Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81 results about "Crown molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

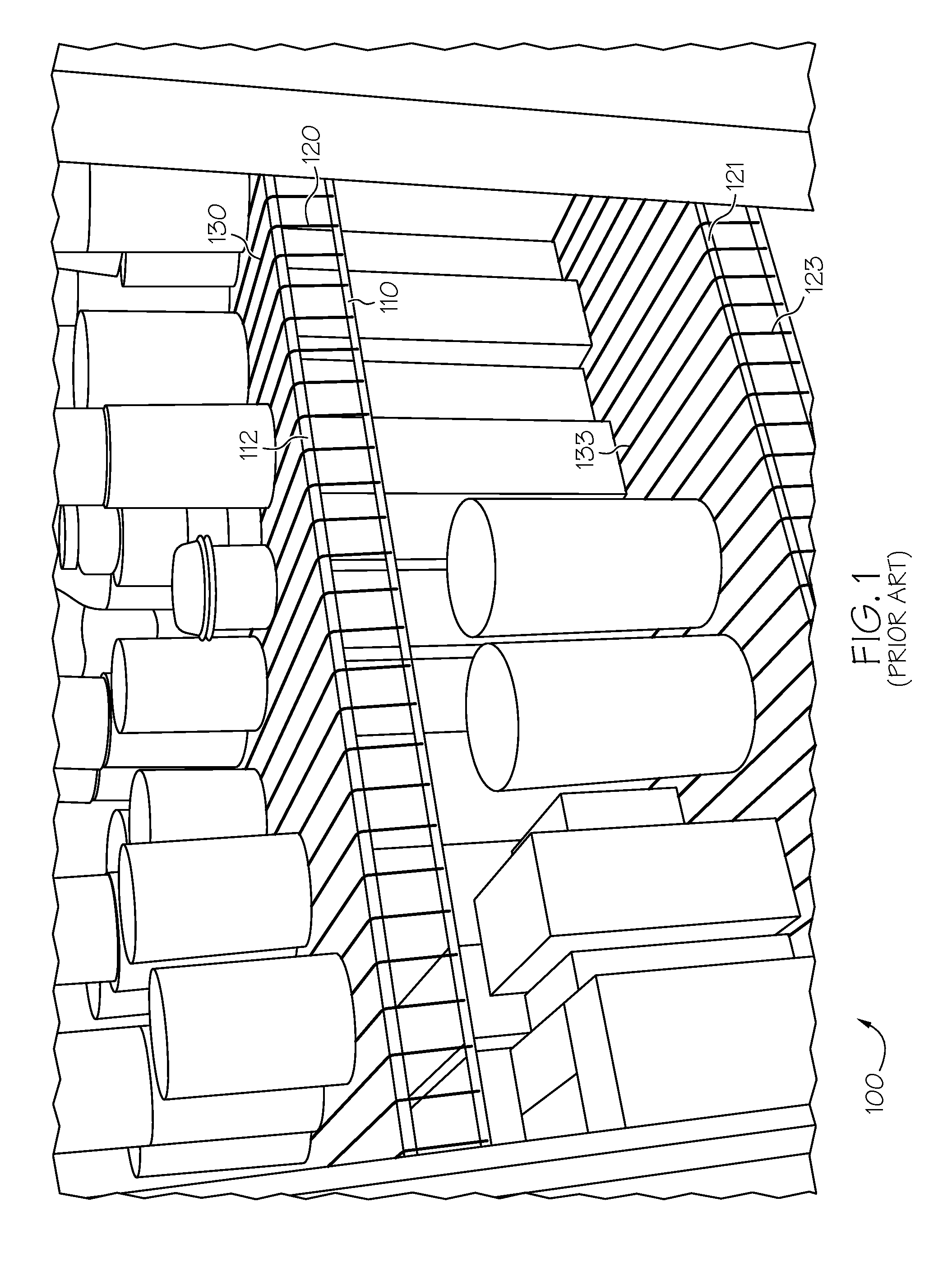

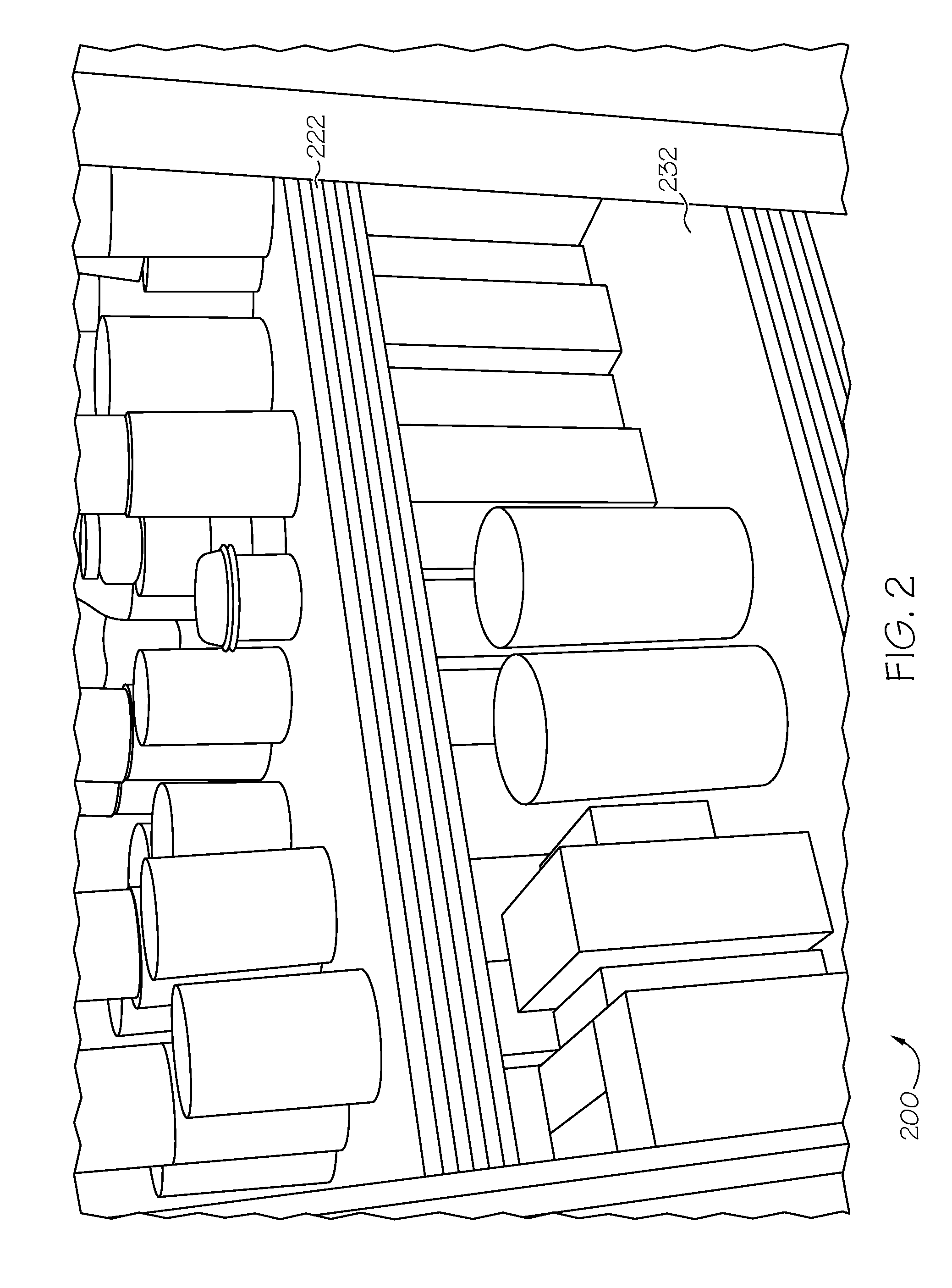

Crown molding encapsulates a large family of moldings which are designed to gracefully flare out to a finished top edge. Crown molding is generally used for capping walls, pilasters, and cabinets, and is used extensively in the creation of interior and exterior cornice assemblies and door and window hoods. In recent times, crown moldings have generally made their appearance as mostly decorated plaster or wooden trim where walls meet ceilings.

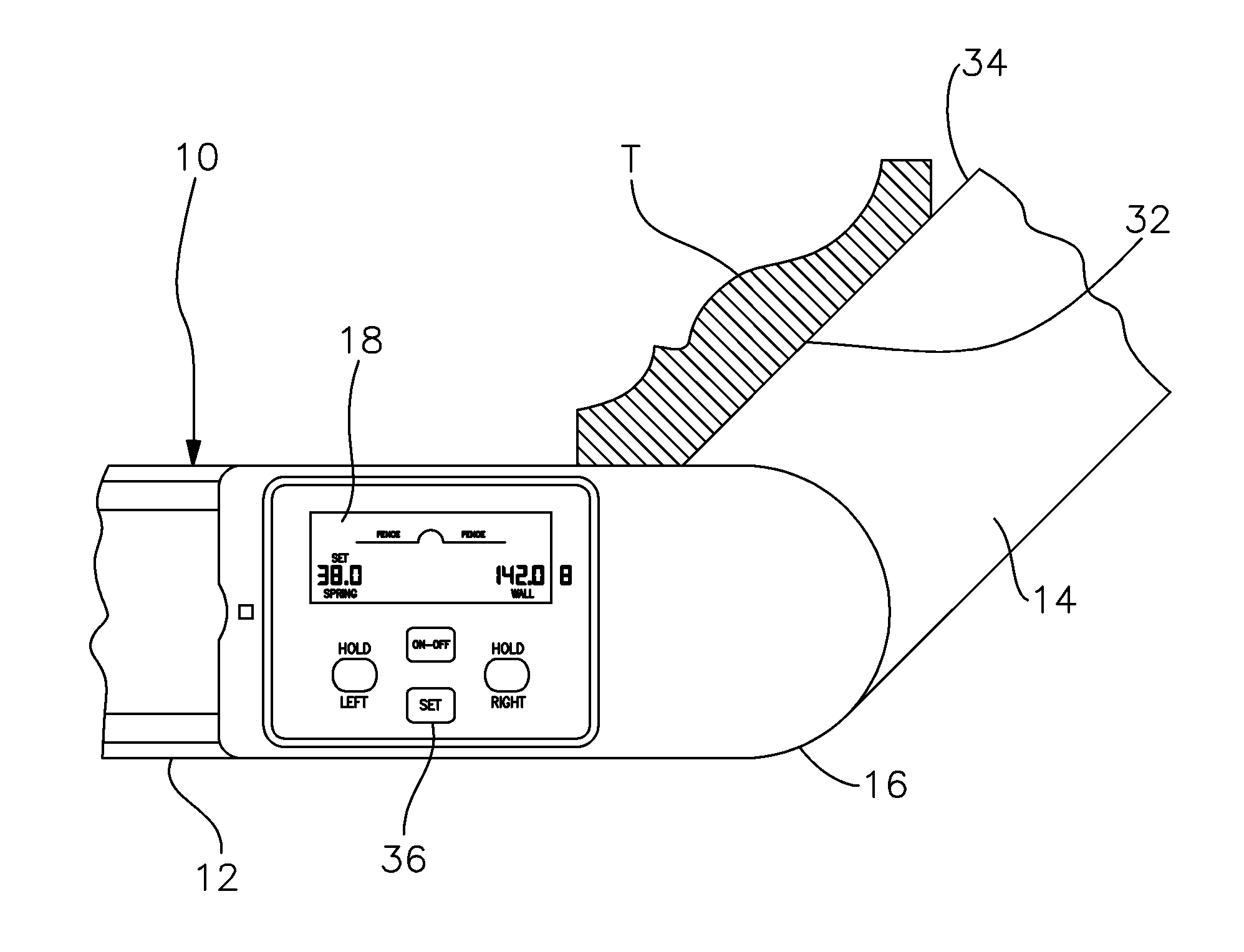

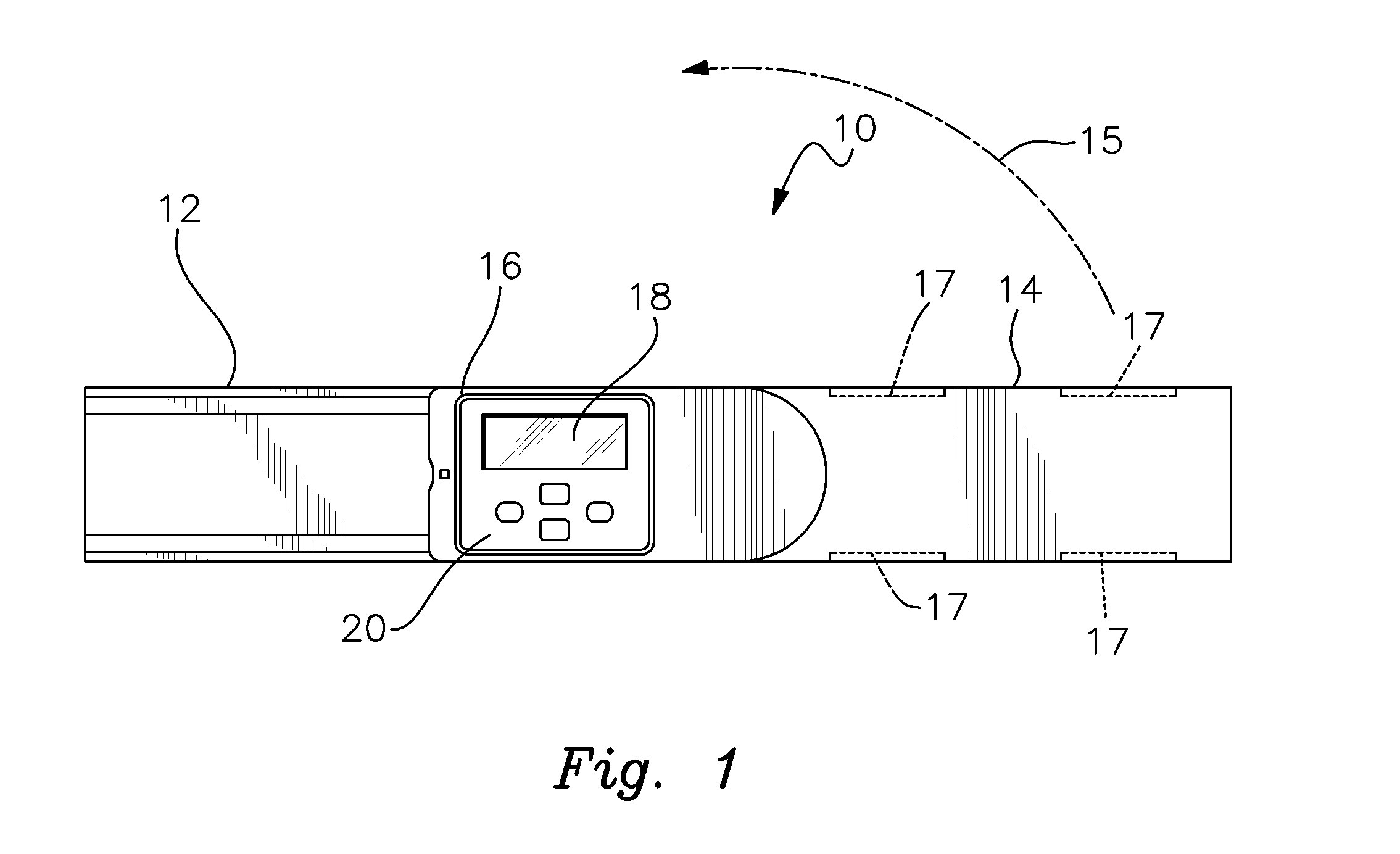

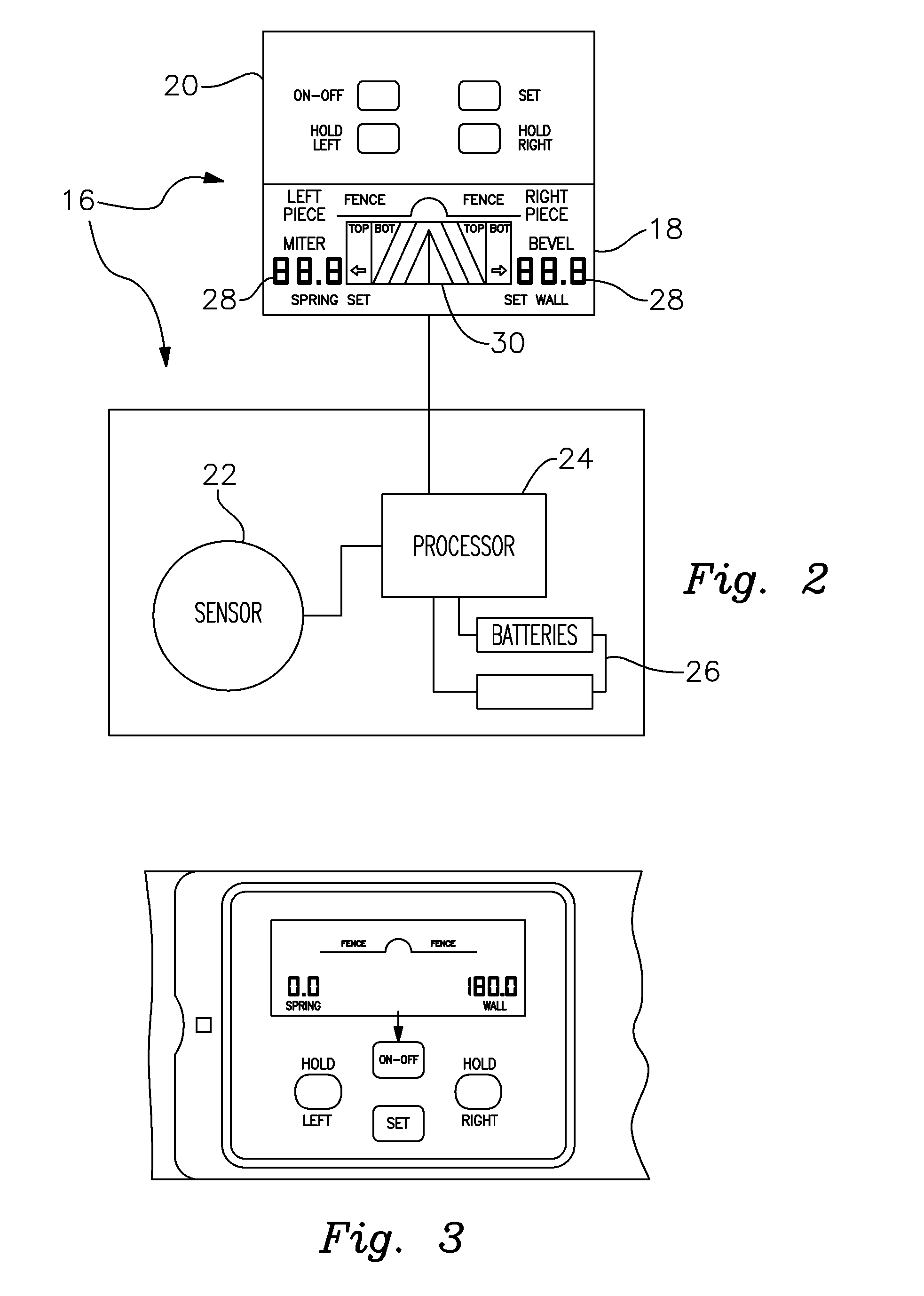

Crown Molding Protractor

InactiveUS20160238365A1Calculated quickly and accuratelyFacilitates and guides adjustmentBuilding constructionsAngles/tapers measurement gaugesProtractorCrown molding

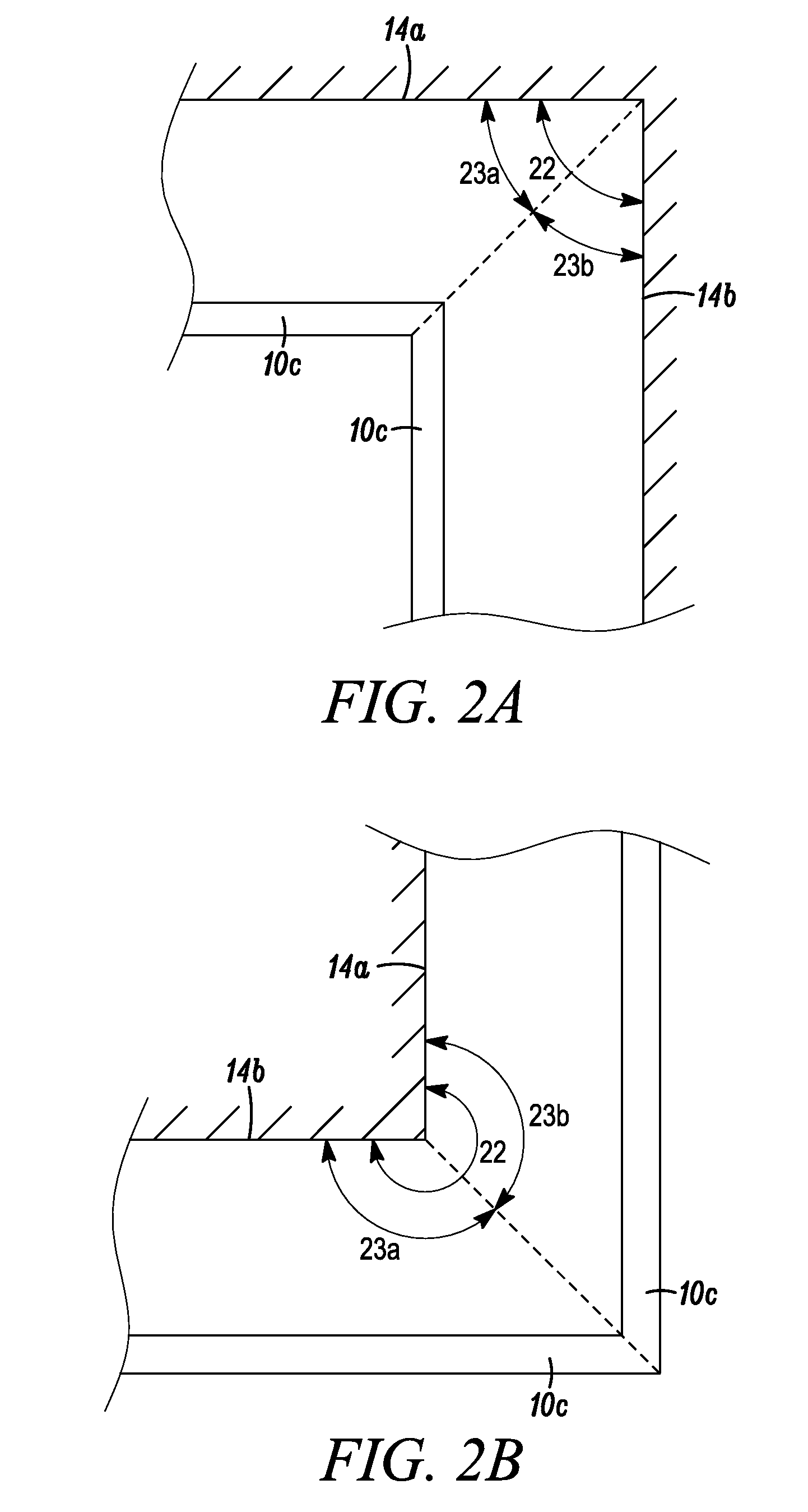

A digital protractor is provided for measuring spring and wall angles and determining and effecting bevel and miter angle adjustments of a miter saw to adjoining pieces of trim in accordance with the measured spring and wall angles. The protractor includes a pair of pivotally interconnected arms. At least one sensor is attached to one of the arms and a digital readout is secured to the other arm. The readout includes means for determining the bevel and miter angles such that the protractor can be set to those angles to properly adjust the miter saw in accordance with the calculated angles.

Owner:WIXEY BARRY DOUGLAS +2

Synthetic wood component having a foamed polymer backing

InactiveUS6863972B2Superior resistance to wear and tearImprove the immunityHair accessoriesDead plant preservationLow-density polyethyleneLinear low-density polyethylene

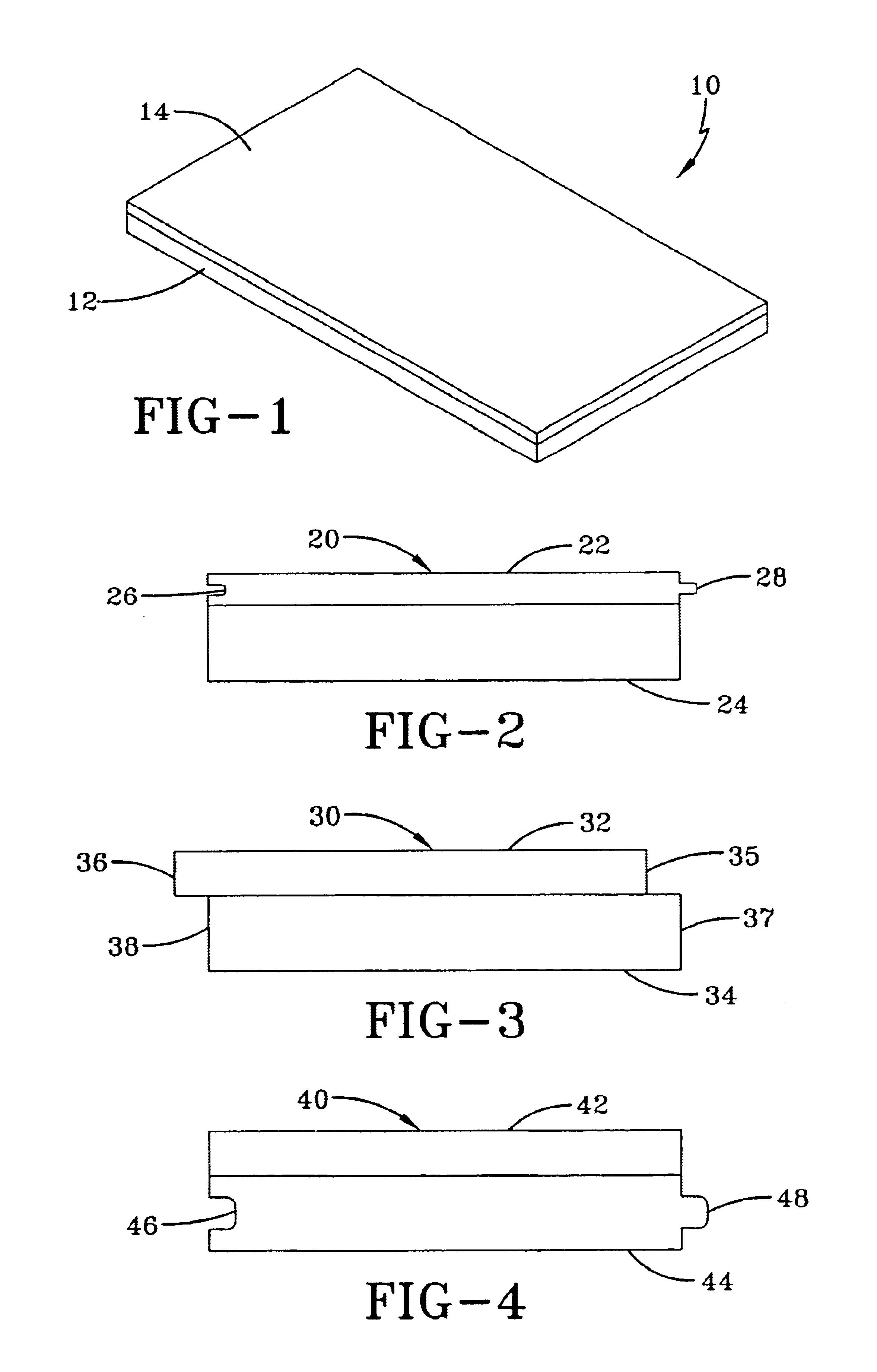

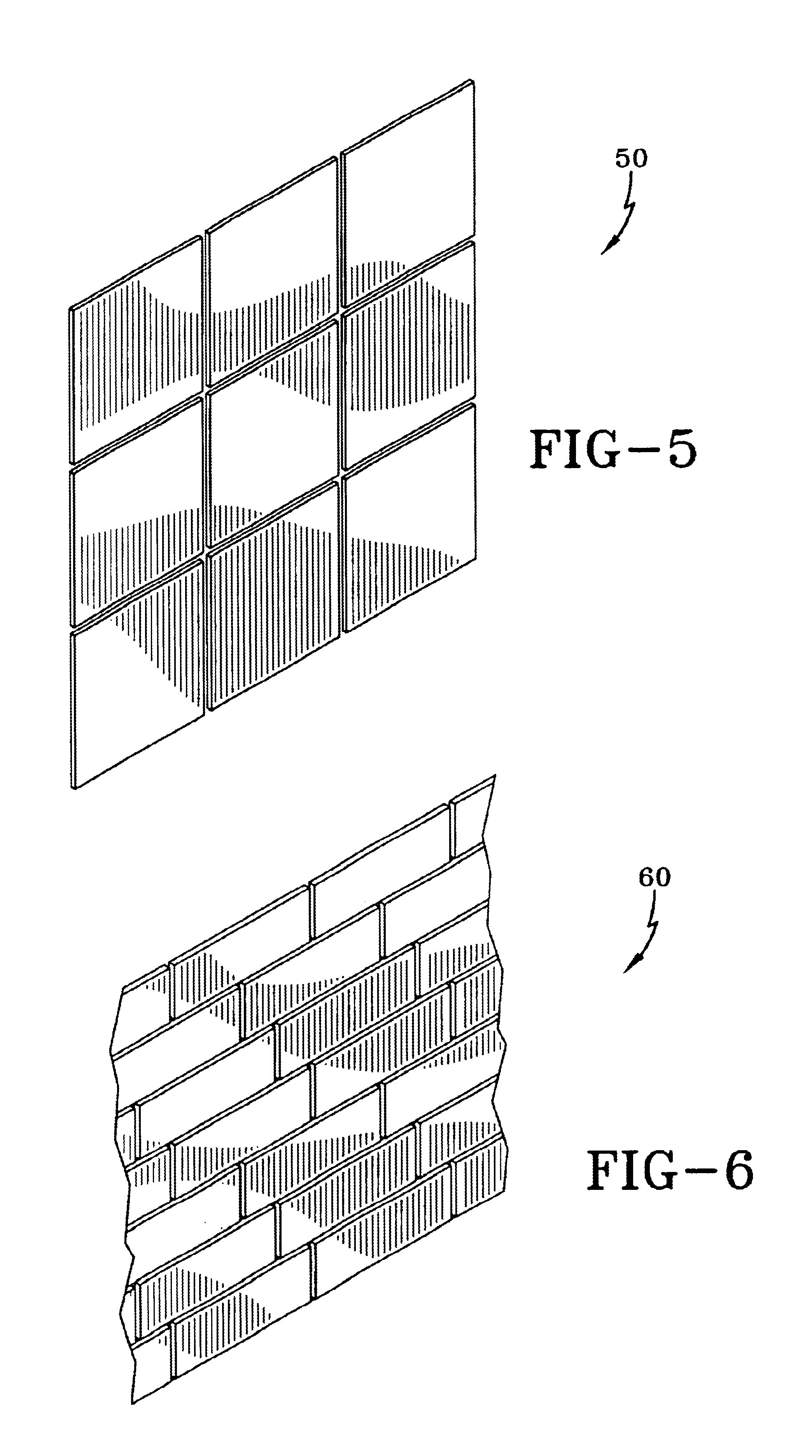

The present invention is a component having a synthetic wood layer that is secured to a foamed polymer layer. The foamed polymer layer is comprised of a polymer selected from the group consisting of high density polyethylene, polypropylene, polyvinyl chloride, low density polyethylene, chlorinated polyvinyl chloride, acrylonitrile butadiene styrene, ethyl-vinyl acetate, and polystyrene. The component can be used for a variety of different purposes such as fencing, furniture, cabinets, storage devices, lawn edging, flower boxes, flooring, roofing, wall covering, building siding, basement flooring, basement wall covering, interior and exterior decorative house moldings, crown moldings, chair rails, picture frames, porch decks, deck railings, window moldings, window components, door components, door moldings, various other lawn and garden uses, various other below grade uses, and various other indoor and outdoor uses.

