Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

119 results about "Cork stopper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

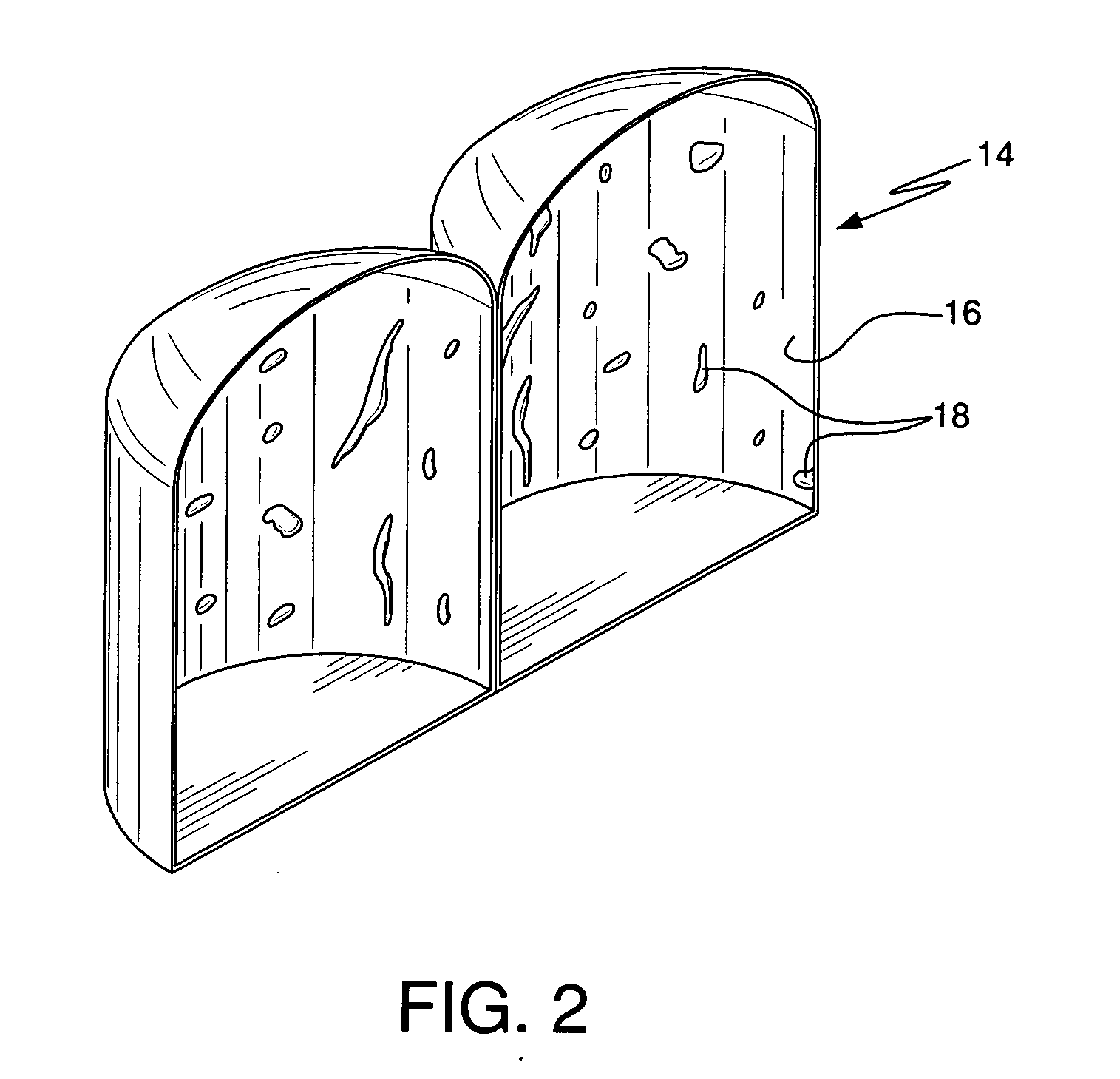

Modified barrier layers in liners for container closures, capable of providing varible, controlled oxygen ingress

InactiveUS20090123766A1Shortened shelf-life issuesFacilitated DiffusionDomestic sealsBottlesMetal foilCork stopper

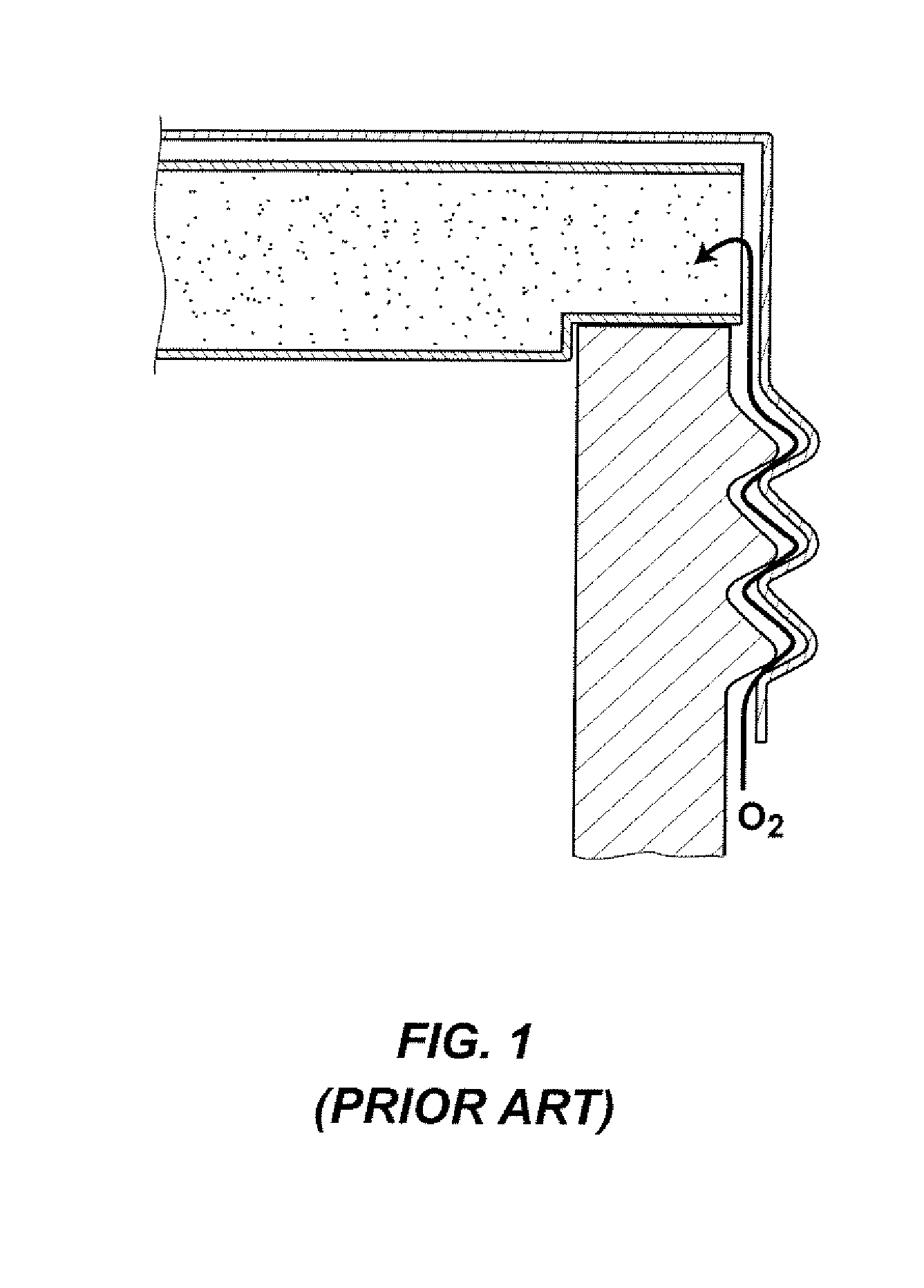

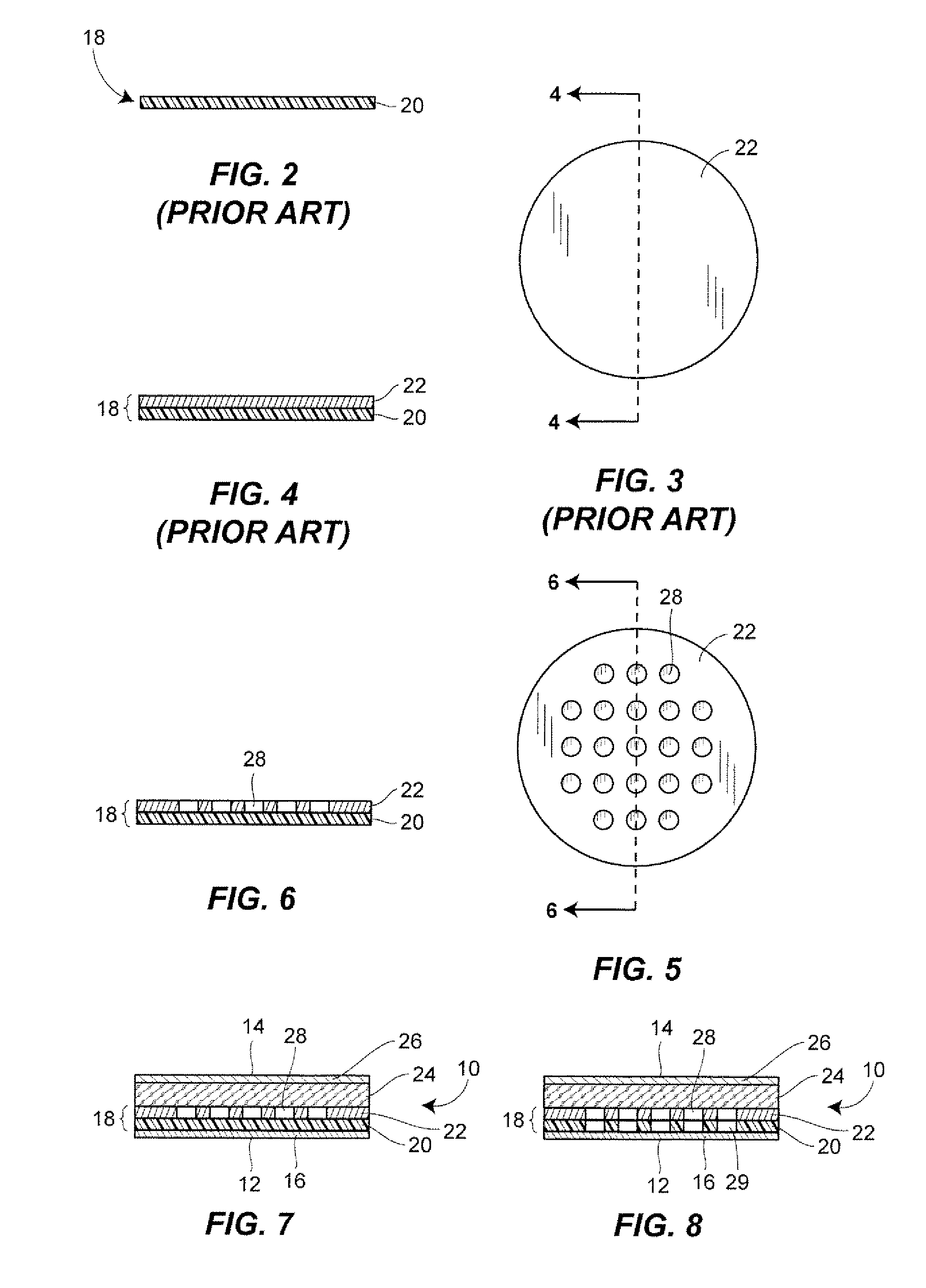

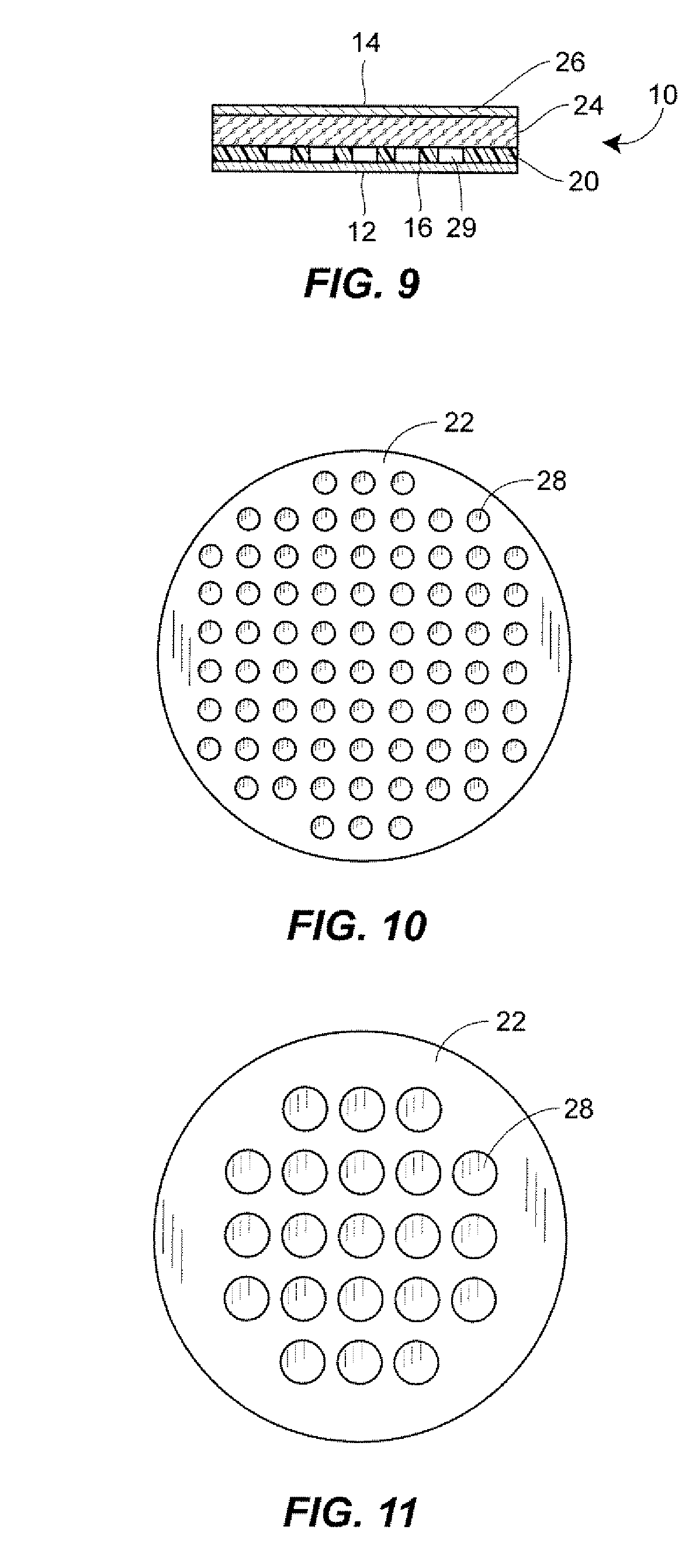

A liner for bottle caps and method for controlling the oxygen diffusion rate of closures. The oxygen barrier layer of a laminated cap liner or seal over cork stopper for a container closure, such as a metal foil or PVDC, is provided with perforations, formed, for example, by laser. Perforations permit an increased oxygen diffusion rate as compared to conventional barrier layers having imperforate metal foil, while permitting the liner or seal to retain a lower oxygen diffusion rate as compared to other conventional liners having no oxygen barrier. The oxygen diffusion rate can be further adjusted by changing the cumulative area of perforations in the metal foil of the barrier laminate, by varying the number of perforations, or by varying the size of the individual perforations.

Owner:G3 ENTERPRISES

Wine cap

InactiveUS6029836ASlow venting of gas pressureAvoid explosionCapsPower operated devicesWine bottleEngineering

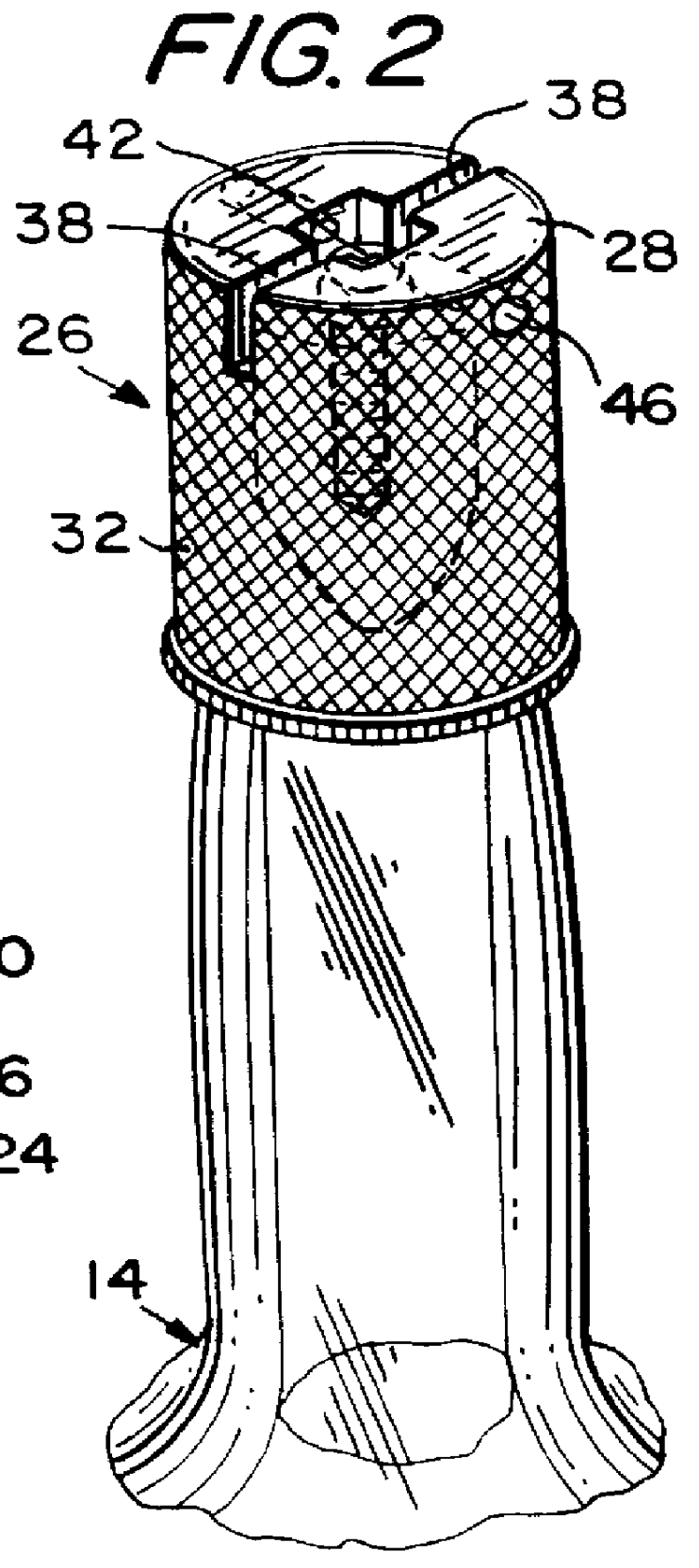

A cap device, particularly for a wine bottle, is disclosed as including a cap having a recessed top opening for receiving a screw for threadable insertion into the cork of the wine bottle. The recess at the top of the cap is of basically square shape with two recess extensions for receiving a butter knife, or the like, for turning the cork and screw as a unit and thereby unscrewing the cap, which is threadably attached to the outside of the neck of the wine bottle. The threading direction of the threads of the cap and neck of the wine bottle are opposite to the threading direction between the cork and the screw. Additionally, the cap is structured to extend a distance above the extent of the cork in the neck of the wine bottle, the cork is bullet-shaped and channels are defined transverse to the threads extending outwardly of the neck of the wine bottle, in order to allow the escape of compressed carbon dioxide in a sparkling wine or champagne bottle as the cap is unscrewed and the cork lifted. The top of the screw defines a spherical projection in order to assist guiding the cork in, with respect to the recess of the cap, when reinserting the cork after use.

Owner:LIGERAS ACHILLES P

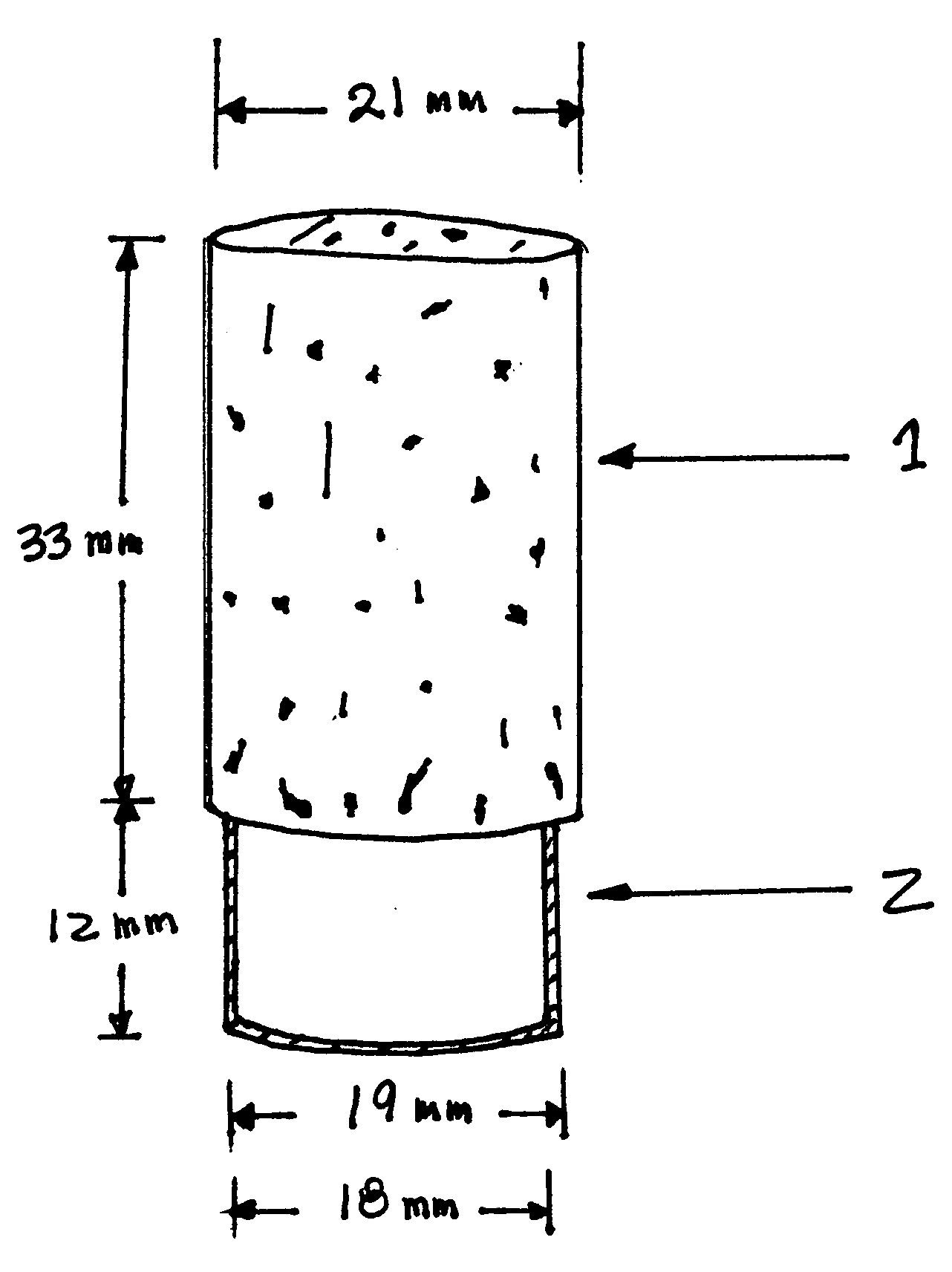

Synthetic Cork Stopper

InactiveUS20090253818A1Good shape followabilityExcellent gas-barrier propertyClosuresPolymer scienceFoaming agent

A synthetic cork stopper which has excellent gas-barrier properties and is satisfactory in sealing properties and suitability for opening. The synthetic cork stopper is obtained by foaming a composition including (a) an isobutylene-based block copolymer comprising a polymer block comprising isobutylene as its main component and a polymer block formed from a cationic polymerizable monomer ingredient in which isobutylene is not its main component; and a foaming agent.

Owner:KANEKA CORP

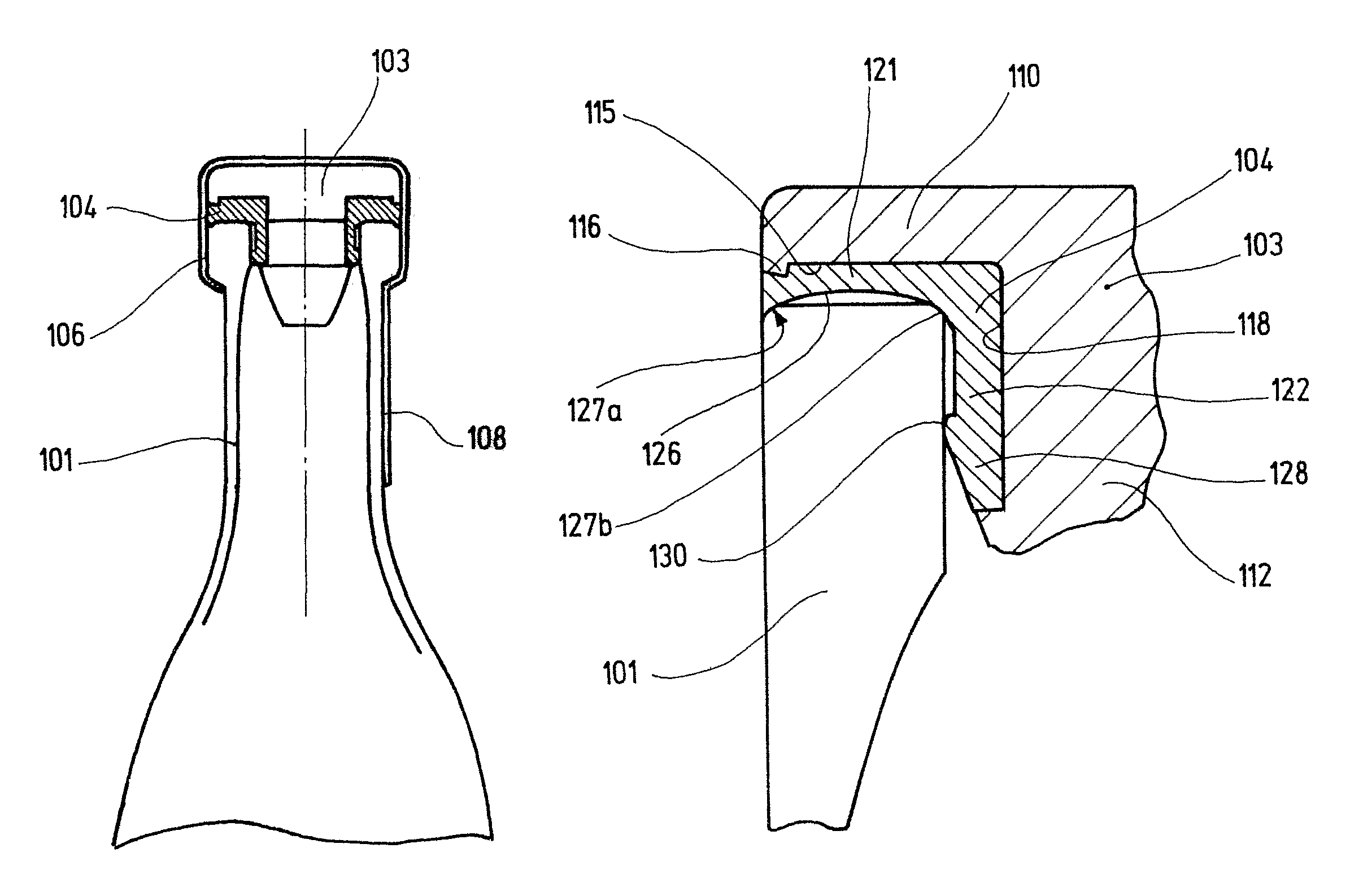

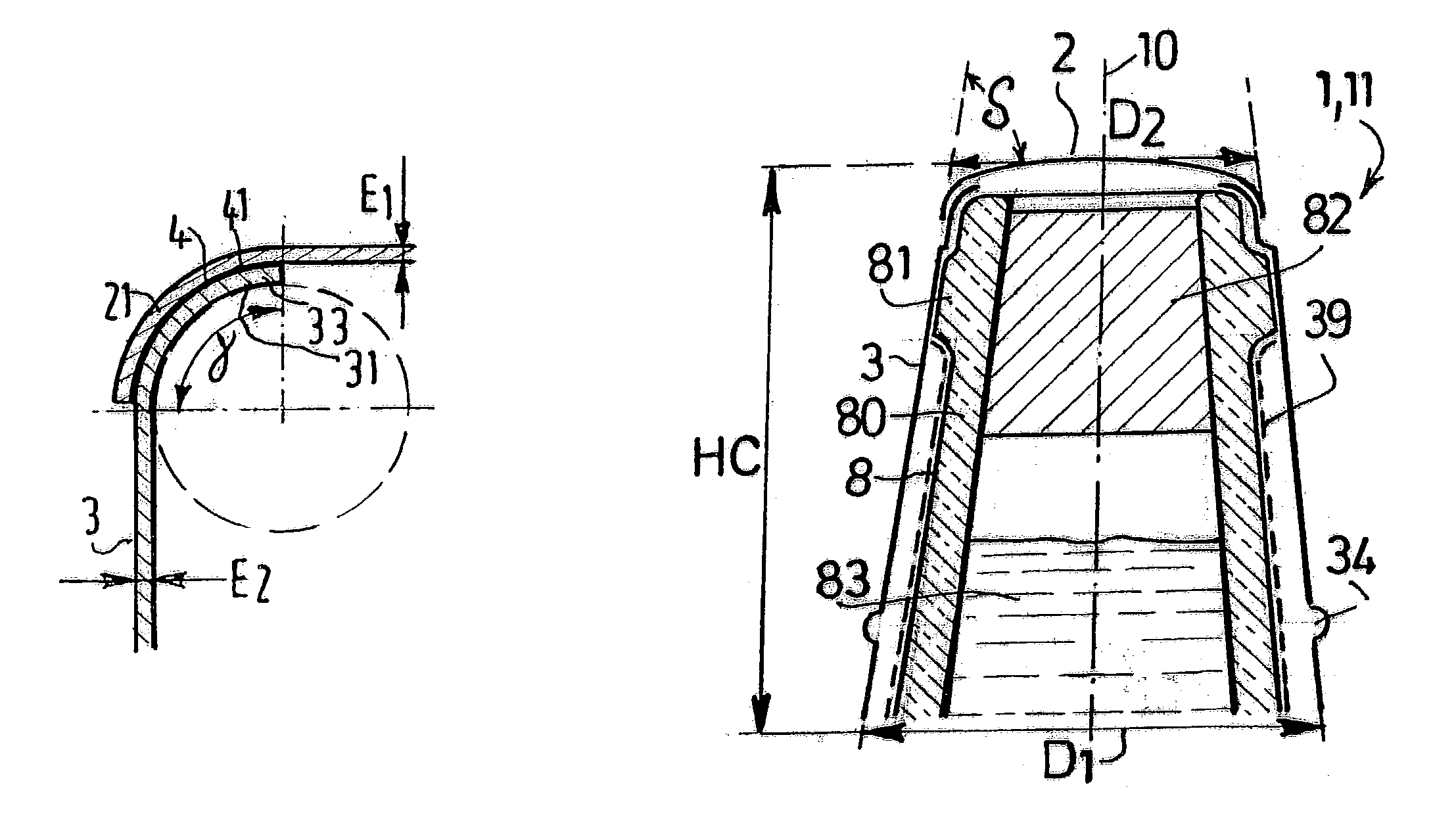

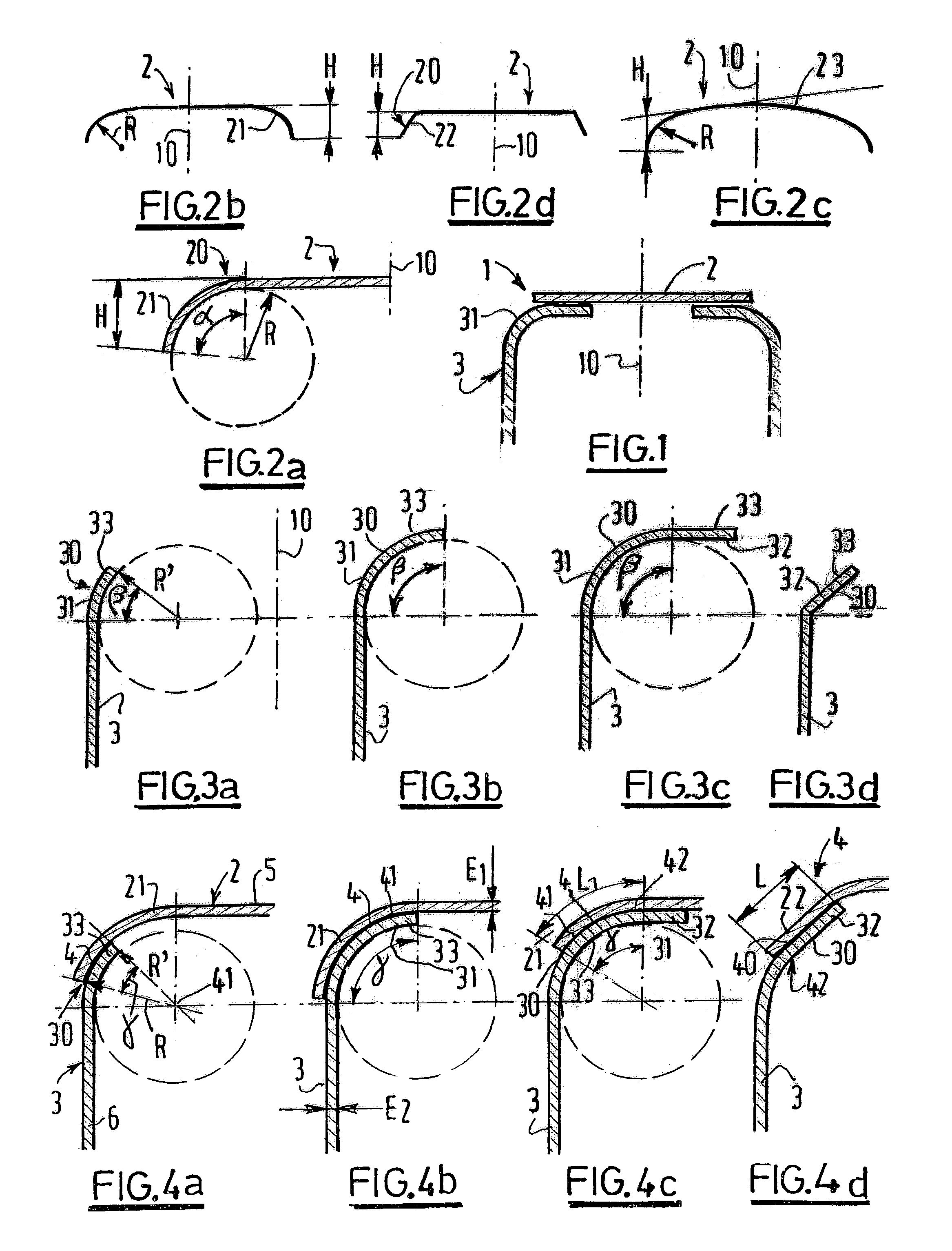

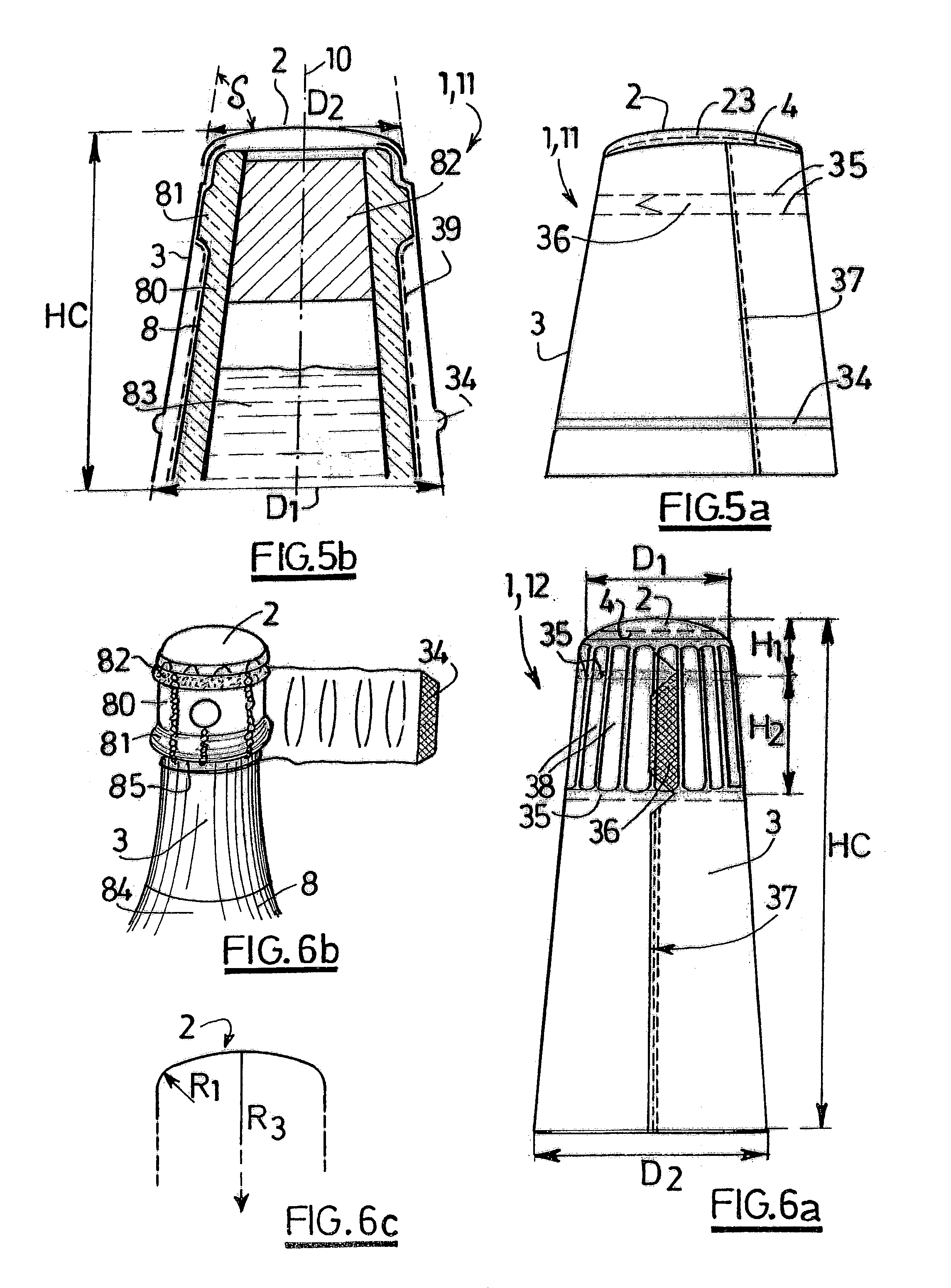

Container, particularly a beverage bottle

ActiveUS8573424B2Long maintenance periodSafe and reliable storageCapsClosure using stoppersPlastic materialsWine bottle

