purity heparan sulfate. According to the method, the problem that heparan sulfate is difficult to separate from dermatan sulfate, chondroitin sulfate and heparin sodium is solved, the yield and purity of heparan sulfate are improved, and in addition, the method is simple to operate, stable in product quality and suitable forlarge-scale production.

Owner:HUBEI YINUORUI BIOLOGICAL PHARMA

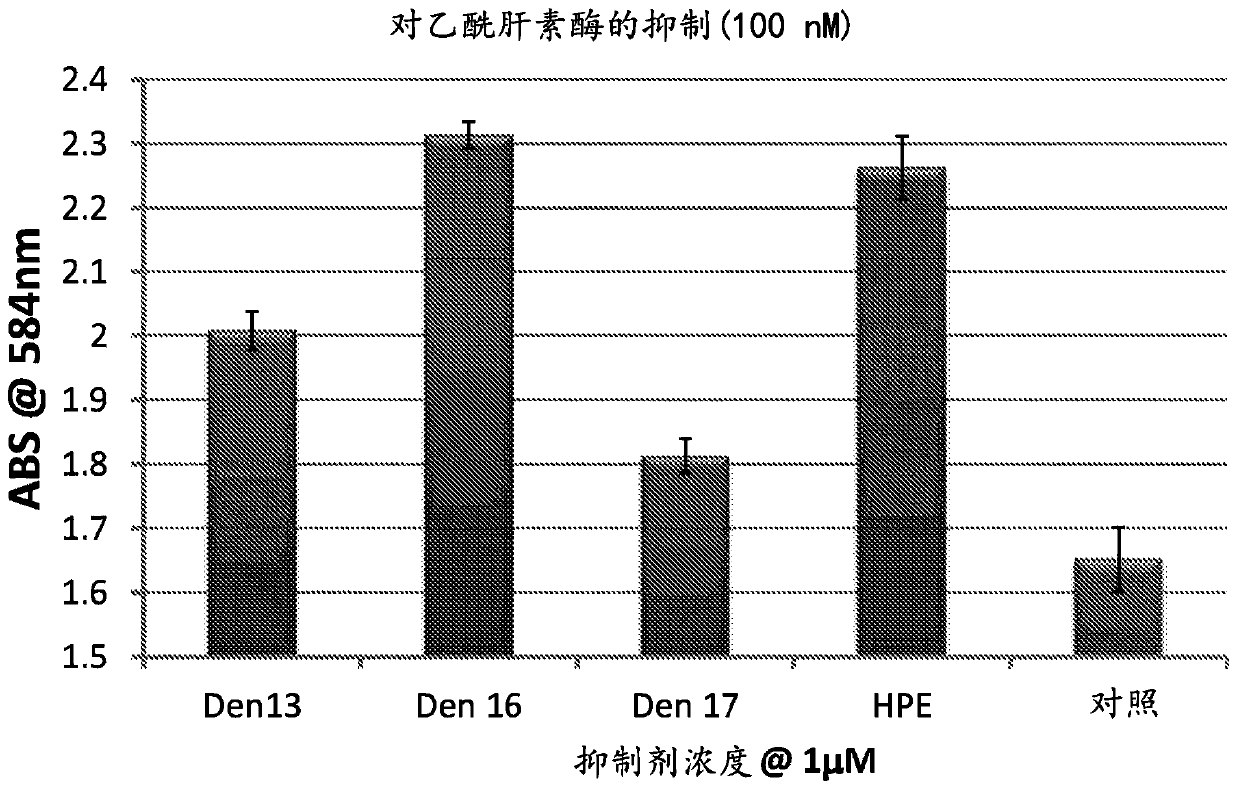

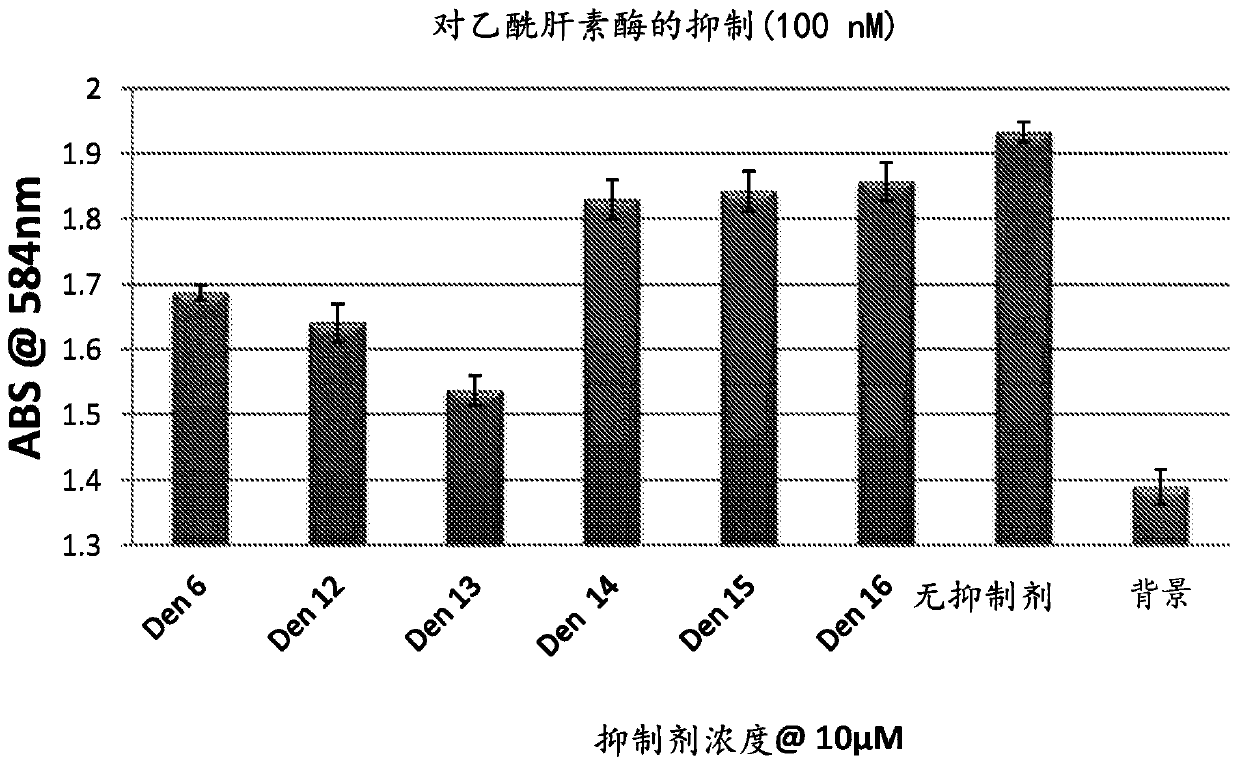

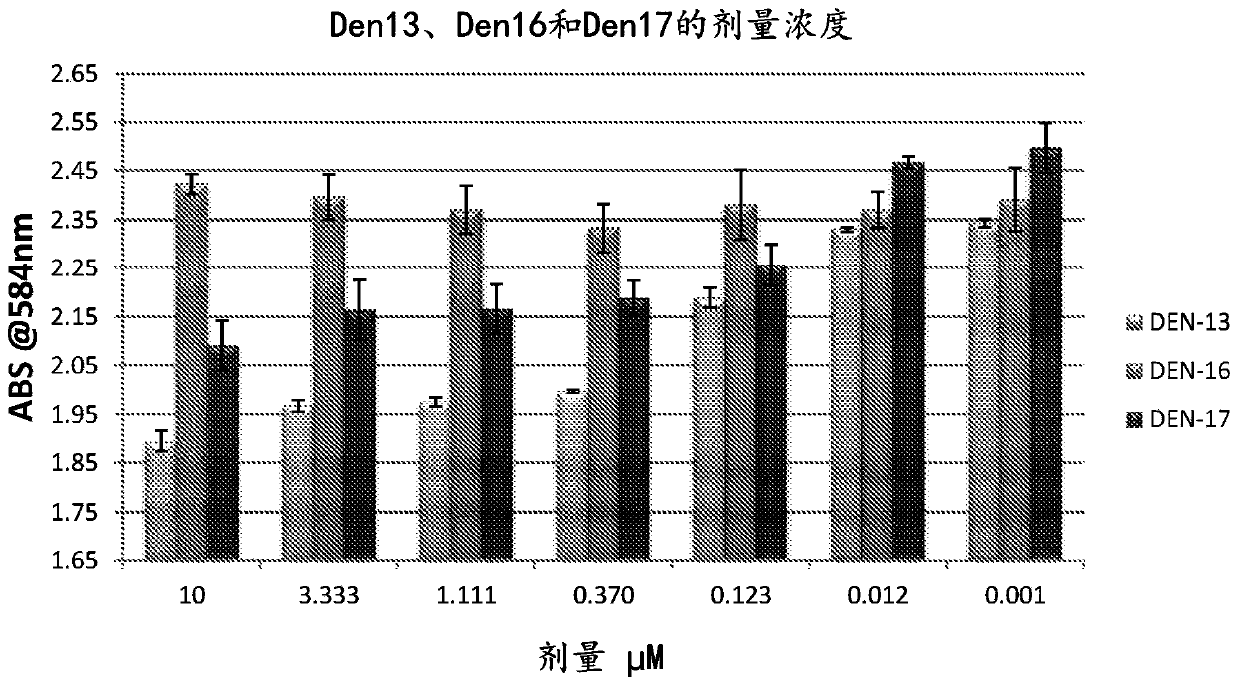

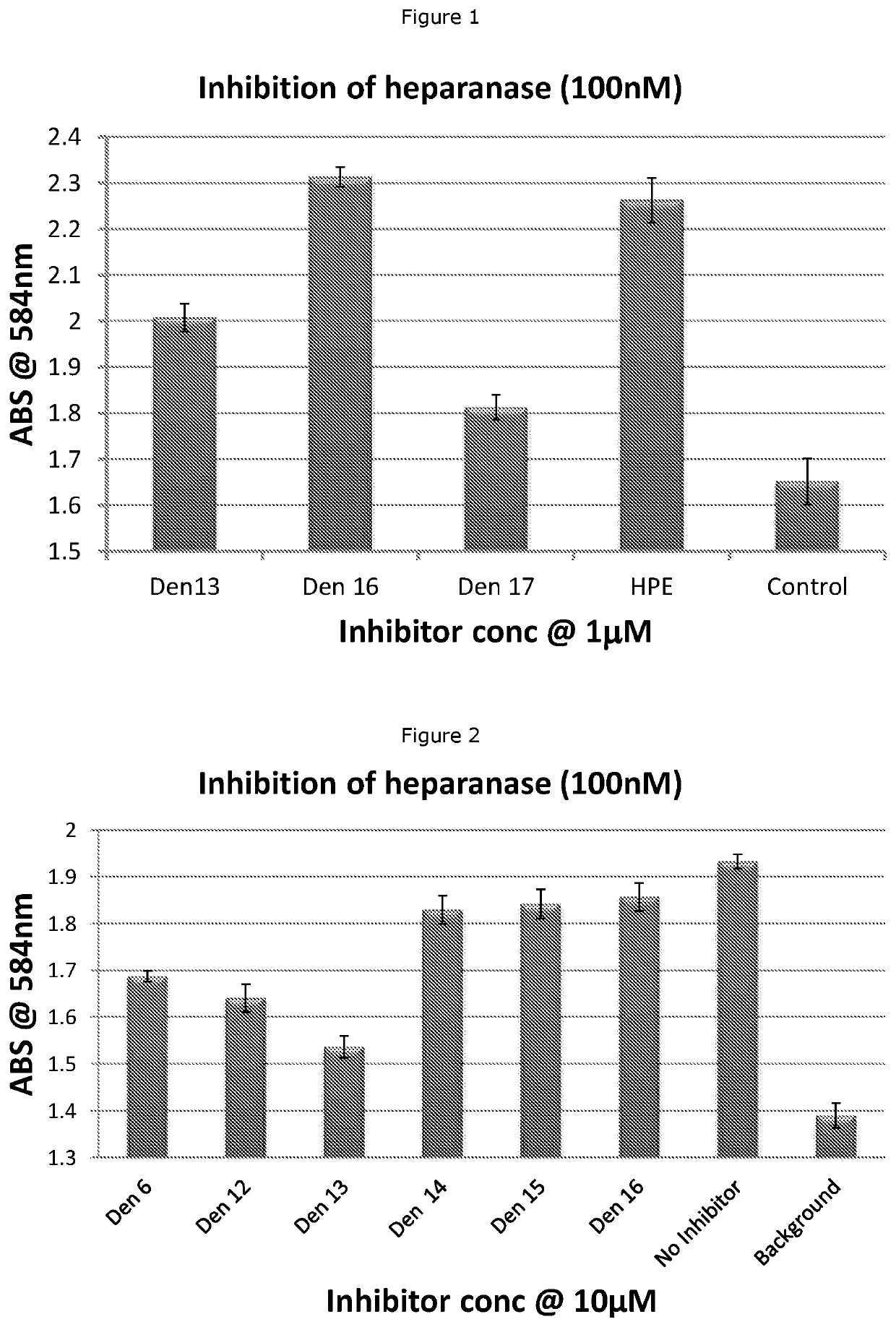

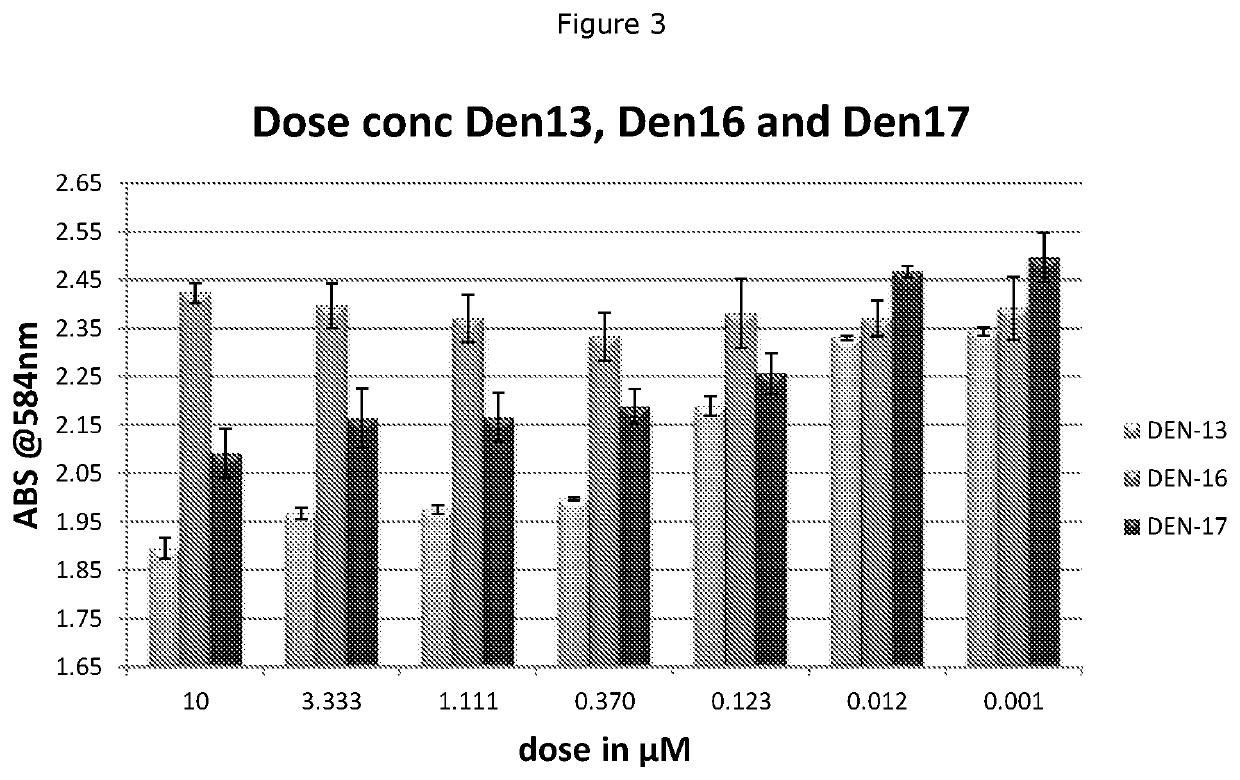

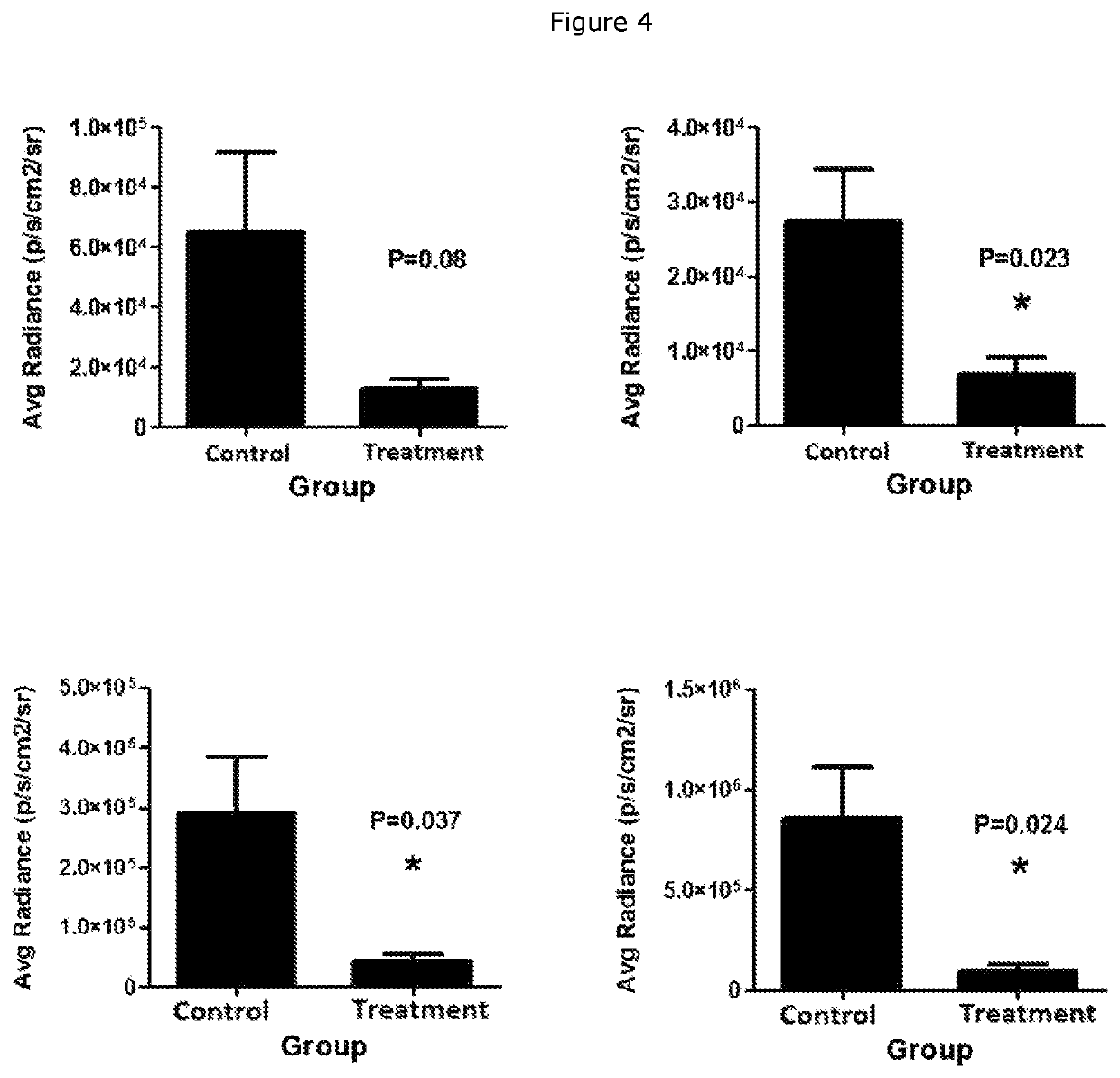

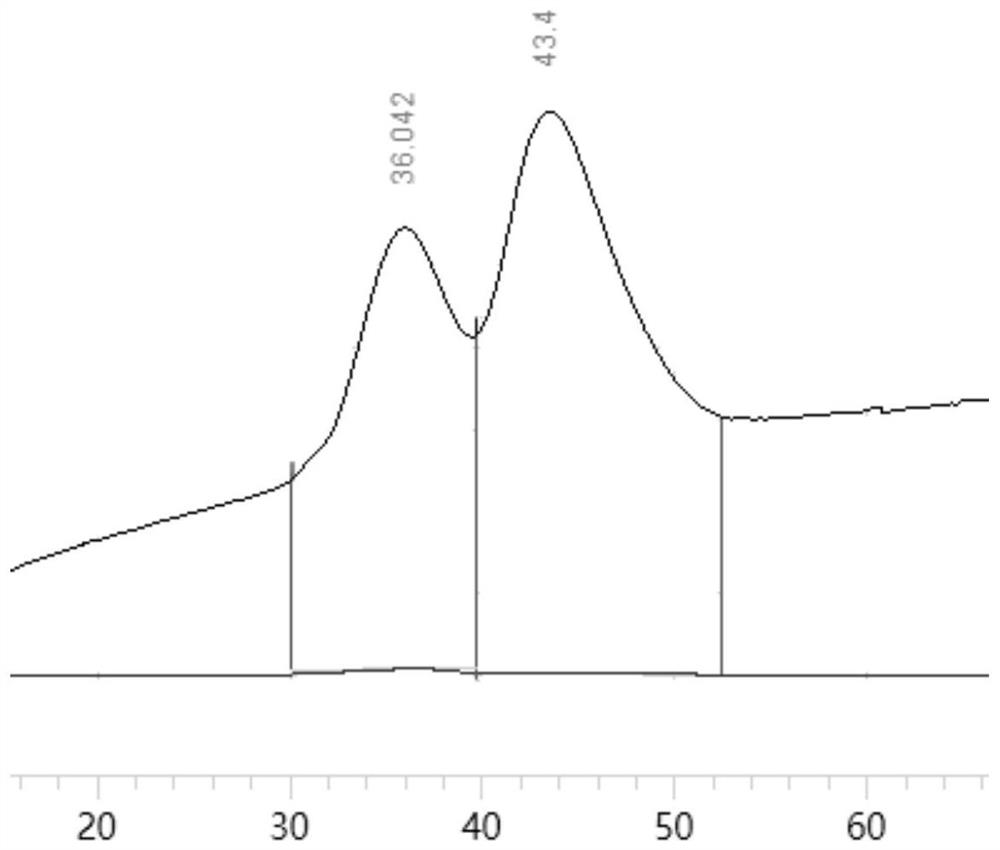

Heparan sulfate glycomimetic compounds and their pharmaceutical and cosmeceutical uses

