Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

152 results about "Combustion phasing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

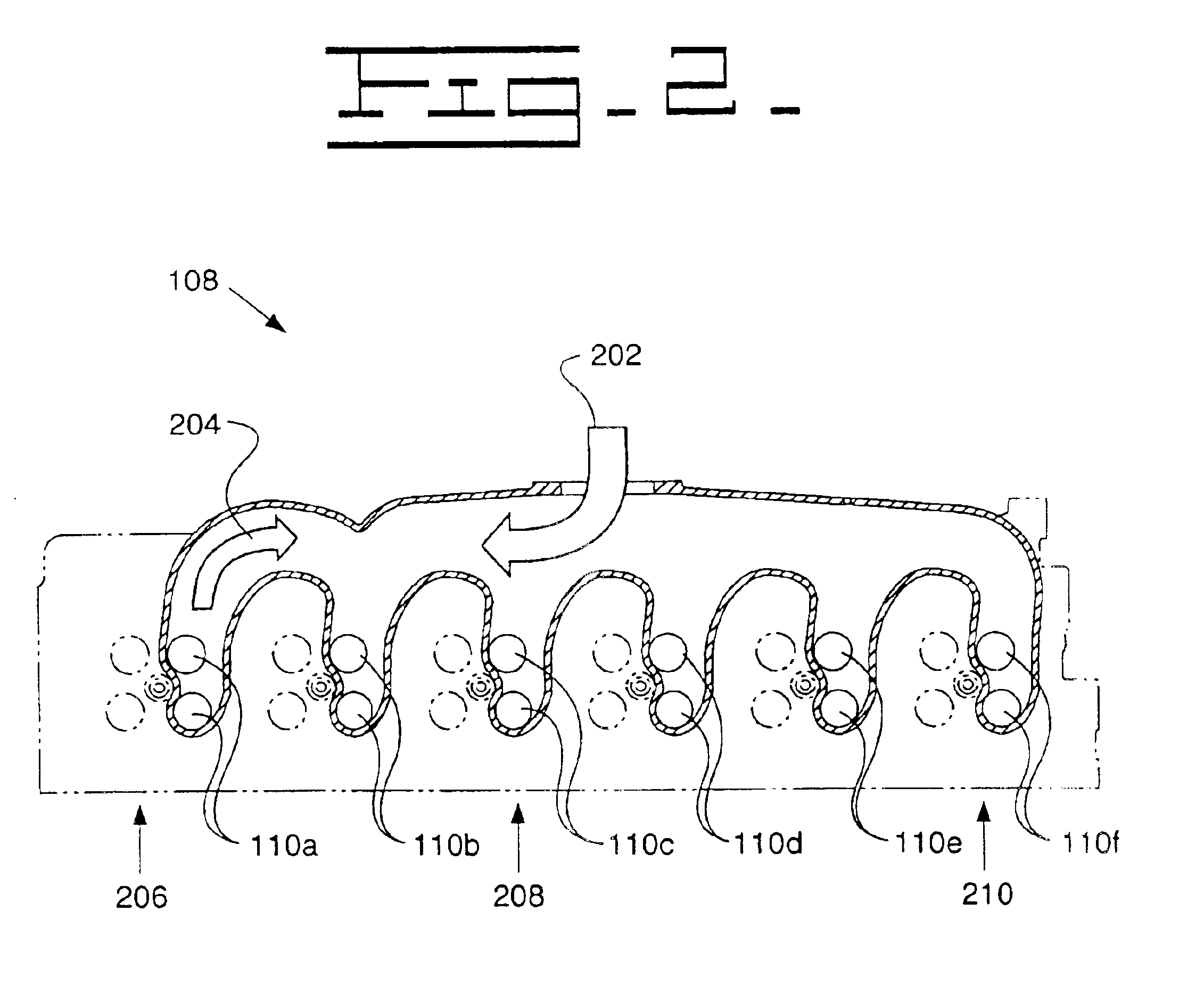

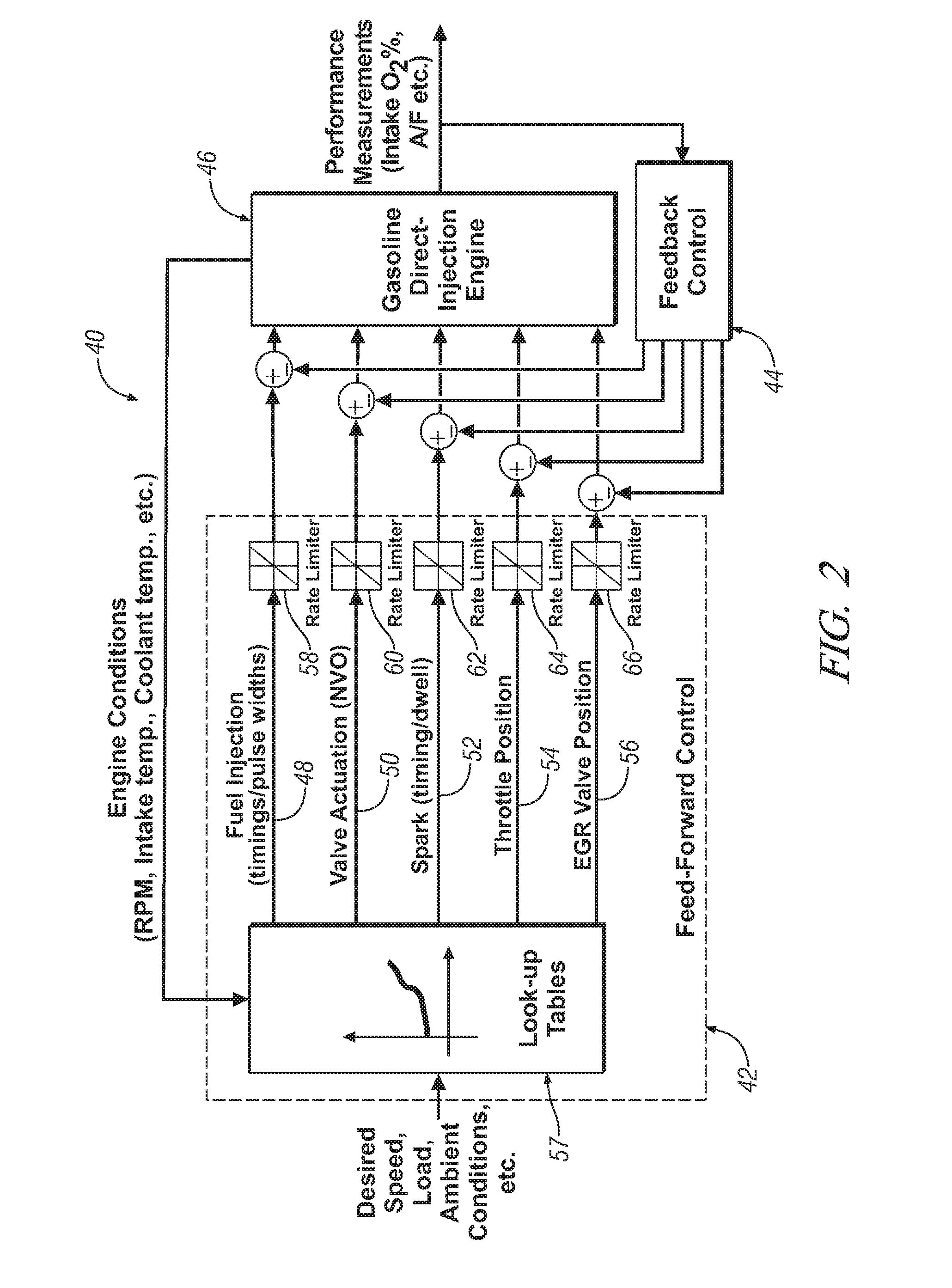

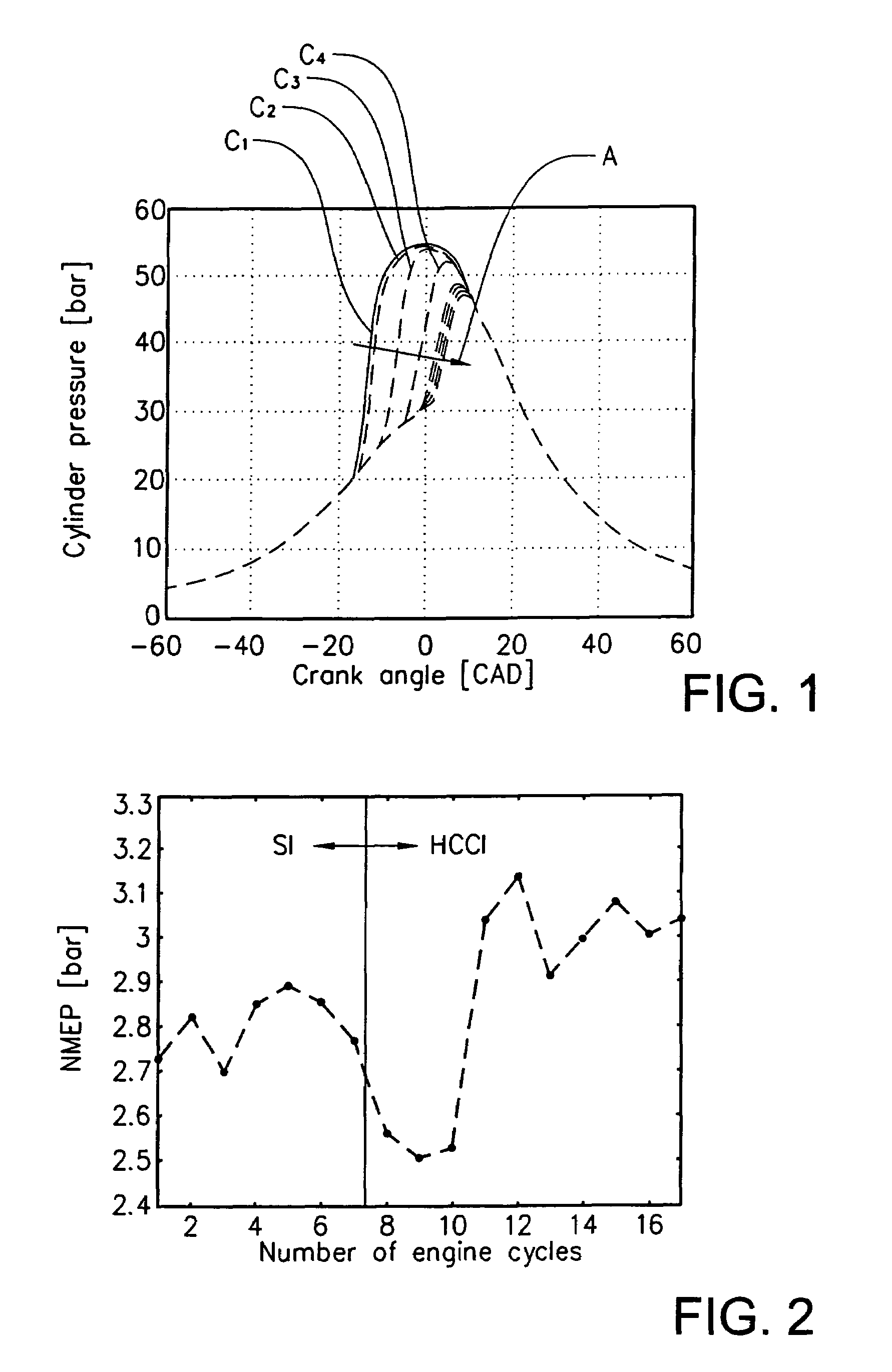

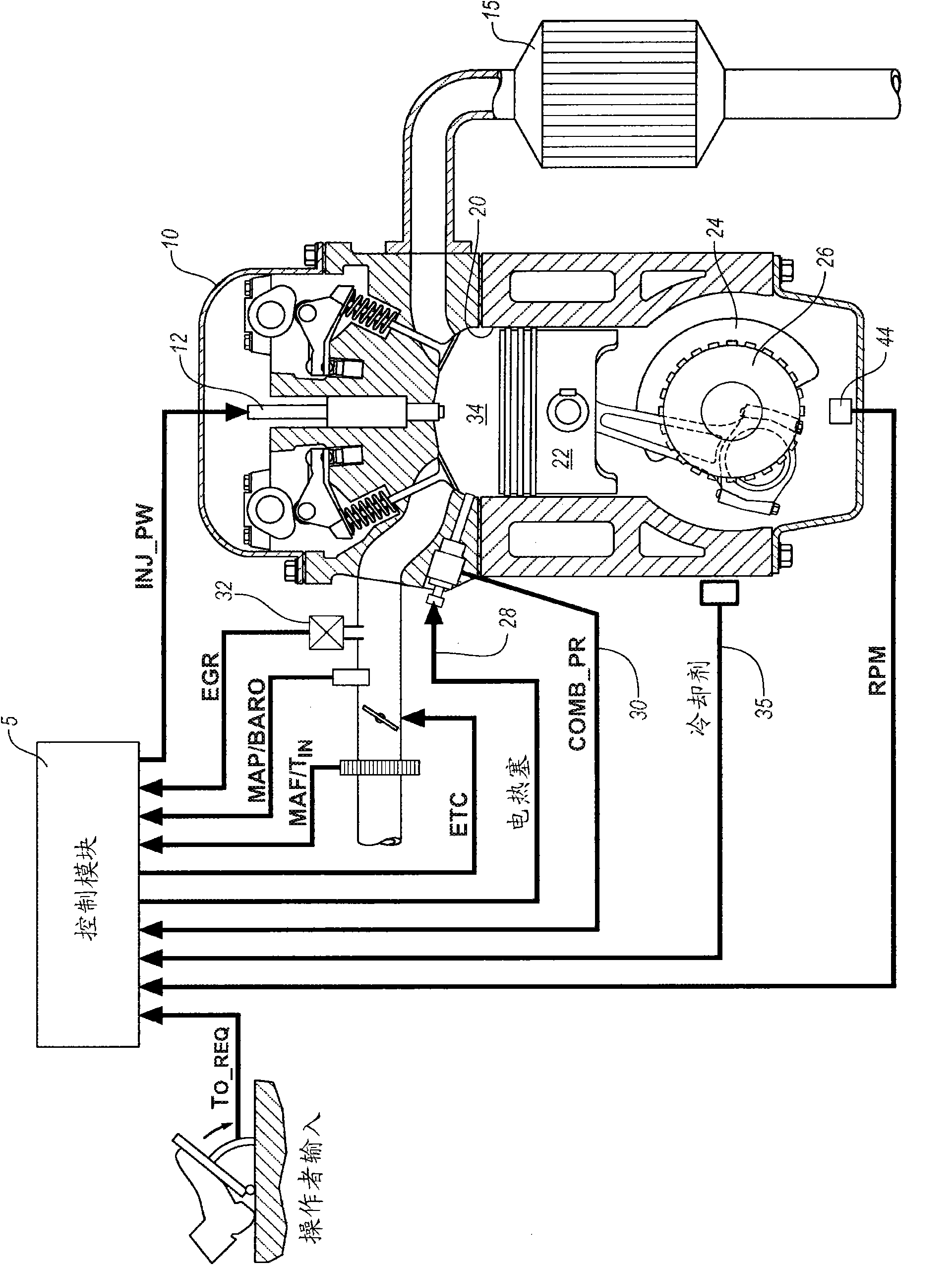

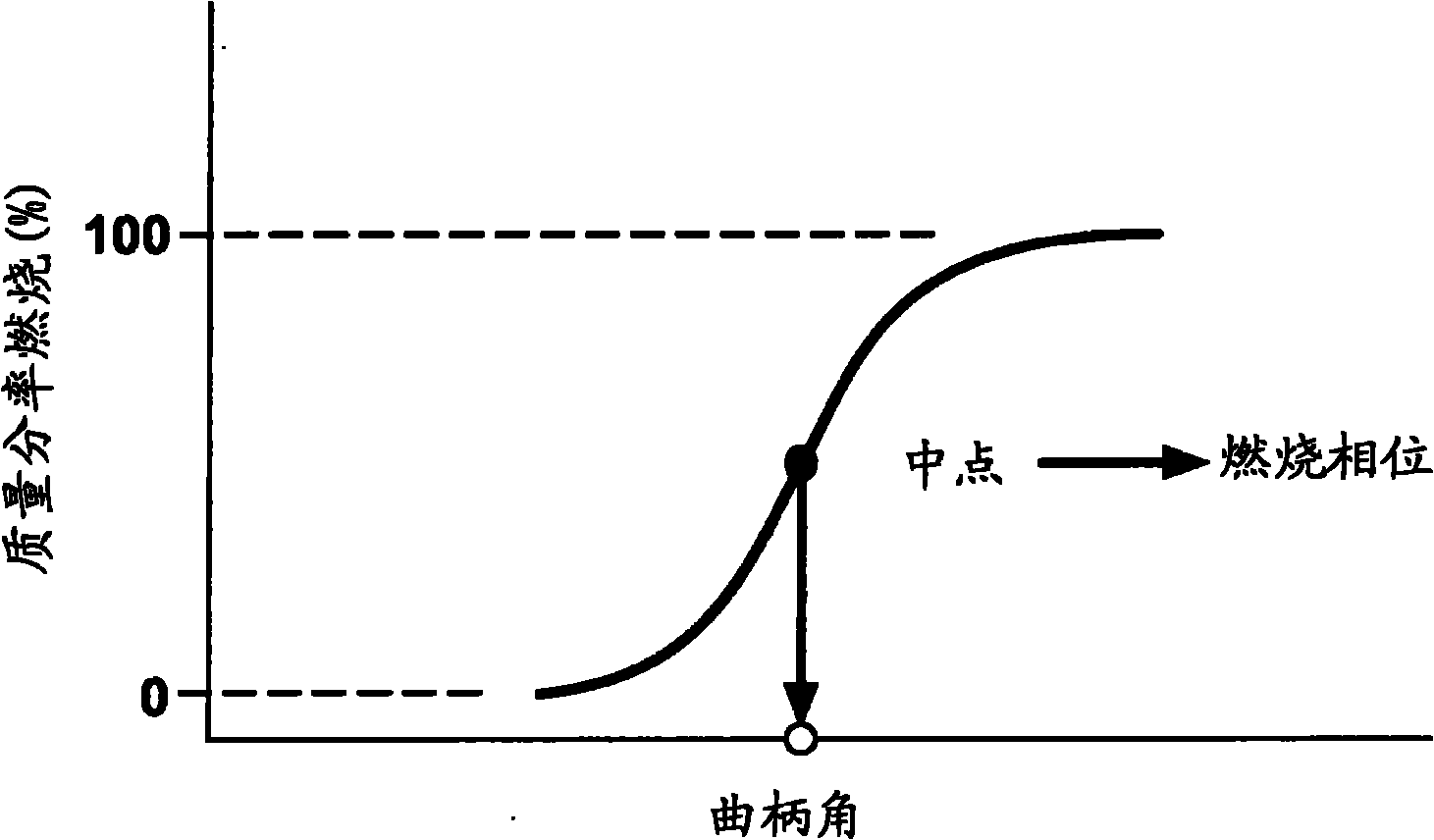

One way to induce these property changes is through varying the phasing of combustion. Combustion phasing can be defined as the time in the engine cycle, specifically the compression and expansion strokes, where combustion occurs. A change in combustion phasing causes a change in combustion duration.

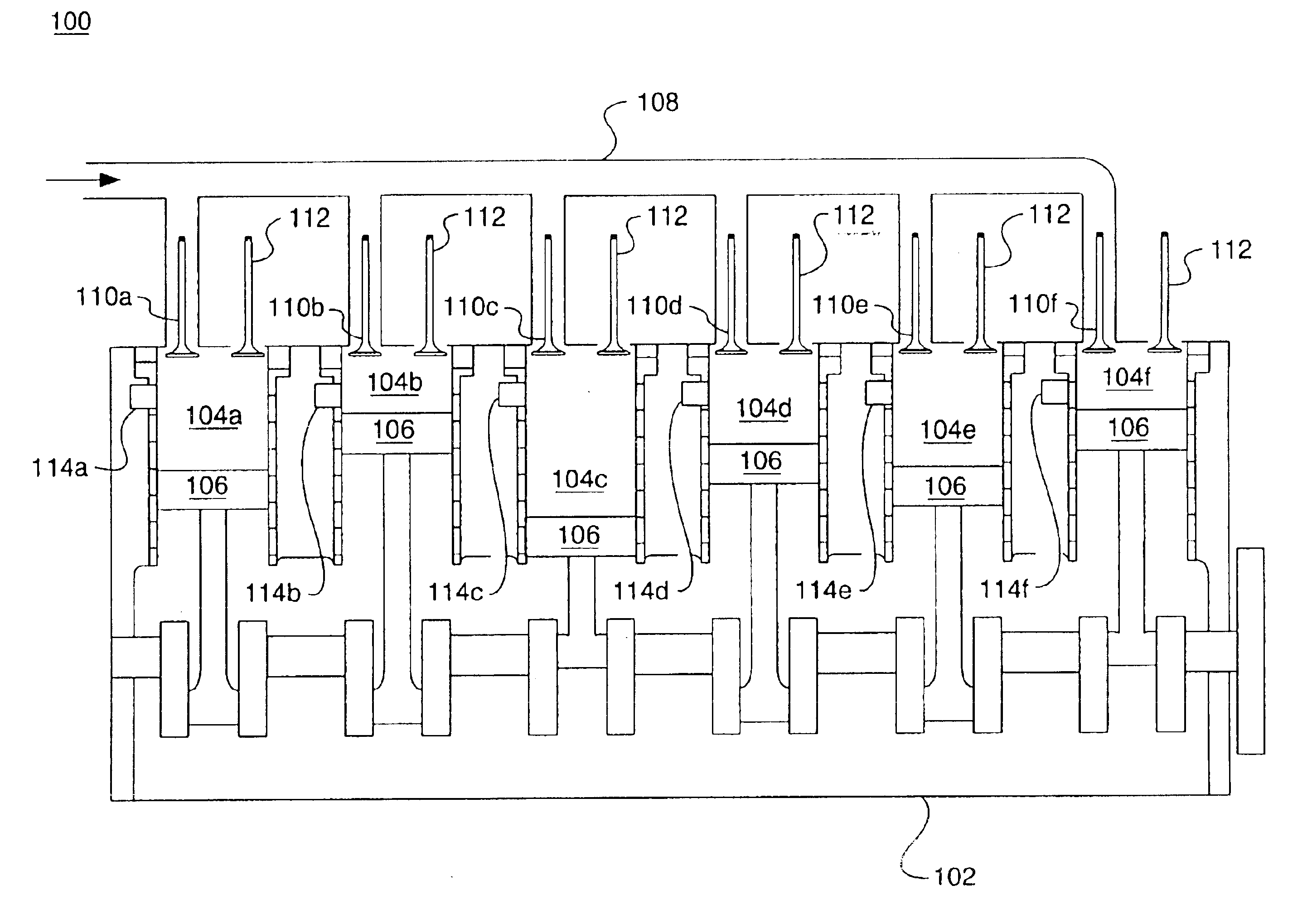

Cylinder to cylinder balancing using intake valve actuation

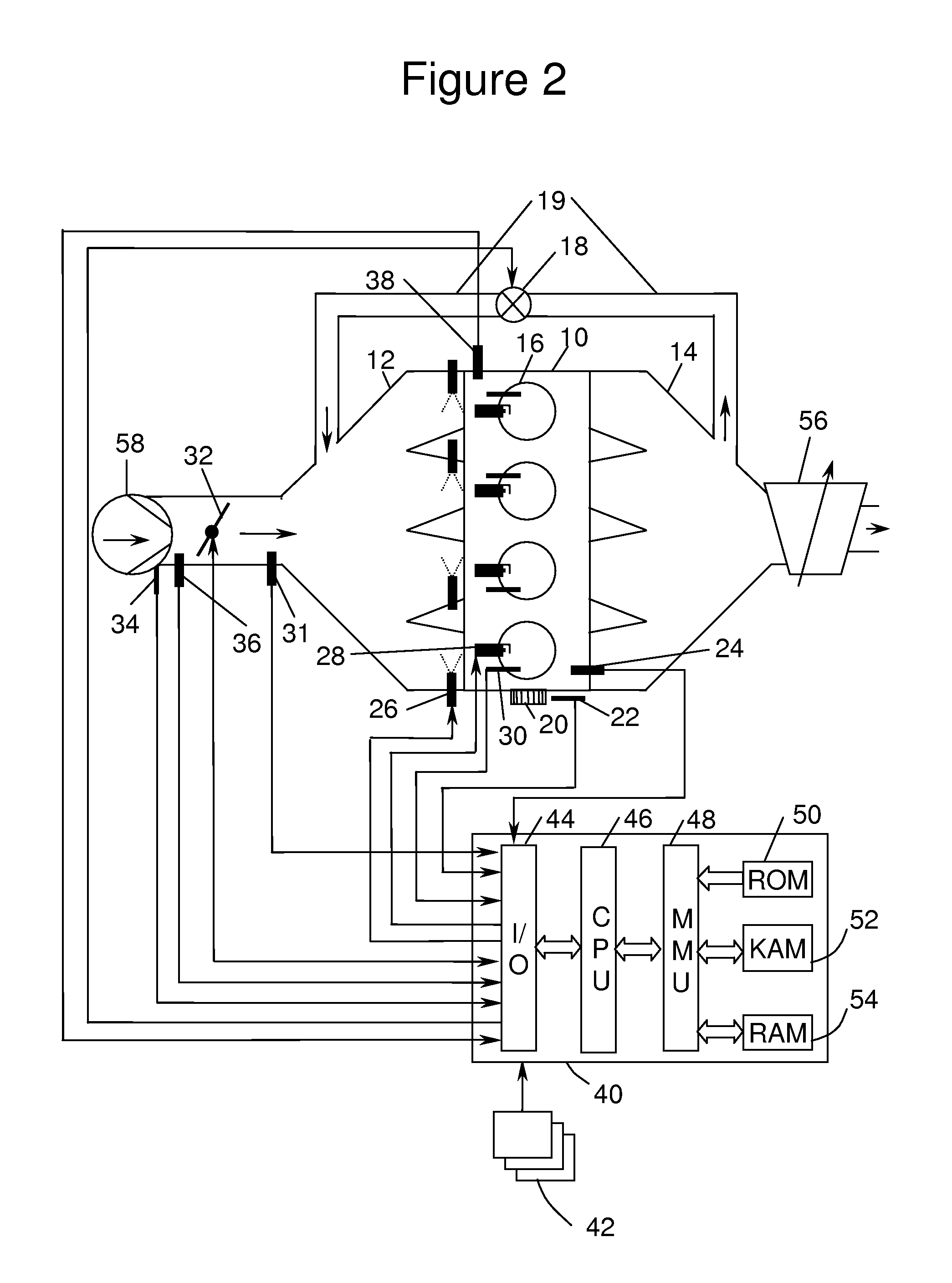

A method and apparatus for balancing a combustion phasing between a plurality of cylinders located in an engine. The method and apparatus includes a determining a combustion timing in each cylinder, establishing a baseline parameter for a desired combustion timing, and varying actuation of at least one of a plurality of intake valves, each intake valve being in fluid communication with a corresponding cylinder, such that the combustion timing in each cylinder is substantially equal to the desired combustion timing.