Owner:CRANE BUILDING PRODS

Window and Door Frame Assembly Apparatus and Method

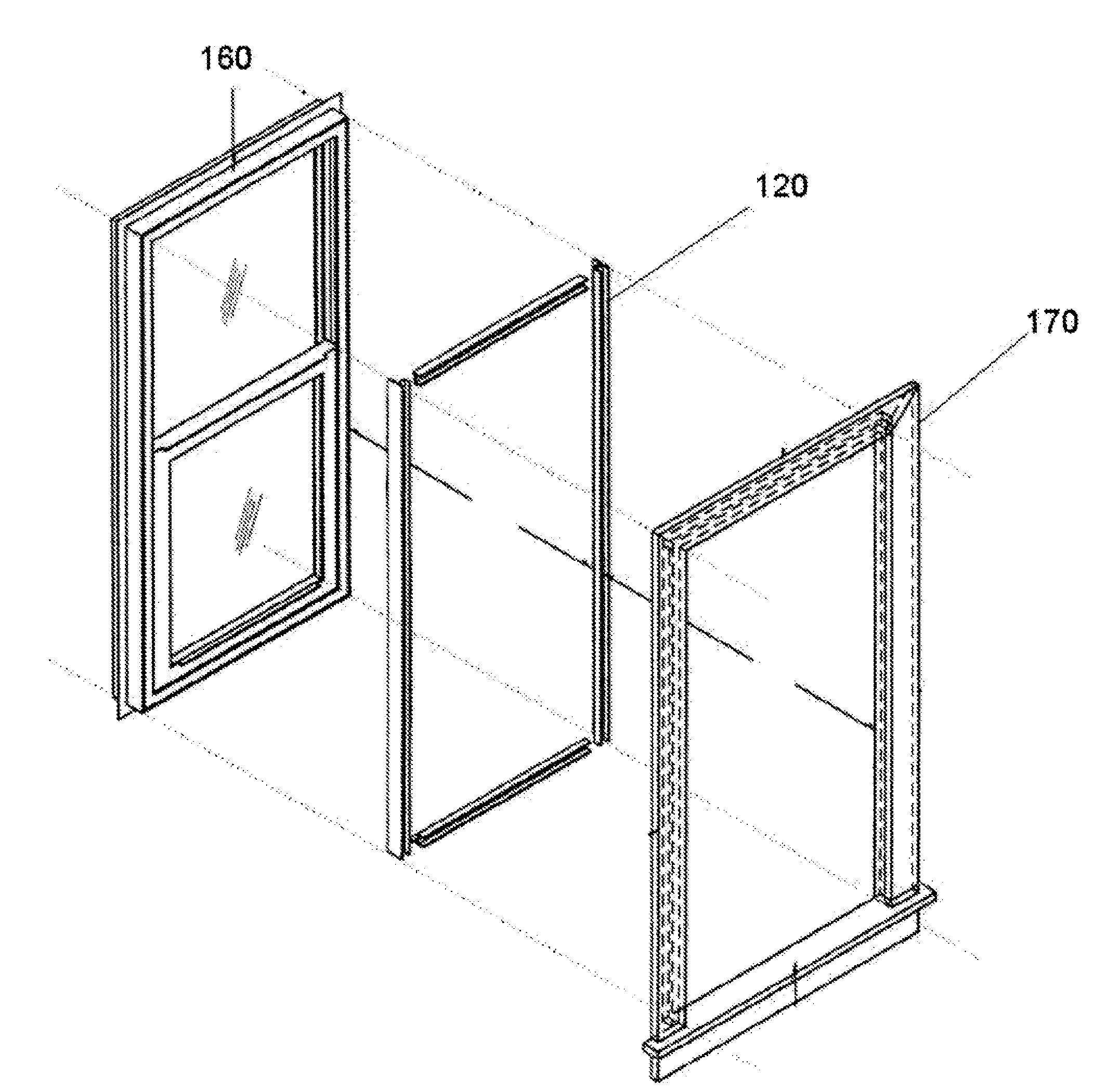

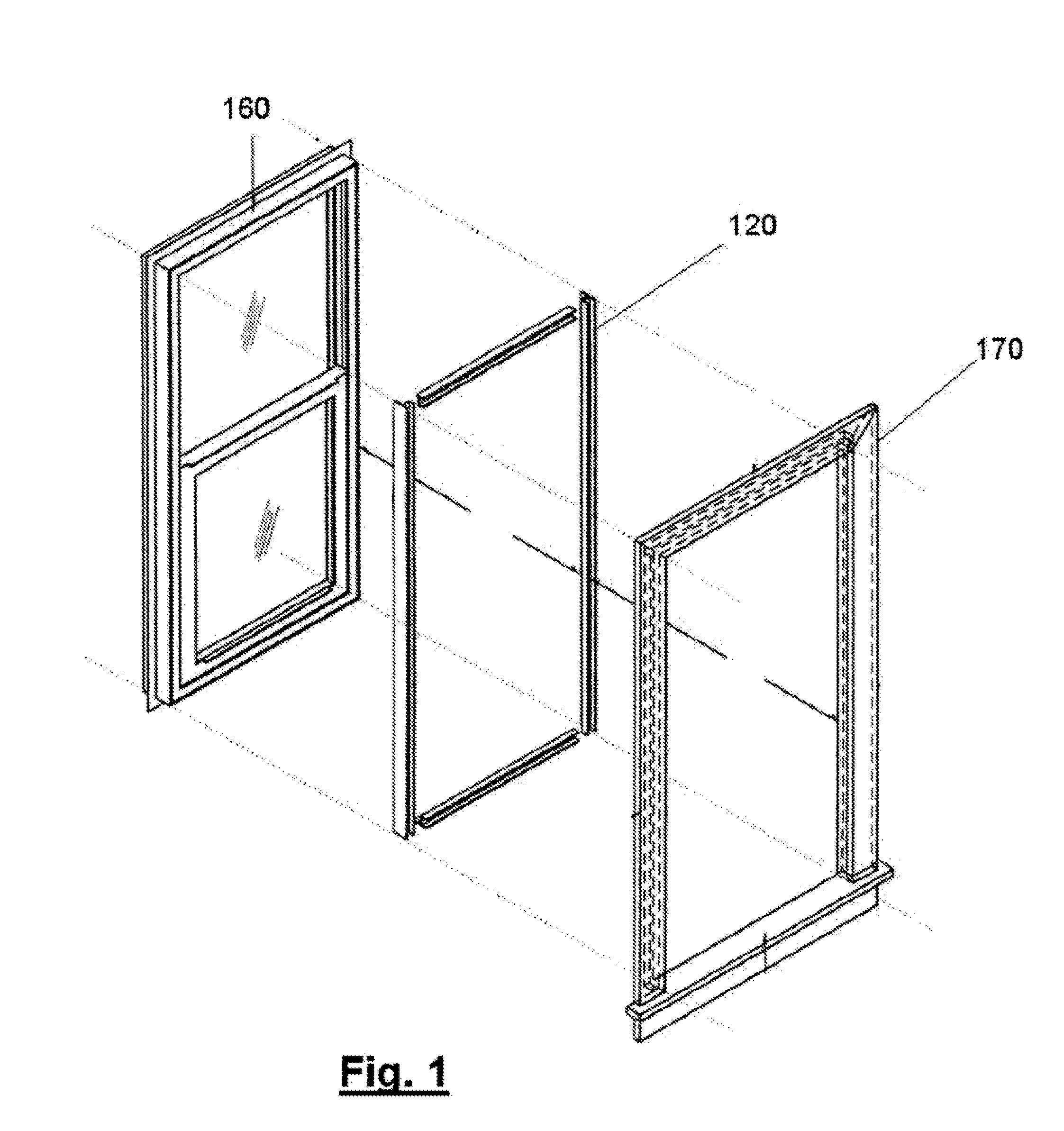

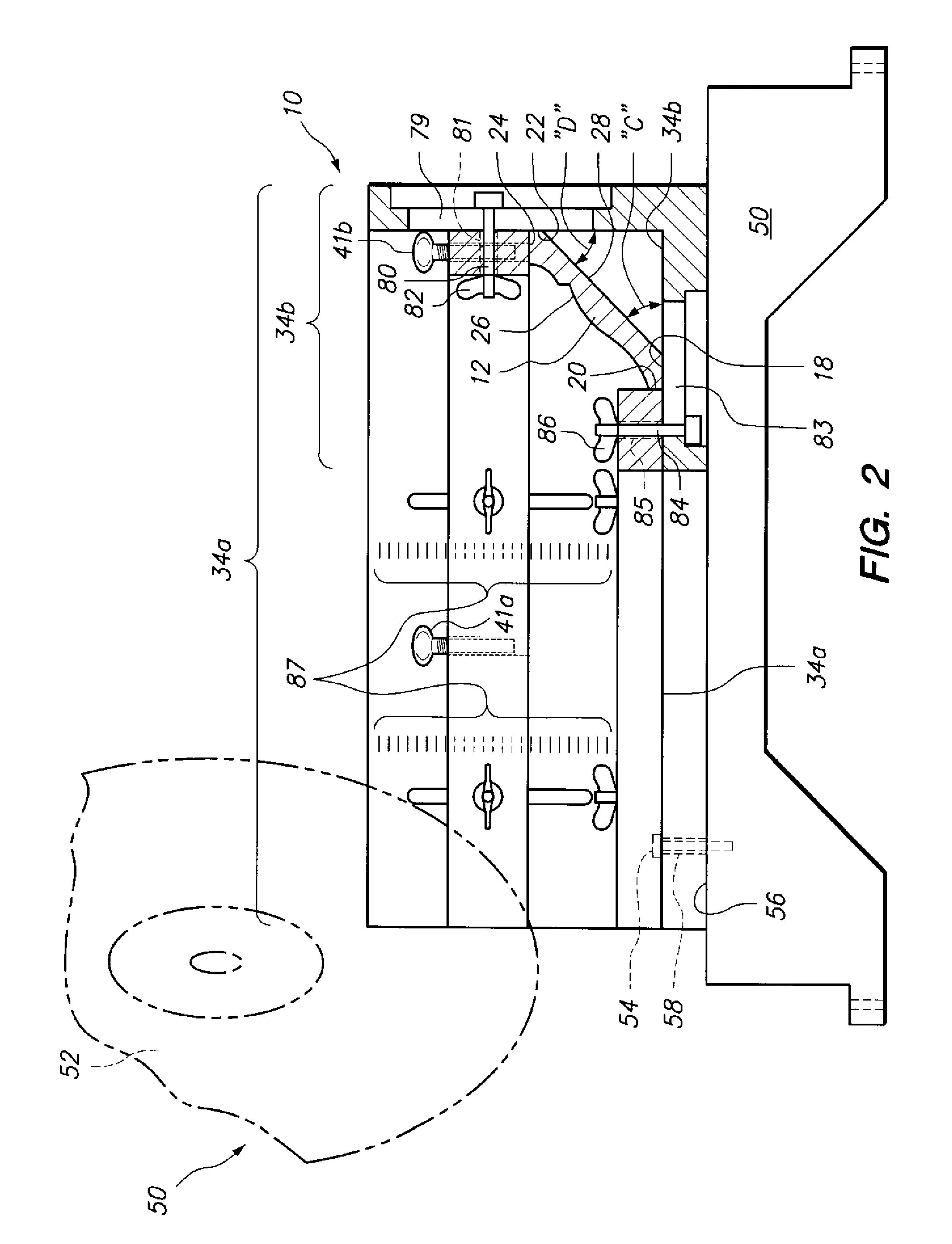

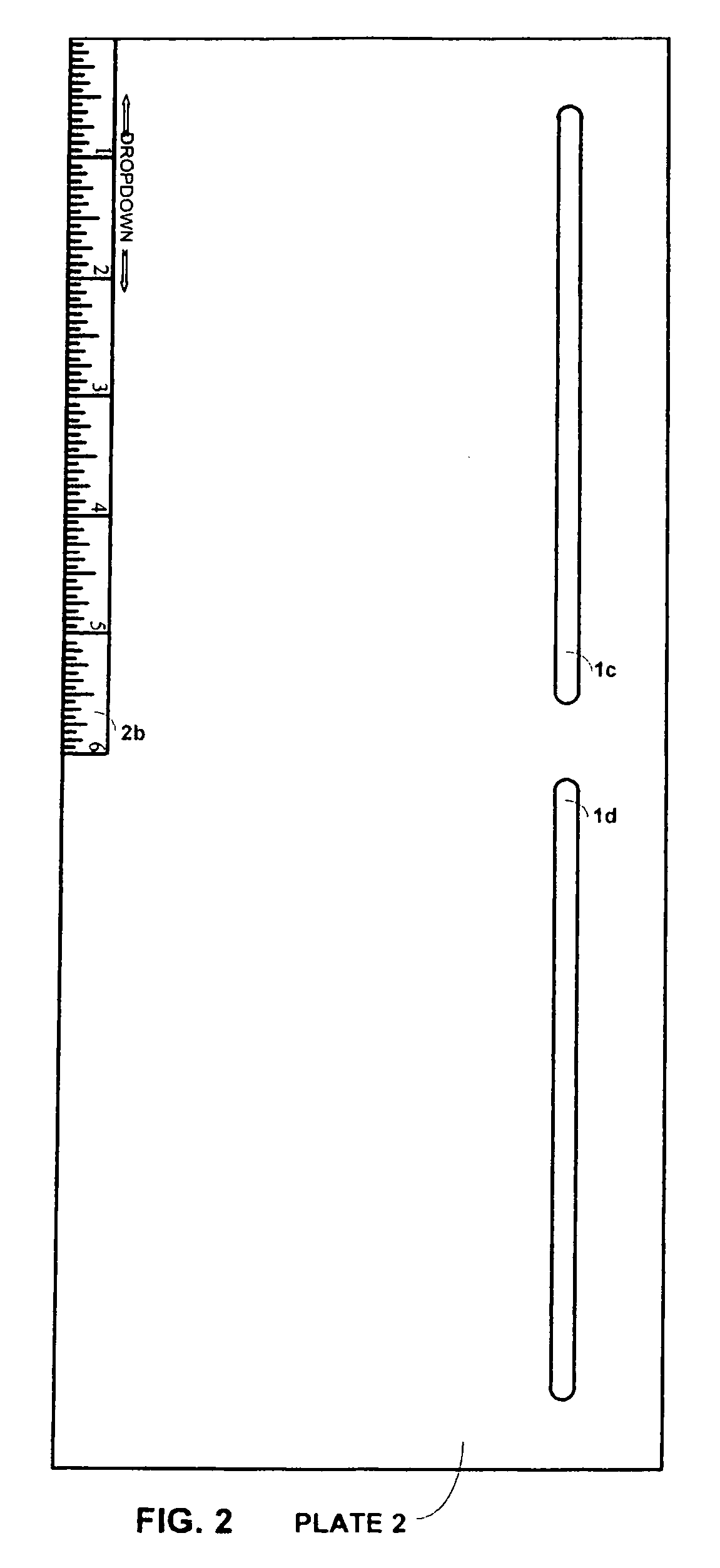

ActiveUS20090044466A1Easy to assembleReduce labor costsBuilding repairsWindow/door framesCrown moldingEngineering

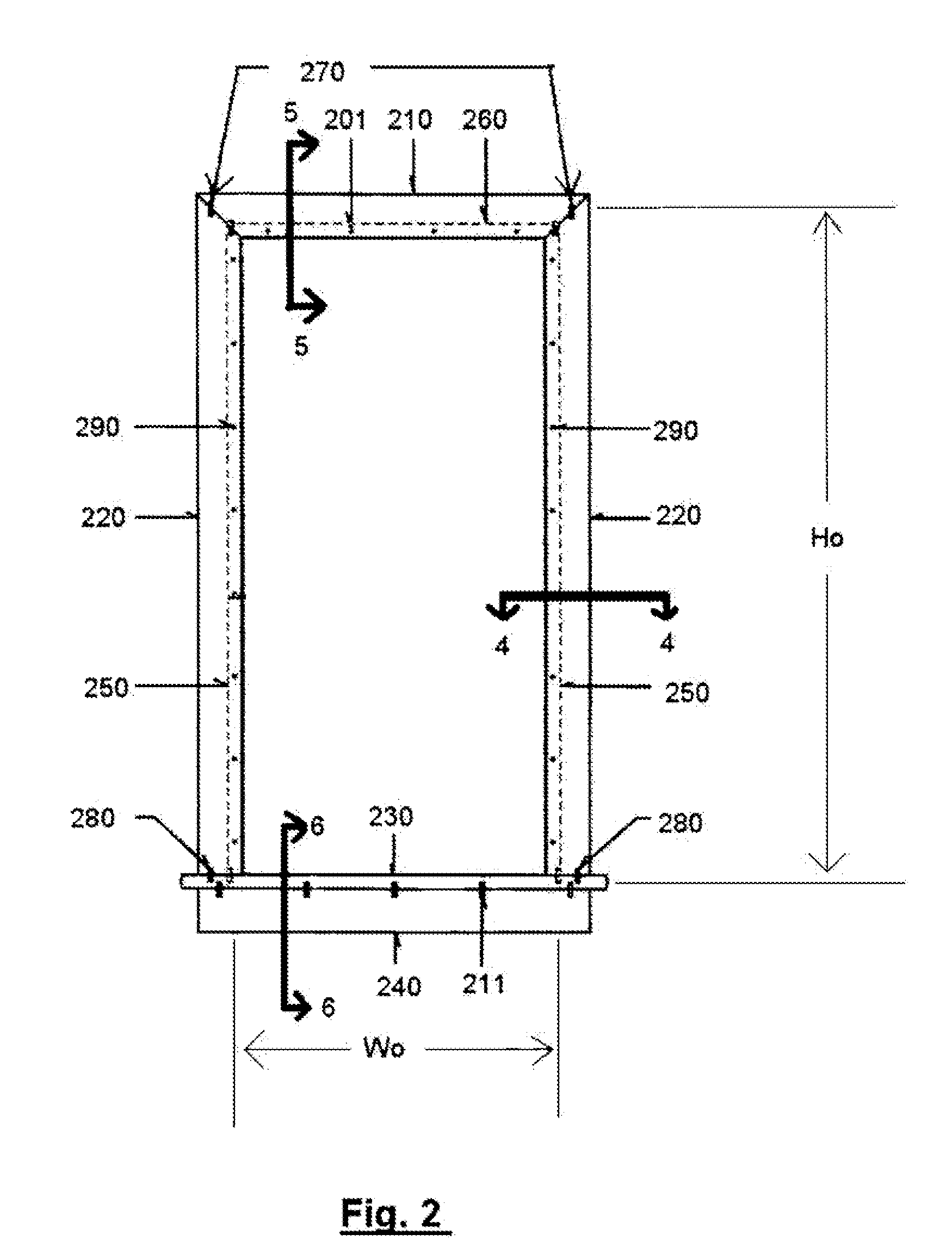

Pre-fabricated kits are provided for window / door trimming / casing that are designed and tailored for various window / door openings, architectural styles and / or manufacturers. According to one aspect, the kit is easy to assemble with everything in the box including prefabricated mutually engaging fasteners to allow all the pieces to be fastened together quickly and by hand. According to another aspect, the kit is prefabricated in a prepared and finished condition with all the pieces already painted, stained and finished, so no finishing such as painting required during or after installation. The kit can be manufactured to fit for any type of window / door and opening as long as the dimensions of openings are substantially known. Optional add-ons such as curtain rods, valances, closet shelves, poles, cabinets, shutters and cornices can also be included in the kit in pre-fabricated condition. The principles of the invention can also be extended to other types of molding such as crown molding and baseboards. Among many advantages, the invention reduces labor costs dramatically, improves quality and consistency in craftsmanship, and provides economies of scale to be applied the production of finished products that has never been previously available.

Owner:EZ TRIM KIT

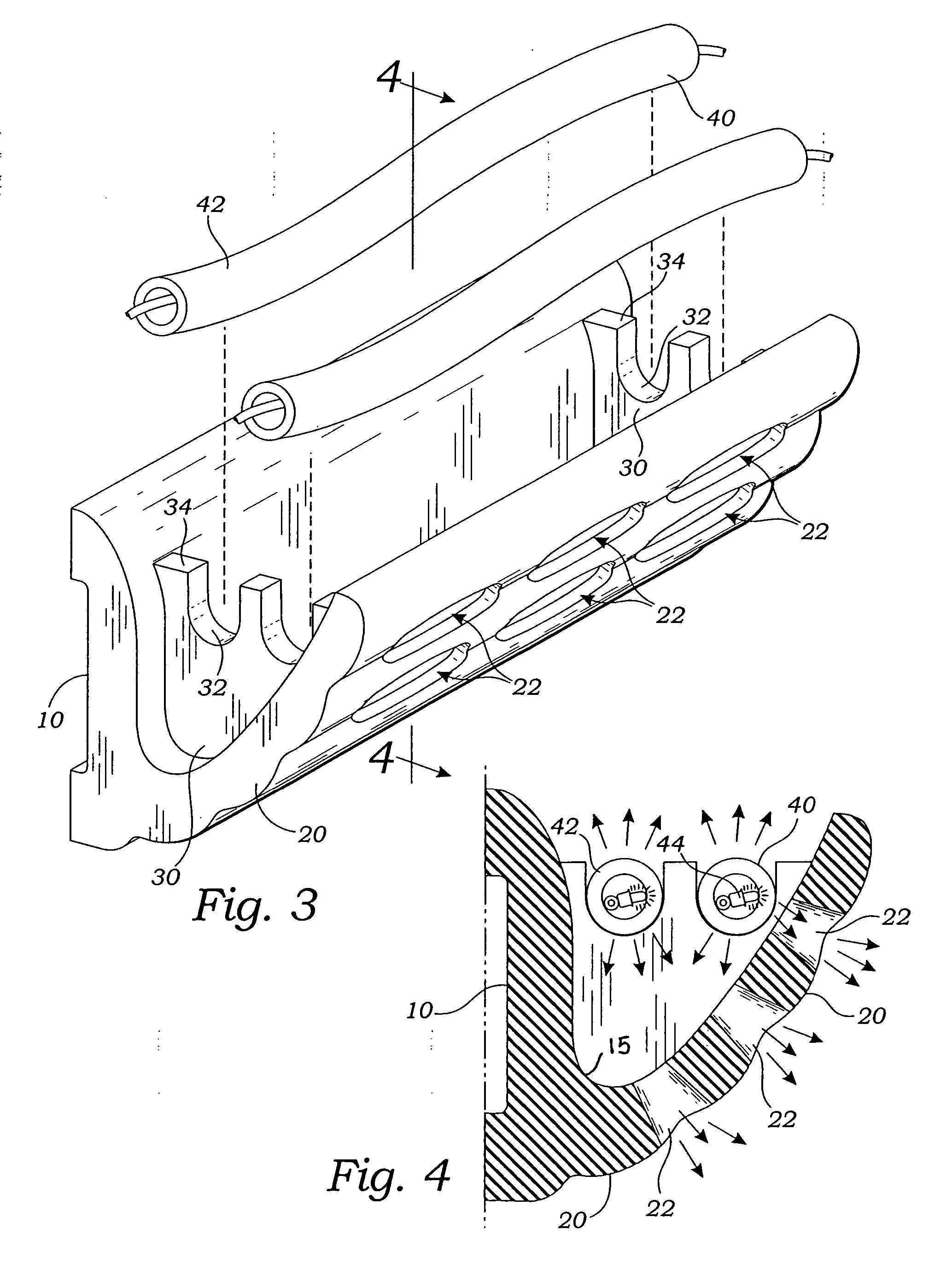

Light rope crown molding

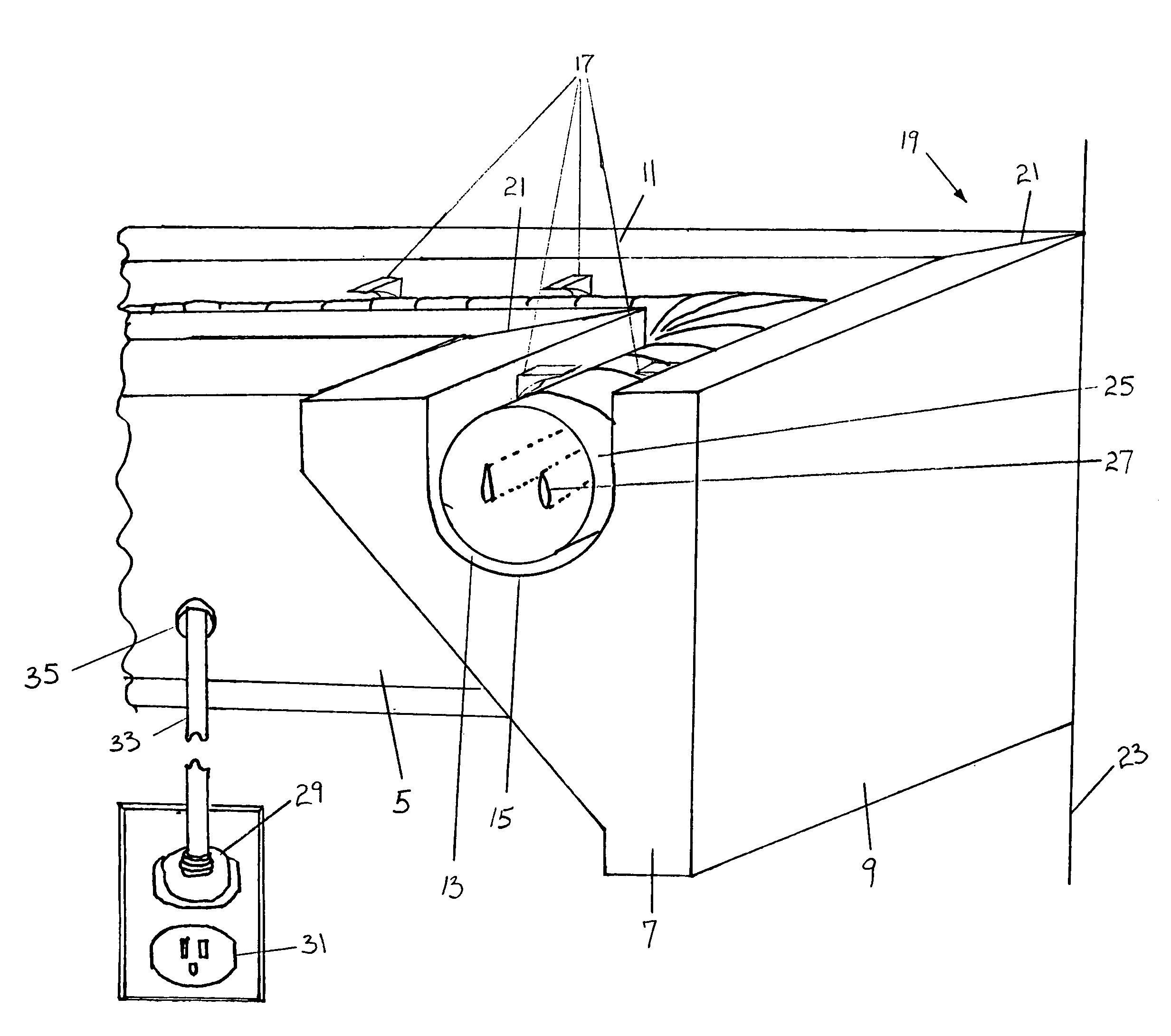

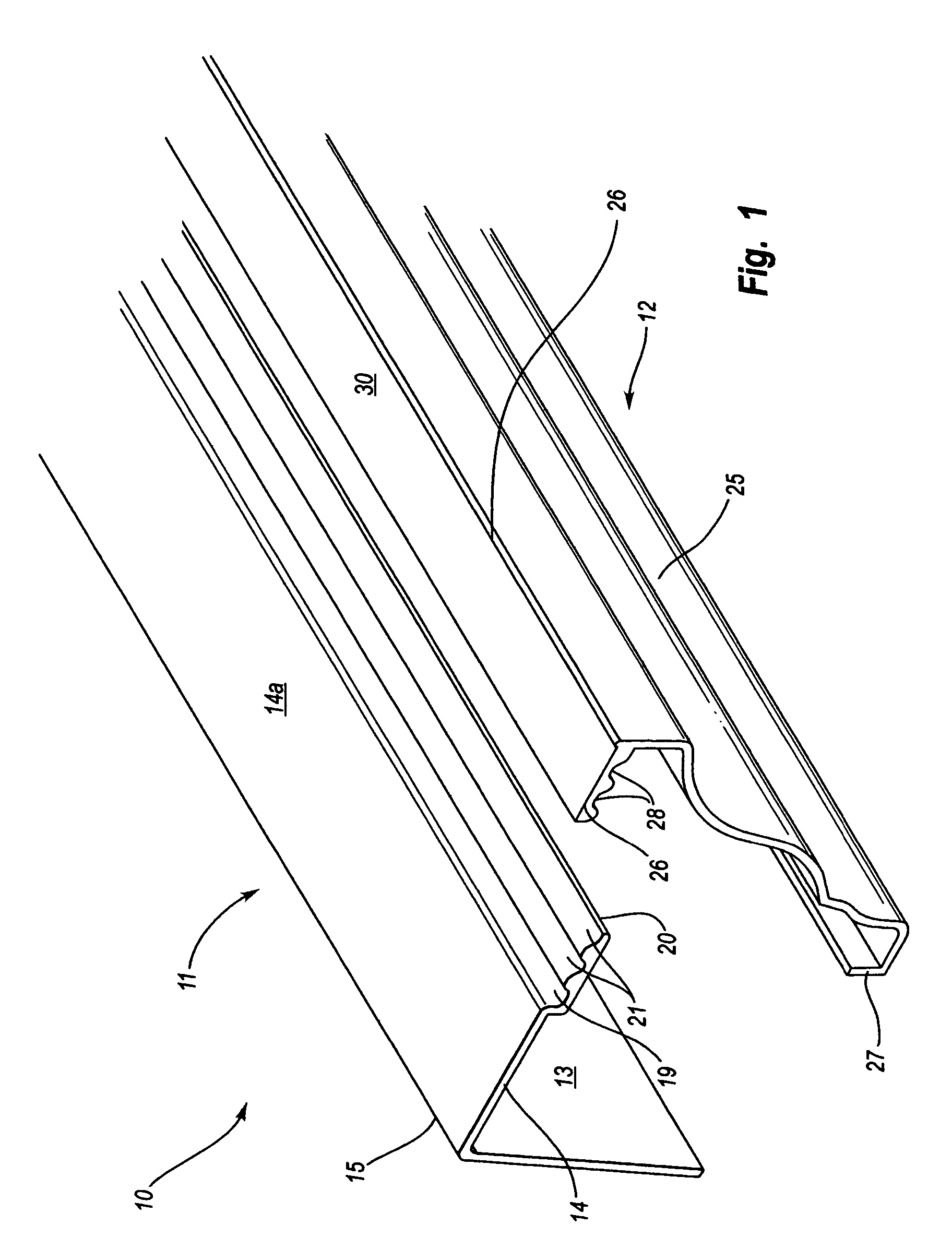

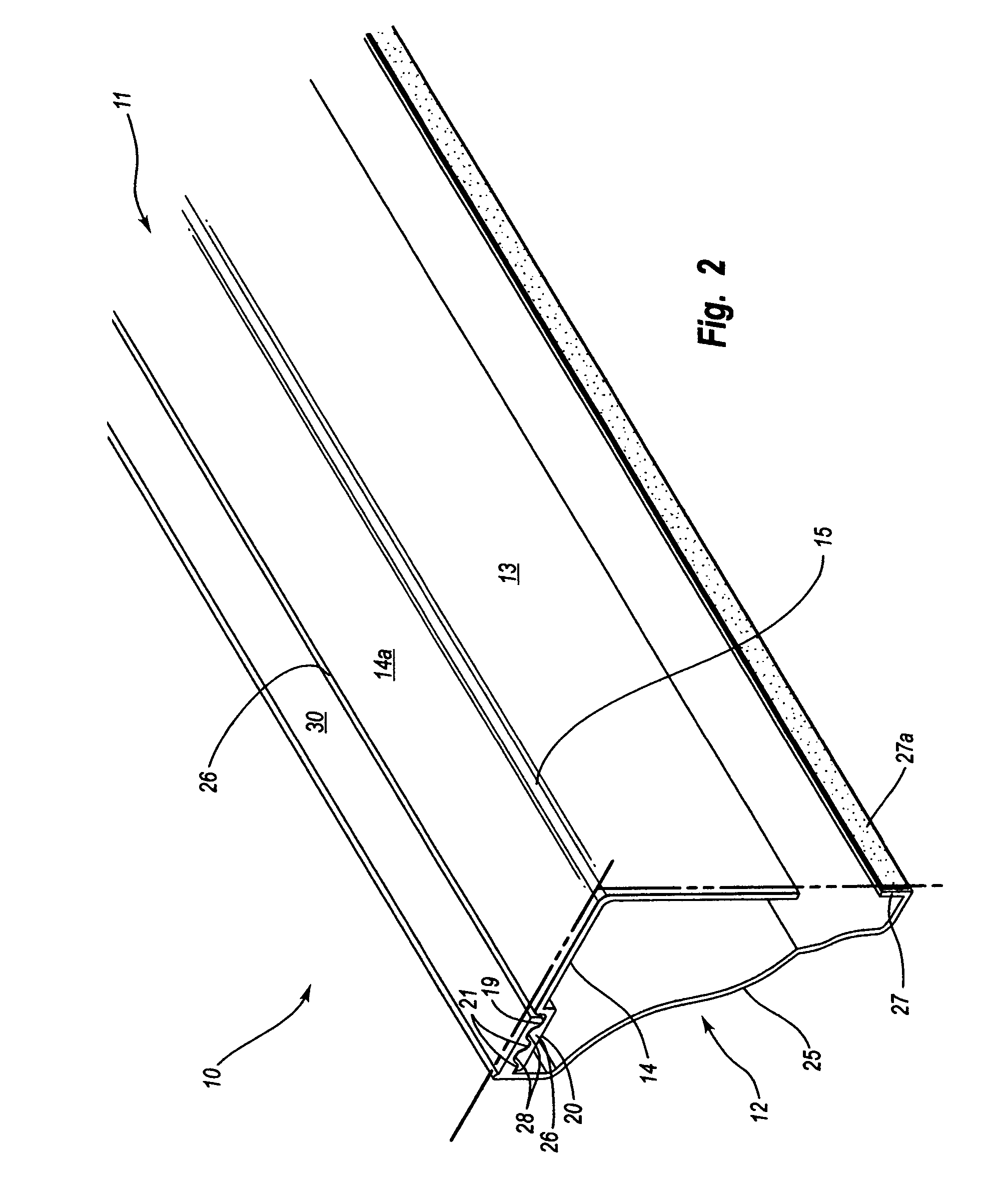

The present invention is an apparatus for providing indirect illumination to a building interior or exterior using crown molding with specialized grooves for holding light ropes or other types of light sources. The invention generally consists of modular pieces of crown molding with an elongated groove in a top surface running parallel to the front surface. A light rope or other types of illumination are installed in the groove and provide indirect light on the wall, ceiling or other objects above the crown molding. Molding may also be used as picture frame and shelving accent lighting. Clips hold the light rope or other source of illumination inside the groove.