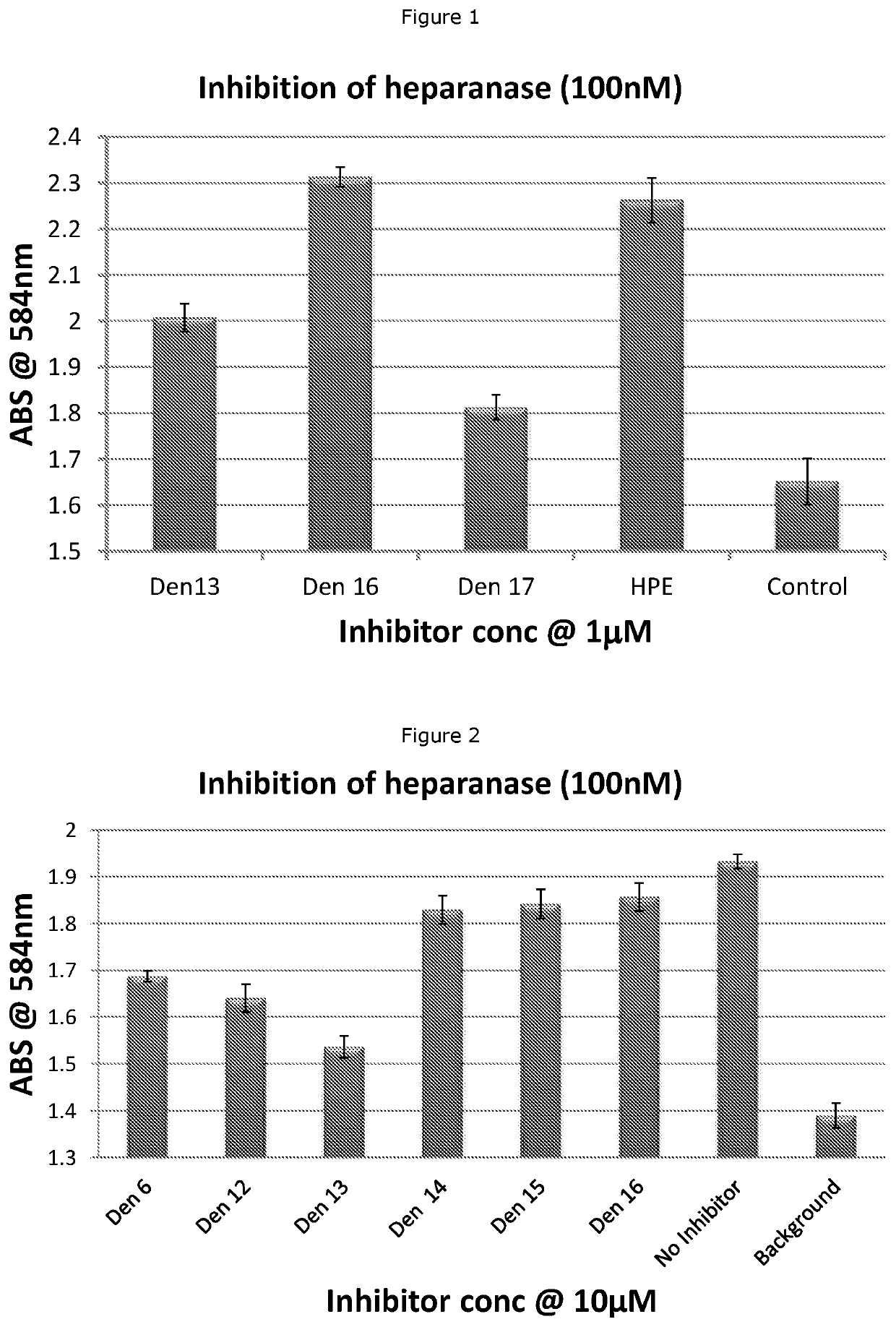

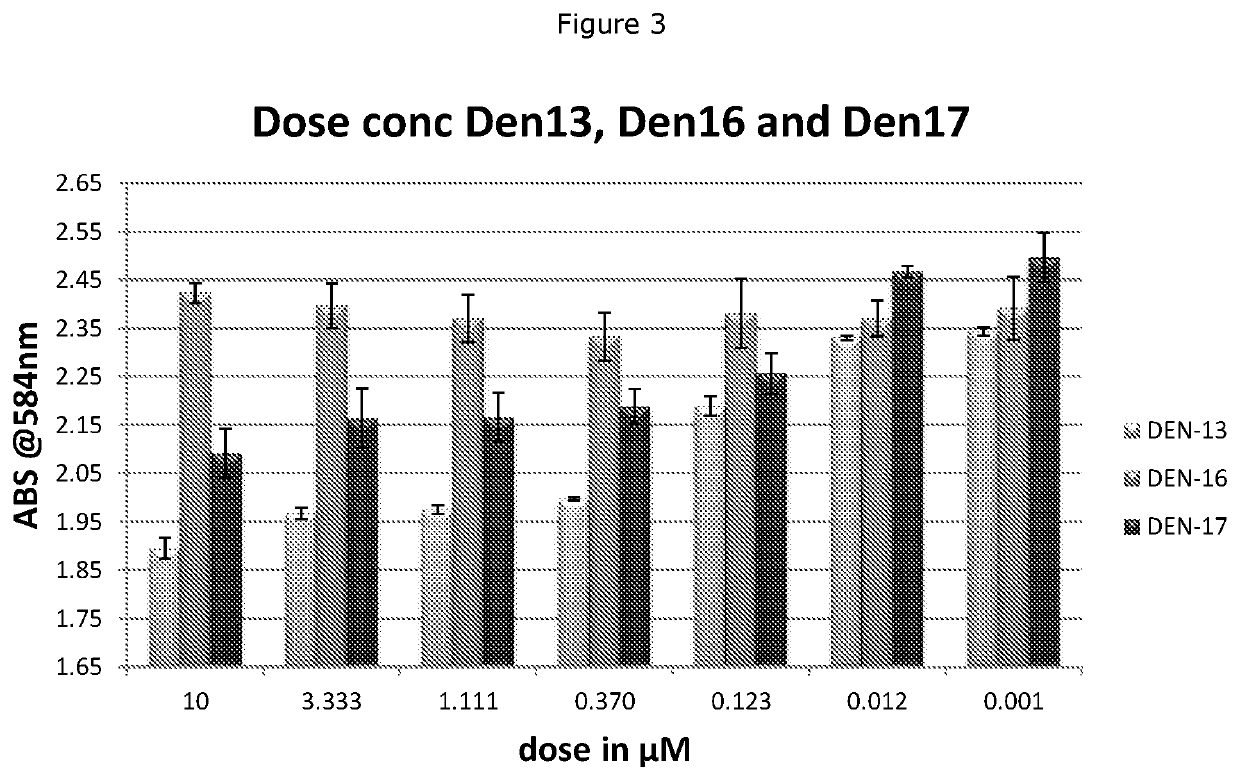

The invention relates to dendritic compounds, the use of these compounds as pharmaceuticals, pharmaceutical and cosmeceutical compositions containing the compounds, and methods of treating cancer, inflammation, diabetic nephropathy, neurodegenerative disorders, Niemann-Pick Type C disease, or dermatological conditions.