Owner:ALCOA DEUTLAND

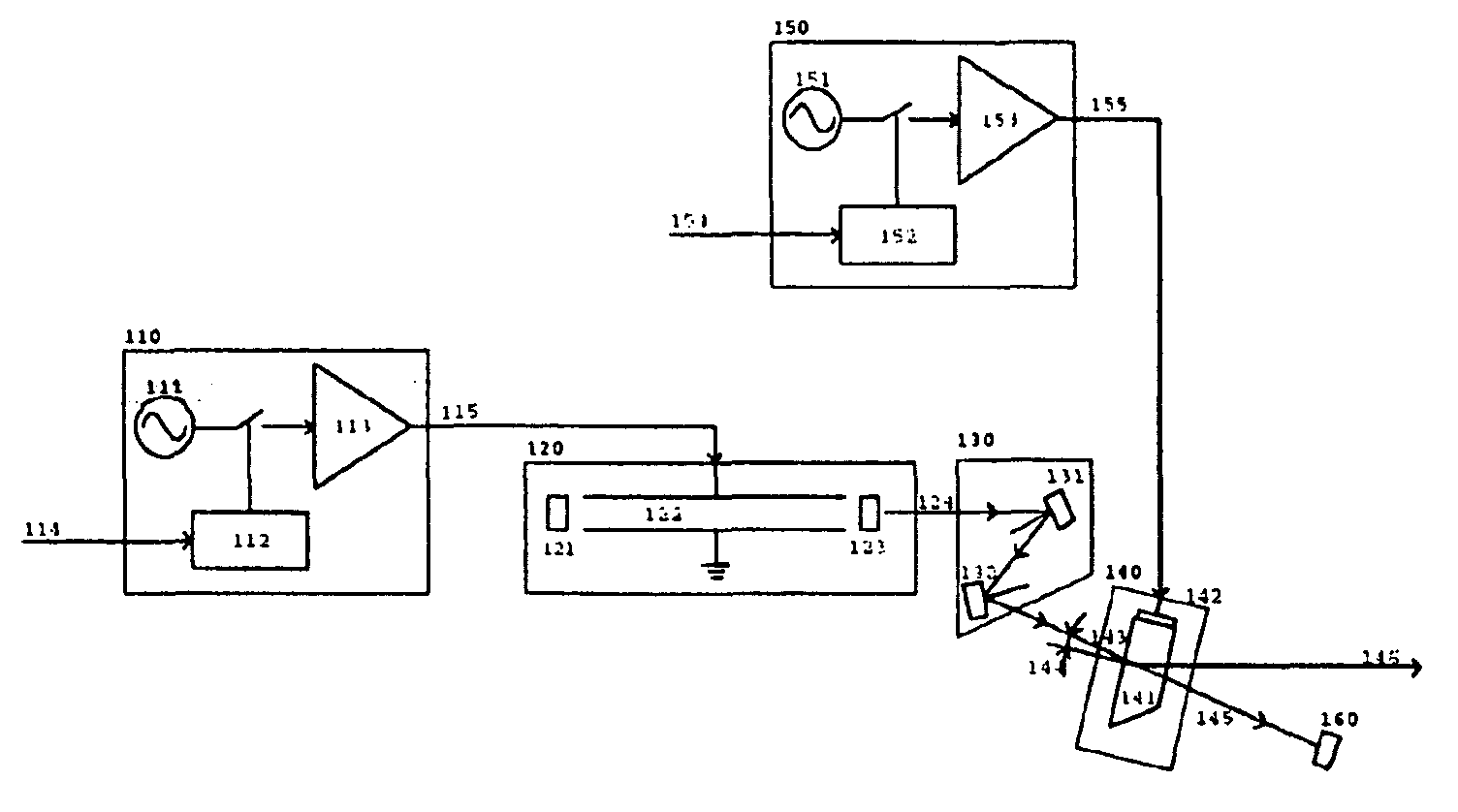

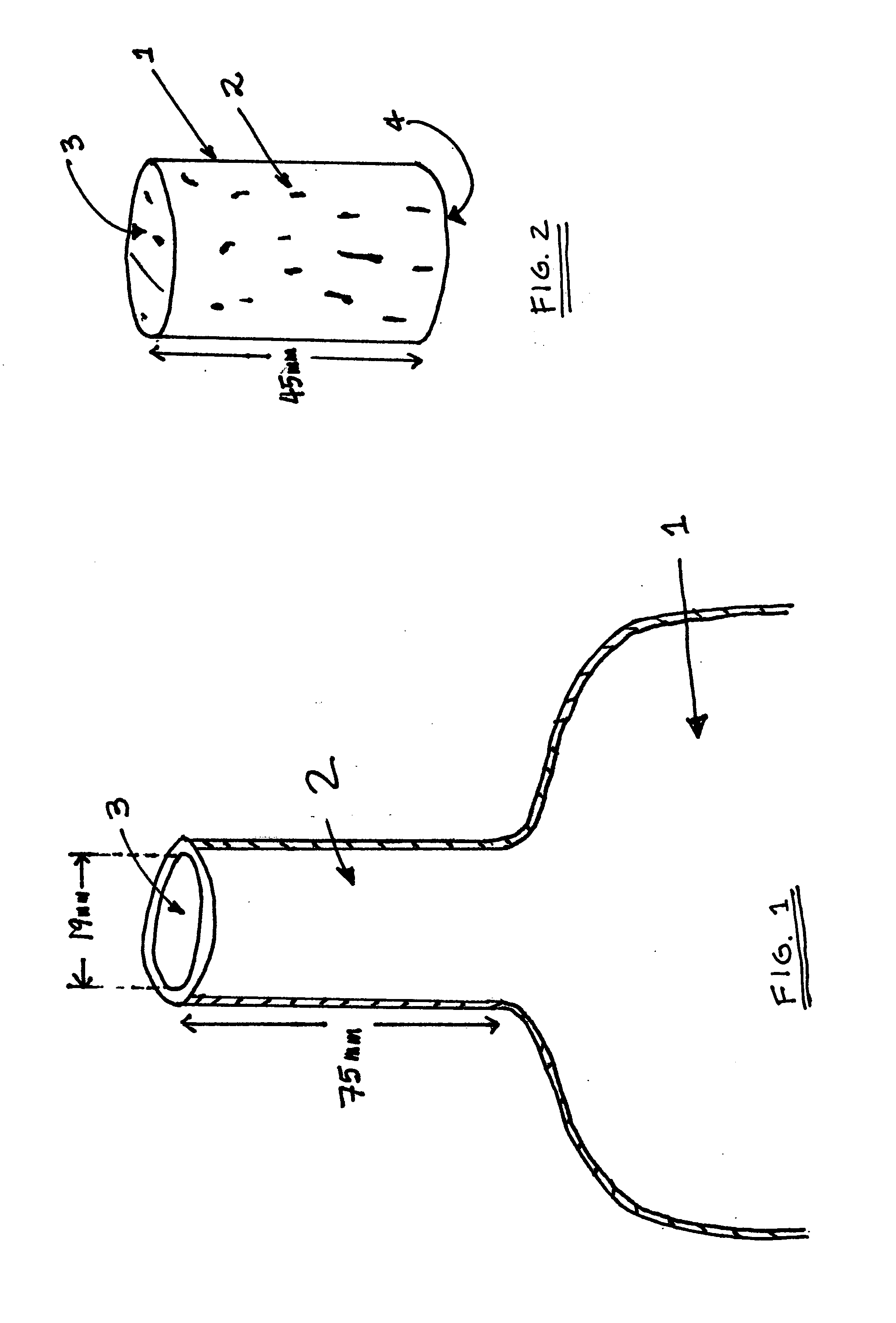

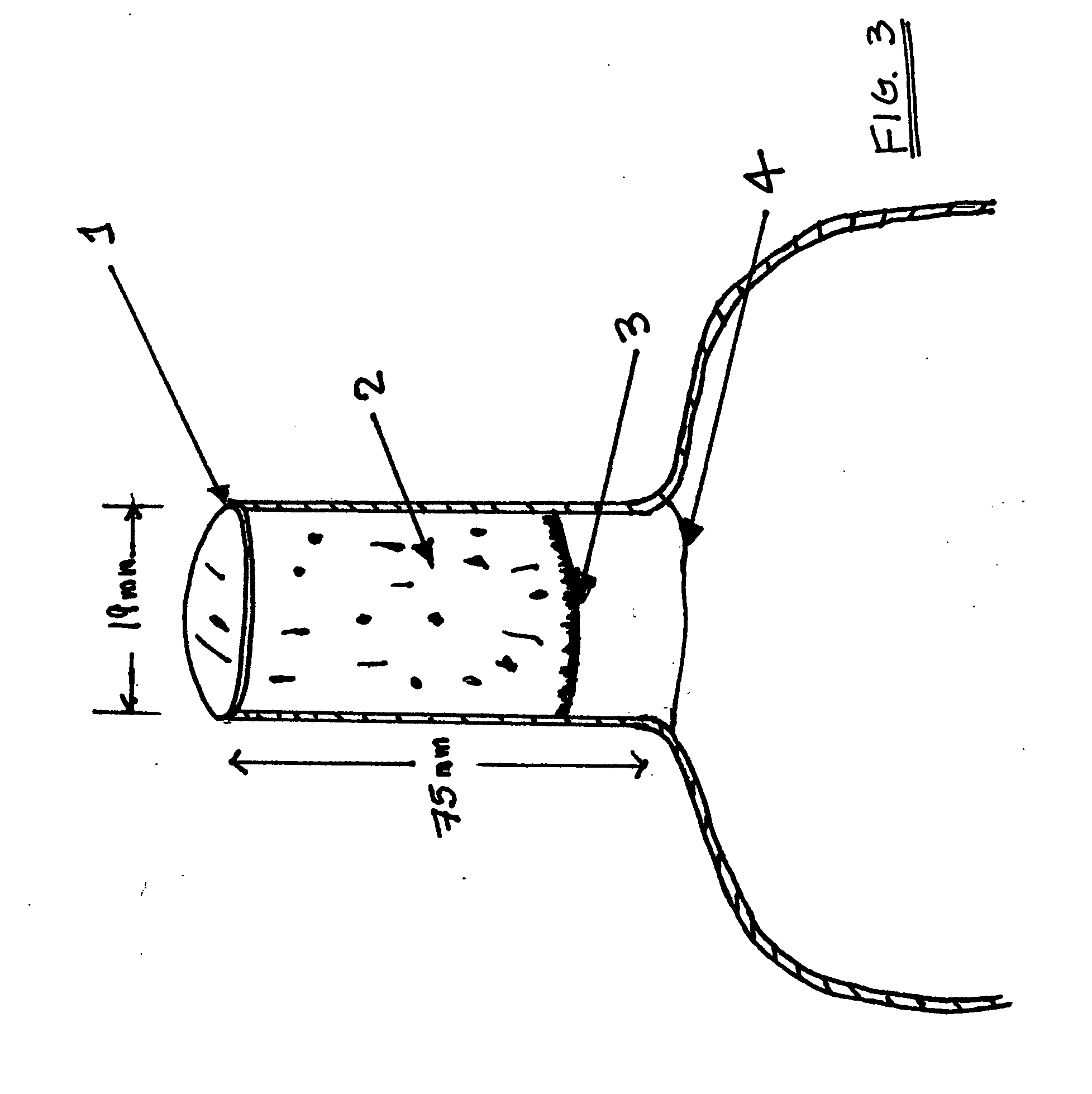

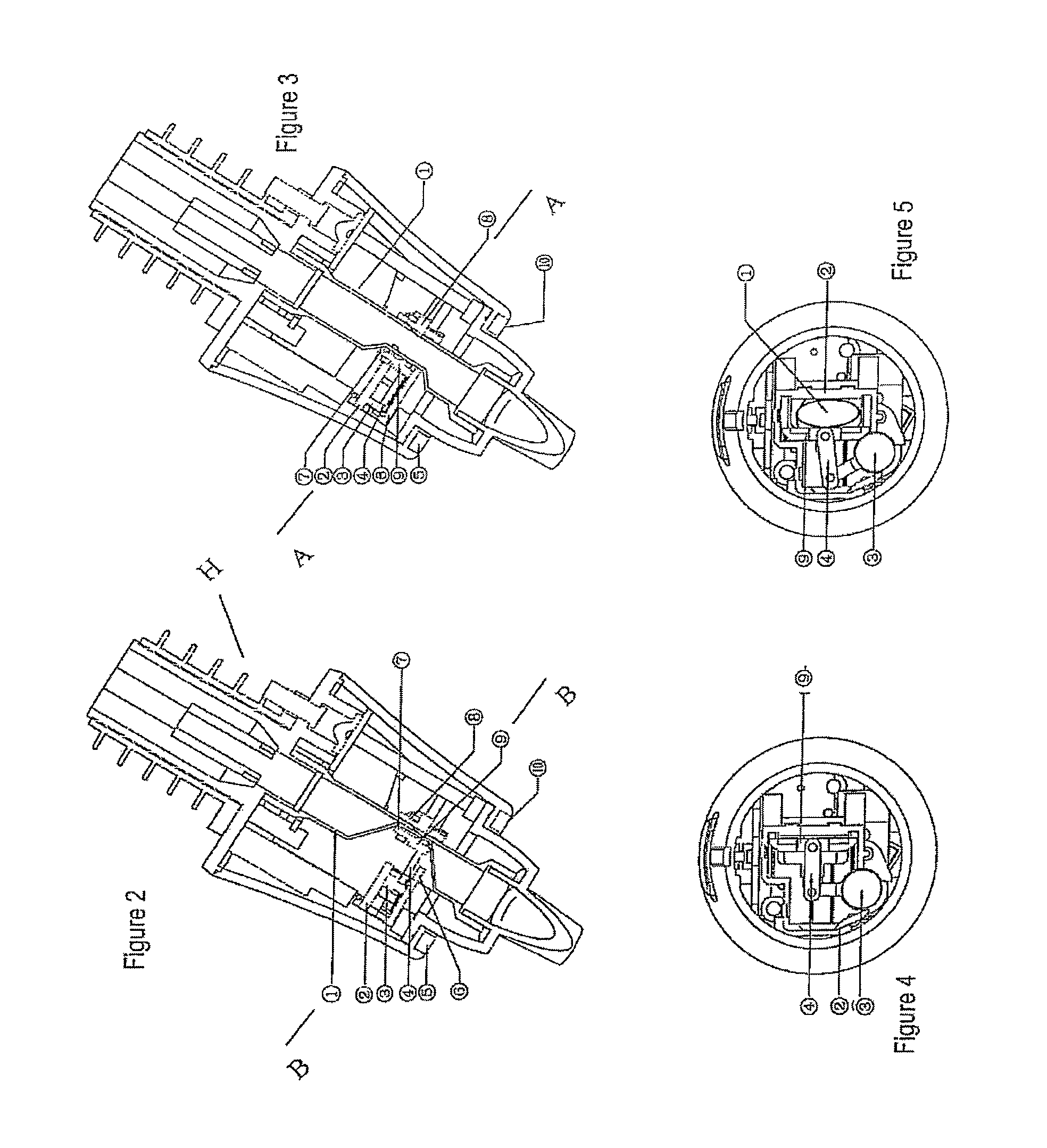

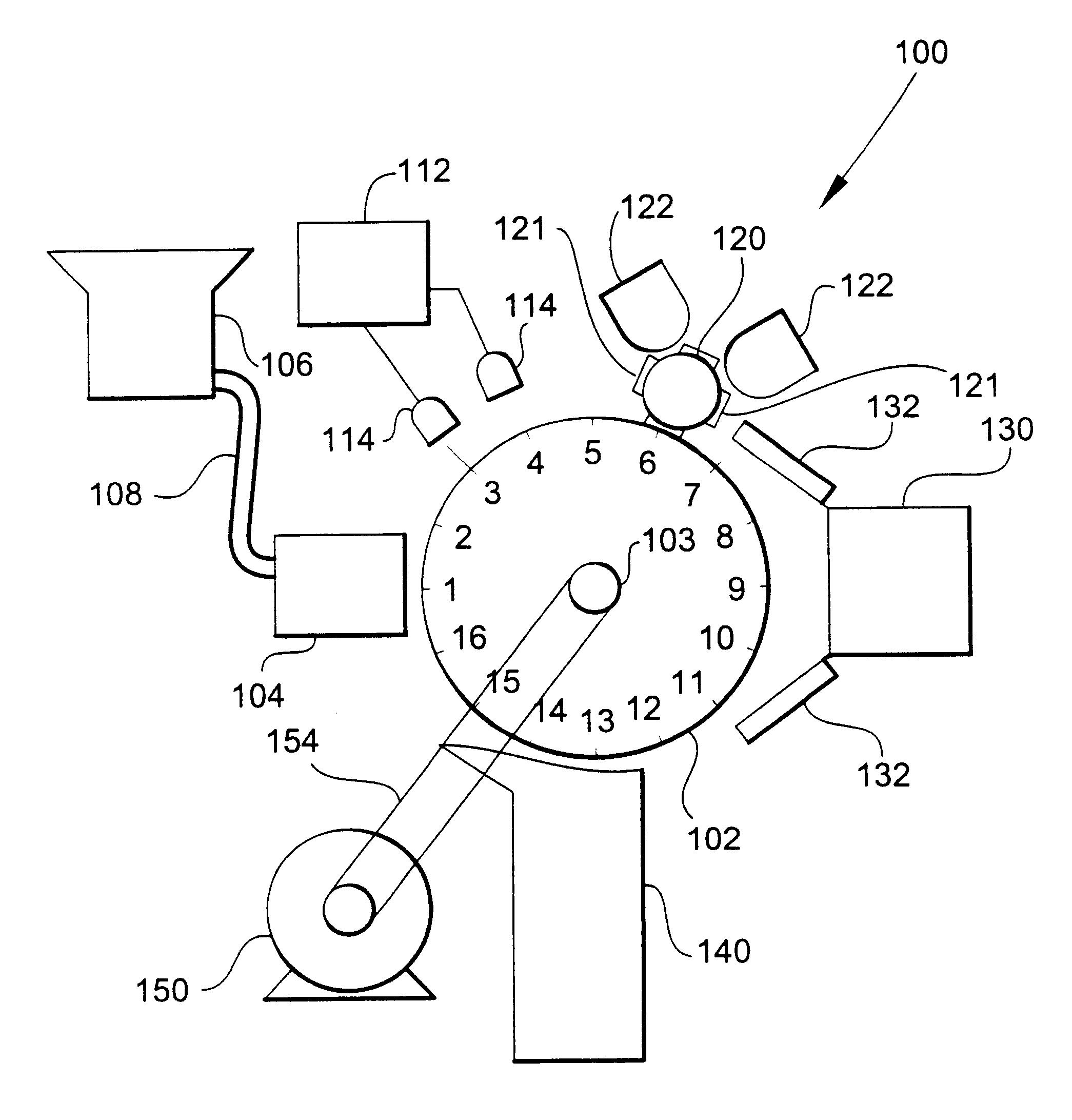

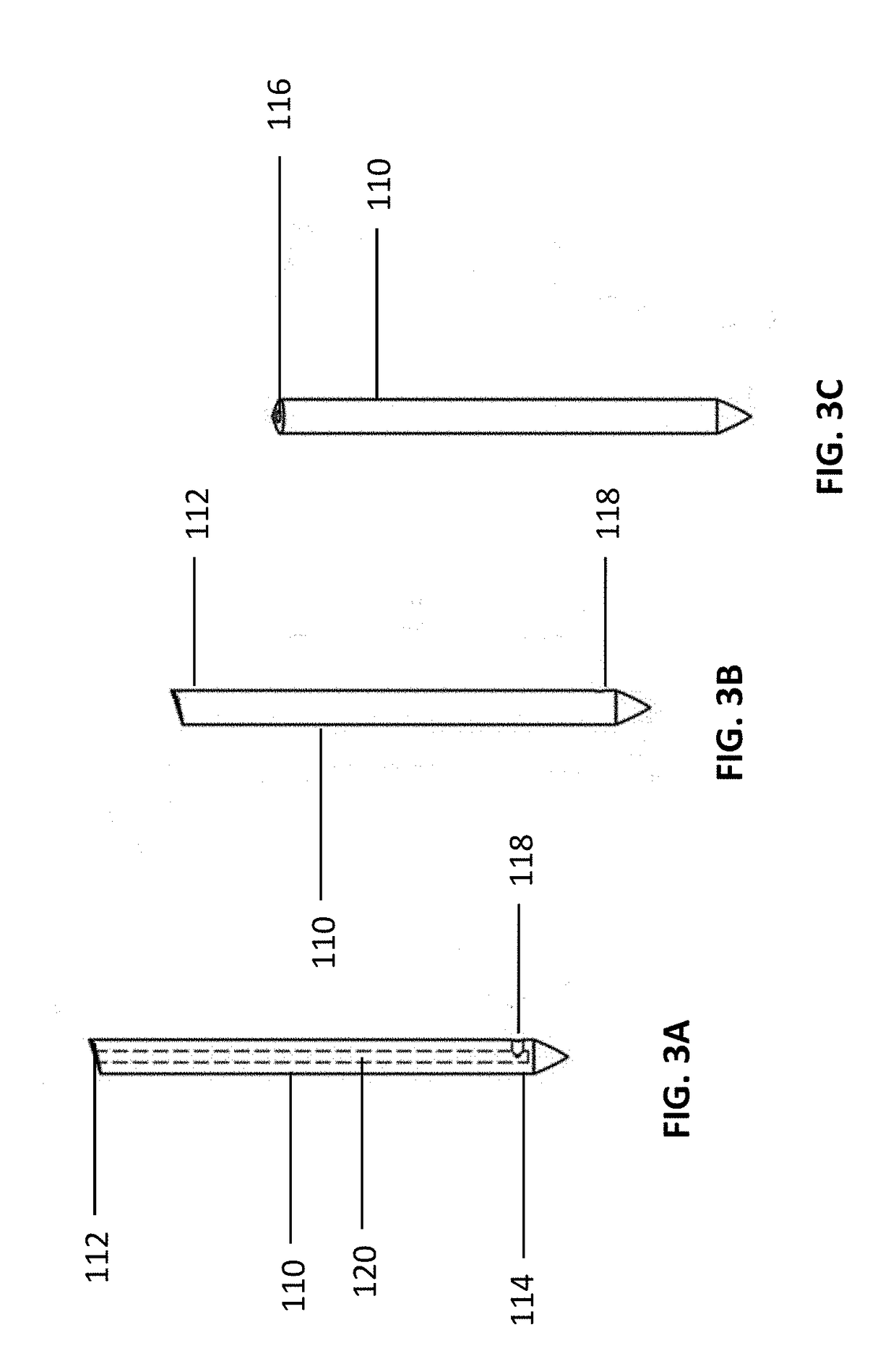

Method and device for rotational marking

ActiveUS20100283825A1Easy to insertEasy extractionRecording apparatusElectrode and associated part arrangementsSynthetic materialsOptical correction

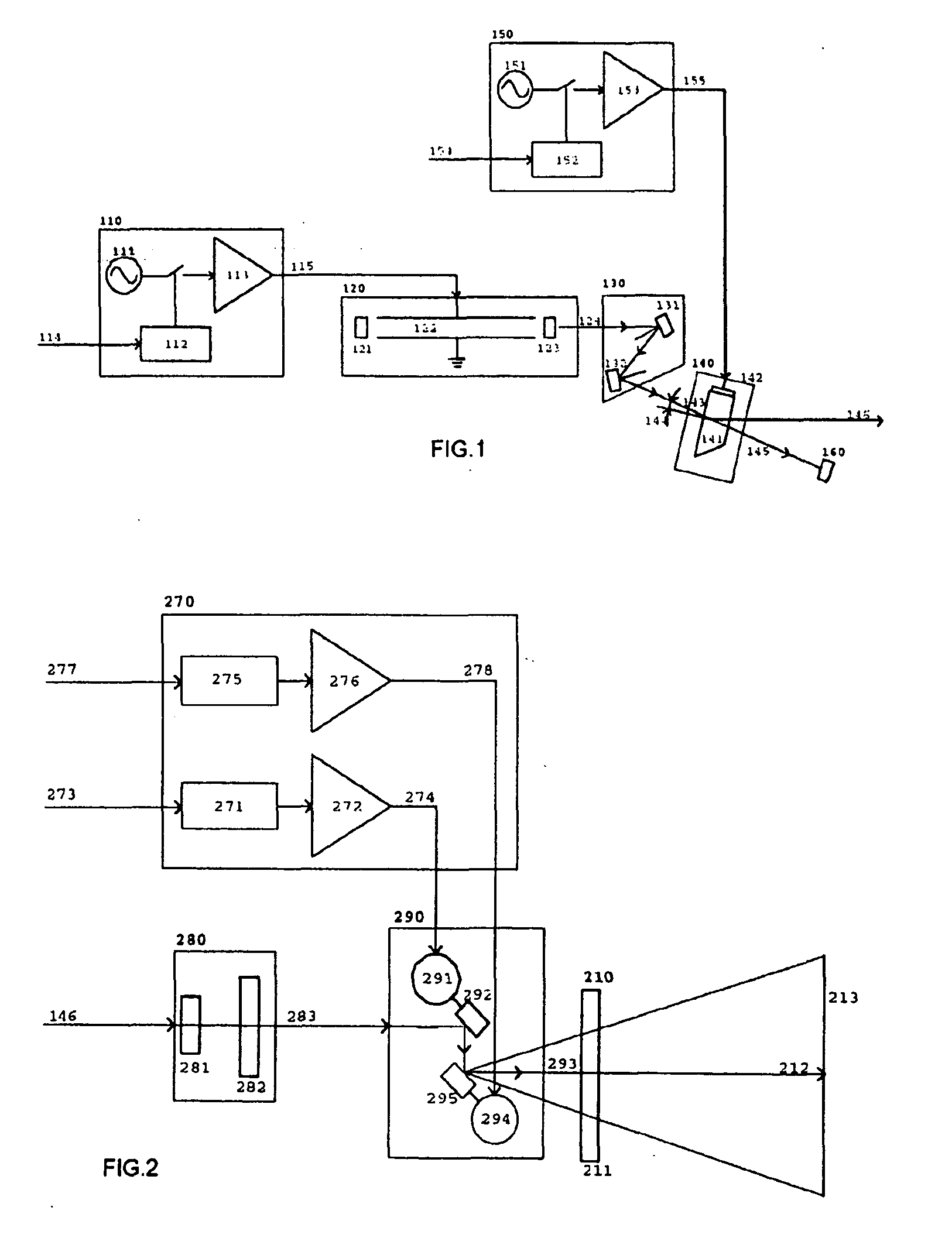

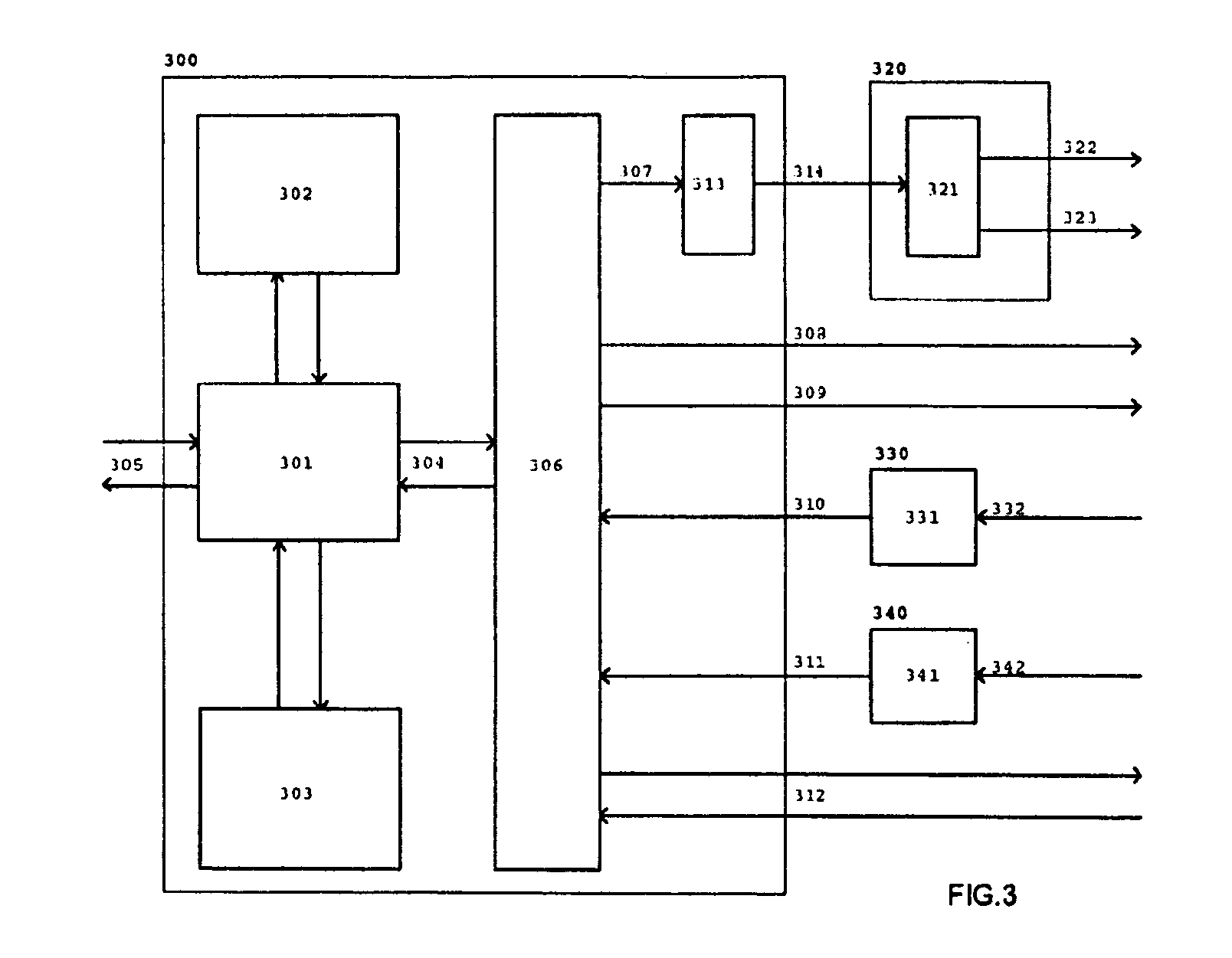

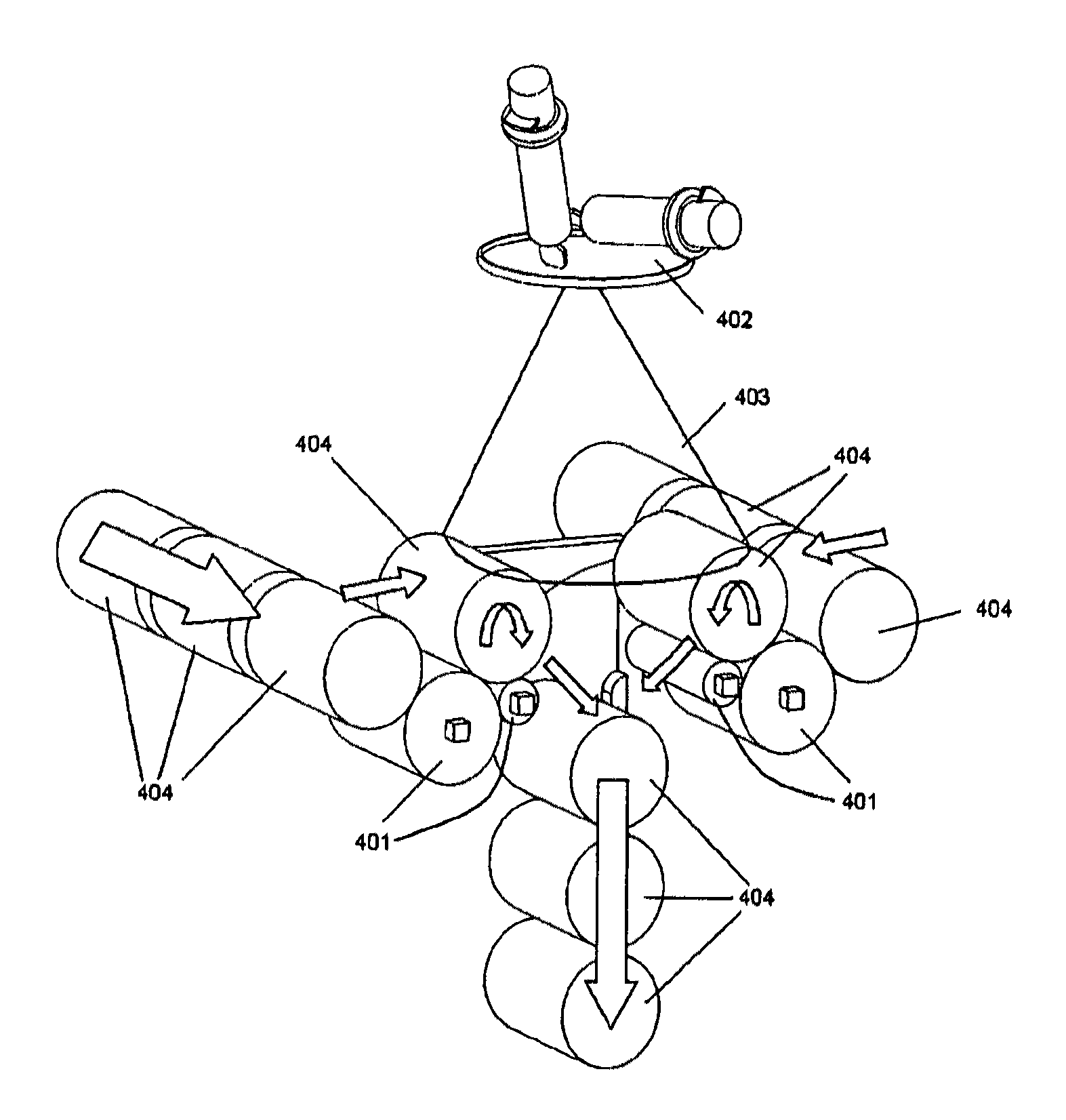

The invention provides a method and device for rotary marking or machining of cylindrical materials, preferably natural cork stoppers, agglomerated cork or synthetic materials used to close wine bottles and the like. The device includes at least one feeder system of cylindrical elements, preferably natural and synthetic cork stoppers; means of sensing the presence of such cylindrical elements, a laser system, means to produce the rotation of the cylindrical elements on its axis of revolution, at a variable speed, in a tangential movement compared to the focal plane of the laser system, means of measuring the instantaneous velocity tangential to its surface and direction of rotation, optical correction and focusing means, microprocessor control based means, and means for extracting the cylindrical elements. The laser system comprises means of generating at least one laser beam; means of temporal modulation and switching for the laser beam, and means of spatial modulation of each of the laser beams in a synchronized manner with the instant tangential speed on the surface of the cylindrical element.