Owner:LILLY DONALD W

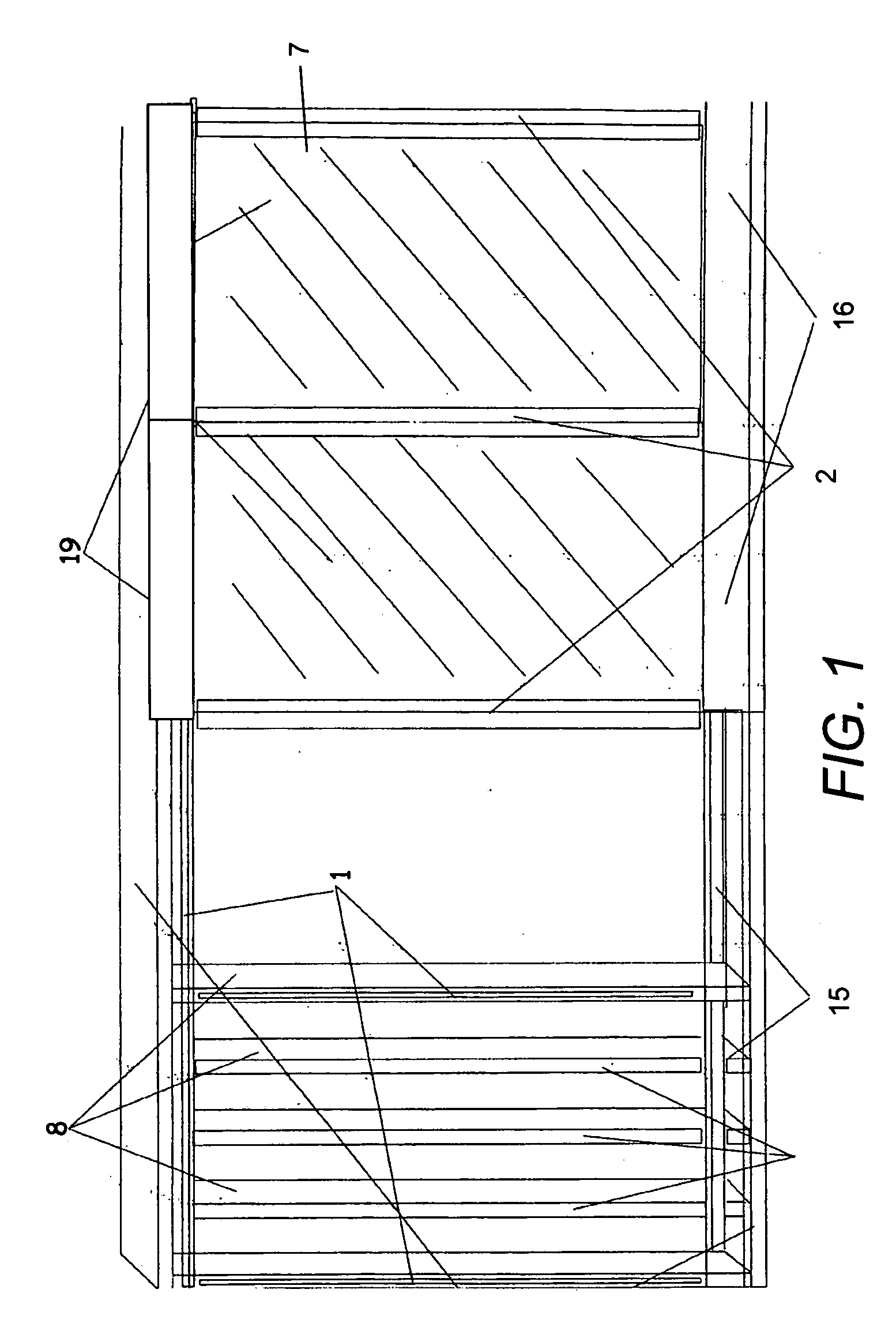

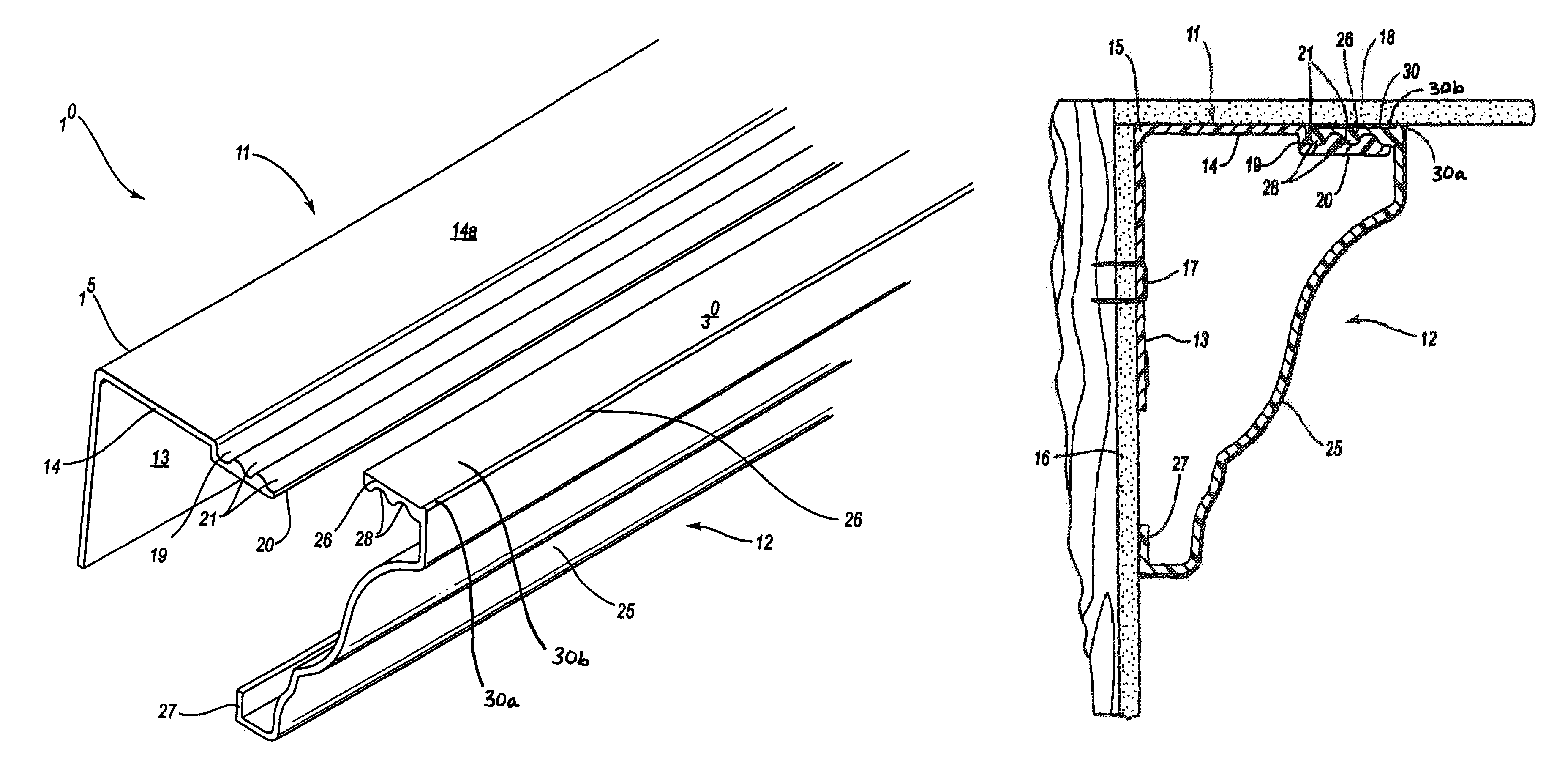

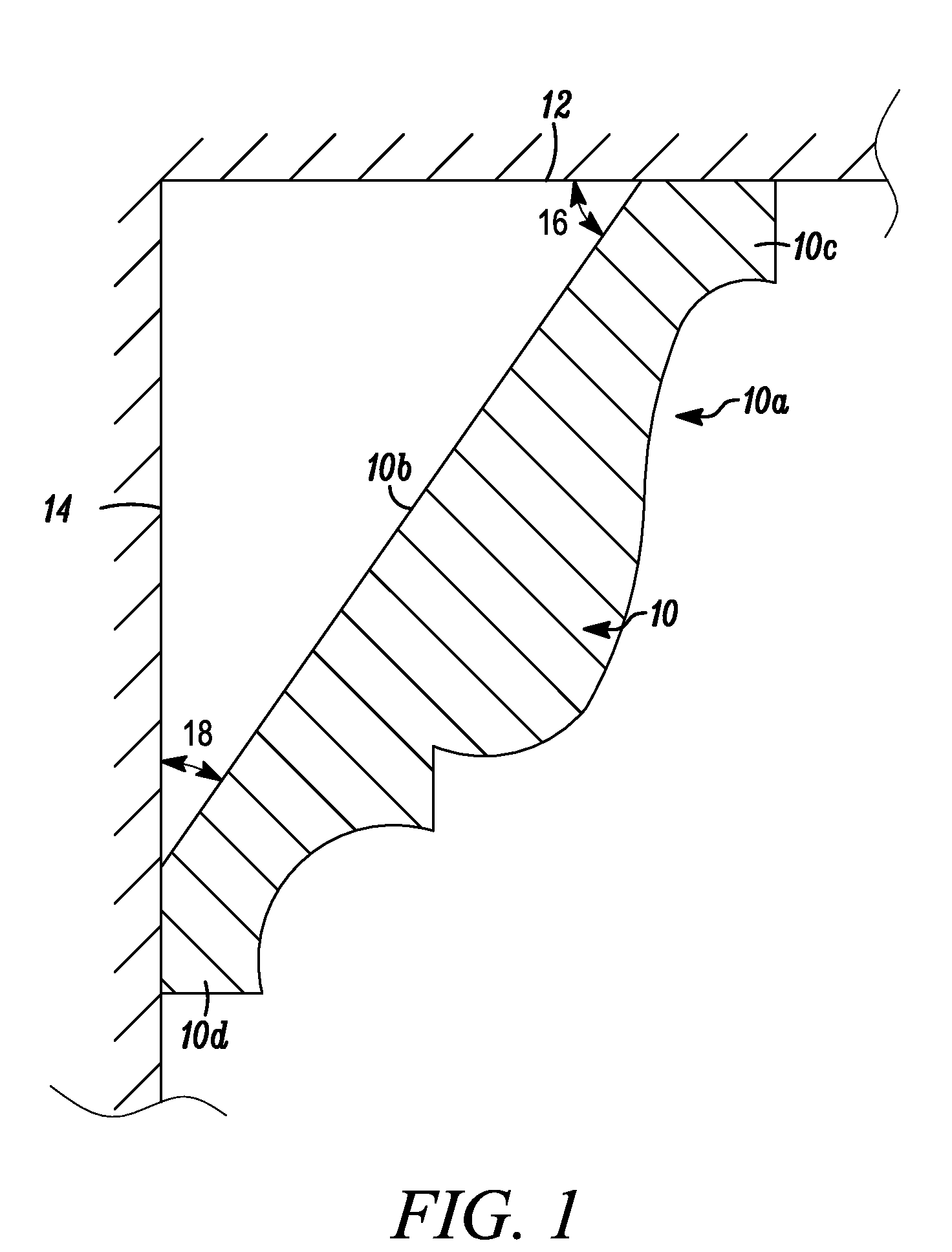

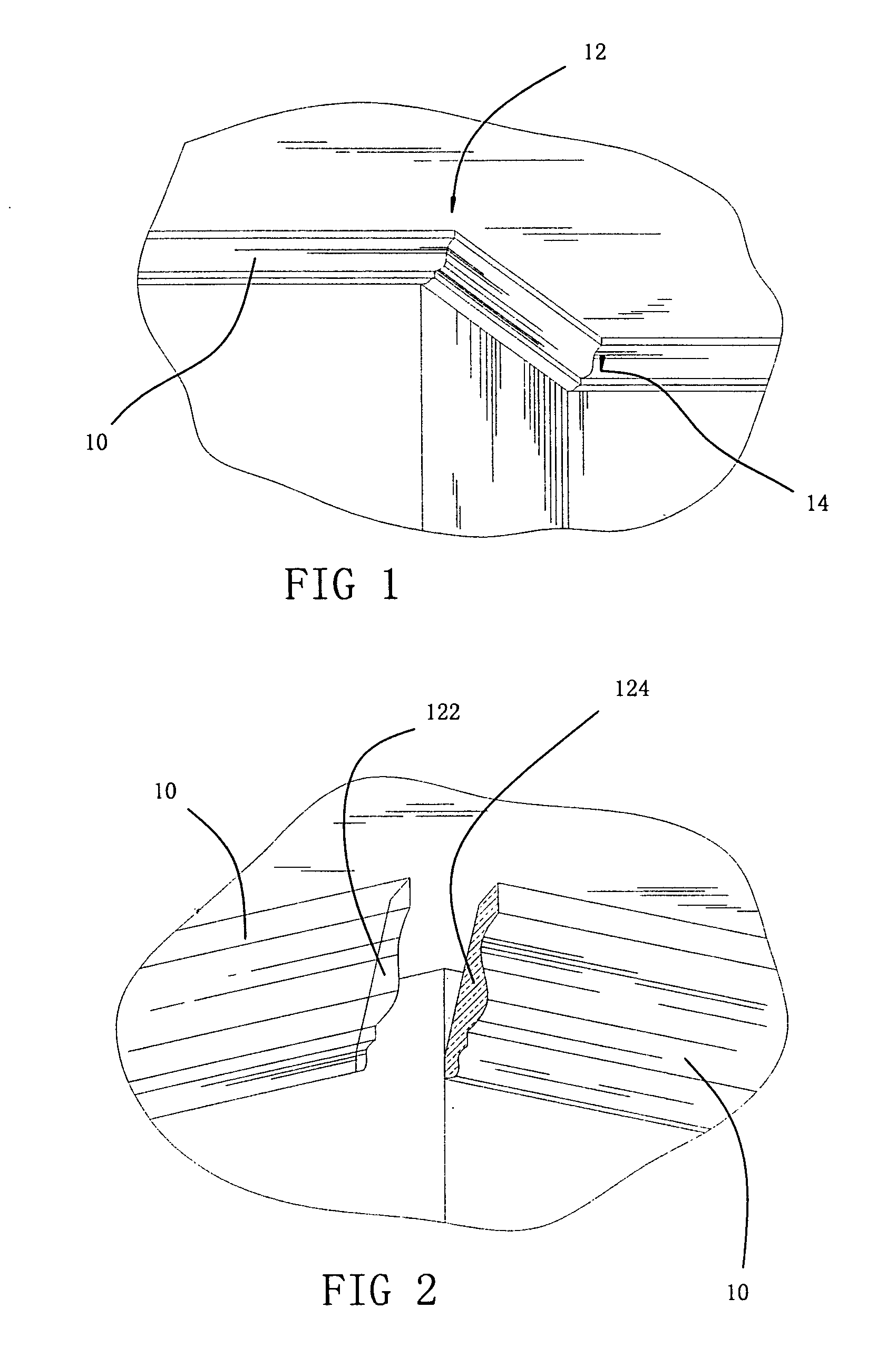

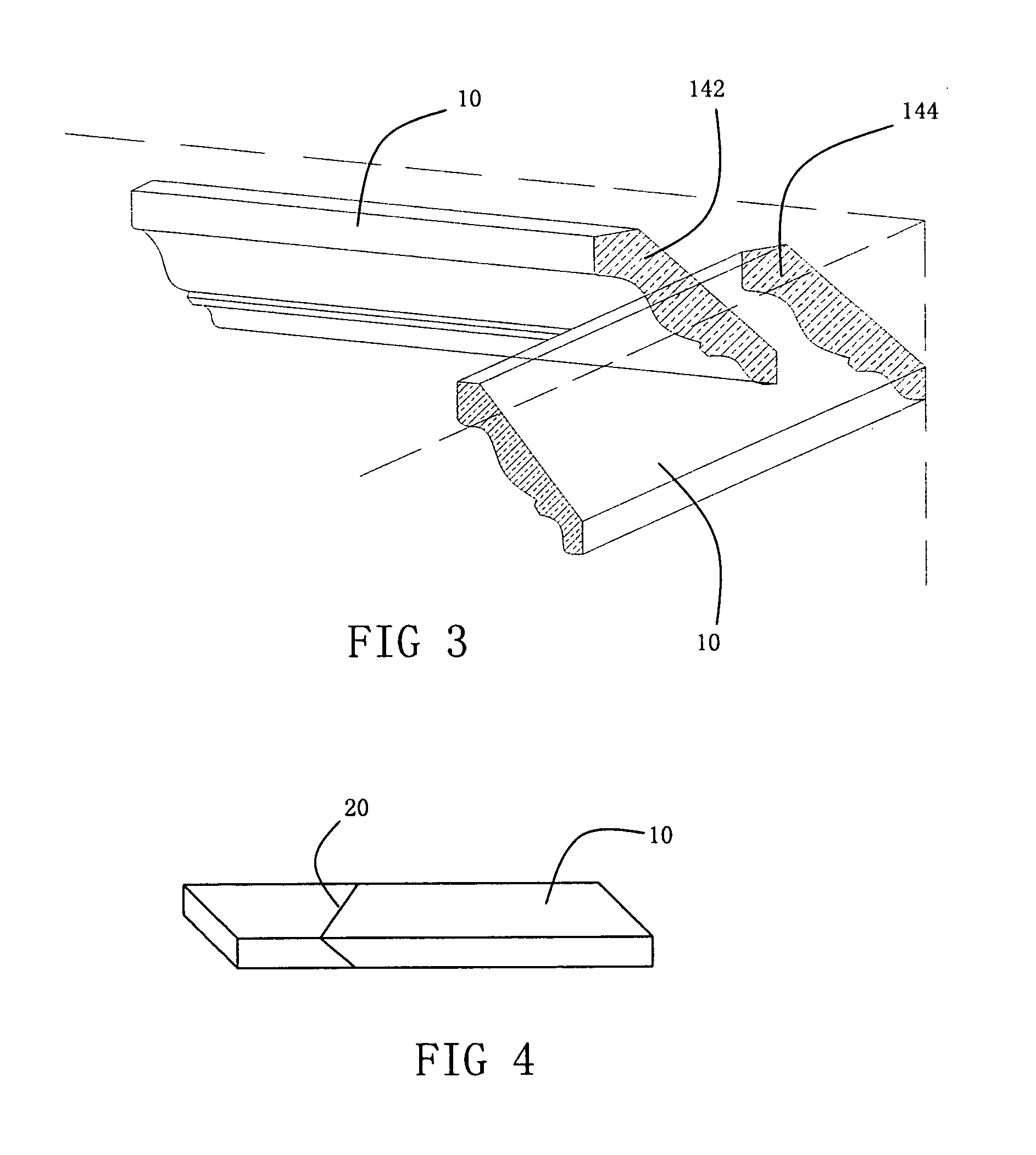

Crown molding

A crown molding and system for its use where the crown molding is formed from a specially blended plastic as extrusions to have a roughened surface and consisting of an inverted “L” bracket and a facing crown mold member for each crown molding section. The inverted “L” bracket is formed as a right angle section having right angle legs and is to be attached to a wall at points along its lower leg, with the right angle bend fitting into the wall to ceiling junction, and with the top leg end having a coupling end for connecting to a mount of a facing crown molding member. Which coupling edges are preferably mirror image corrugations that fit over and lock together, and with the facing member ends flanges to contact the wall and ceiling surfaces.

Owner:SPEXCO

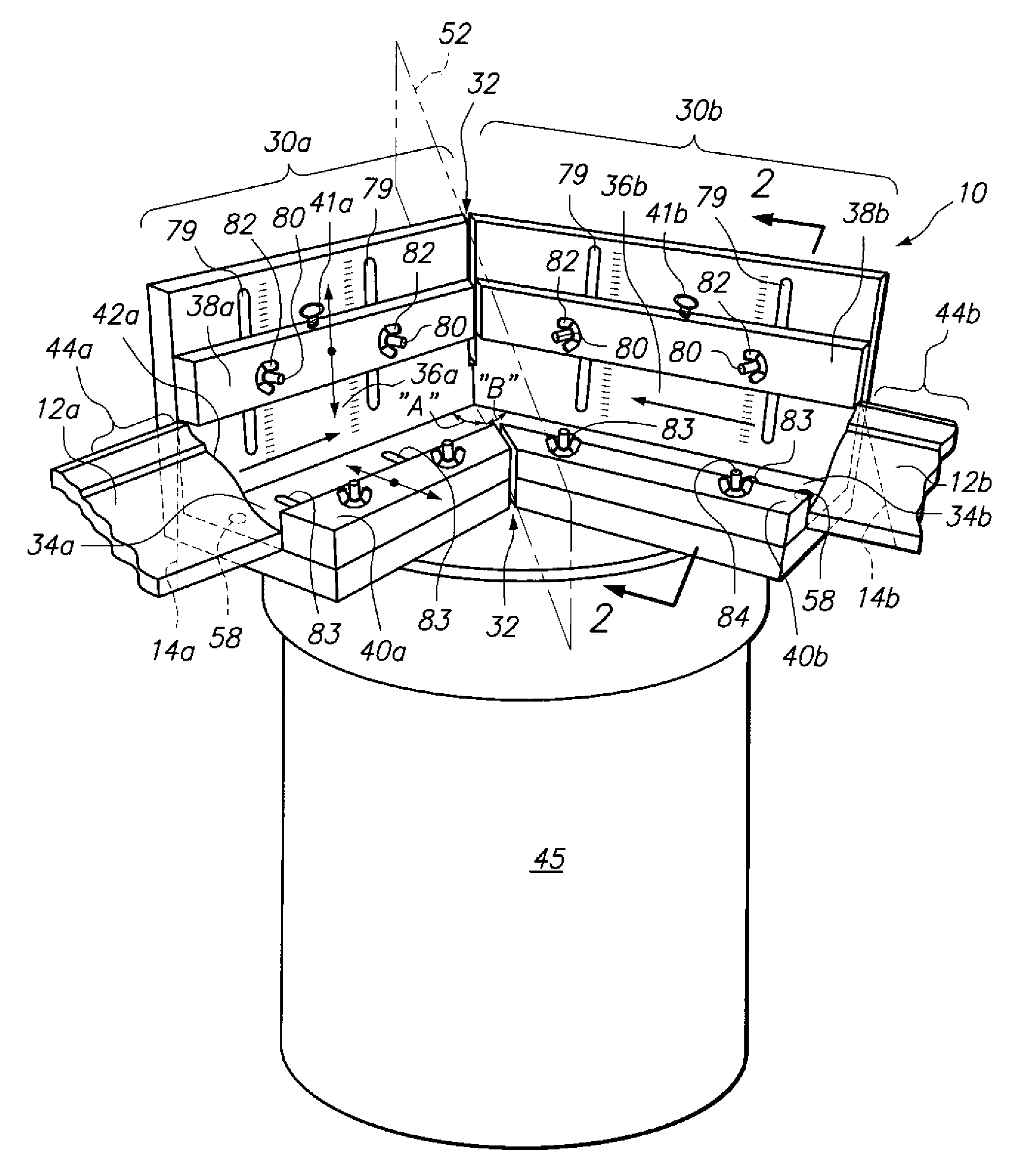

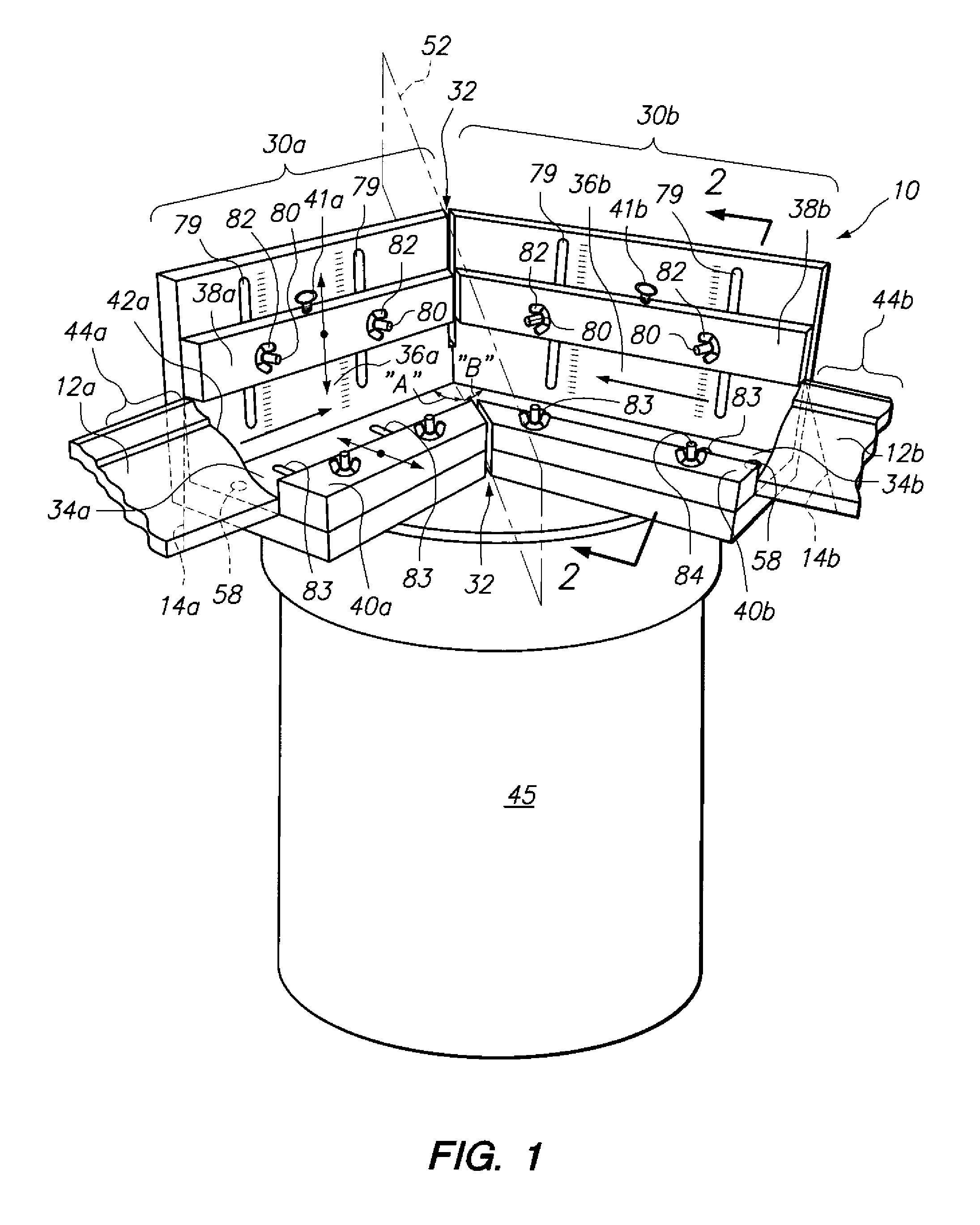

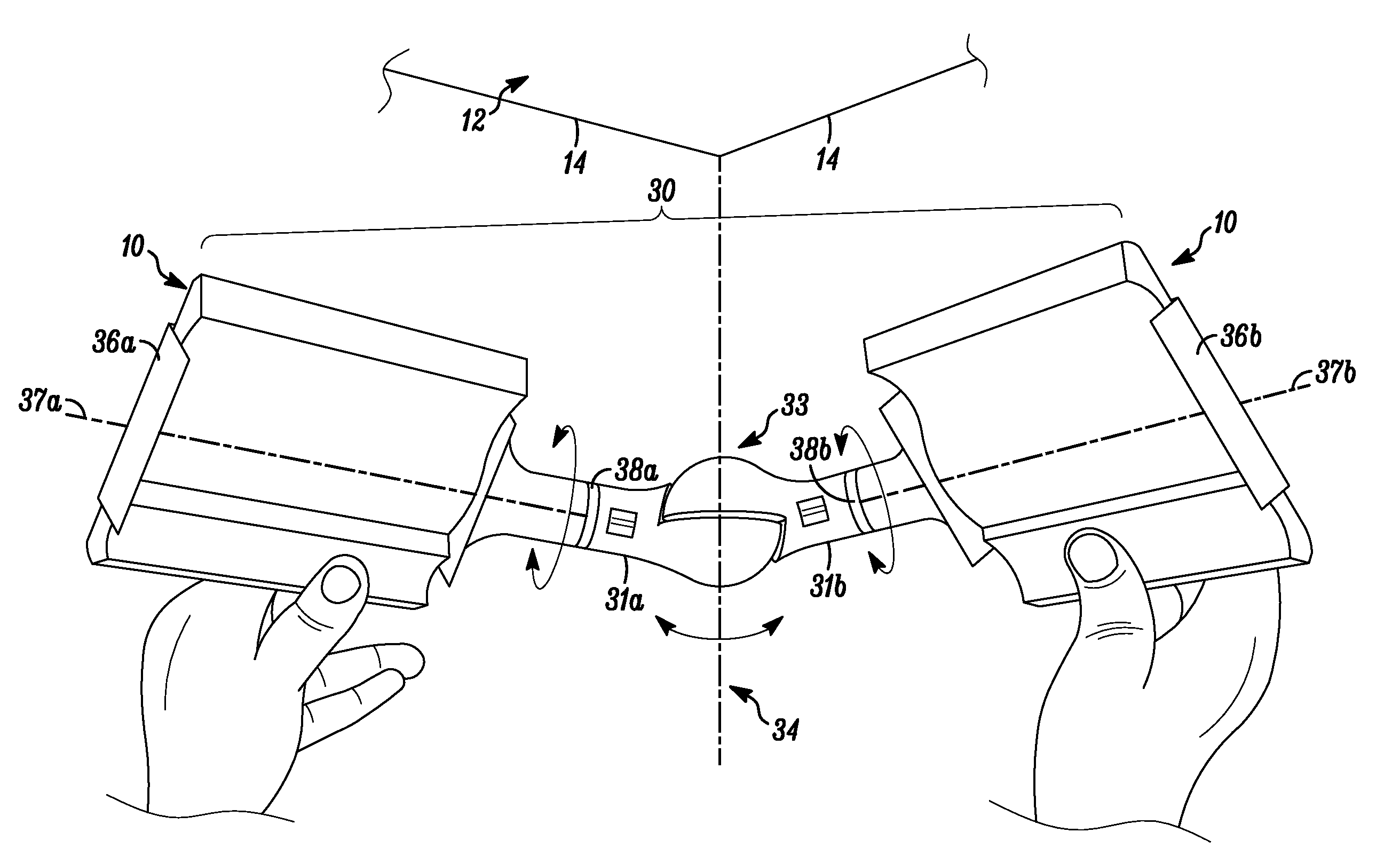

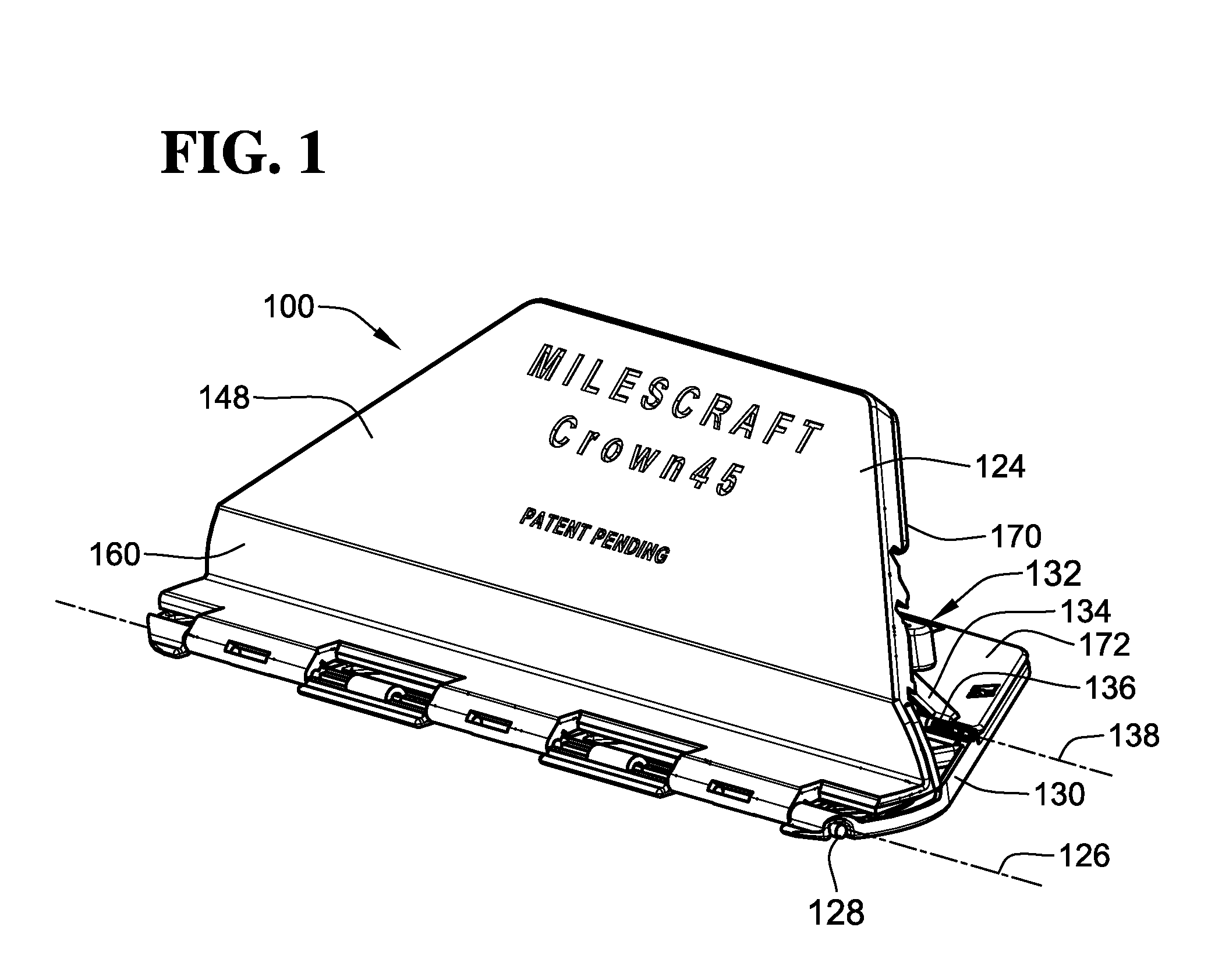

Crown molding and door installation tools

A crown molding jig may have a first guide and a second guide. Each of the guides may be sized and configured to receive a crown molding. A saw guide may be disposed between the first and second guides for guiding a saw blade and cutting a compound angle cut in the crown molding. A crown molding holder may have a base member for engaging the crown molding and an extension pole pivotally attached to the base member such that the crown molding holder may be wedged between the crown molding disposed at the ceiling and the floor. A door installation jig may have a U-shaped member sized and configured to receive a door and an inflatable tube for lifting the door to position adjacent a door frame.