Owner:VICTORIA LINK LTD

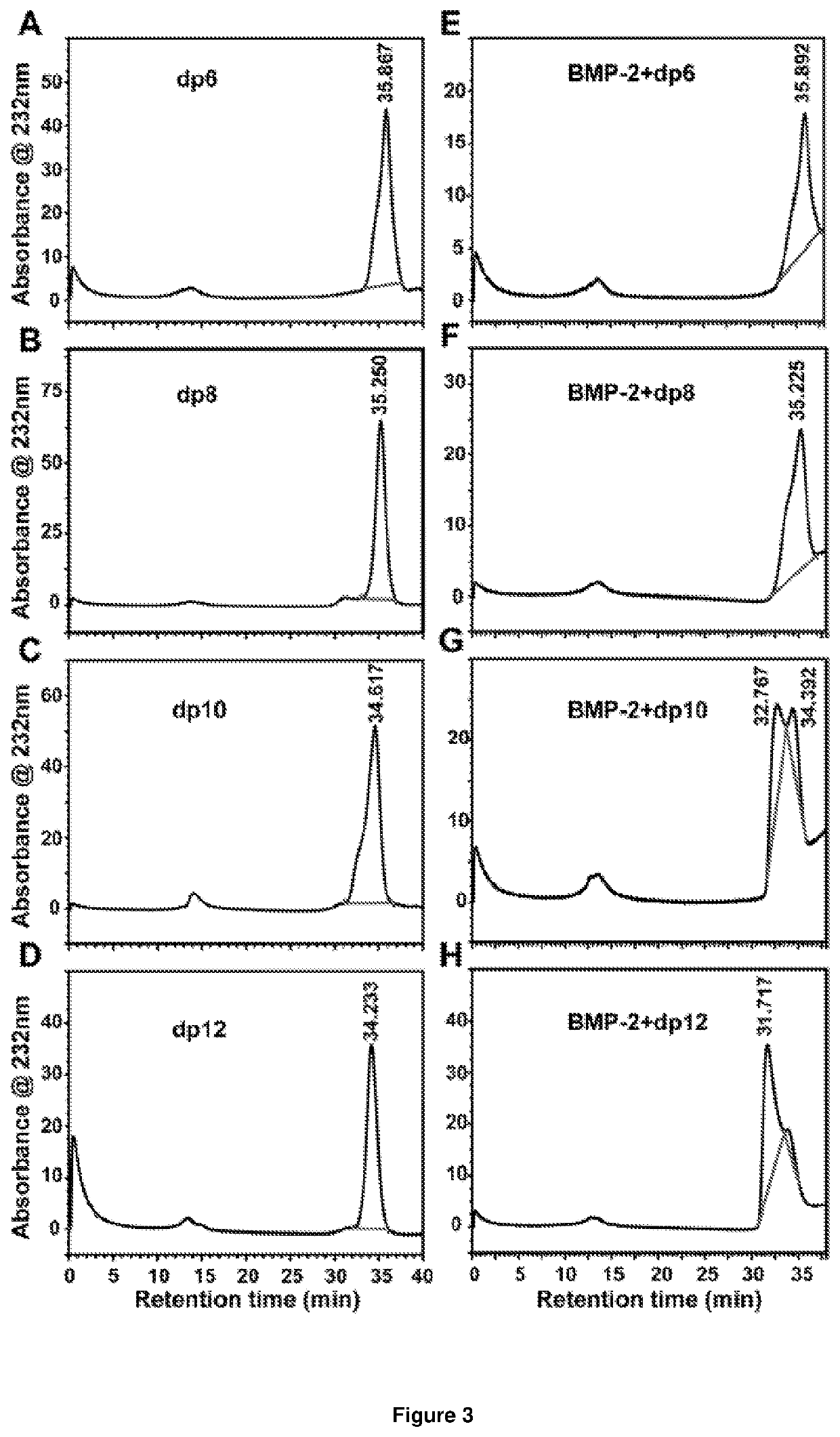

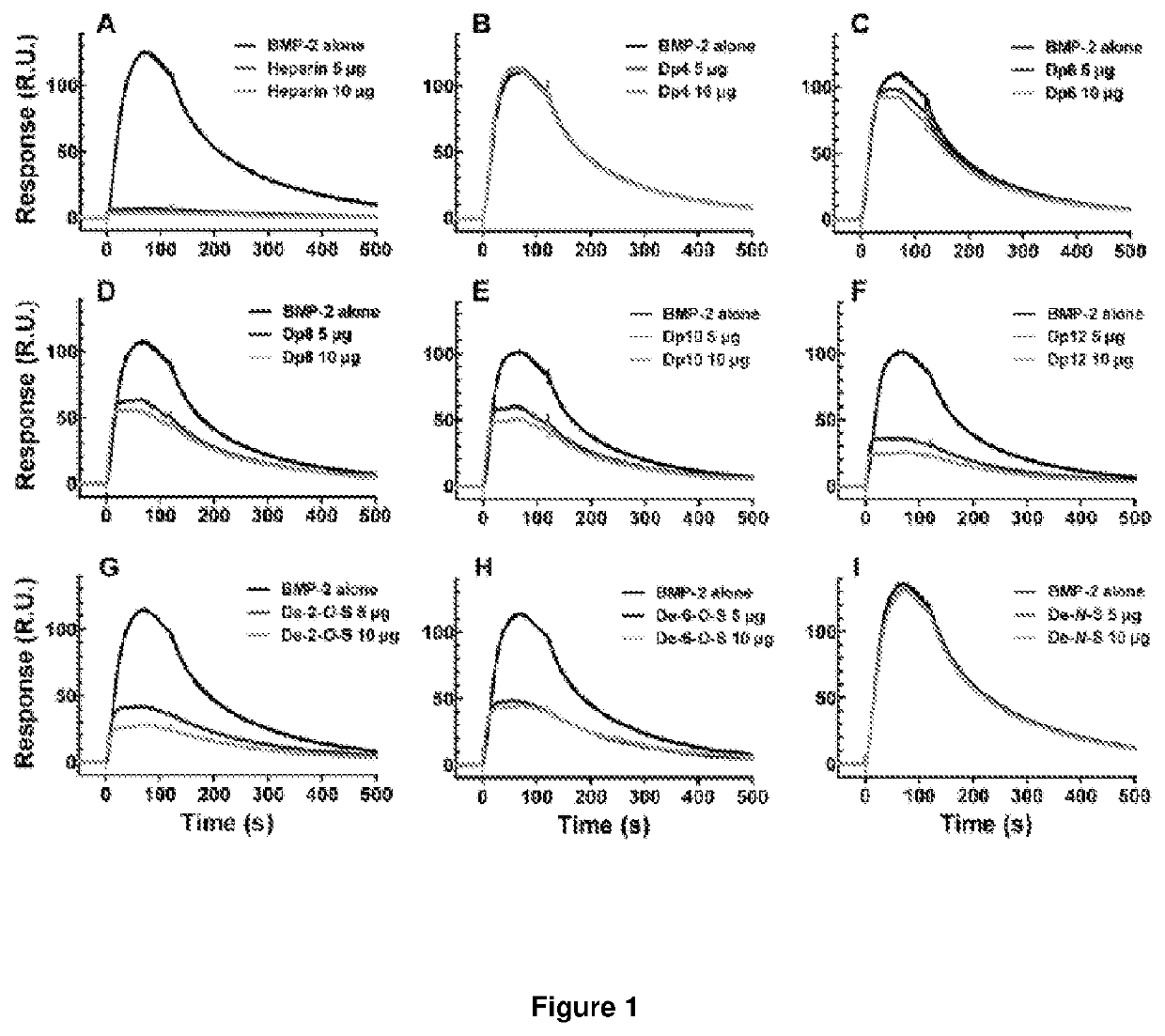

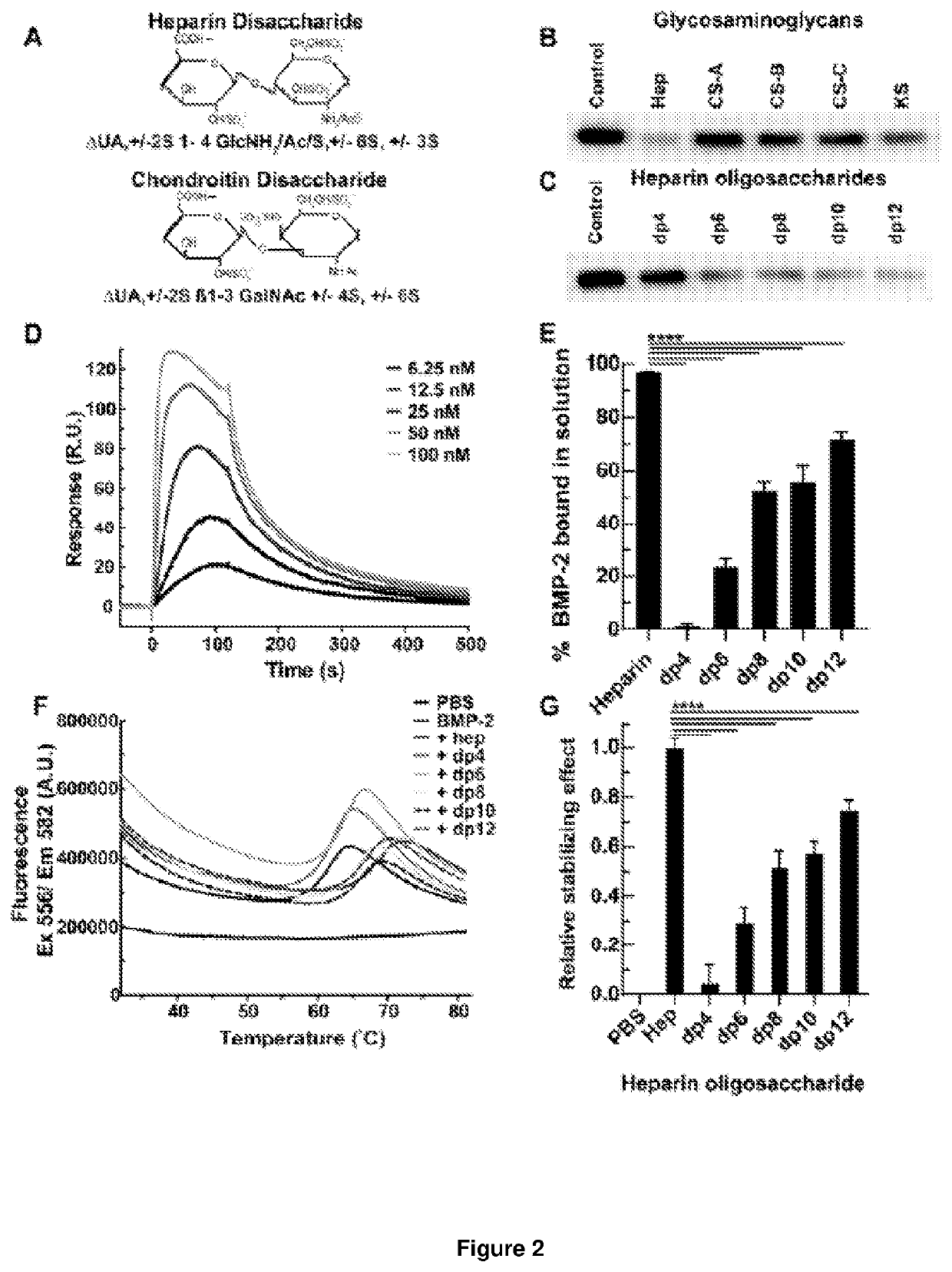

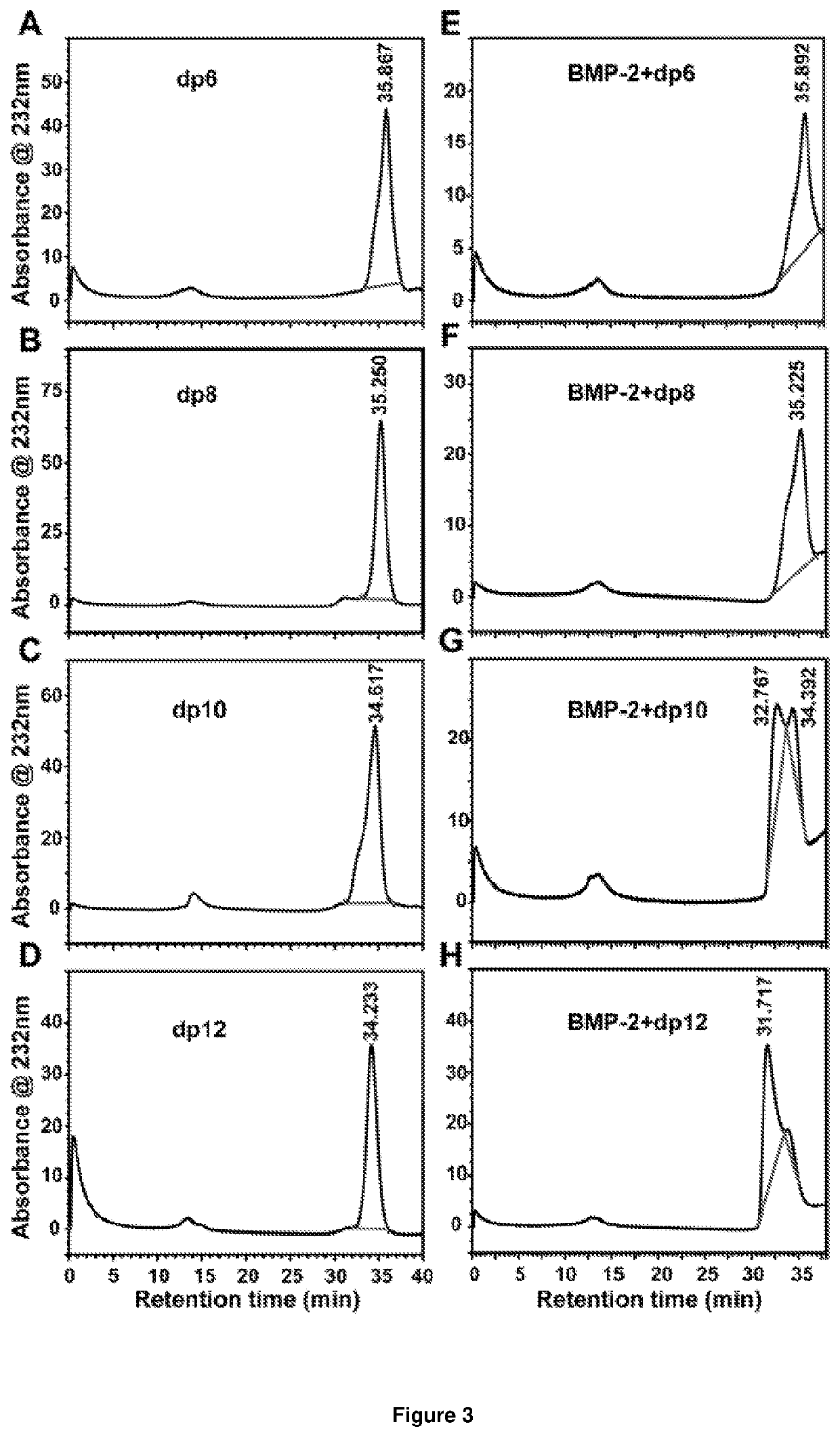

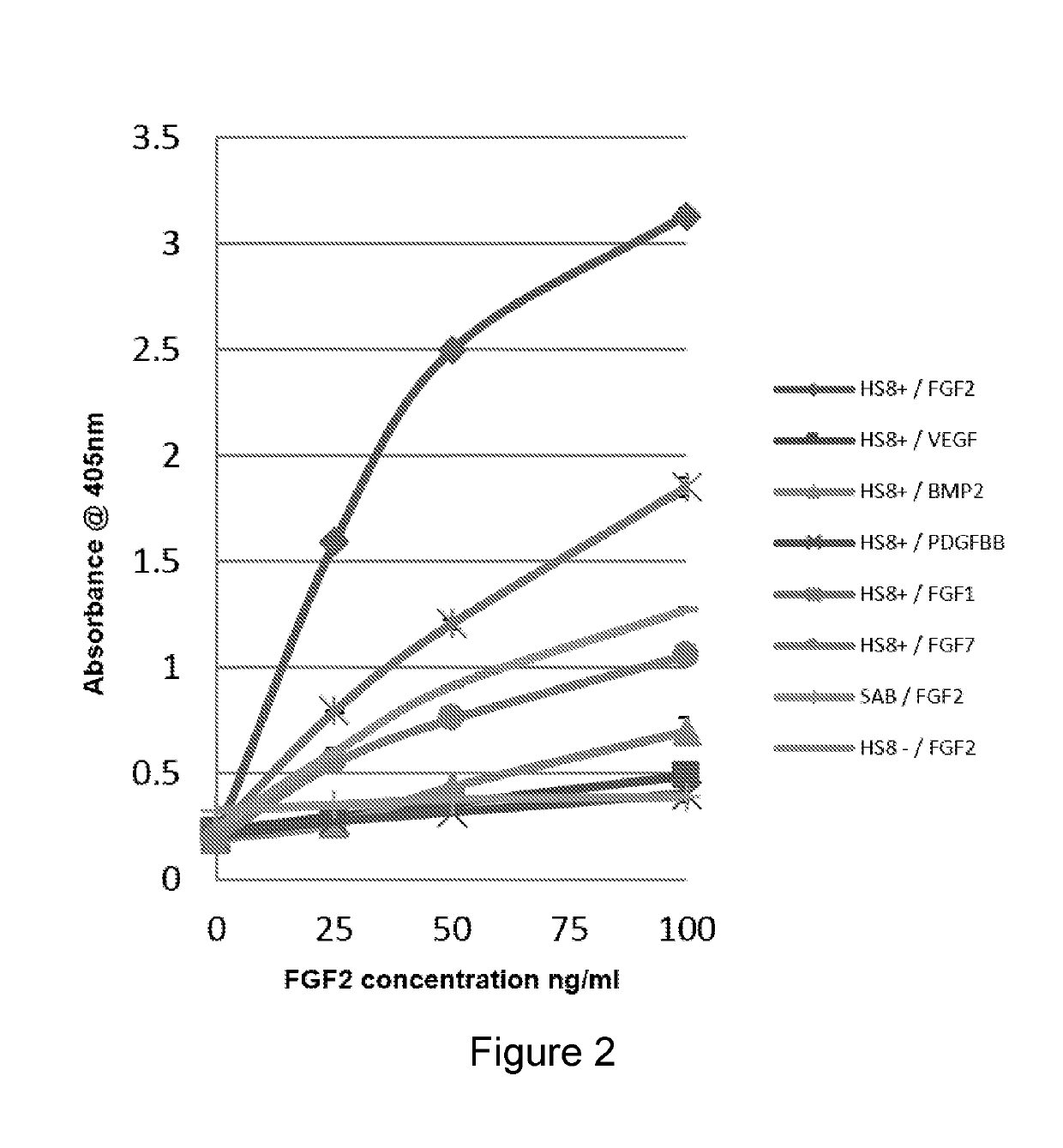

Heparin and heparan sulphate oligosaccharides

ActiveUS20210161945A1High activityPromote repairOrganic active ingredientsSkeletal disorderConnective tissue fiberPharmaceutical drug

Isolated heparin or heparan sulphate oligosaccharide fragments having a chain length of at least 10 saccharides and no more than 50 saccharides, which are capable of binding BMP2, are disclosed. Also disclosed is the use of the same heparin or heparan sulphate oligosaccharide fragments in kits and pharmaceutical compositions, and the use of the same heparan sulphate oligosaccharide fragments in the repair and / or regeneration of connective tissue and bones, and the treatment of wounds.