Owner:ON LASER SYST & APPL

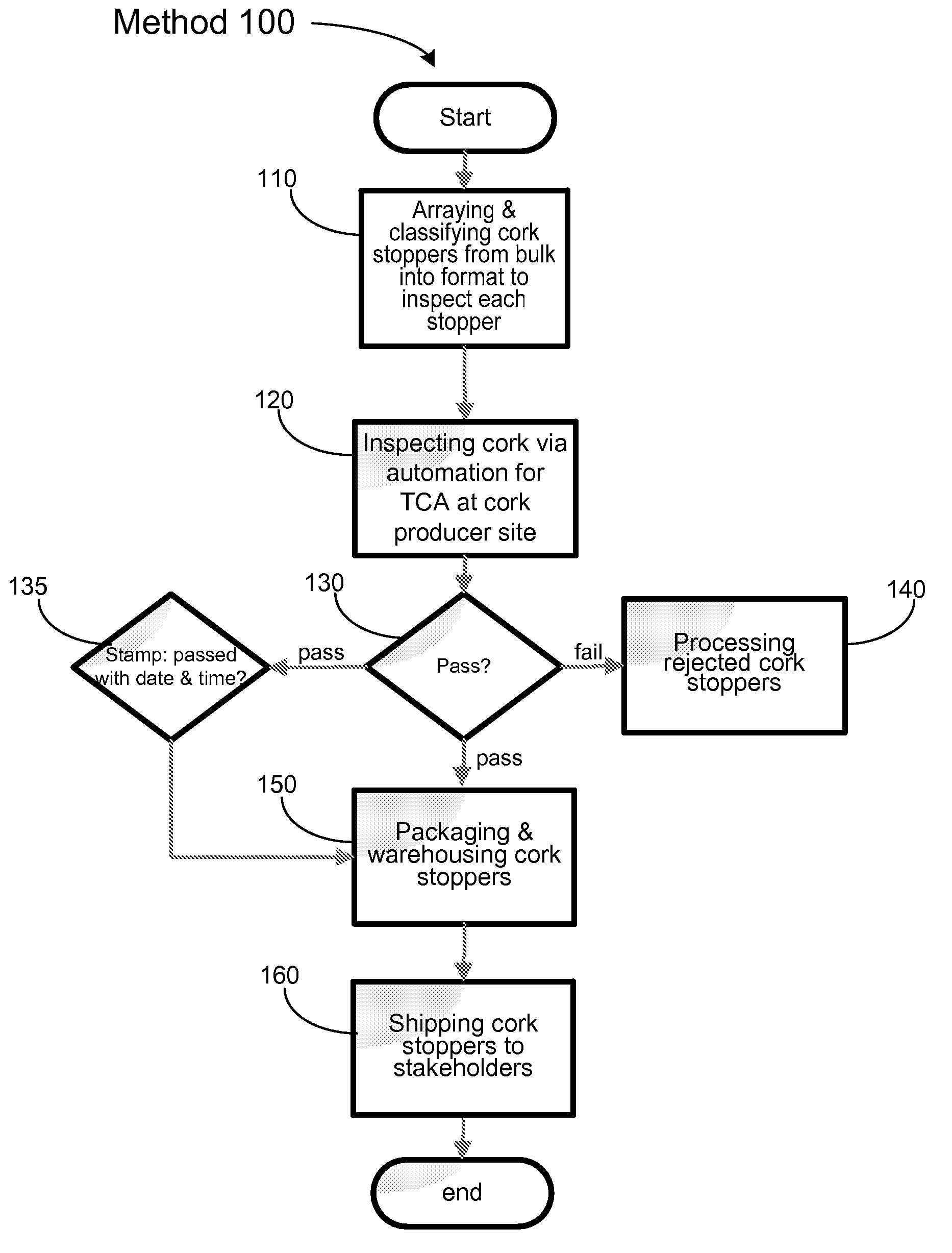

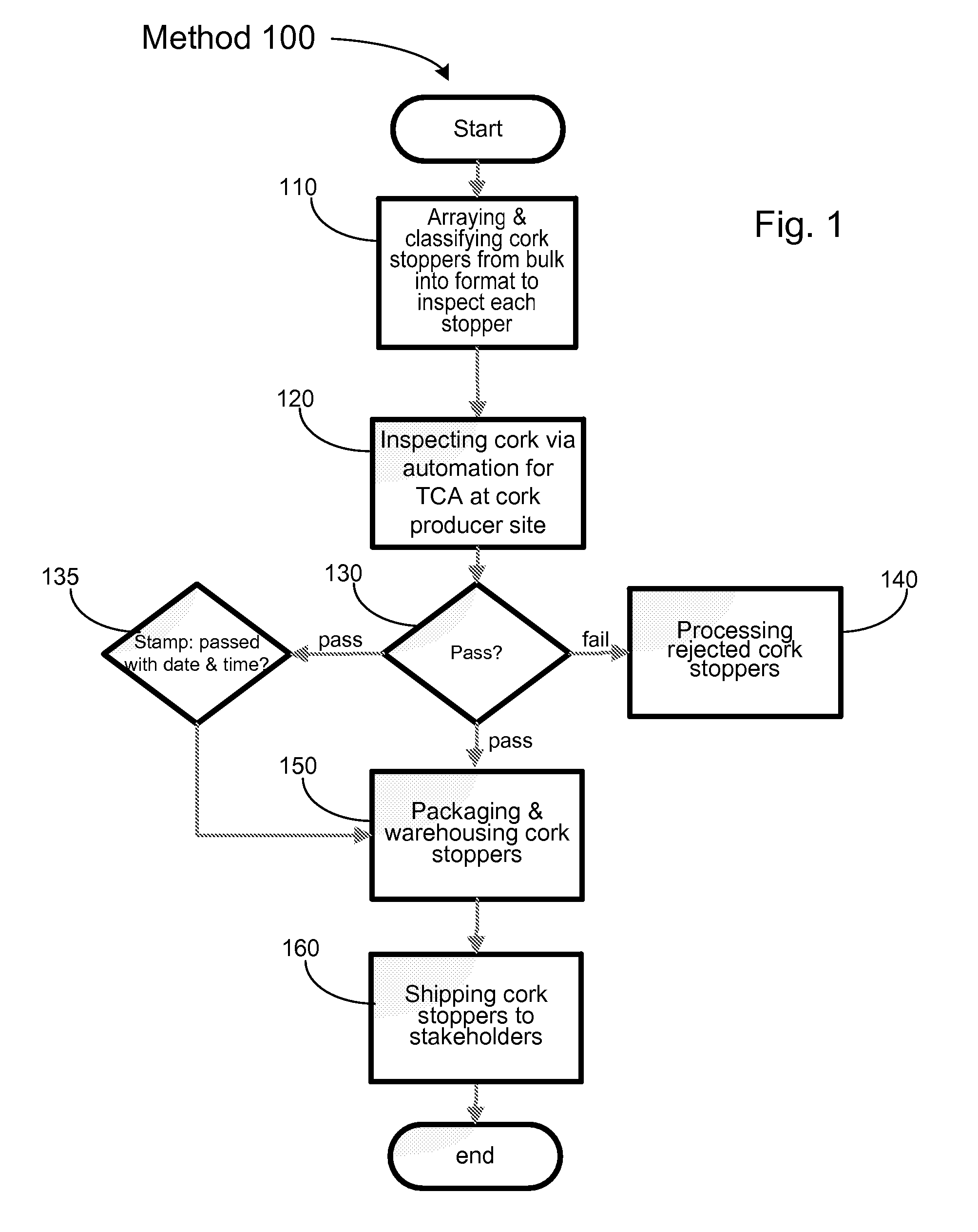

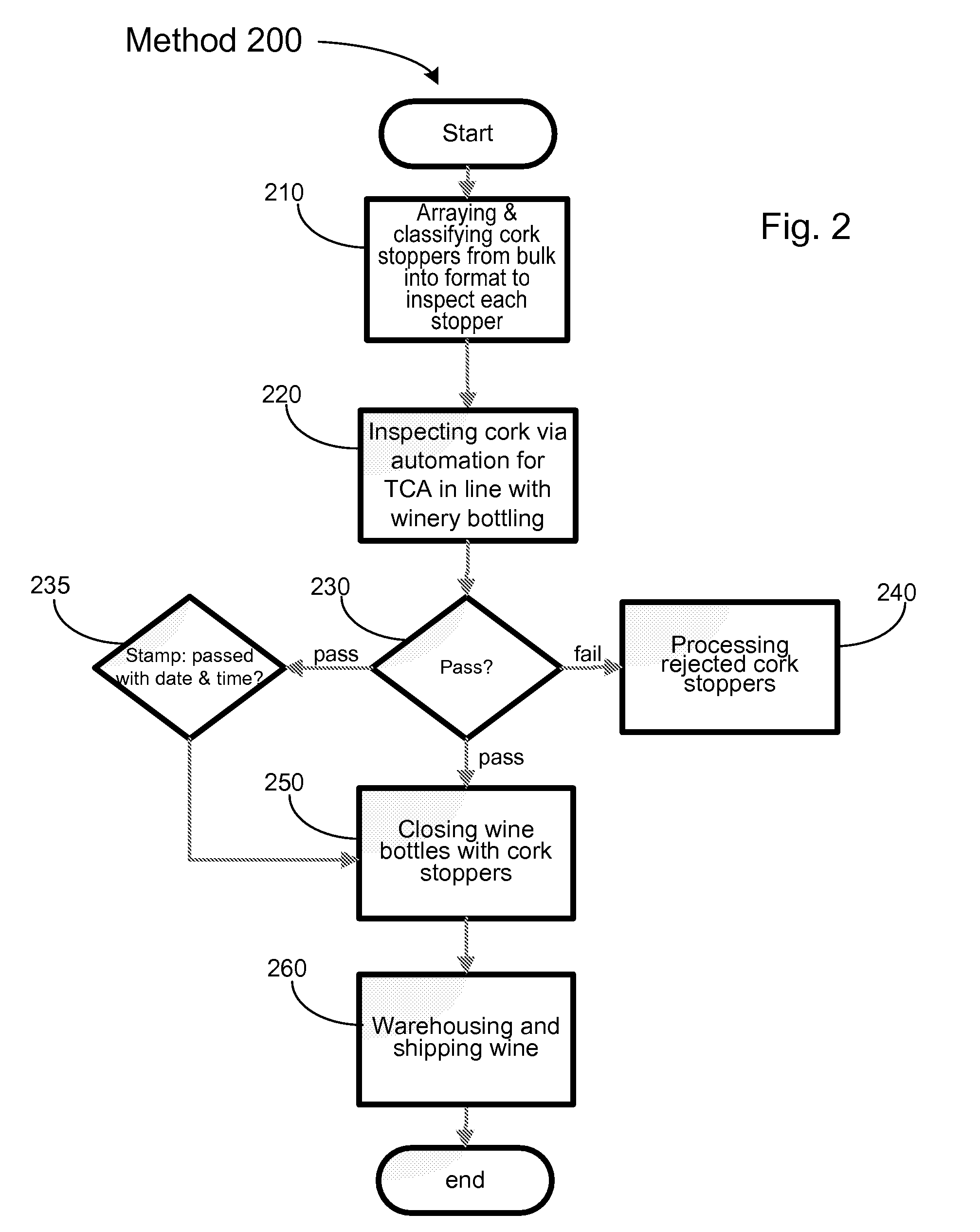

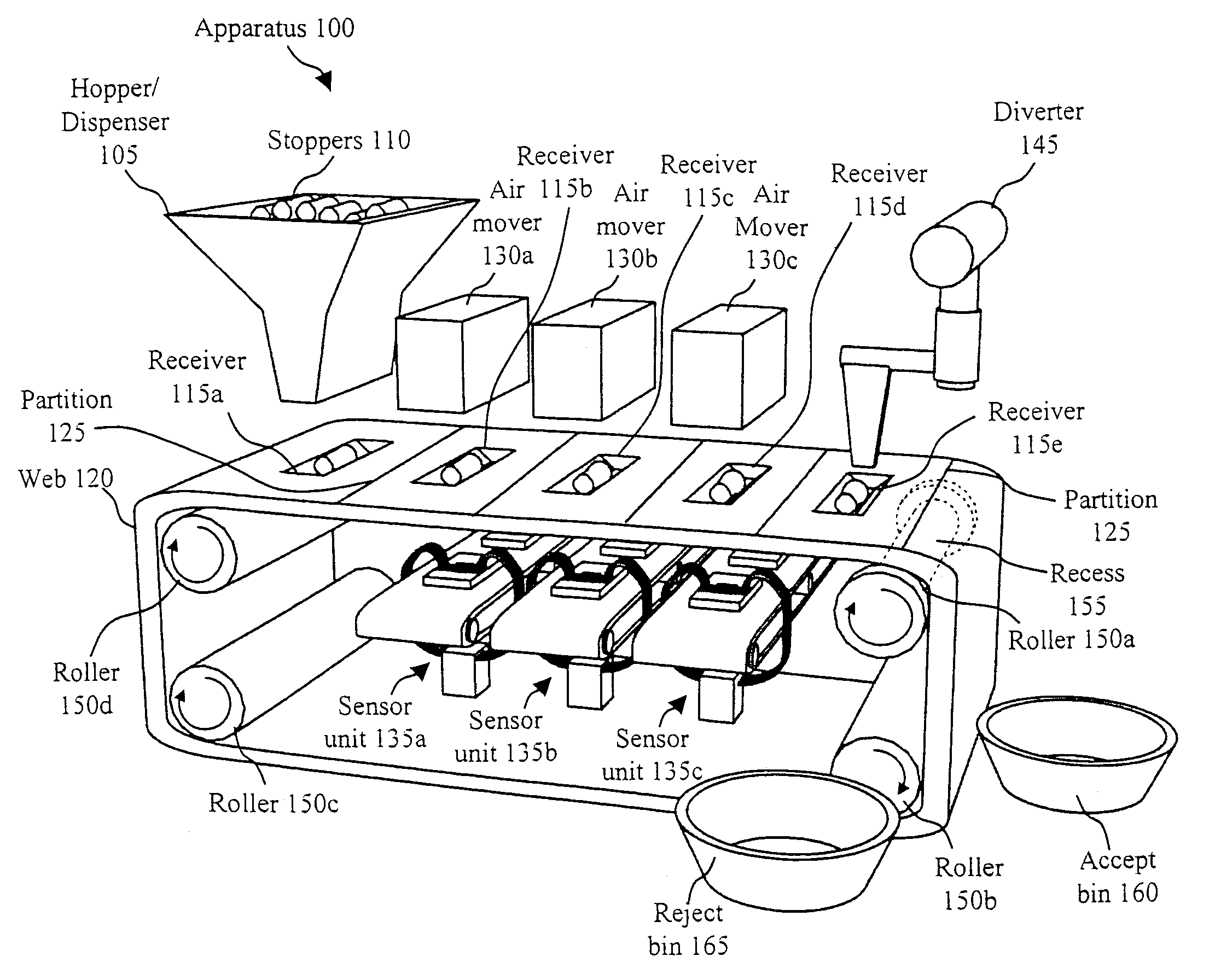

Methods of detecting and eliminating tainted cork wine bottle stoppers

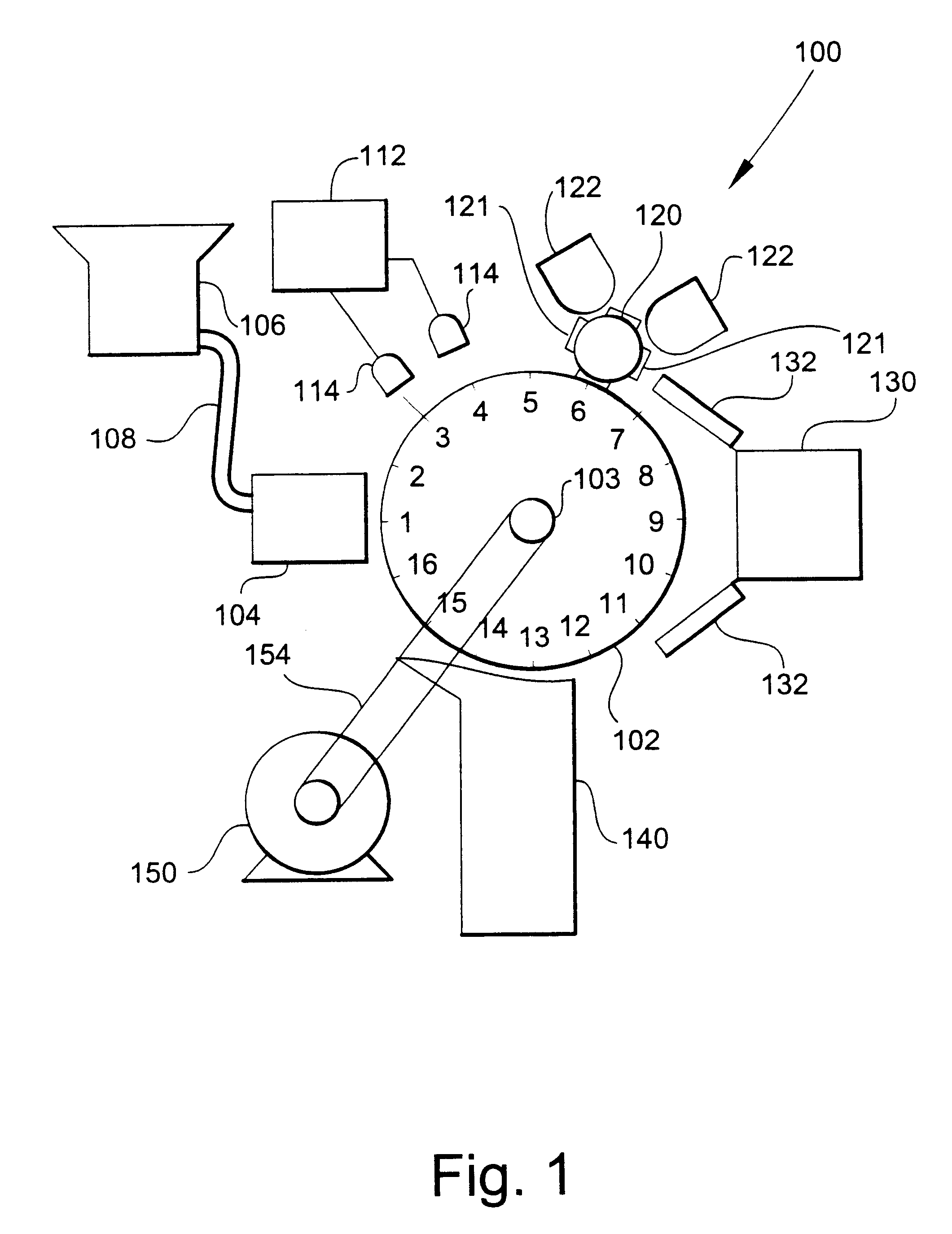

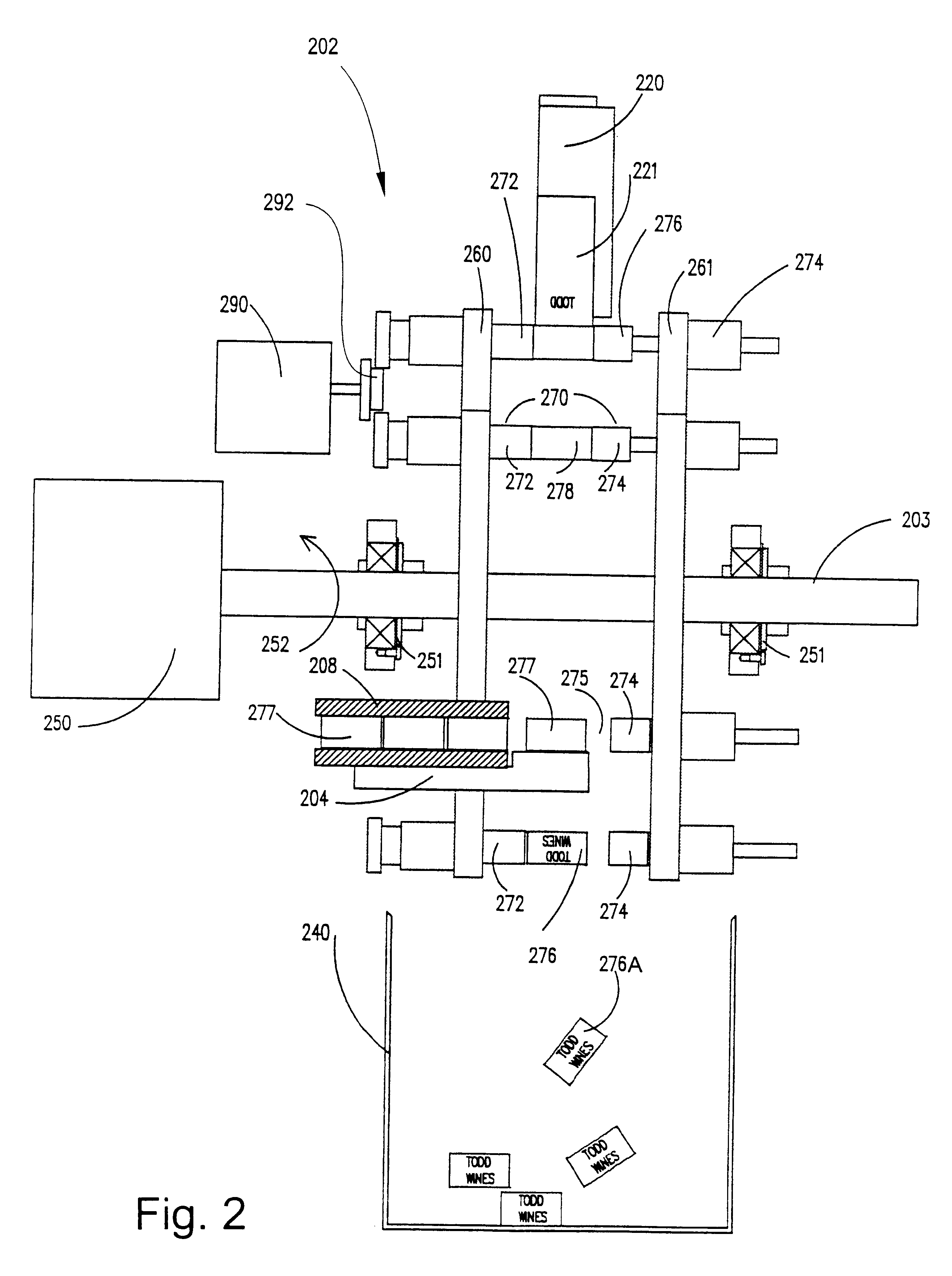

Methods are provided for detecting the presence of one or more chemical contaminants in / on a plurality of items, e.g., cork stoppers. According to one embodiment of the present invention, a method of selecting cork stoppers substantially free of cork taint is provided. The method comprises the steps of arraying and classifying one or more cork stoppers into a formatted array to enable inspecting each stopper; inspecting each cork stopper within the formatted array for the presence of cork taint using an automated means of inspection; and sorting the cork stoppers within the formatted array into either (i) a rejected group consisting of those stoppers found in the inspecting step to have cork taint or (ii) an accepted group consisting of those stoppers found in the inspecting step to be substantially free of cork taint. These methods avail of apparatus that may use detection sensor electronics that separate from nose chips such that each nose chip can be either reused or discarded after use. Testing apparatus may use multiple sensor units to simultaneously test multiple cork stoppers for chemical contaminants (e.g., TCA). These methods provide 100% testing of cork stoppers cost effectively at high speed, whether at bottling-line speed or in off-line and third-party settings.