Owner:CATERPILLAR INC

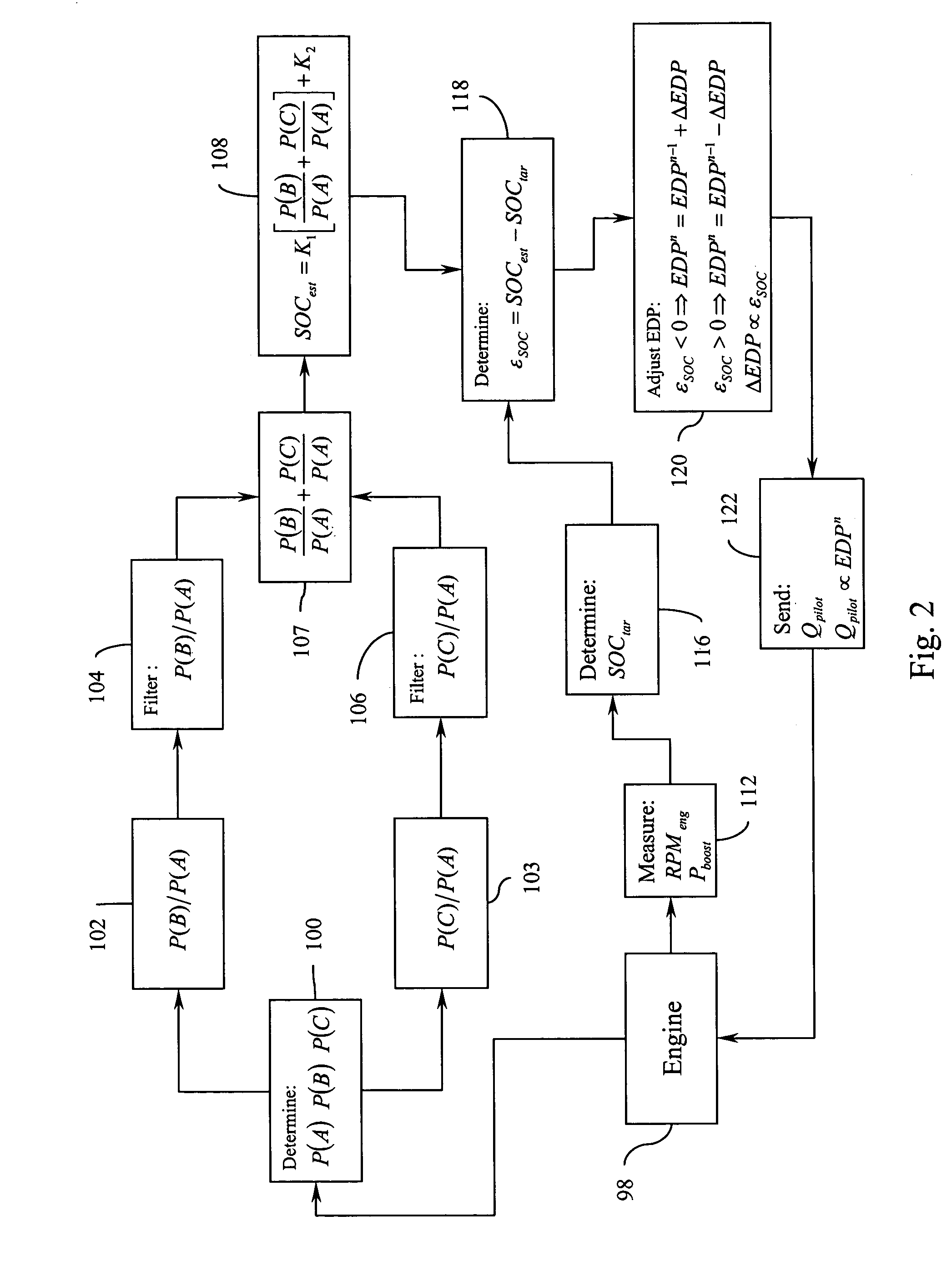

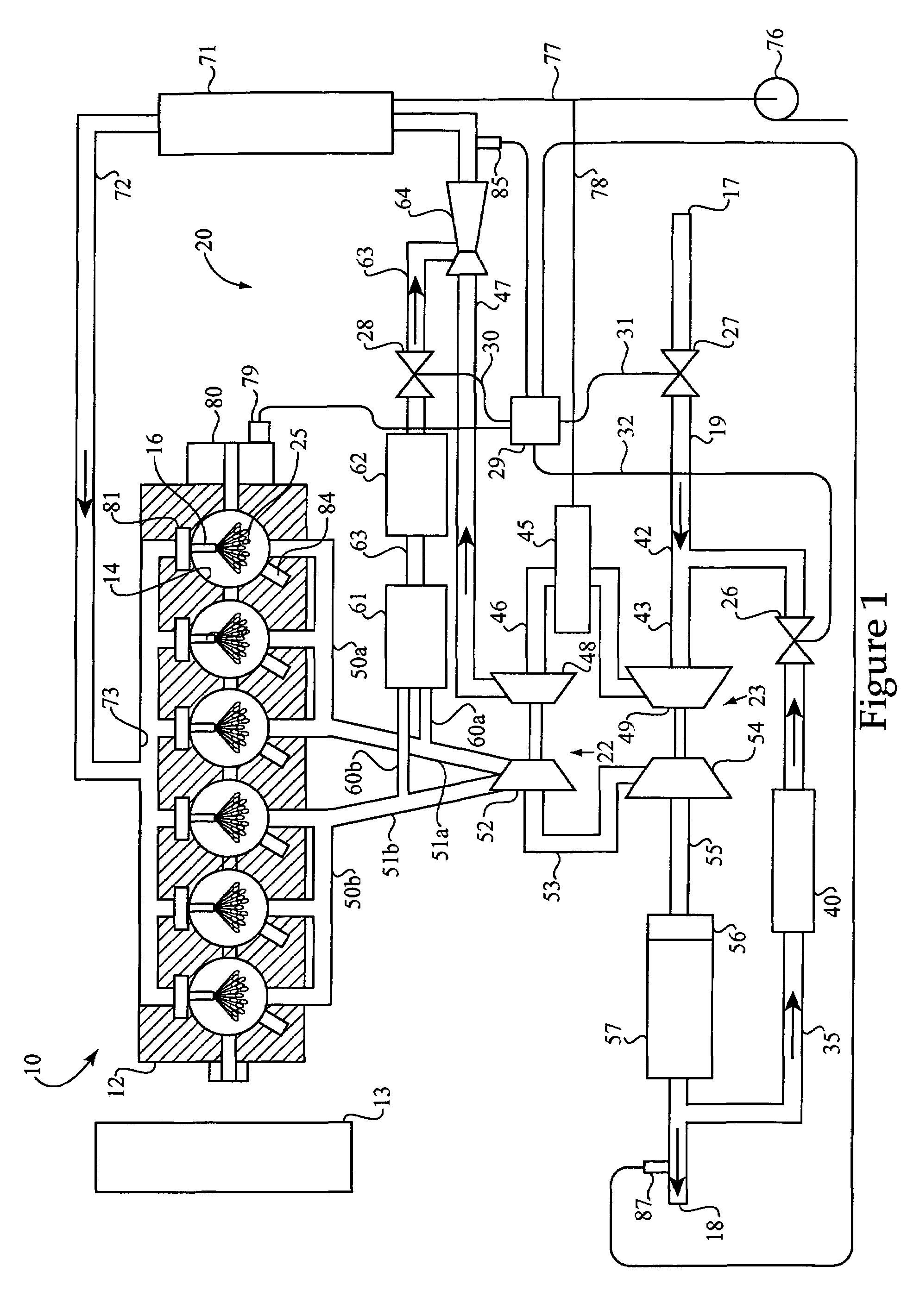

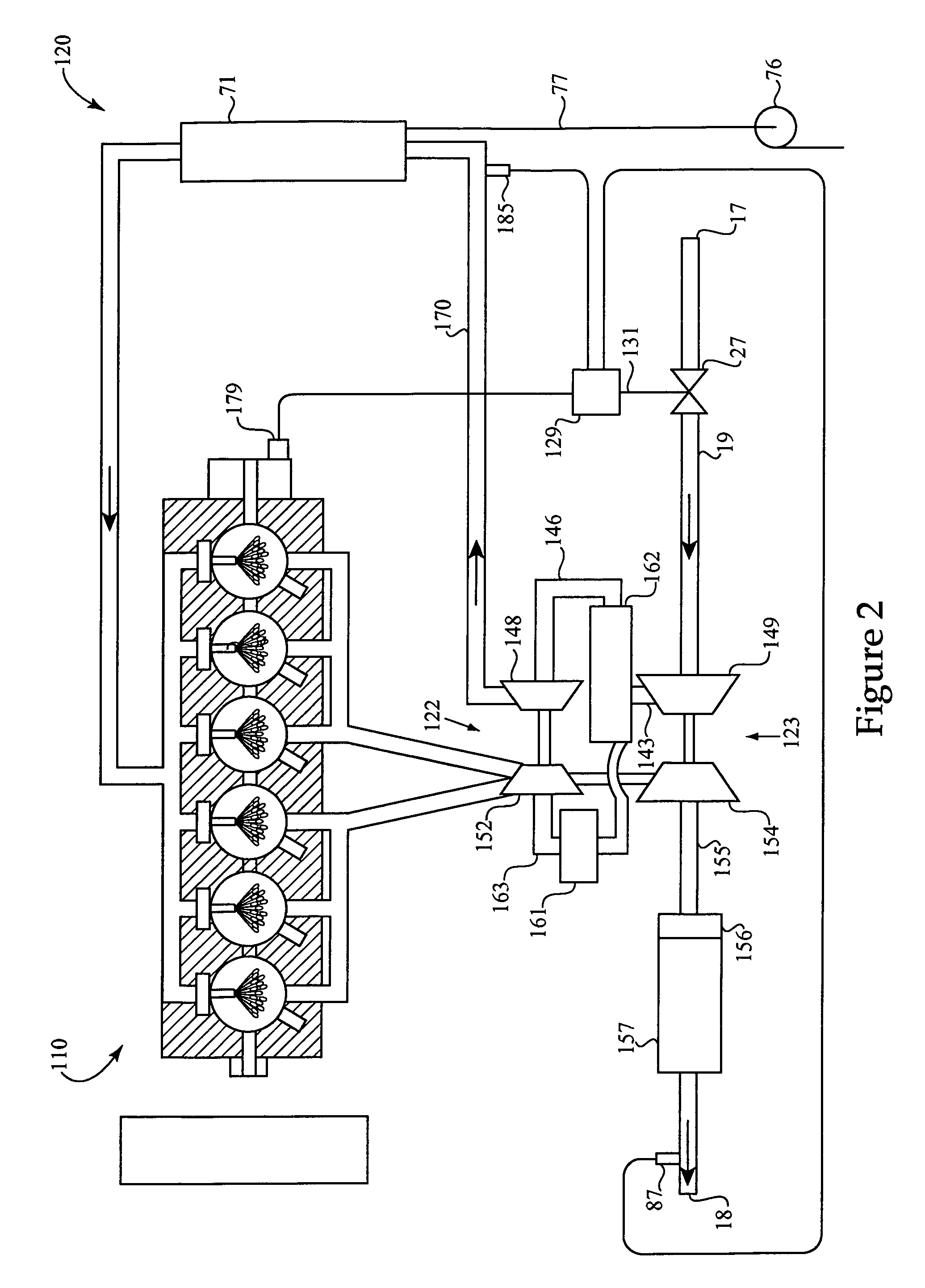

Method and apparatus for controlling an internal combustion engine using combustion chamber pressure sensing

InactiveUS7000596B2Difficult to auto-igniteQuick changeElectrical controlInternal combustion piston enginesThermodynamicsCombustion chamber