Owner:AGENCY FOR SCI TECH & RES

Analytical method for glycosaminoglycans

PendingUS20210132040A1Measure sensitivelyComponent separationPreparing sample for investigationSugar amineUronic acid

A method for decomposing dermatan sulfate and heparan sulfate contained in a sample into a disaccharide, respectively, whereinthe dermatan sulfate is decomposed into a disaccharide in which a uronic acid and an amino sugar are joined with an α-1,3 bond, and the heparan sulfate is decomposed into the disaccharide in which the uronic acid and the amino sugar are joined with the α-1,4 bond, and wherein,the dermatane sulfate is decomposed by heating in hydrogen chloride methanol solution containing 2,2-dimethoxypropane, at a temperature of 60 to 80° C., and for 20 to 100 minutes, andthe heparan sulfate is decomposed by heating in hydrogen chloride methanol solution containing 2,2-dimethoxypropane, for 80 to 180 minutes, and at a temperature of 65 to 85° C.

Owner:JCR PHARMA

A method for extracting high-purity heparan sulfate from heparin production waste

The method discloses a method for extracting high-purity heparan sulfate from heparan production wastes, and aims at providing a method used for extracting purified heparan sulfate taking the heparanproduction wastes as raw material. The method has the advantages of low cost, convenient operation and easy industrial scaling. The method is characterized by comprising the steps that 1), the heparanproduction wastes are prepared into a solution; 2), acid is added to adjust the pH to 1.9-2.3, ethanol is added, and stirring, centrifugation and standing are conducted; 3), supernatant liquid is collected, aqueous alkali is added to adjust pH to 6-8, and water is added; 4), absorbent is added to the solution is step 3), and stirring is conducted until all mucopolysaccharide in the solution is absorbed by the absorbent; 5), the absorbent is collected and washed with clean water, a sodium chloride solution is added to conduct elution, elution liquid is collected after the elution is completed,and precipitant is added for precipitation; 6), precipitations are collected and dried; the method belongs to the field of mucopolysaccharide pharmaceuticals.

Owner:深圳市格利科生物科技有限公司

PDGF-B /PDGF-BB binding variants of heparan sulfates

ActiveUS10723813B2Increased proliferationPromote migrationOrganic active ingredientsPeptide/protein ingredientsSkin InjurySkin repair

Affinity purification of platelet-derived growth factor-binding heparan sulphate from porcine mucosa (HS6) is disclosed. Also disclosed is the use of HS6 in repair and regeneration of the skin for treating wounds, burns, ulcers and other skin injuries.

Owner:AGENCY FOR SCI TECH & RES

Heparan sulfate glycomimetic compounds and their pharmaceutical and cosmeceutical uses

The invention relates to dendritic compounds, the use of these compounds as pharmaceuticals, pharmaceutical and cosmeceutical compositions containing the compounds, and methods of treating cancer, inflammation, diabetic nephropathy, neurodegenerative disorders, Niemann-Pick Type C disease, or dermatological conditions.

Owner:VICTORIA LINK LTD

Anti-HIV composition, production method thereof and medicament

InactiveUS7494975B2Inhibits gp120/48dIncrease infectivityOrganic active ingredientsBiocideEpitopeChemical composition

The present invention relates to an anti-HIV composition and to the method for producing it.The composition of the present invention comprises a polyanion and a molecule capable of inducing the exposure of the CD4i epitope of the gp120 viral protein. The polyanion may be chosen, for example, from the group consisting of heparin, heparan sulphate, and a polyanion equivalent to heparin or to heparan sulphate. The molecule capable of inducing the exposure of the CD4i epitope of the gp120 viral protein is a CD4 peptide or a derivative thereof.The present invention also relates to the use of said composition for producing a medicinal product, in particular a medicinal product intended for the treatment of AIDS.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

