Crown molding with improved mounting surfaces

a technology of mounting surfaces and crown molding, which is applied in the direction of fixed installation, lighting and heating equipment, walls, etc., can solve the problems of failing to teach the lateral groove system used with the prior art longitudinal grooves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The above described drawing figures illustrate the described apparatus and its method of use in at least one of its preferred, best mode embodiment, which is further defined in detail in the following description. Those having ordinary skill in the art may be able to make alterations and modifications what is described herein without departing from its spirit and scope. Therefore, it must be understood that what is illustrated is set forth only for the purposes of example and that it should not be taken as a limitation in the scope of the present apparatus and method of use.

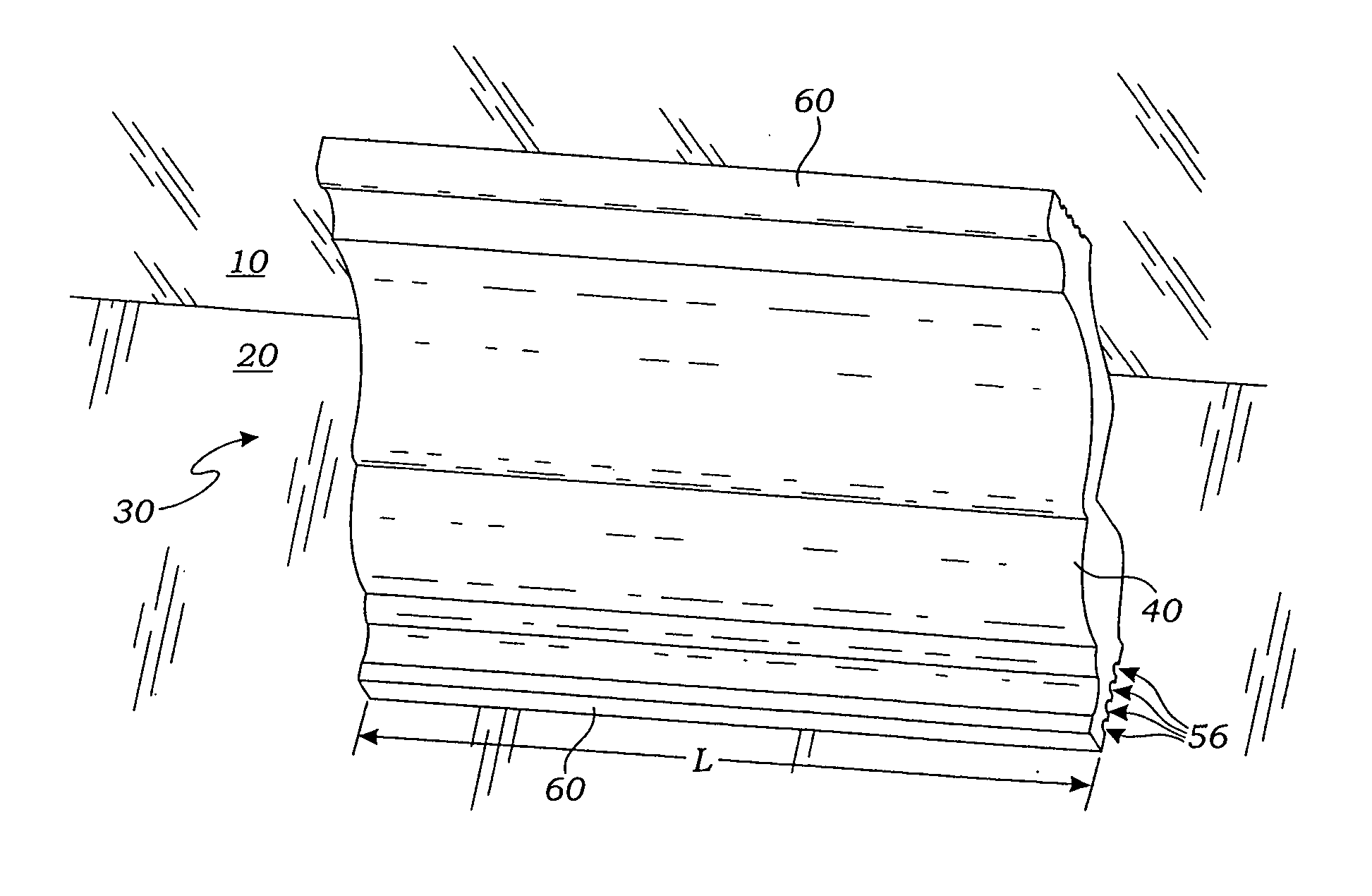

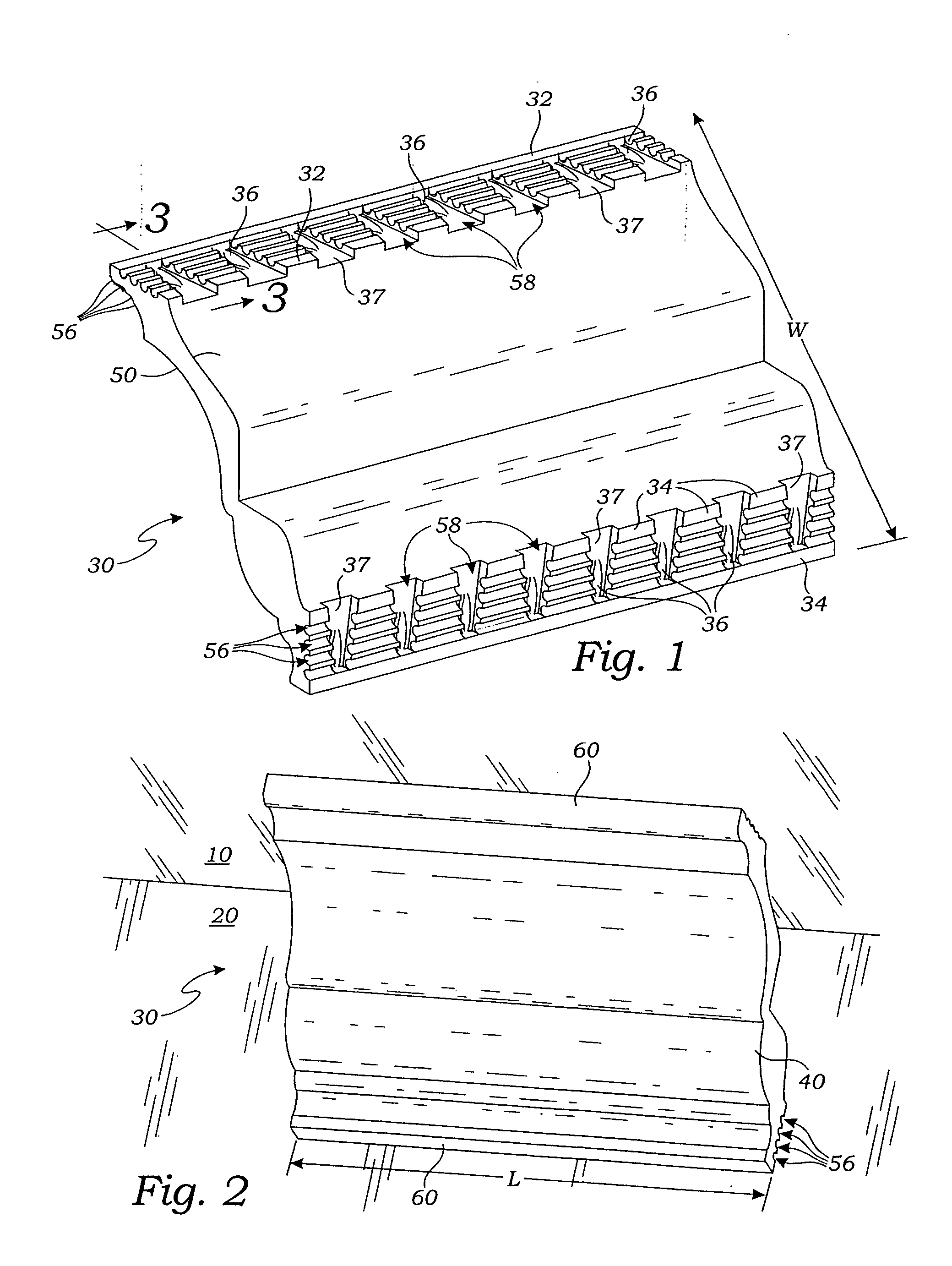