Owner:KHAN VIKTOR

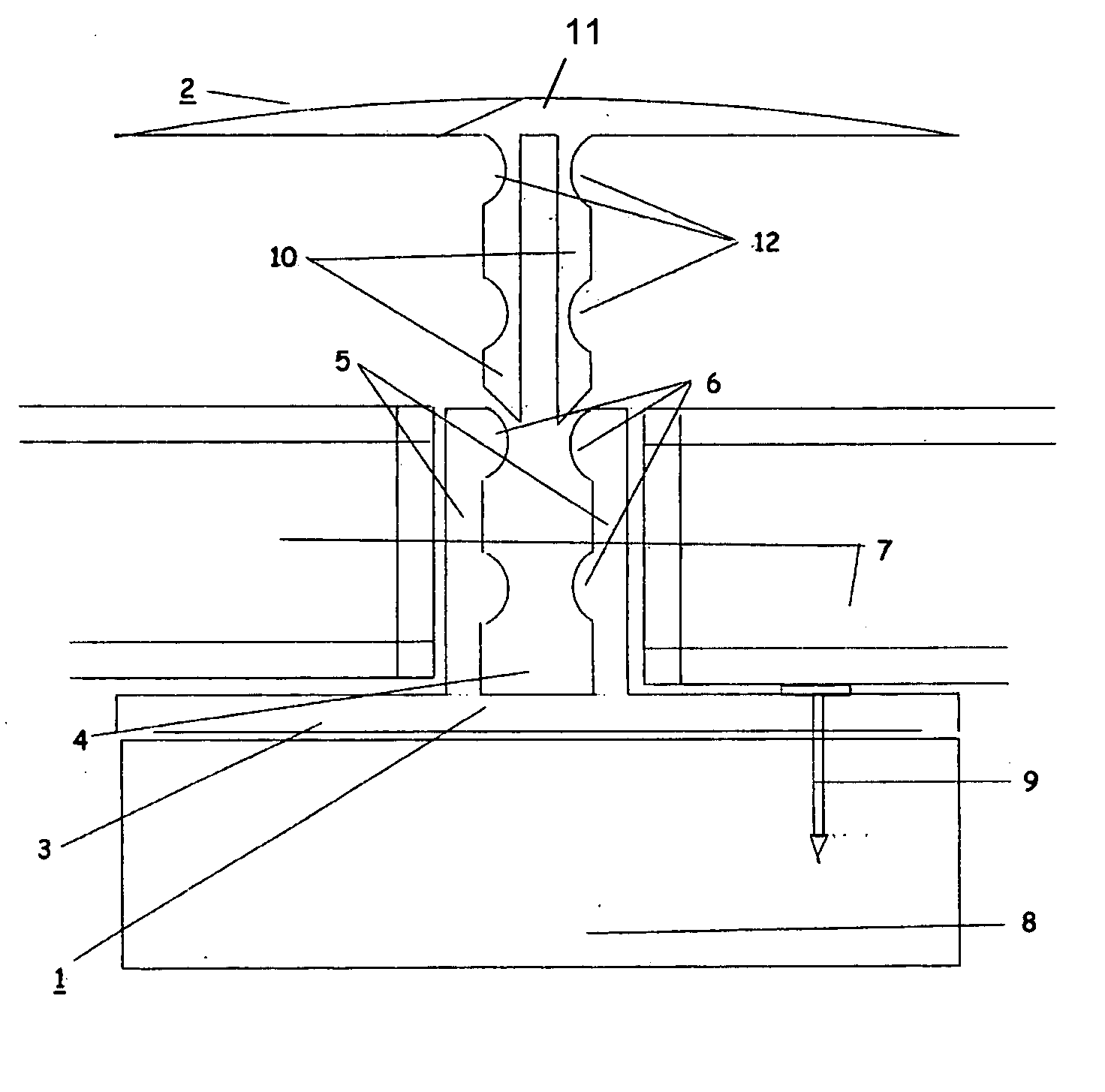

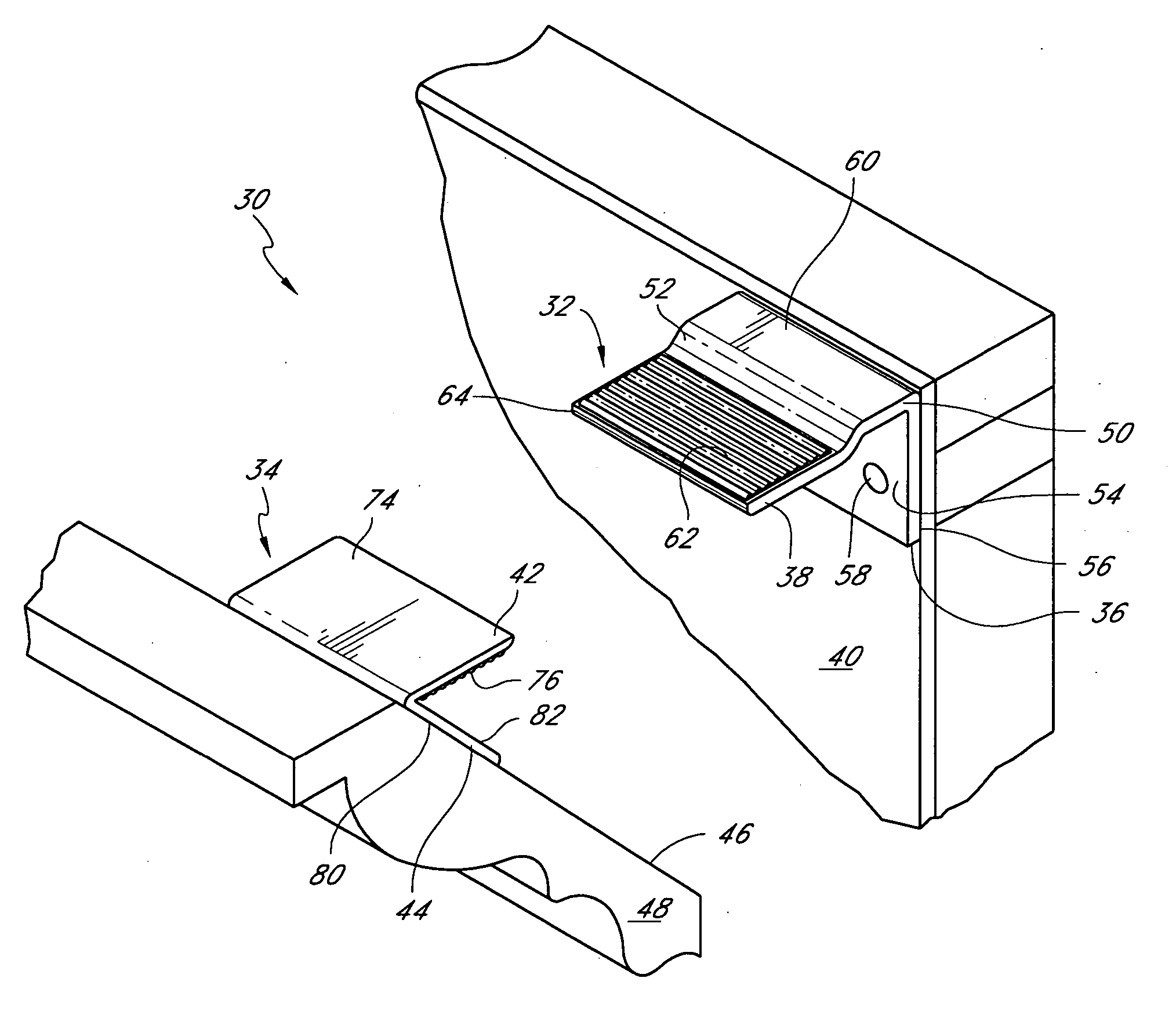

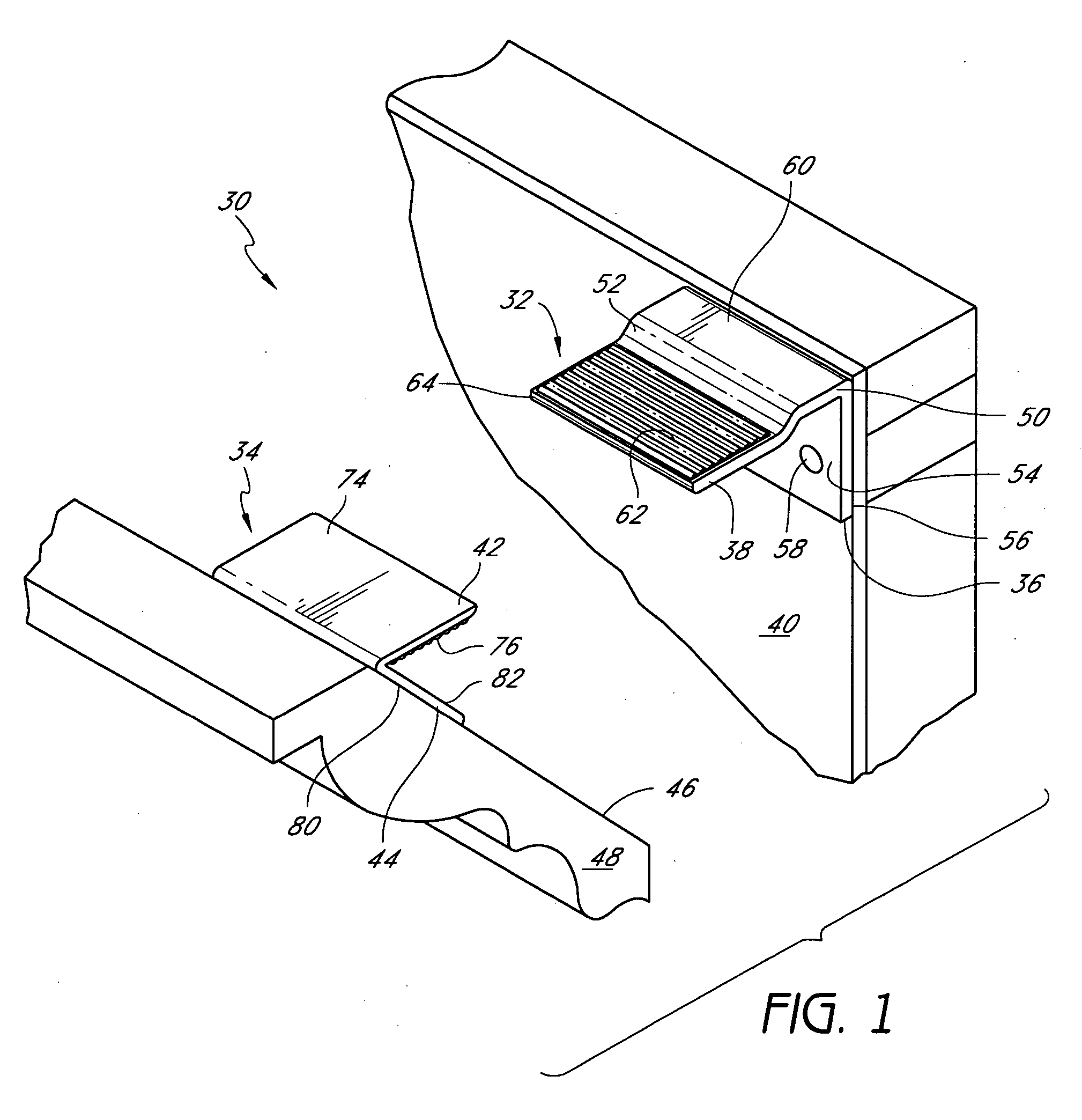

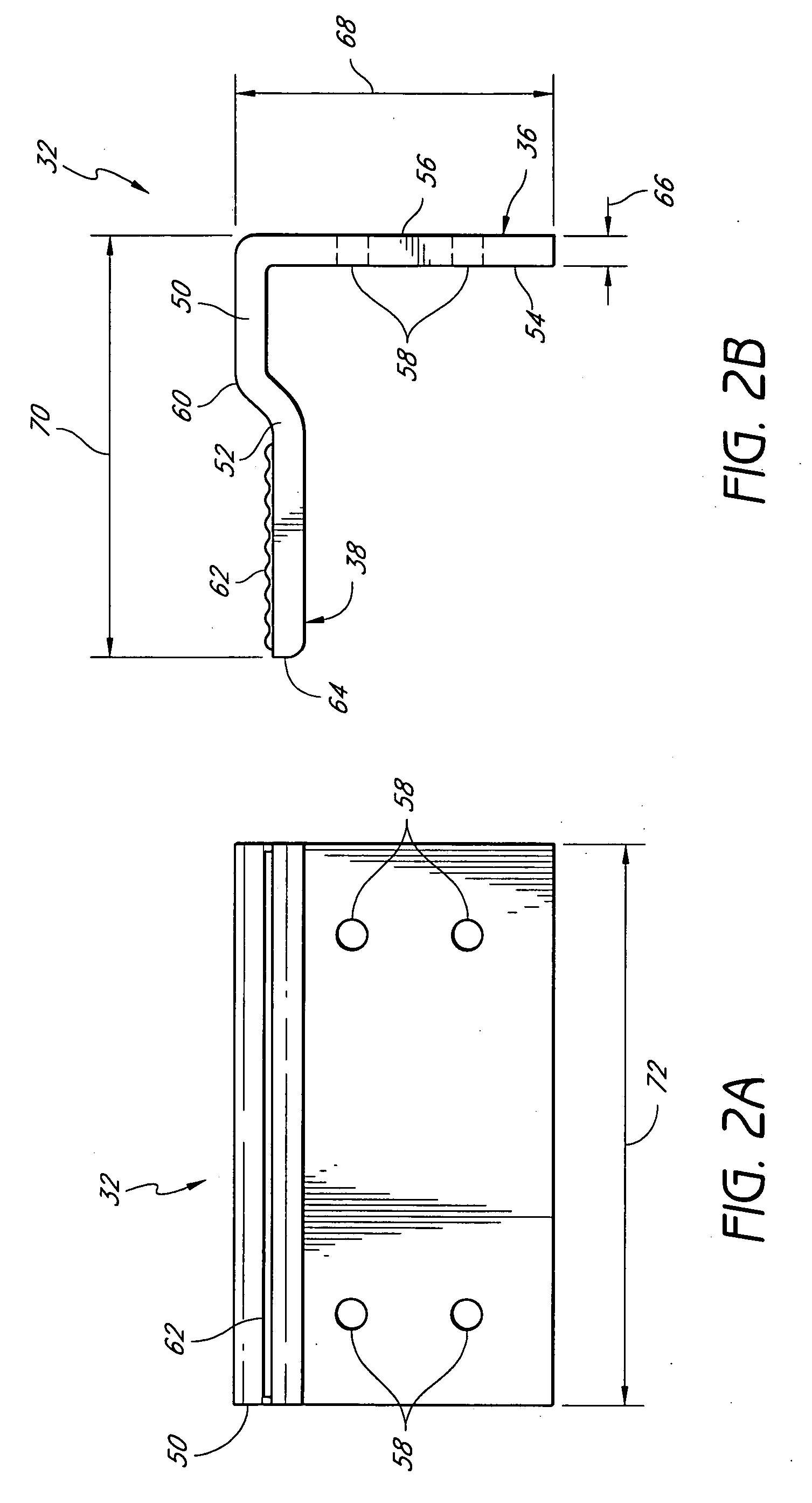

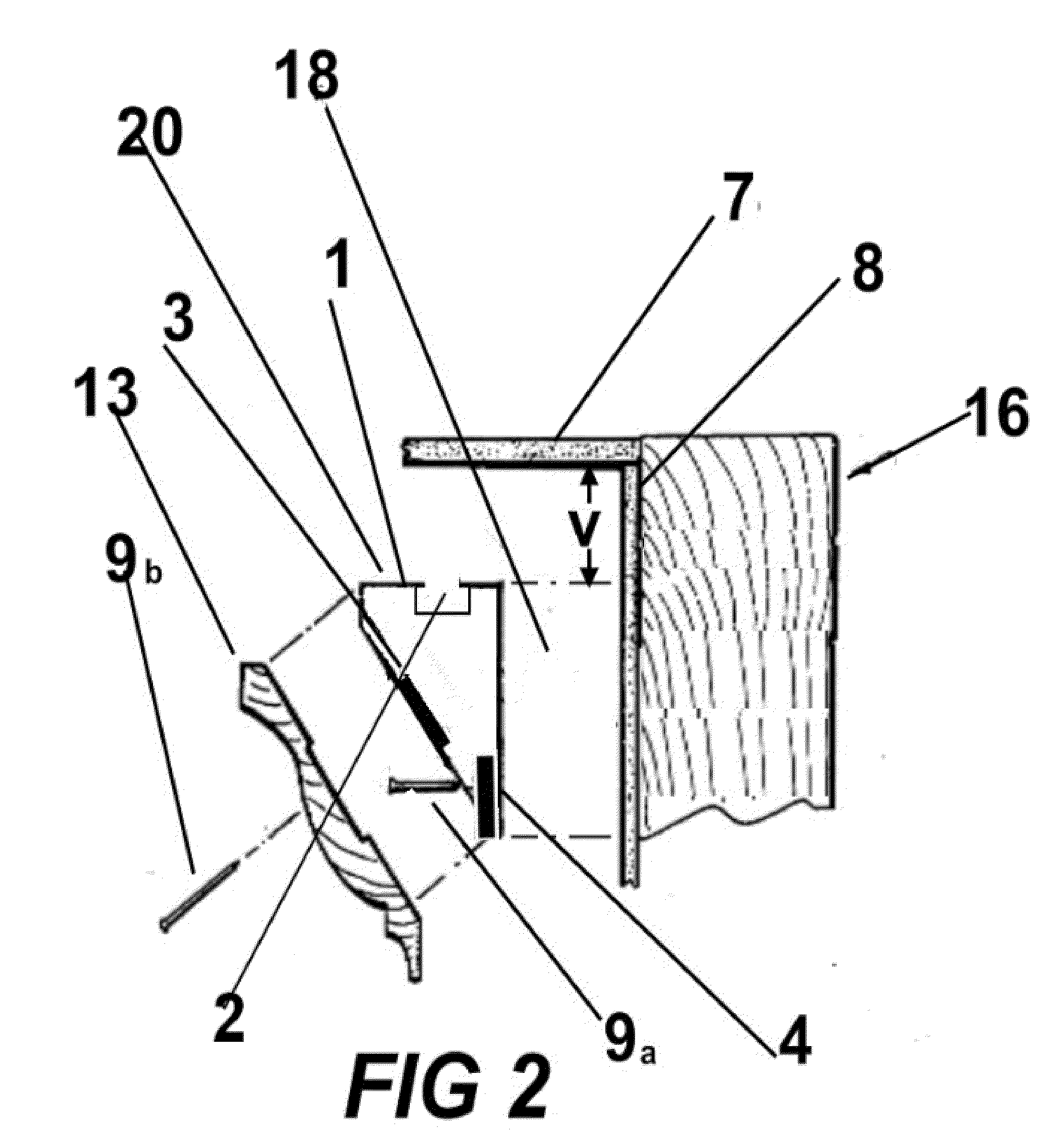

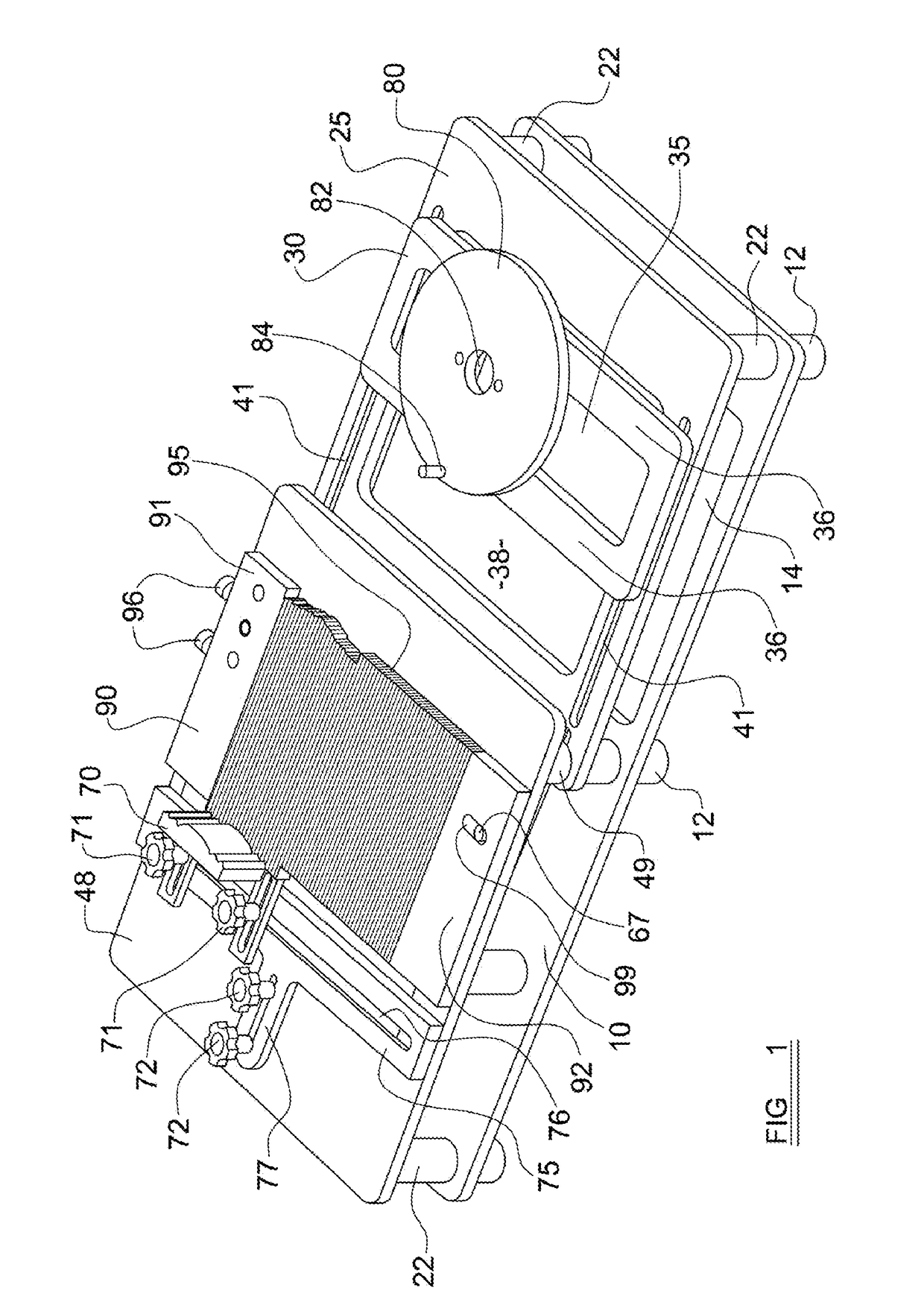

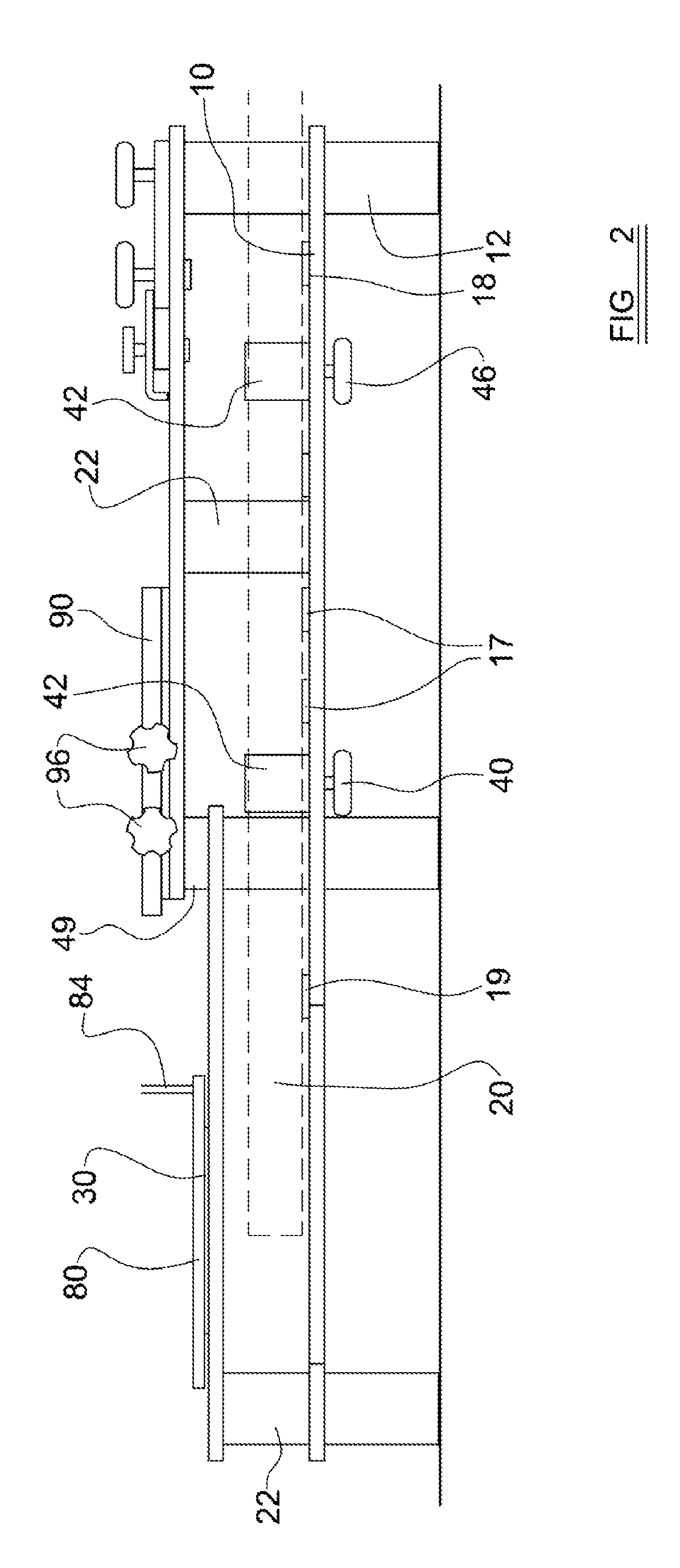

Removable Wallboard System

InactiveUS20090077922A1Quicker and cleaner and easy retail and office and restaurant and commercial wall modificationCovering/liningsWallsCrown moldingEngineering

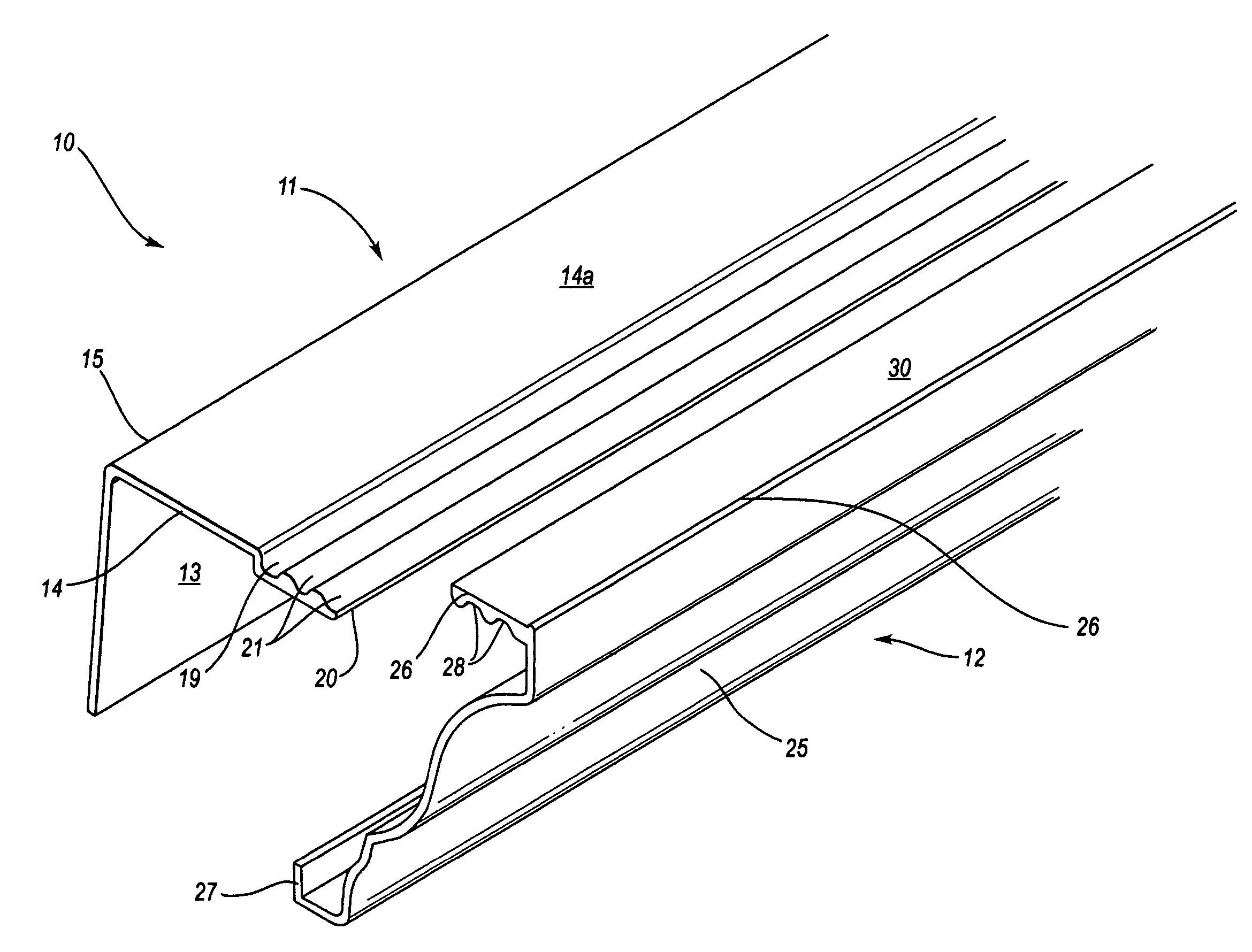

The present invention is a novel removable wallboard system. It includes a plurality of receiver strips [1] which are attached to framing members [8] of a structure to be paneled. Each receiver strip has a receiving channel [4]. Wall panels 7 are placed snugly between the receiver strips [1]. Trim units [2] are elongated strips having insertion strips [10] which are designed to fit into and be retained by receiving channels [4] of the receiver strips [1]. Since the trim units [2] are designed to have a low profile, and they cover the seams between the wall panels [7], there is no need for further finishing or caulking. Therefore, these wall panels [7] may be removed and replaced with minimal effort or cleanup. The system also includes easily installable, removable and replaceable base molding [16], crown molding [19], and chair rail molding [29]. These may be designed to create chase ways [18, 74] allowing hidden routing of electrical, utility cables, pipes and hoses. Since the system may interactively be constructed and removed, it is useful in business settings in which offices are constantly adjusted.

Owner:PETTINE THOMAS +1

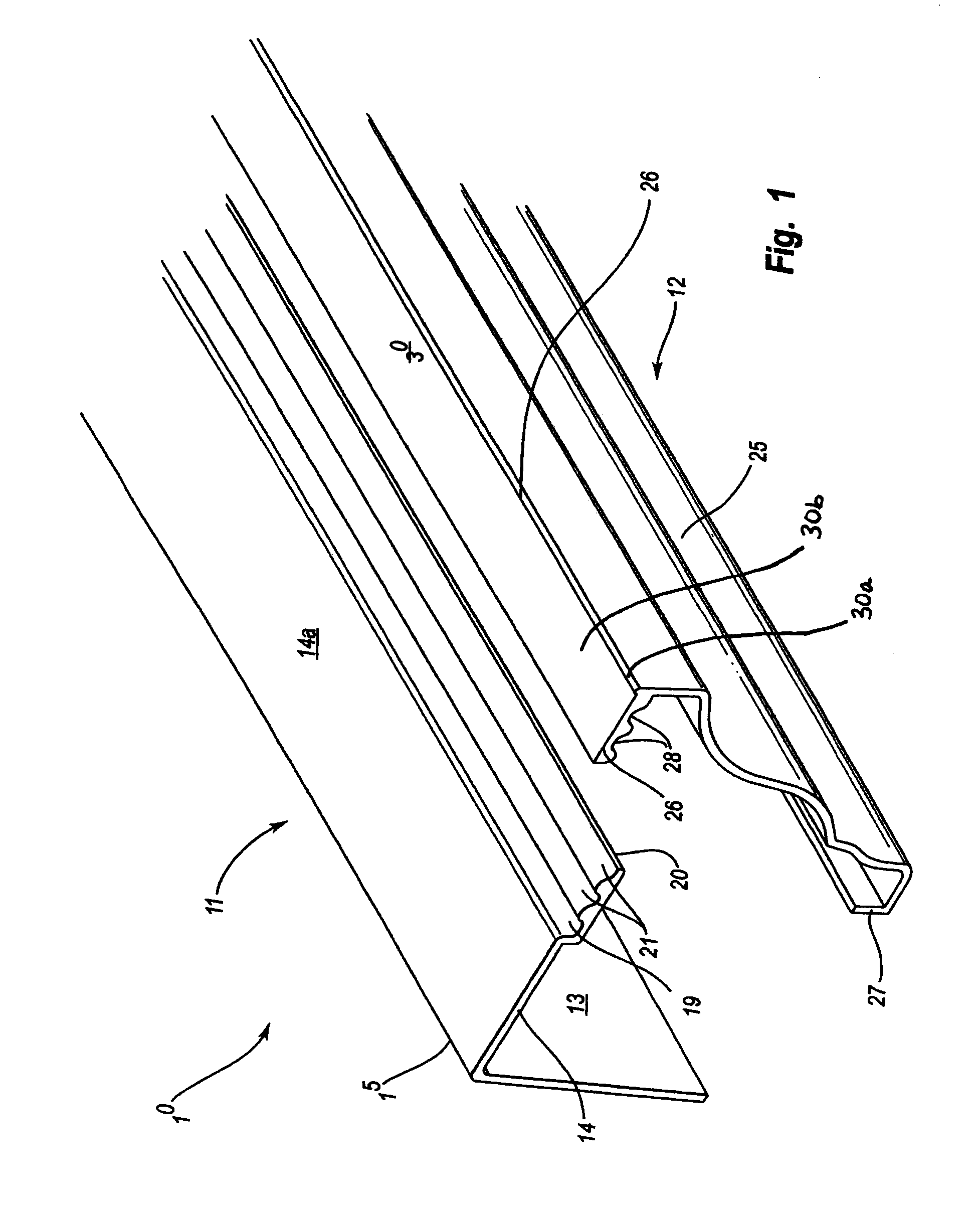

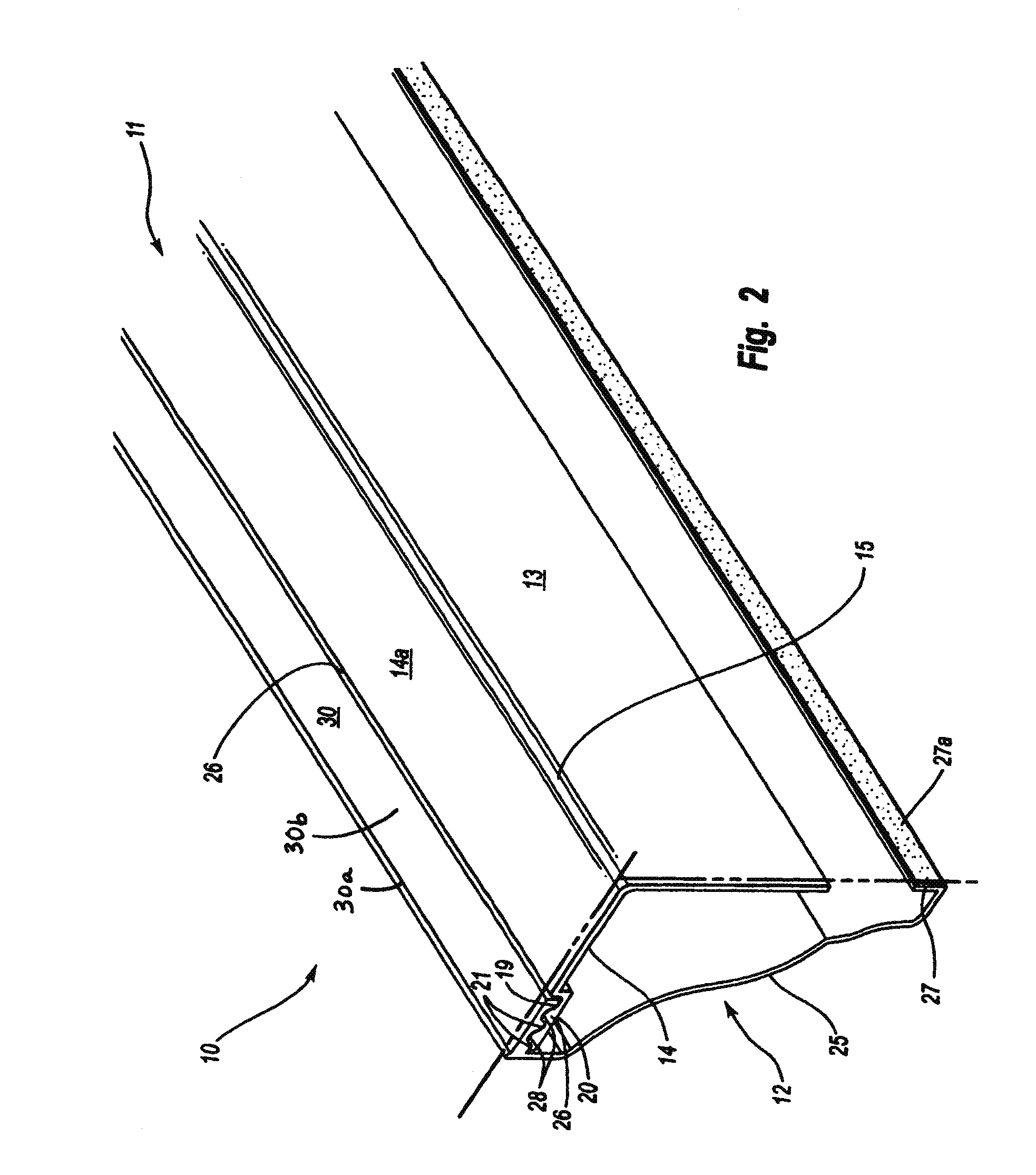

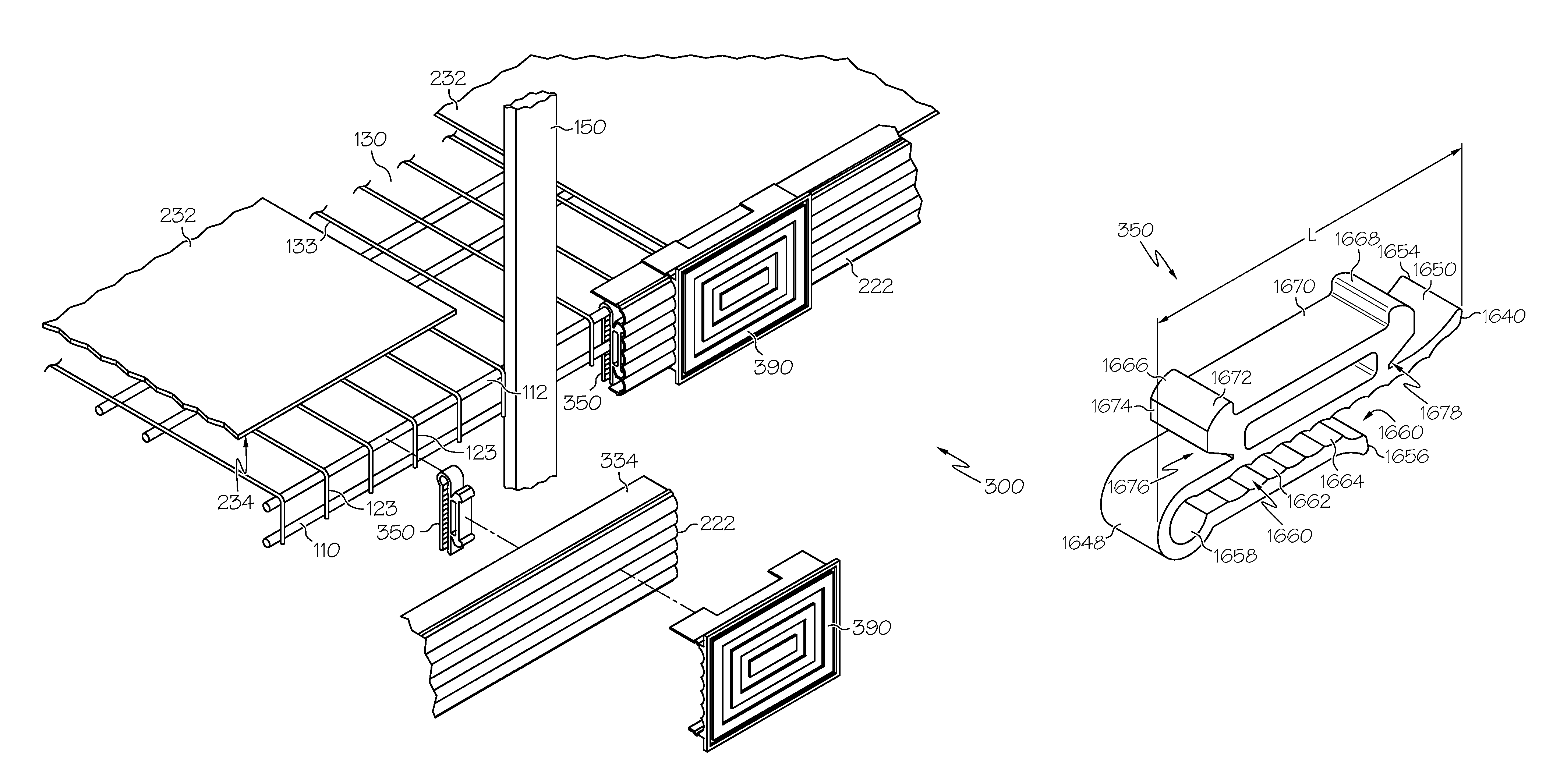

Crown molding and deck material attachments

ActiveUS20060156679A1Easy and inexpensive processReduce installation timeSnap fastenersCovering/liningsCrown moldingBiomedical engineering

Owner:PIERRET DENNIS M TRUSTEE OF THE DENNIS PIERRET REVOCABLE TRUST

Crown molding

Owner:SPEXCO

Protractor for calculating miter and bevel angles for installing molding

Taught herein is a protractor capable of measuring angles within a room and angles related to the intended orientation of molding with respect to the room. Using these angles, the present invention will calculate and display the appropriate angles at which a miter saw must be set to produce mitered joints for the installation of trim and crown molding.

Owner:SANDEN CORP

Ventilated shelf cover with spring clasp

InactiveUS9149119B2Function increaseKeep items from tipping or fallingShow shelvesShow hangersCrown moldingEngineering

Owner:CUSTOMER MOTIVATORS

Decorative molding trimming system and method of installing

InactiveUS20100313498A1Roof covering using slabs/sheetsConstruction materialCrown moldingMechanical engineering

This invention generally relates to a method and system for installing decorative moldings including a mounting block made of a soft and light material adapted to be secured to a wall and extended about a border thereof, said mounting block having a first contacting surface parallel to the wall and a second contacting surface oriented at an angle to a mounting surface of a crown molding, said first contacting surface having a parallel rigid member thereon for securing the mounting block to the wall and the second contacting surface having an angular oriented rigid member thereon for securing the decorative molding to the mounting block.

Owner:PAIDAR REZA +1

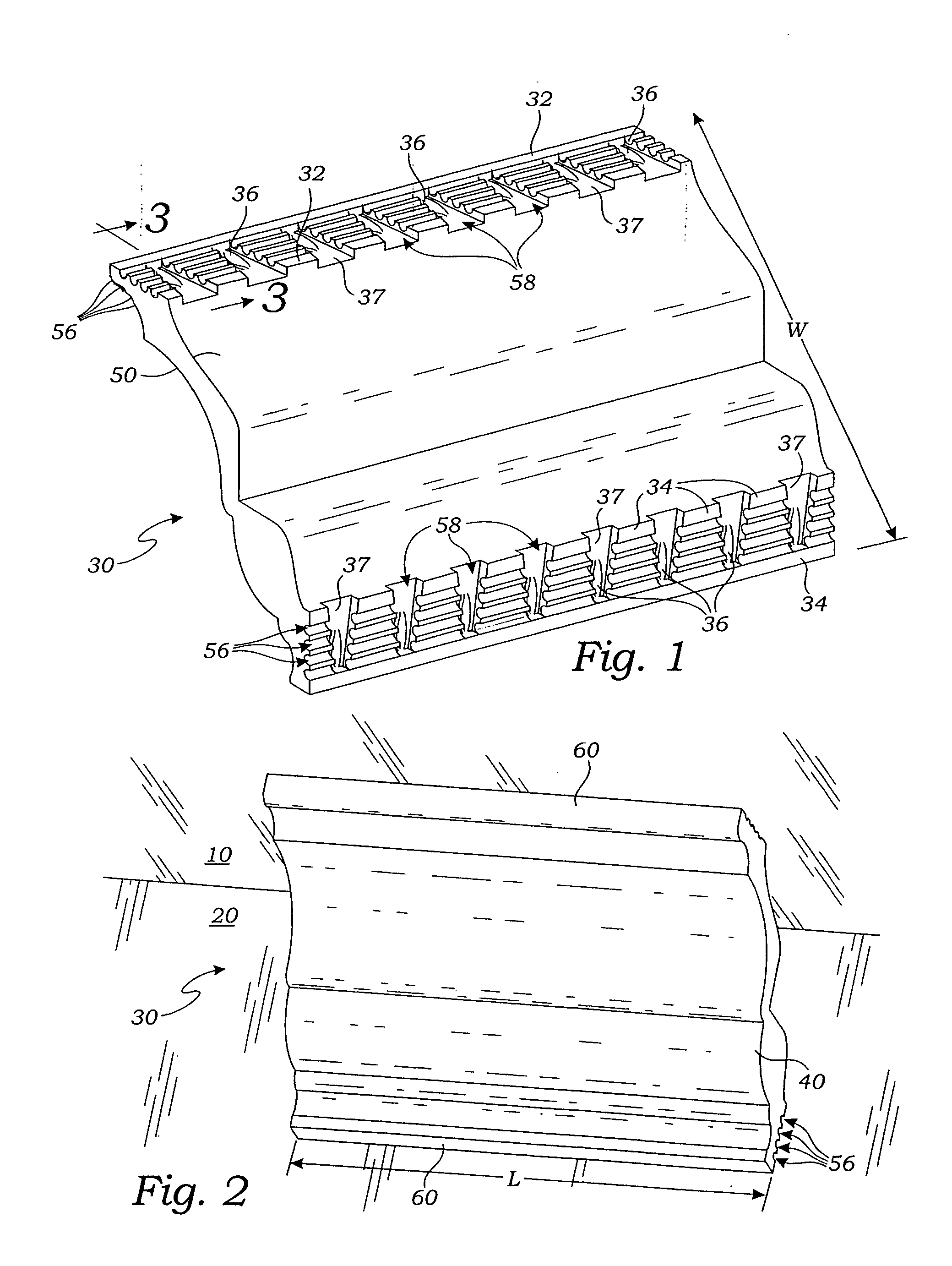

Crown molding with lighting effects

A crown molding has a vertically oriented mounting leg joined with an outwardly angled decorative leg in a modified “V” configuration. A plurality of spaced apart webs are each extensive between the mounting leg and the decorative leg. Each of the webs provides at least one concave groove on an upwardly directed top edge, thereby forming a plurality of such grooves in longitudinally spaced apart positions. A flexible lighting tube is engaged within the grooves and extensive longitudinally. Apertures are placed in the decorative leg to allow light from the lighting tube to filter downwardly.

Owner:HAHN RICHARD

Automated molding cut-off saw and method

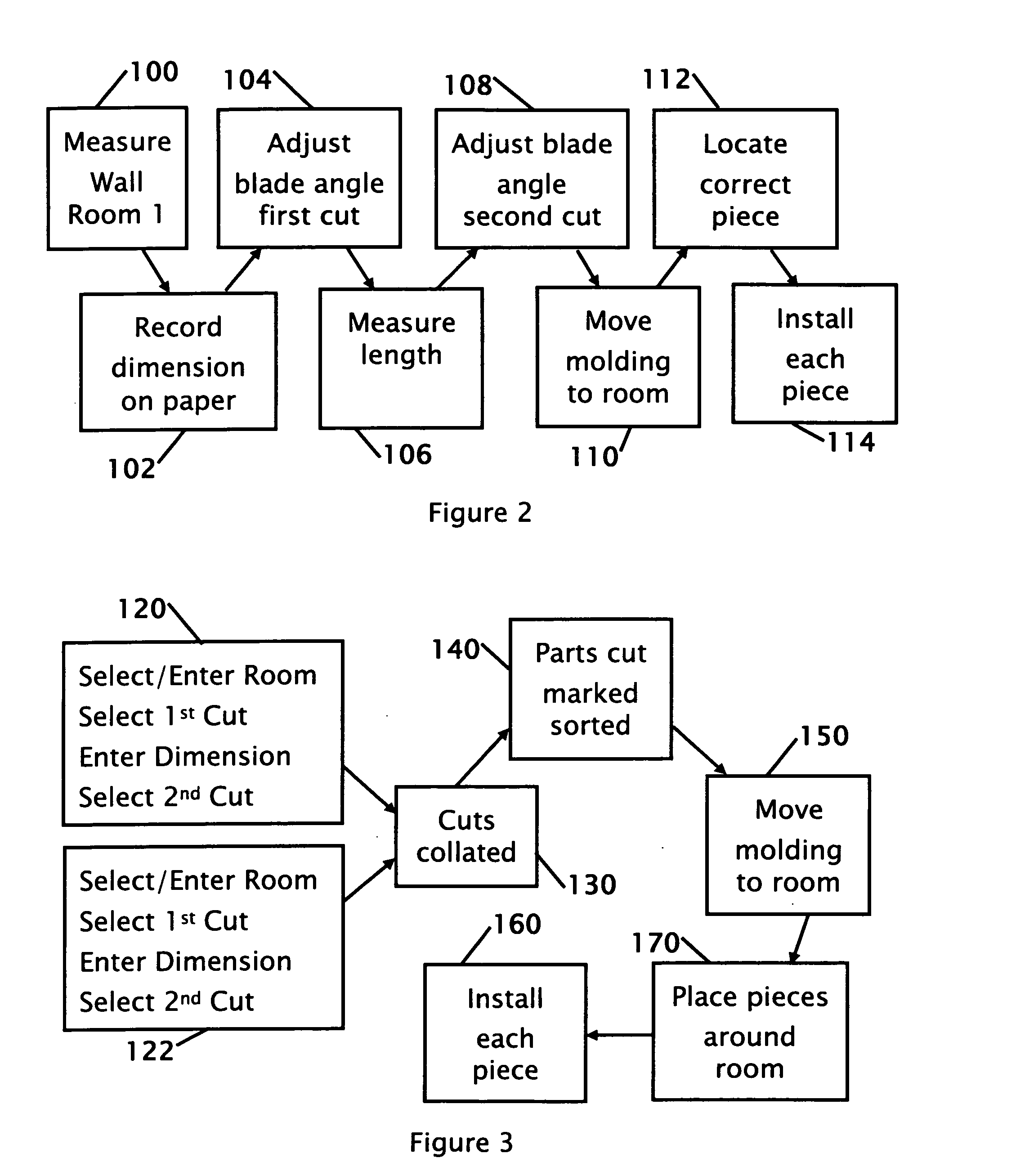

Improvements in a cut-off miter saw for floor, wall, crown molding, wood, plastic, metal and the like are disclosed that includes an automated or manually fed cut-off saw where measurements are dynamically entered into a wireless communications device. The measurements are organized and sent to a cut-off saw where the material is cut with a first angle, indexed and cut at a second angle. The parts are further marked or organized and routed to the installer. This offers a tremendous improvement and reduction in the amount of time presently required to perform these operations in a serial order. It is particularly useful in measuring, cutting and nailing floor molding in houses, or other buildings where each room has slightly different dimensions and each length is custom fit.

Owner:MEKKELSEN THOMAS C JR

Seam cover system for crown molding installations

InactiveUS20090064613A1Quickly and easily securedEasily secured in placeCovering/liningsNatural patternsAdhesiveCrown molding

By providing a plurality of support brackets which are quickly and easily mounted to any desired surface and are constructed for receiving and supportingly retaining elongated, lineal crown molding strips, inside and outside corner seam covers, and lineal seam covers, each of which are formed from a wide variety of decorative and visually distinctive appearances, a cornice or crown molding system is achieved which is capable of being quickly and easily installed in any desired location by any unskilled individual, without requiring the use of mitered corners, abutting junctures, nails, adhesives, and the like. By employing a combination of the components of the present invention, any desired location can be quickly and easily decorated with a completely installed molding system for enhancing the visual and aesthetic appeal of any room or building.

Owner:FOCAL POINT PRODS

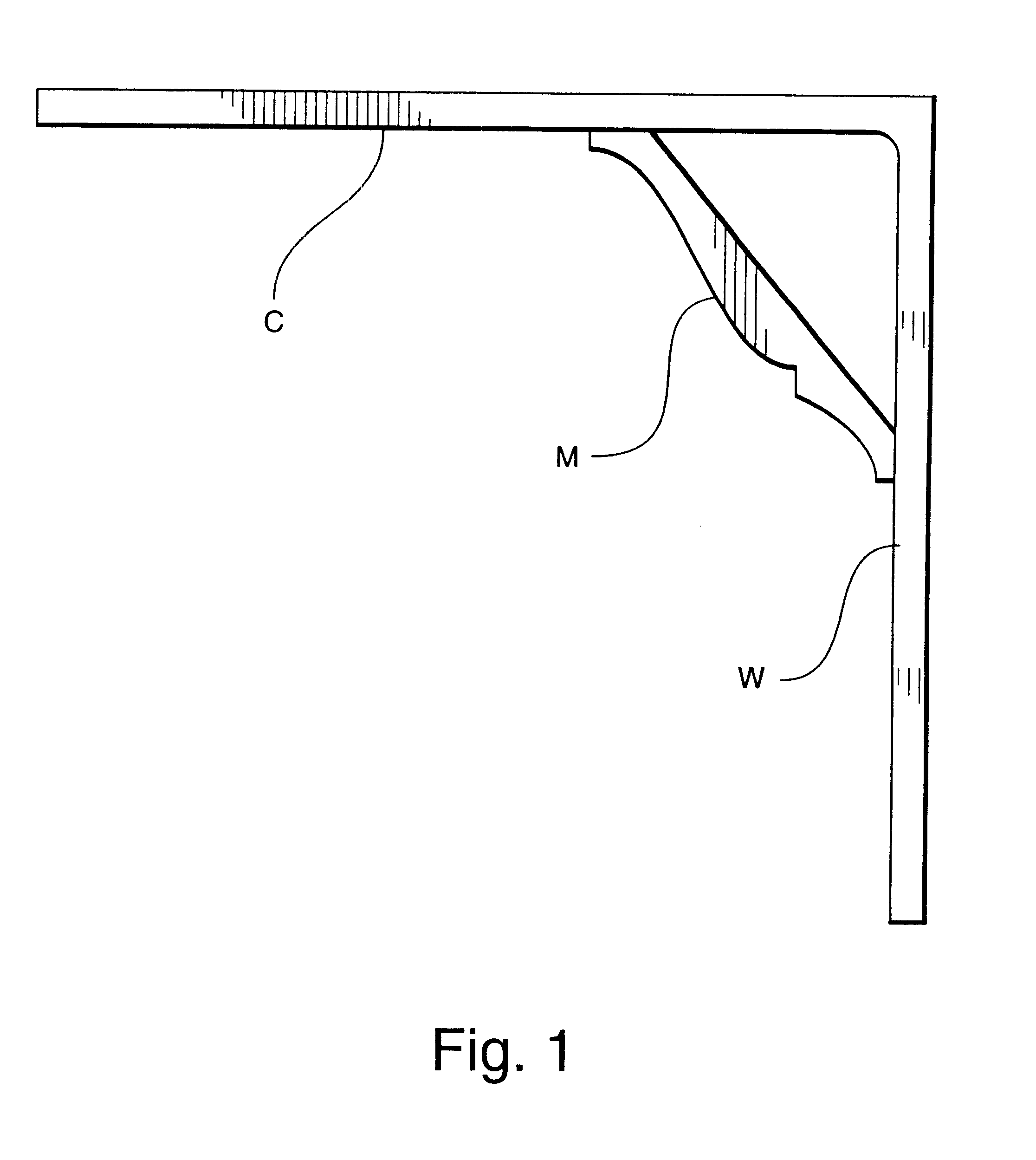

Apparatus and method for facilitating accurate placement and installation of crown molding

InactiveUS6415520B1Accurate placementEasy to installBuilding constructionsStraightedgesCrown moldingEngineering

A tool for facilitating accurate placement and installation of crown molding at an intersection of a ceiling and wall, the crown molding having a wall-engaging portion and a ceiling-engaging portion. The tool includes first and second extension arms, each extension arm having respective inner and outer major surfaces and respective proximal and distal ends. The first and second extension arms are connected together at their respective proximal ends such that their respective inner major surfaces face each other at right angles for receiving and orienting a sample section of the crown molding. The sample section includes a first longitudinal side edge representing the wall-engaging portion of the crown molding for residing adjacent the first extension arm and a opposing second longitudinal side edge representing the ceiling-engaging portion of the crown molding for residing adjacent the second extension arm. Measurement indicia are marked on each of the inner major surfaces of the first and second extension arms for measuring the sample section and determining the position of the crown molding at intersection of the ceiling and wall.