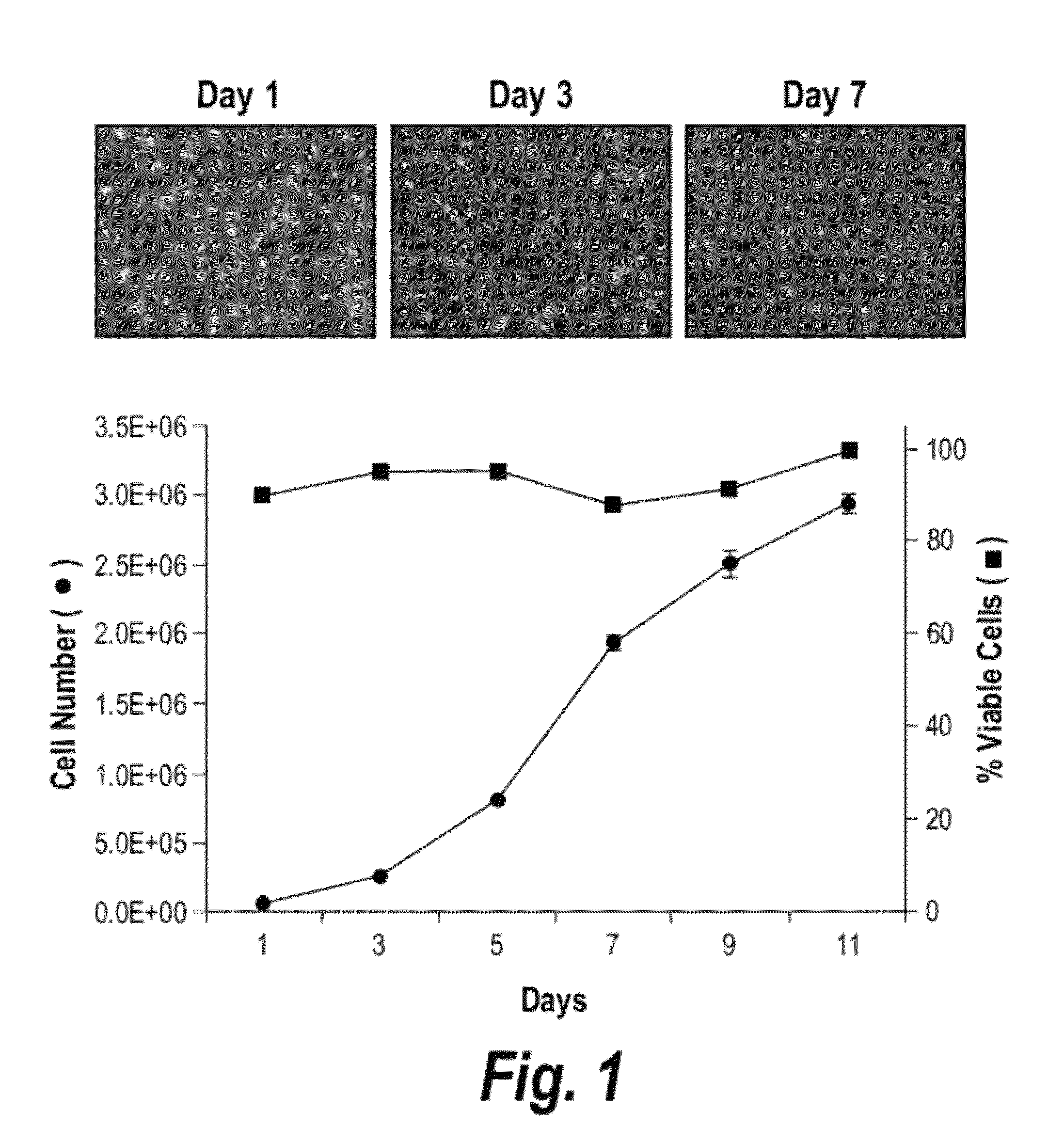

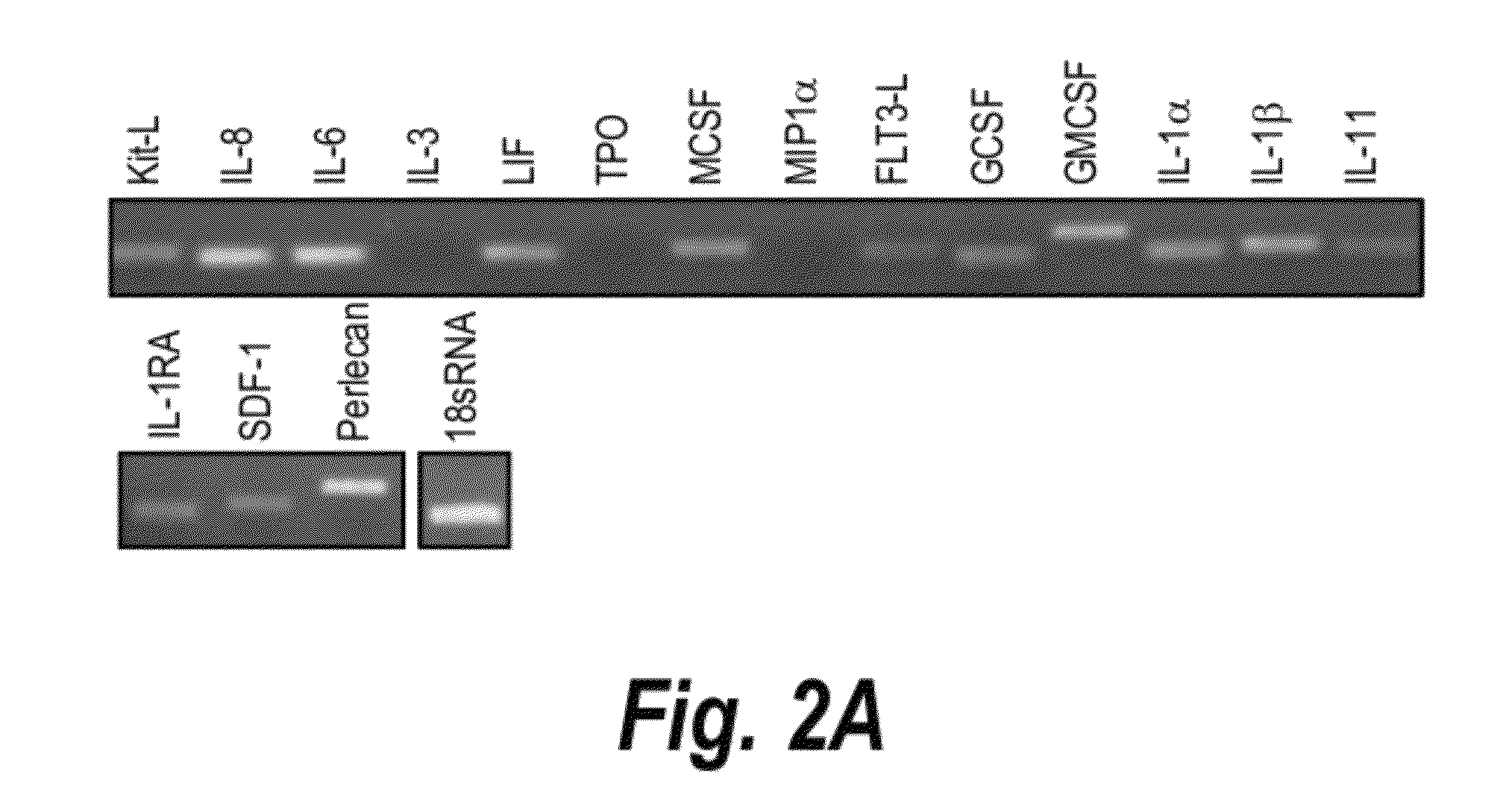

Heparan sulphate

InactiveUS9044496B2Enhance the lineage-commitment of hematopoietic stem cellsEnhance BMP-2 induced osteogenesisBiocideOrganic active ingredientsHeparan sulphateBone marrow stroma