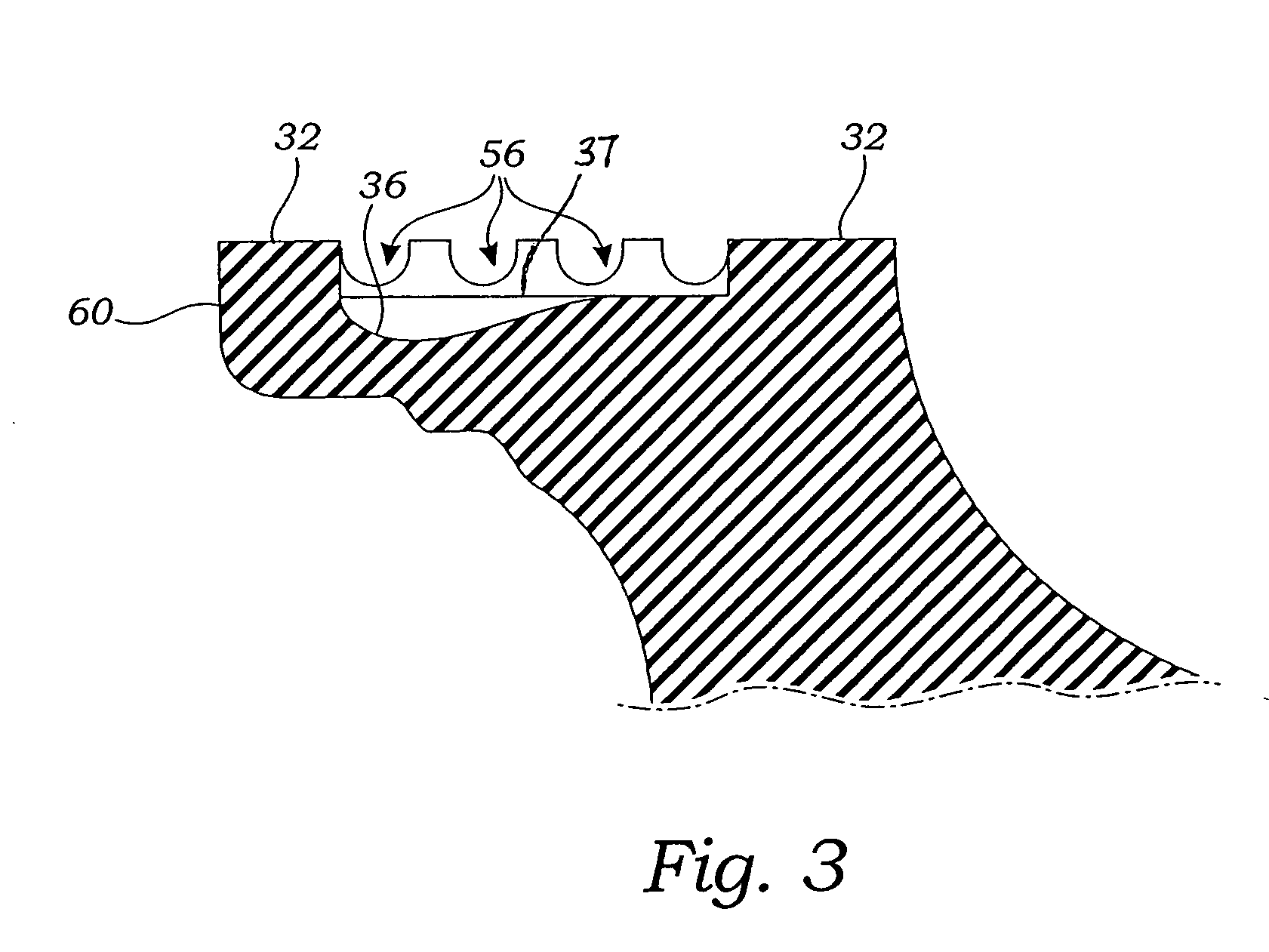

[0030] The apparatus described below and shown in the accompanying drawing figures is a crown molding which is mounted at the intersection of a ceiling surface 10 and an adjacent wall surface 20 of a room, as is well known in the art. The apparatus is preferably a molded unit 30 made of plaster or plastic materials and having a length “L”, shown in FIG. 2, establishing a longitudinal direction of the unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com