Owner:HEAD MICHAEL S +1

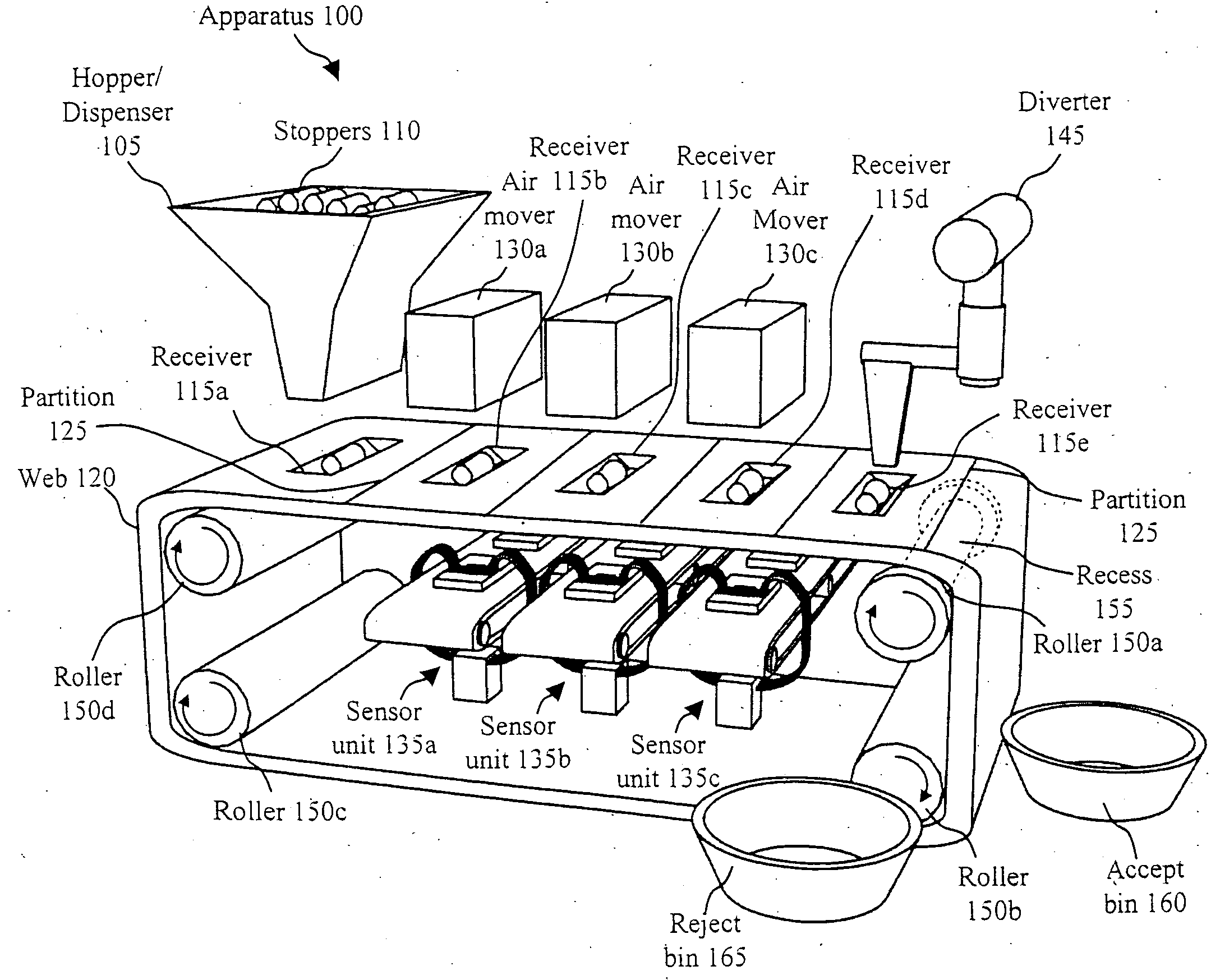

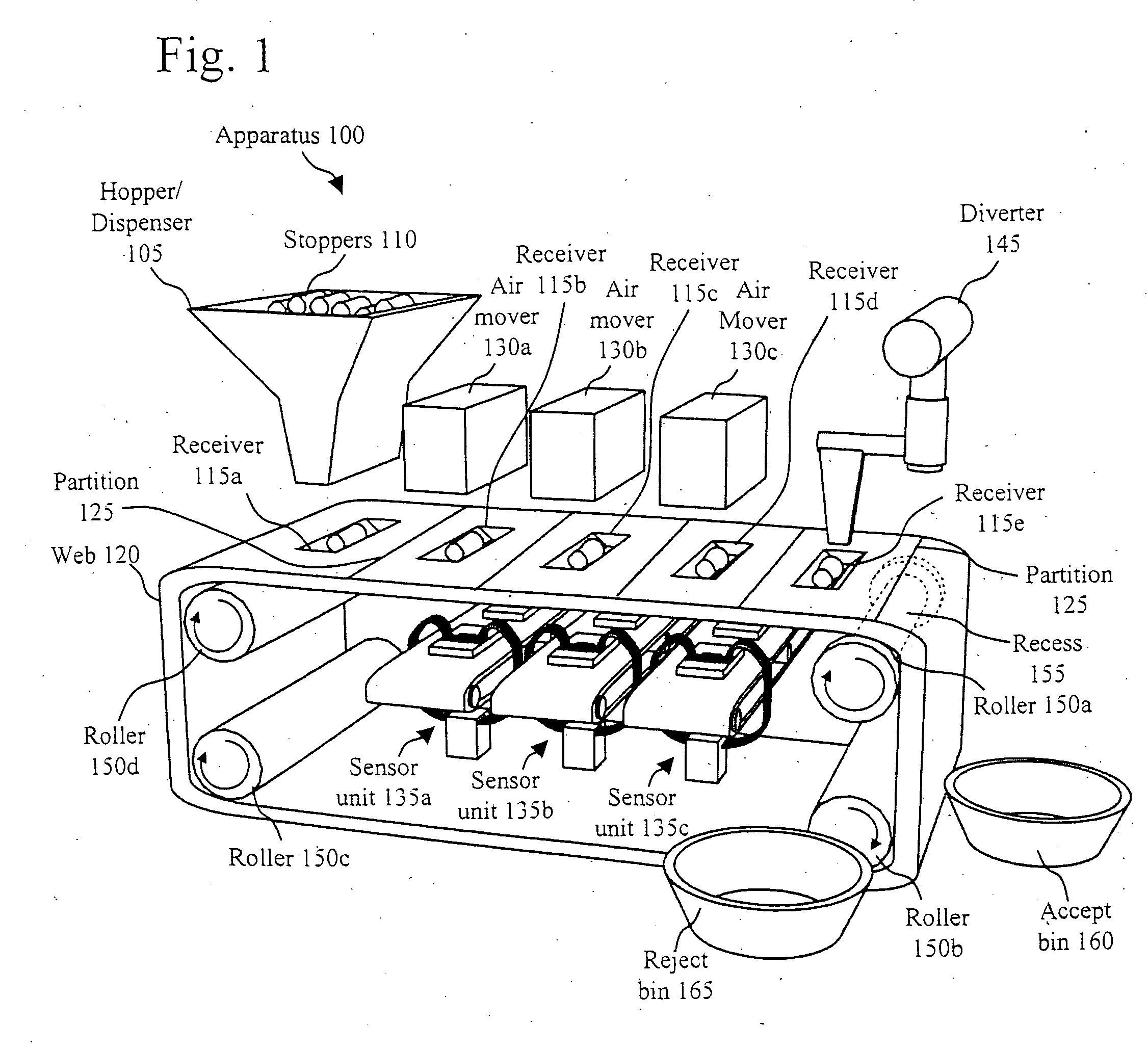

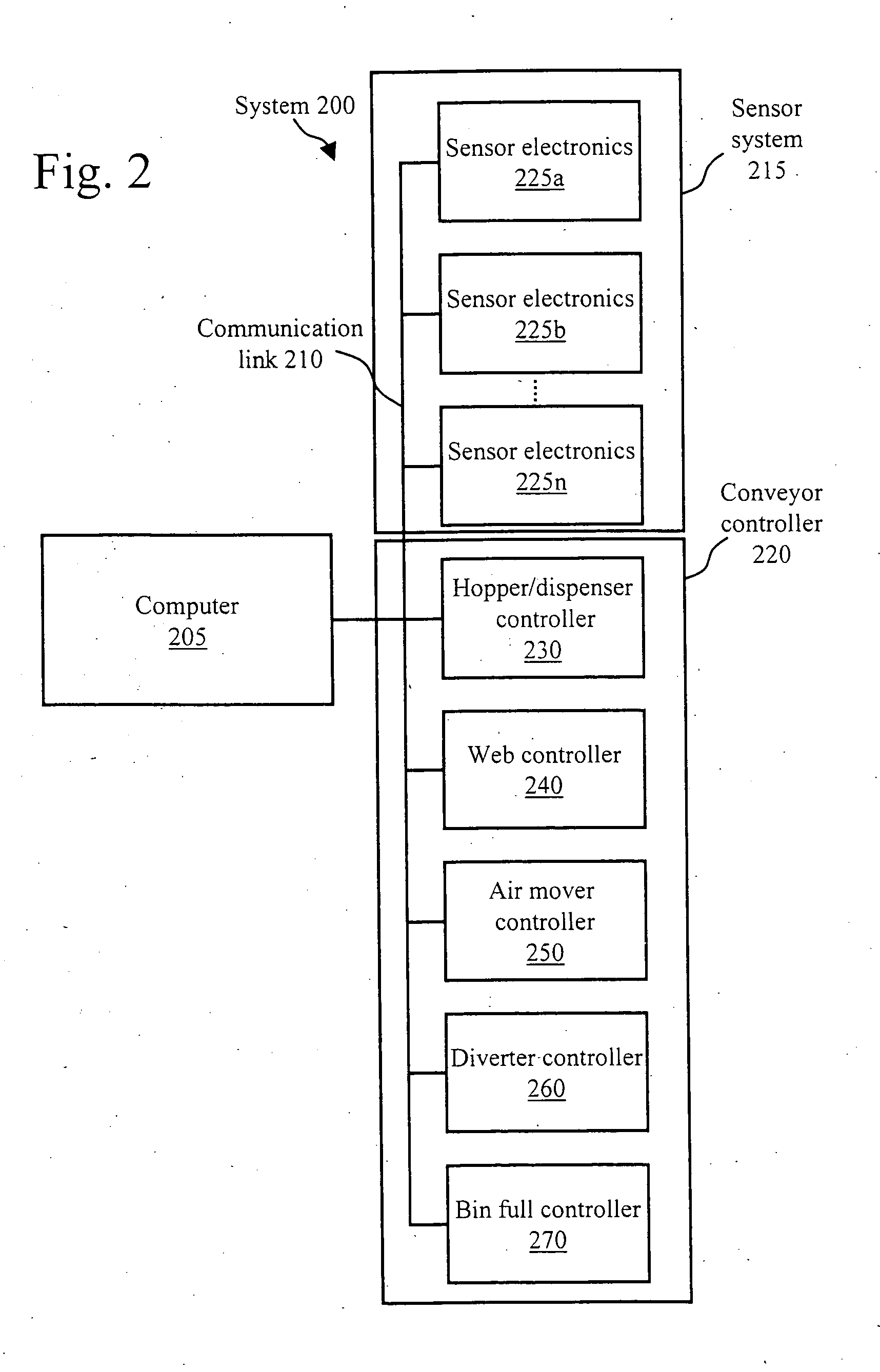

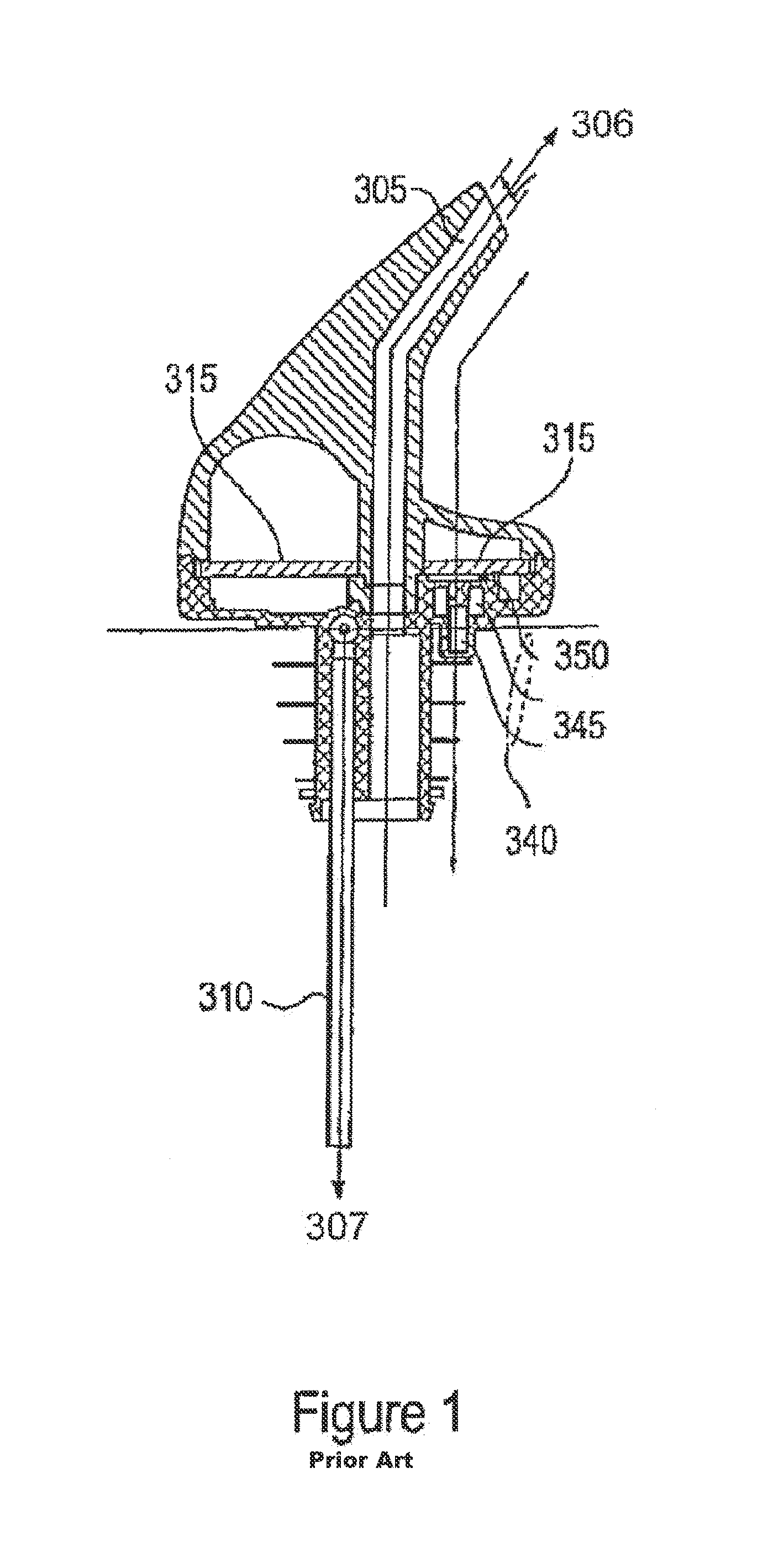

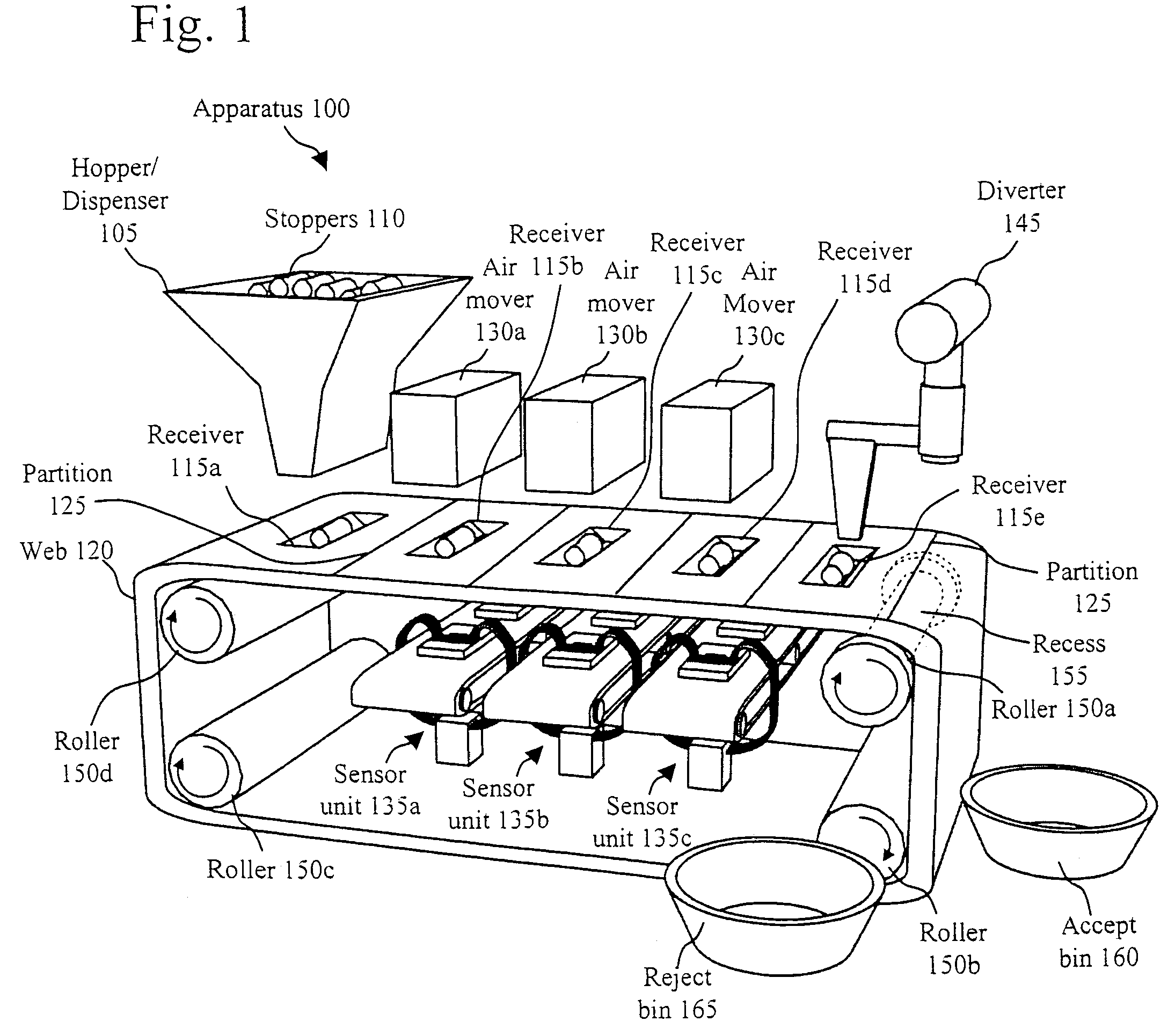

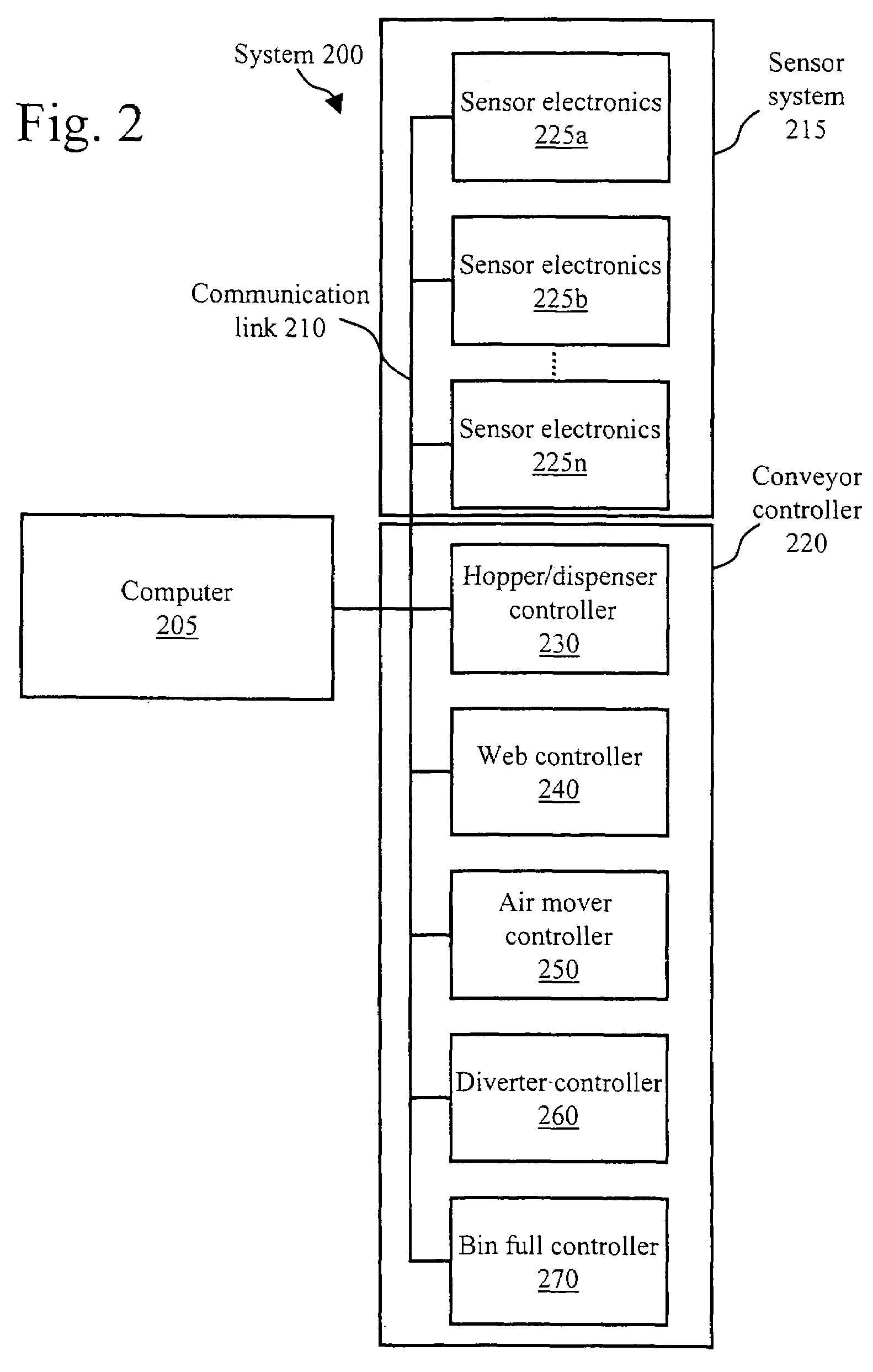

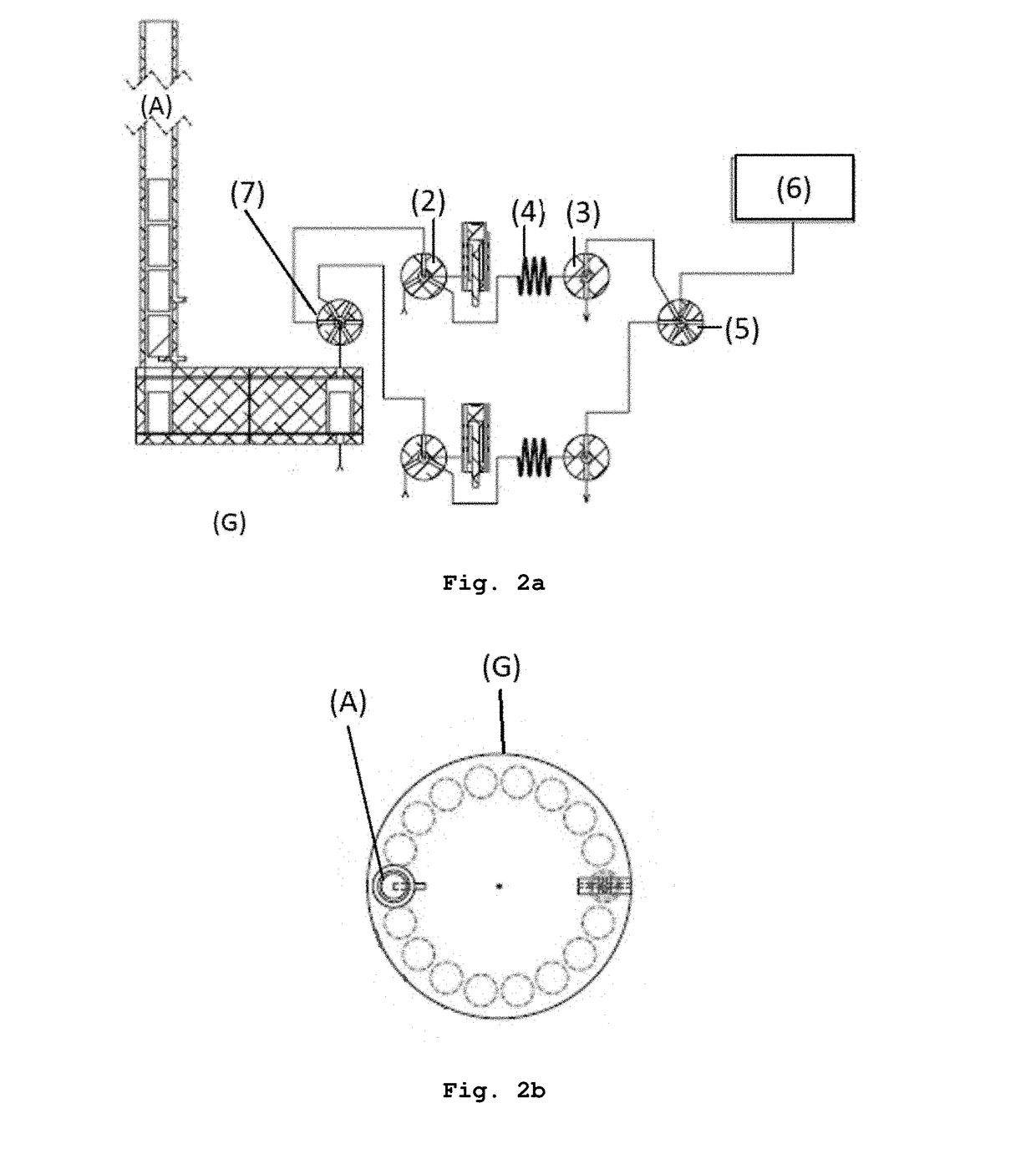

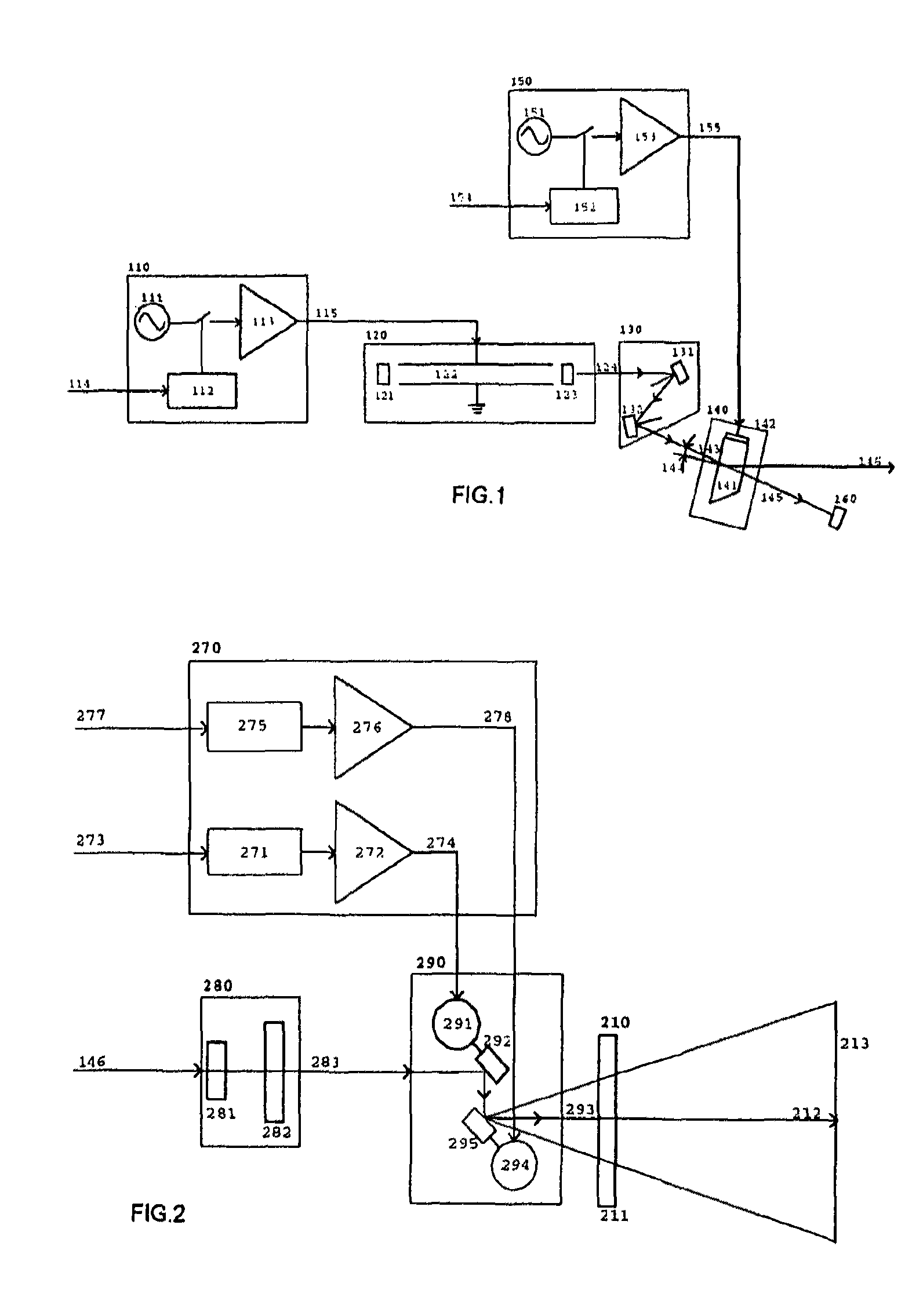

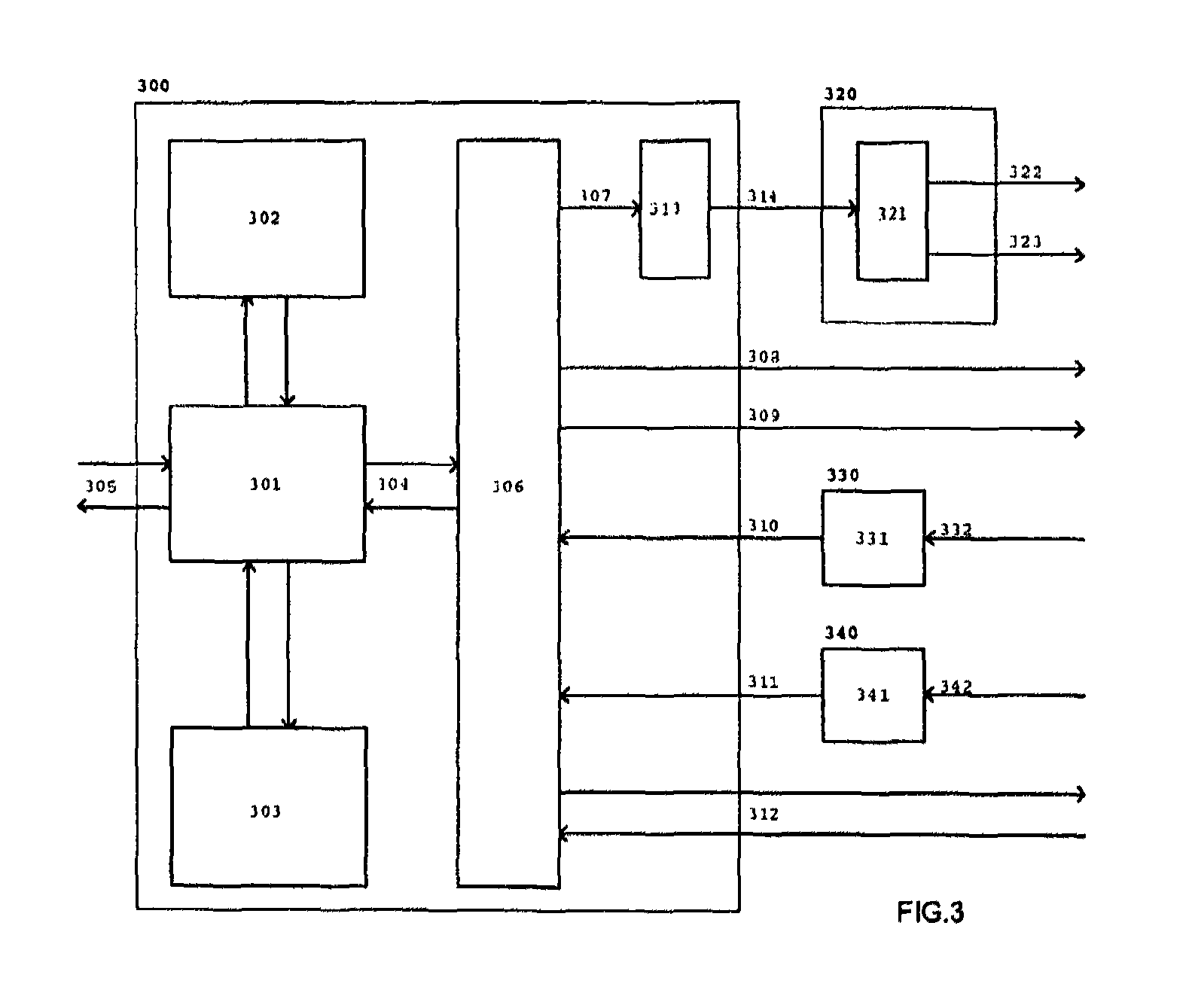

Apparatus and method for detecting an analyte

An apparatus (100) and method (400) for detecting the presence of one or more chemical contaminants in / on a plurality of items, e.g., cork stoppers (110), using nose chips (310). The apparatus utilizes detection sensor electronics (225) that are separate from the nose chips such that each nose chip can be either reused or discarded after use. The apparatus moves the nose chips and the cork stoppers independently to align the cork stopper and a corresponding nose chip with one another. The testing apparatus uses multiple sensor units (135) to simultaneously test multiple cork stoppers for chemical contaminants (e.g., TCA). The invention provides a low-cost, reliable process for testing 100% of cork stoppers in a fast and cost-effective manner that is scalable to the general consumer product market.

Owner:HEAD MICHAEL S

Plastic cap protector for bottle corks

The components used in this invention has never been utilized in this special type of arrangement ever before. Plastic caps are basically used in other applications such as for sealing water pipes and bottles such as sodas, vitamin bottles and so on, but always on the outside of the bottle, but never in the inside of the bottle, in combination with a wine cork in order to protect the wine from contacting any potential contaminants inside the cork.

Owner:GALVEZ RAMOS ANTONIO MARTIN

Making process for kirschwasser

InactiveCN103468465AGuaranteed qualityAchieve sterile hygieneAlcoholic beverage preparationYeastTrace element

The invention relates to a making process for kirschwasser. The process includes the steps of: 1) subjecting cherries to peduncle removing, washing, drying, disinfection and crushing; 2) letting cherry juice and peels contact, adding a distiller's yeast according to a proportion to make them ferment together; 3) in the fermentation process, making the pigment and aroma in the peels dissolved in wine; 4) after the fermentation, carrying out peel pomace separation to separate the original wine from the peel pomace and wine sediment, and then performing cylinder pouring to make the wine liquid clear and transparent; 5) fermenting the separated original wine; 6) ageing the separated original wine liquid; 7) carrying out clarification and gelatin charging at the end of ageing to make a gel net generated in the wine liquid, and filtering out the peels; 8) performing freezing treatment after the clarification treatment; 9) conducting heat treatment after the freezing treatment; 10) performing deployment after the heat treatment to deploy various trace elements of the kirschwasser; 11) then removing sediment and floating matters to make the wine liquid clear and stable; and 12) canning the filtered wine juice by a stainless steel canning machine, performing packaging by an aseptic packaging machine, and conducting sealing by a cork stopper.

Owner:王战乐

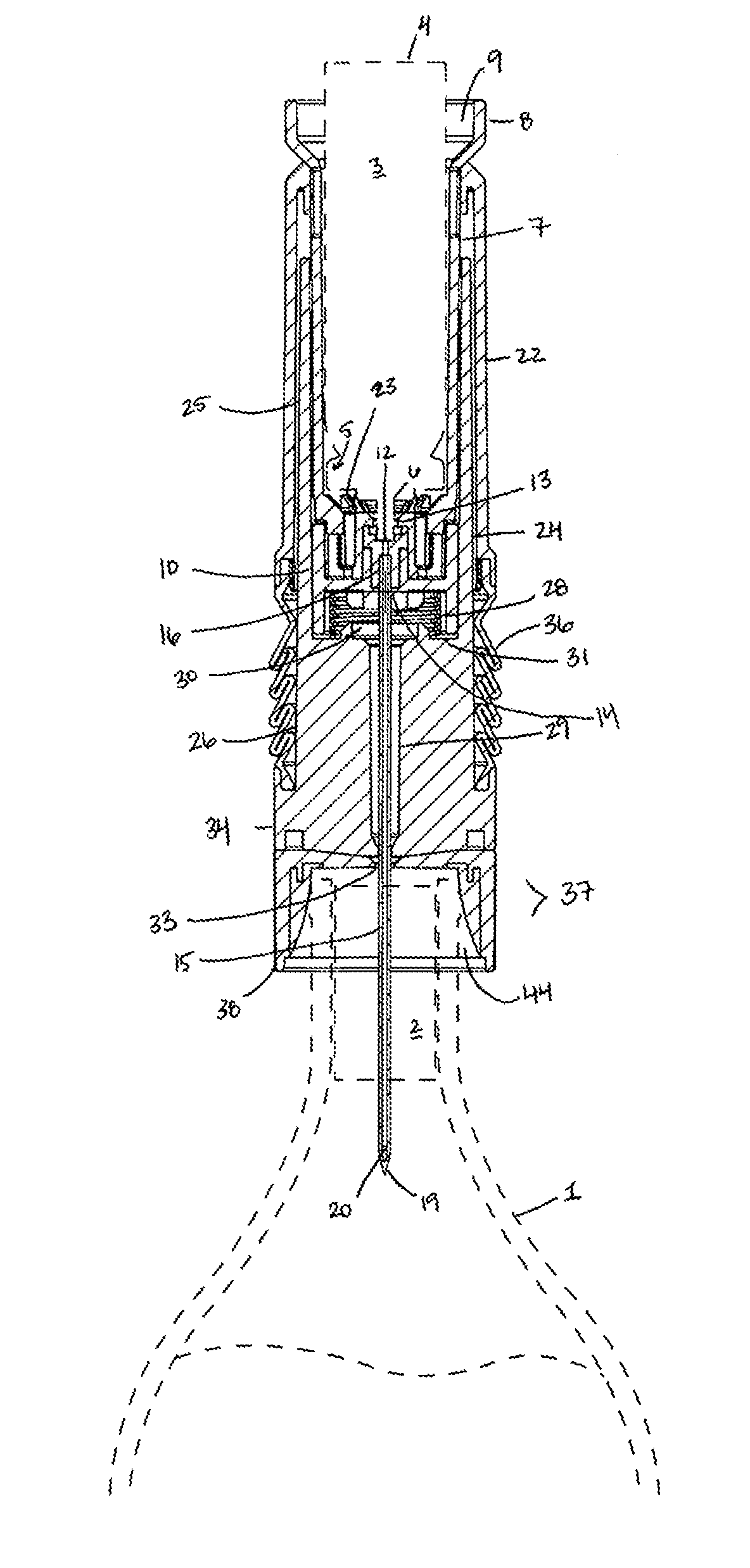

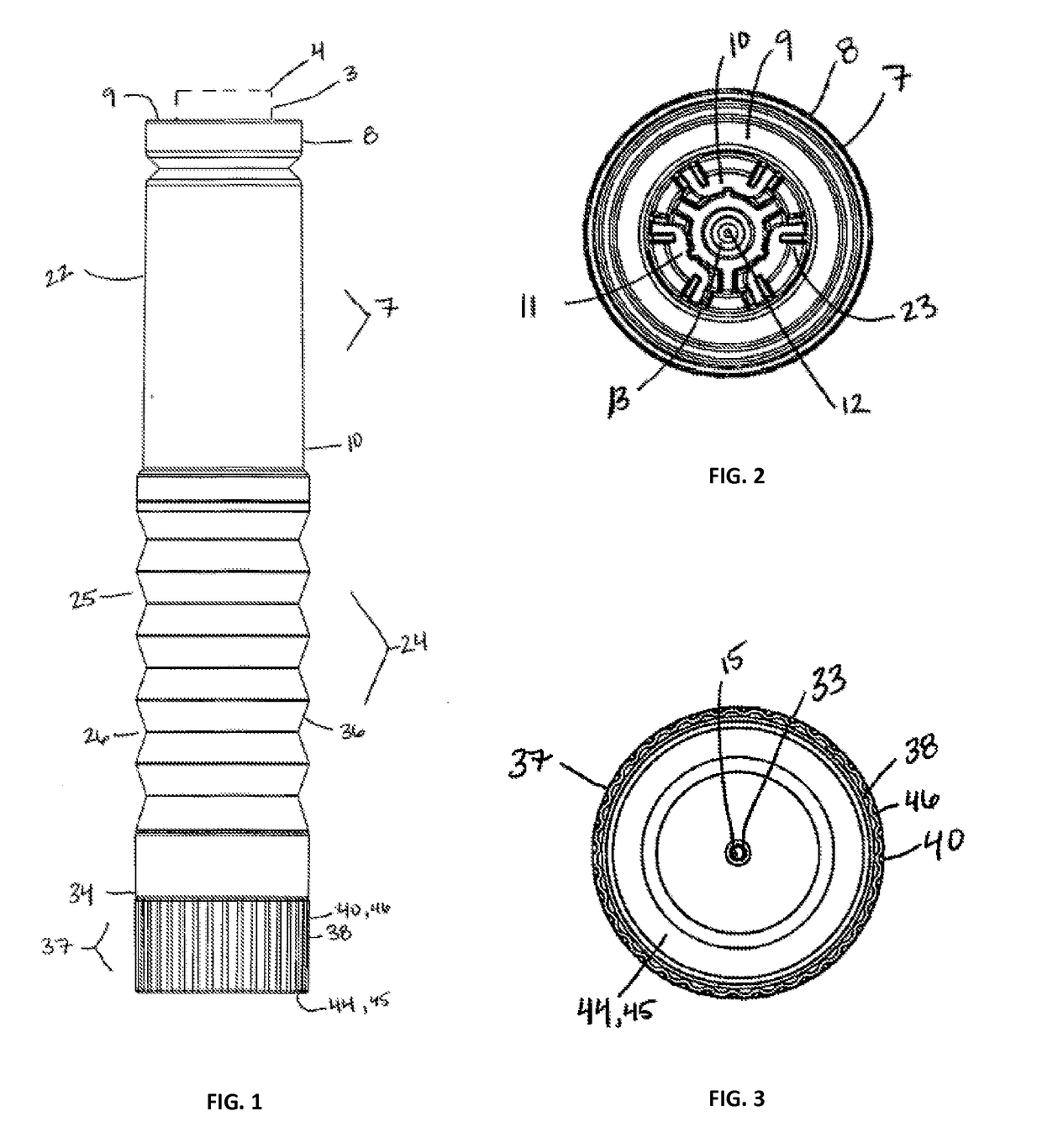

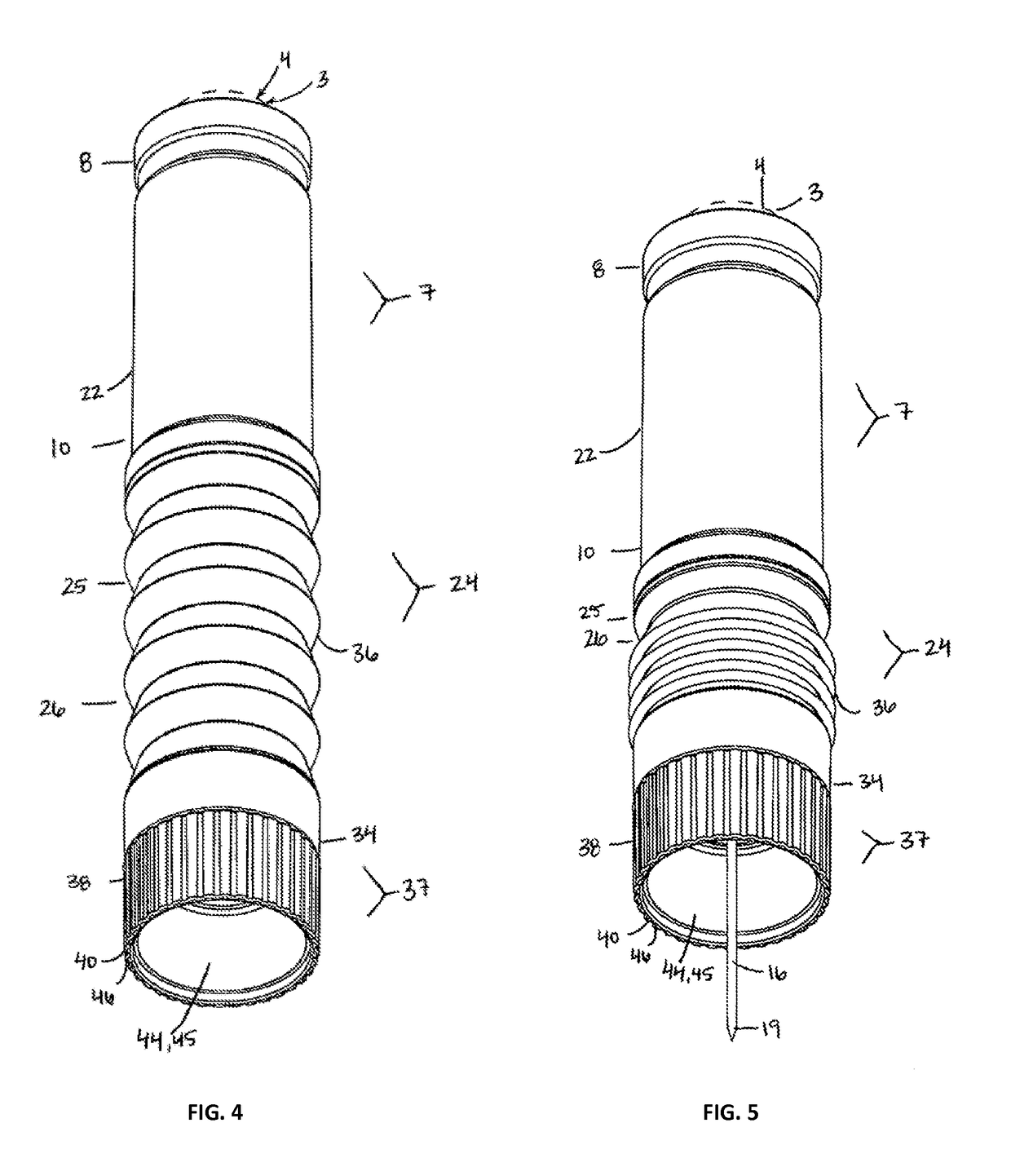

Cork Extractor

ActiveUS20170129758A1Facilitate removalTight sealStopper removalBiomedical engineeringCompressed fluid

An extractor device for use with a removable compressed fluid container having a containing section, sliding section, positioning section, and a hollow needle. A method of extracting a cork from a bottleneck utilizing a compressed fluid injected from a removable container, housed within a containing section of the device, to the bottle through a hollow needle affixed to the containing section of the device. The cork extractor device can include a rotationally projected component to forcibly displace a removed cork from the needle.

Owner:TRUE FABTIONS

Waterproof sealing device for cement hydration heat test

InactiveCN103072750AProtect liquid environmentWon't enterMaterial heat developmentSealingWater bathsEngineering

The invention relates to a waterproof sealing device for a cement hydration heat test. The waterproof sealing device comprises a wide-opening thermos bottle, a copper pipe and a cork stopper, wherein a silicon seal is sleeved at an adaptation position outside the opening of the wide-opening thermos bottle; the cork stopper is plugged in the opening; a fastening piece of which the outer ring is provided with threads is sleeved at the exterior of the silicon seal; the fastening piece is connected with a gland outside the fastening piece by virtue of the threads; a rubber stopper with the copper pipe is inserted in the upper port boss of the gland; and the rubber stopper props against the upper end of the cork stopper. The waterproof sealing device can be used for solving the problem that the cork stopper and the wide-opening thermos bottle are difficult to seal, and achieving a favorable waterproof sealing effect; and in addition, all the components of the waterproof sealing device can be subjected to cyclic utilization and are long in service life, so that while a water bath tank liquor environment is protected, resources are saved, and great convenience is brought to users.