Owner:LOCKLEAR THOMAS

Crown molding clamp

A clamp for use in installing crown molding which has a top front lip, a bottom rear lip and a bridging segment extending diagonally between them, comprising a clamp part for engaging the ceiling of a room and for engaging the top front lip of the crown molding from in front, and another clamp part for engaging the bottom rear lip of the crown molding from below and engaging the room wall behind the crown molding.

Owner:BLAU KARL T

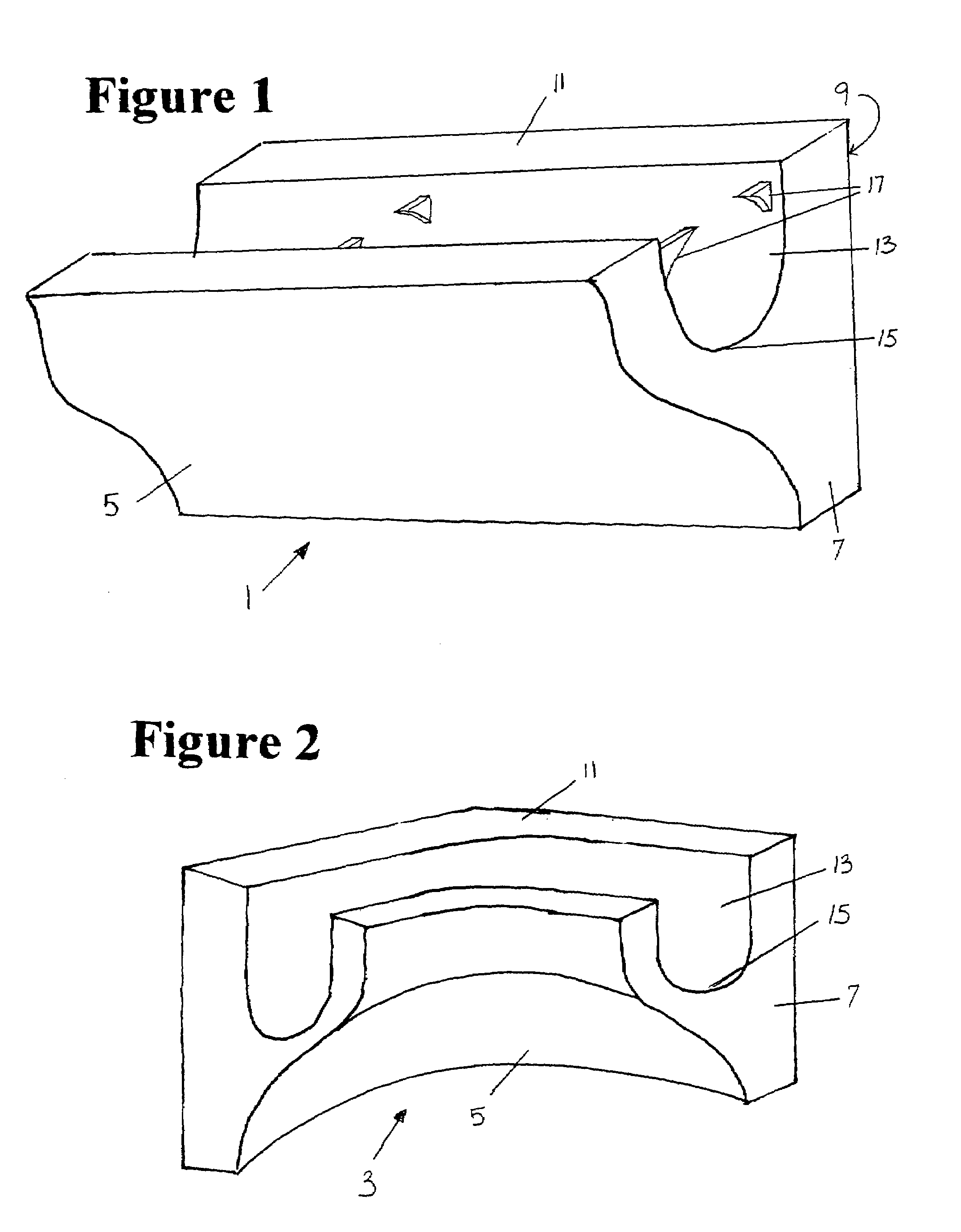

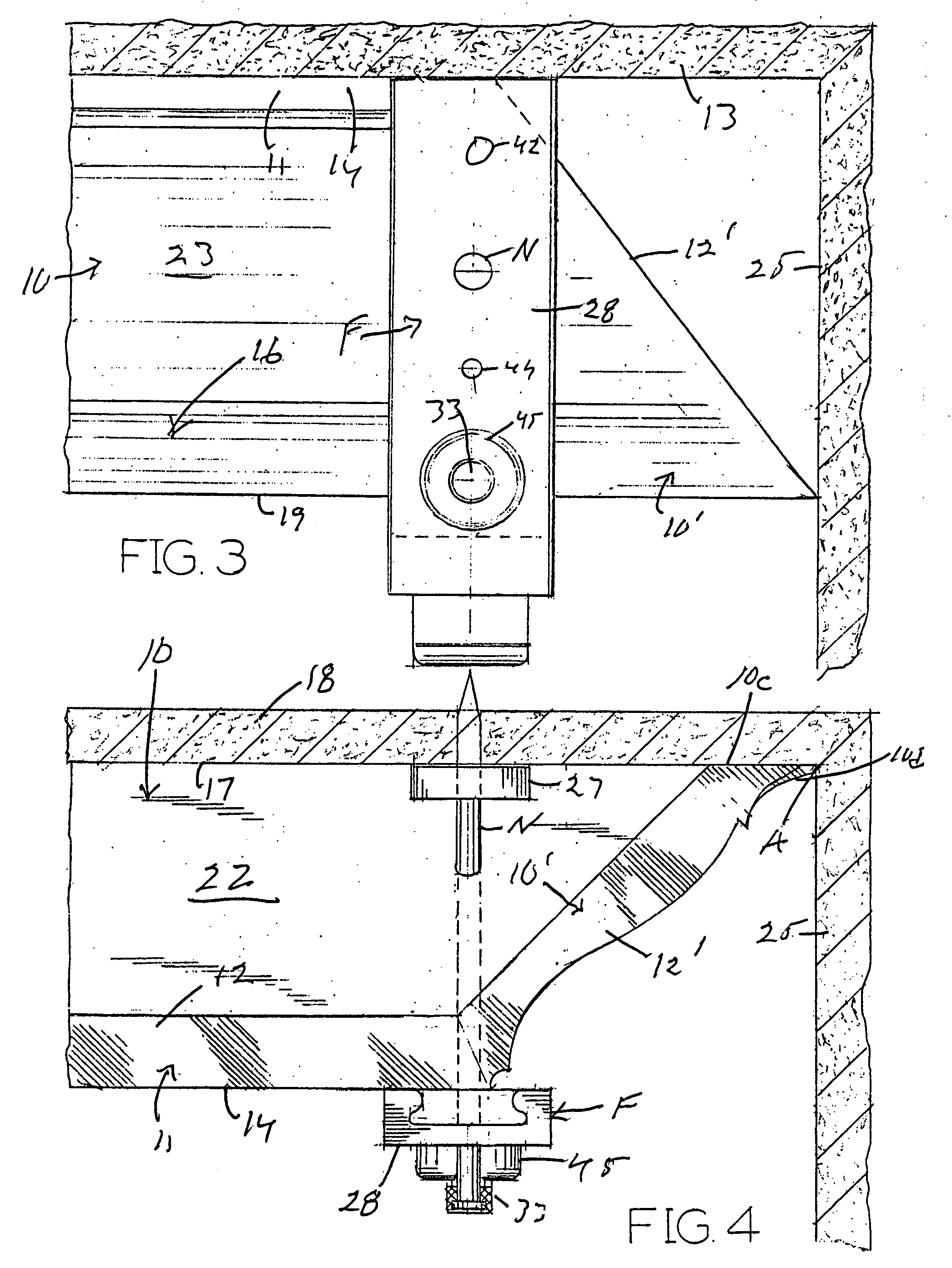

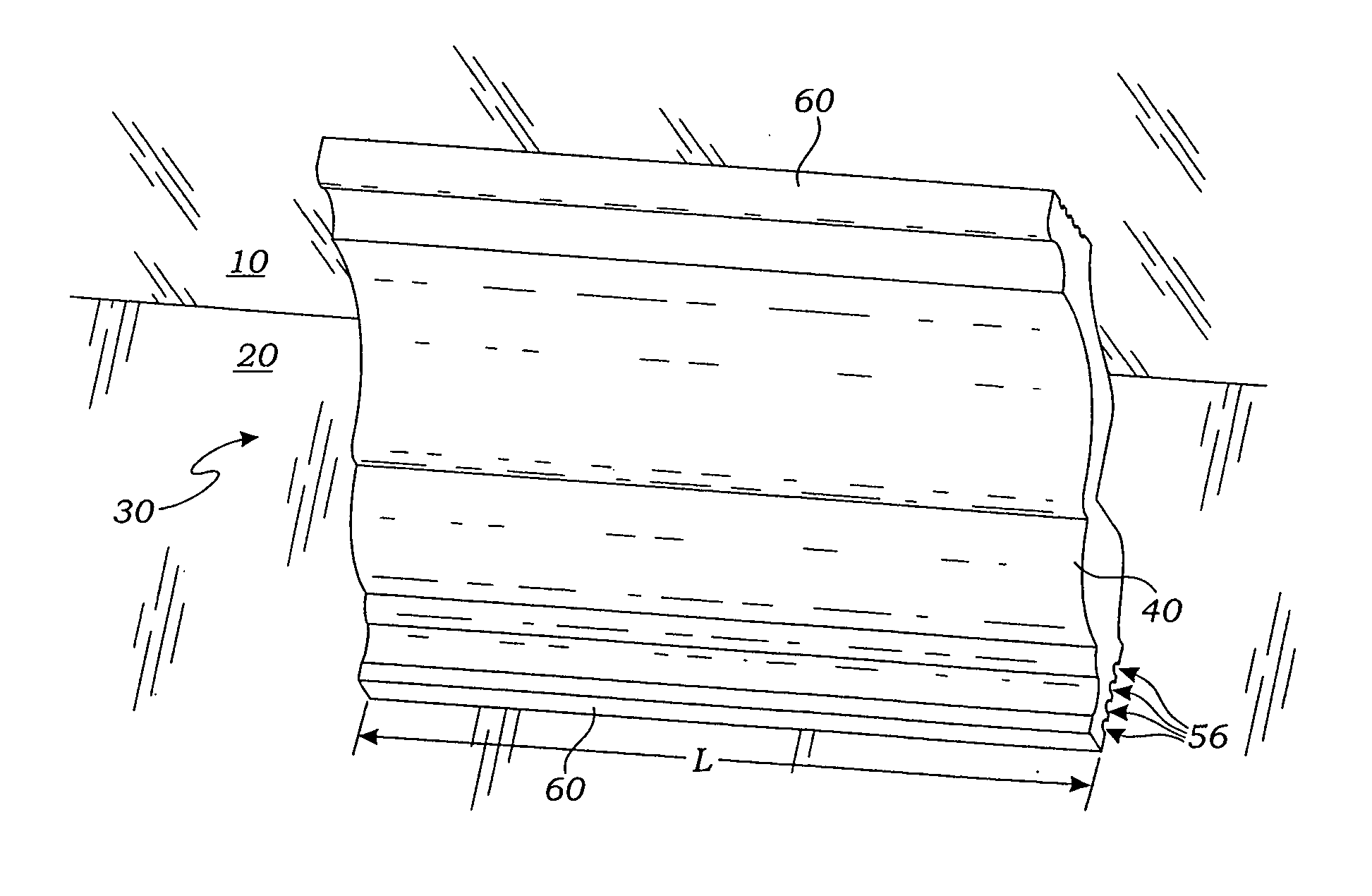

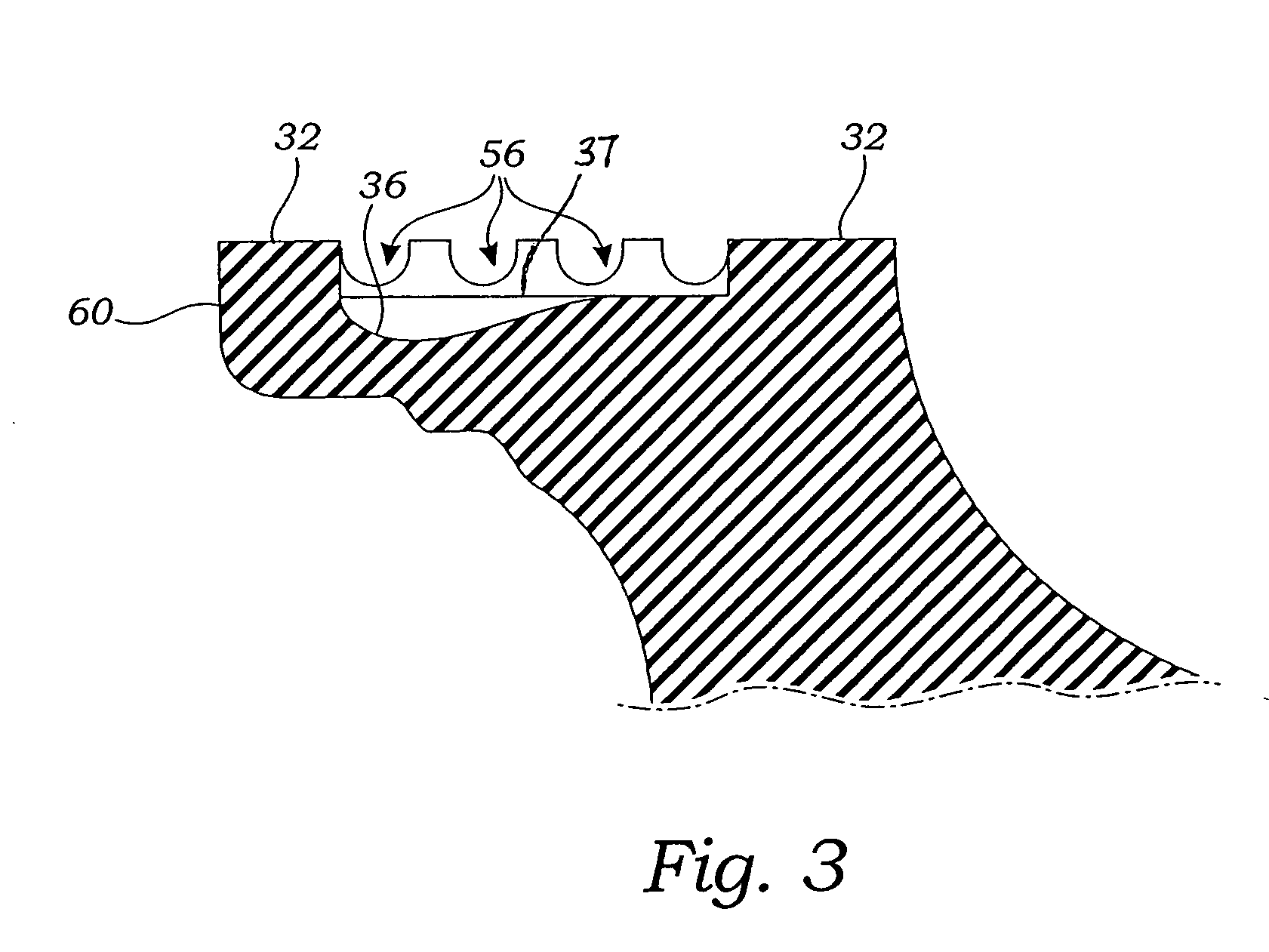

Crown molding with improved mounting surfaces

A crown molding unit for engagement with a ceiling surface and an adjacent wall surface of a room has a first surface positioned for flush contact with a ceiling surface and simultaneously, a second surface positioned for flush contact with a wall surface. Each of the first and the second surfaces provide a plurality of side-by-side parallel longitudinal grooves and a plurality of side-by-side parallel lateral grooves, the lateral grooves lie orthogonal to the longitudinal grooves and converge to a depression in the apparatus.

Owner:HAHN RICHARD

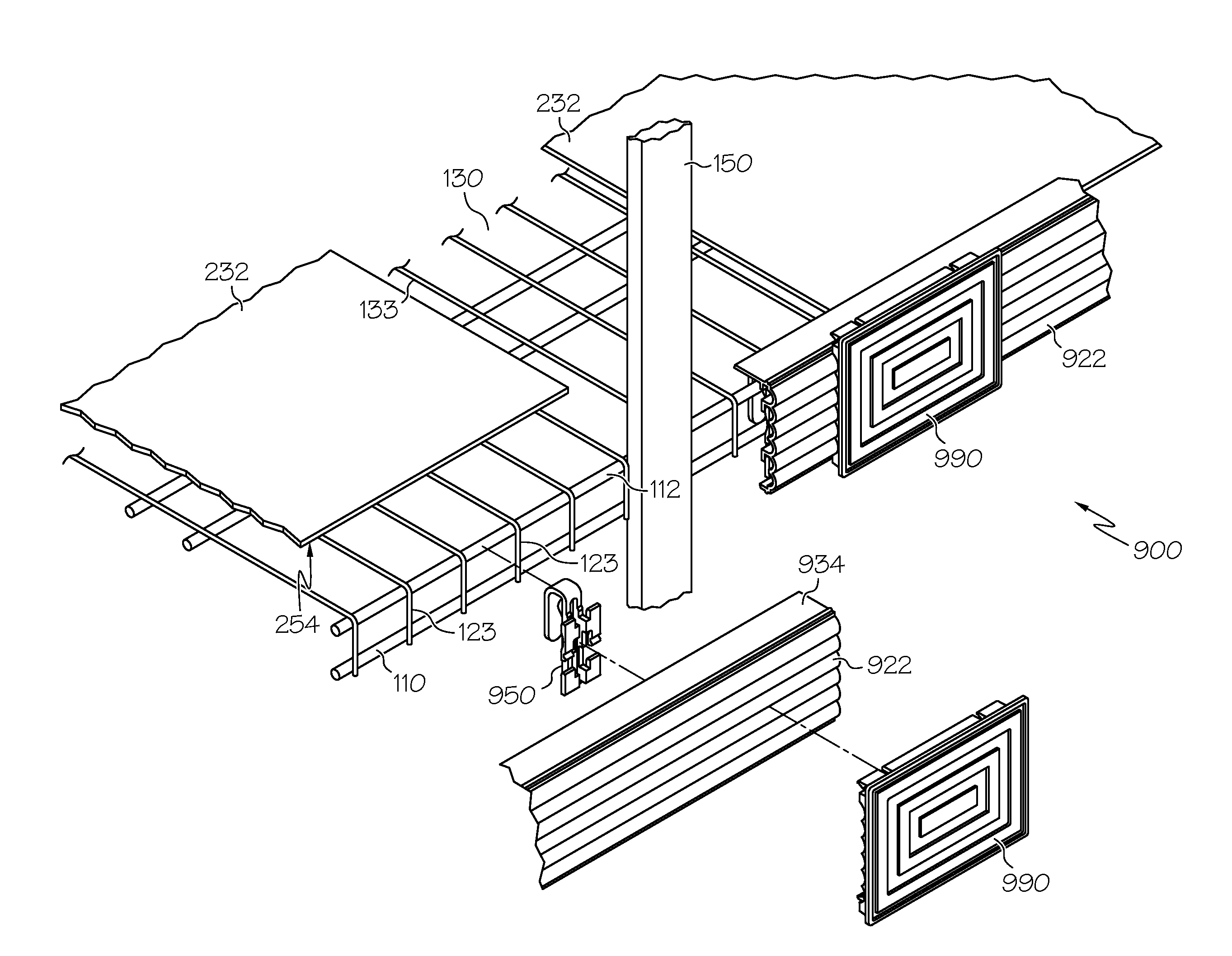

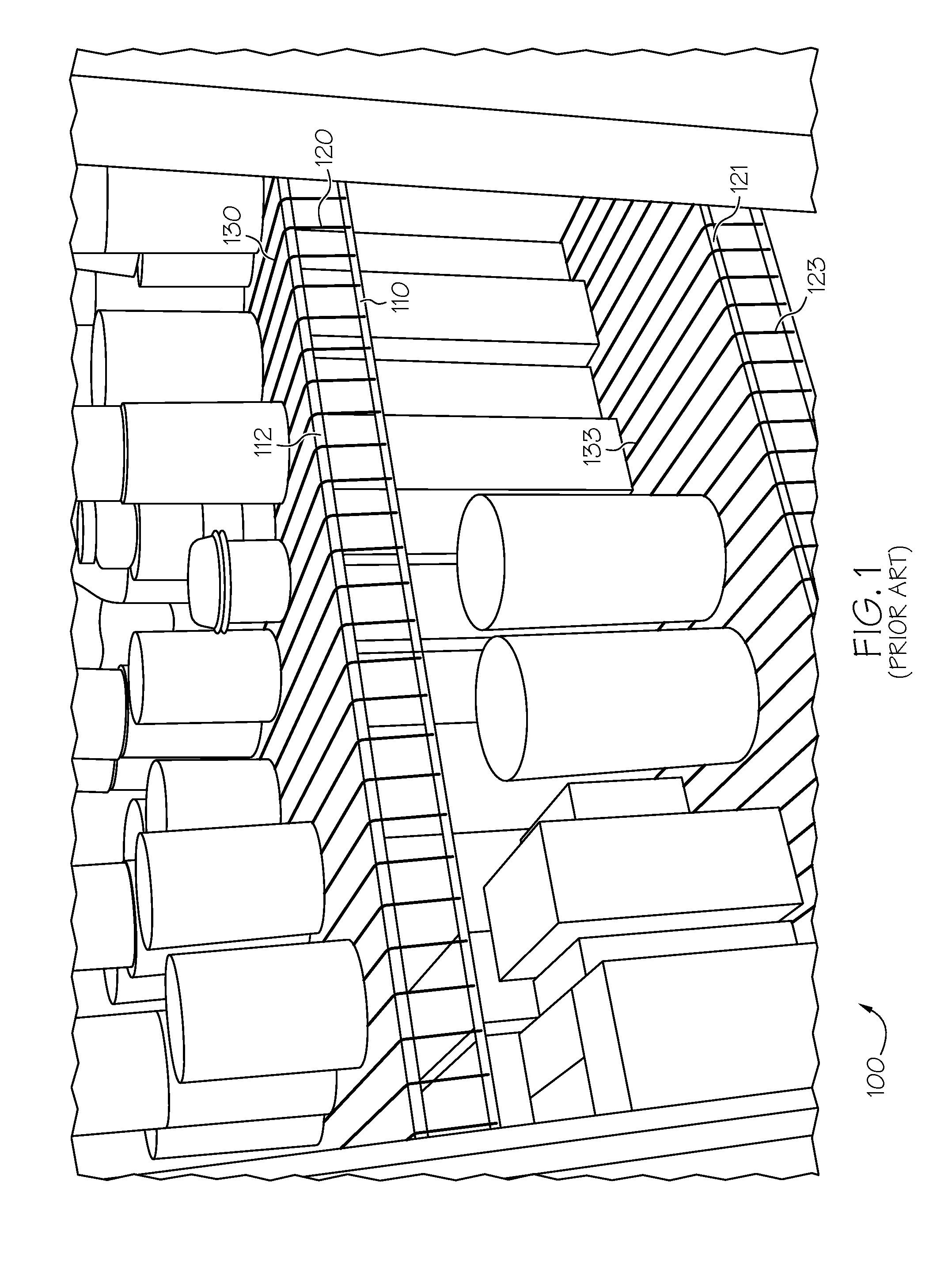

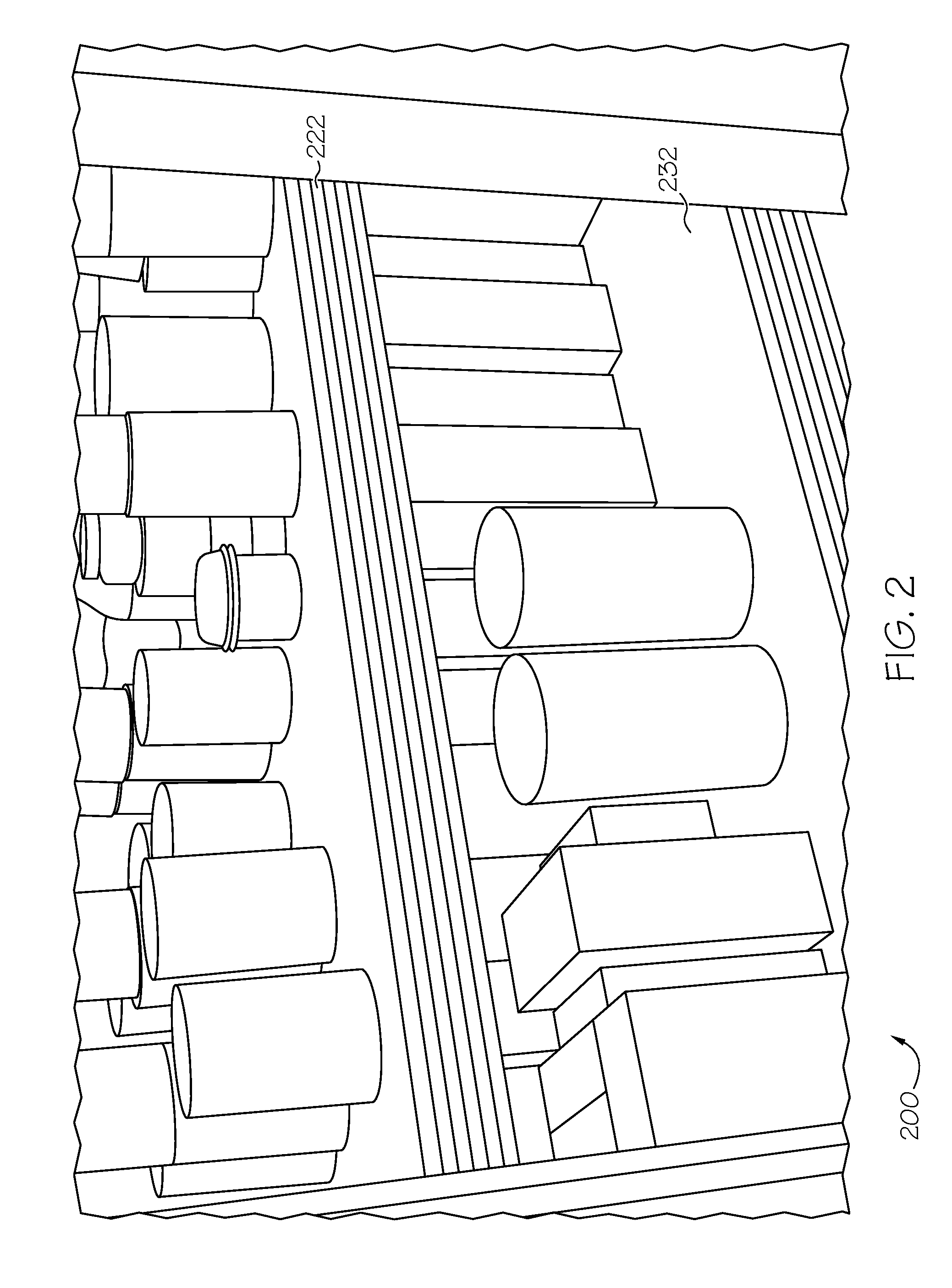

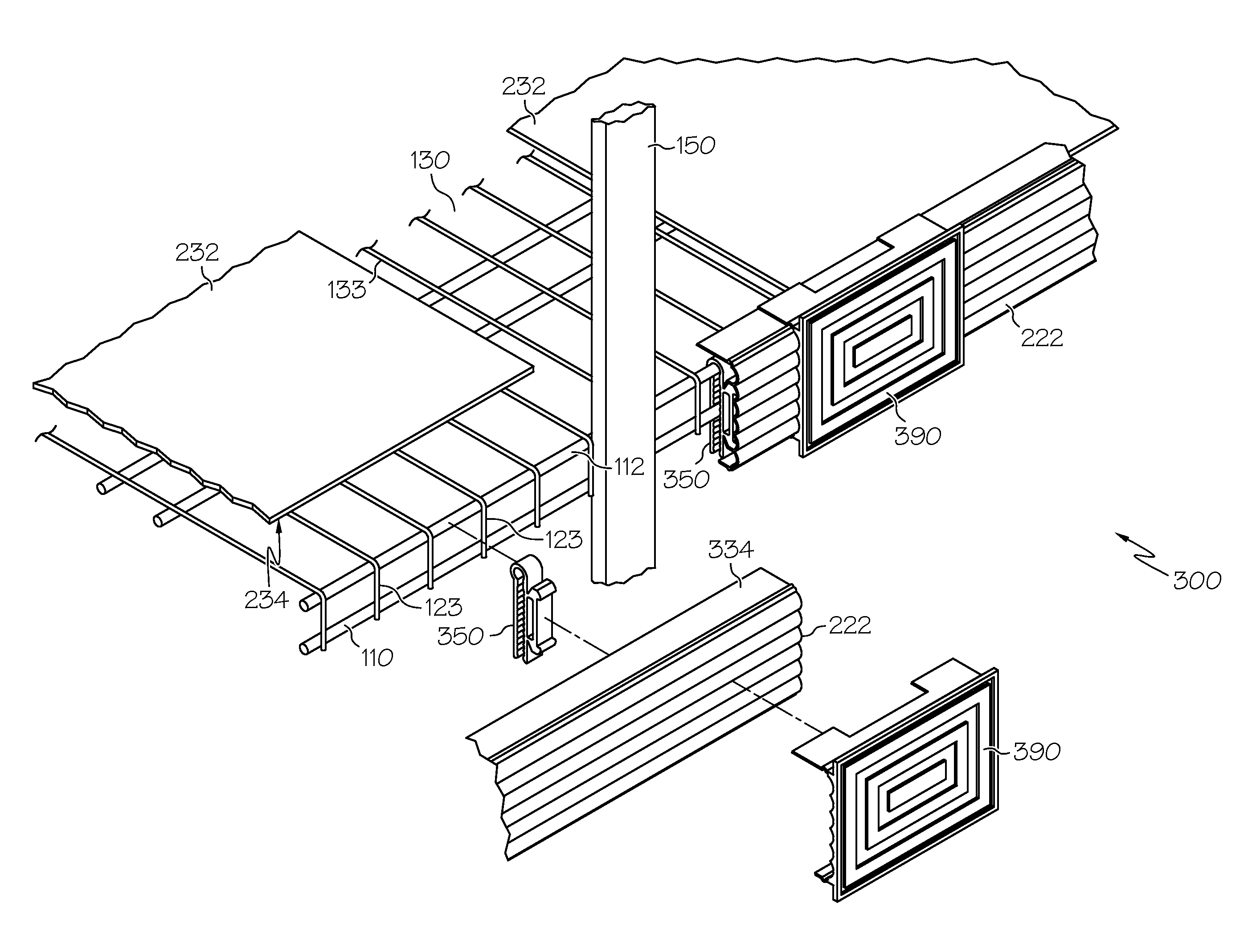

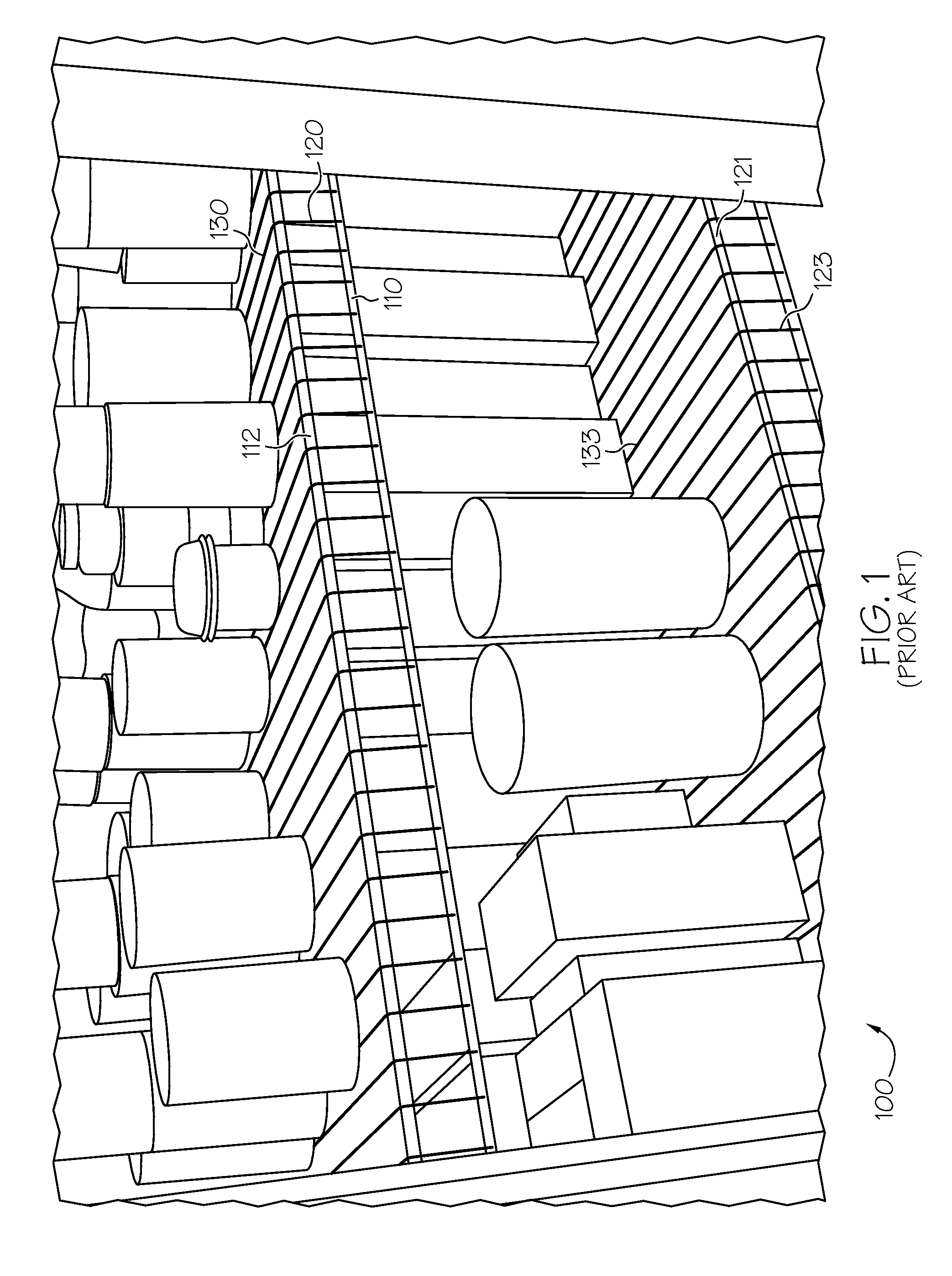

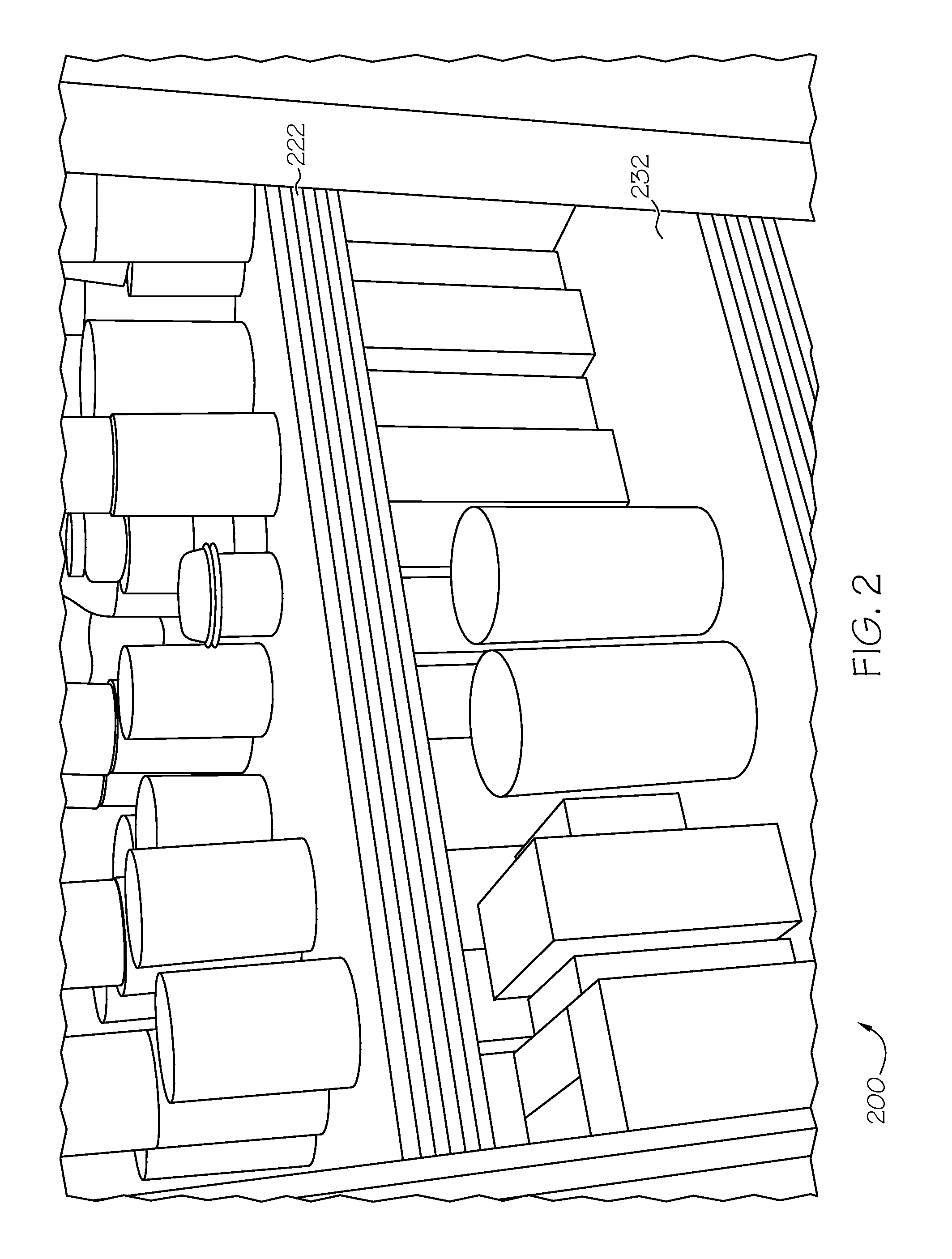

Ventilated shelf cover with spring clasp

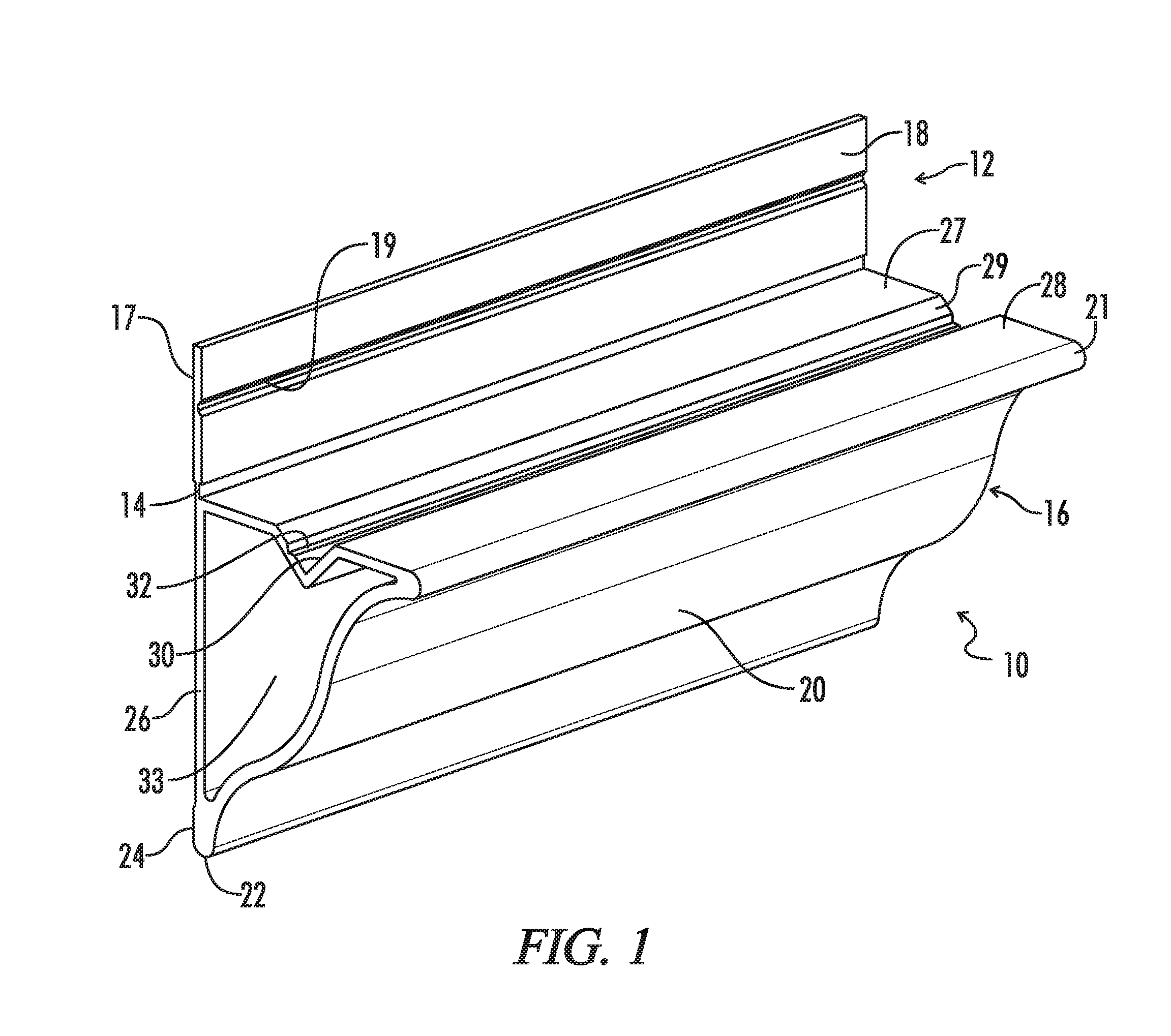

ActiveUS20140263131A1Function increaseKeep items from tipping or fallingShow shelvesShow hangersCrown moldingEngineering