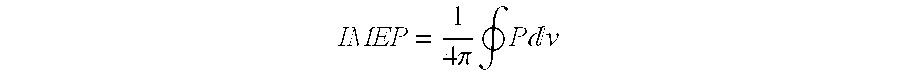

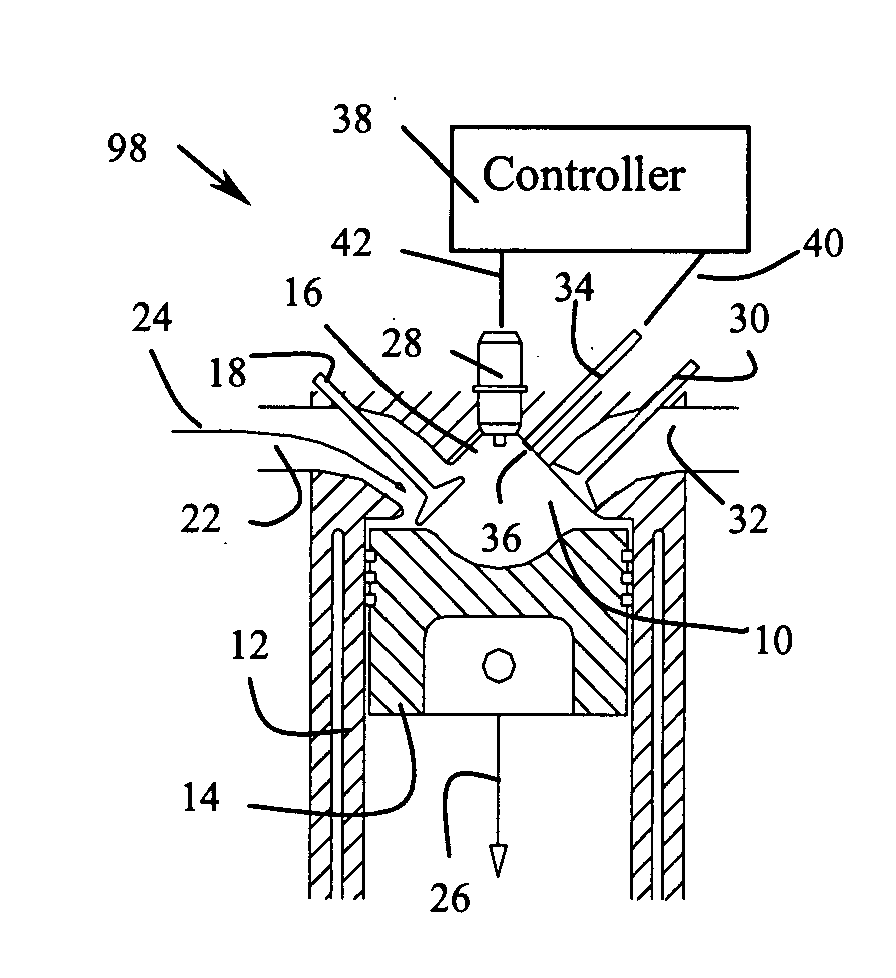

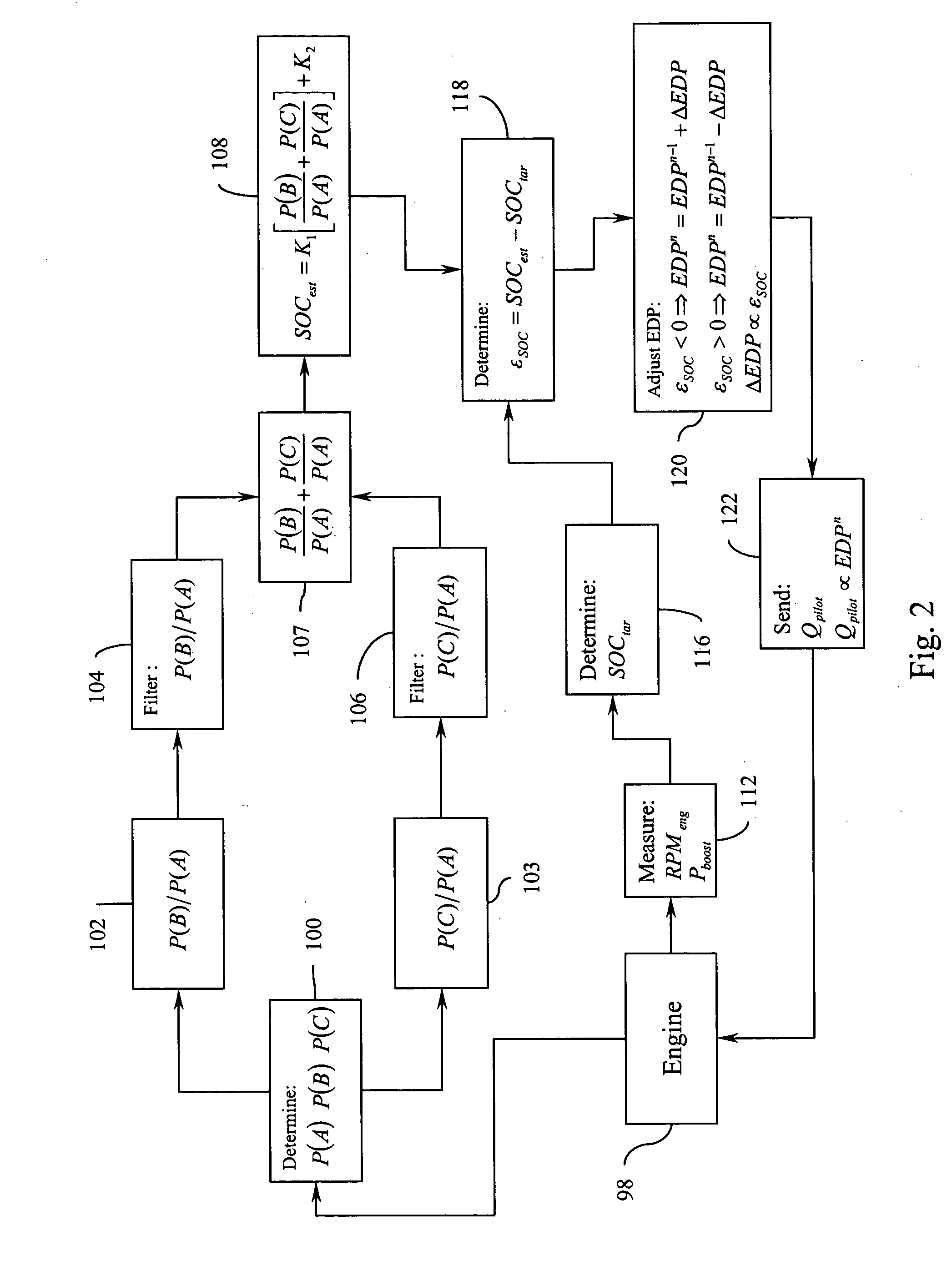

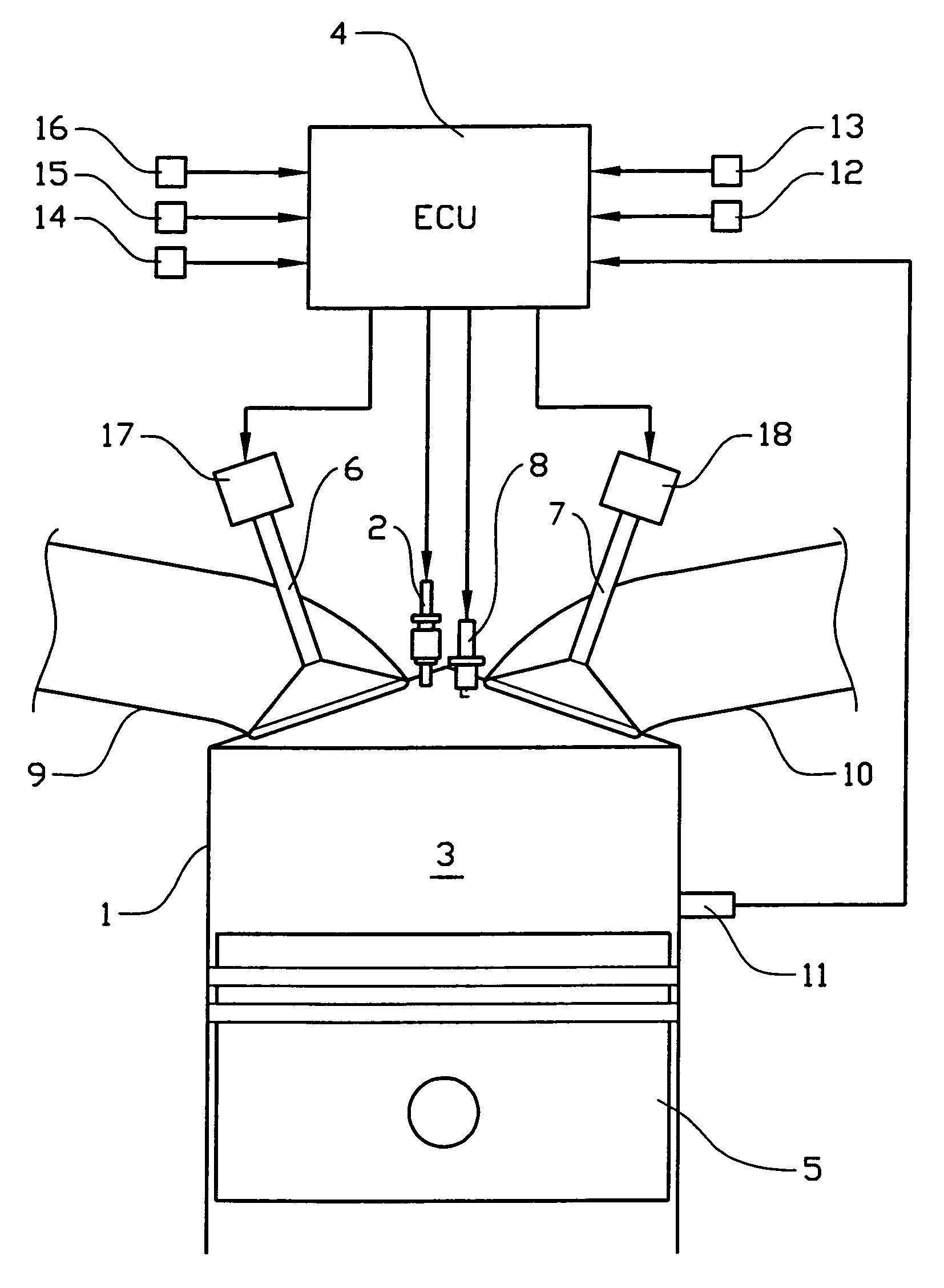

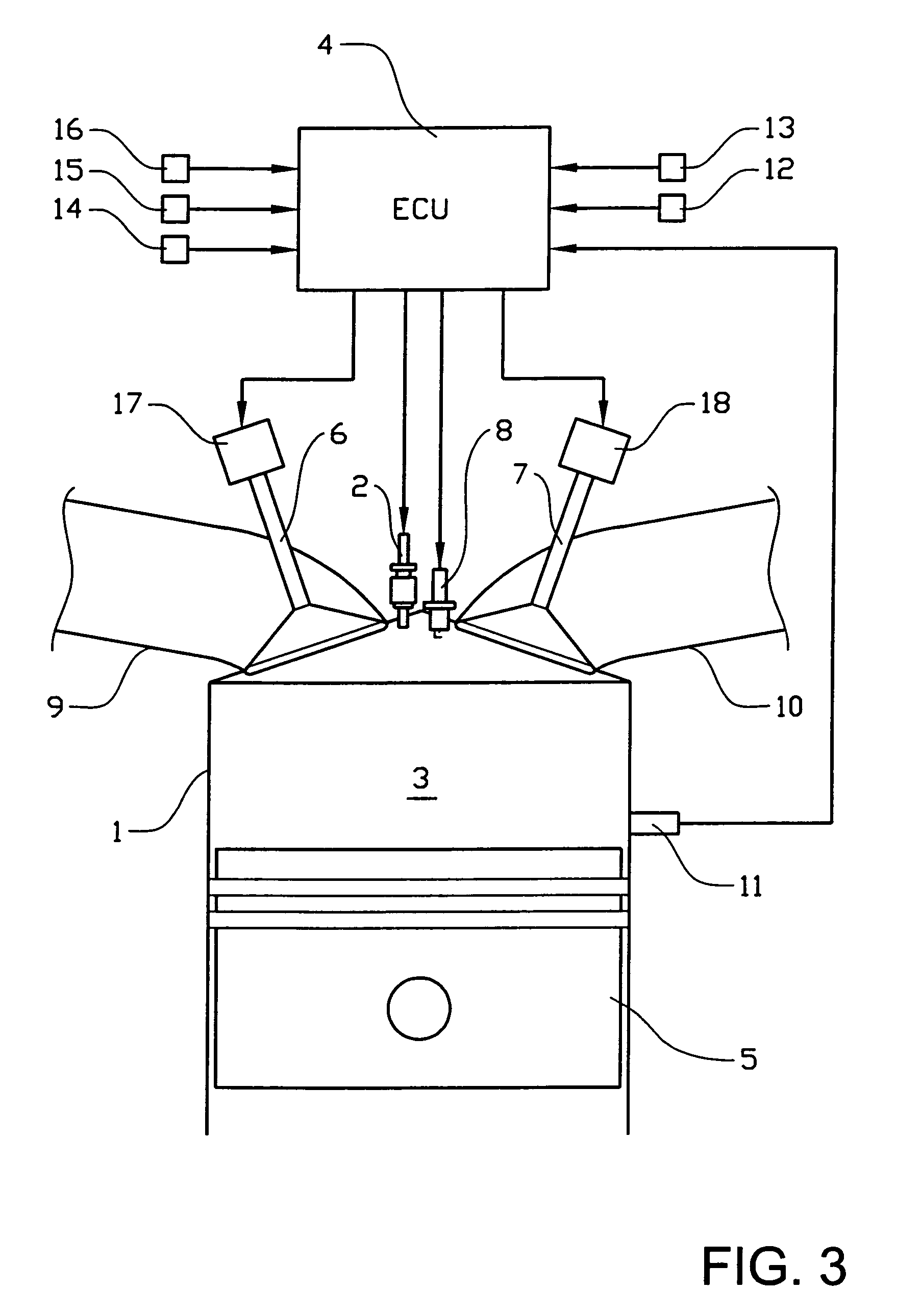

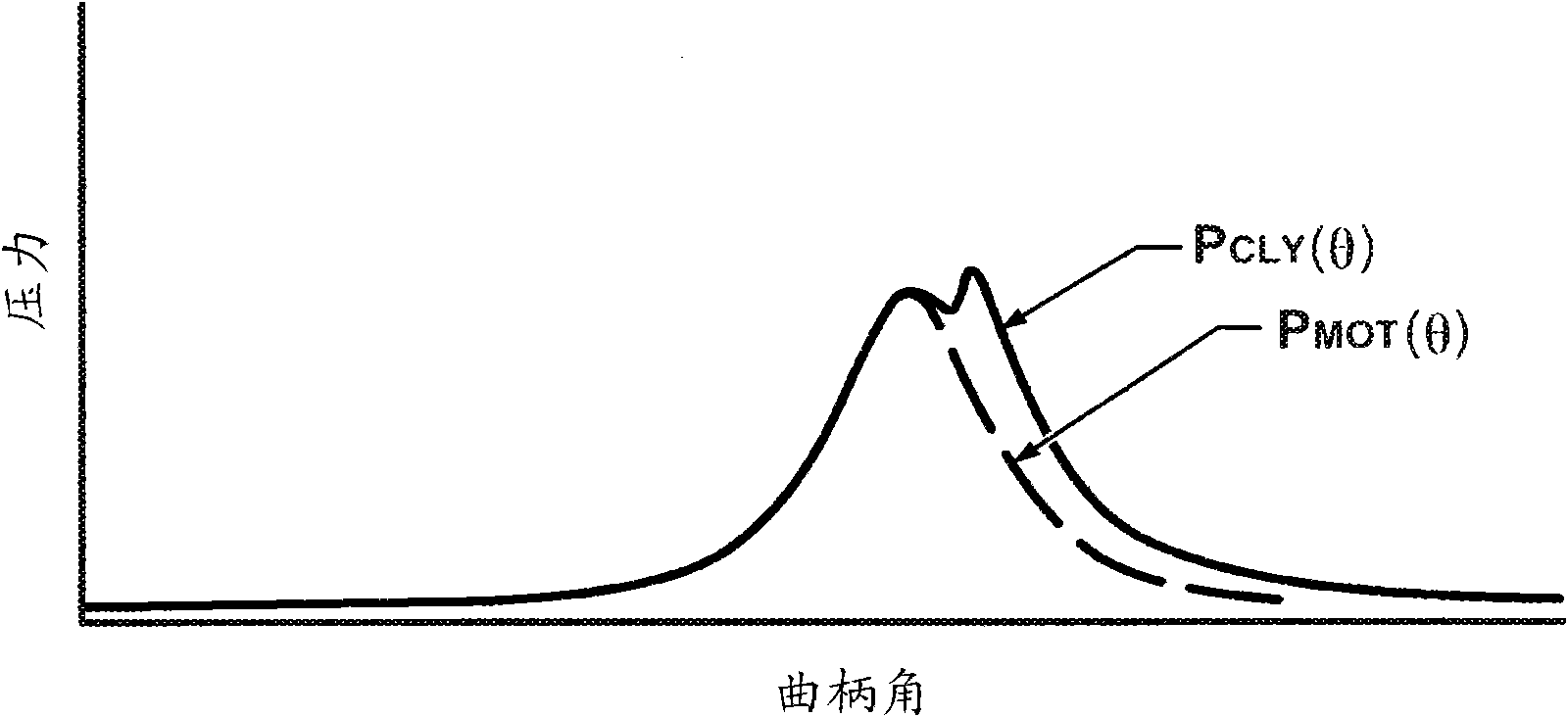

The present method and apparatus employ a signal indicative of cylinder pressure within the combustion chamber of an internal combustion engine to control combustion phasing or start of combustion (SOC) in subsequent cycles of the engine where the engine is driven by combustion of both a fuel / air premixed charge and a directly injected quantity of fuel. A ratio of signals indicative of pre-combustion pressure and post-combustion pressure within a cycle are employed to estimate SOC and then, based on a predetermined target SOC, an ignition lever is employed to adjust subsequent SOC. A preferred ignition lever is, in a pilot fuel ignited engine, pilot fuel quantity.