Owner:SHENYANG JIANZHU UNIVERSITY

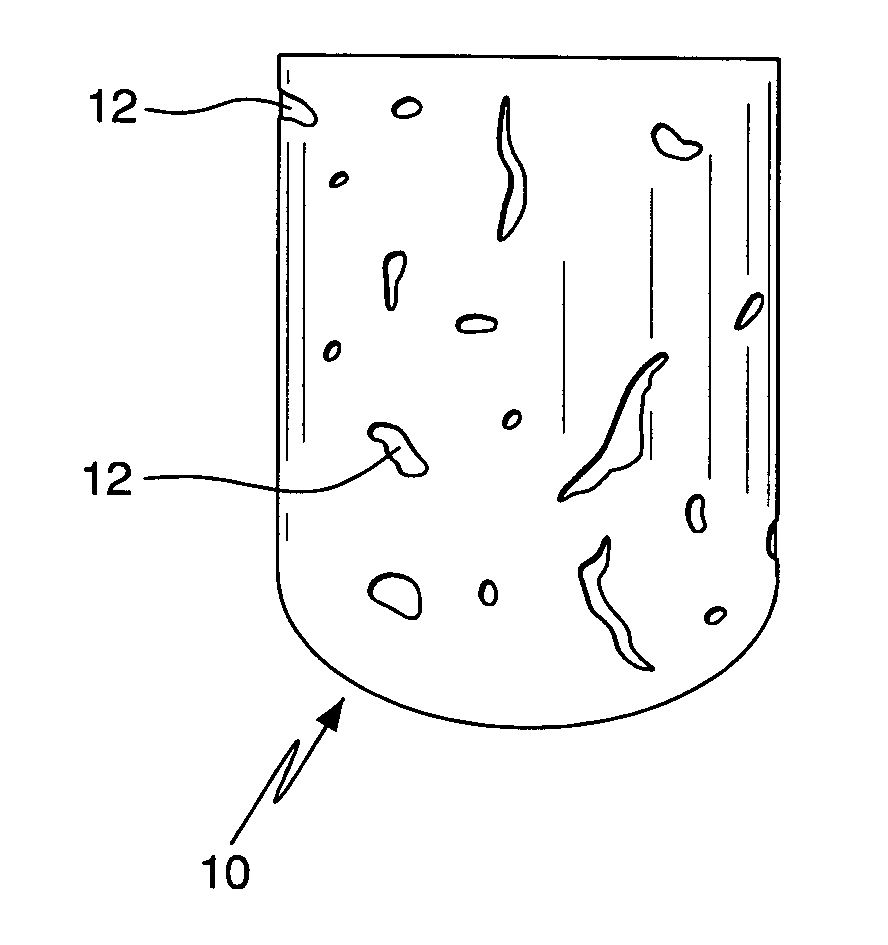

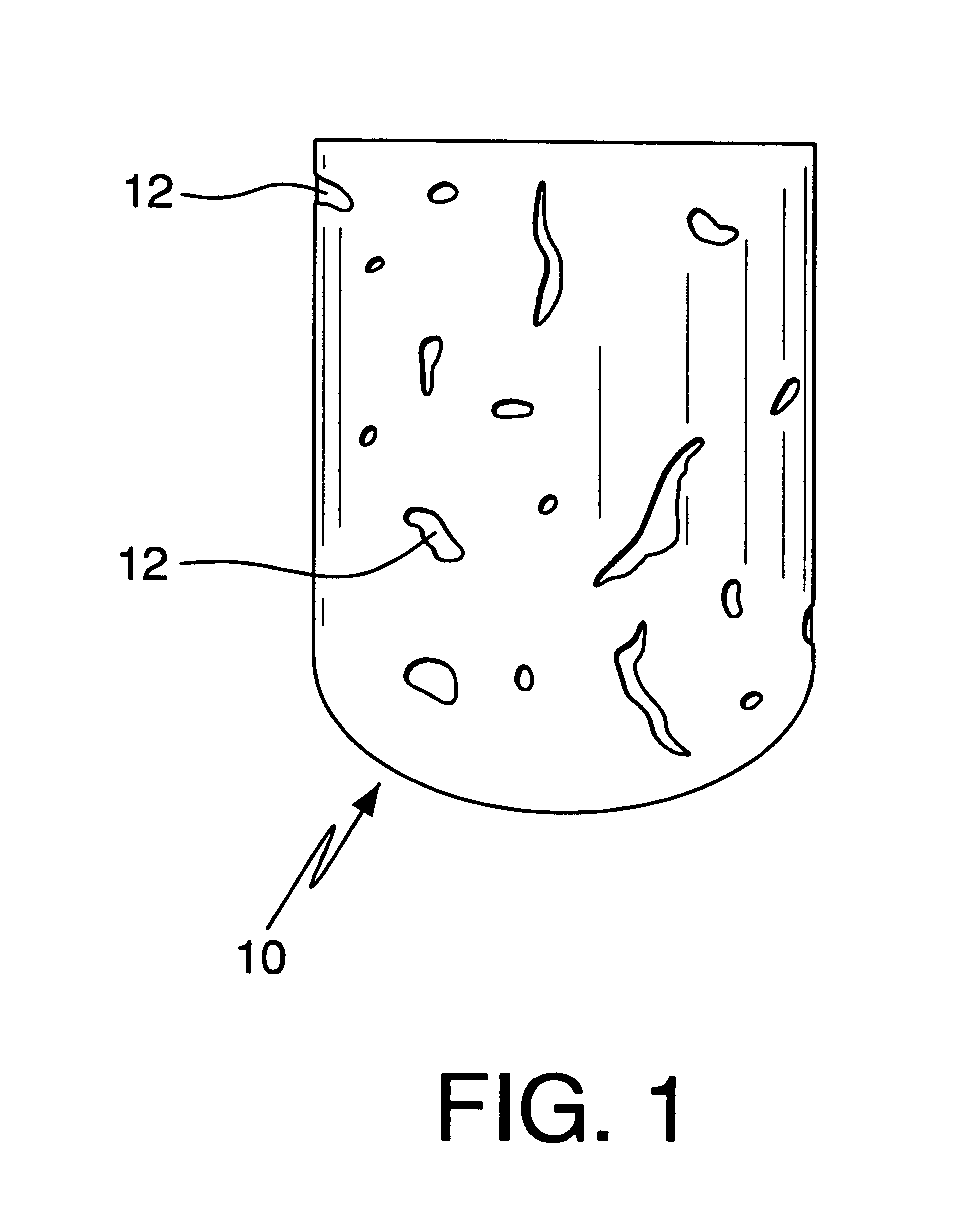

Synthetic cork with a natural cork appearance and method of making it

A method of producing random and irregular markings and impressions on synthetic cork stoppers so as to closely mimic the surface texture of natural cork, and the stoppers produced thereby. In one embodiment, the stopper is produced in a mold featuring a textured inner surface. In another embodiment, the stopper is extruded.

Owner:TAPI NORTH AMERICA DE C V

Wireless spout and system for dispensing

ActiveUS8925769B2Extrusion process is simpleStop the flowTime indicationPower operated devicesProcess engineeringColored light

Owner:L2F INC

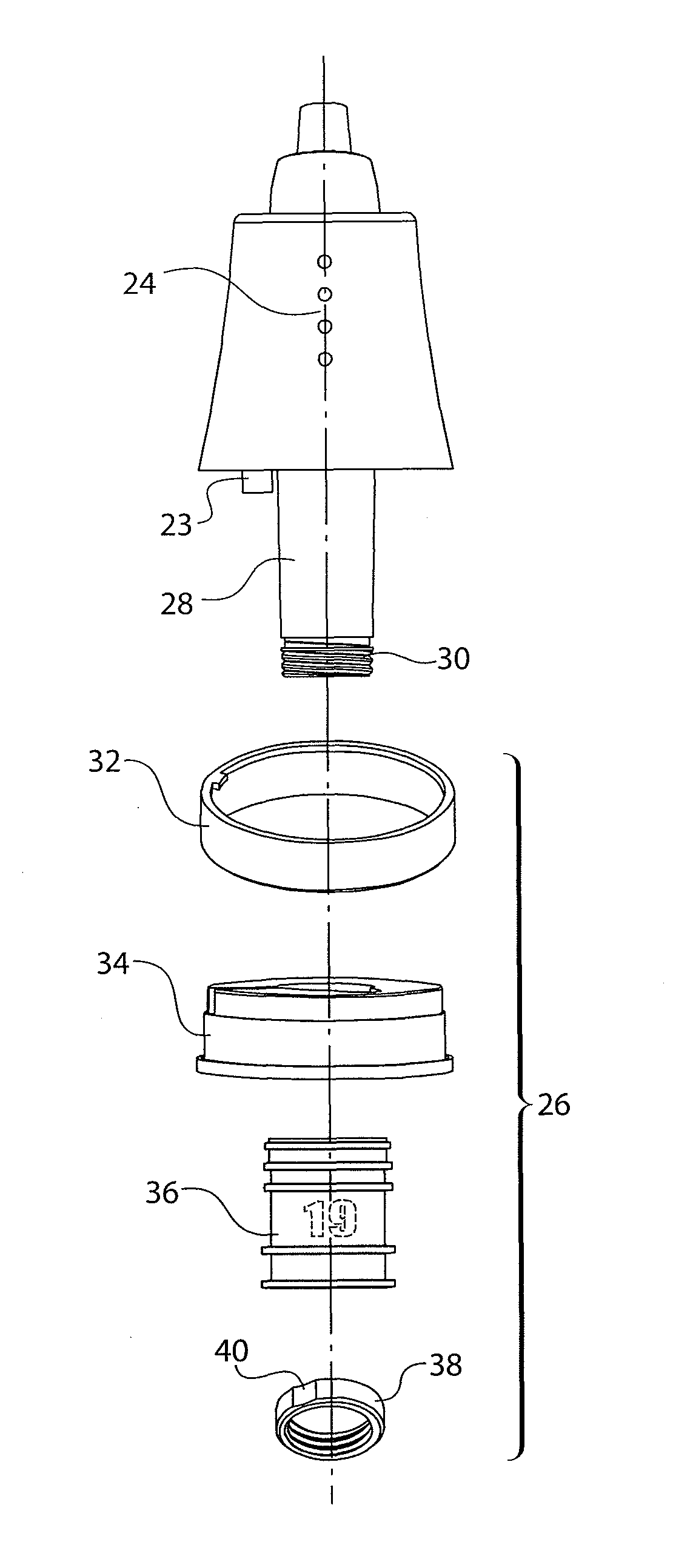

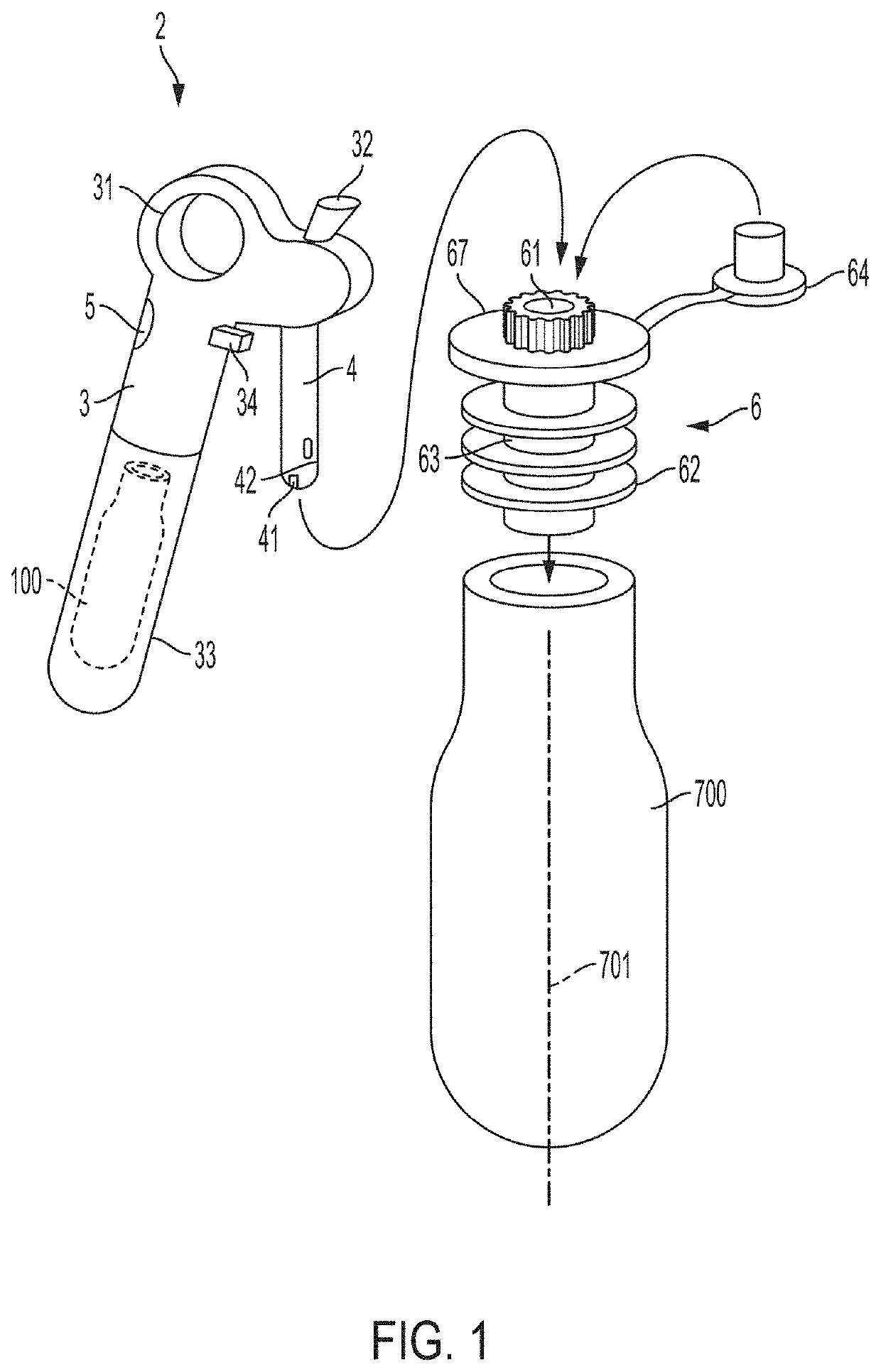

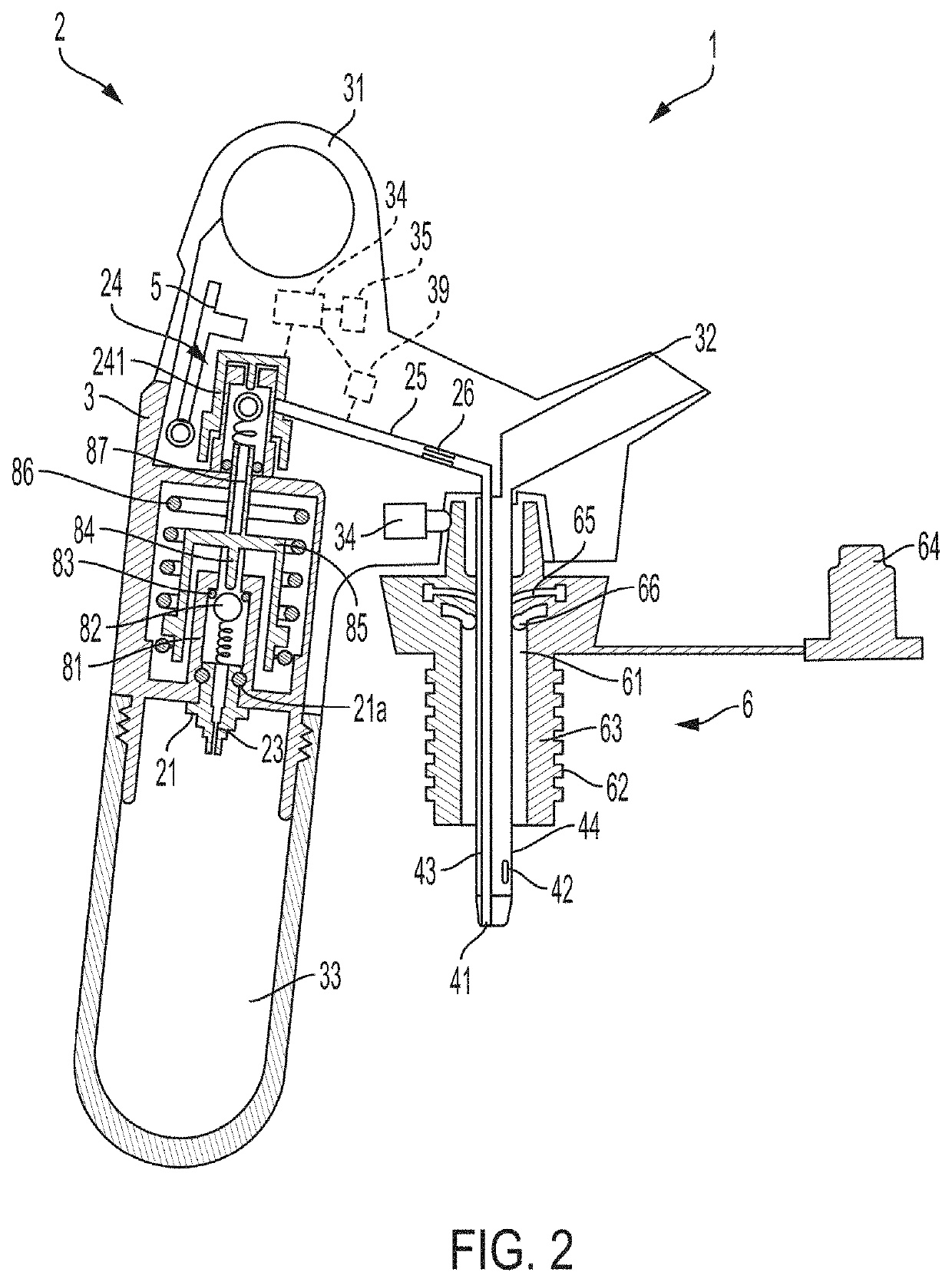

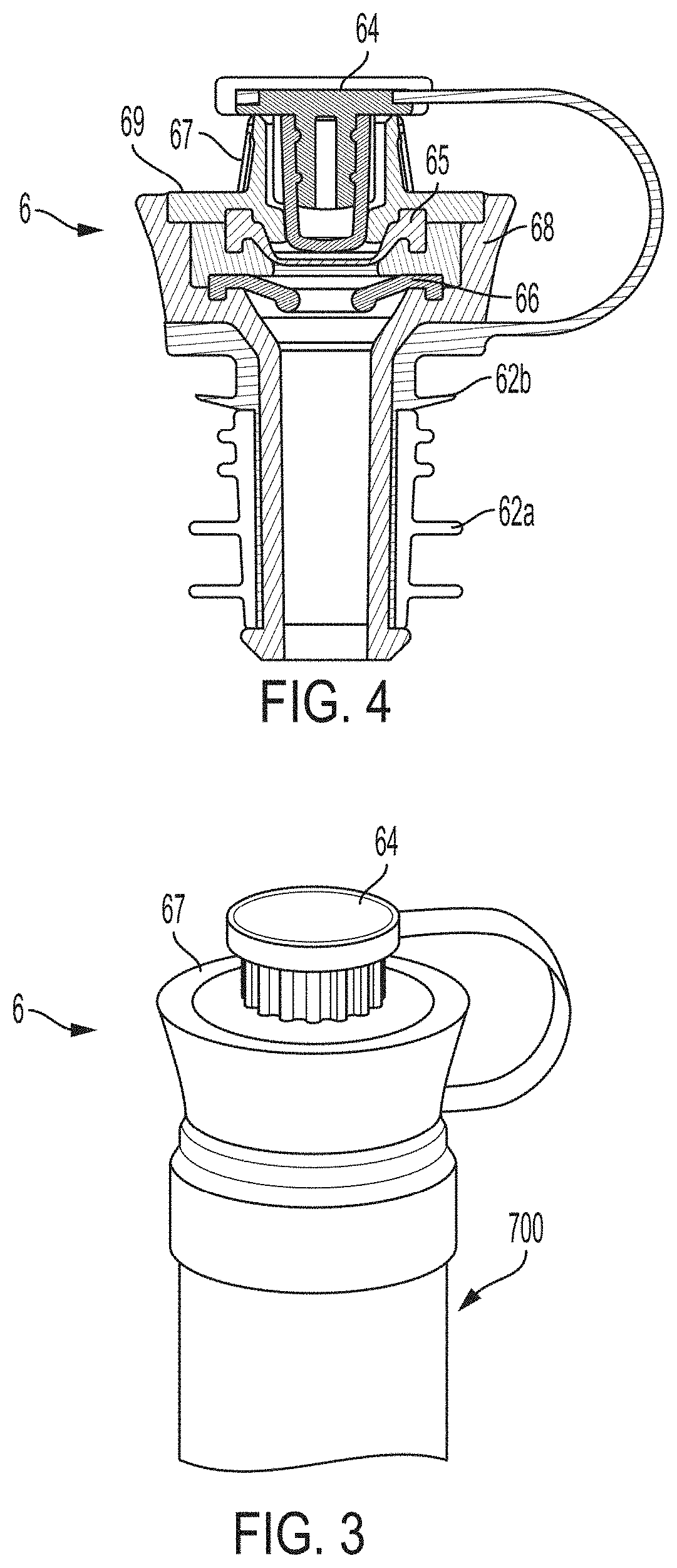

Beverage dispenser and container stopper

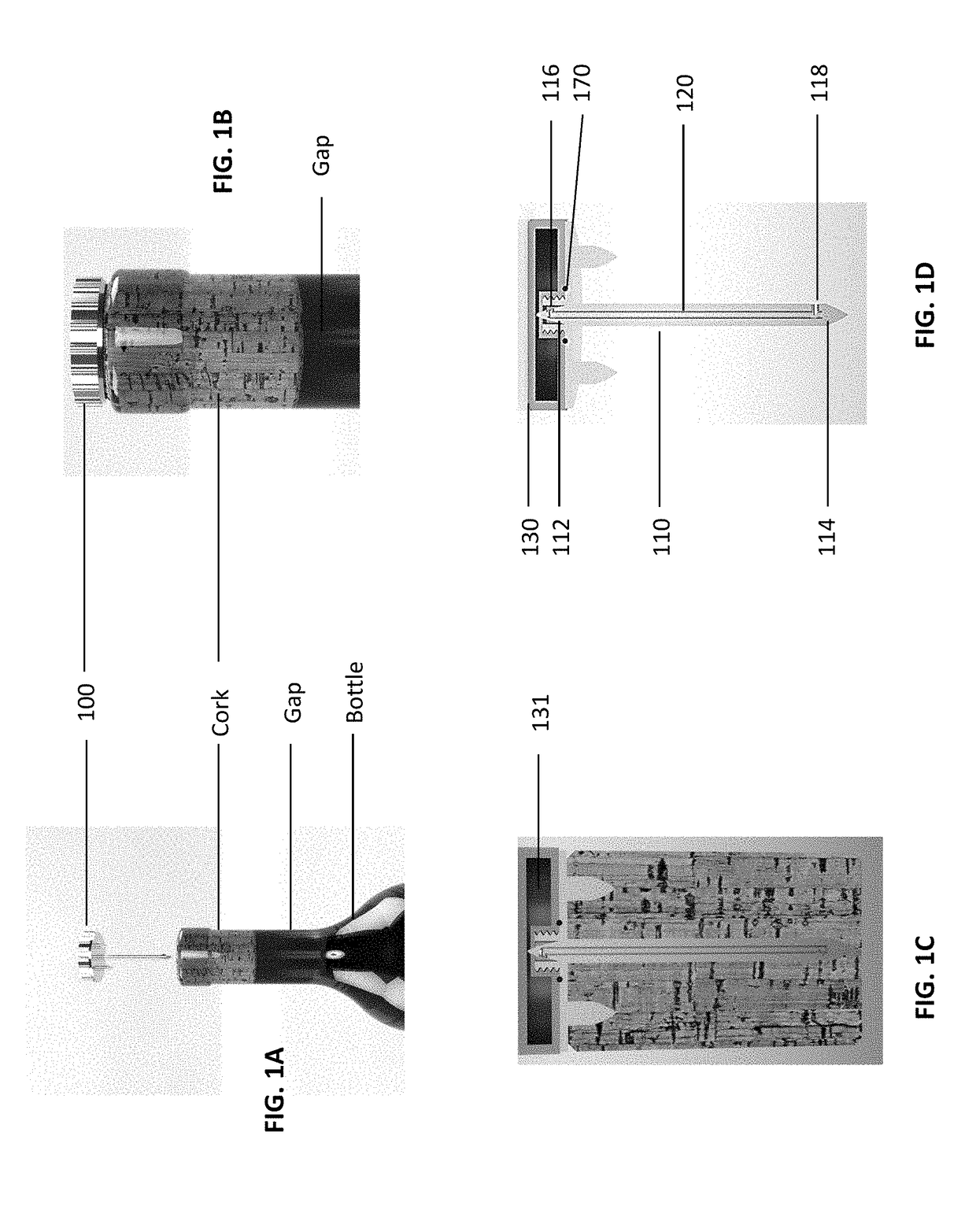

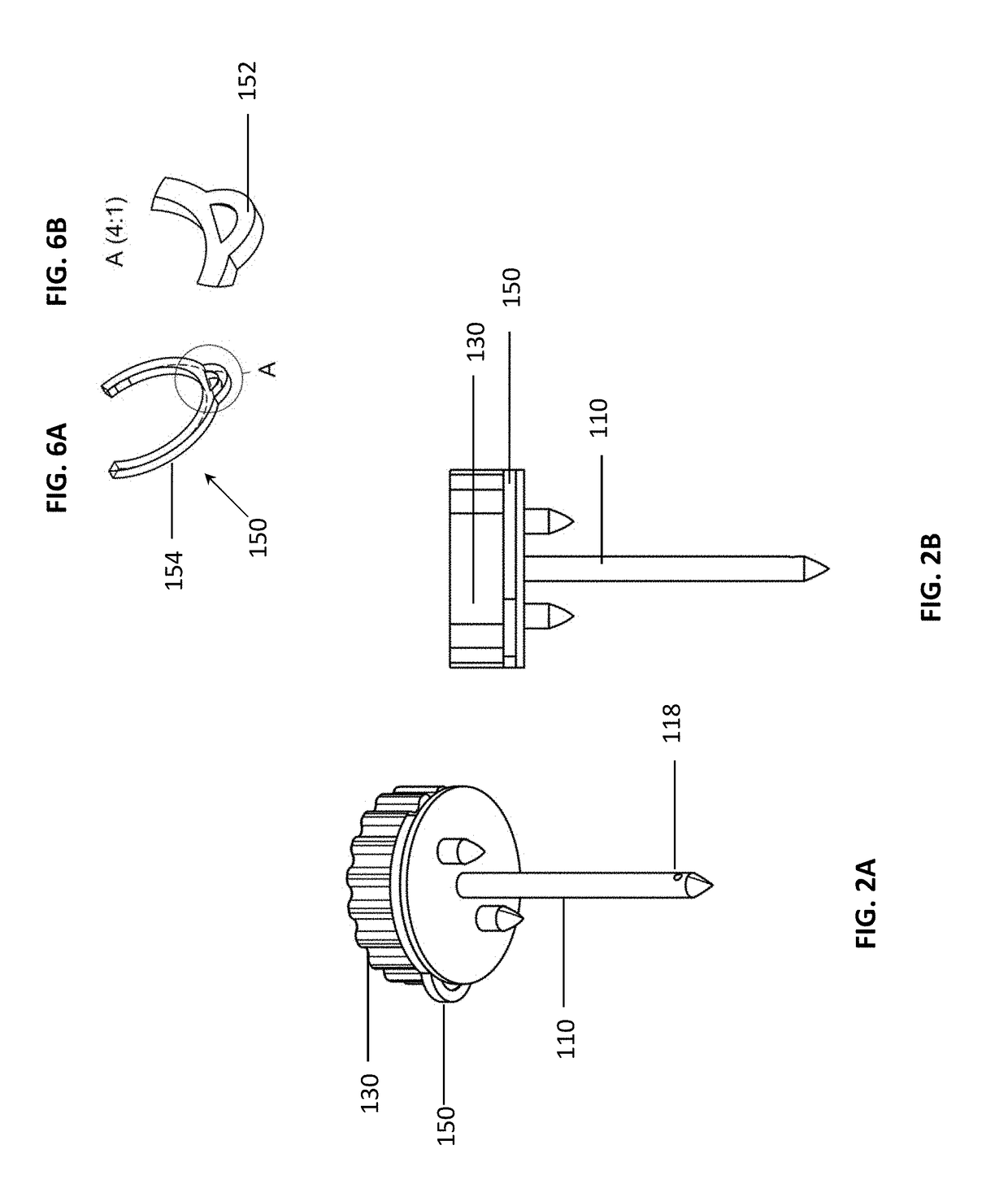

ActiveUS10815113B2Little or no effect on beverage qualityImprove sealingLiquid dispensingWine bottleEngineering

A beverage dispensing apparatus may include a beverage dispenser and associated stopper. The stopper may be used to replace a cork, cap or other closure of a beverage container, such as a wine bottle. A needle of the beverage dispenser may be inserted through a passageway of the stopper so that pressurized gas can be introduced into the container to force beverage liquid to exit the container via the needle. The stopper may suitably seal the container after dispensing is complete, e.g., to resist exposing the beverage to oxygen.

Owner:CORAVIN

Apparatus and method for detecting an analyte

An apparatus (100) and method (400) for detecting the presence of one or more chemical contaminants in / on a plurality of items, e.g., cork stoppers (110), using nose chips (310). The apparatus utilizes detection sensor electronics (225) that are separate from the nose chips such that each nose chip can be either reused or discarded after use. The apparatus moves the nose chips and the cork stoppers independently to align the cork stopper and a corresponding nose chip with one another. The testing apparatus uses multiple sensor units (135) to simultaneously test multiple cork stoppers for chemical contaminants (e.g., TCA). The invention provides a low-cost, reliable process for testing 100% of cork stoppers in a fast and cost-effective manner that is scalable to the general consumer product market.

Owner:HEAD MICHAEL S

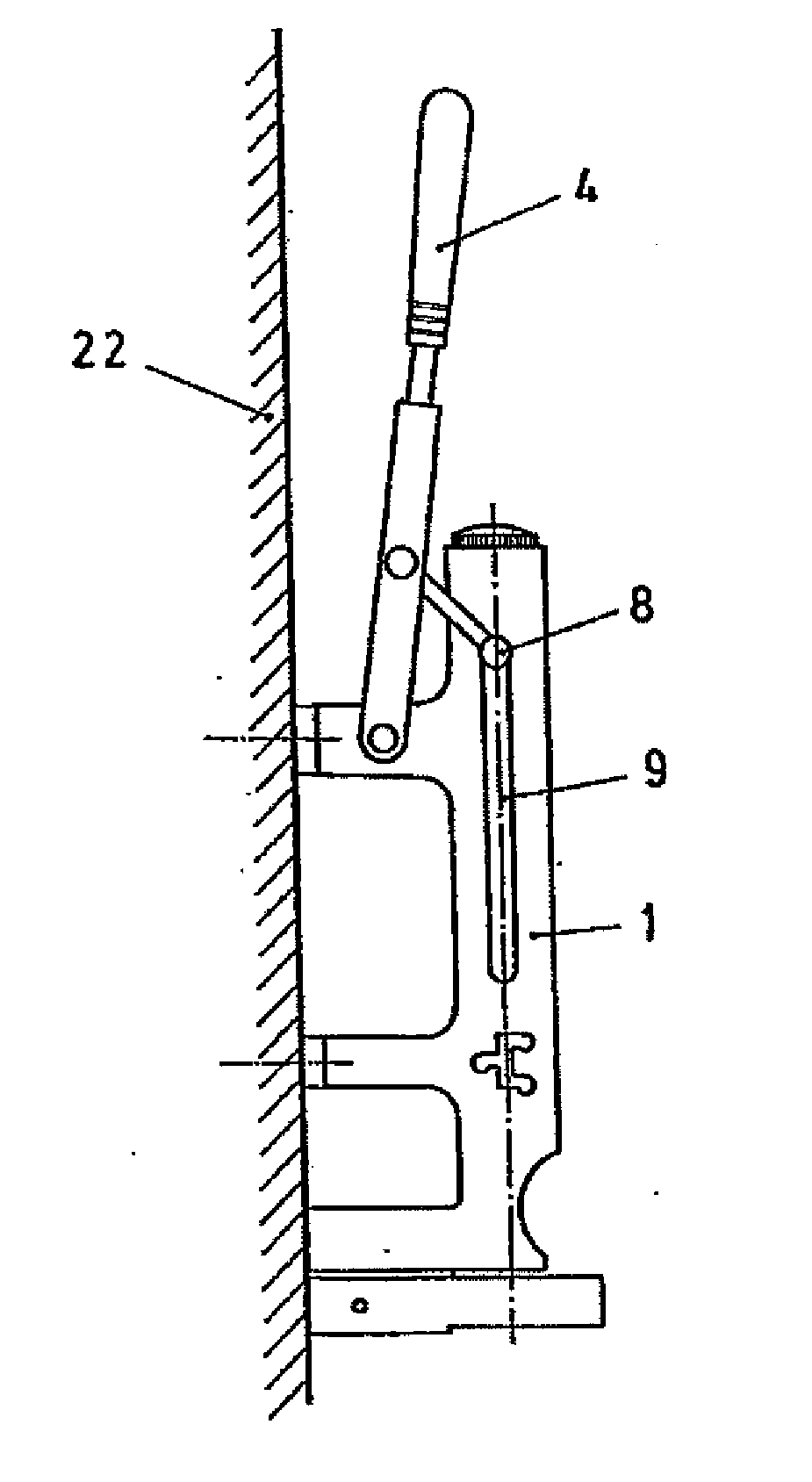

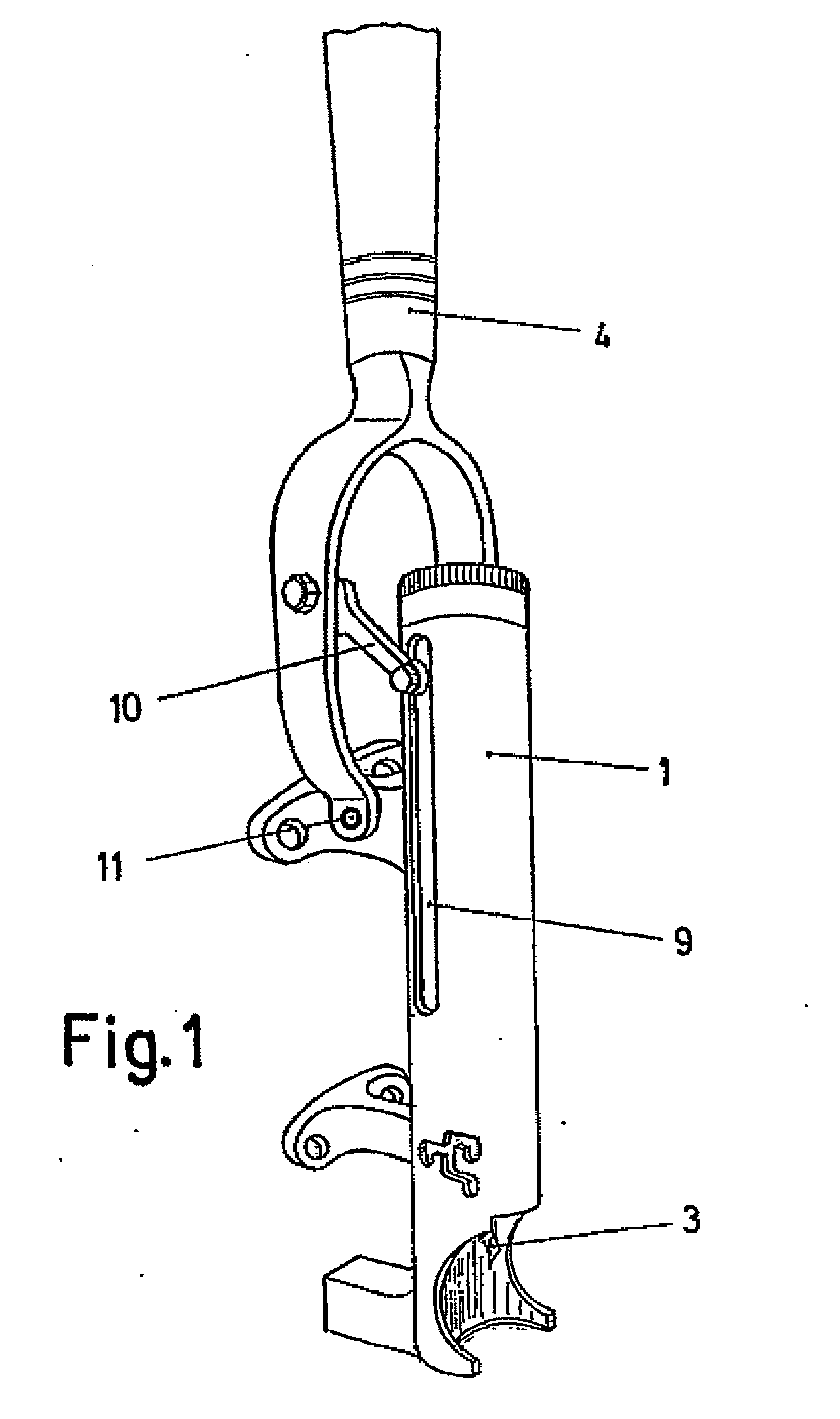

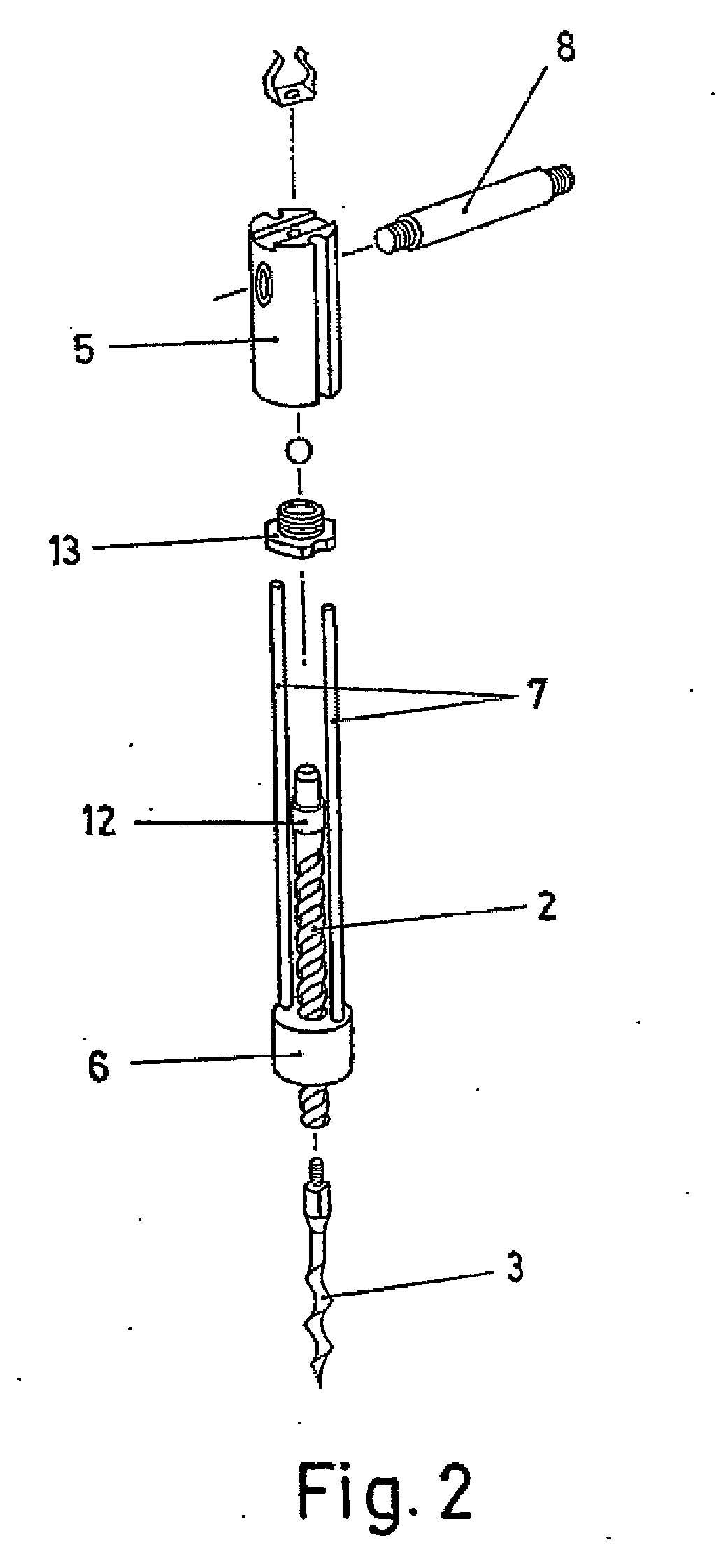

Wall-Mounted Corkscrew

InactiveUS20070289411A1Efficient solutionAdvantageous functional featureBottle/container closurePower operated devicesClassical mechanicsStructural engineering

The invention relates to a wall-mounted corkscrew comprising a mechanism which includes the helical shaft to be inserted into the cork and which is connected to an actuating lever. The aforementioned mechanism is housed inside a one-piece tubular body which is closed at one end and said mechanism comprises a plastic cylindrical part (15) in which a helical-shaft-bearing screw (2) is positioned with an axial freedom of movement. In addition, a backstop is disposed between a striction (7) inside the part (15) and a transverse shaft (8) which passes therethrough.