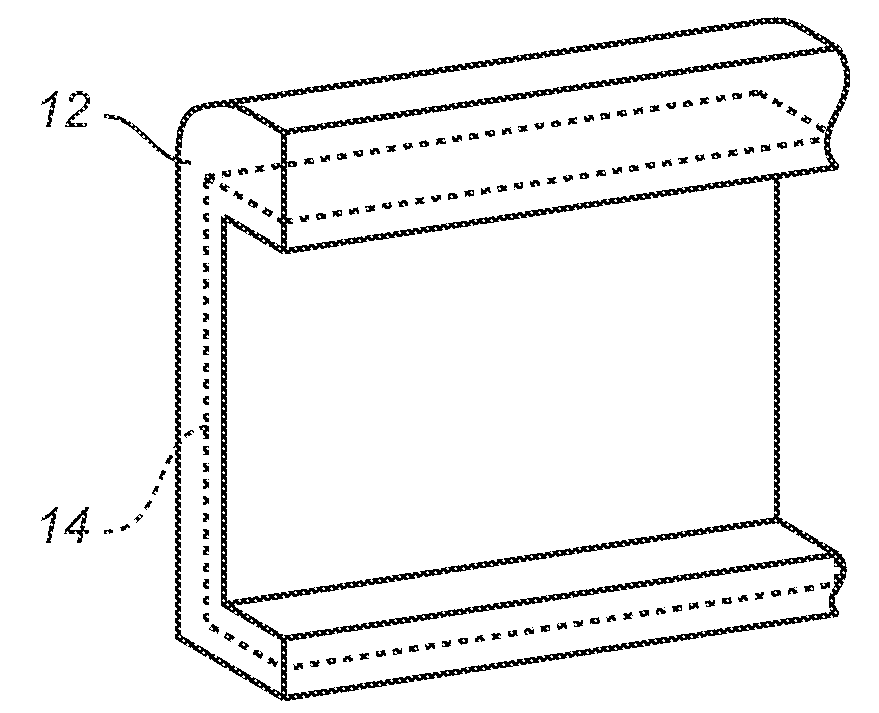

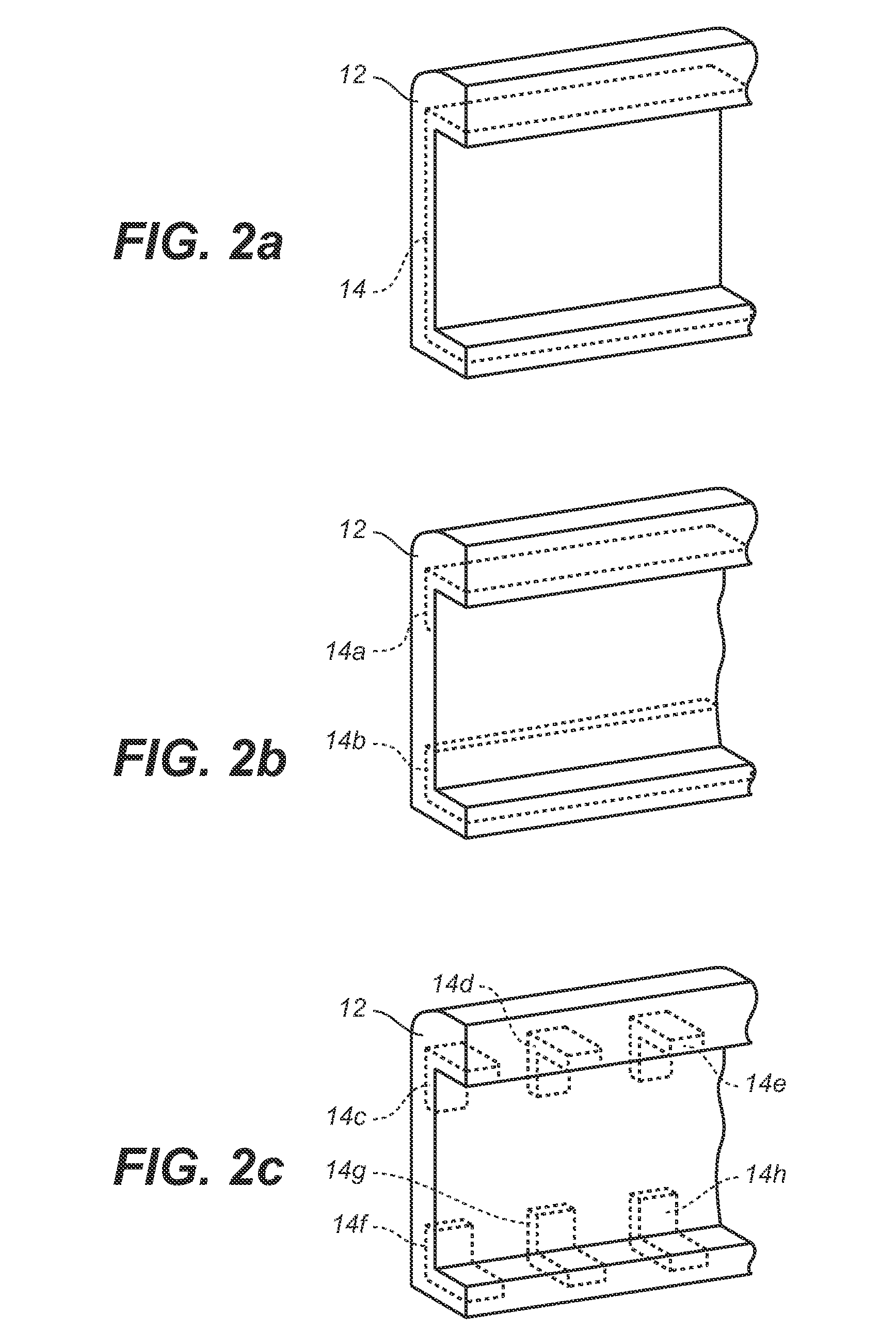

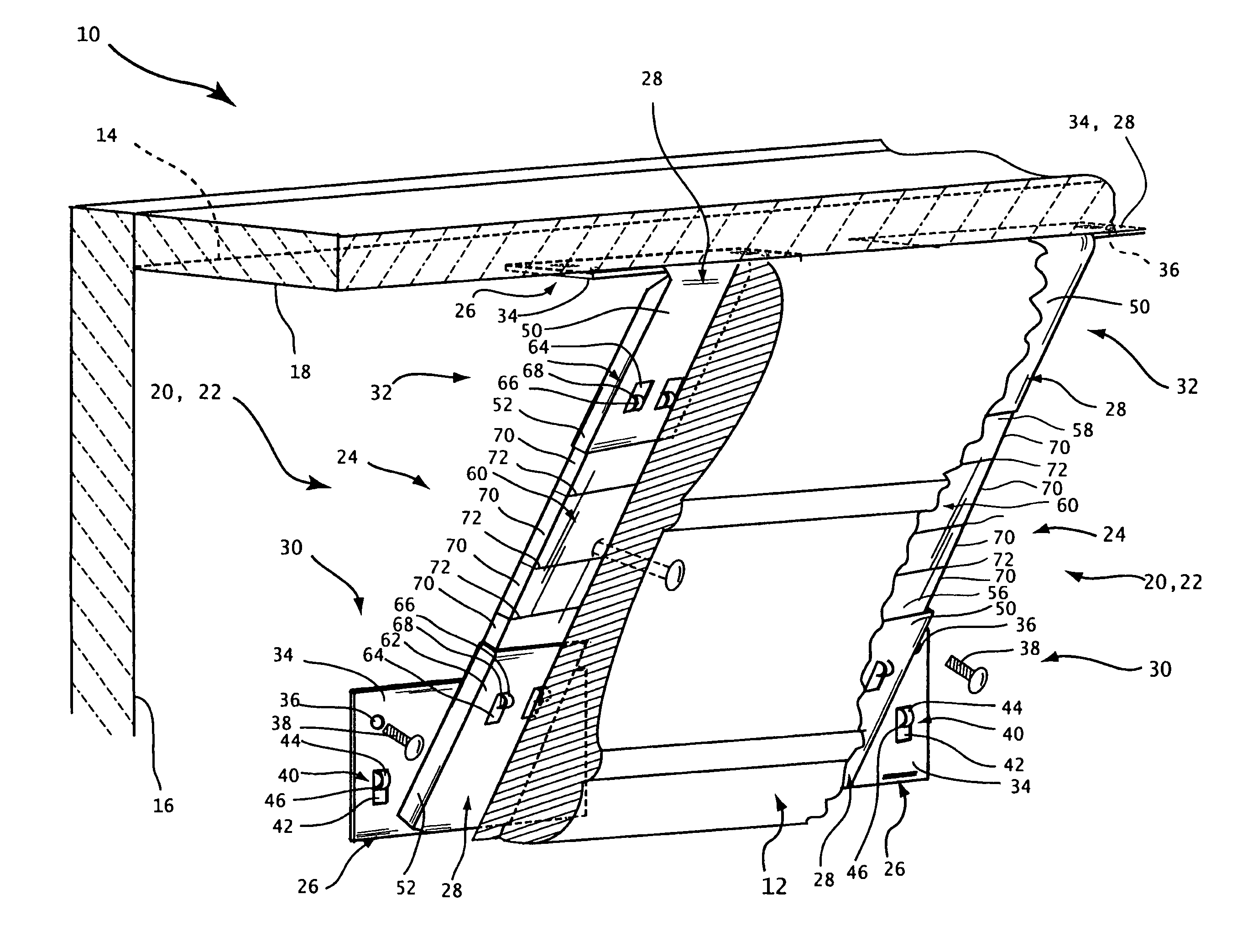

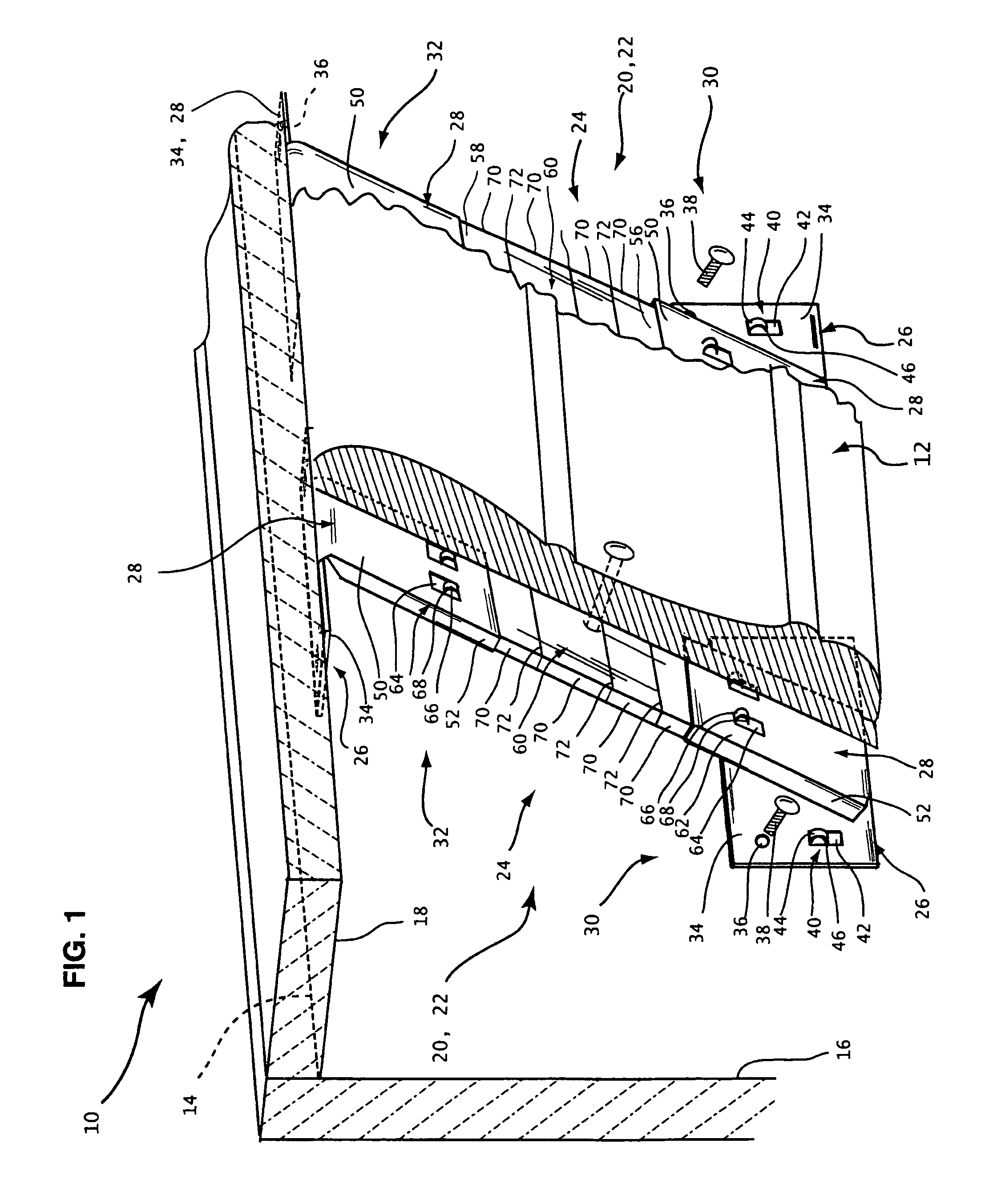

A novel ventilated shelving cover is disclosed that transforms the appearance of wire shelves to cover the white vertical and horizontal bars with a clean sleek decorative trim (crown molding) giving the shelves a custom made look. While also utilizing a custom insert / liner to enhance the functionality by keep items from tipping or falling through the wire portion of the shelves. This system contains a decorative trim piece, decorative cover, specially engineered clasps and an insert / liner. The system also includes a custom saw and miter to provide “All You Need” to accomplish the transformation of your pantry, linen, bedroom closets or garage shelves.

Owner:CUSTOMER MOTIVATORS

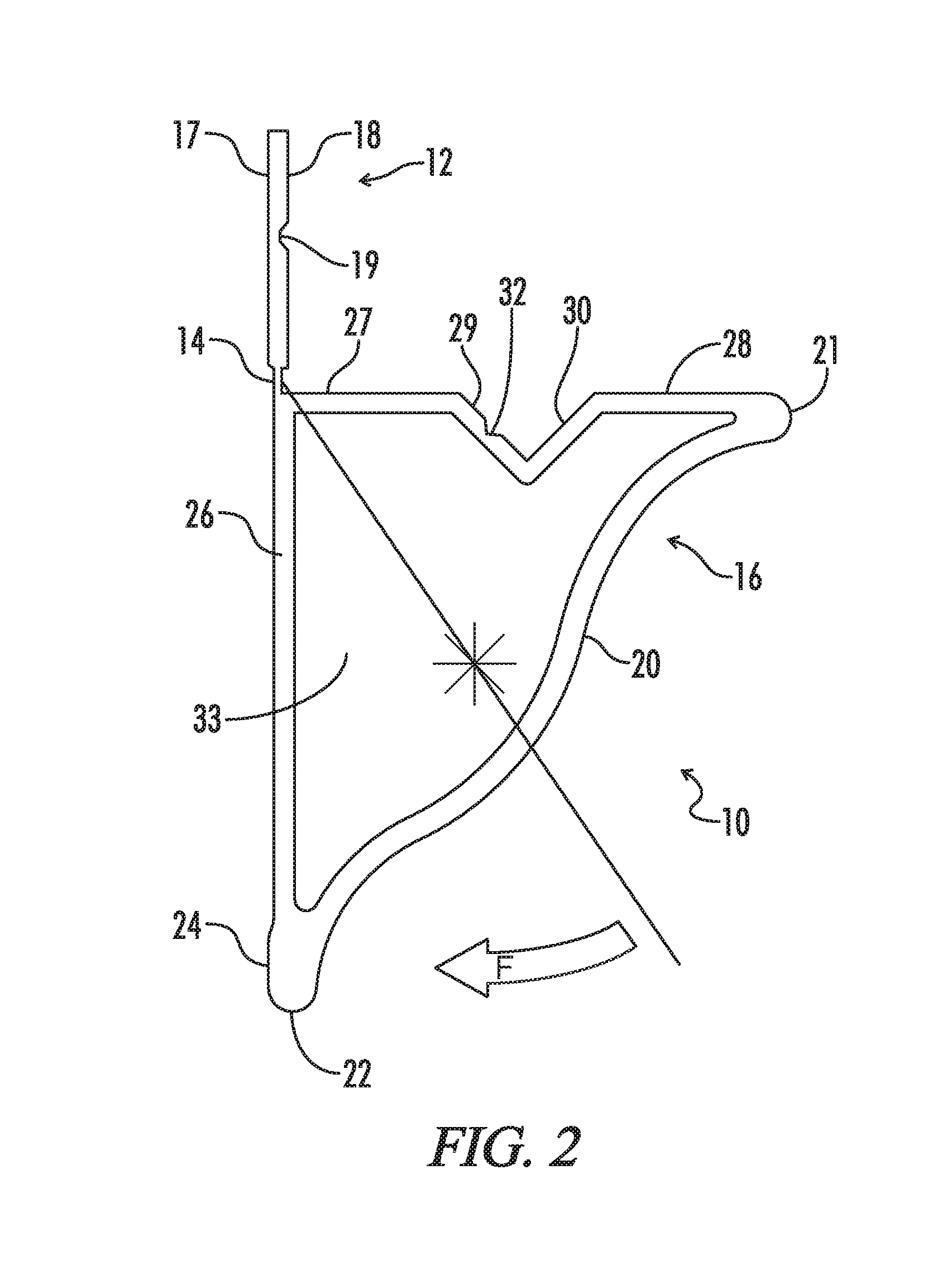

System and Method for Installation of Crown Molding on Imperfect Walls

A molding system installed at or near the top of a vertical wall having a molding portion and an attachment portion, where the attachment portion is attached securely to the wall above at least the center of mass of the molding portion, and the molding portion has an outwardly visible decorative face which extends down to where the lower edge of the molding portion meets the wall. The attachment portion is enabled to flex as it is firmly attached to an imperfect wall, and the structure of the molding portion is such that the decorative face of the molding system remains preferentially straight and preferentially positioned as the molding system is installed on an irregular wall. A hinge-like flex is enabled along the length of the molding above the center of mass of the molding portion such that the decorative face of the molding can pivot like a pendulum ensuring the lower edge of the molding is placed against the wall. None of the methods of installation of this system violate the decorative face of the molding and a consistent decorative face profile extends around the entire installation.

Owner:HOFFMAN JEREMY P +1

Router jig for cutting decorative profiles

Owner:SCRIBE MASTER

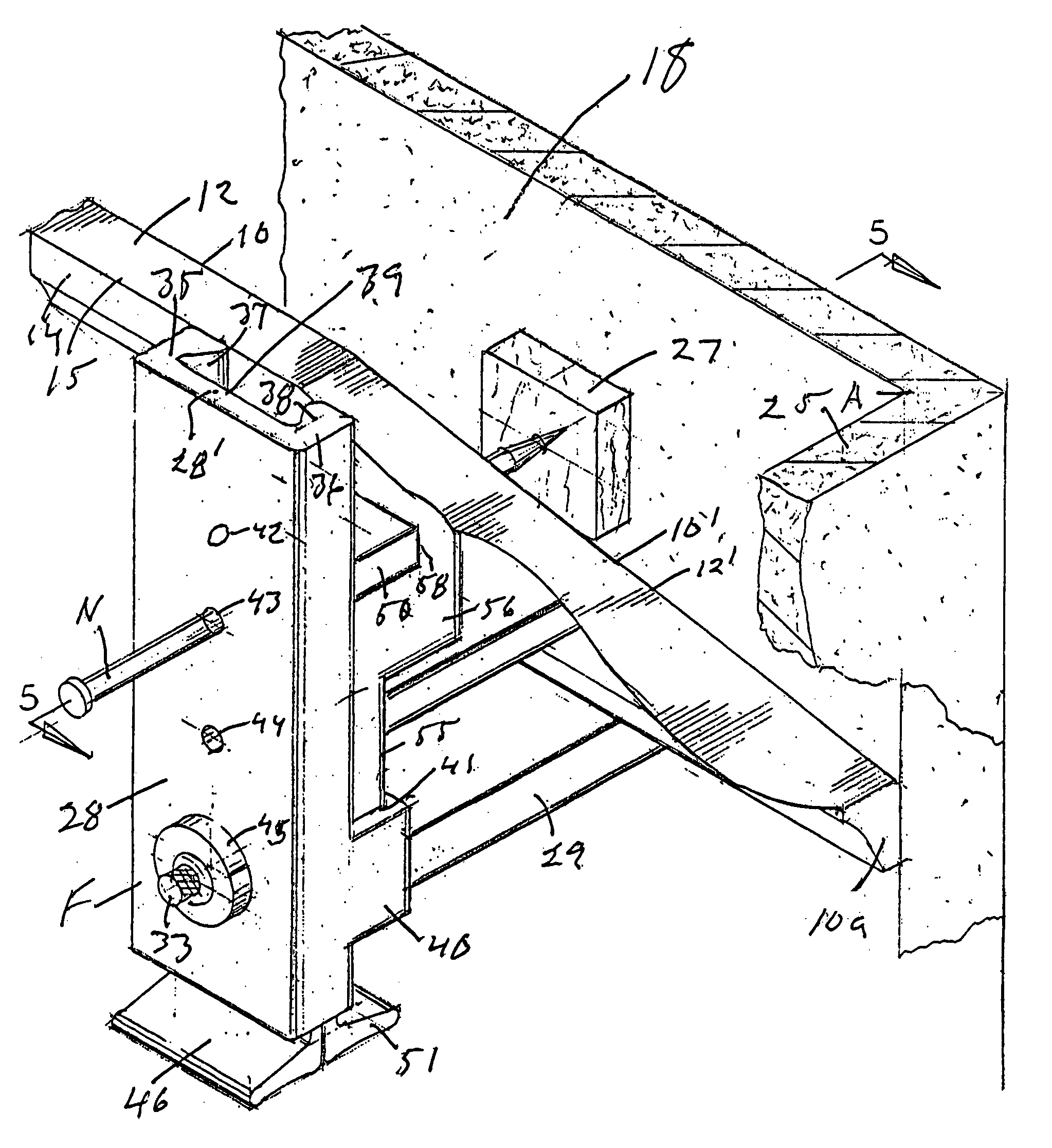

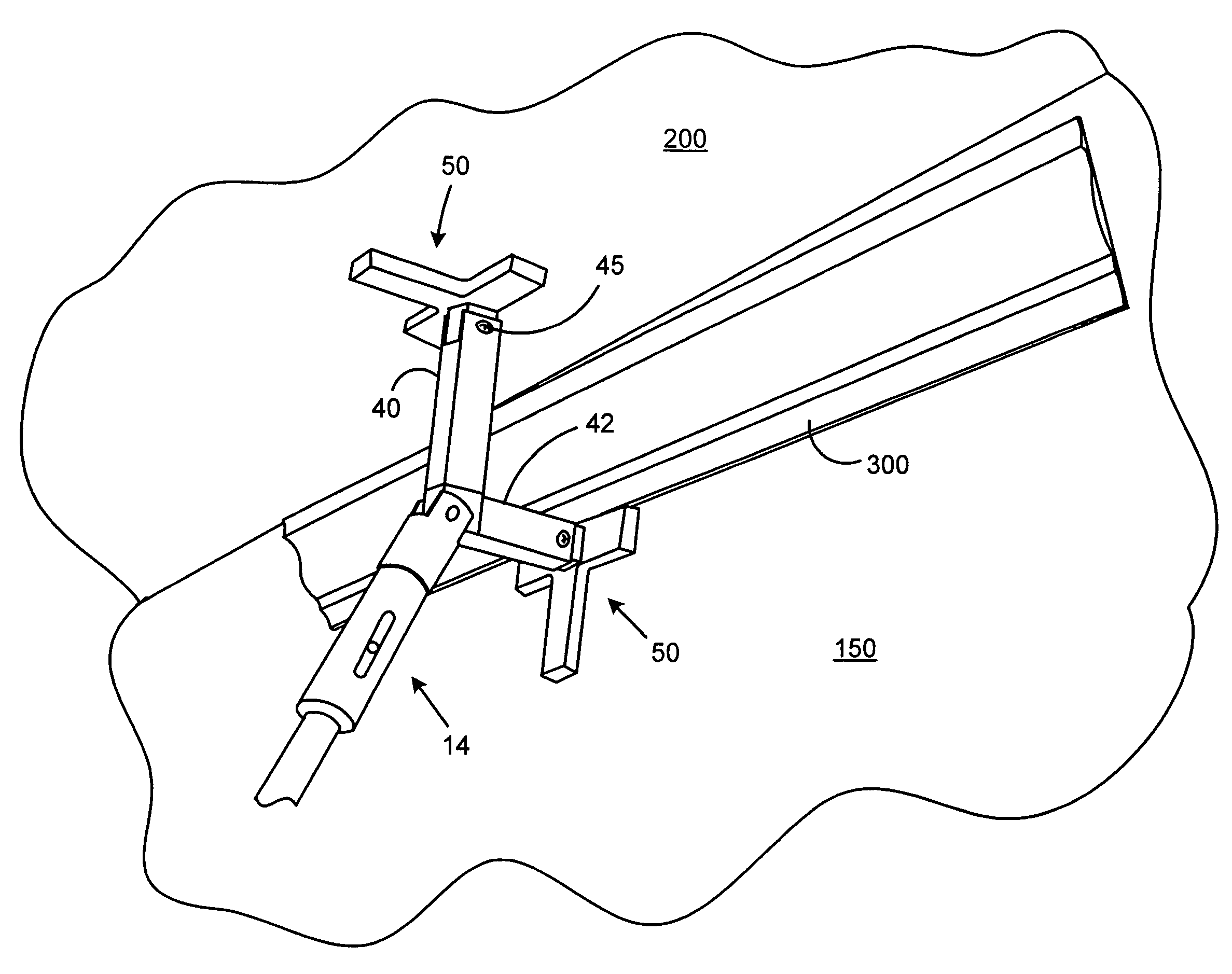

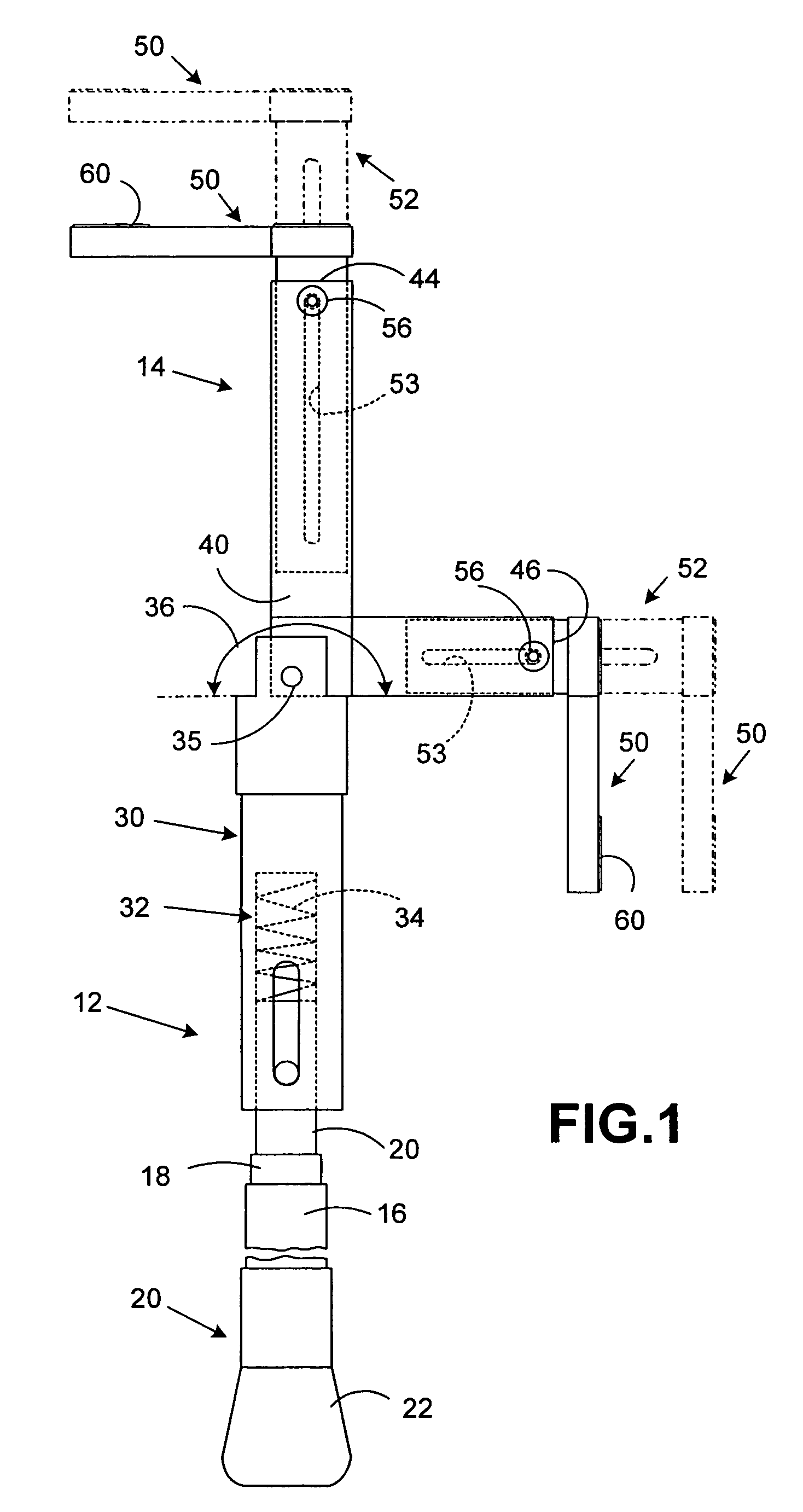

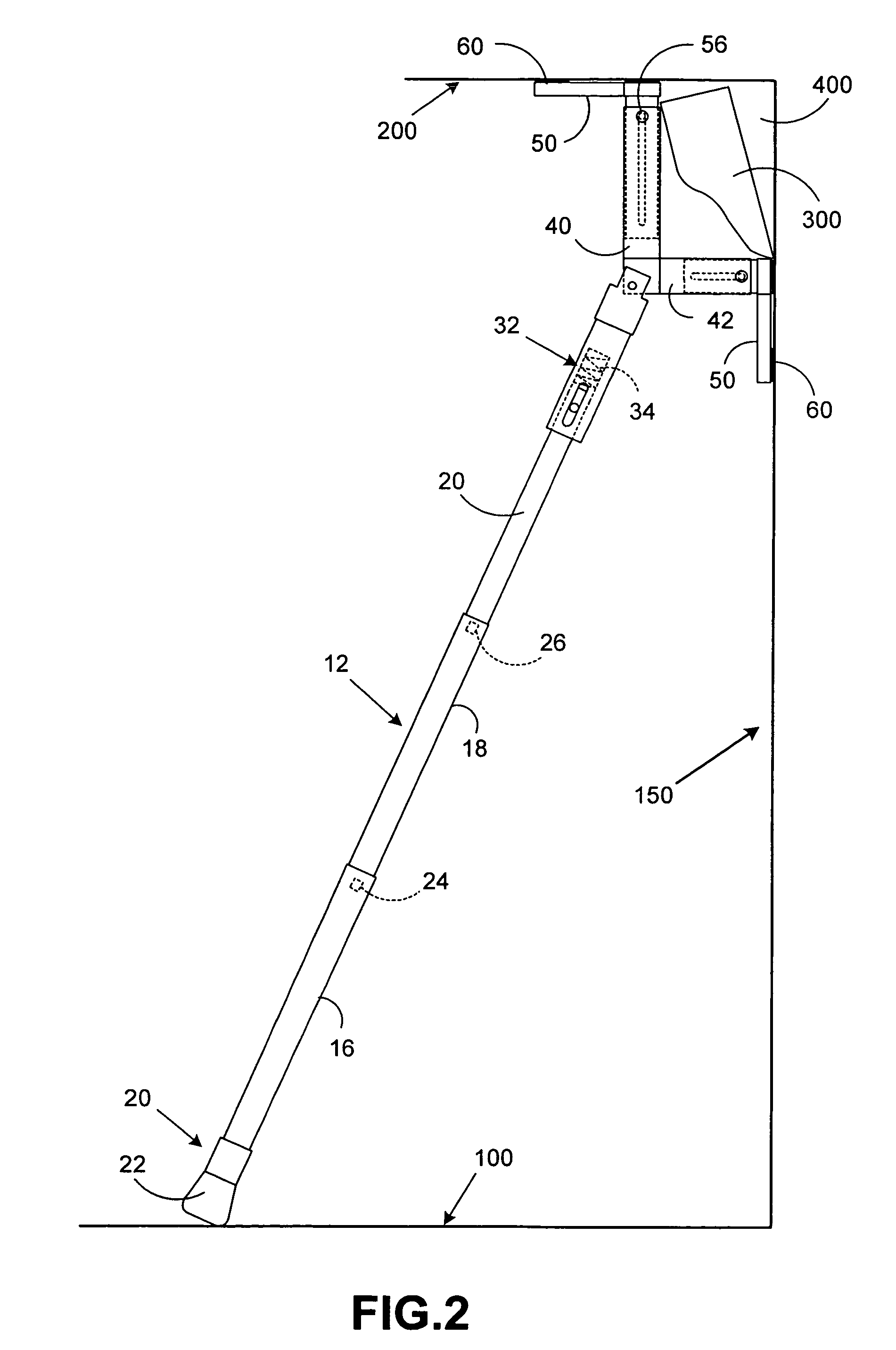

Apparatus for supporting molding pieces

An apparatus for supporting a molding piece such as a piece of chair molding or crown molding against a wall surface at a prescribed distance from a floor surface. The apparatus includes an elongate body having opposing first and second ends and a head assembly coupled to the first end of the elongate body. The head assembly is configured to encapsulate and support a portion of the molding piece that is disposed adjacent the wall surface at a prescribed distance from said floor surface while the second end of the elongate body is disposed adjacent to the floor surface and the first end of the elongate body is disposed adjacent the wall surface. The apparatus thereby supports the encapsulated portion of the molding piece that is disposed adjacent the wall surface at said prescribed distance from said floor surface without further intervention.

Owner:LEWIS THOMAS M

Ventilated shelf cover

InactiveUS8871324B2Function increaseKeep items from tipping or fallingLayered productsTablesCrown moldingEngineering

A novel ventilated shelving cover is disclosed that transforms the appearance of wire shelves to cover the white vertical and horizontal bars with a clean sleek decorative trim (crown molding) giving the shelves a custom made look. While also utilizing a custom insert / liner to enhance the functionality by keep items from tipping or falling through the wire portion of the shelves. This system contains a decorative trim piece, decorative cover, specially engineered clasps and an insert / liner. The system also includes a custom saw and miter to provide “All You Need” to accomplish the transformation of your pantry, linen, bedroom closets or garage shelves.