Owner:WESTPORT POWER

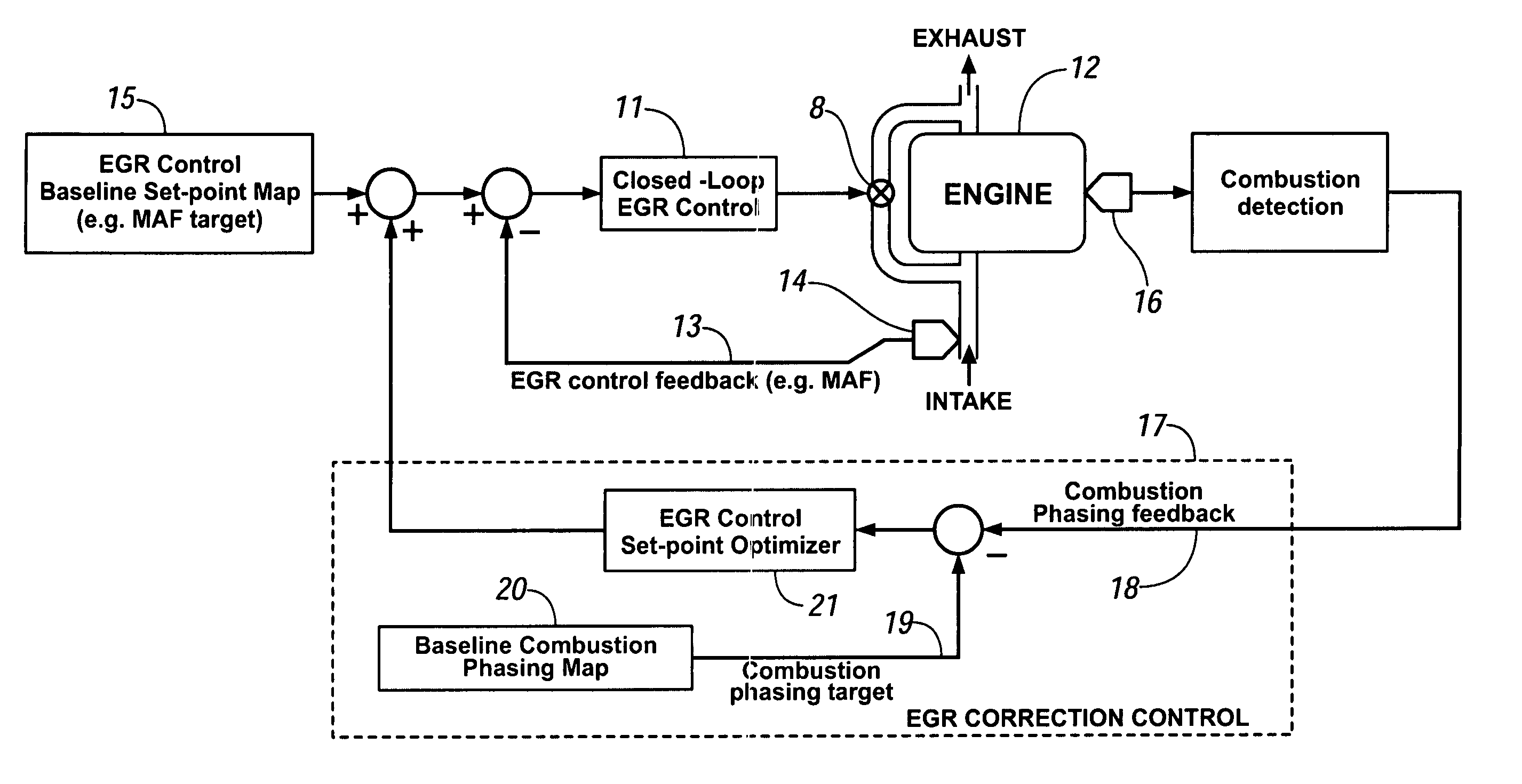

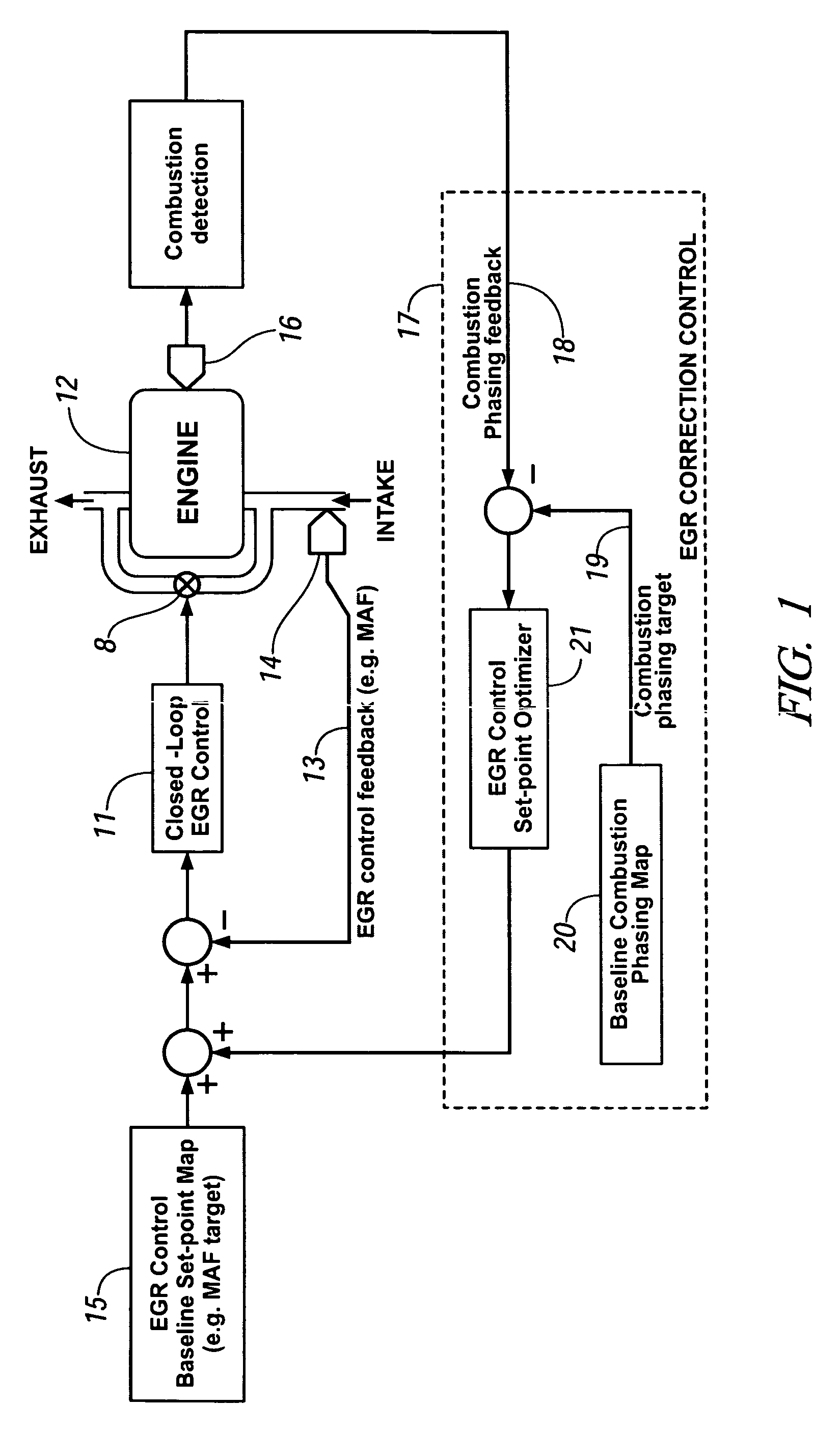

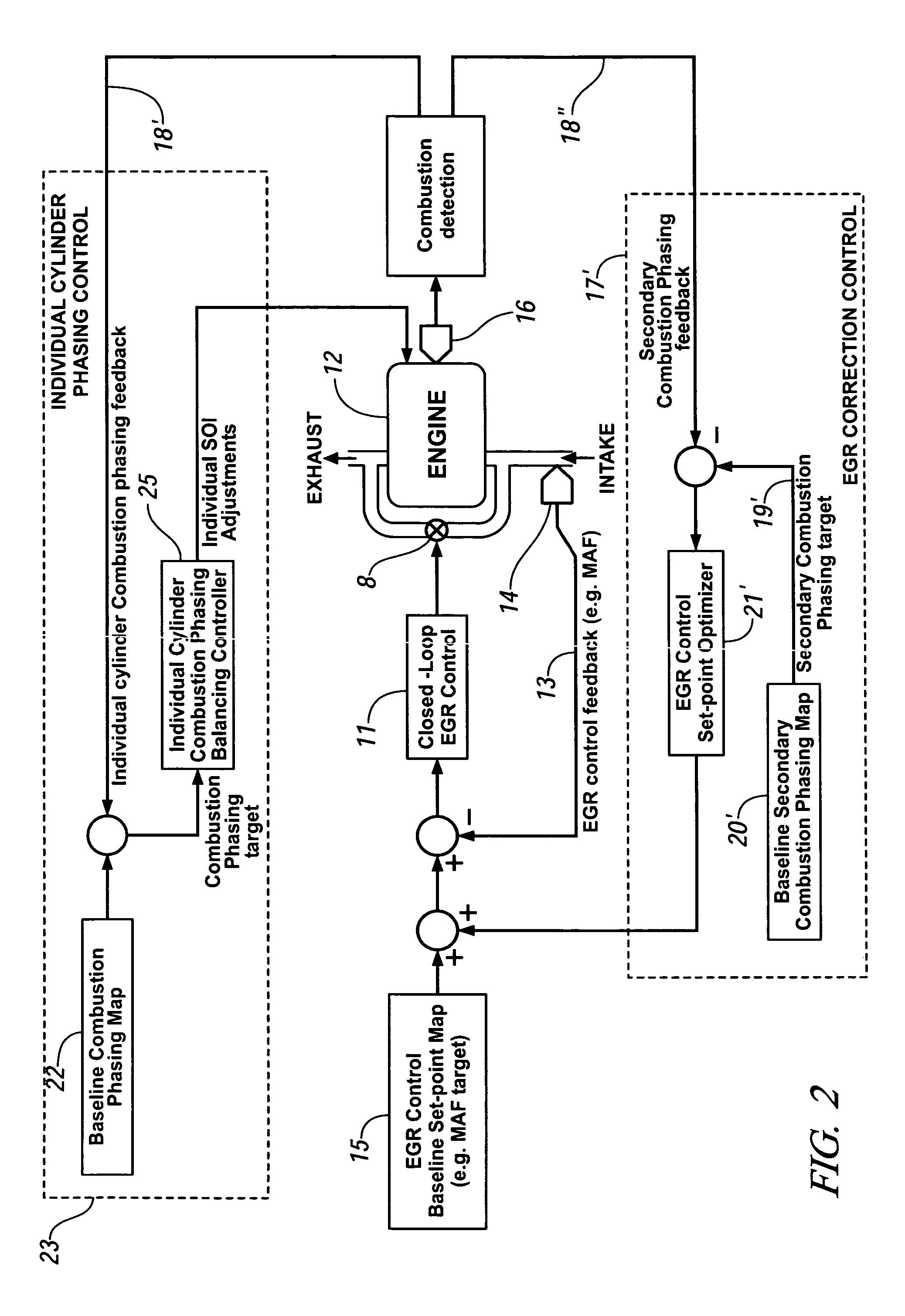

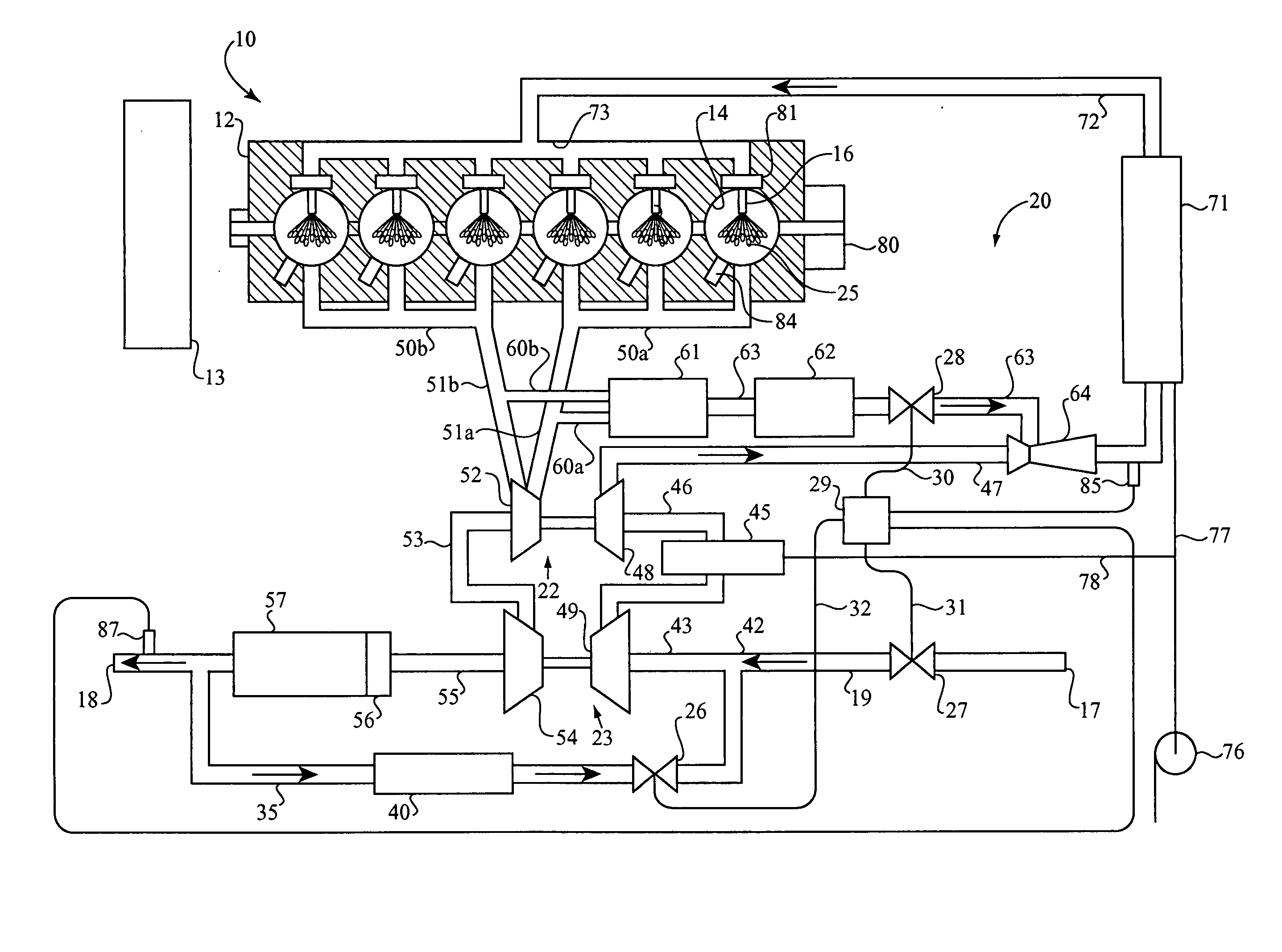

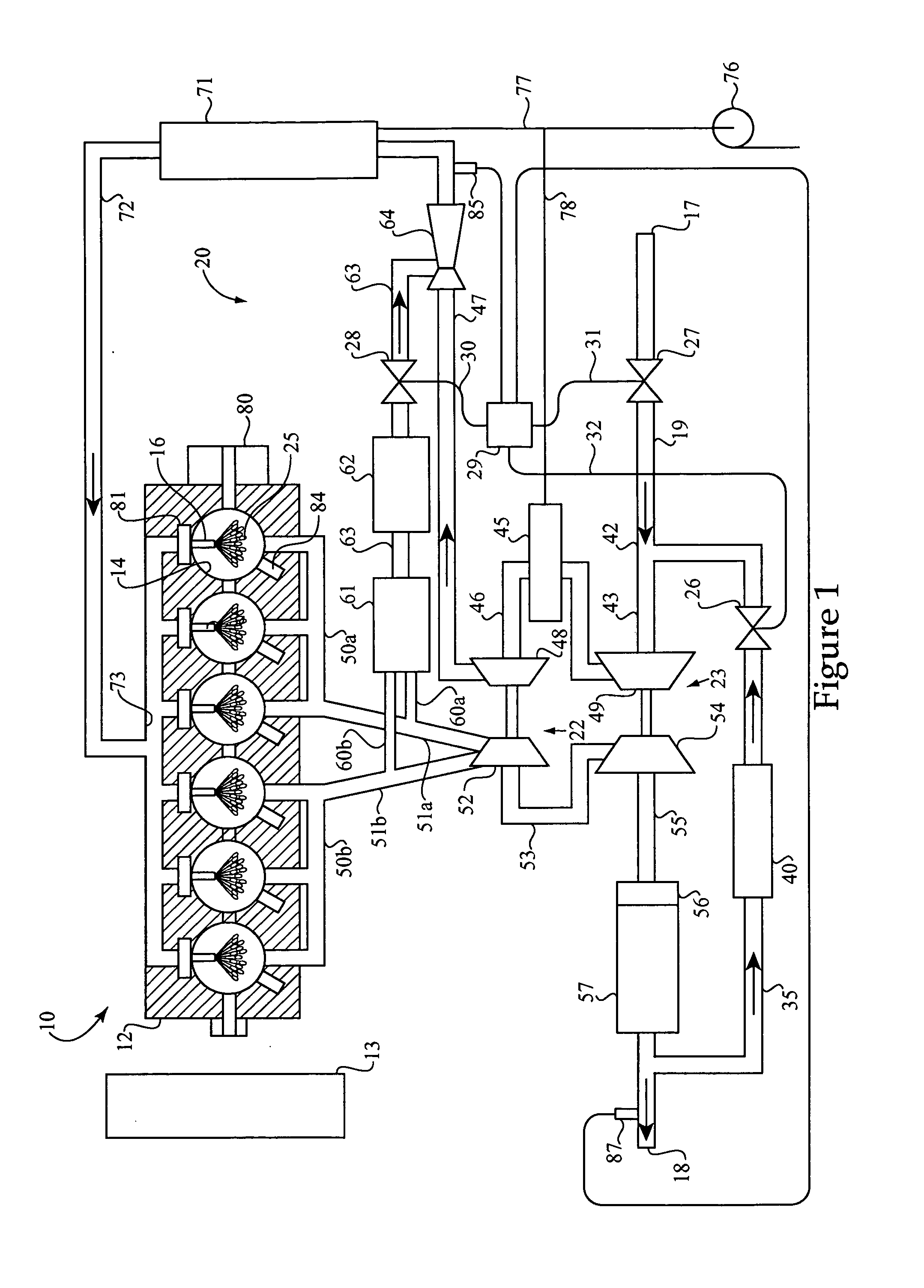

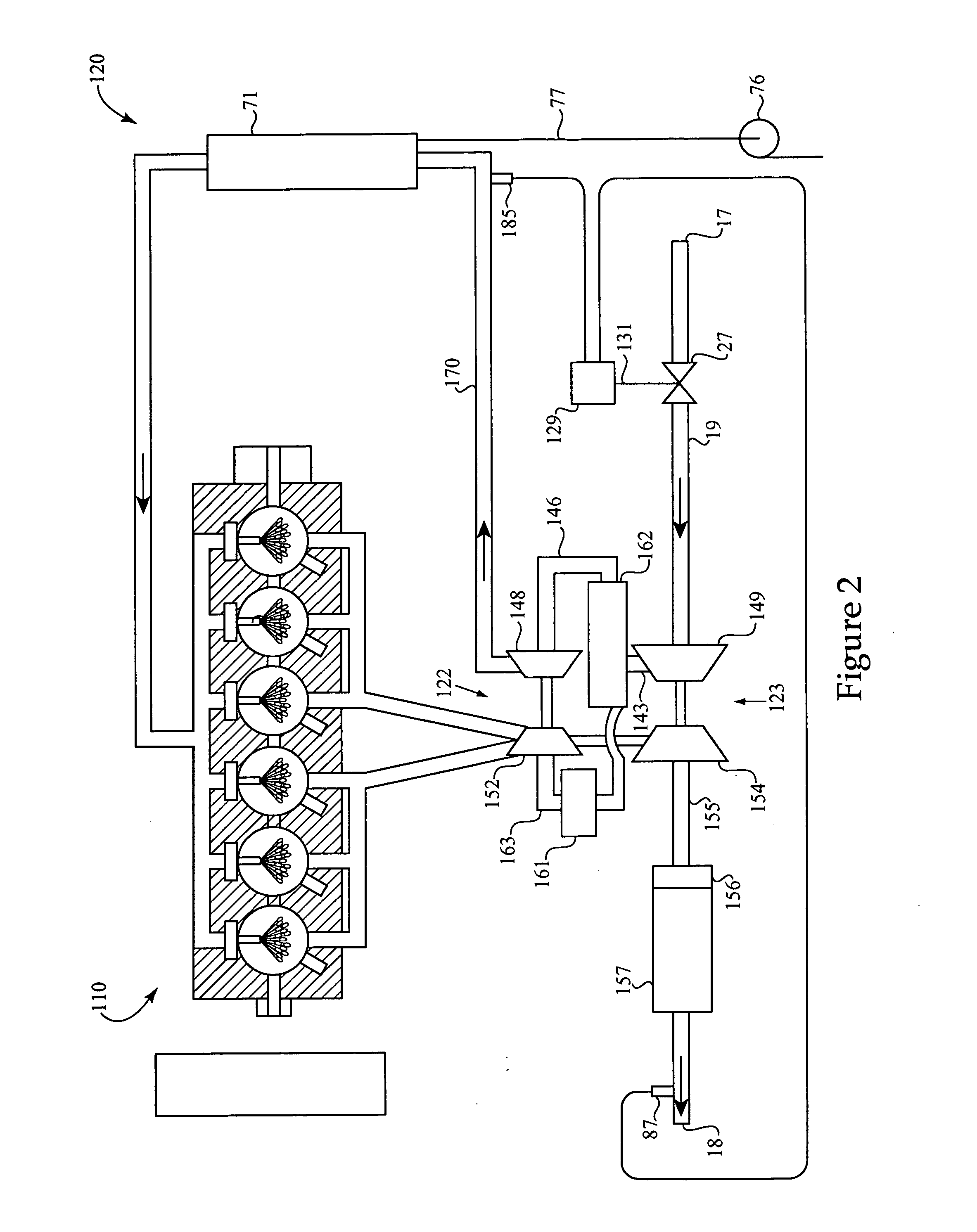

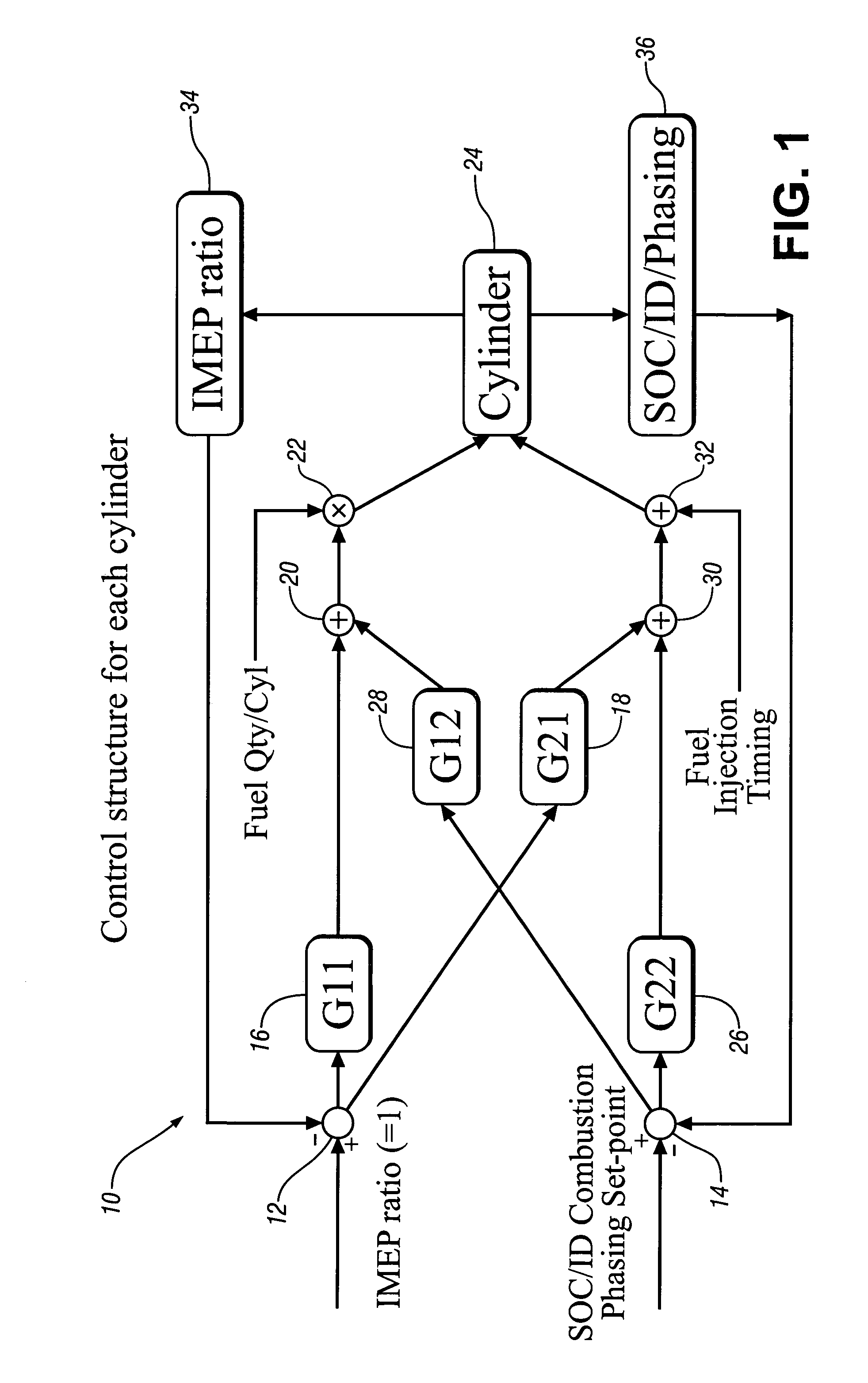

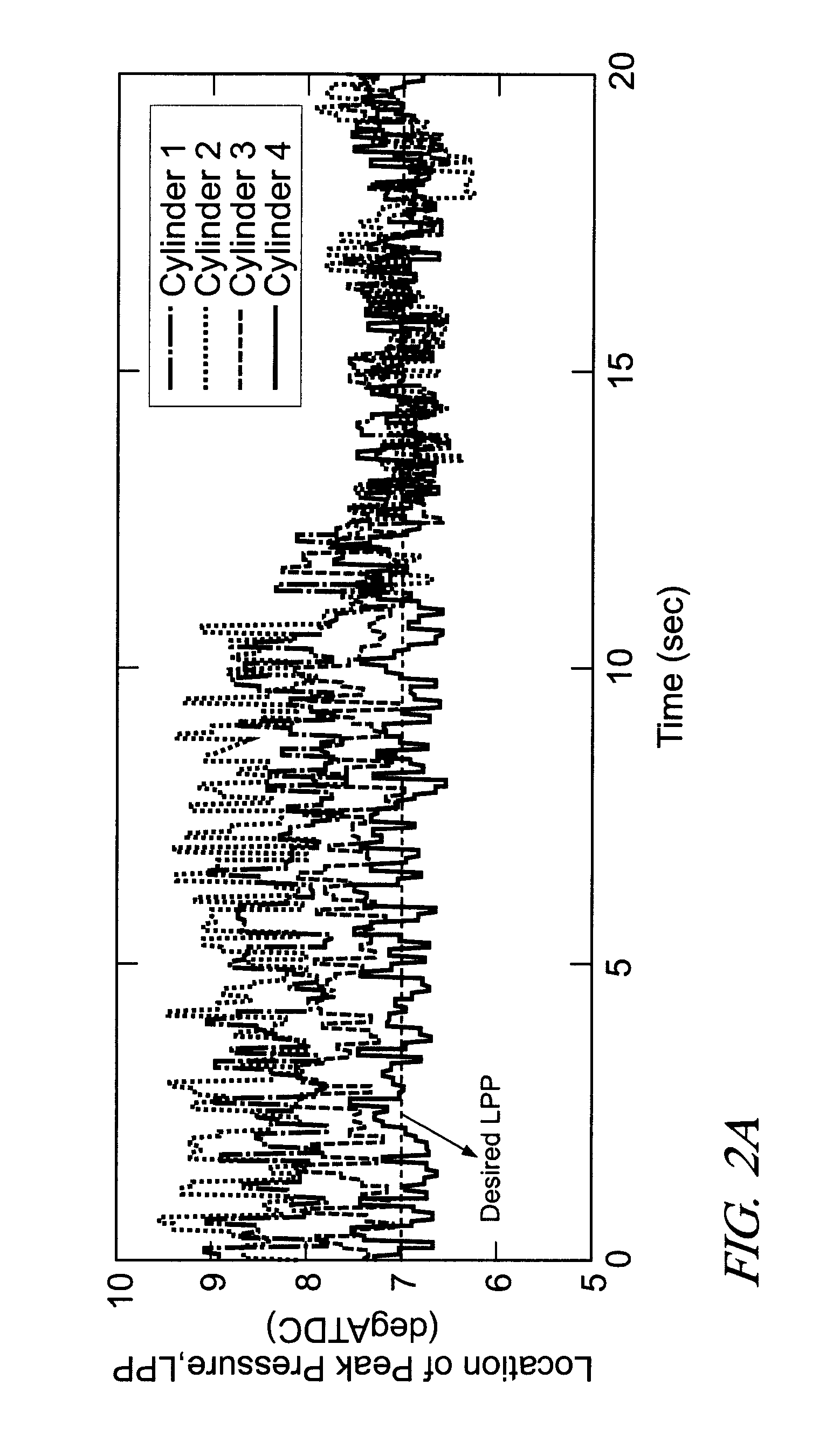

Simultaneous EGR correction and individual cylinder combustion phase balancing

ActiveUS7231906B1Electrical controlNon-fuel substance addition to fuelExternal combustion engineExhaust gas recirculation

An internal combustion engine is configured with combustion chamber pressure sensing and exhaust gas recirculation apparatus. Fuel injection timing is adjusted based on combustion phasing and exhaust gas recirculation is controlled based on average fuel injection timing adjustments.

Owner:GM GLOBAL TECH OPERATIONS LLC

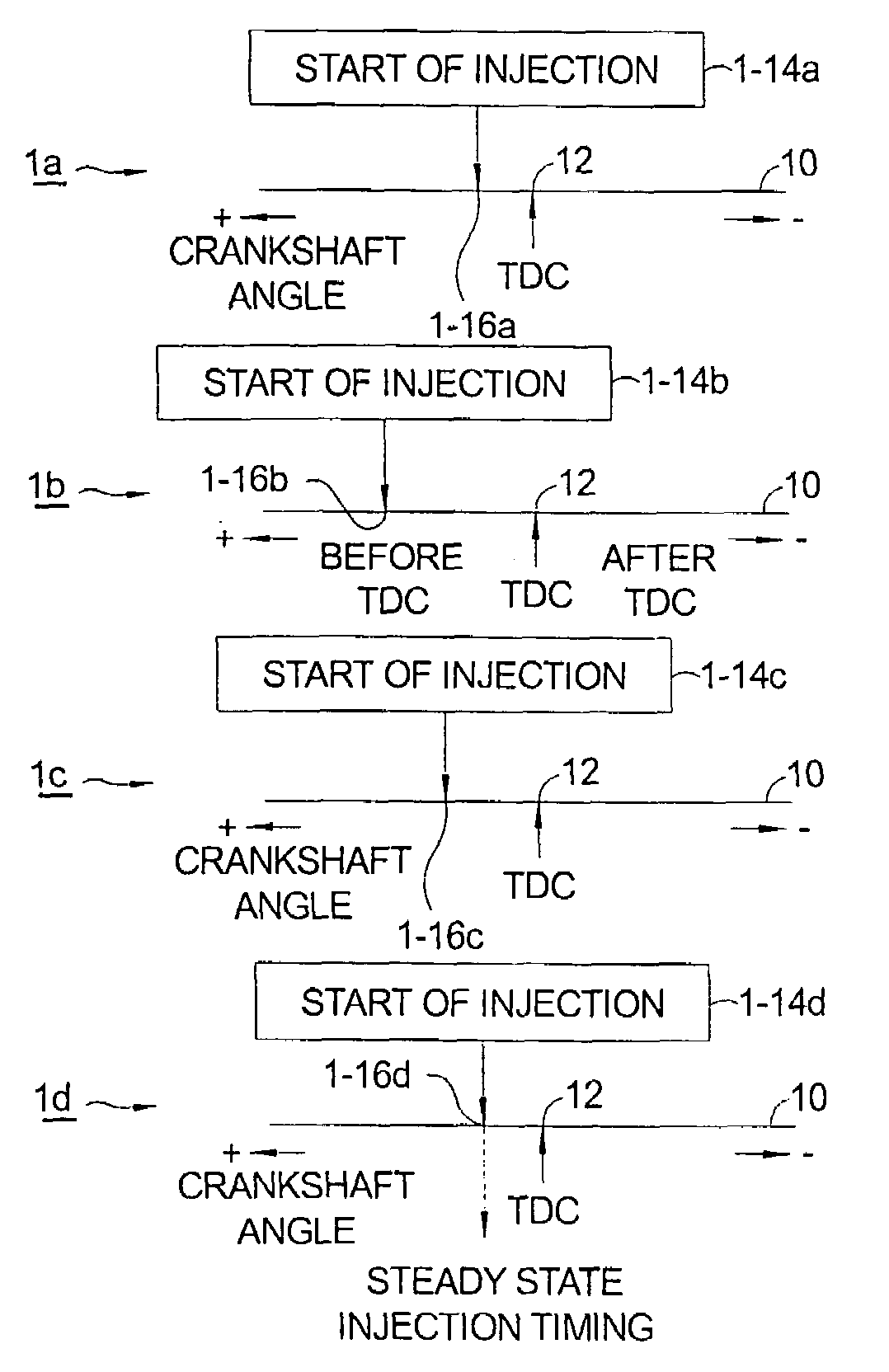

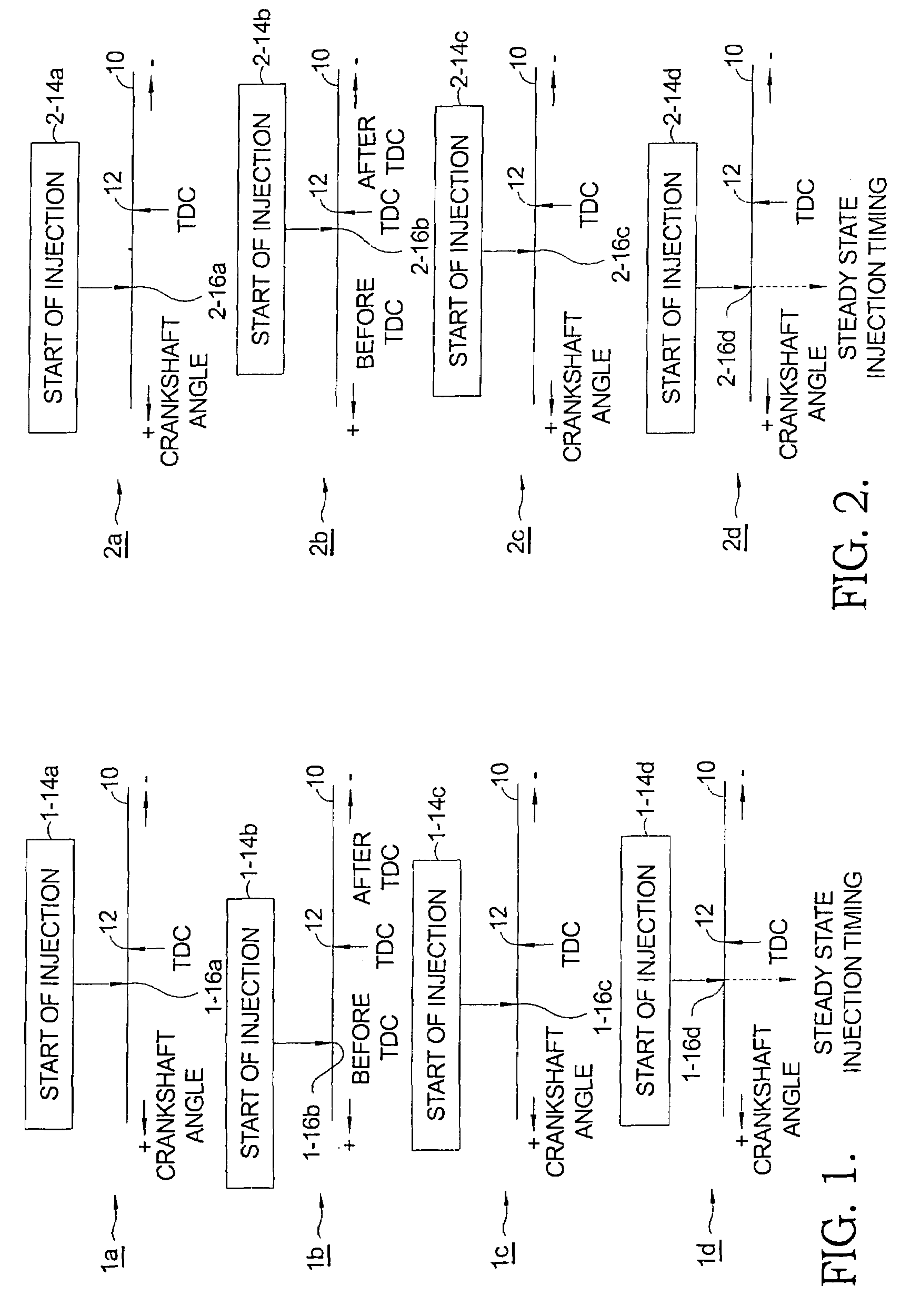

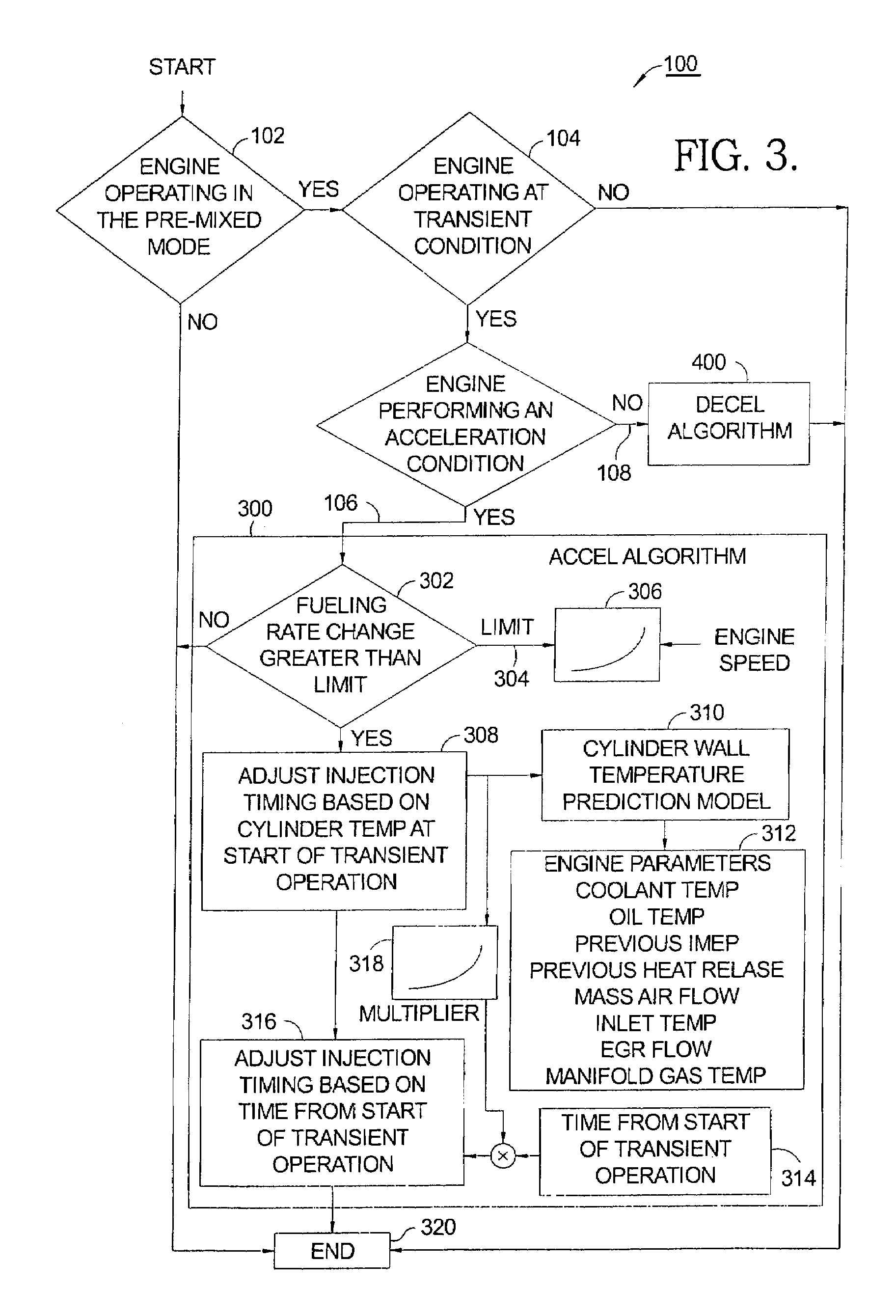

Method for compensating injection timing during transient response of pre-mixed combustion

ActiveUS7475671B1Avoid lostElectrical controlInternal combustion piston enginesCombustion chamberIgnition delay