Owner:B OLANETA Y JUARISTI SA

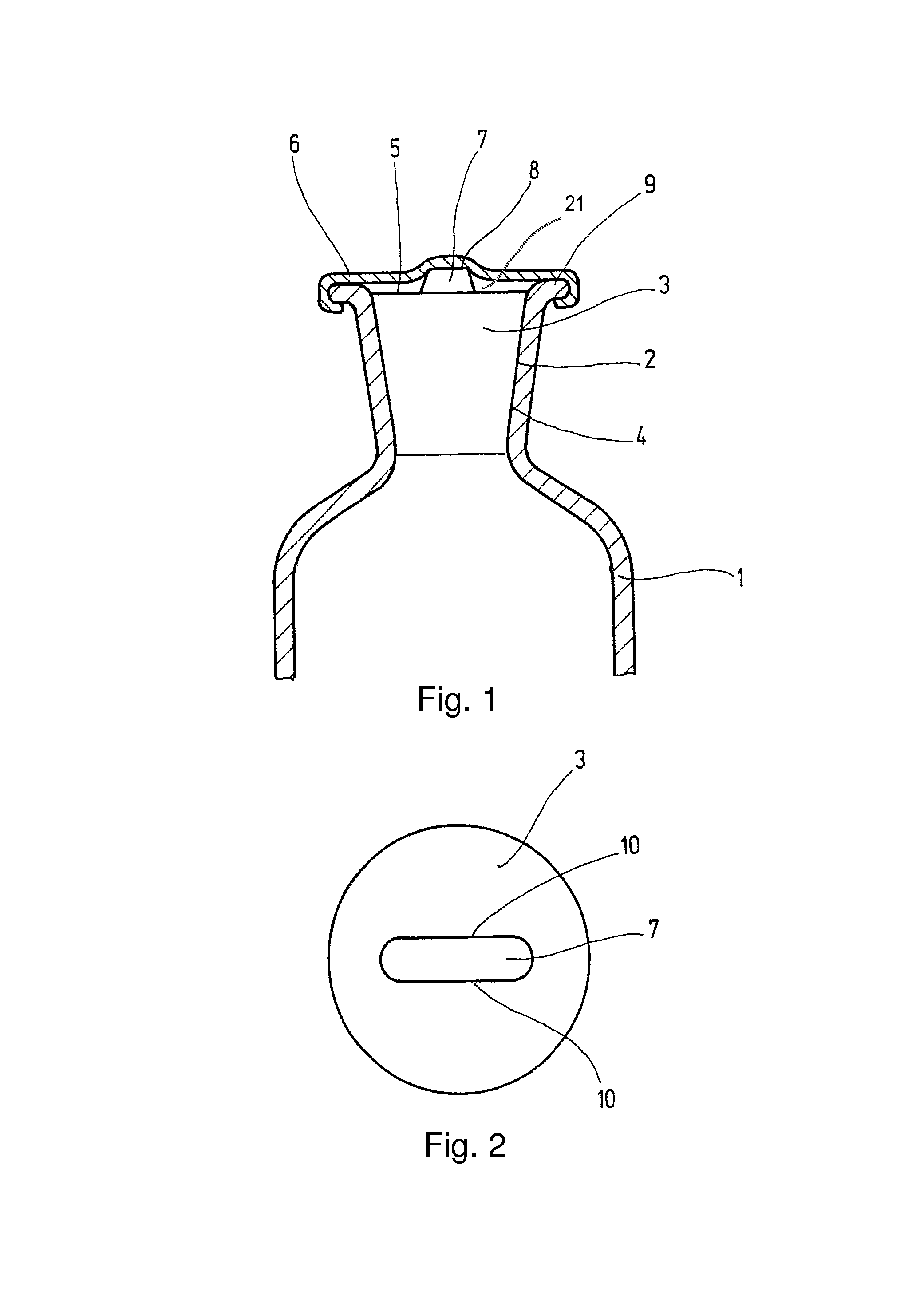

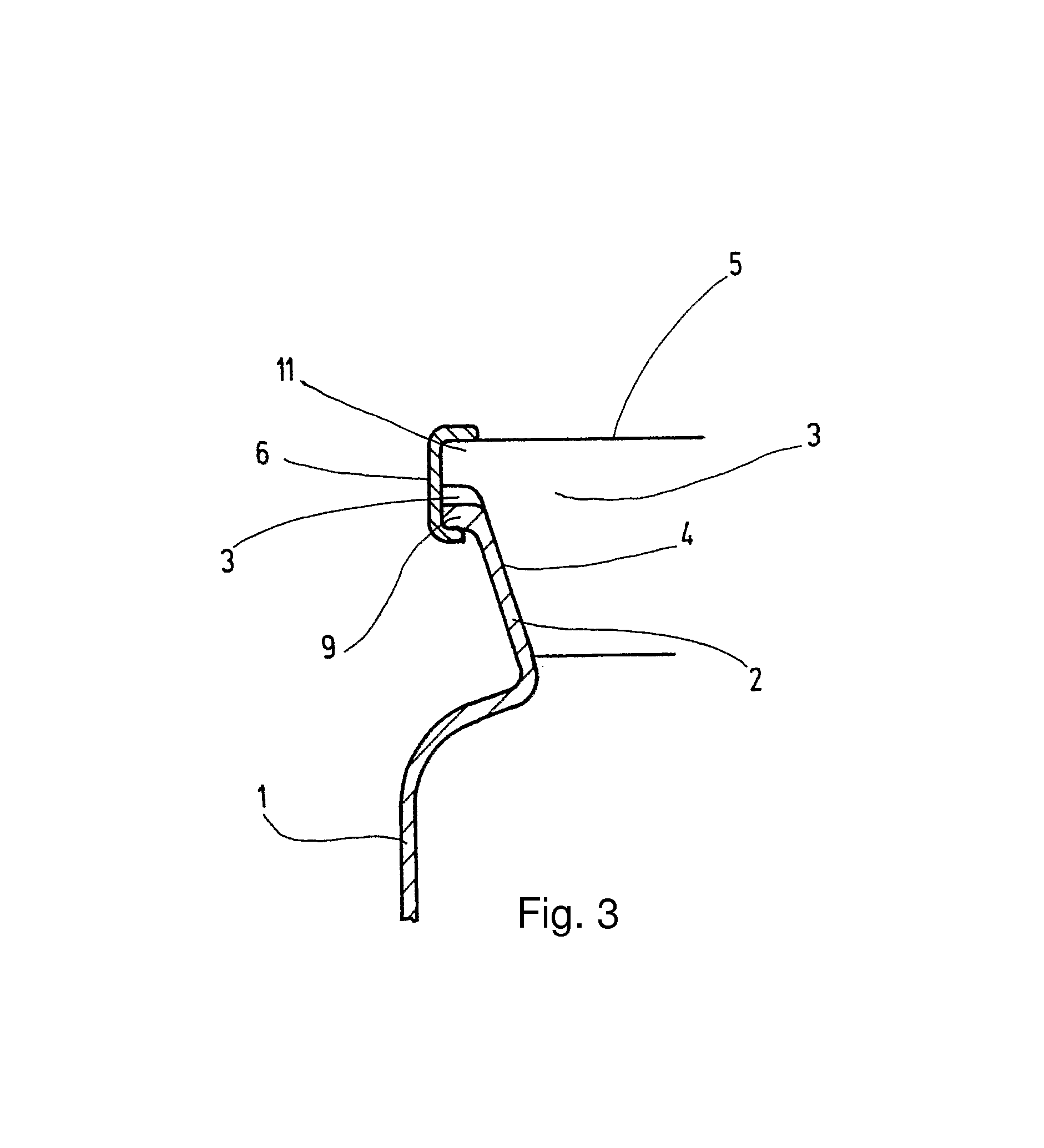

Overcap closures with rolled apron

Owner:RECHINEY CAPSULES

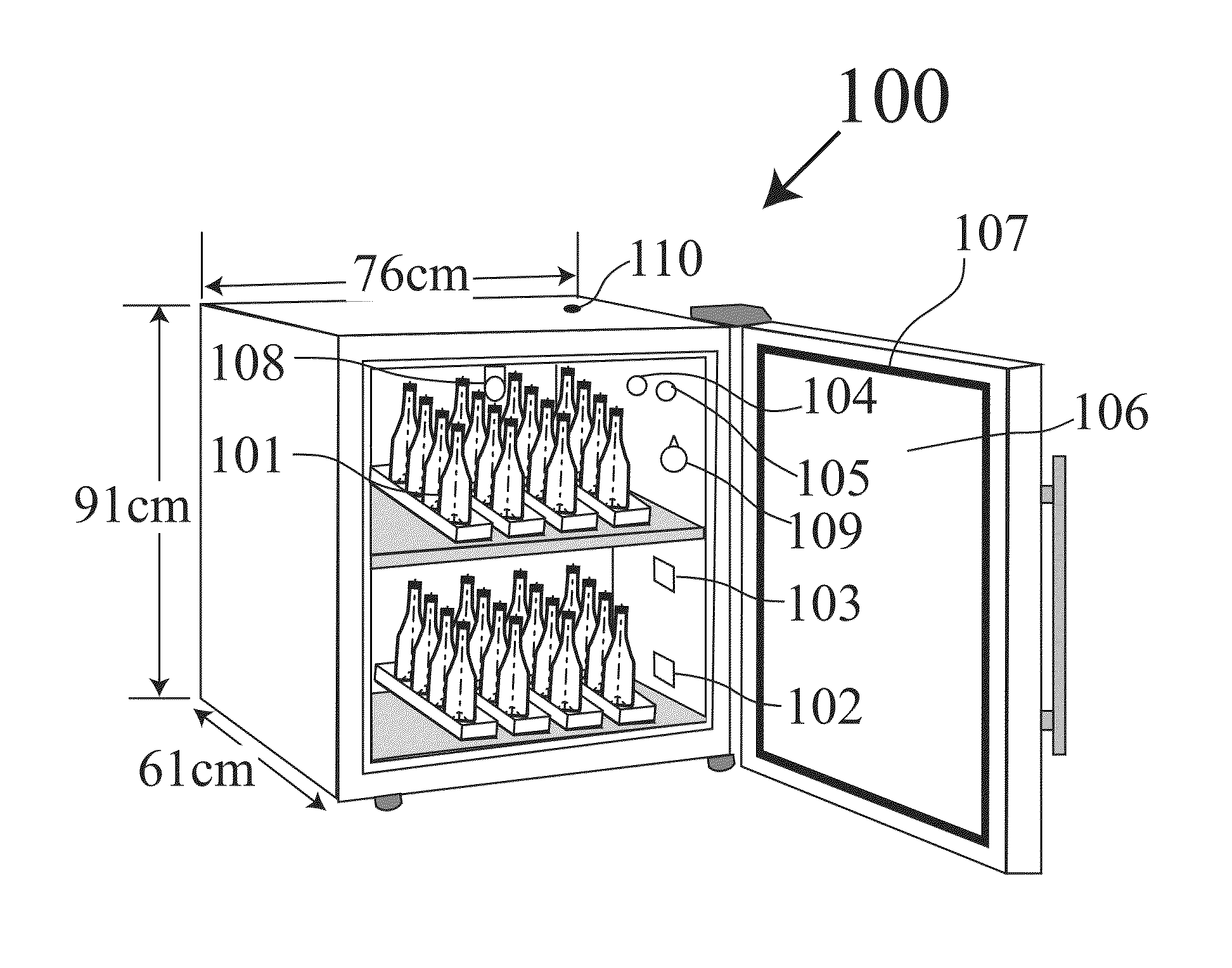

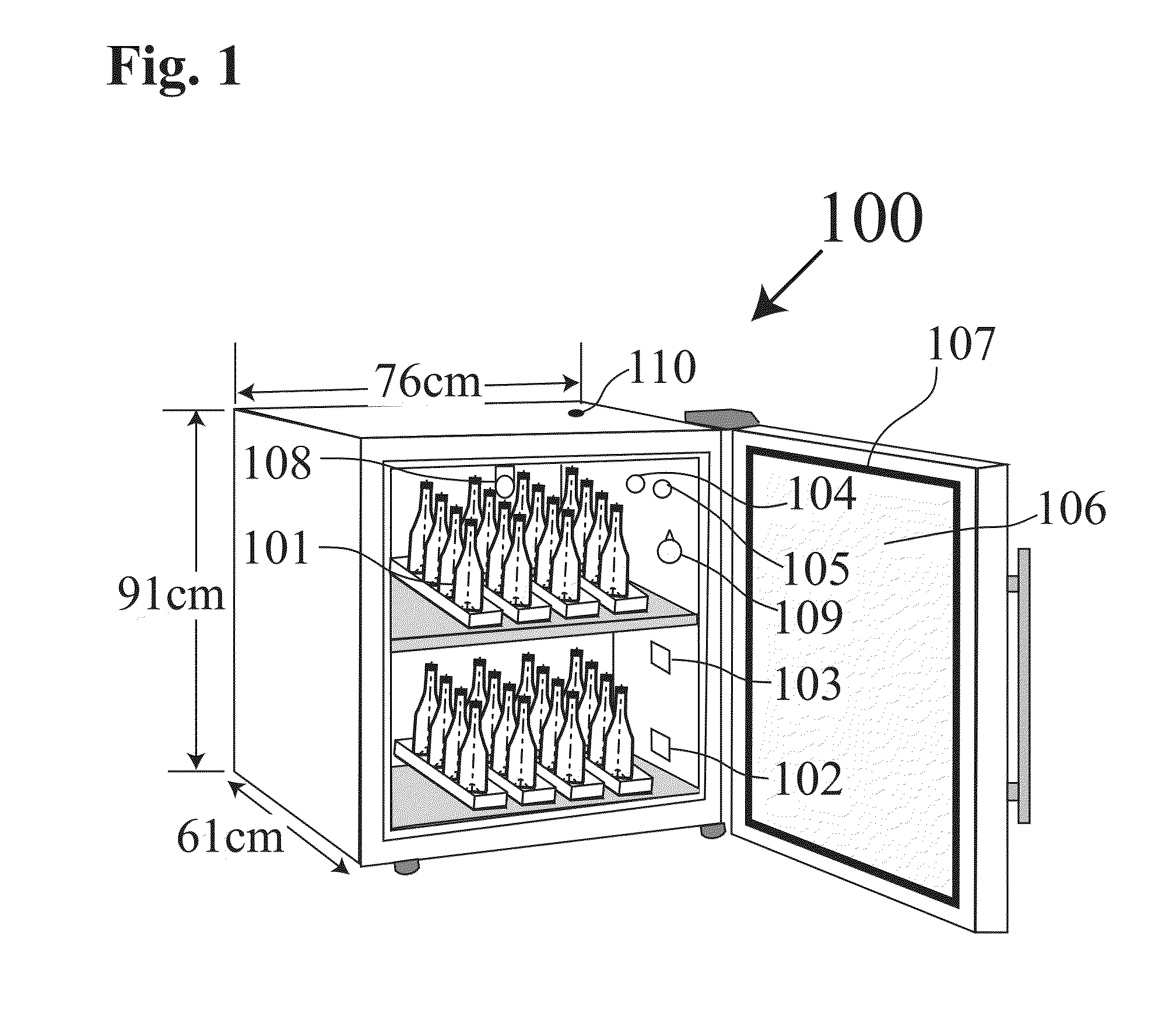

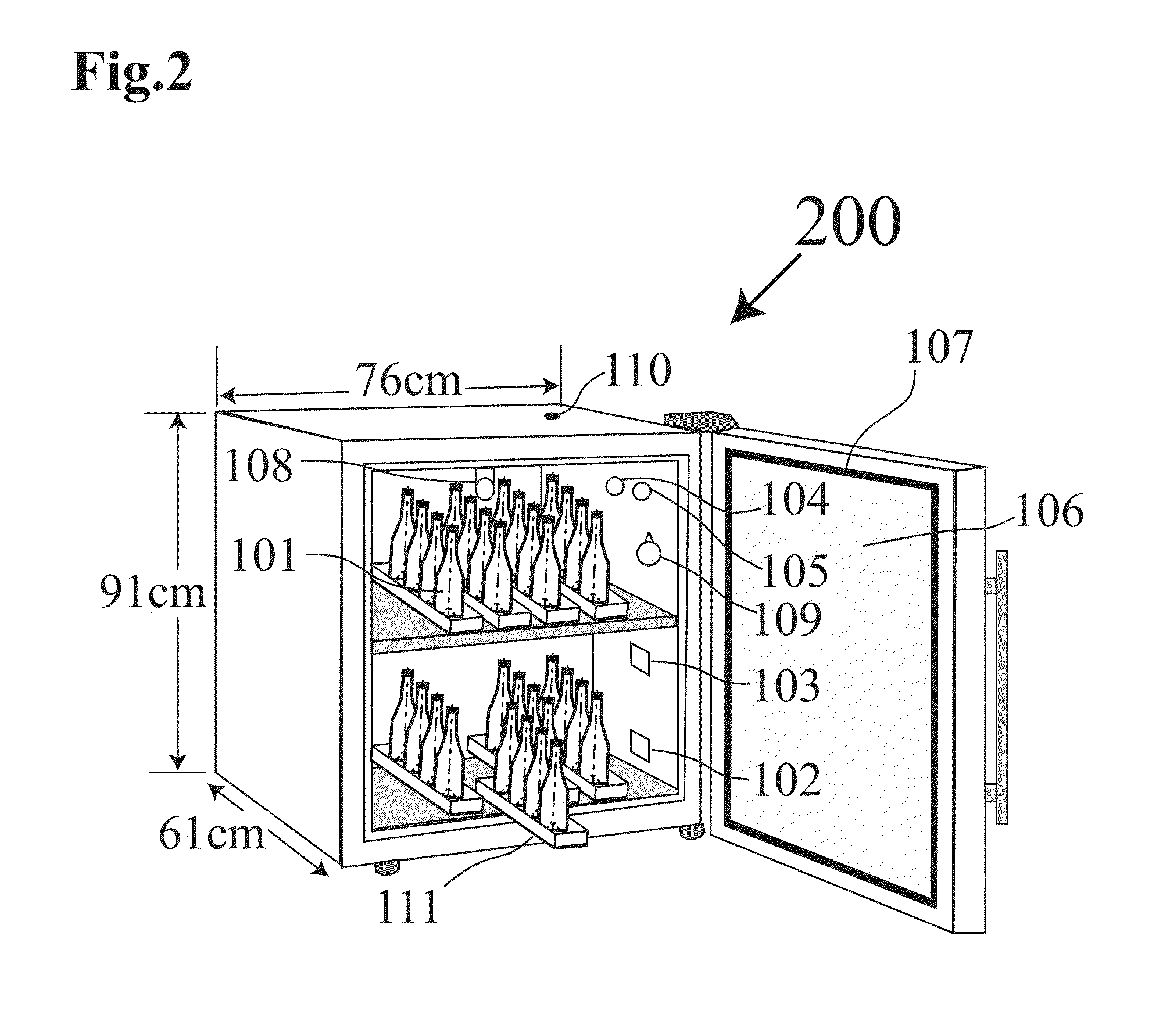

System for aging beer

ActiveUS9434918B1Easy to placeAccurate agingAlcoholic beverage preparationMachines using electric/magnetic effectsEngineeringRefrigeration

An insulated beer fridge stores and ages corked craft beer in a vertical orientation for a period of several months to years without degrading the cork stopper used to seal the bottle. Cork shrinkage is prevented by controlling the humidity within the beer fridge container within a range of 50% to 70% relative humidity. An optimal beer aging temperature in the range of 10° C. (50° F.) to 15.6° C. (60° F.) is maintained by a refrigeration system. Relative humidity within the beer fridge containment is actively maintained by a humidity replenishment mechanism. A controller calculates the amount of water needed to bring the relative humidity to 50% to 70% at the beer fridge temperature. Beers are stored in the beer fridge on trays, which can be pulled for removal of aged beer and addition of new corked craft beer.

Owner:NARASIMHAN SANDYA LAKSHMI +2

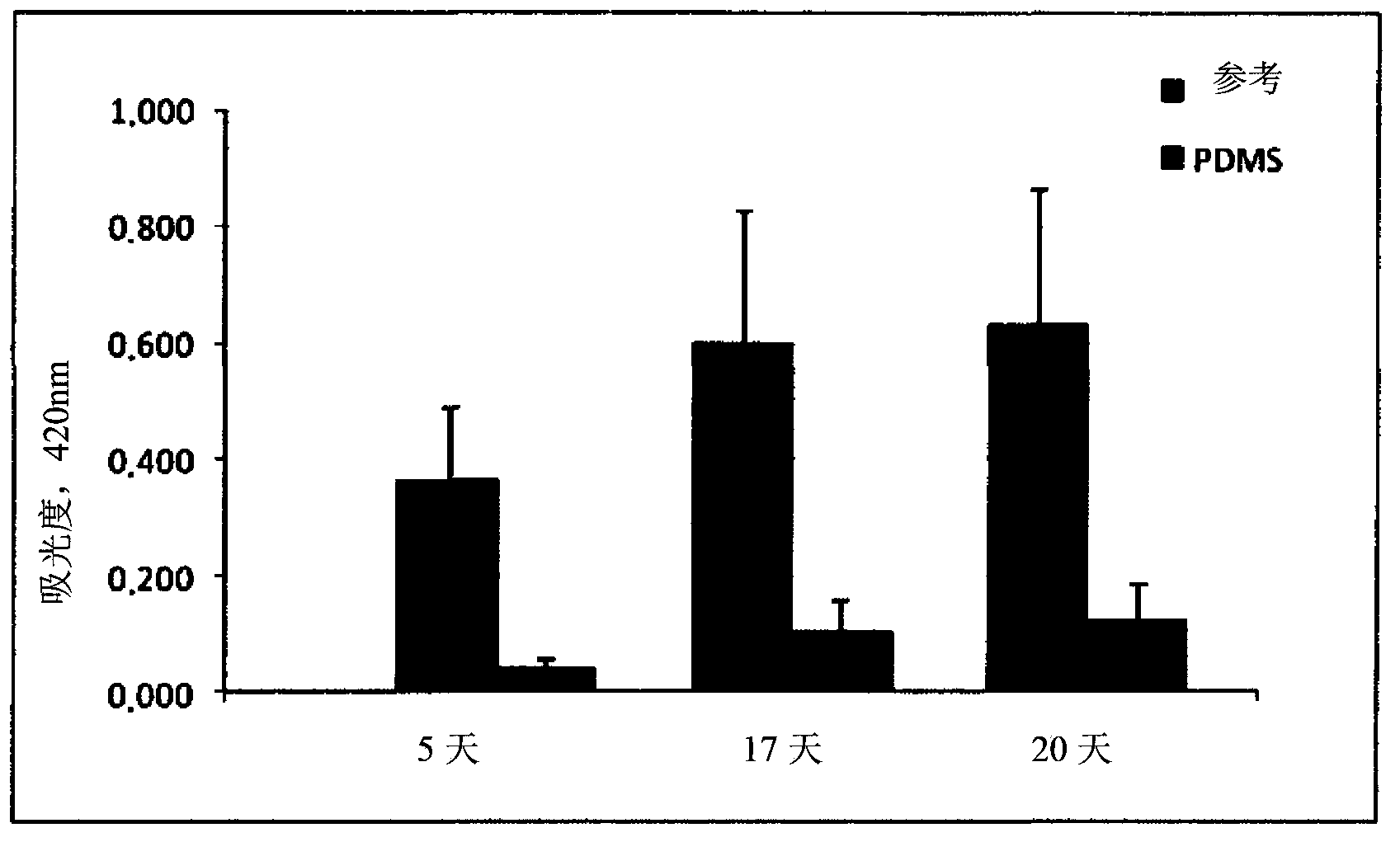

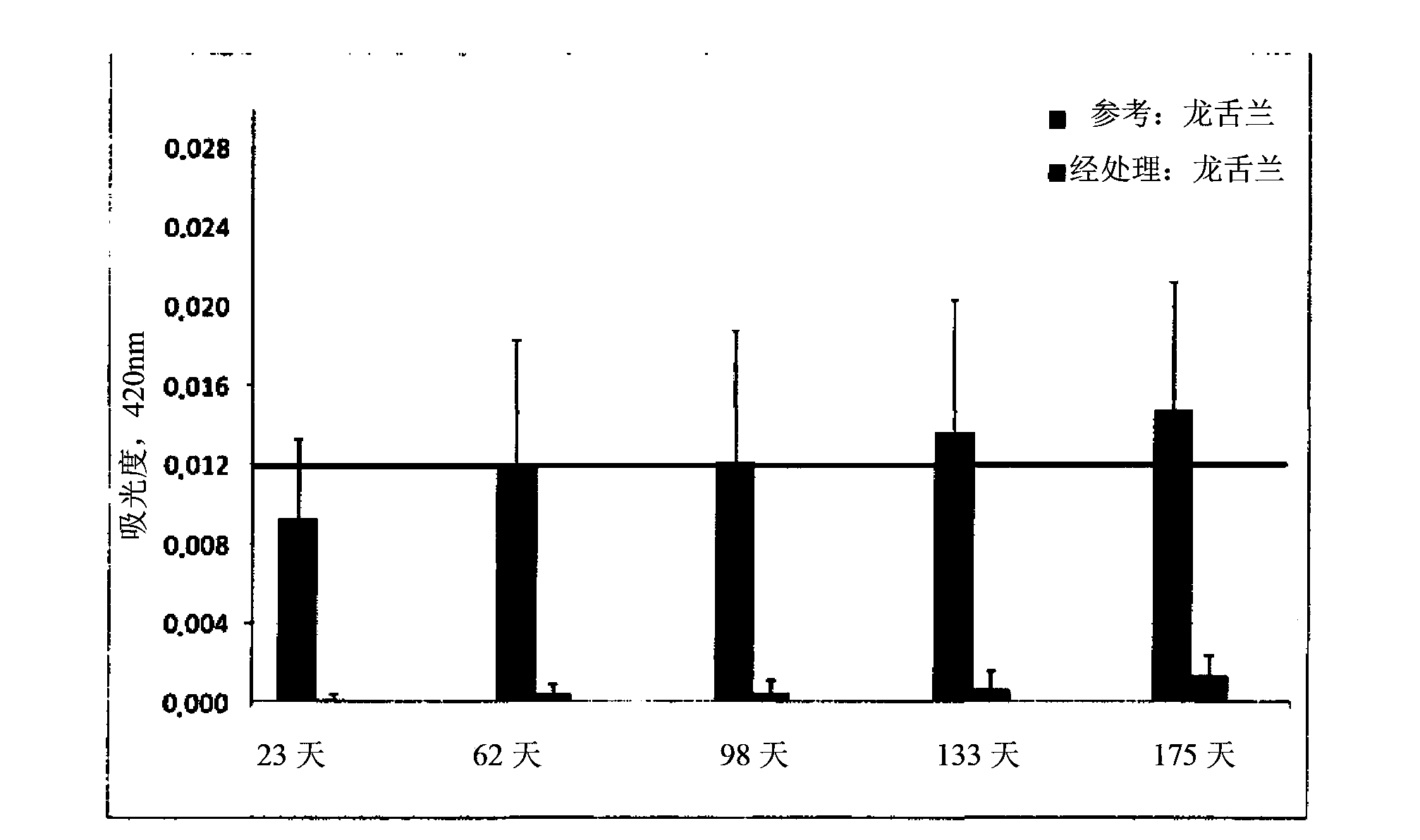

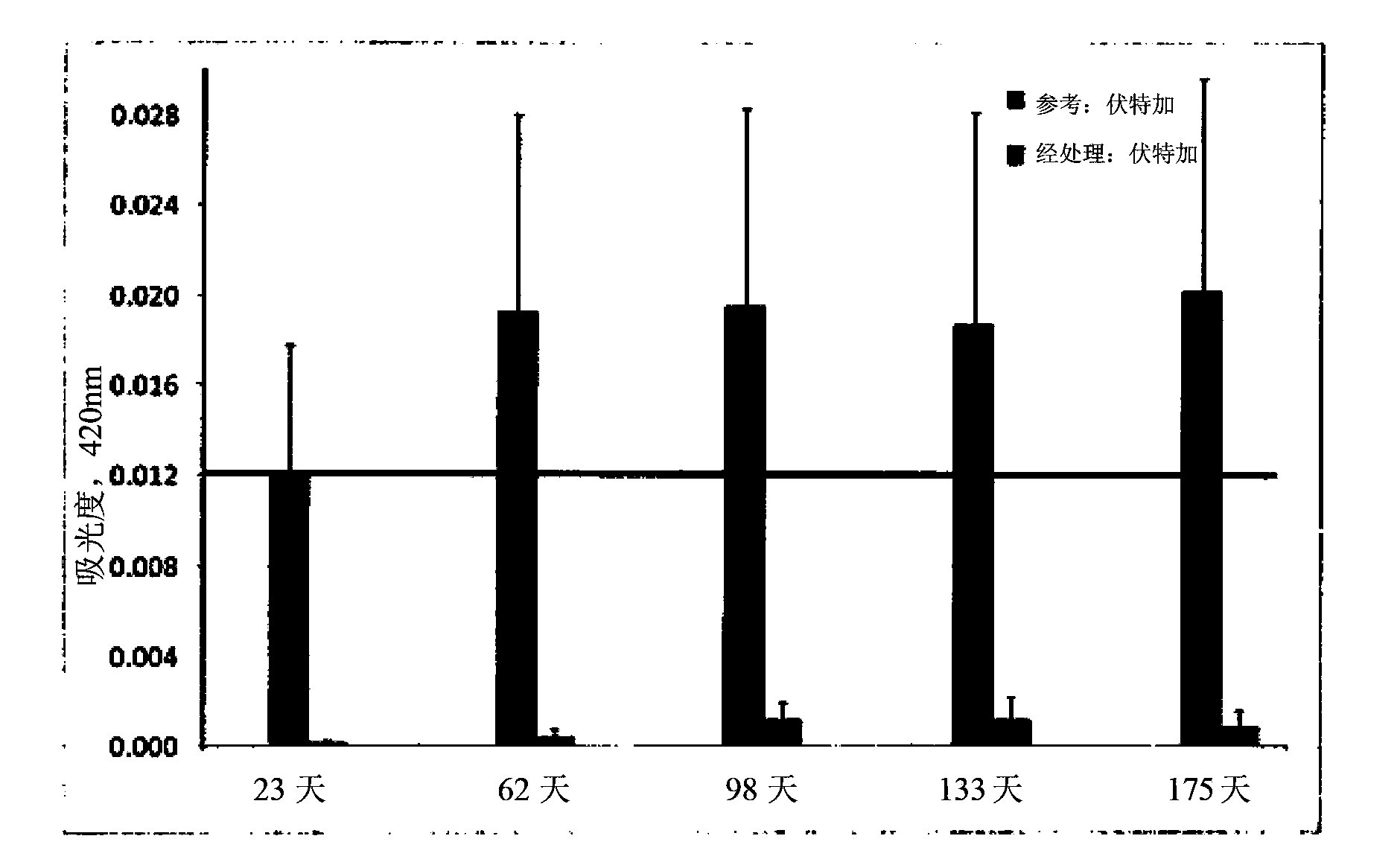

Process for applying polymeric coating on cork stoppers

InactiveCN103534039APromote migrationReduce barrier effectClosuresClosure using stoppersBarrier effectCork stopper

The present invention discloses a process for applying a polymeric coating that provides an efficient barrier effect to the migration of coloured compounds, namely polyphenols, from the cork stopper into a white alcoholic beverage. For this effect the process of the invention comprises the steps of: 1) depositing a polymeric film on cork stoppers to provide a non-cured polymeric coating on the stoppers; 2) gradual curing of the polymeric coating by applying a temperature variation rate in the range of about 3 DEG C / min to about 6 DEG C / min, in order to gradually raise the temperature from about 40 DEG C to about 110 DEG C; and 3) final curing of the polymeric coating at constant temperature in the range of about 70 DEG C to 120 DEG C for at least 5 minutes. The efficacy of this coating will make possible the implementation at industrial level of cork stoppers in the market of white alcoholic beverages.