Owner:CUSTOMER MOTIVATORS

Magnetic trim

InactiveUS20080217506A1Easy to removeEasy to replaceStands/trestlesBuilding constructionsCrown moldingBaseboard

Magnetic trim (baseboards, crown molding, door jams, etc.) that will be secured to permanent structures (walls or ceilings), using magnetic attraction between a magnet and a magnetic conductor is disclosed. The magnetic properties between the magnets within the trim and the magnetic conductor placed on the permanent structure will keep the trim securely in place while providing for easy removal and replacement of the trim.

Owner:COHOON DENISE M

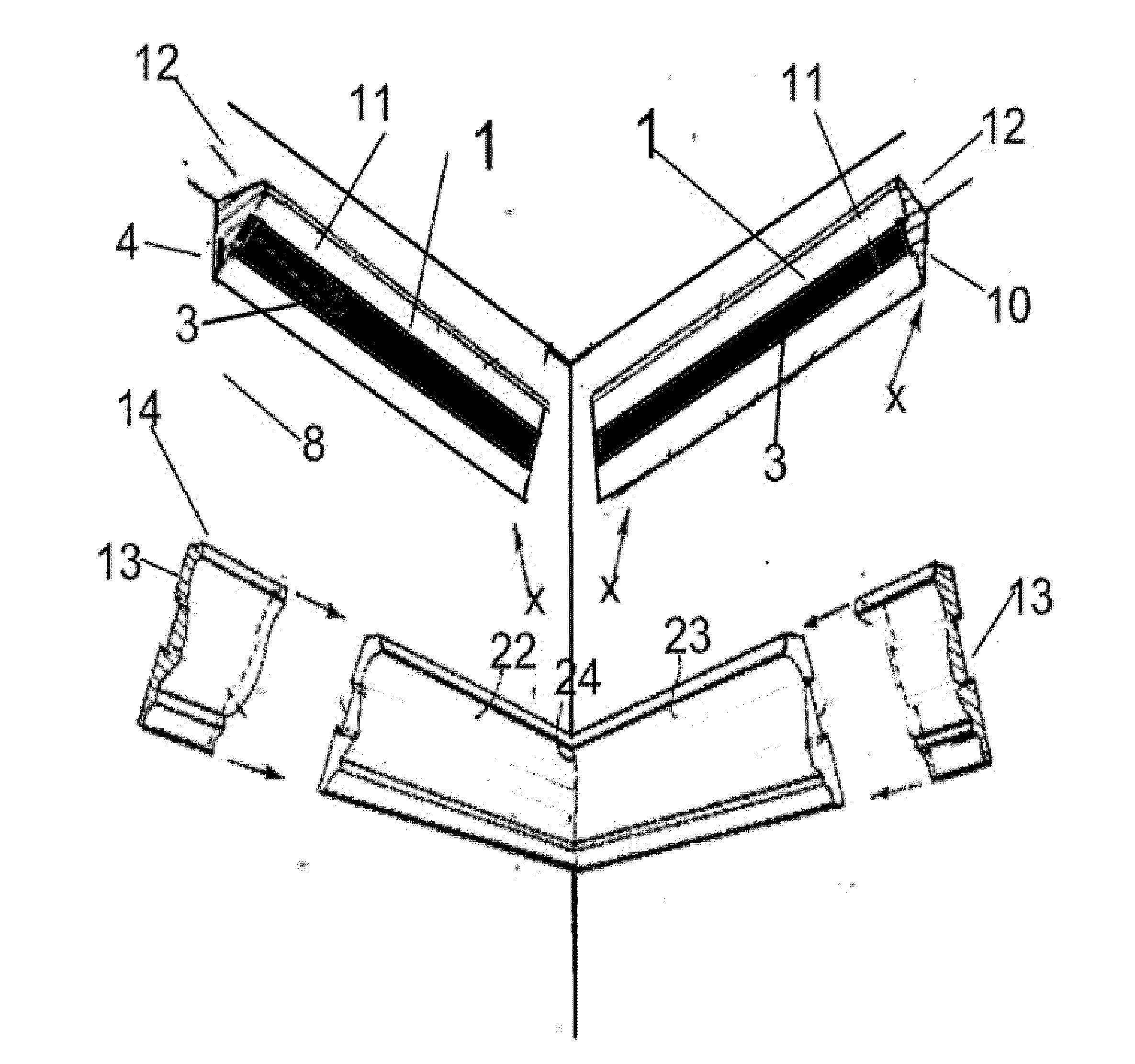

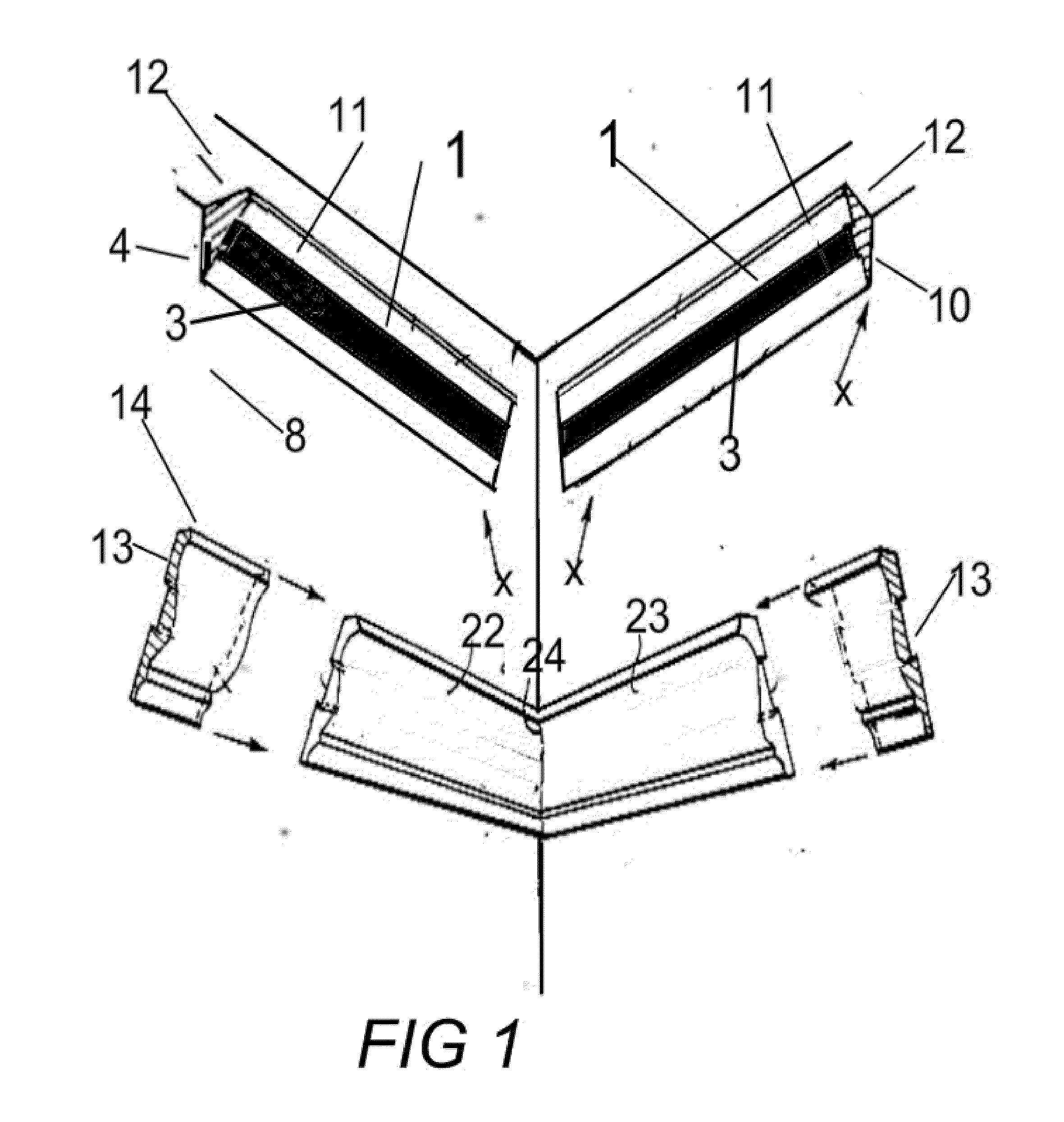

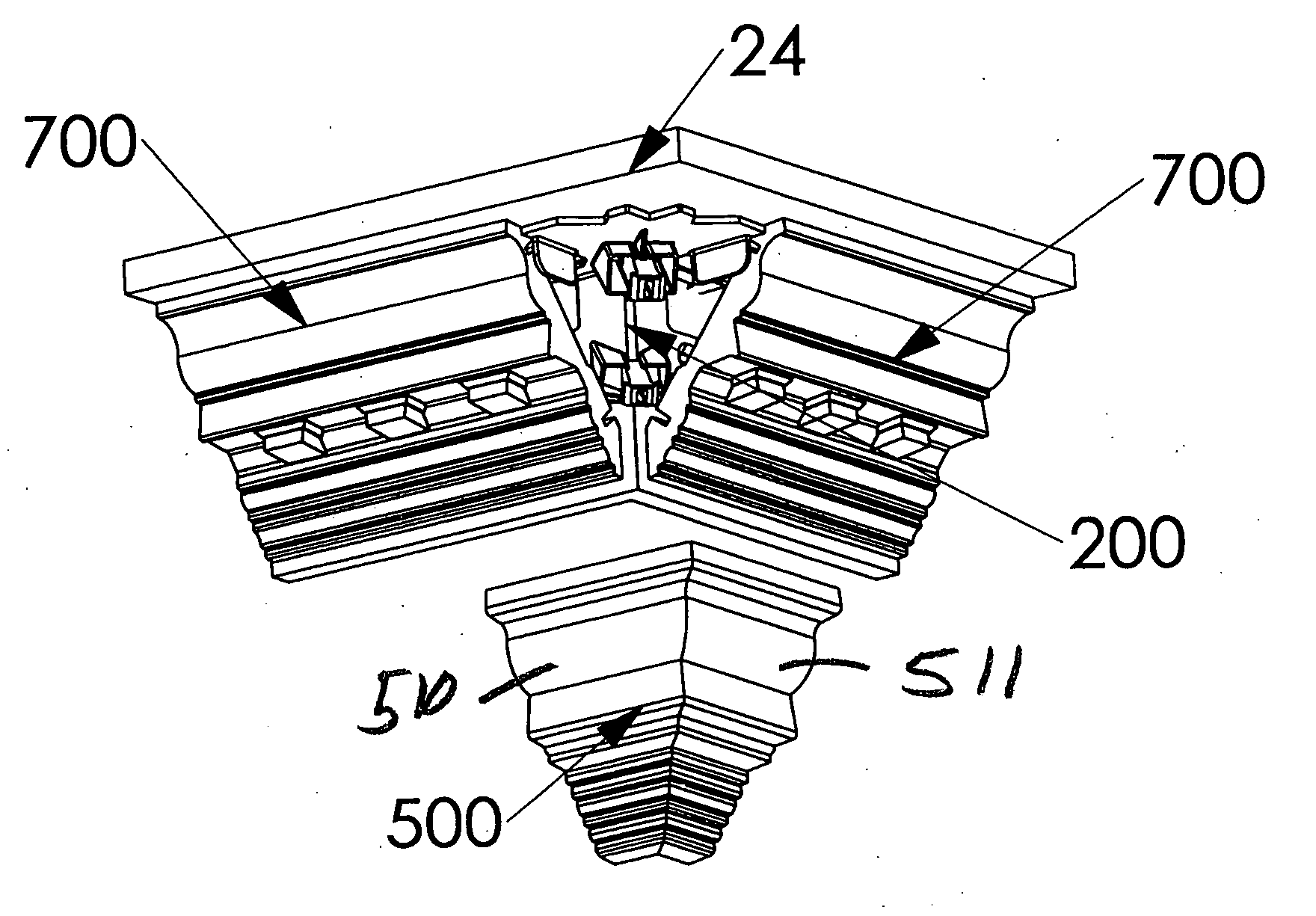

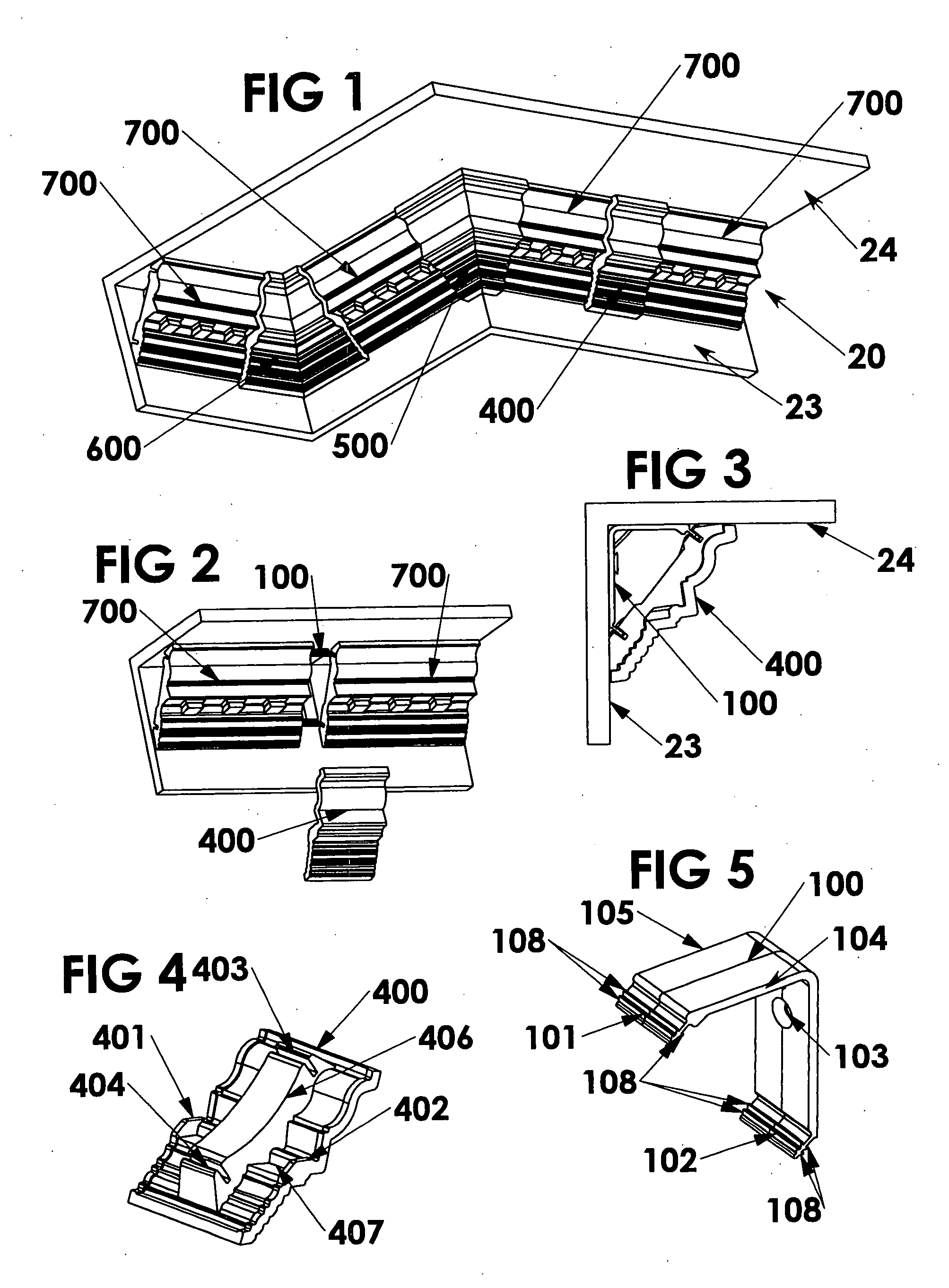

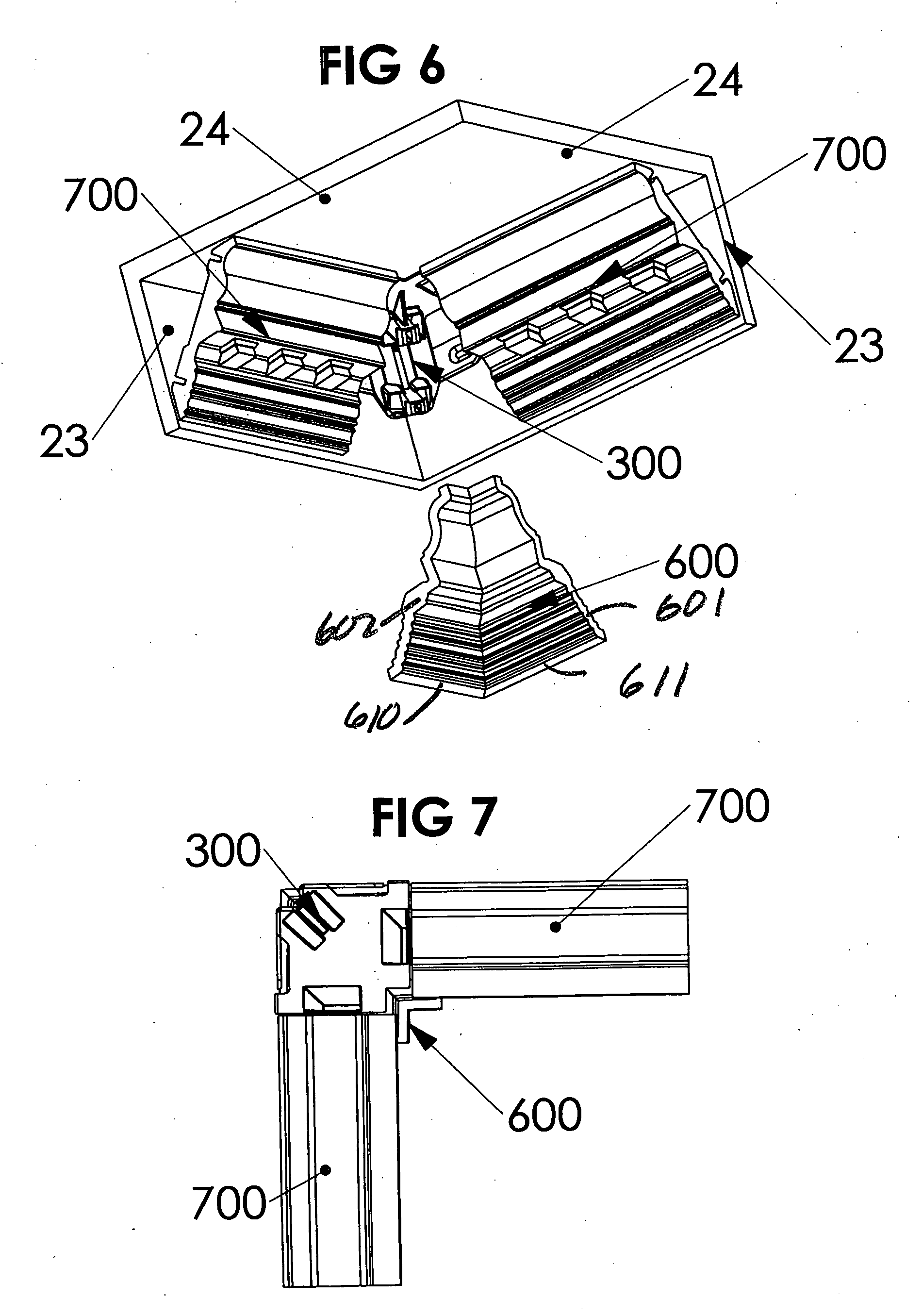

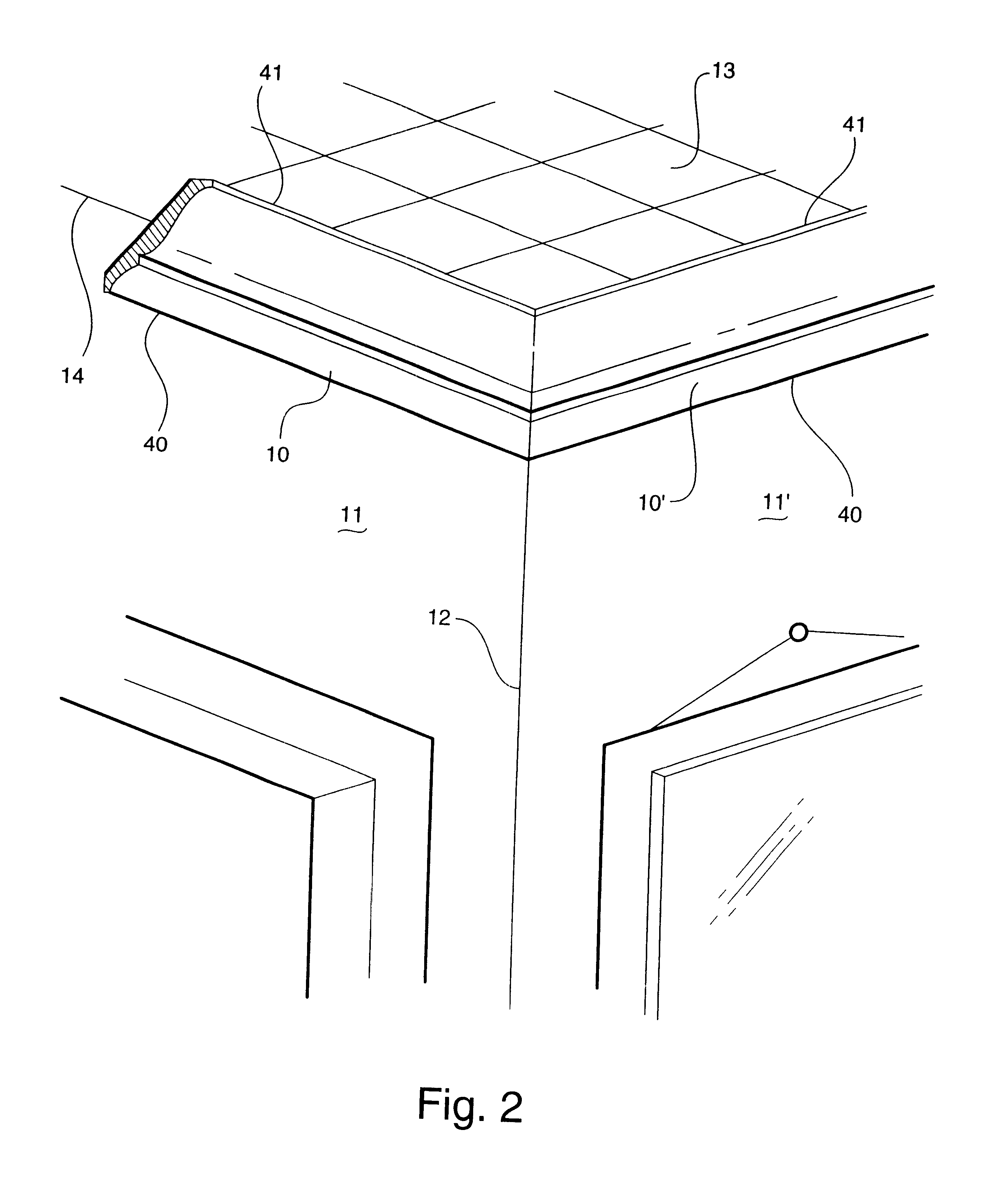

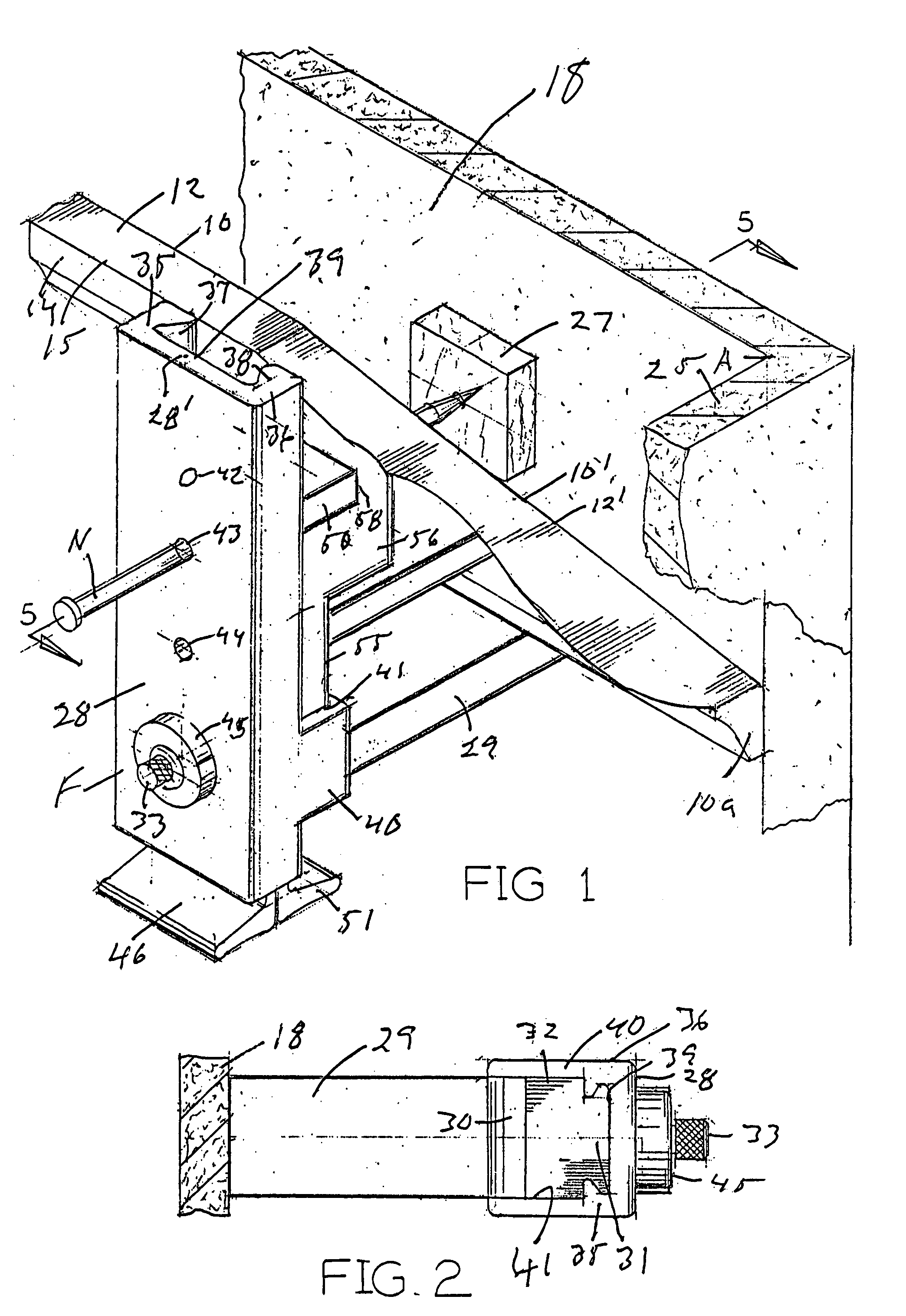

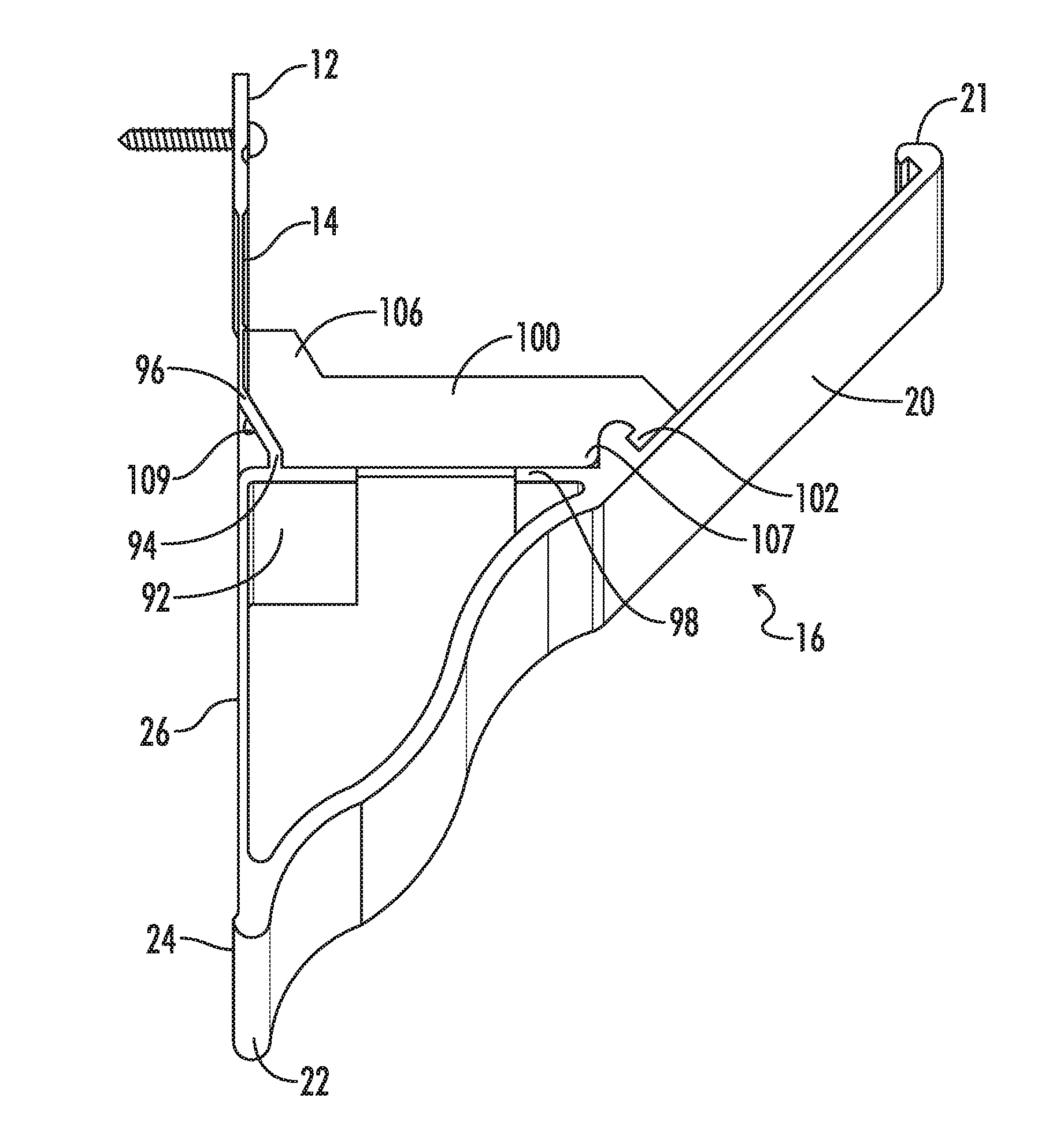

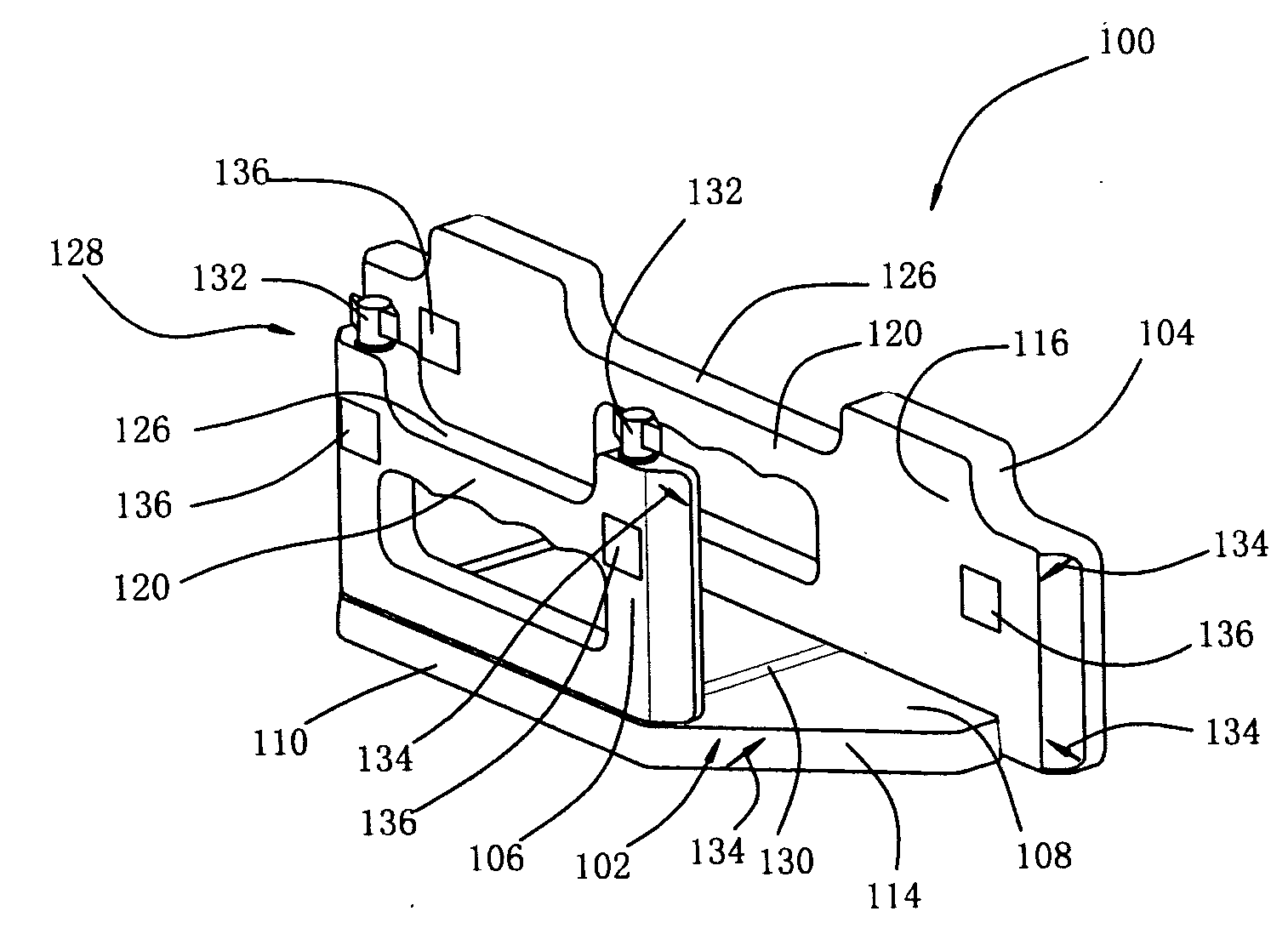

Installation bracket and system for crown molding

An installation bracket system for use in combination with a length of crown molding for securing the crown molding adjacent to the junction of a wall surface and a ceiling surface, the installation bracket system including one or more installation brackets, each of the one or more installation brackets having first support member and a second support member, each of the support members having a mounting portion and an integrally formed supporting portion, the mounting portion having a base formed with apertures to receive fasteners therethrough for securement of the first support member and the second support member to the wall surface and ceiling surface, respectively, and a backing member extending between the first support member and the second support member, the backing member having a front surface, the crown molding being secured against the front surface of the backing member.