Owner:DELPHI TECH IP LTD

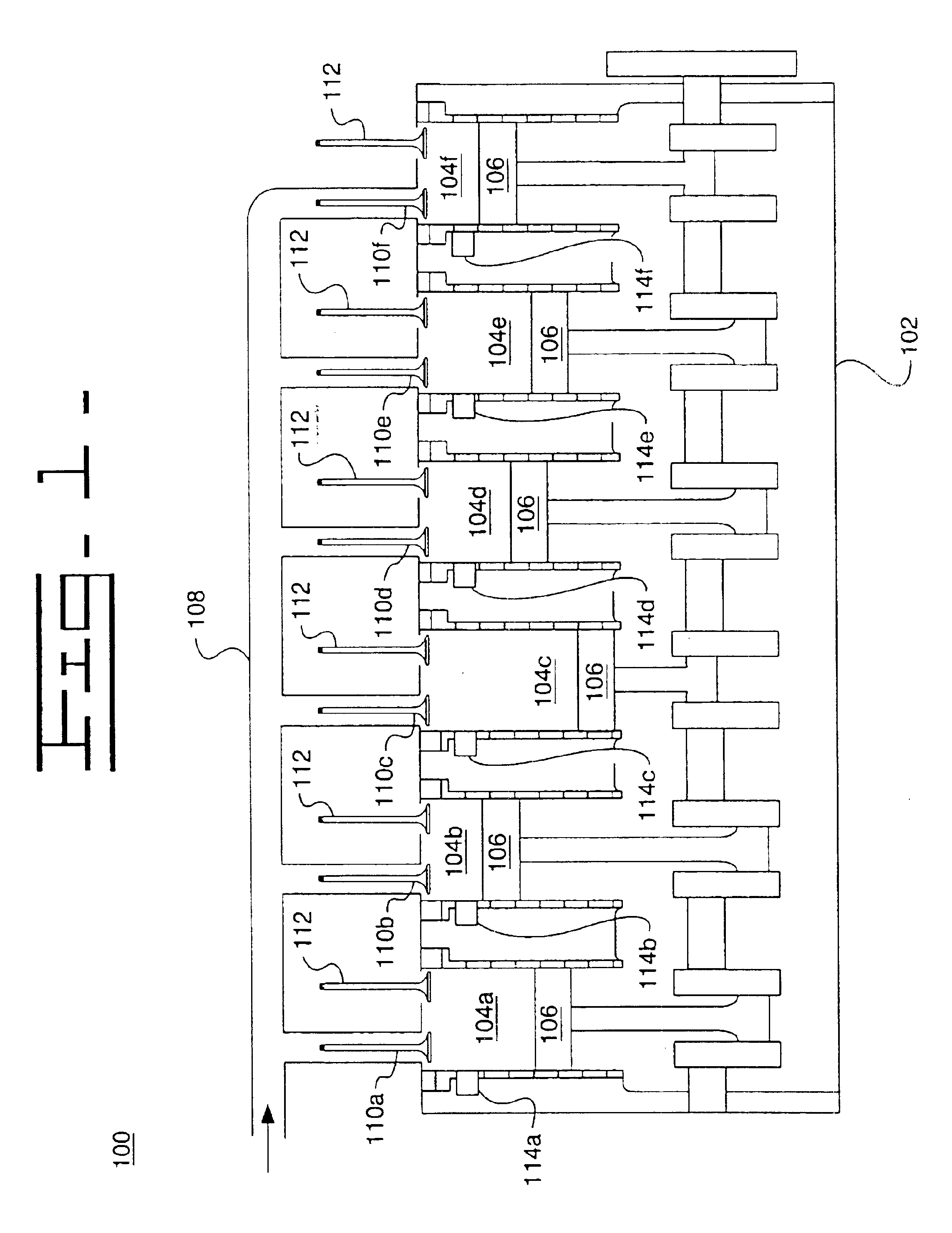

Combustion balancing in a homogeneous charge compression ignition engine

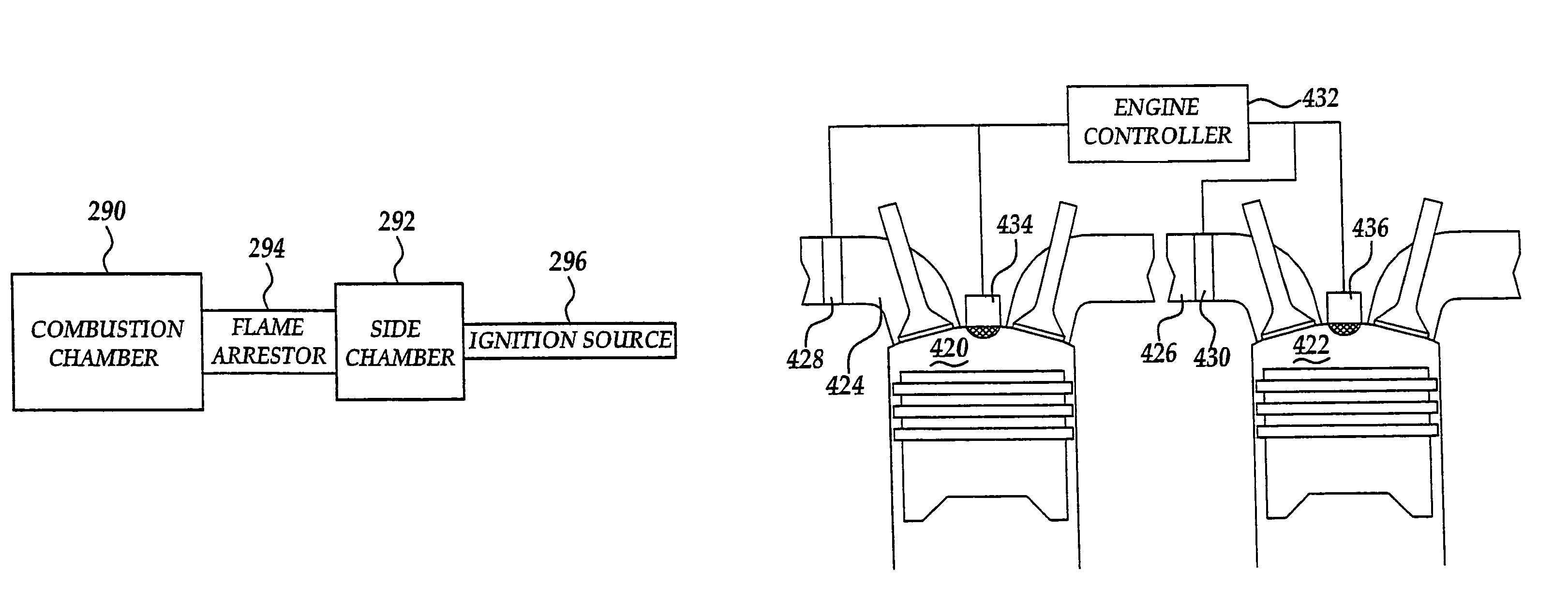

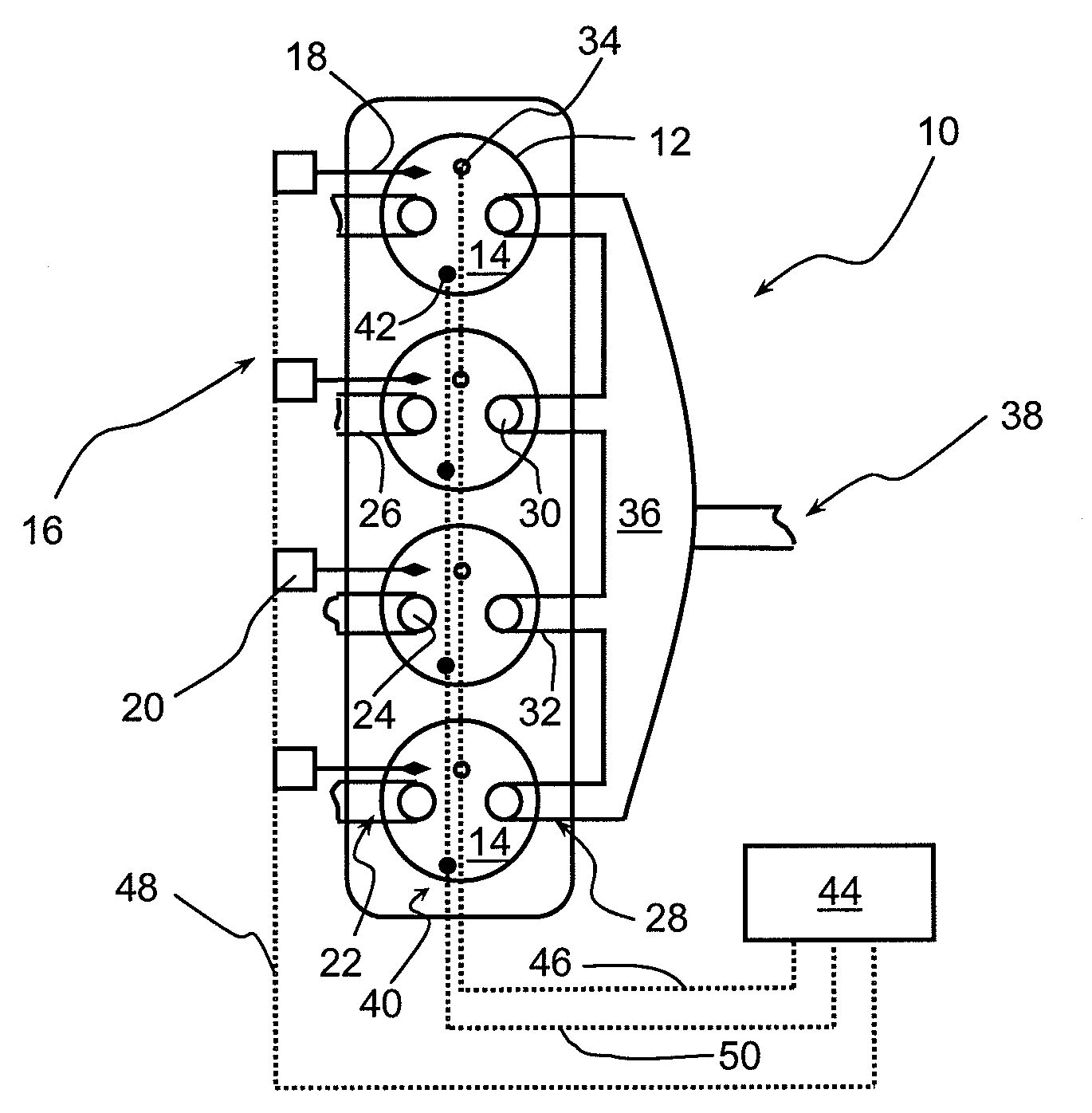

A multi cylinder homogeneous charge compression ignition engine includes actuators and an engine controller configured to reduce variations in combustion phasing and / or combustion energy release among the different engine cylinders. By sensing both the phasing and magnitude of the combustion energy release, the engine controller generates control signals to combustion phase controllers and combustion energy release controllers for the engine cylinders. The control signals may be different from one another to reduce variations across the group of engine cylinders. A combustion energy release controller may be a direct injection fuel injector, and the combustion phase controller may be a variable intake valve actuator. Reducing variations in these aspects of the combustion events, allows the engine to operate at higher speeds and loads.

Owner:CATERPILLAR INC

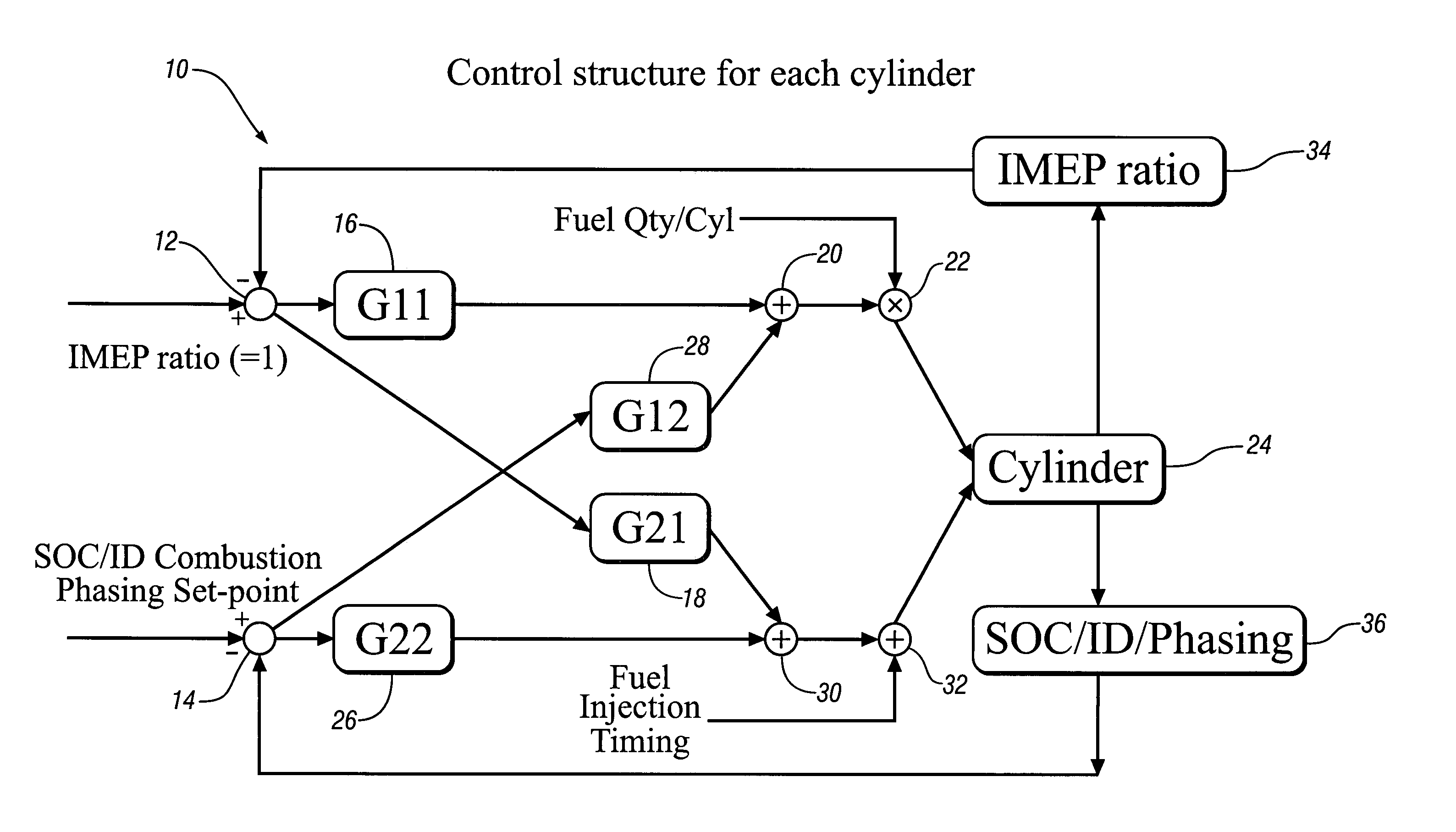

Engine cylinder-to-cylinder variation control

A control system and method for balancing output and exhaust emission values of the various cylinders of an engine having individual cylinder fuel delivery control. Selected output and emission related values for one cylinder, selected as a base cylinder, are compared to the same values for the other cylinders, and fuel injection quantity and timing (or another combustion phasing variable) are adjusted in the other cylinders to output and emission values of the base cylinder. The adjustments are weighted based on the degree to which changes in both the injection quantity and timing (or other variable) influence changes in both the output and emission values as determined from the sensed readings of pressure sensors in each of the cylinders.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method and apparatus for controlling an internal combustion engine using combustion chamber pressure sensing

InactiveUS20050072402A1Quick changeElectrical controlInternal combustion piston enginesCombustion chamberPresent method

The present method and apparatus employ a signal indicative of cylinder pressure within the combustion chamber of an internal combustion engine to control combustion phasing or start of combustion (SOC) in subsequent cycles of the engine where the engine is driven by combustion of both a fuel / air premixed charge and a directly injected quantity of fuel. A ratio of signals indicative of pre-combustion pressure and post-combustion pressure within a cycle are employed to estimate SOC and then, based on a predetermined target SOC, an ignition lever is employed to adjust subsequent SOC. A preferred ignition lever is, in a pilot fuel ignited engine, pilot fuel quantity.

Owner:WESTPORT POWER

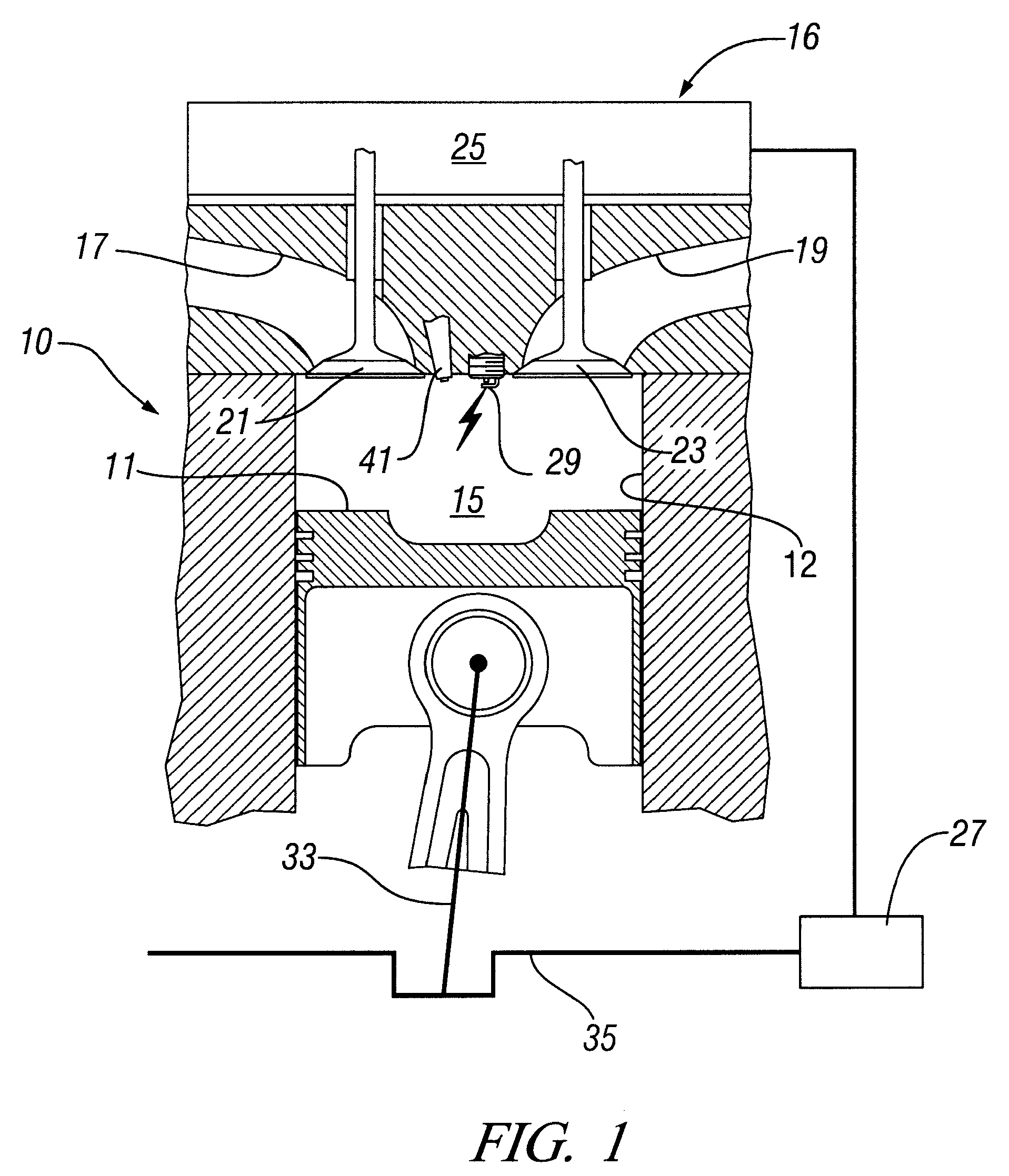

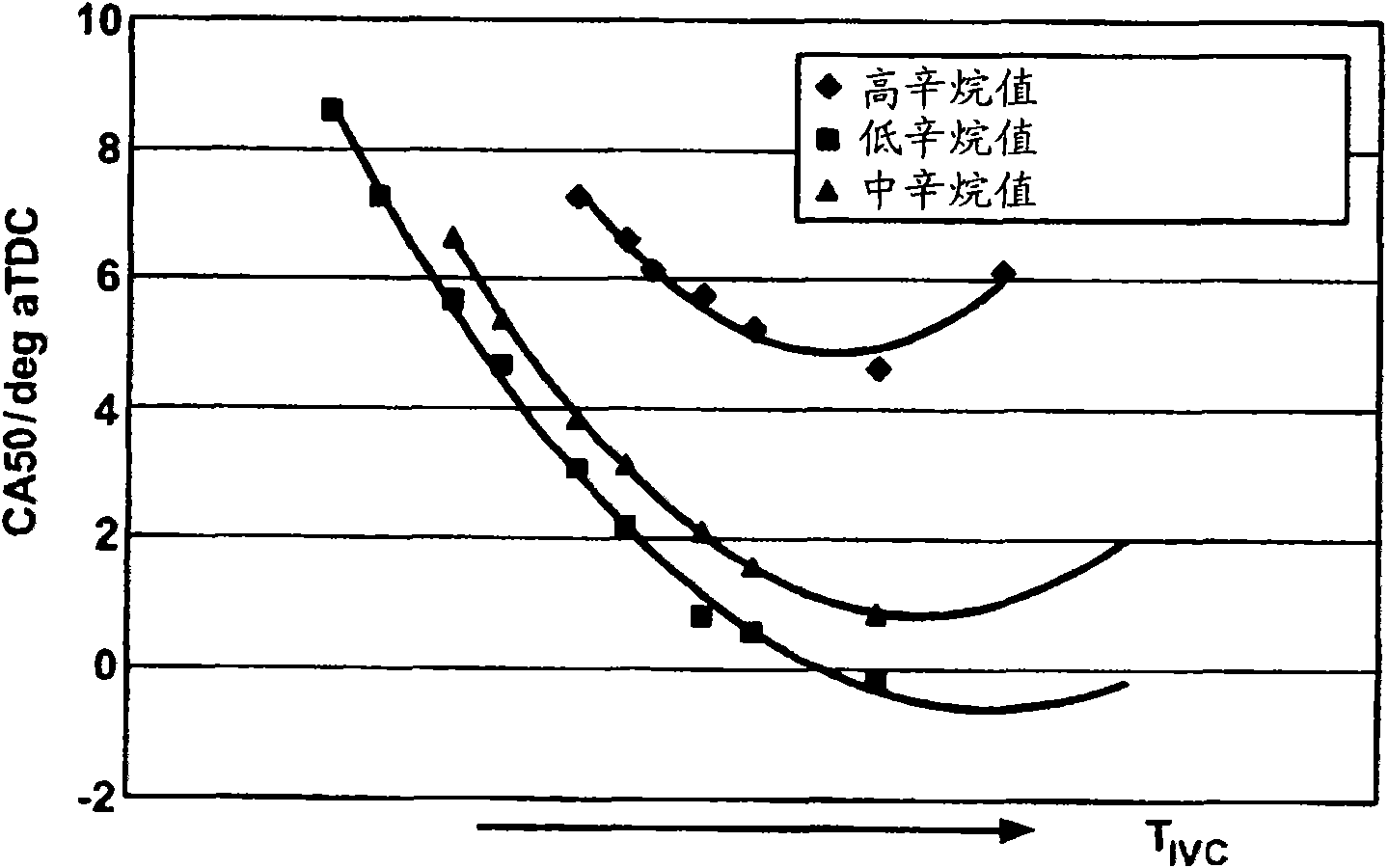

Fuel adaptation in a homogeneous charge compression ignition engine

InactiveUS20070119417A1Improve combustion stabilityExtended lean operationValve arrangementsElectrical controlEngineeringMechanical engineering

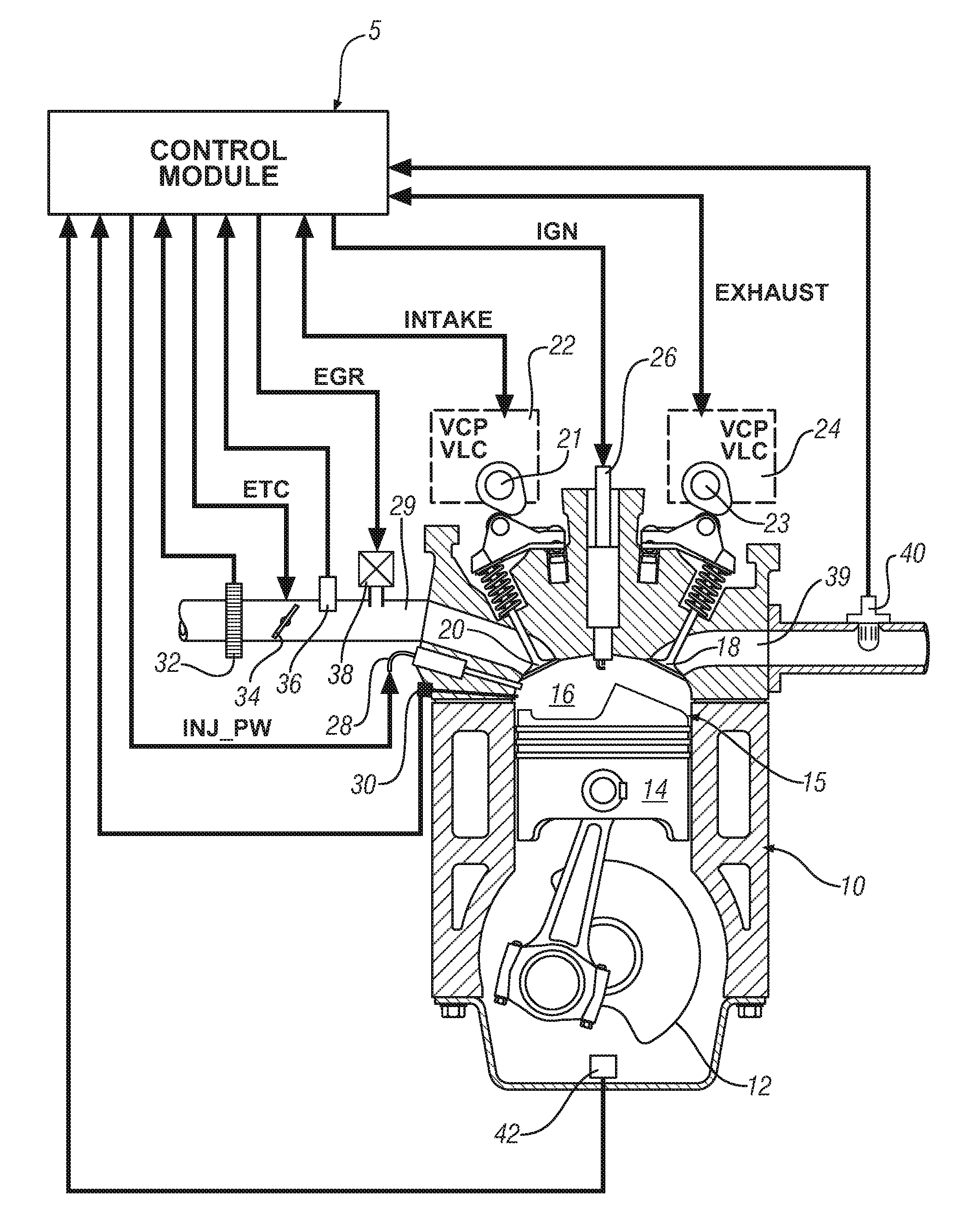

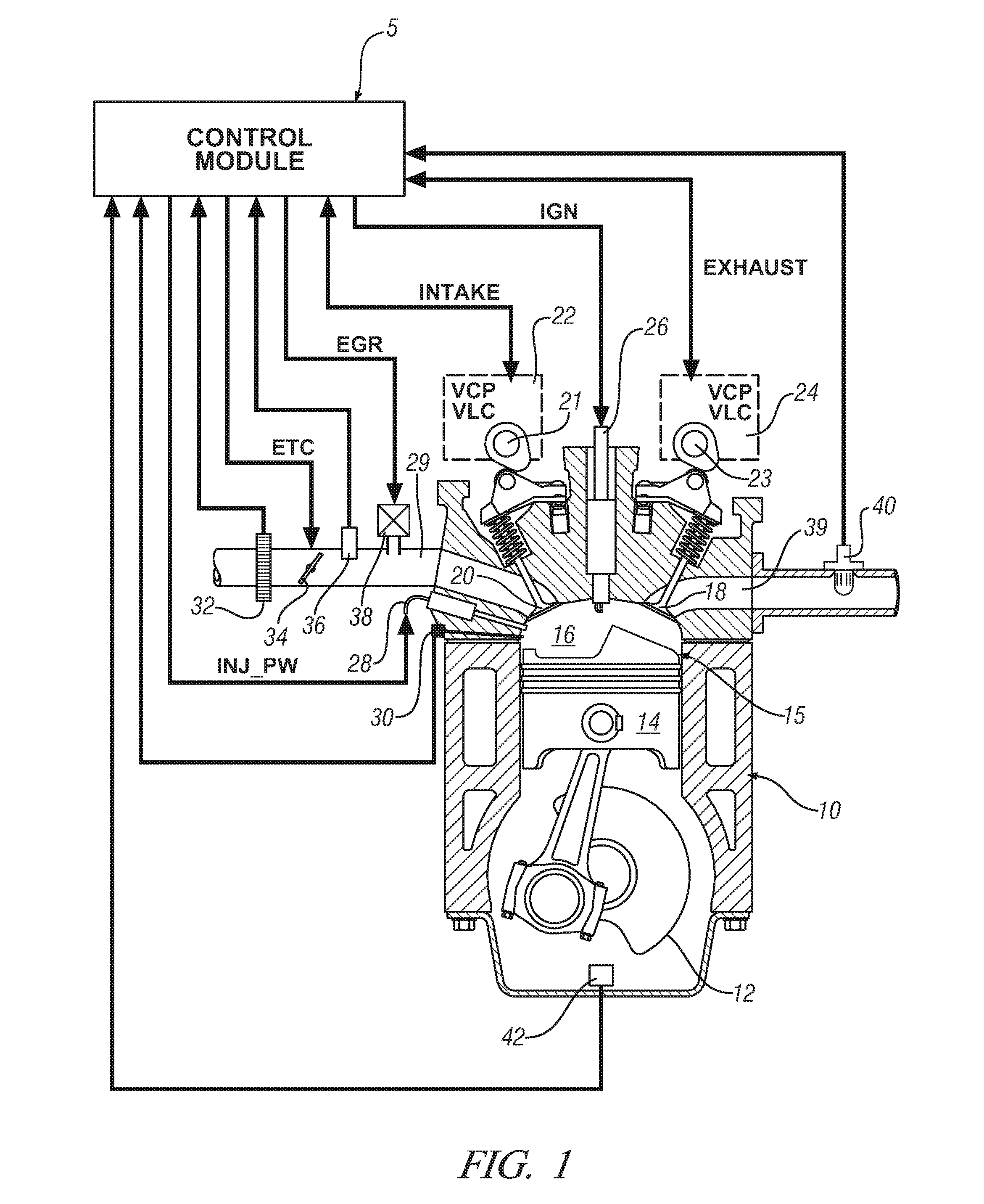

Operation of a homogeneous charge compression ignition engine is adapted to fuel variations. A variable valve actuating system is employed to effect conditions conducive to homogeneous charge compression ignition operation. Nominal valve timing is selected and adjustments thereto are made based on deviations in combustion phasing from a desired combustion phasing. Fuel delivery timing and quantity are adjusted once valve timing authority limits are reached to achieve further combustion phasing improvement.