Owner:AMORIM & IRMAOS

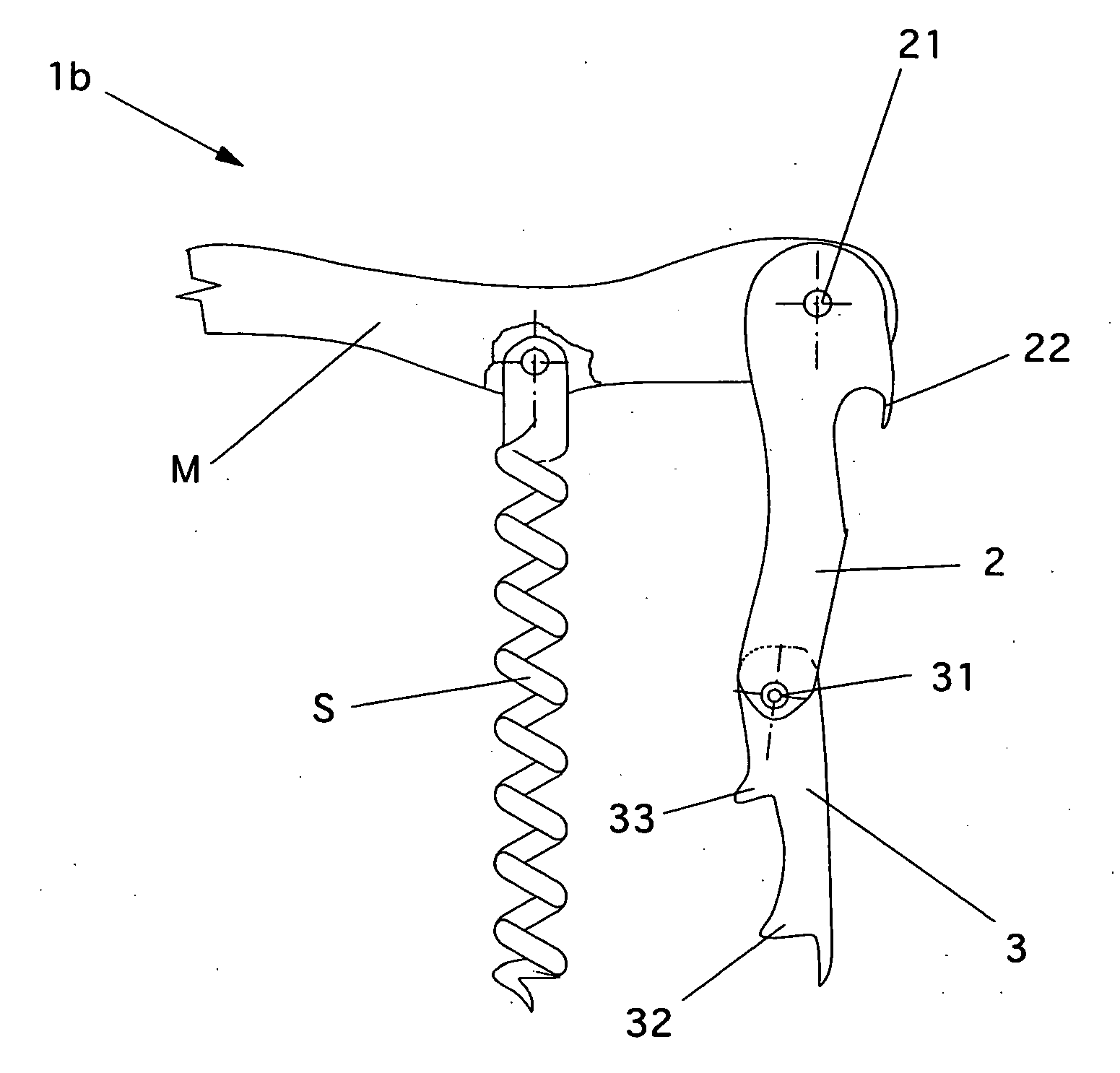

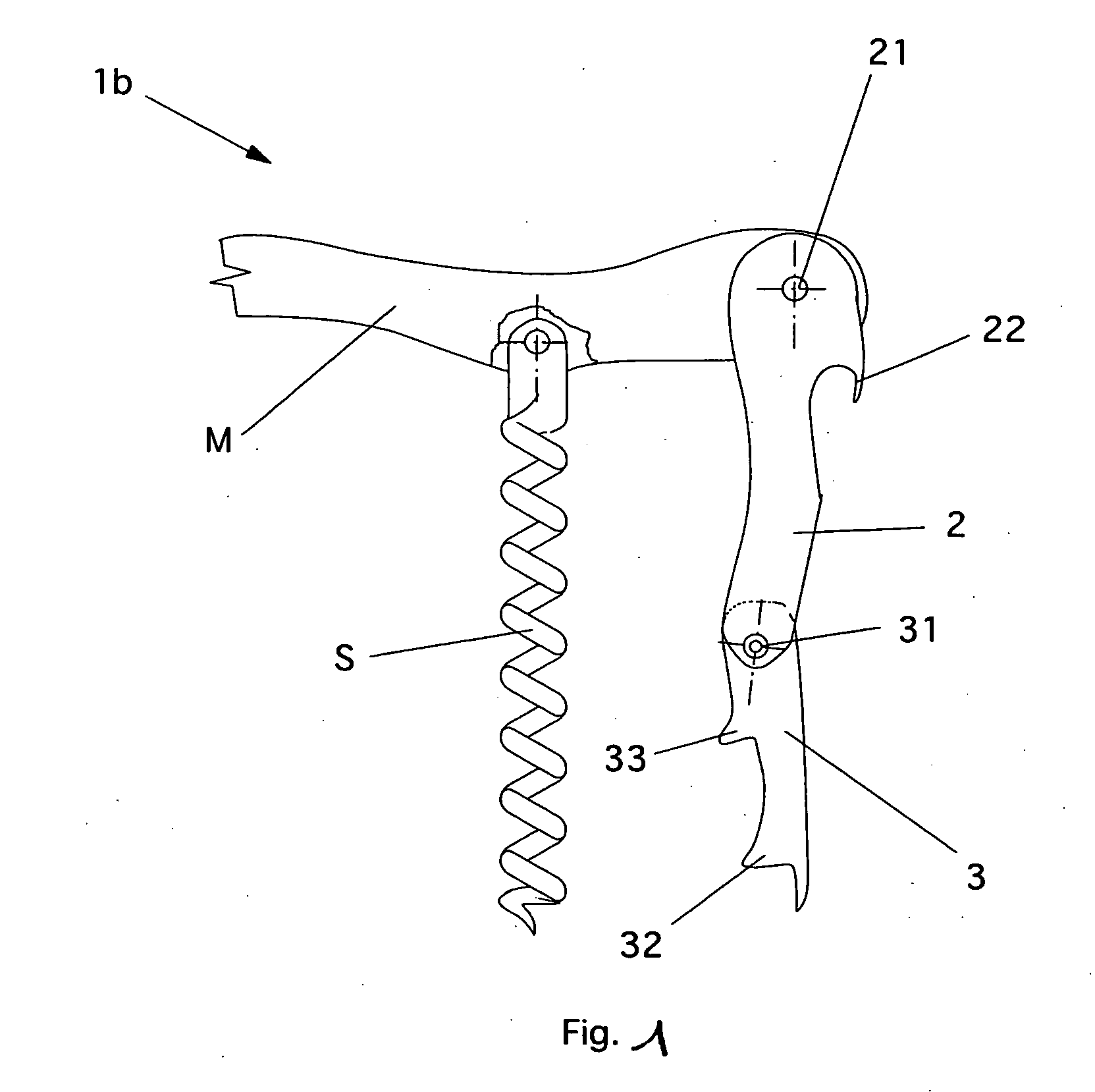

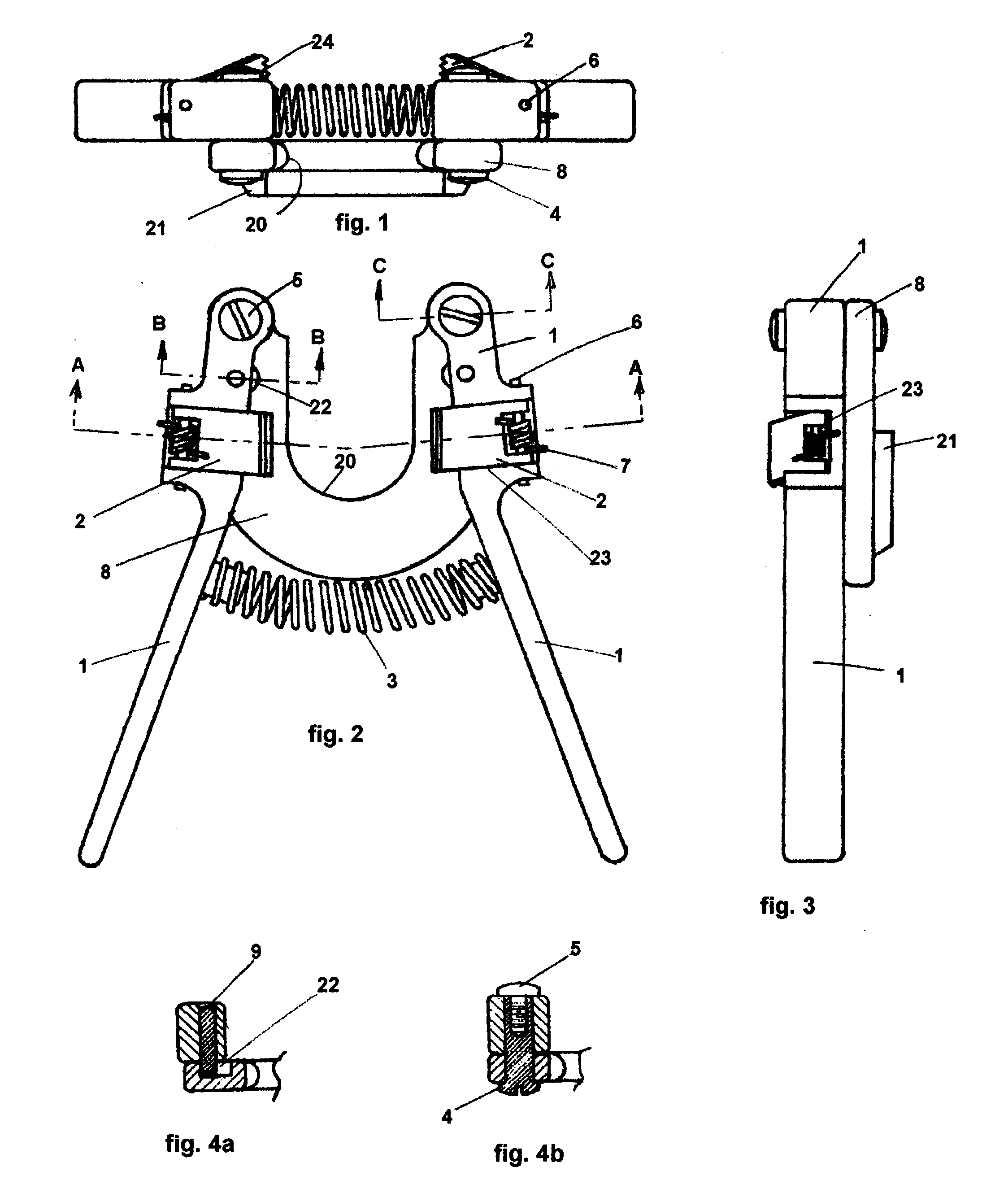

Cork-screw with double propping lever

ActiveUS20070051205A1Without bluntingWithout fastidious hooking lossesBottle/container closurePower operated devicesEngineeringStructural engineering

Cork-screw with double propping lever, with an adjacent extraction cork-screw, in which the double propping lever presents a first base lever hinged which one end to the handle of the tool, and a second extension lever for the propping hinged at the end of said first base lever, whereby said second extension lever for the propping presents two propping support teeth, one support teeth at the end and one support teeth close to its articulation to the print base lever.

Owner:FARFALLI DANIELE +1

Environment-friendly cork compound material, adhesion agent and preparation method for products thereof

InactiveCN103072177AAntioxidantUsableWood working apparatusDomestic articlesPlant fibrePulp and paper industry

The invention discloses an environment-friendly cork compound material, an adhesion agent and a preparation method for products thereof. After the adhesion agent for the environment-friendly cork compound material is prepared, the adhesion agent is applied to the cork compound material and the products thereof. The environment-friendly cork compound material comprises a cork waste material, a natural plant fiber, the adhesion agent and an essence, wherein the cork waste material is a red wine cork recycling material. The preparation method for the products of the environment-friendly cork compound material comprises the following steps: a, crushing a red wine cork; b, mixing all the raw materials of the compound material; c, split-charging the fully mixed raw materials; and d, completely pouring the mixed raw materials in an utensil into a cavity of a mould for the required products, and hotly pressing and shaping. The products made of the cork compound material are environment-friendly and non-toxic, has the effects of antibiosis, mildew resistance, anti-oxidation, and the like, and meanwhile has an excellent mechanical property.

Owner:杨鸿雨 +1

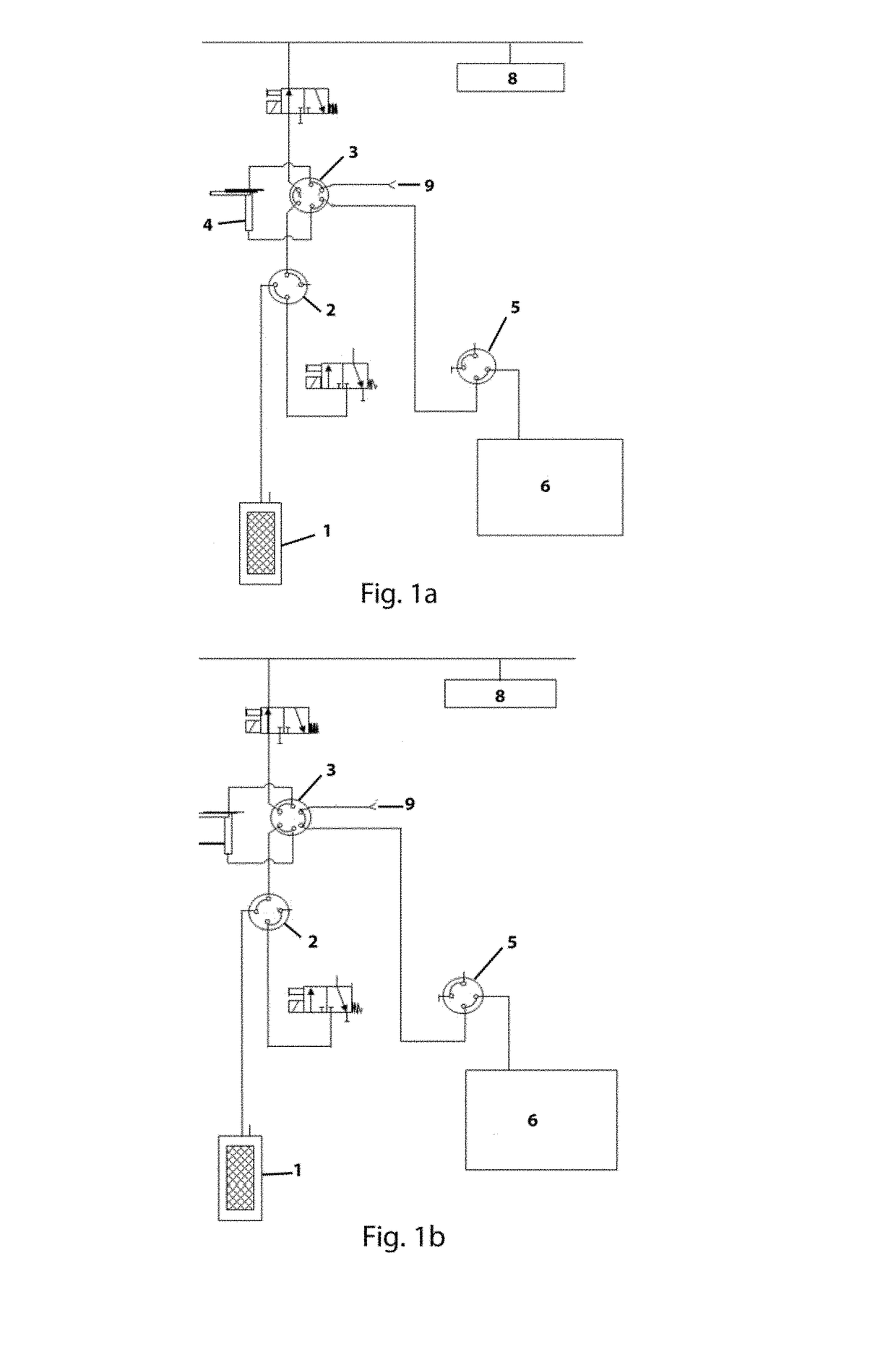

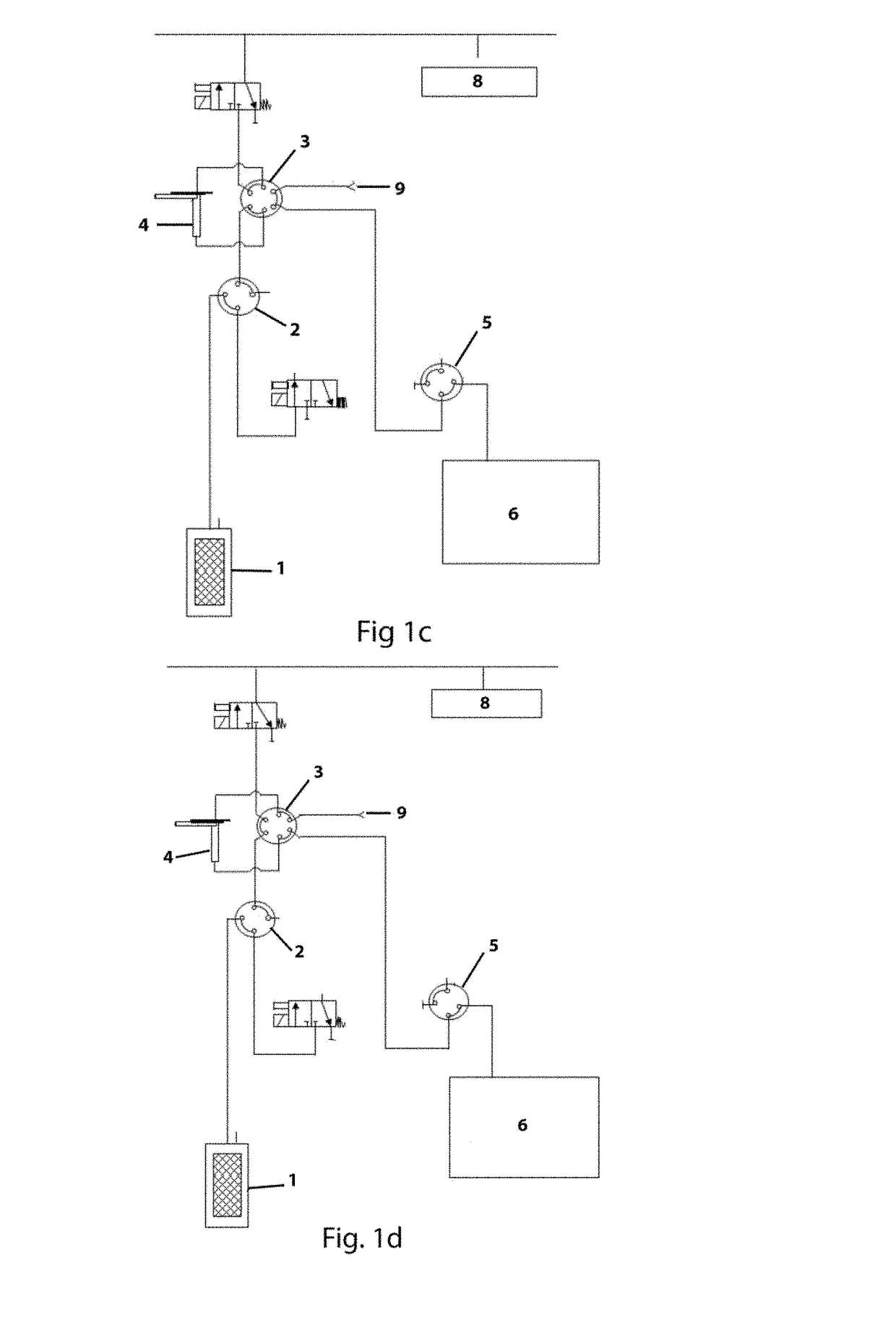

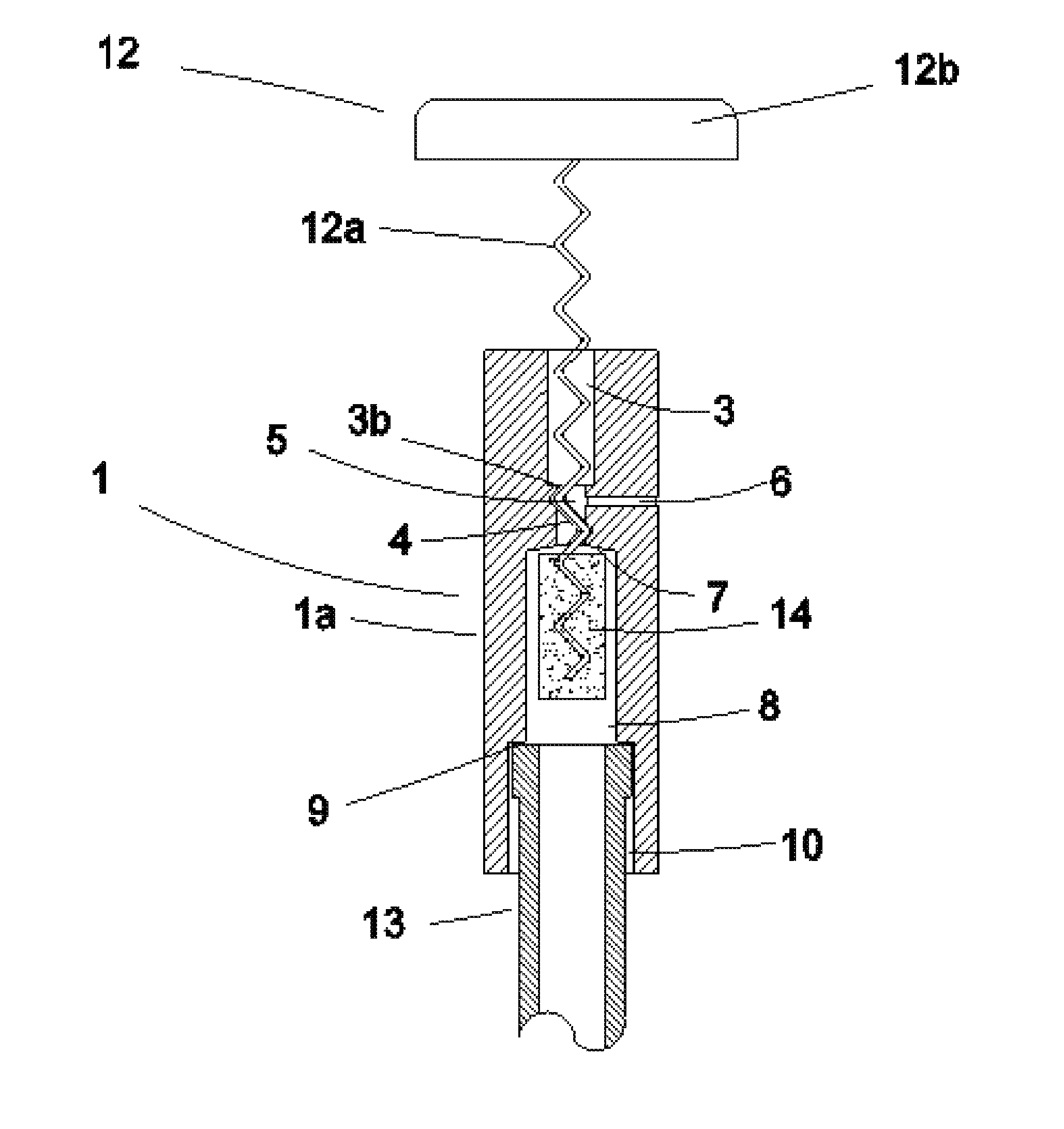

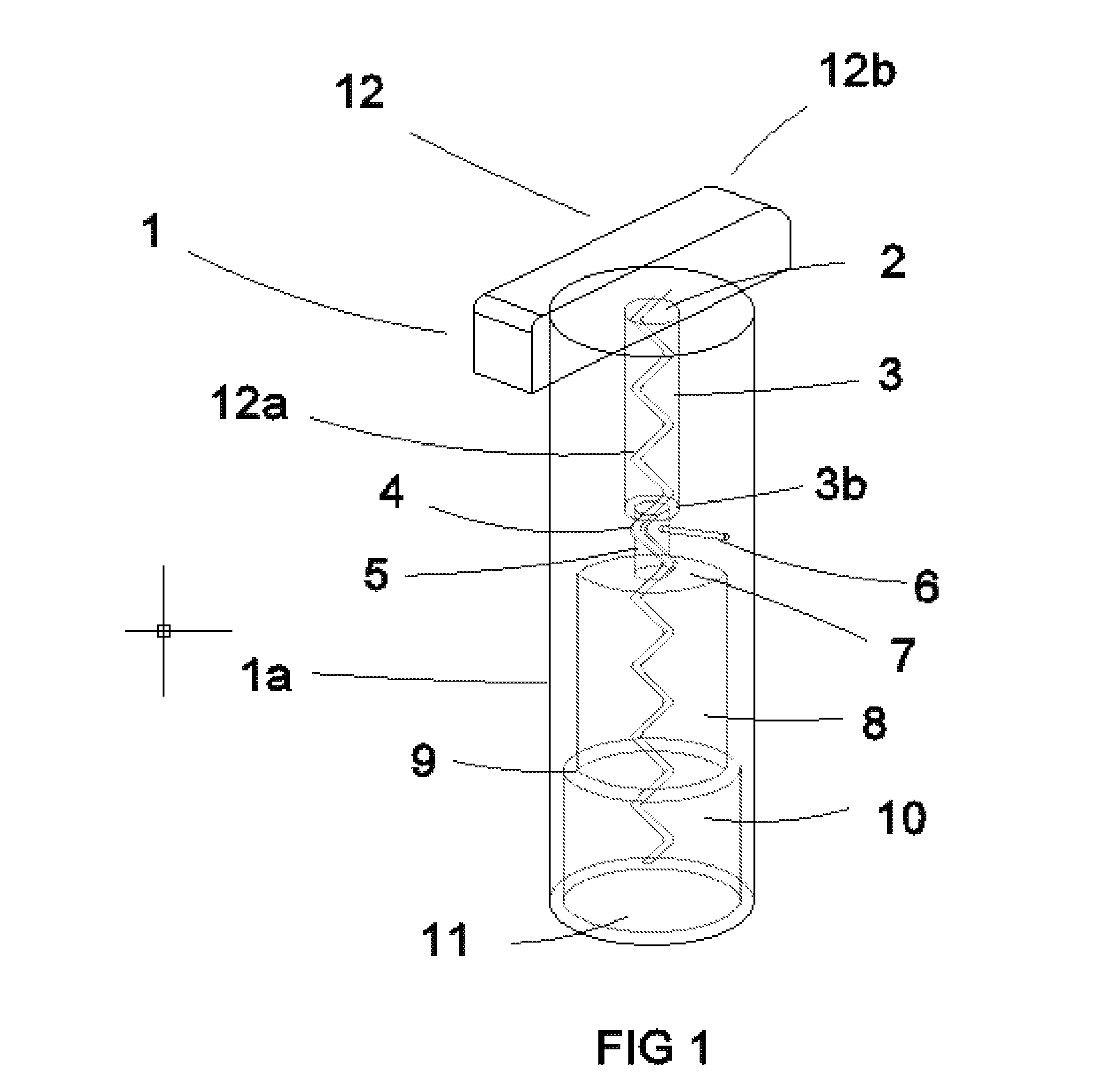

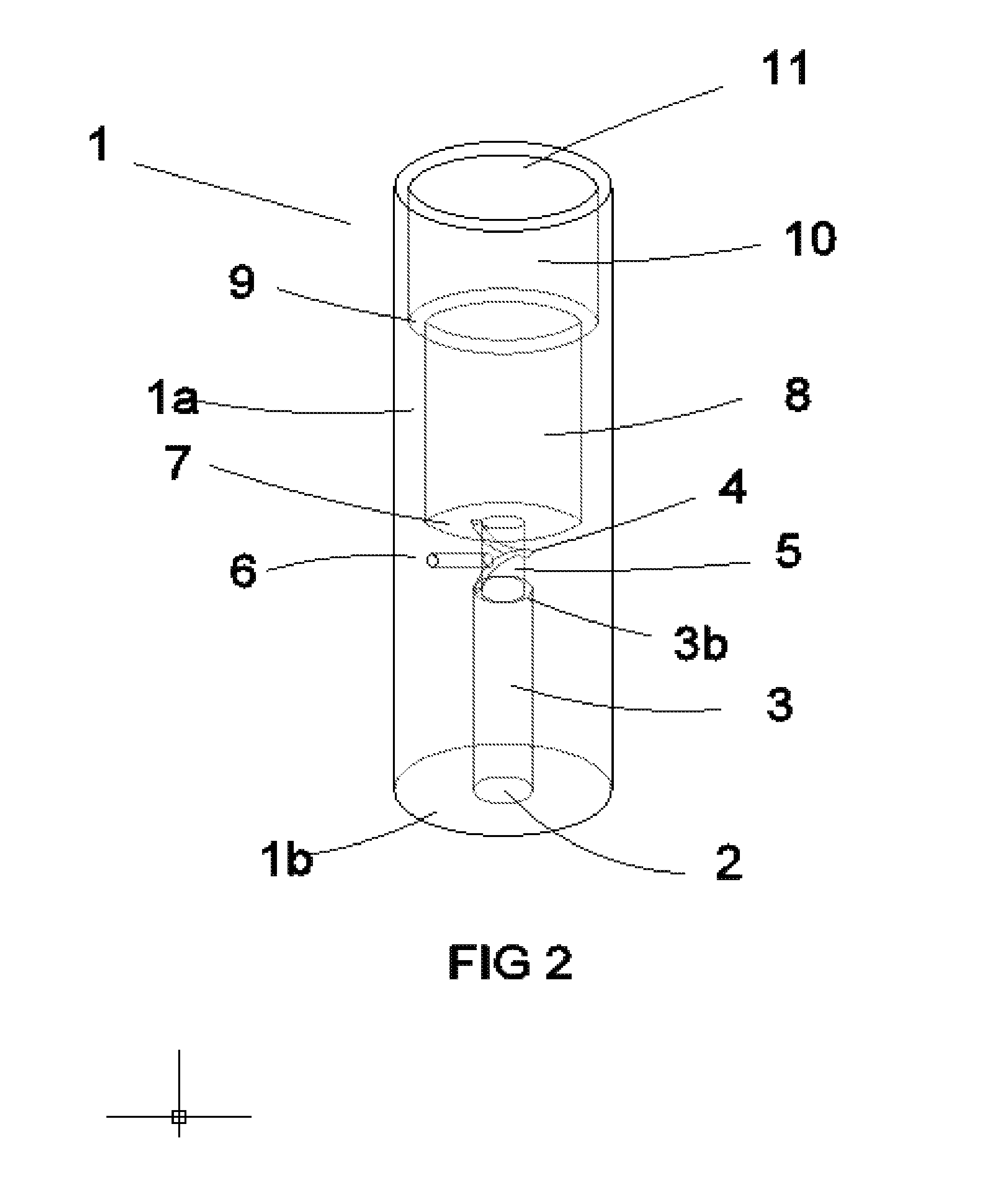

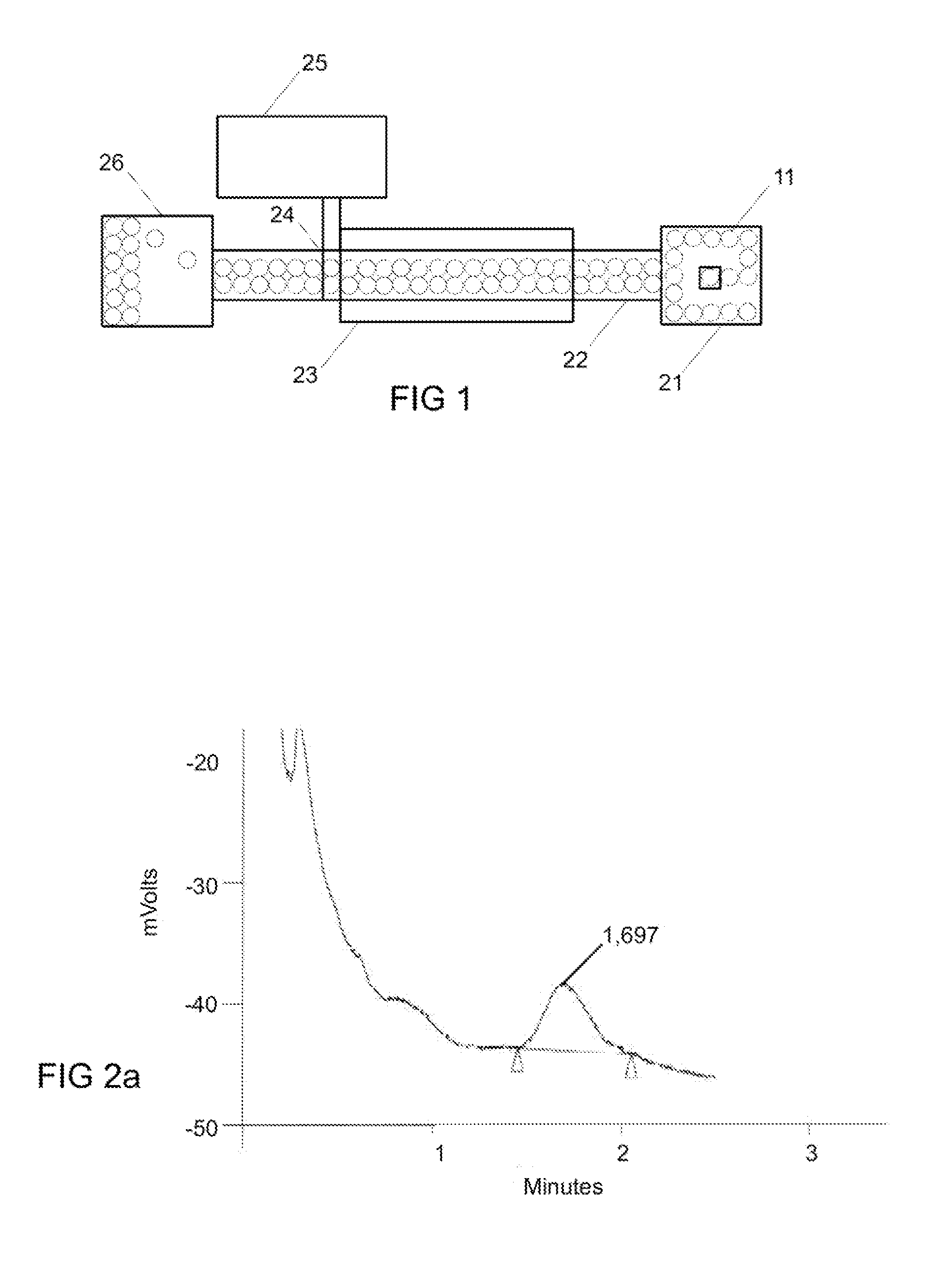

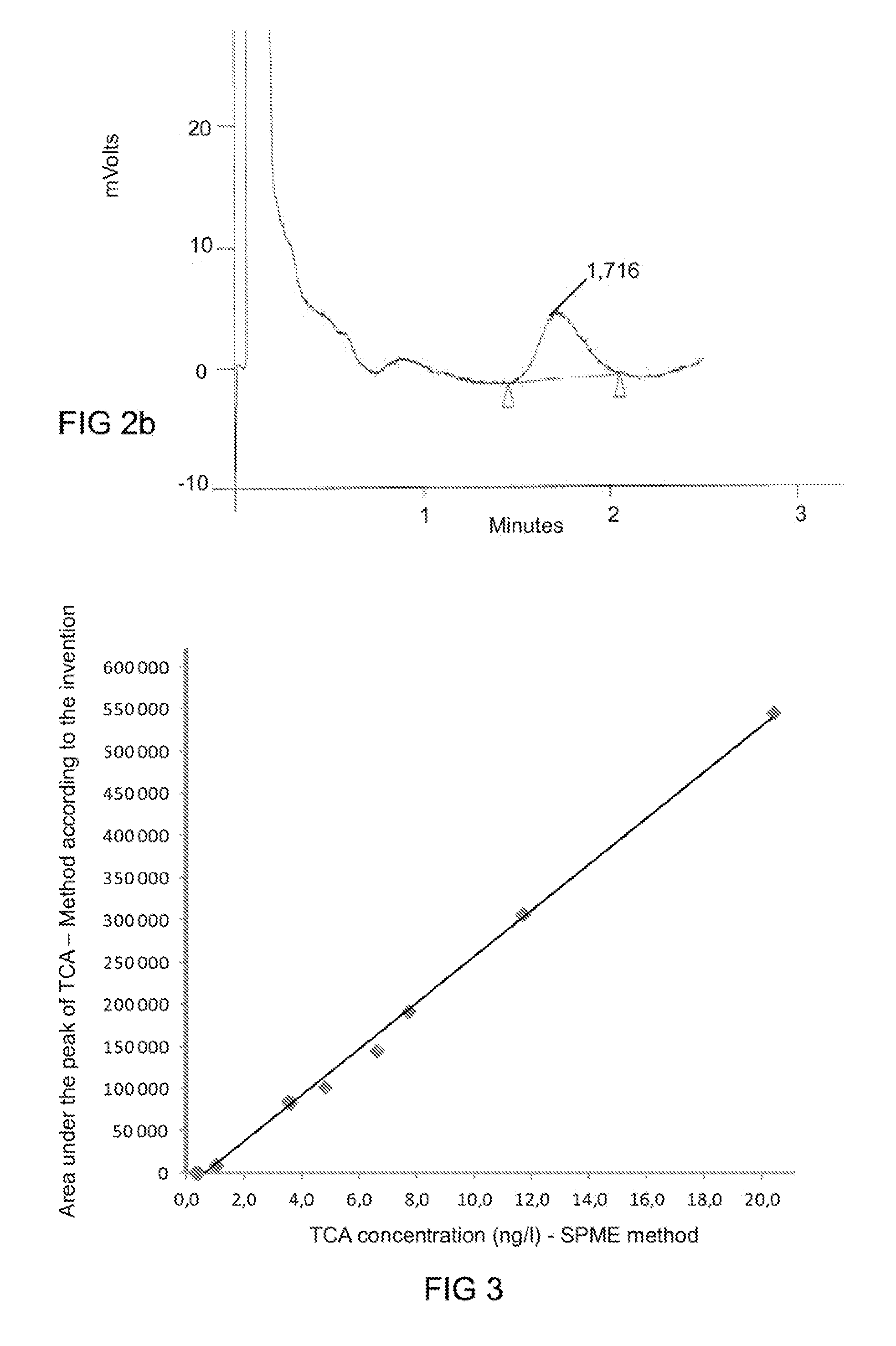

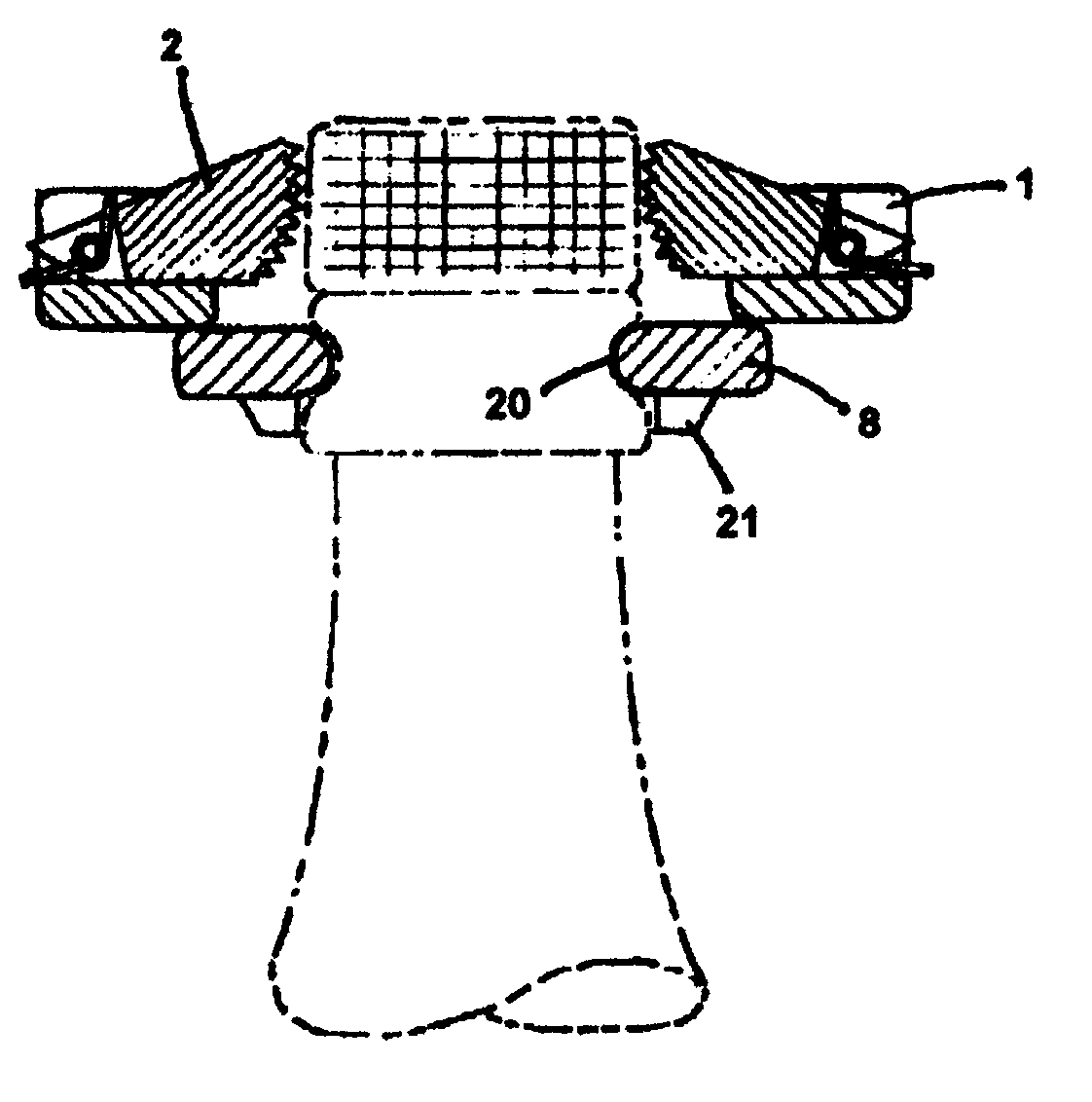

Method for detecting a volatile analyte for classing and sorting cork stoppers depending on the concentration of the analyte

ActiveUS20170241967A1Good chemical stabilityWithdrawing sample devicesTesting plants/treesAnalyteDesorption

A method for detecting a volatile analyte to class and sort cork stoppers depending on concentration of the analyte, detection being performed of concentrations in the order of ng / L (parts per trillion), in a concentrated gas applied to the cork stoppers in closed containment. Under said method, cork stoppers are conveyed individually or groups to an incubation chamber (1); air / nitrogen is injected into the incubation chamber (1), the gas enriched with cork volatile compounds is entrained and carried to the concentration system containing a trap (4) heated by desorption of volatile compounds; the volatile compounds are carried by entraining gas to a detection system (6) recording a signal associated with presence of the analyte, the signal being used for classing the stopper / groups of stoppers; a software receives and compares the signal with a minimum limit, deciding to approve or reject the stopper. A system for implementing this method is described.