Owner:DE RAUCOURT JEAN CLAUDE

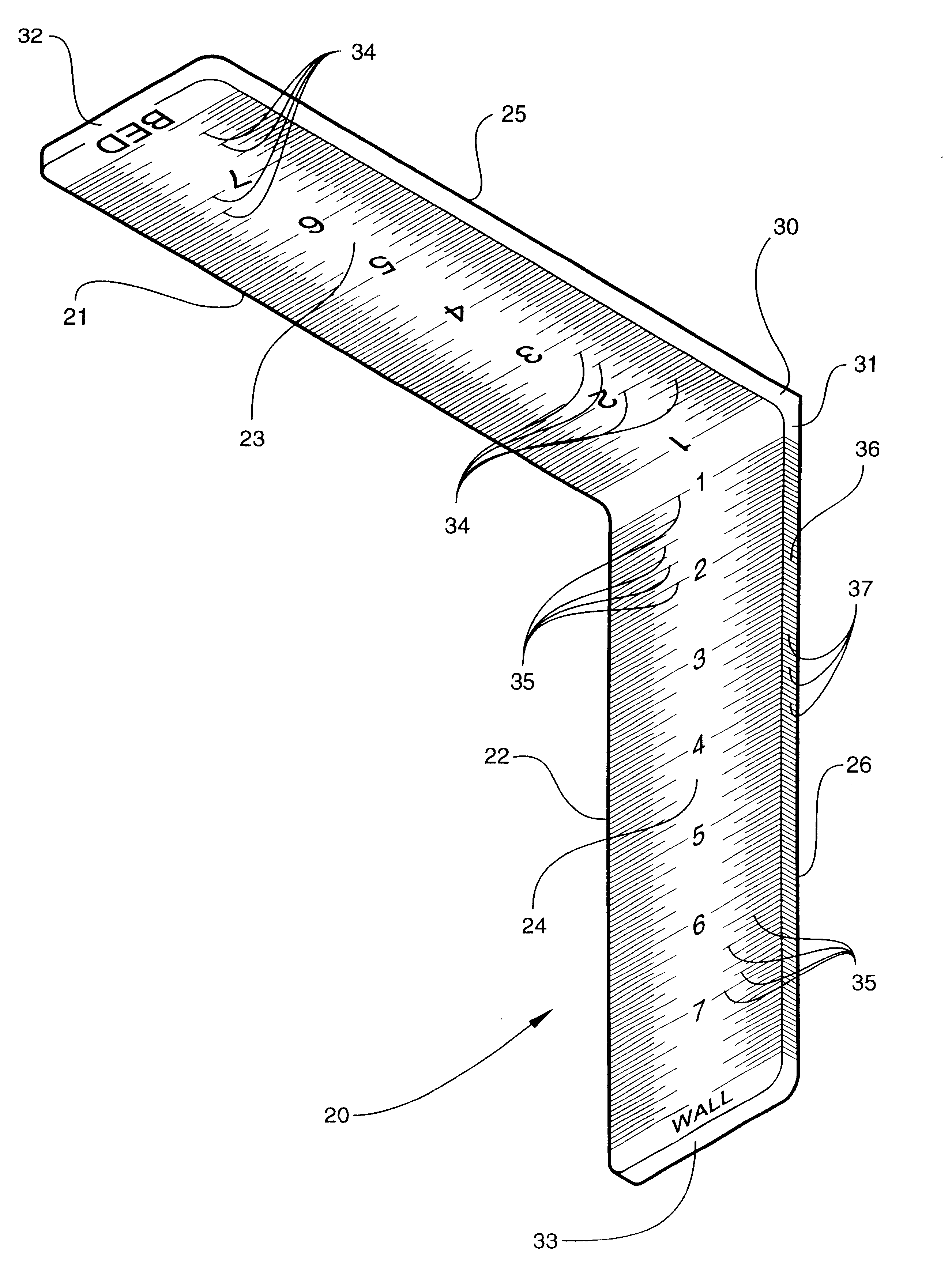

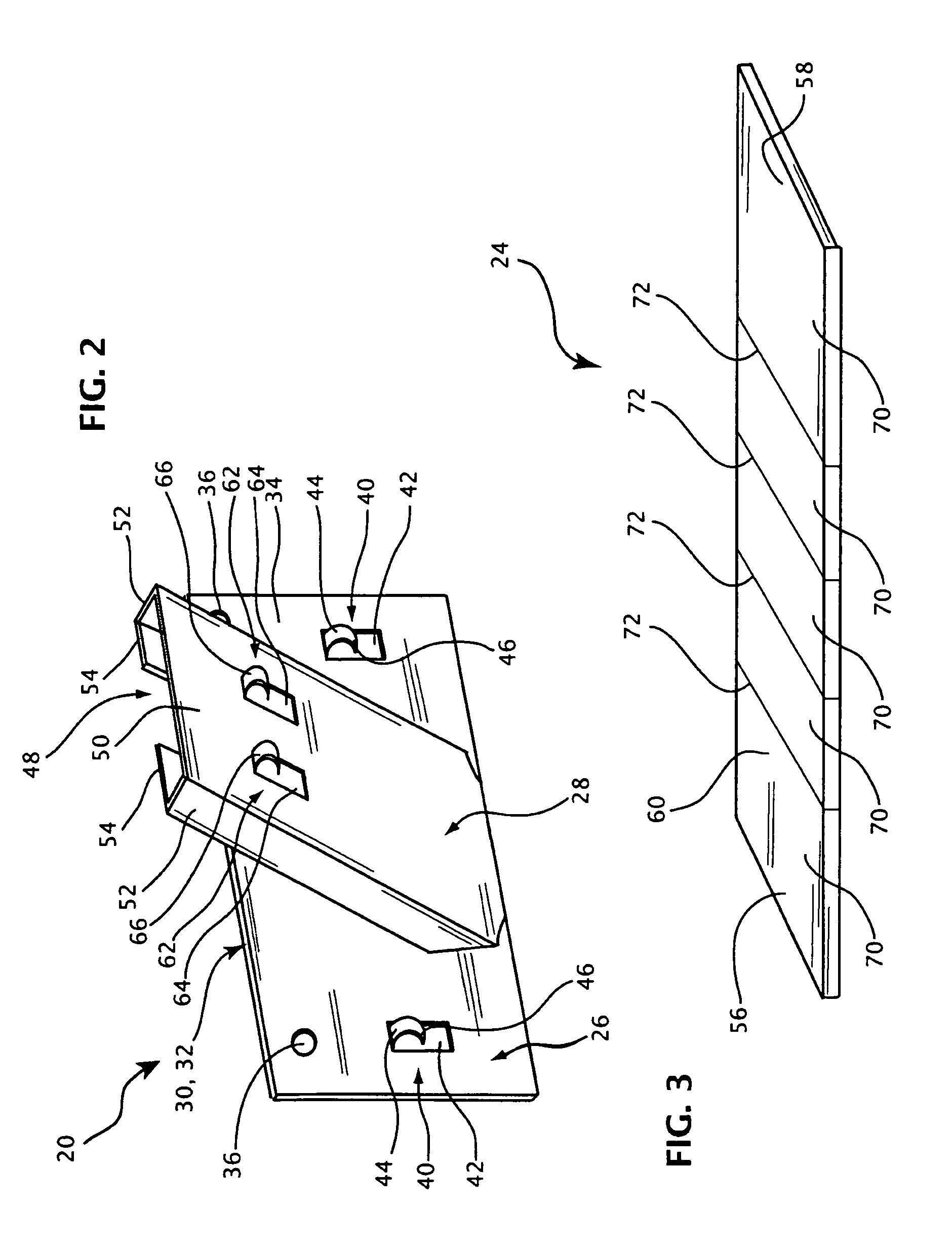

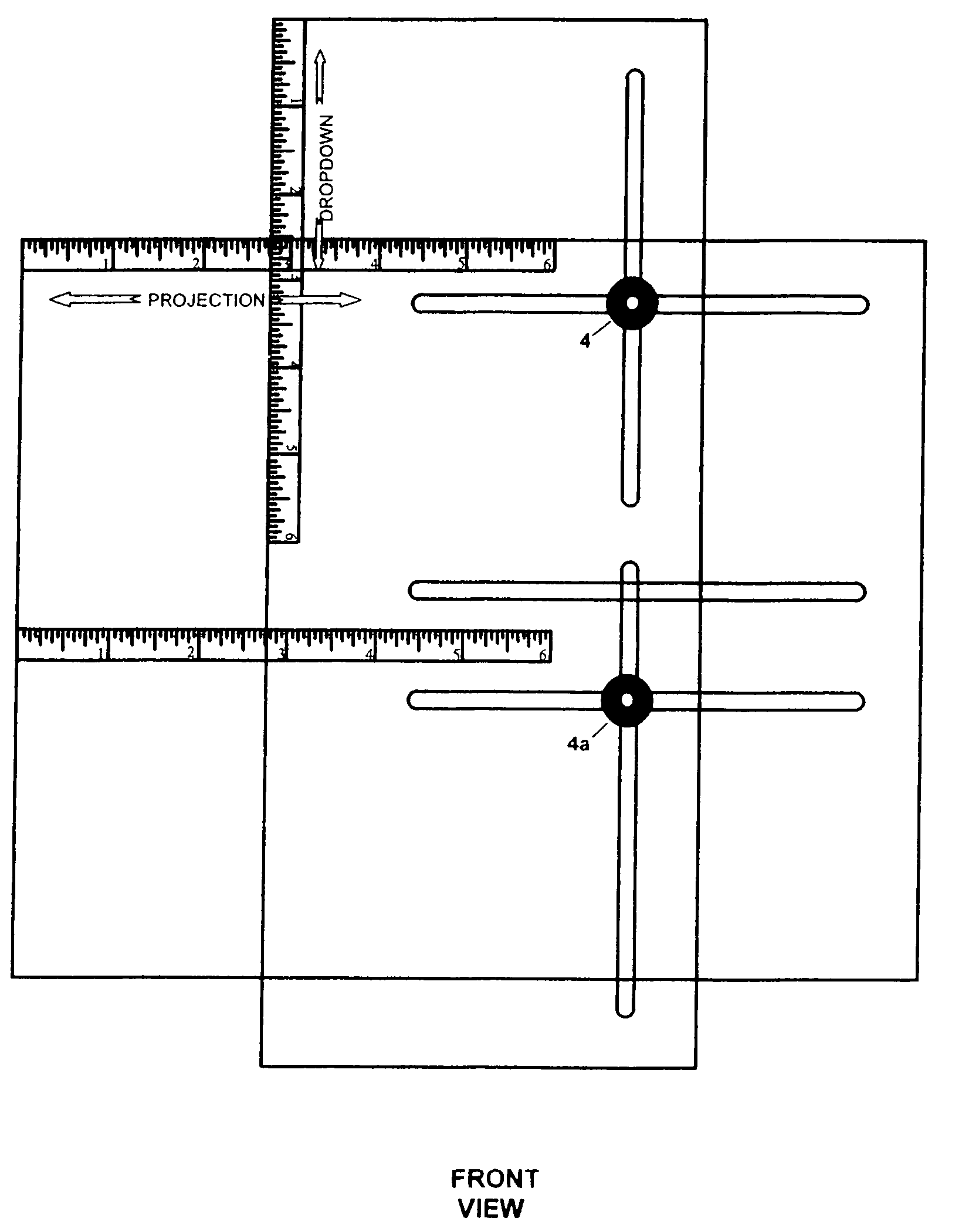

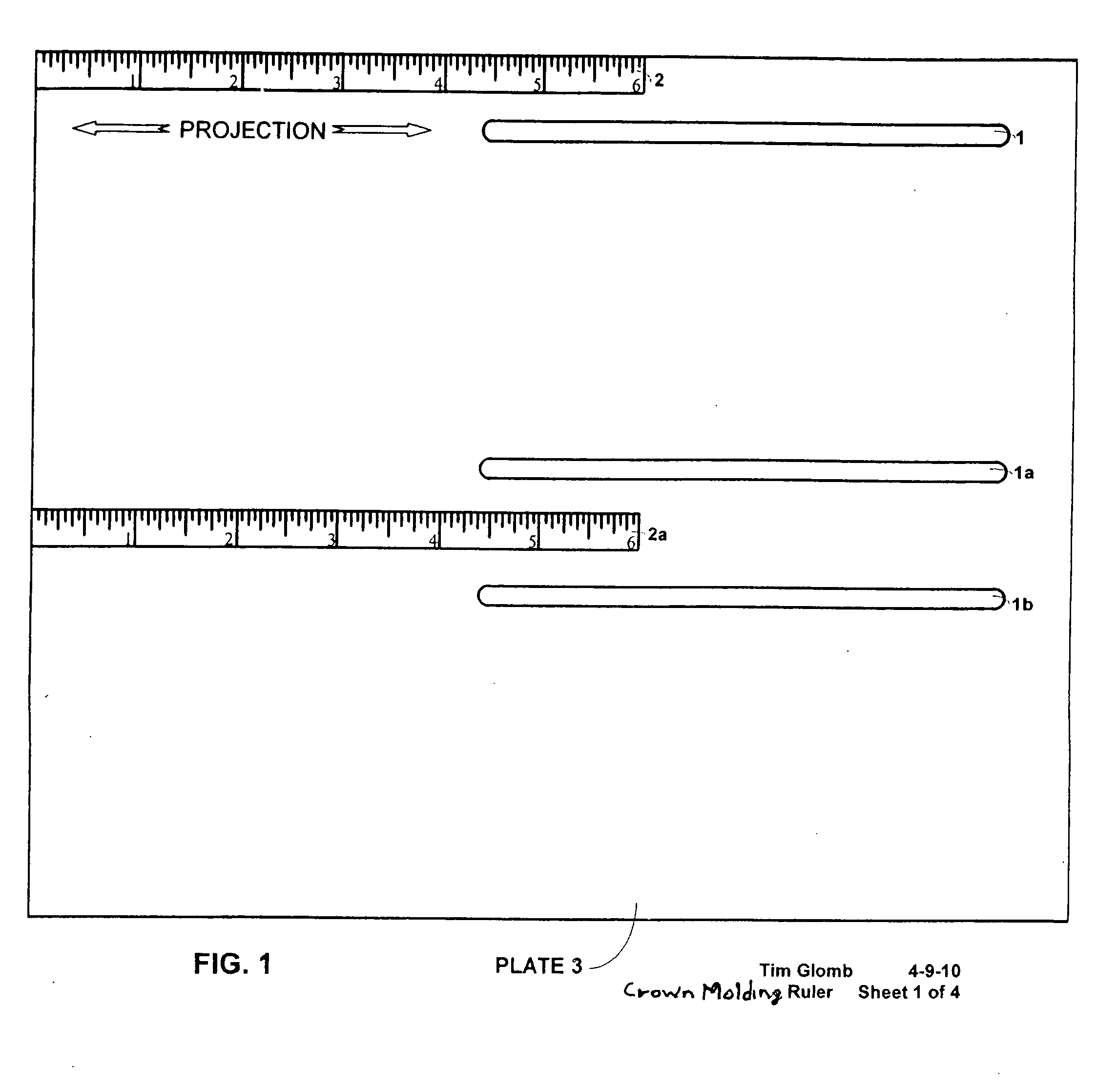

Crown molding ruler

The present invention provides an apparatus and method for measuring and / or marking simultaneously the projection dimension and the dropdown dimension of crown molding.

Owner:GLOMB SR TIMOTHY J

Device for positioning a workpiece to be cut and a method of using the same

InactiveUS20070137450A1Facilitate hand operationPrecise cuttingMetal sawing devicesGuide fencesCrown moldingJoint surface

A device for stabilizing a workpiece, i.e. a crown molding, so as to facilitate cutting angled joint surfaces which are able to be jointed together to form a corner. The device comprises a base plate, a first supporting wall, a second supporting wall and an adjusting device disposed between the base plate and the second supporting wall for adjusting a position of the second supporting wall on a base plane. A method of using the stabilizing device comprises the following steps: to place a stabilizing device on a miter saw, to abut a first supporting wall or a first side edge of the base plate against a fence of the miter saw; after a first cutting is completed, to abut a second supporting wall or a second side edge of the base plate against the fence to perform a second cutting.

Owner:NANJING CHERVON IND

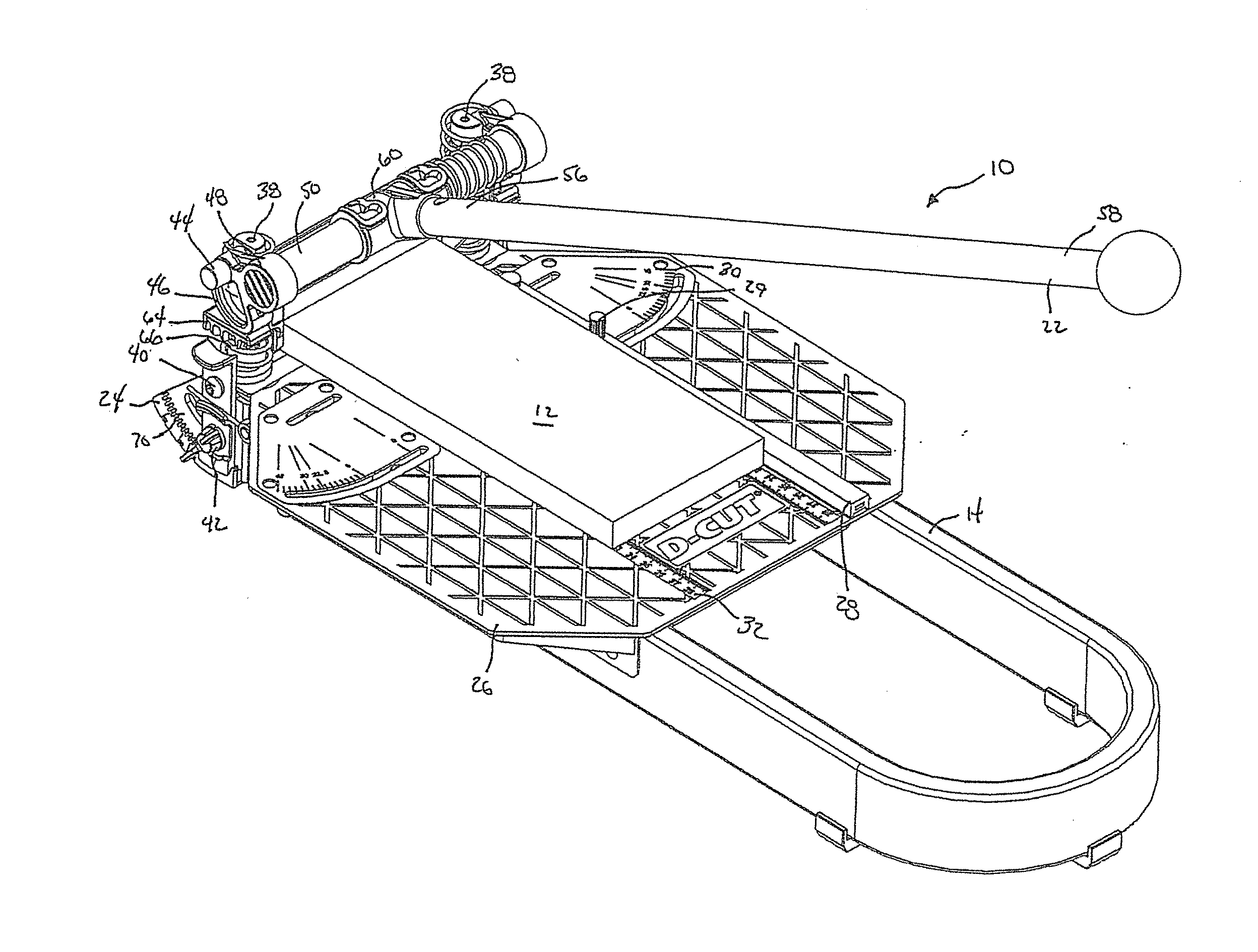

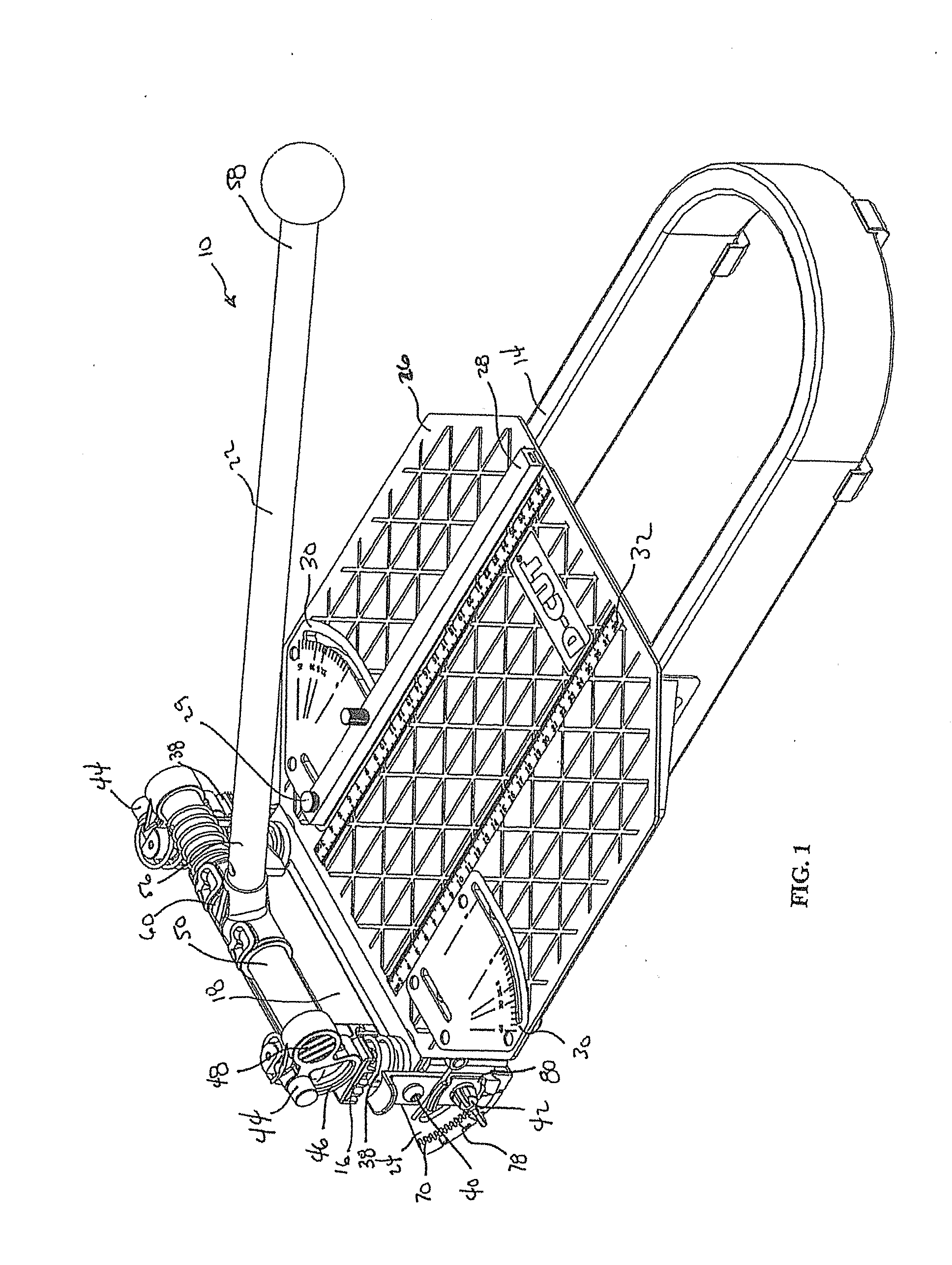

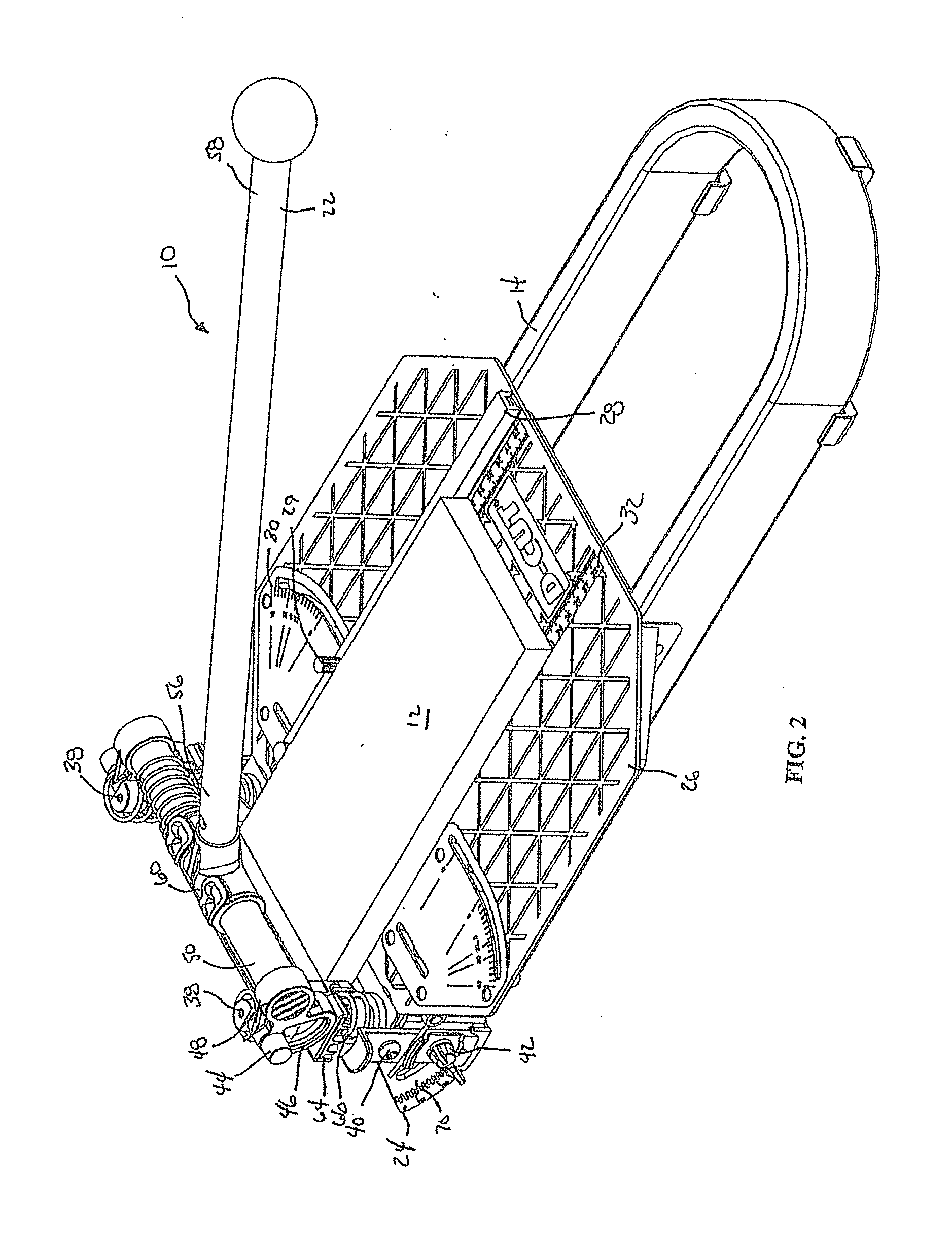

Cutting tool

A cutting tool for cutting flexible building materials, such as, for example, rubber or vinyl baseboards, chair rails and crown molding, at an angle. The cutting tool includes a pair of risers moveably connected near a center of a base with a hinge connection. A blade holder and blade positioned between the risers and moveable from a starting position to a cutting position. The blade can be set to a range of angles relative to the base by rotating the risers and locking the risers in an angle relative to the base.

Owner:D CUT PROD

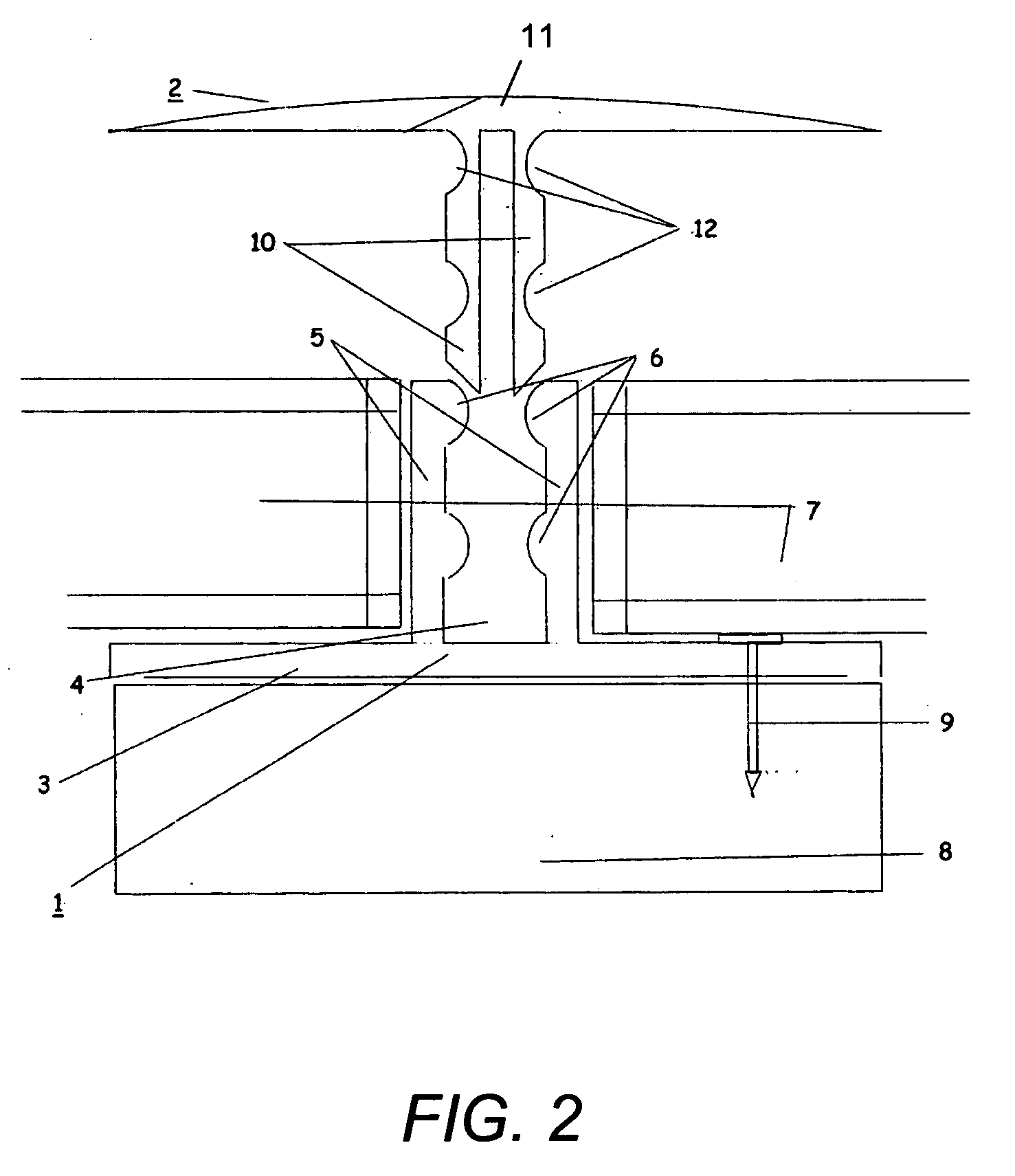

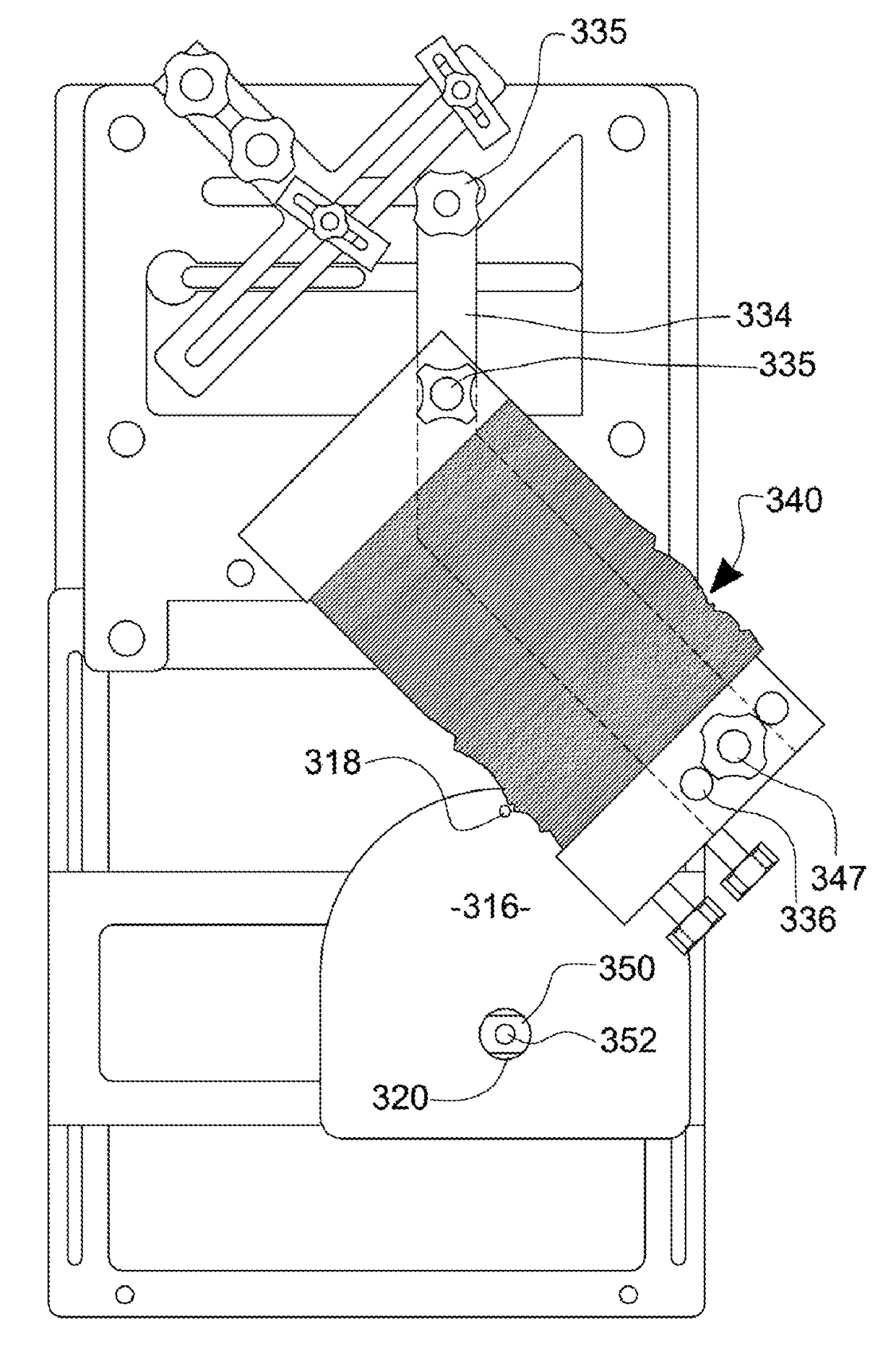

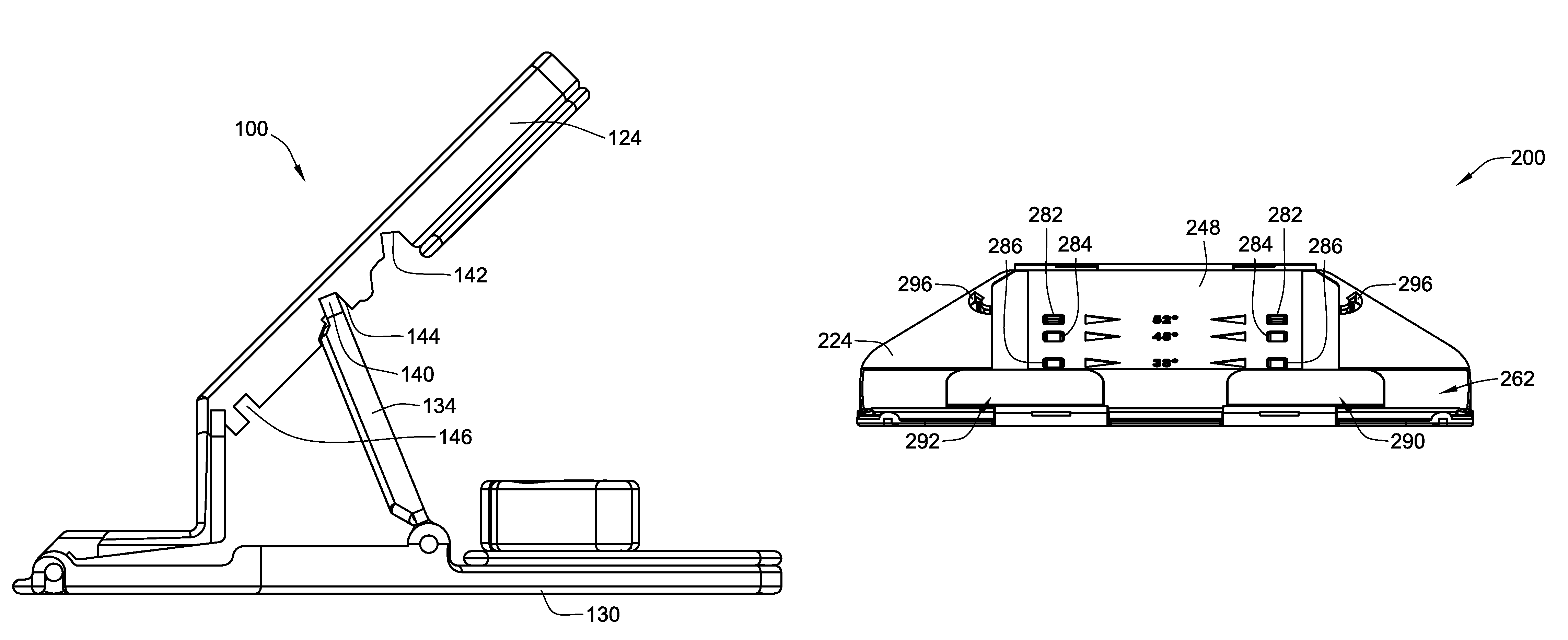

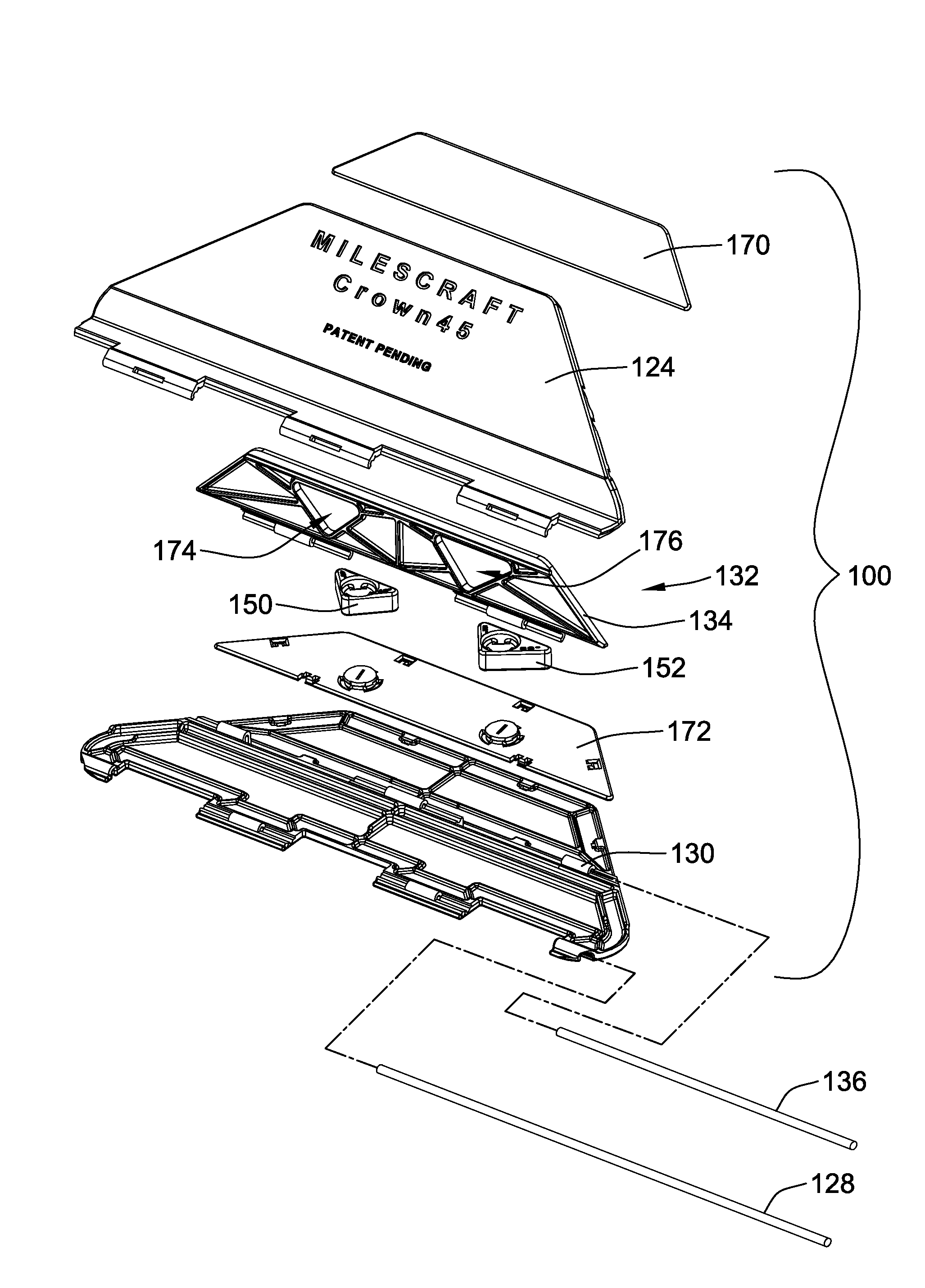

Crown molding cutting apparatus and method

ActiveUS7930961B2Help positioningMetal sawing devicesPrecision positioning equipmentCrown moldingAngular degrees

A method and apparatus are provided, for positioning a work piece, such as a piece of crown molding, through use of an apparatus including a work piece support plate pivotably attached along a pivot axis to a base. The base is adapted to rest on a horizontal reference plane, such as the table of a meter saw, for pivoting motion of the support plate about the pivot axis to a desired angle with respect to the base, while the pivot axis is simultaneously positioned to extend substantially parallel to a longitudinal line of intersection between a horizontal and a vertical reference plane, established by the table and fence of the meter saw, to hold the work piece at a desired tilt angle with respect to the vertical reference plane, so that the work piece may be cut in substantially the same orientation as it will be mounted.

Owner:NOMIS LLC

Crown Molding Cutting Apparatus And Method

ActiveUS20080276779A1Help positioningMetal sawing devicesPrecision positioning equipmentCrown moldingHorizontal and vertical

A method and apparatus are provided, for positioning a work piece, such as a piece of crown molding, through use of an apparatus including a work piece support plate pivotably attached along a pivot axis to a base. The base is adapted to rest on a horizontal reference plane, such as the table of a mitre saw, for pivoting motion of the support plate about the pivot axis to a desired angle with respect to the base, while the pivot axis is simultaneously positioned to extend substantially parallel to a longitudinal line of intersection between a horizontal and a vertical reference plane, established by the table and fence of the mitre saw, to hold the work piece at a desired tilt angle with respect to the vertical reference plane, so that the work piece may be cut in substantially the same orientation as it will be mounted.

Owner:NOMIS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com