Owner:GM GLOBAL TECH OPERATIONS LLC

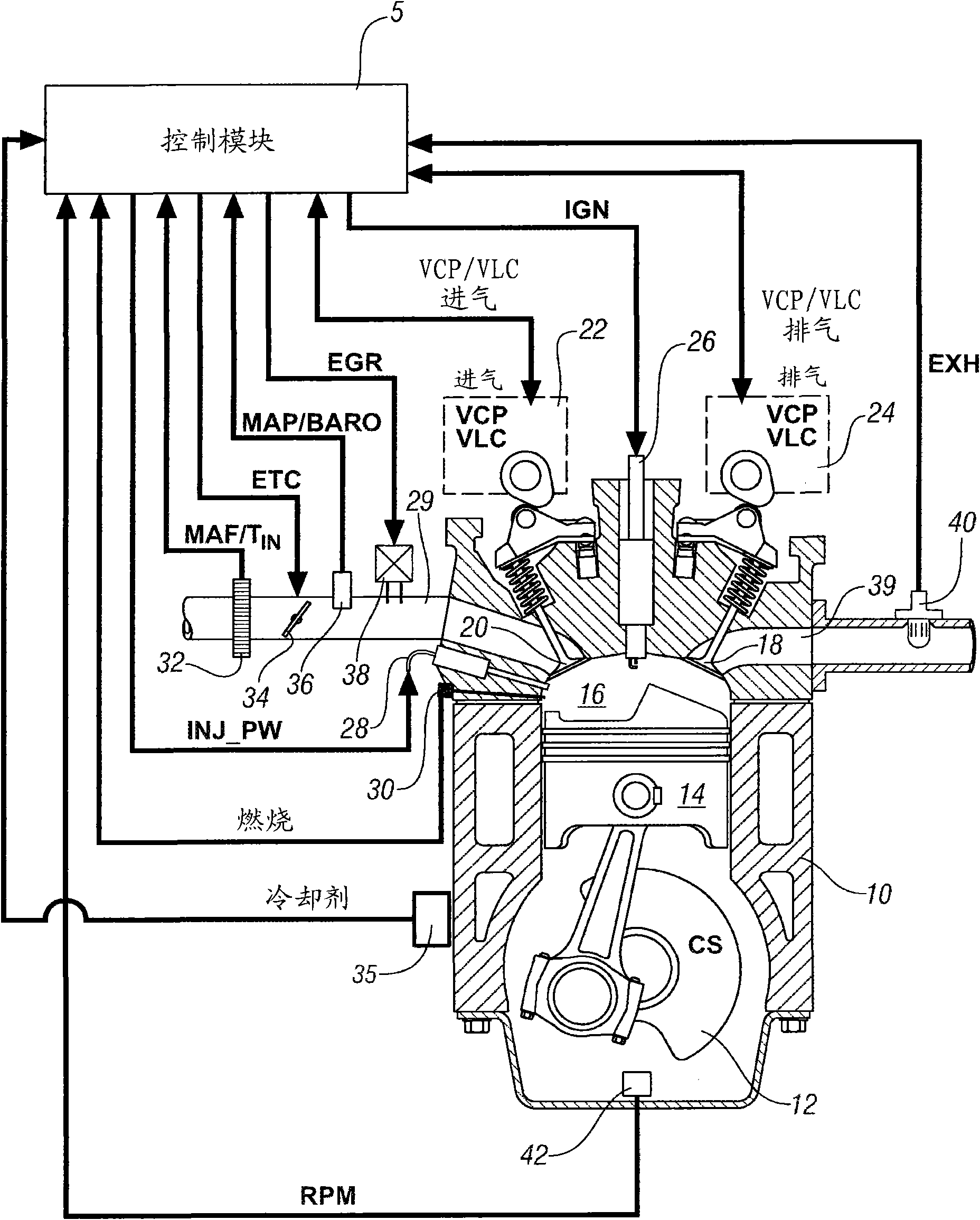

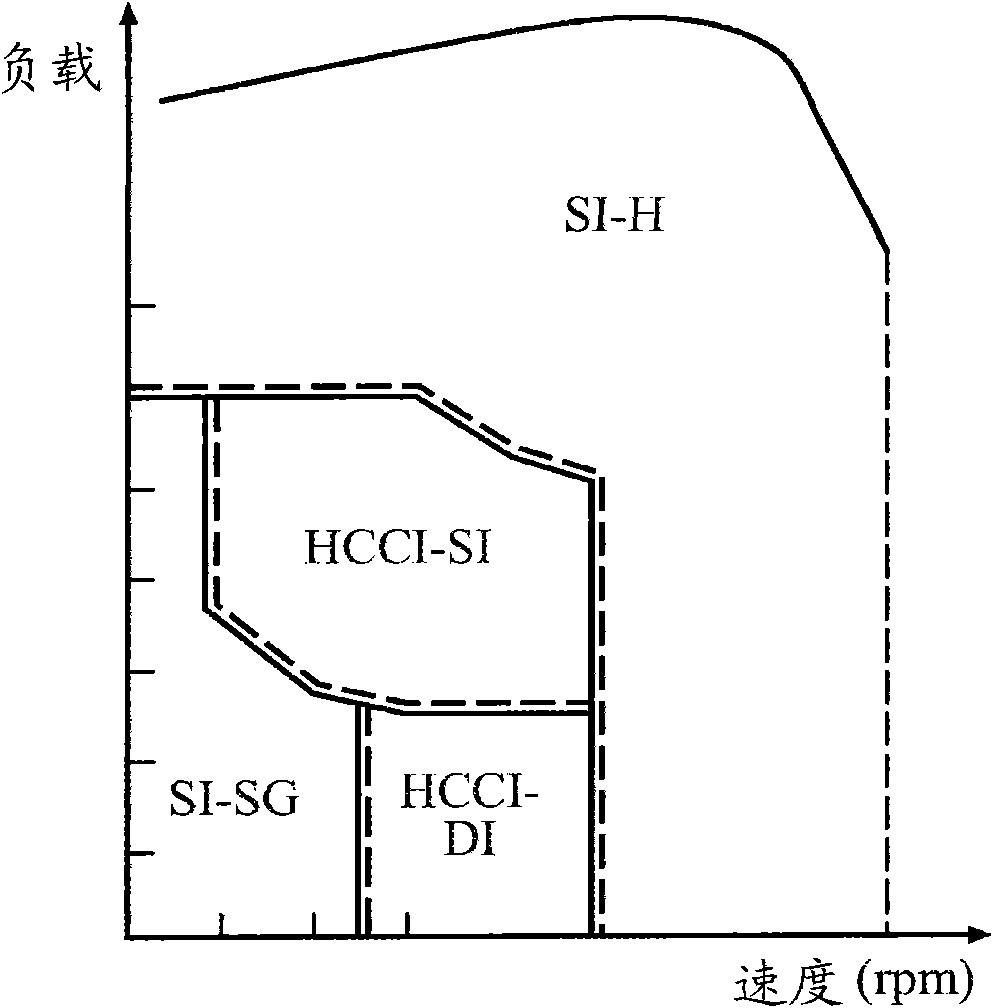

Control system of HCCI/SI double-mode harmonization press-combustion engine and method therefor

ActiveCN101070791AImprove fuel economyImprove robustnessElectrical controlMachines/enginesThree levelMicrocontroller

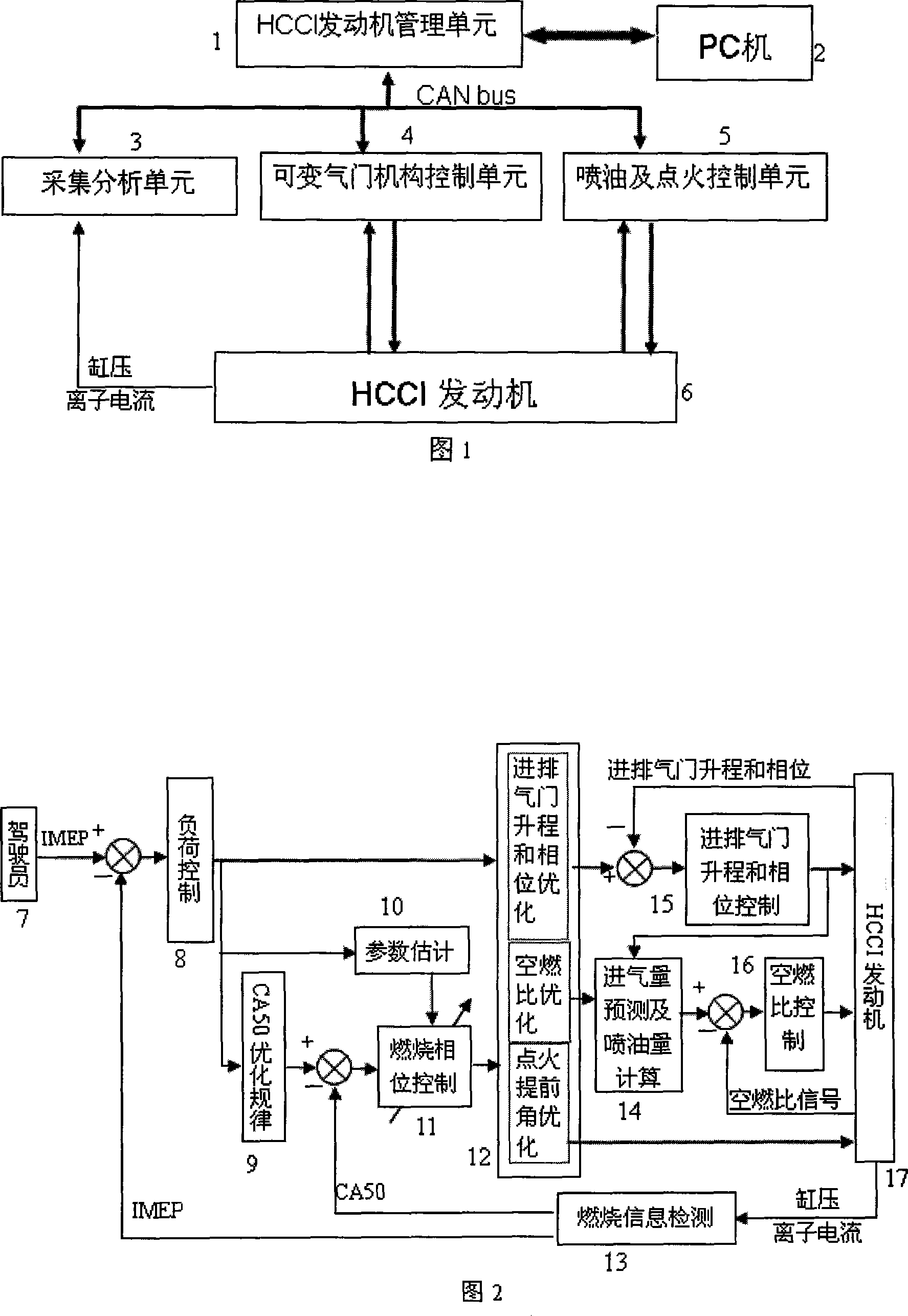

This invention relates to HCCI / SI dual-mode engine control systems and control methods. Based on SCM and CAN Bus, HCCI / SI dual-mode engine distributing control systems includes engine management unit, the fuel injection control unit ignition, valve train control unit and combustion information collection and analysis modules. HCCI / SI dual-mode HCCI engine control method uses a hierarchical closed-loop management strategies, dividing control of the whole engine into load control, combustion control and the control of phase three levels, which have adopted corresponding closure central control. The present invention considers the engine load control as the main line, by controlling the combustion phase to ensure the stability of HCCI combustion. The invention controls each loop separately, streamlining its coupling relations. The idea of closed-loop hierarchical control is not only of clear, easy to implement, but also especially helps improve the robustness of the control system.

Owner:TIANJIN UNIV

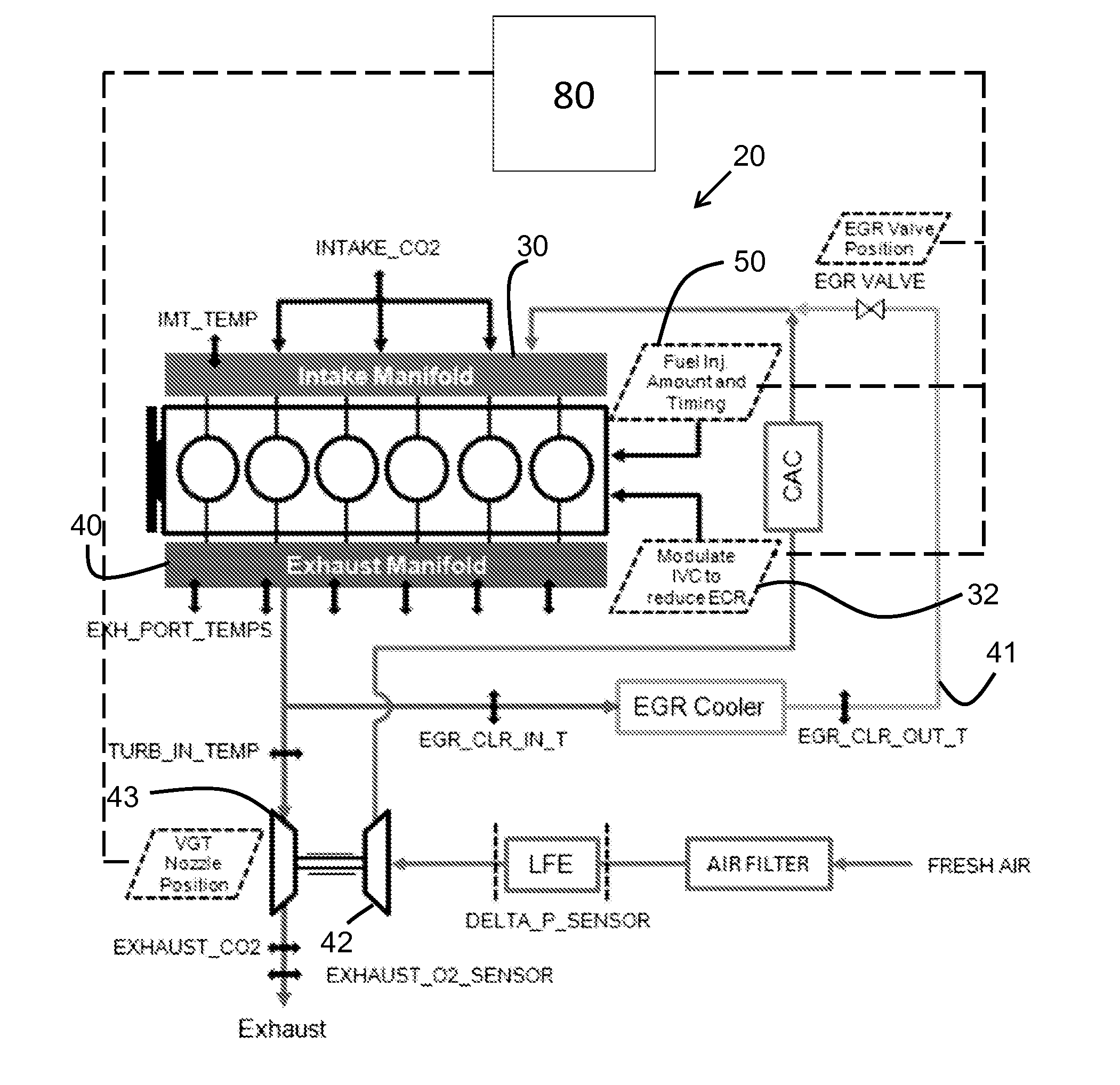

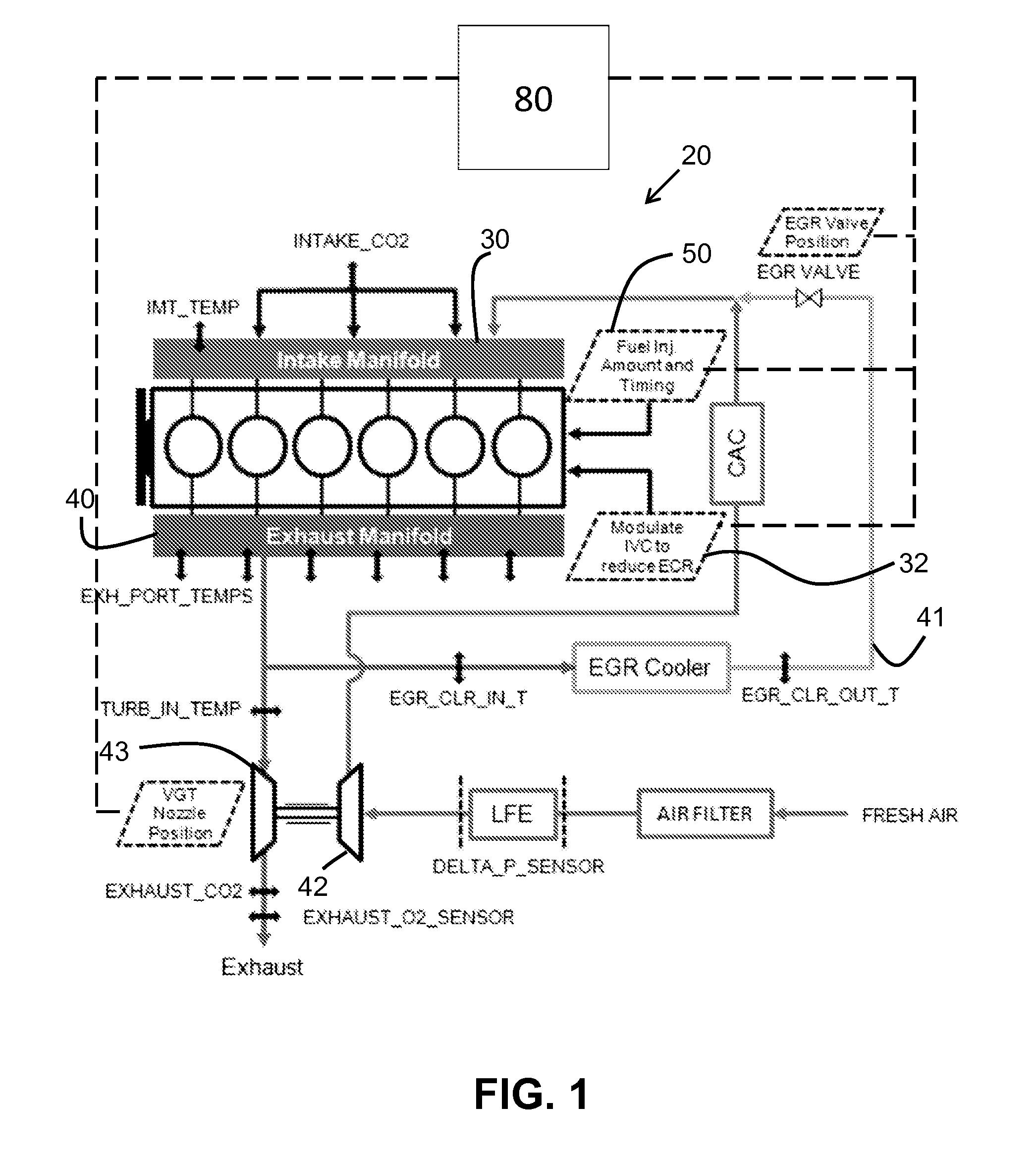

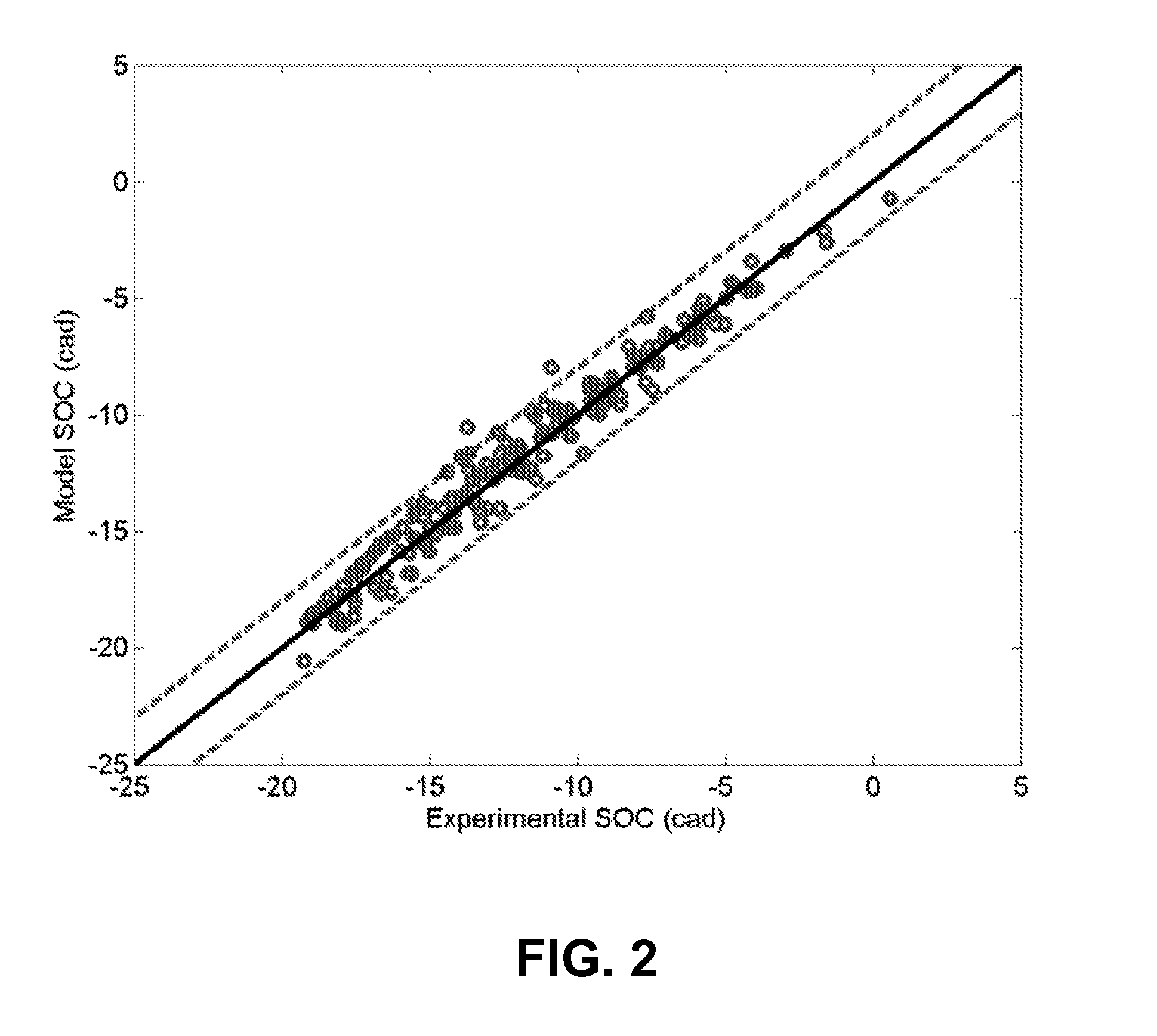

Nonlinear model-based controller for premixed charge compression ignition combustion timing in diesel engines

ActiveUS20150330326A1Electrical controlInternal combustion piston enginesNonlinear modelModel based controller

Advanced combustion modes, such as PCCI, operate near the system stability limits. In PCCI, the combustion event begins without a direct combustion trigger in contrast to traditional spark-ignited gasoline engines and direct-injected diesel engines. The lack of a direct combustion trigger encourages the usage of model-based controls to provide robust control of the combustion phasing. The nonlinear relationships between the control inputs and the combustion system response often limit the effectiveness of traditional, non-model-based controllers. Accurate knowledge of the system states and inputs is helpful for implementation of an effective nonlinear controller. A nonlinear controller is developed and implemented to control the engine combustion timing during diesel PCCI operation by targeting desired values of the in-cylinder oxygen concentration, pressure, and temperature during early fuel injection.