Owner:AGENCY FOR SCI TECH & RES

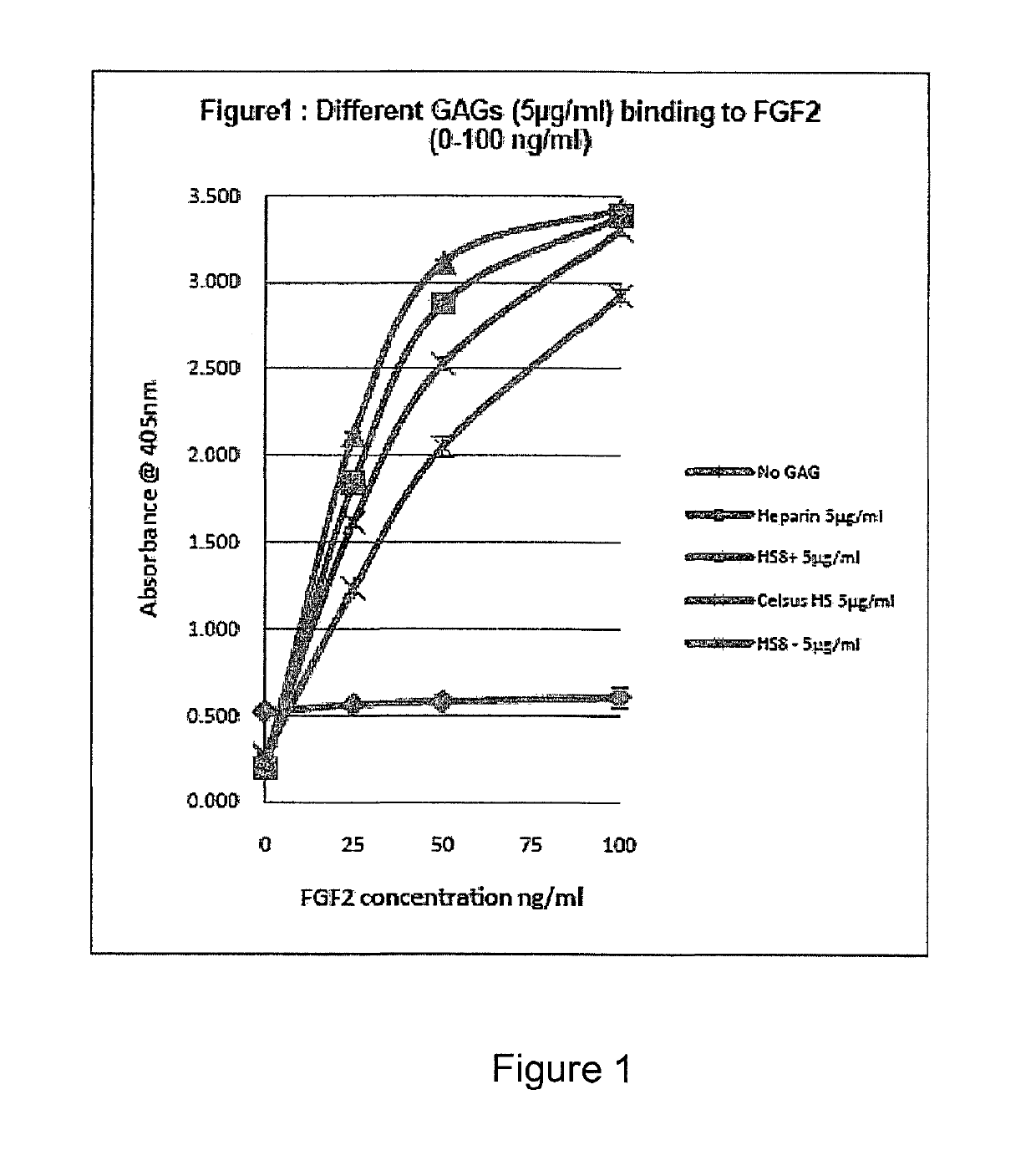

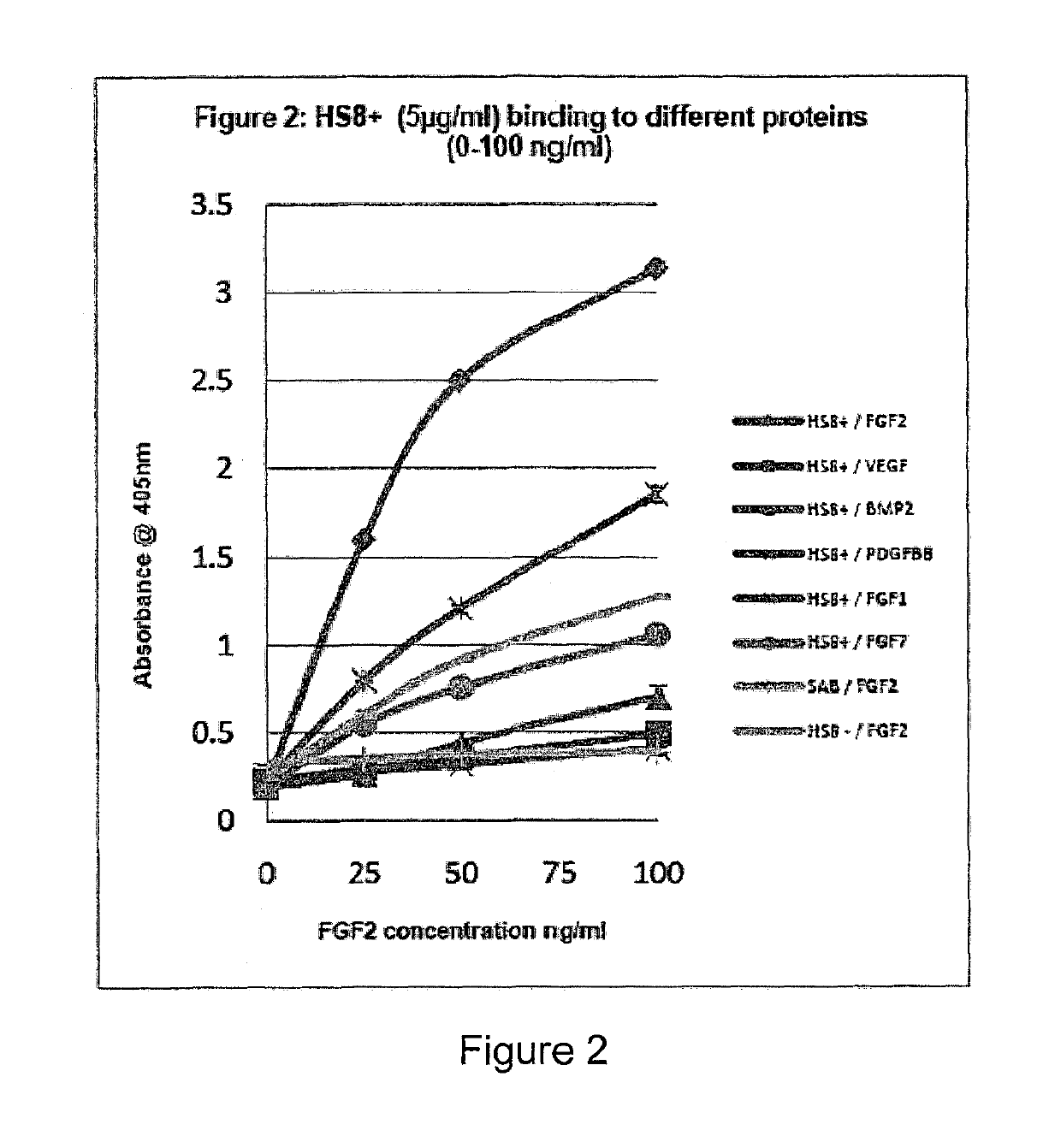

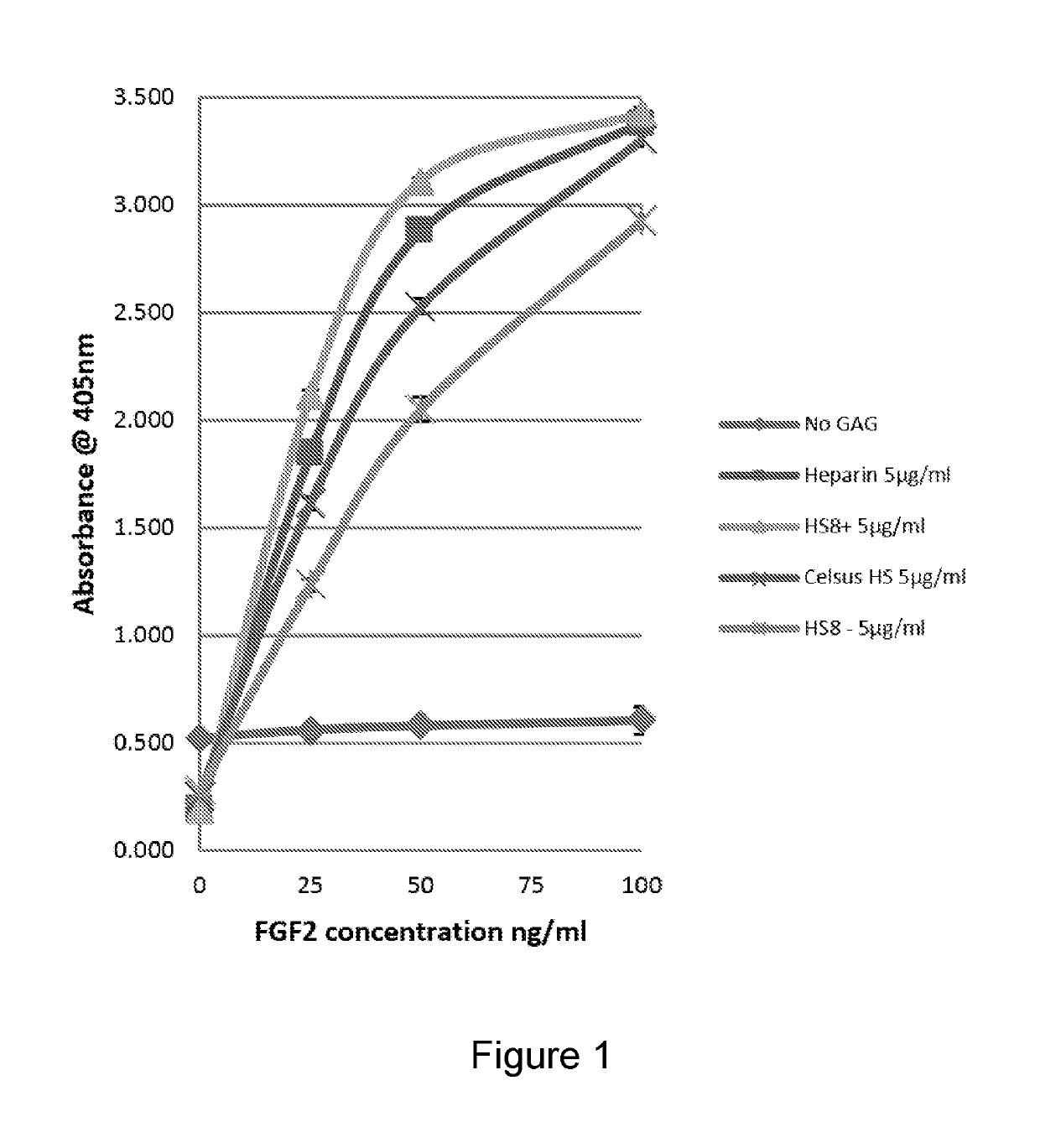

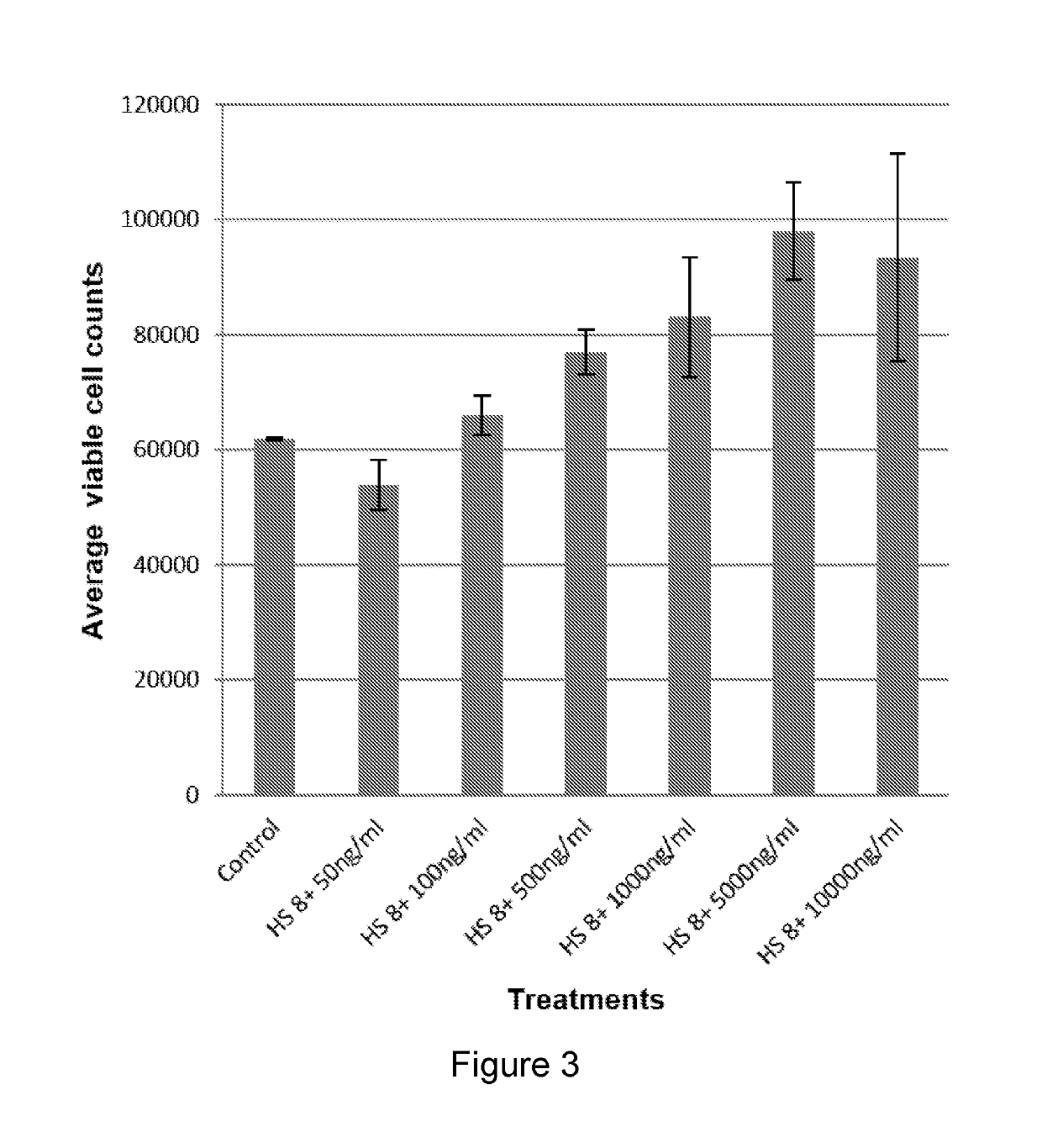

Heparan sulphates for use in repair and/or regeneration of skin

ActiveUS10471091B2Increased proliferationFacilitated DiffusionOrganic active ingredientsPeptide/protein ingredientsSkin InjuryHeparan sulphate

Affinity purification of fibroblast growth factor 2-binding heparan sulphate from porcine mucosa (HS8) is disclosed. Also disclosed is the use of HS8 in repair and regeneration of the skin for treating wounds, burns, ulcers and other skin injuries.

Owner:AGENCY FOR SCI TECH & RES

Heparan sulfate glycomimetic compounds and their pharmaceutical and cosmeceutical uses

The invention relates to dendritic compounds, the use of these compounds as pharmaceuticals, pharmaceutical and cosmeceutical compositions containing the compounds, and methods of treating cancer, inflammation, diabetic nephropathy, neurodegenerative disorders, Niemann-Pick Type C disease, or dermatological conditions.

Owner:VICTORIA LINK LTD

A method for separating heparan sulfate and dermatan sulfate in heparin

The present invention relates to a separation method of heparan sulfate and dermatan sulfate in heparin, which comprises the following steps: (a) dissolving heparin in water to prepare heparin solution; (b) passing the heparin solution through anion resin Adsorption; (c) Gradient elution using 0~1mol / L sodium chloride solution, and collecting the eluent of each component; (d) Concentrating the eluent of each component respectively, adding ethanol for precipitation to obtain sulfuric acid Heparan and dermatan sulfate. In this way, heparin-like by-products produced in the production of crude heparin to high-quality heparin can be used as raw materials, which avoids the loss of active ingredients in the prior art, does not introduce impurities, has simple process, low separation cost, good effect, and is easy to scale up.

Owner:SUZHOU WISMED PHARMA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com