Owner:CORK SUPPLY PORTUGAL

Dry offset rotary printer for labeling wine corks

Owner:APEX MACHINE

Bottle opener cork remover

A device for removing a cork from a bottle, the device including: (a) a hollow needle, adapted to be inserted in the cork; and (b) pressurized gas sealed in an inner volume of a container; wherein the pressurized gas is adapted to be released from the container when a path of fluid communication is formed between a proximal end of the hollow needle and the inner volume of the container, such that the pressurized gas is channeled through the hollow needle, and into the cork or into the bottle, below the cork thereby forcing the cork out of the bottle.

Owner:WINE UP LTD

Combined Corked Bottle Opener and Fluid Aerator

InactiveUS20120111153A1Easy to disassembleAvoid piercingBottle/container closurePower operated devicesEngineeringBottle

An apparatus used for a corked bottle opening and fluid aeration device. It is comprised of a vertical holder with features to receive and guide the bottle and with features to permit and direct fluid flow for aeration; a cork-engaging member with a handle and corkscrew; a fluid receiving section; and a means for connecting the apparatus to the atmosphere. Preferably the features divide the sections by a stop, by a cone shape, and by a shoulder. The apparatus engages the corkscrew to the holder when used as a bottle opener and the apparatus restricts fluid flow enabling a venturi effect when used as an aerator. The apparatus allows a full hand grip on holder and bottle to ease removal of a cork from the bottle.

Owner:WARD WILLIAM P

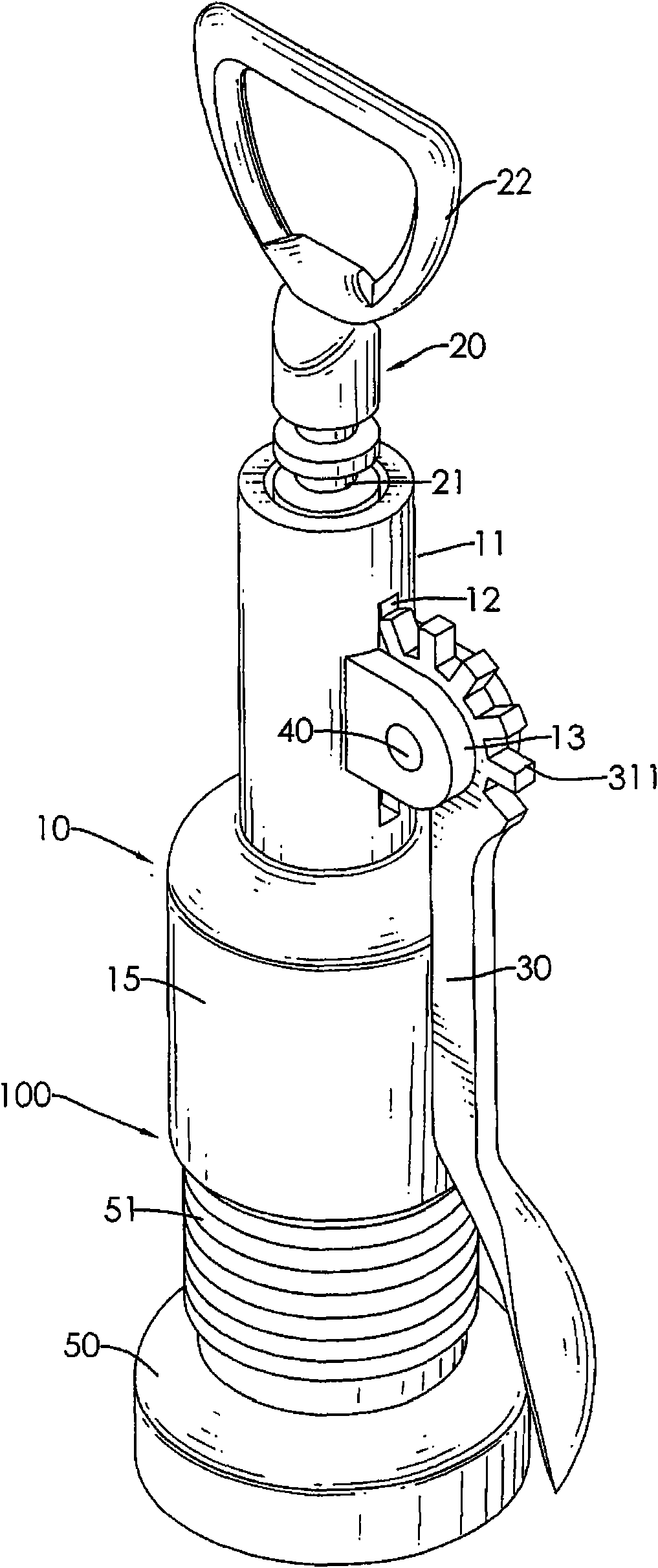

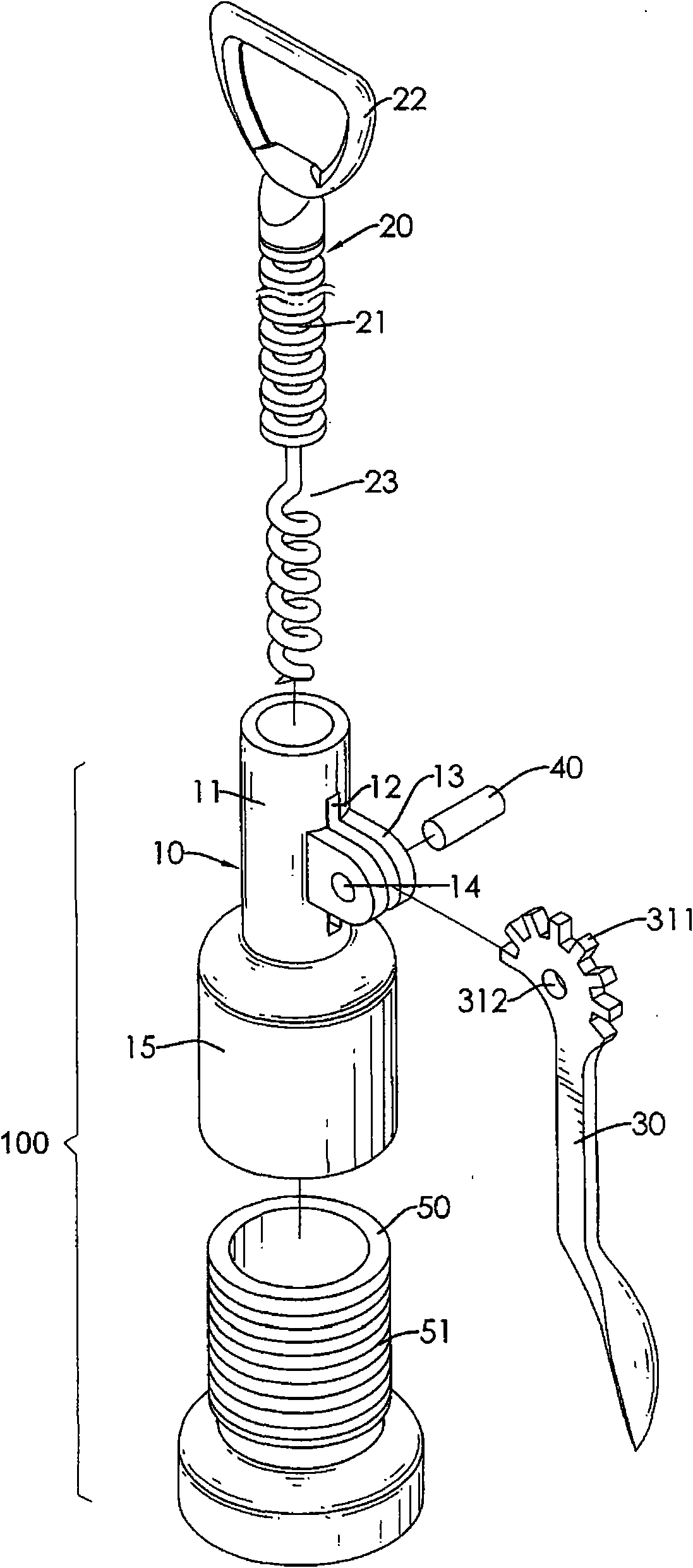

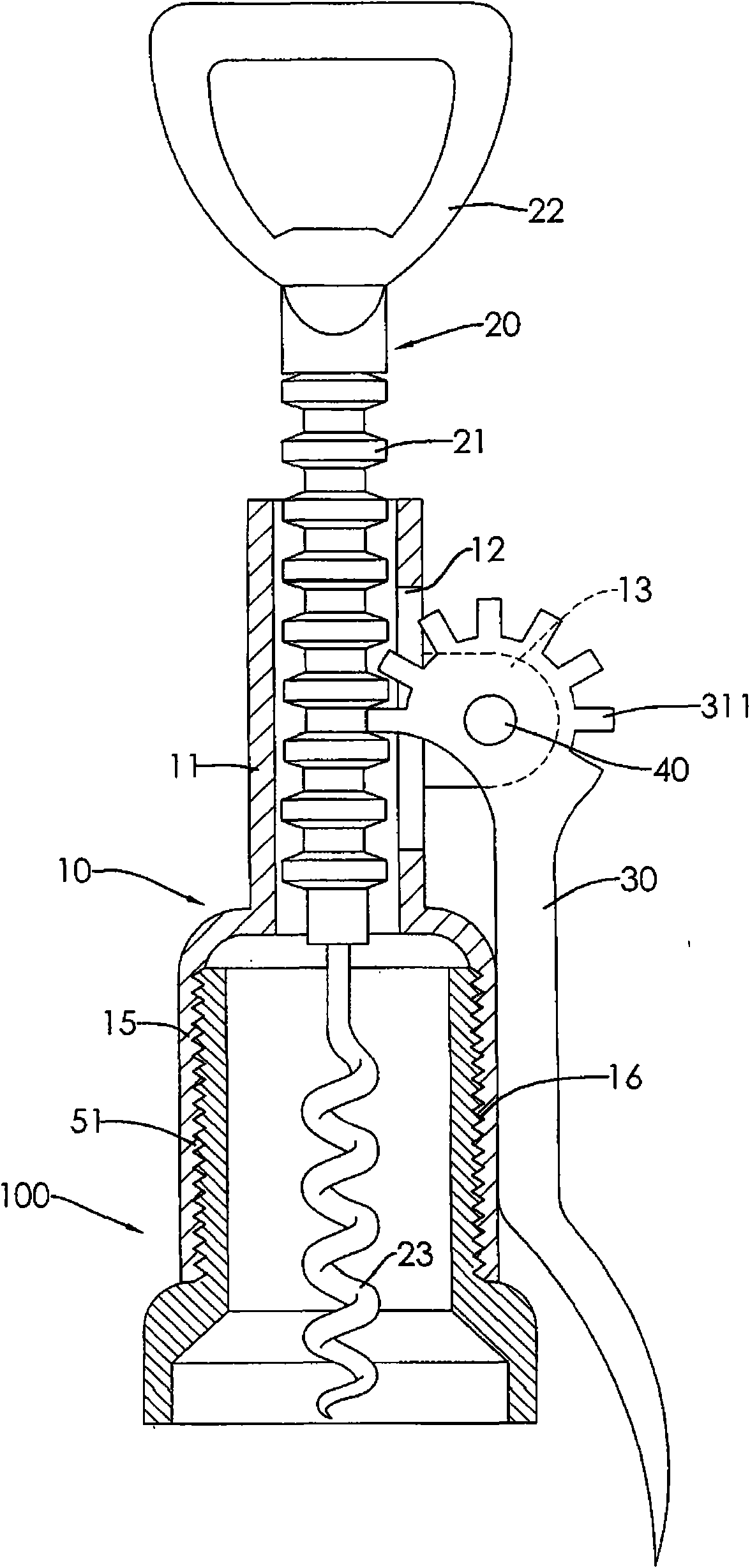

Bottle opener

The invention provides a bottle opener, which mainly comprises a cork drawing piece provided with a grab handle, a turbine section and a spiral drill point, more than one pressure lever and a shell formed by jointing a cylindrical shell and a flexible socket joint cylinder, wherein a discal gear is formed at one end of the pressure lever; a circular hole is formed in the center of the gear; the turbine section of the cork drawing piece is accommodated in a smaller cylinder part of a shell in the shell of the bottle opener, and more than one opening hole is formed on the outer side of the smaller cylinder part; the convex parts for pin joint with pressure levers extend from both sides of the opening hole respectively, and the gears of the pressure levers are engaged with the turbine section of the cork drawing piece; and the flexible socket joint cylinder of the bottle opener can extend relative to a larger cylinder part of the shell to adjust the length of the shell. In the bottle opener, the cork drawing piece is lifted by pressing and rotating the pressure levers, and the cork drawing piece can be lifted for multiple times by the flexible socket joint cylinder for adjusting the shell through extension, so that a cork stopper can be drawn out of a bottleneck completely in a labor-saving manner.

Owner:廖武长

Method for analyzing a cork stopper for the presence of 2,4,6-trichloroanisole and device for performing the same

ActiveUS9588089B2More reliableLess-expensive to implementComponent separationWithdrawing sample devicesNon destructiveEngineering

Owner:CEVAQOE INVEST

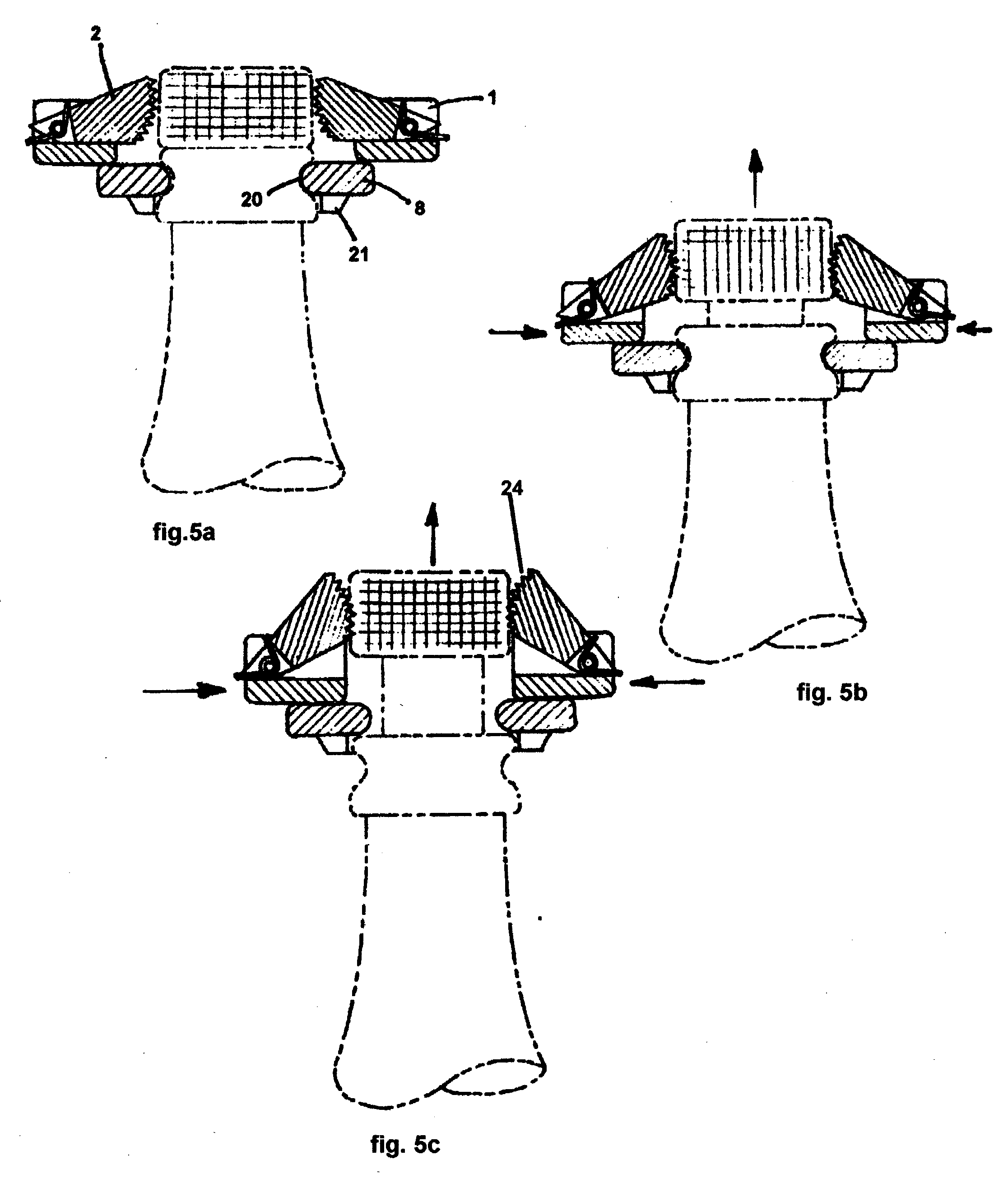

Champagne cork remover

InactiveUS20040074341A1Little effortReduced strengthBottle/container closurePower operated devicesBungEngineering

A hand tool with a U-shaped cutout to slide into the groove at the top of a champagne bottle, and pivoted lever-arms above the cutout straddling the stopper of the bottle. Extractor links connected to these lever-arms, are hinged at the outer end, and have teeth across the inner end, which is aligned with the stopper. Squeezing the lever-arms together causes the extractor links to engage and compress that part of the stopper exposed above the top of the bottle. The extractor links are angled upward toward the toothed end, so that the resulting combined upward force of the two links on opposite sides of the stopper, cause it to be extruded upward. Repeated actuations may be used to remove the stopper completely. The tool grips, and retains the stopper when completely closed.

Owner:MCLUEN CARL T

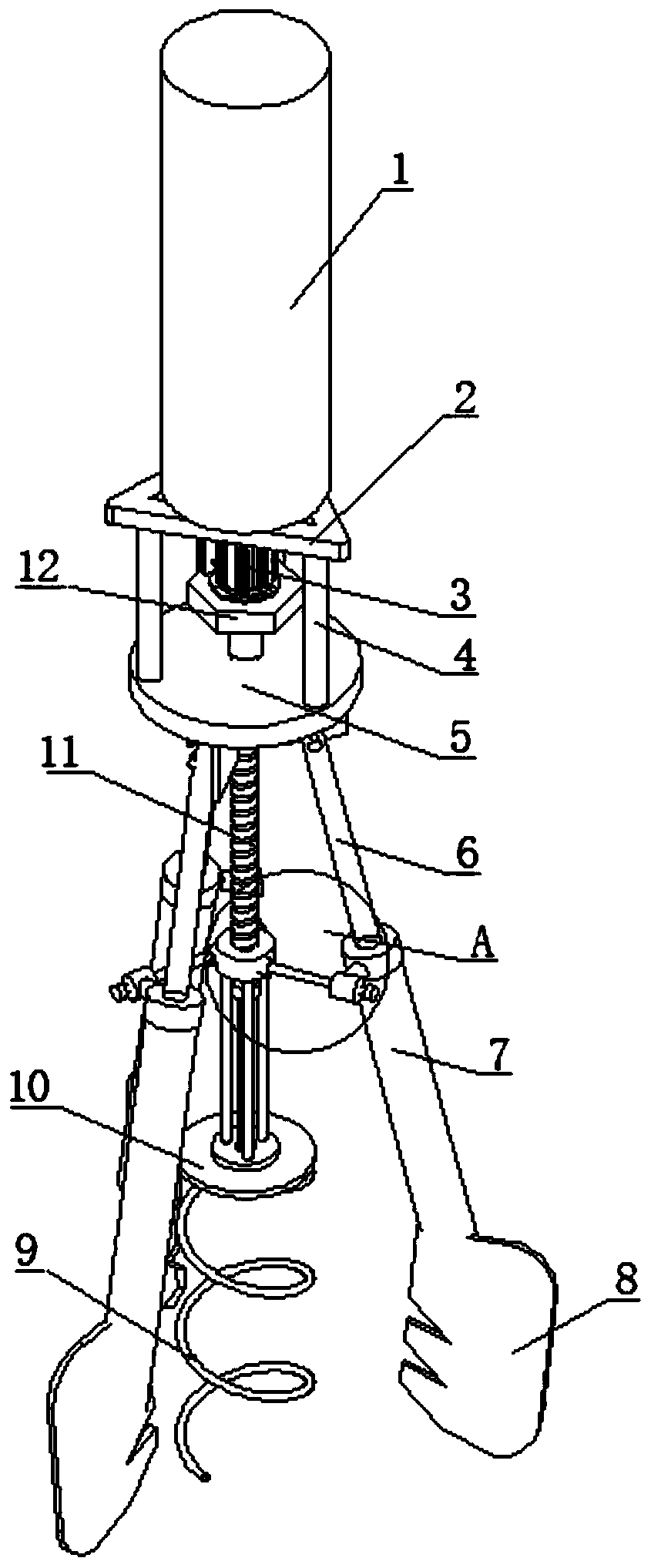

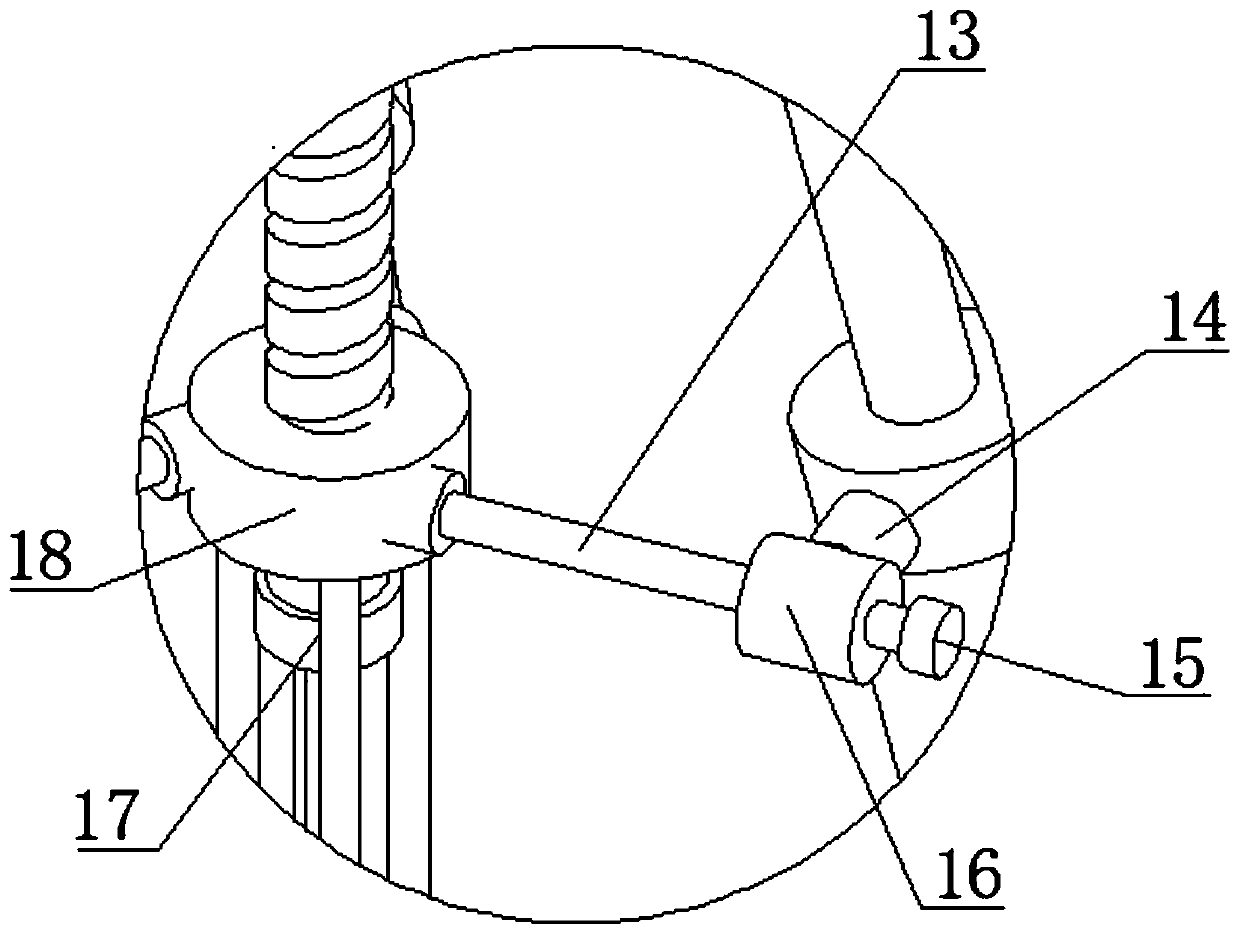

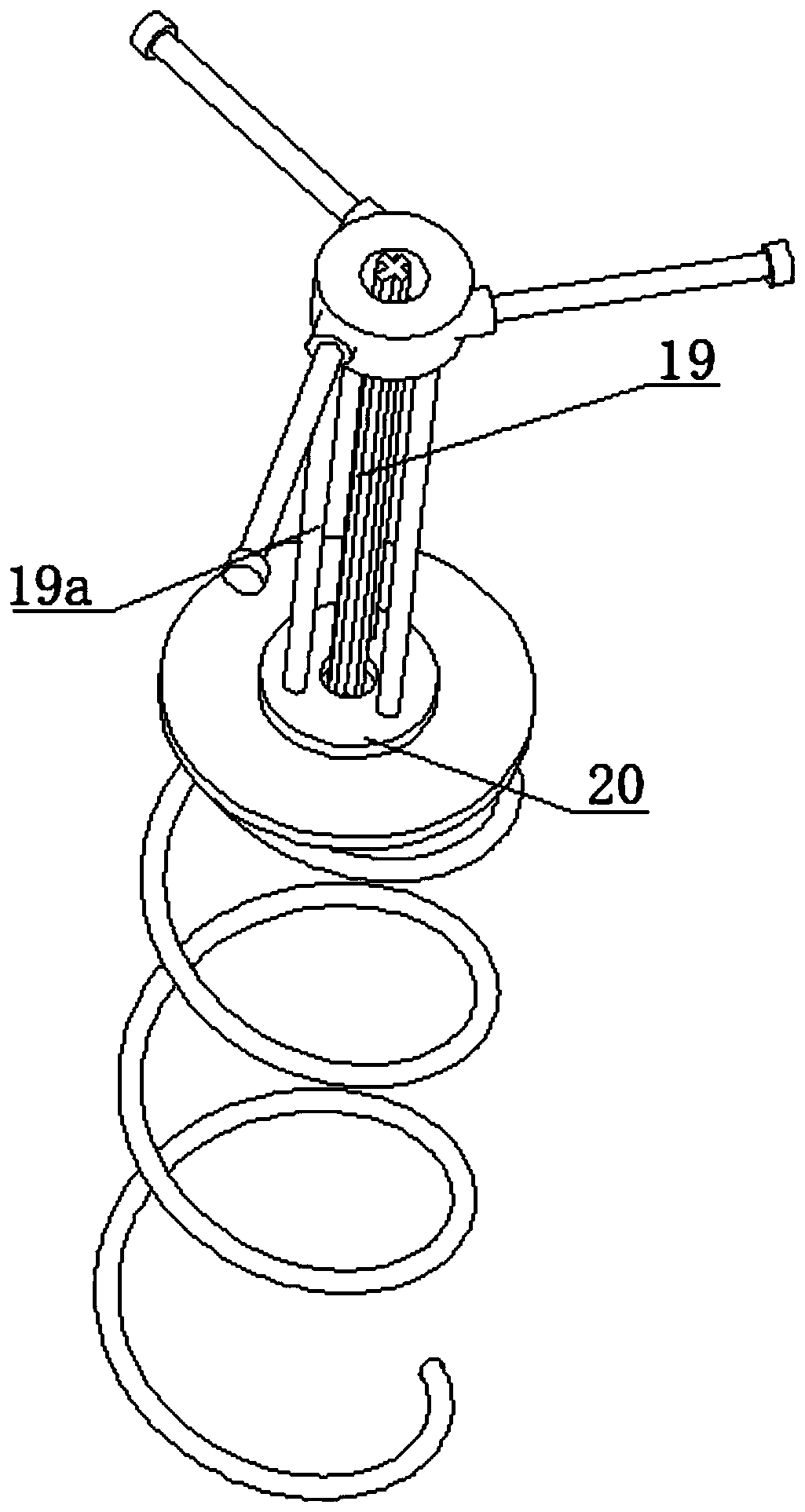

Food and beverage cork uncapping mechanism

ActiveCN110803668ALabor savingEasy to separateBottle/container closurePower operated devicesStructural engineeringCork stopper

The invention discloses a food and beverage cork uncapping mechanism. The mechanism comprises a circular plate, and is characterized in that the center of the circular plate is hinged to one end of ascrew rod; a cross clamping groove is formed in the lower part of the screw rod; a cross rod is inserted in the cross clamping groove; the lower end of the cross rod is fixedly connected with a rotating disc; the lower side of the rotating disc is fixedly connected with one end of a spiral rod; the screw rod is in threaded connection with a sleeve ring; the lower end of the sleeve ring is fixedlyconnected with the upper ends of a set of cylinders uniformly arranged at the periphery; the lower ends of the all the cylinders are fixedly connected with rings; the cross rod is annularly sleeved with the rings; and the rings are hinged to the rotating disc. The invention relates to the field of cork uncapping equipment, in particular to a food and beverage cork uncapping mechanism. The mechanism can replace human hands to screw the spiral rod into corks to conveniently take out the corks.

Owner:常征

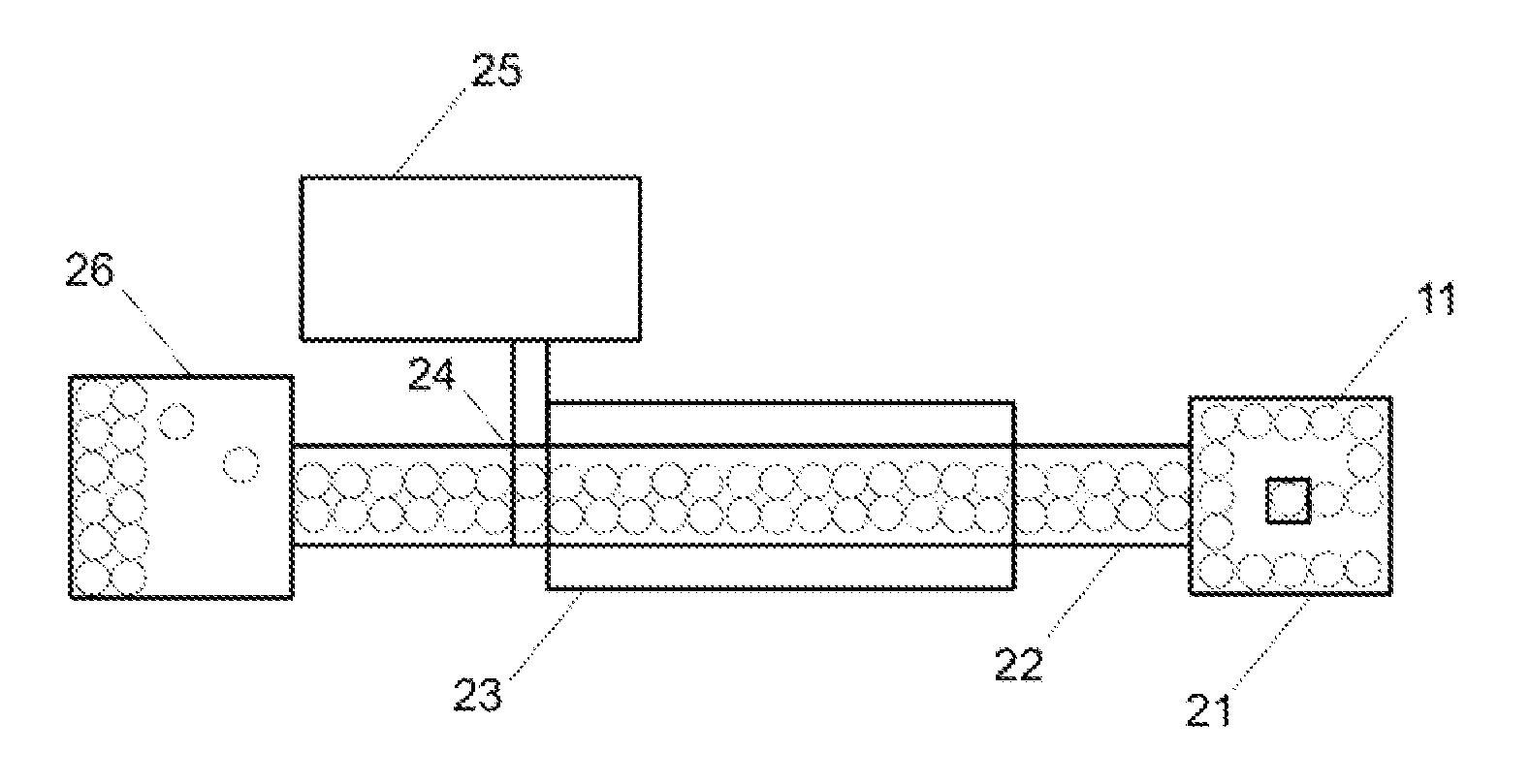

Method and device for rotational marking

ActiveUS8319810B2Low costRecording apparatusElectrode and associated part arrangementsSynthetic materialsWine bottle

The invention provides a method and device for rotary marking or machining of cylindrical materials, preferably natural cork stoppers, agglomerated cork or synthetic materials used to close wine bottles and the like. The device includes at least one feeder system of cylindrical elements, preferably natural and synthetic cork stoppers; means of sensing the presence of such cylindrical elements, a laser system, means to produce the rotation of the cylindrical elements on its axis of revolution, at a variable speed, in a tangential movement compared to the focal plane of the laser system, means of measuring the instantaneous velocity tangential to its surface and direction of rotation, optical correction and focusing means, microprocessor control based means, and means for extracting the cylindrical elements. The laser system comprises means of generating at least one laser beam; means of temporal modulation and switching for the laser beam, and means of spatial modulation of each of the laser beams in a synchronized manner with the instant tangential speed on the surface of the cylindrical element.

Owner:ON LASER SYST & APPL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com