Owner:PURDUE RES FOUND INC

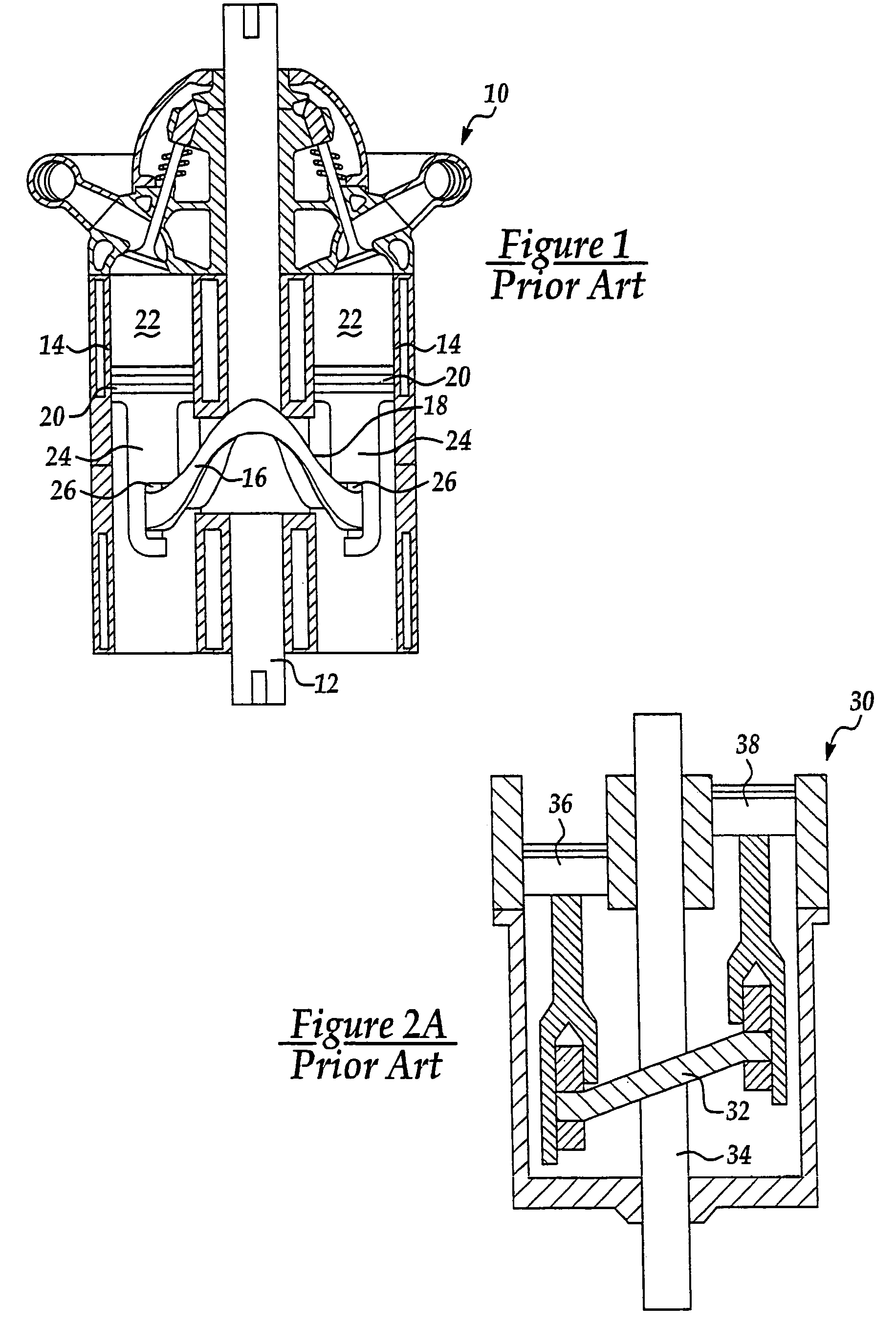

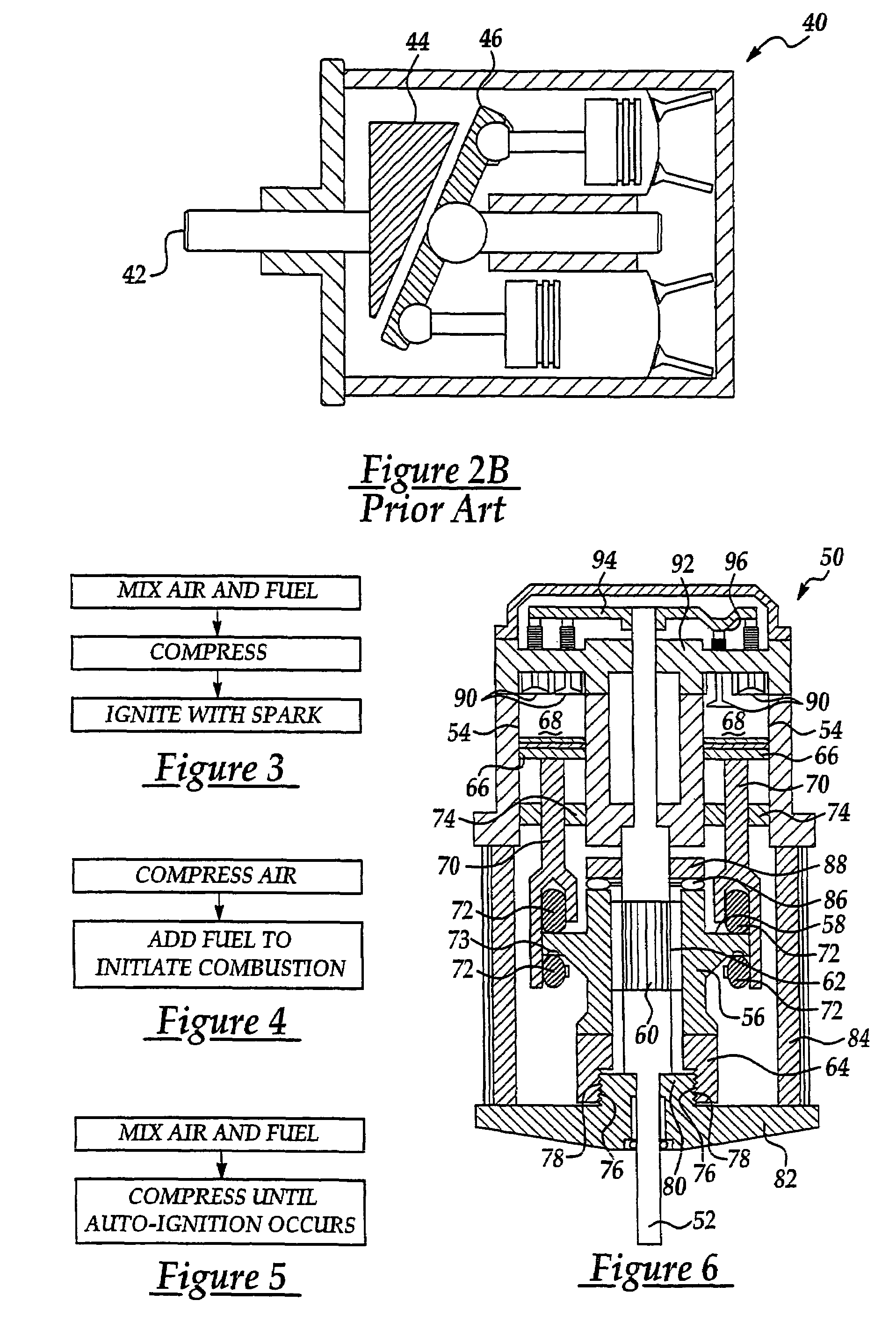

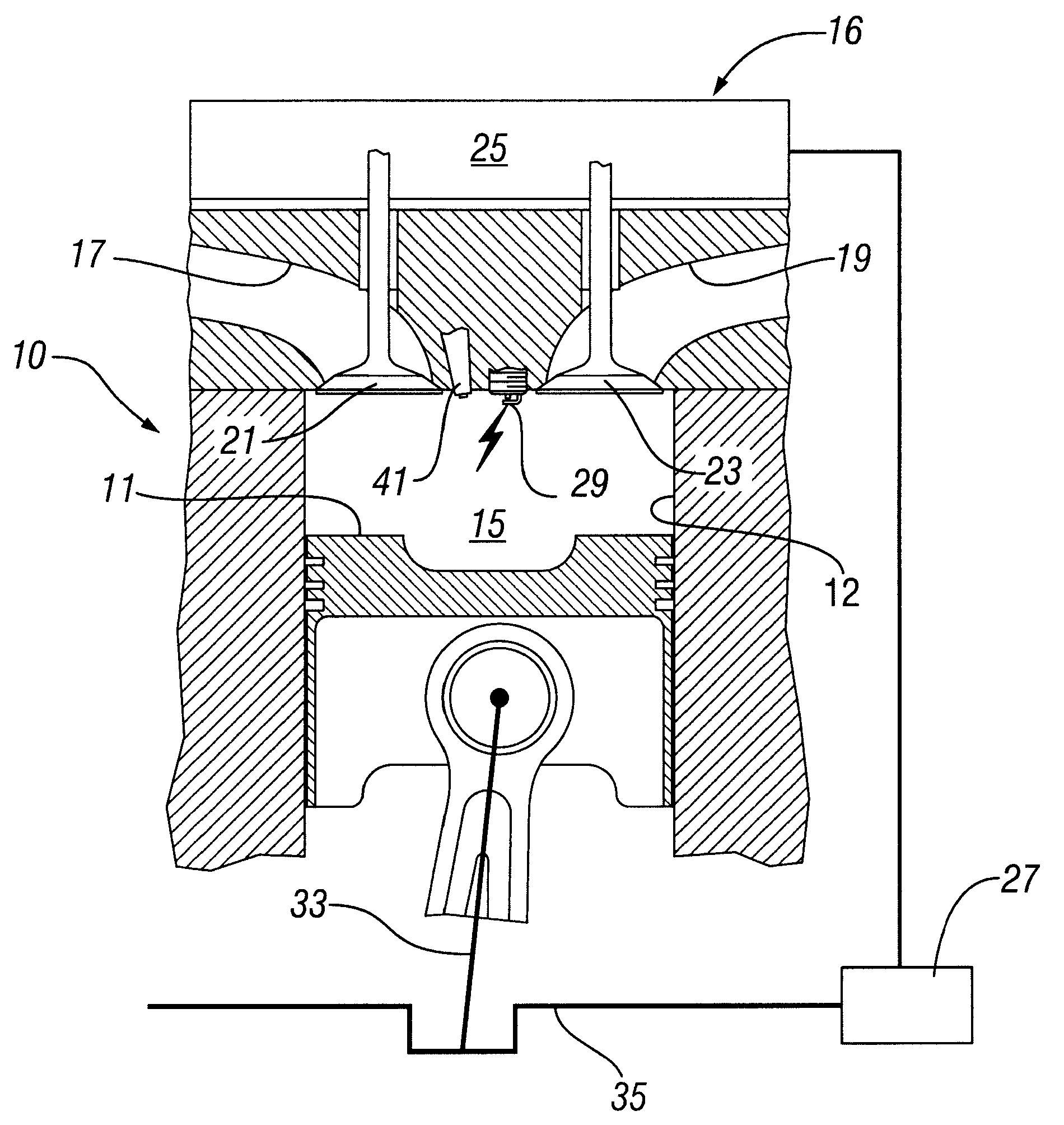

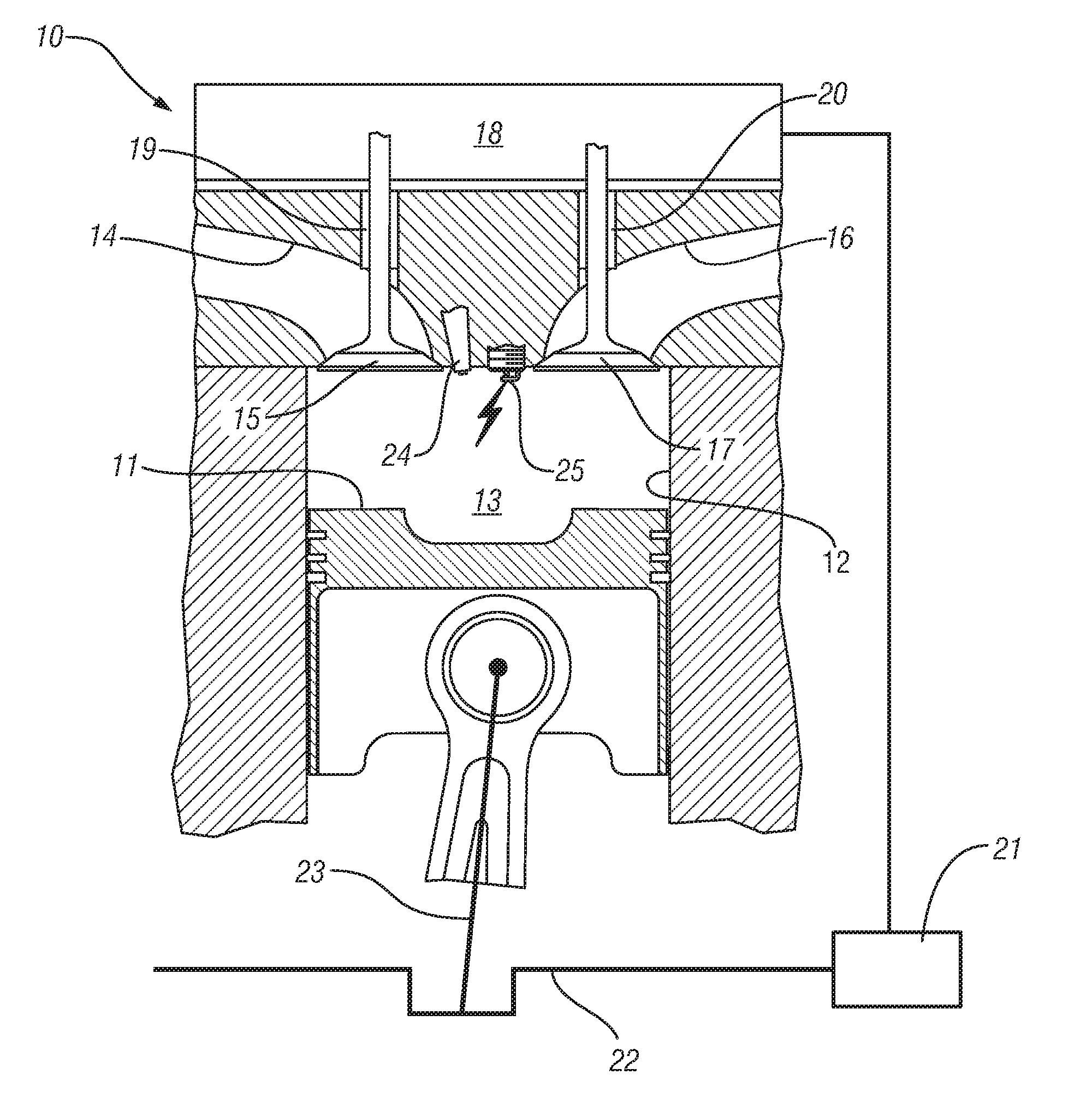

Homogeneous charge compression ignition engine with combustion phasing

InactiveUS7469662B2Rapidly increase compression levelQuick compressionInternal combustion piston enginesEngine componentsPistonAutomotive engineering

The relative combustion phasing of a homogenous charge compression ignition engine is controlled by controlling the introduction of ions and free radicals to cylinders in the engine. The engine has an engine housing with at least a first and second cylinder and an intake system that introduces a combustible mixture of air and fuel to the cylinders. A piston is disposed in each of the cylinders and is operable to compress a combustible mixture until the mixture auto ignites, without the introduction of a spark.

Owner:THOMAS ENGINE CO LLC

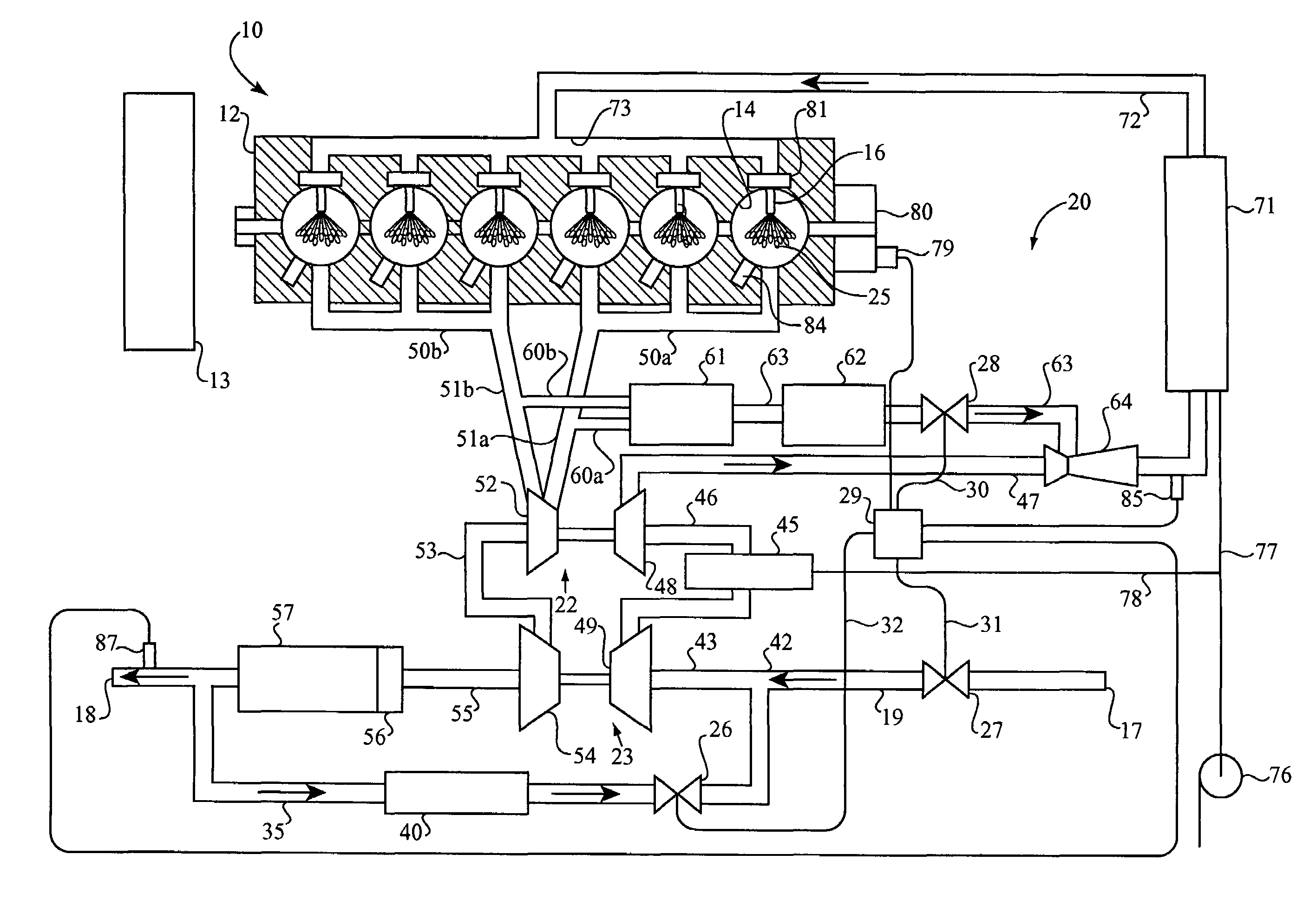

High load operation in a homogeneous charge compression ignition engine

InactiveUS7469181B2Analogue computers for vehiclesElectrical controlExhaust gas recirculationHigh load

A homogeneous charge compression ignition engine is set up by first identifying combinations of compression ratio and exhaust gas percentages for each speed and load across the engines operating range. These identified ratios and exhaust gas percentages can then be converted into geometric compression ratio controller settings and exhaust gas recirculation rate controller settings that are mapped against speed and load, and made available to the electronic engine controller. This provides the engine controller with a look up table of what compression ratio and exhaust gas rates should be at each speed and load. The engine controller also balances at least one of combustion phasing and energy release among a plurality of cylinders in order to enable higher load operation.

Owner:CATERPILLAR INC

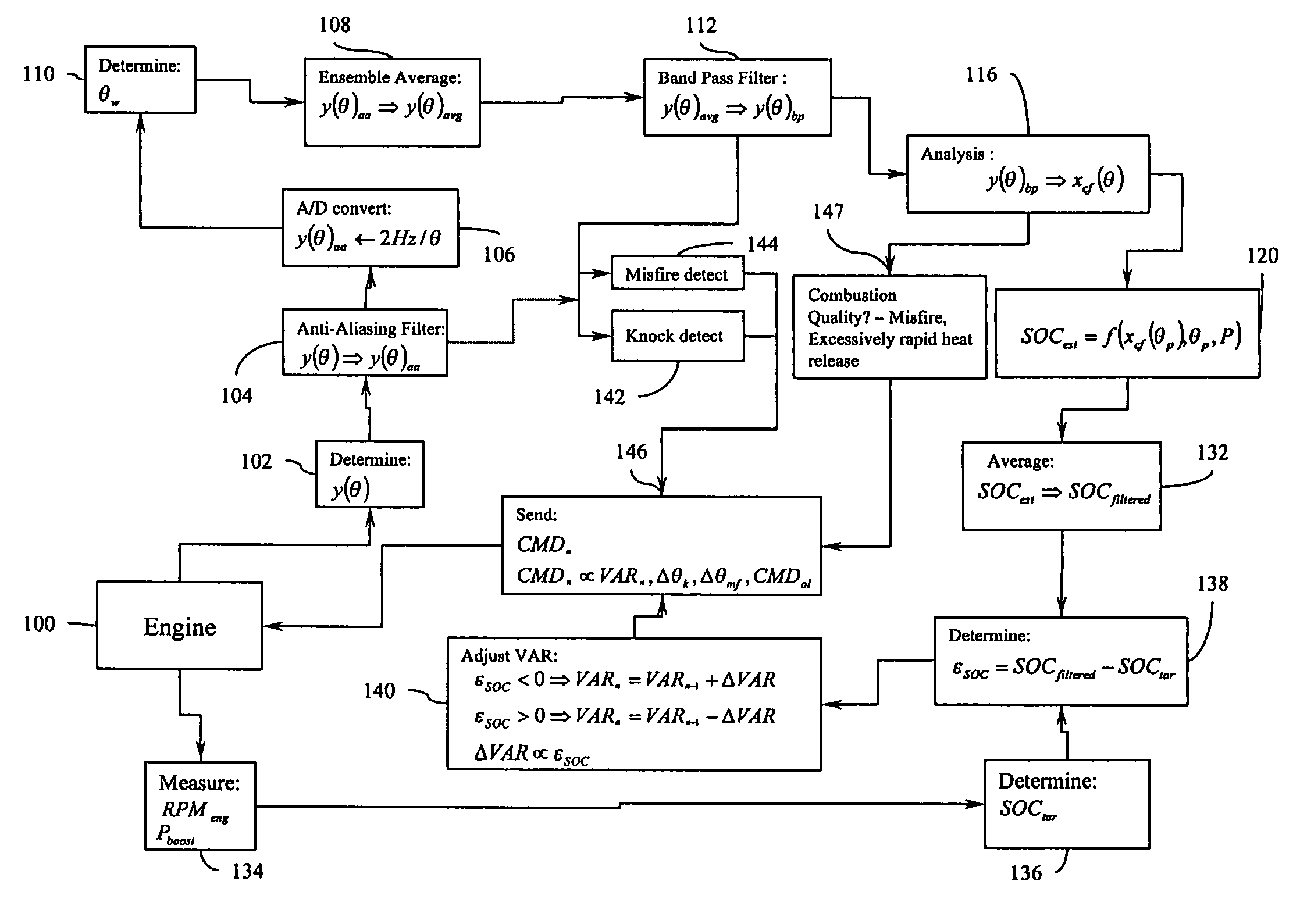

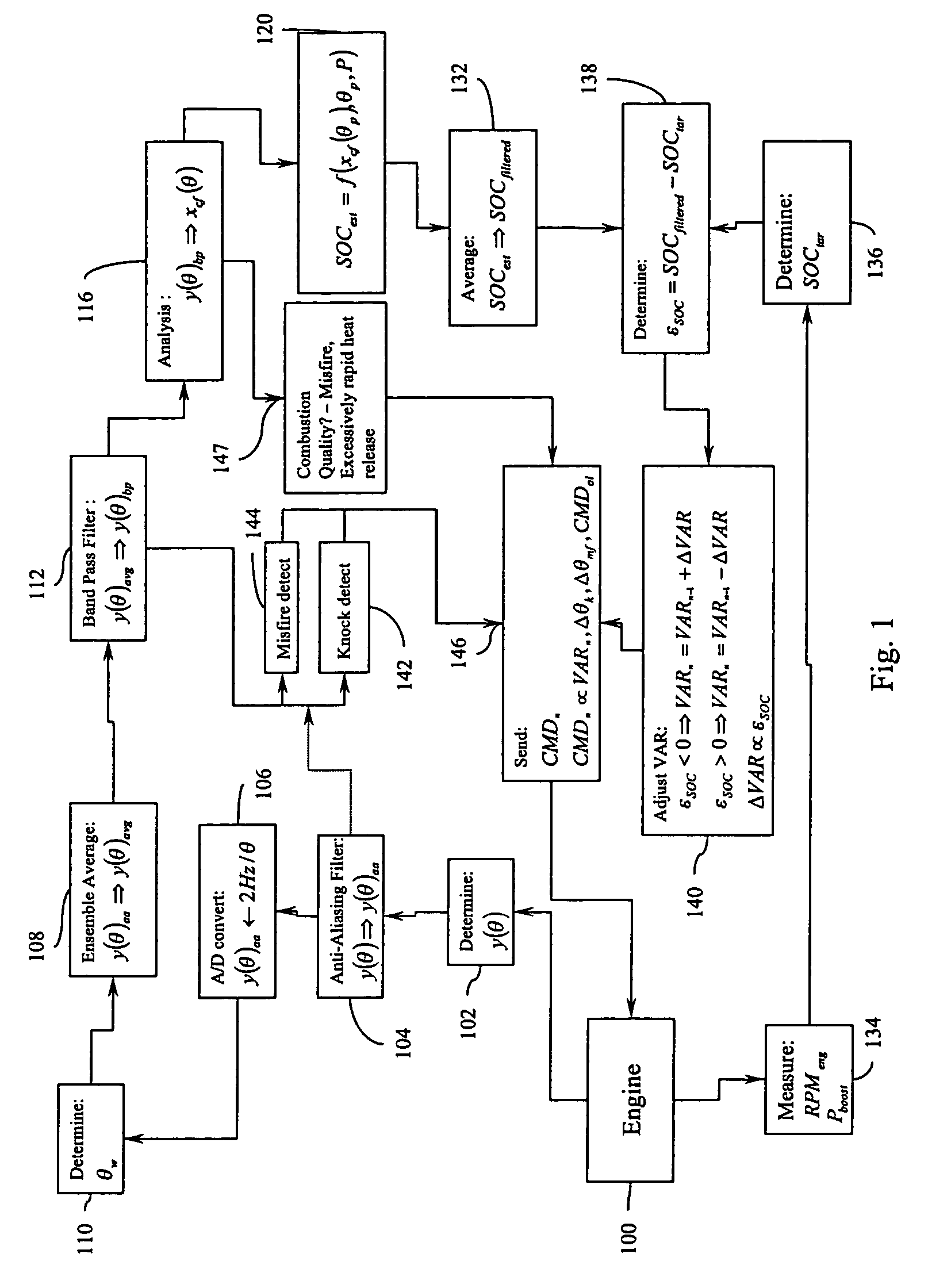

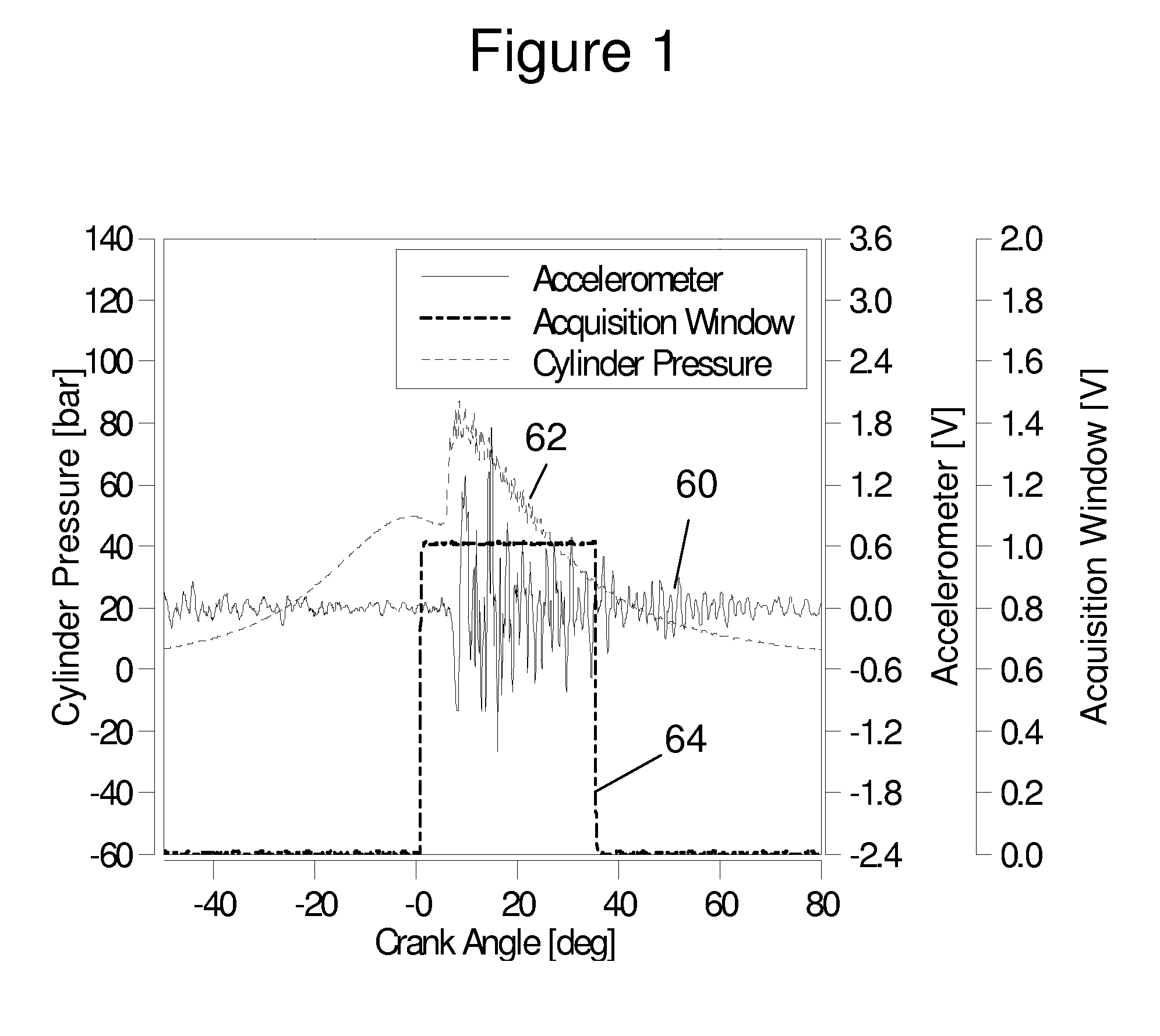

Method and apparatus for controlling an internal combustion engine using accelerometers

ActiveUS7133761B2Closely matchedAnalogue computers for vehiclesElectrical controlShock waveAccelerometer data

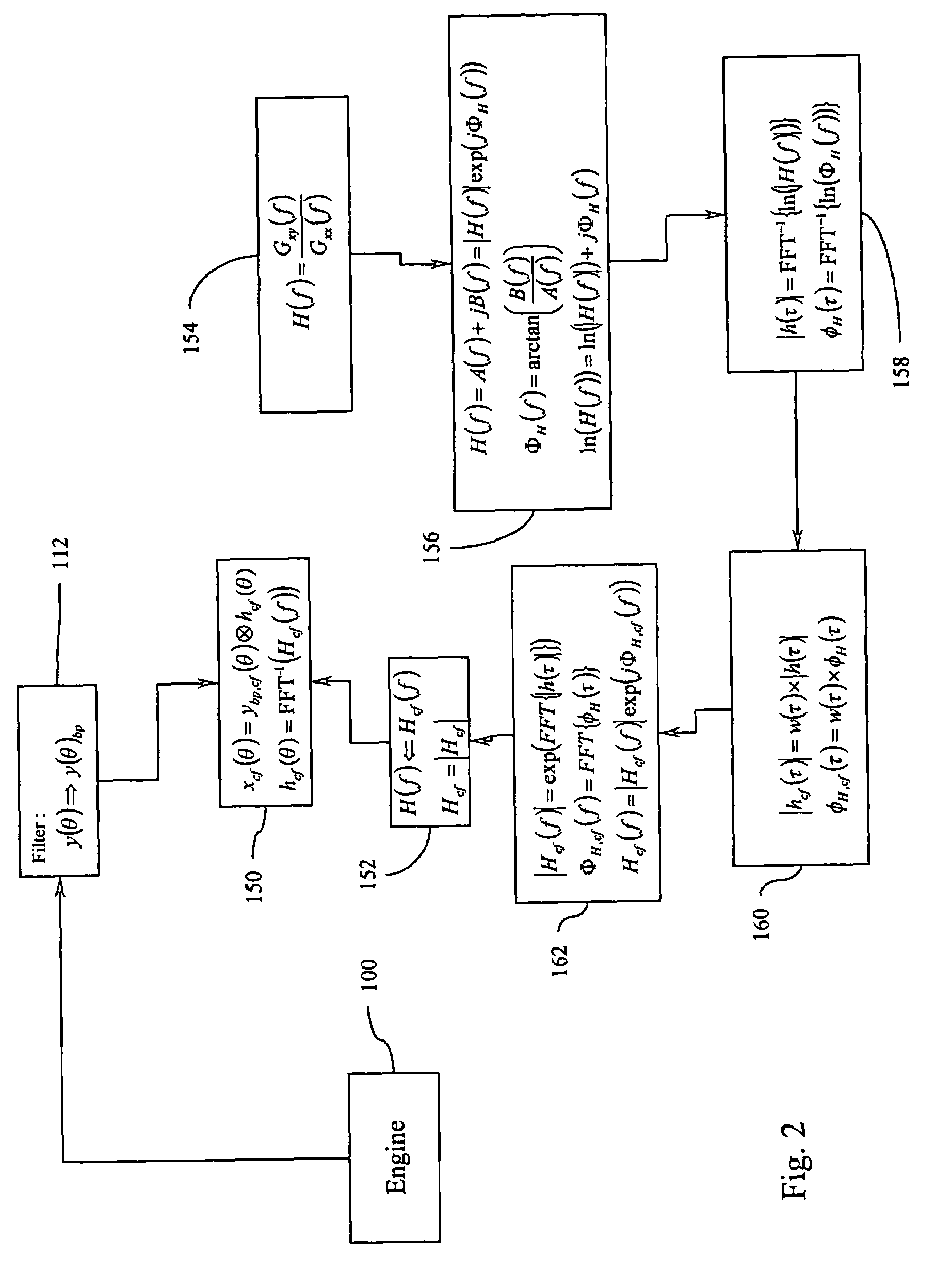

A method for processing an accelerometer data set generated from an operating internal combustion engine is disclosed. The processed accelerometer data is cepstrally filtered and a heat release trace is pulled from the accelerometer data set. That heat release trace is then used to estimate combustion quality and combustion phasing within the engine and control future combustion events using this information. Misfire and knock sensing is also incorporated into the engine controls. The method provides controls for an engine to allow it to adjust combustion from cycle window to cycle window generally without the need for expensive and less durable direct pressure measurement devices as compared to accelerometers. The resulting fuel injection speed results in the fuel passing through shock waves within the combustion chamber, which, in turn, promotes combustion of the fuel by promoting mixing of the fuel and intake charge within the combustion chamber.

Owner:WESTPORT FUEL SYST CANADA INC

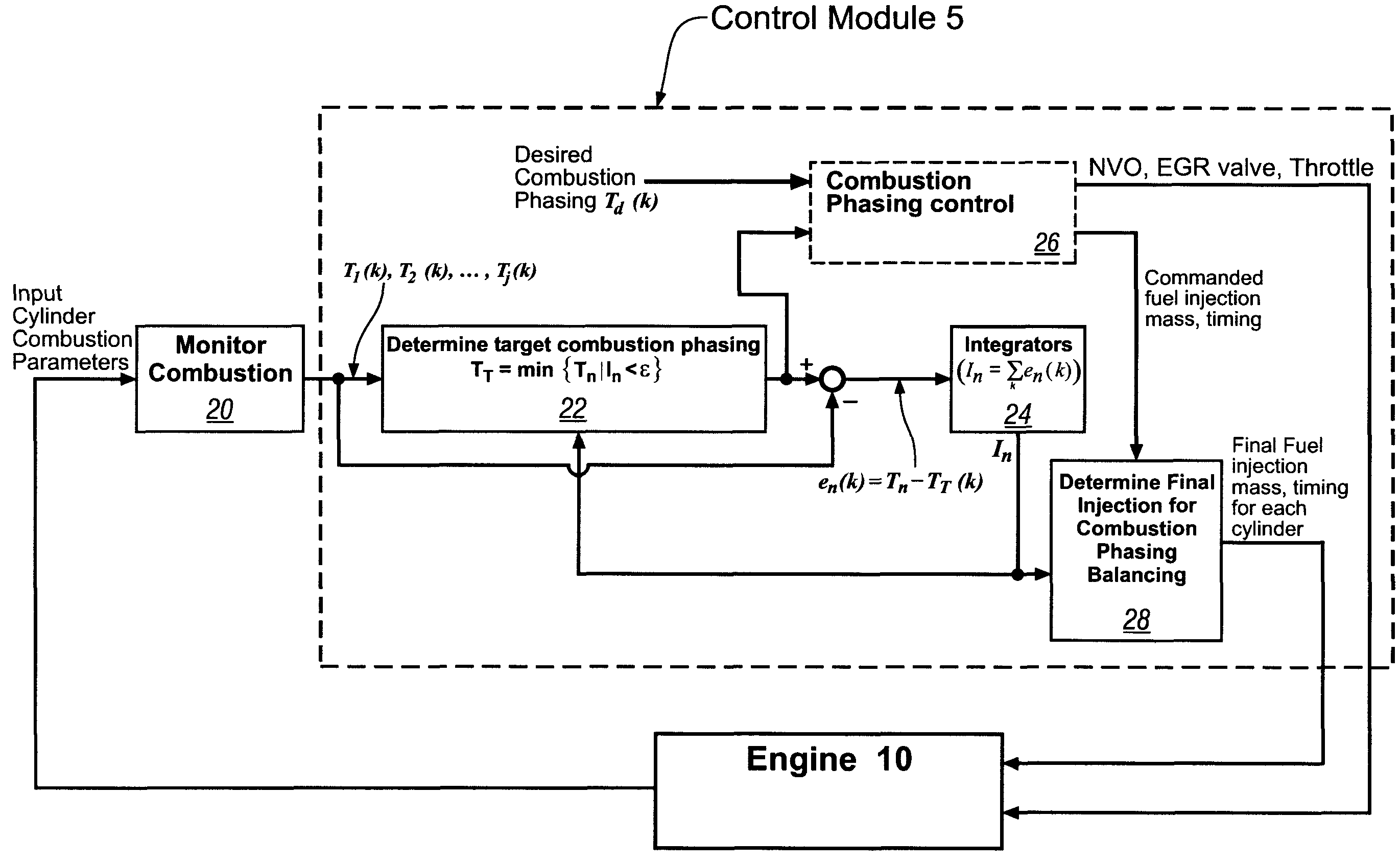

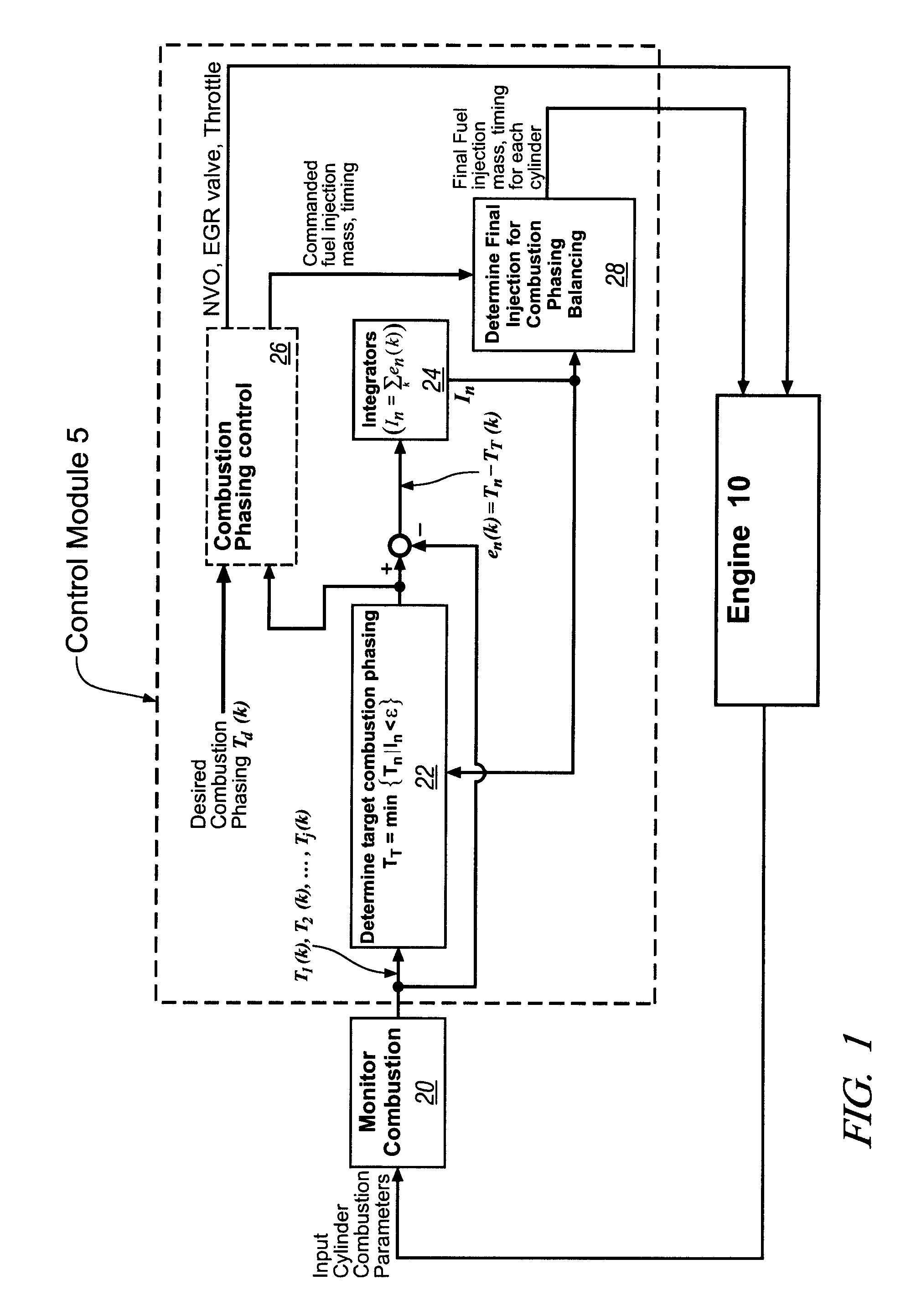

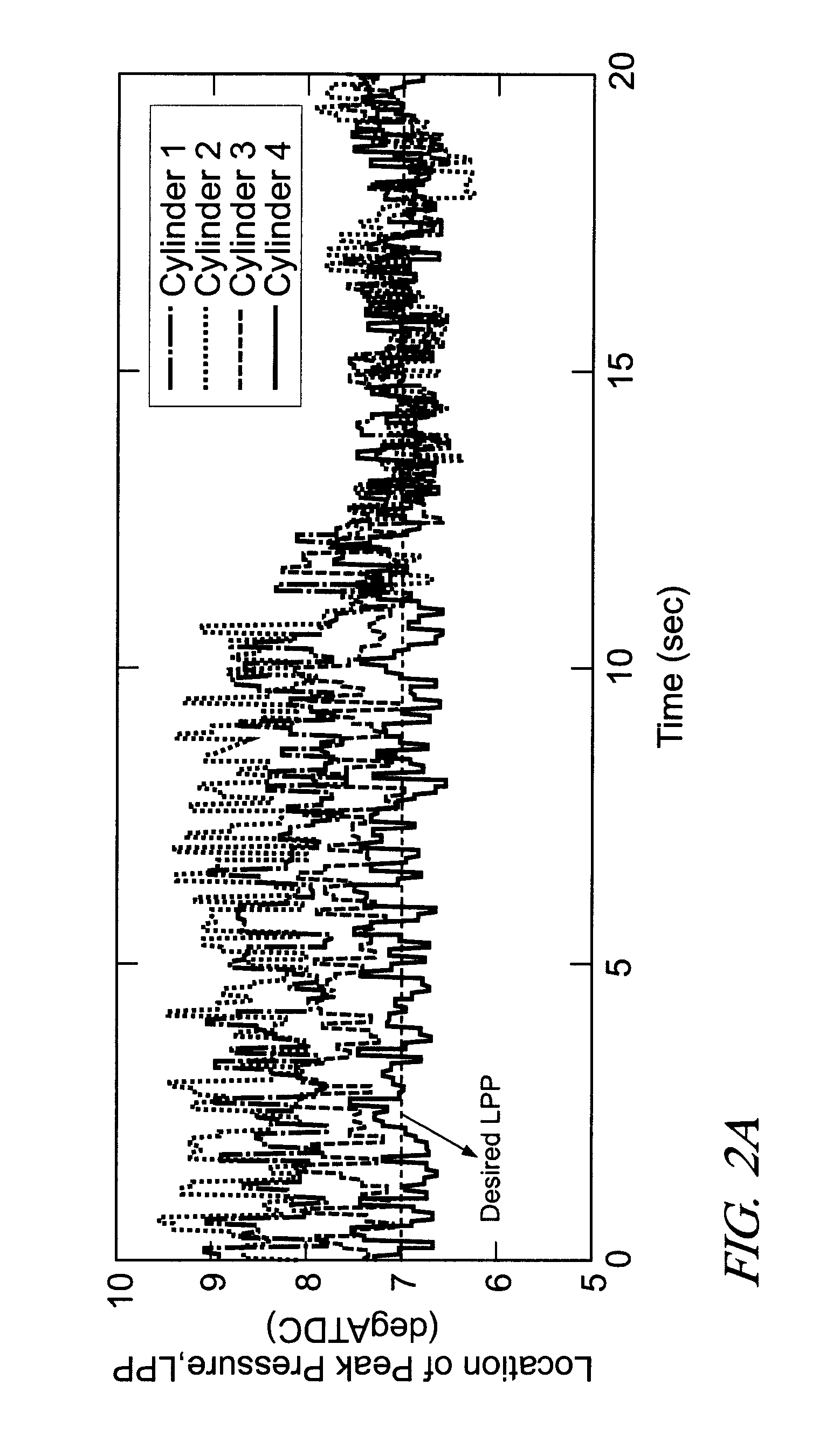

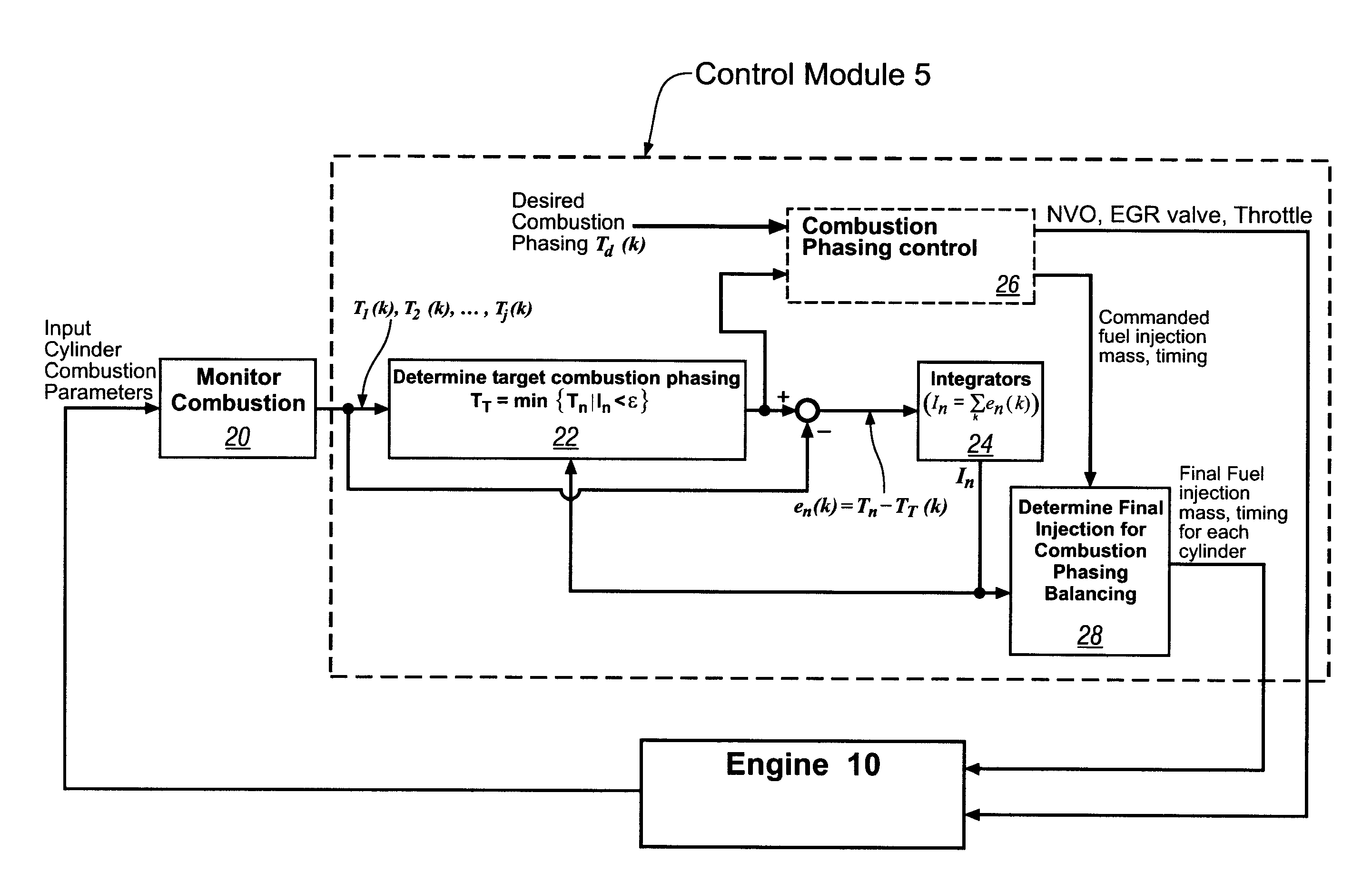

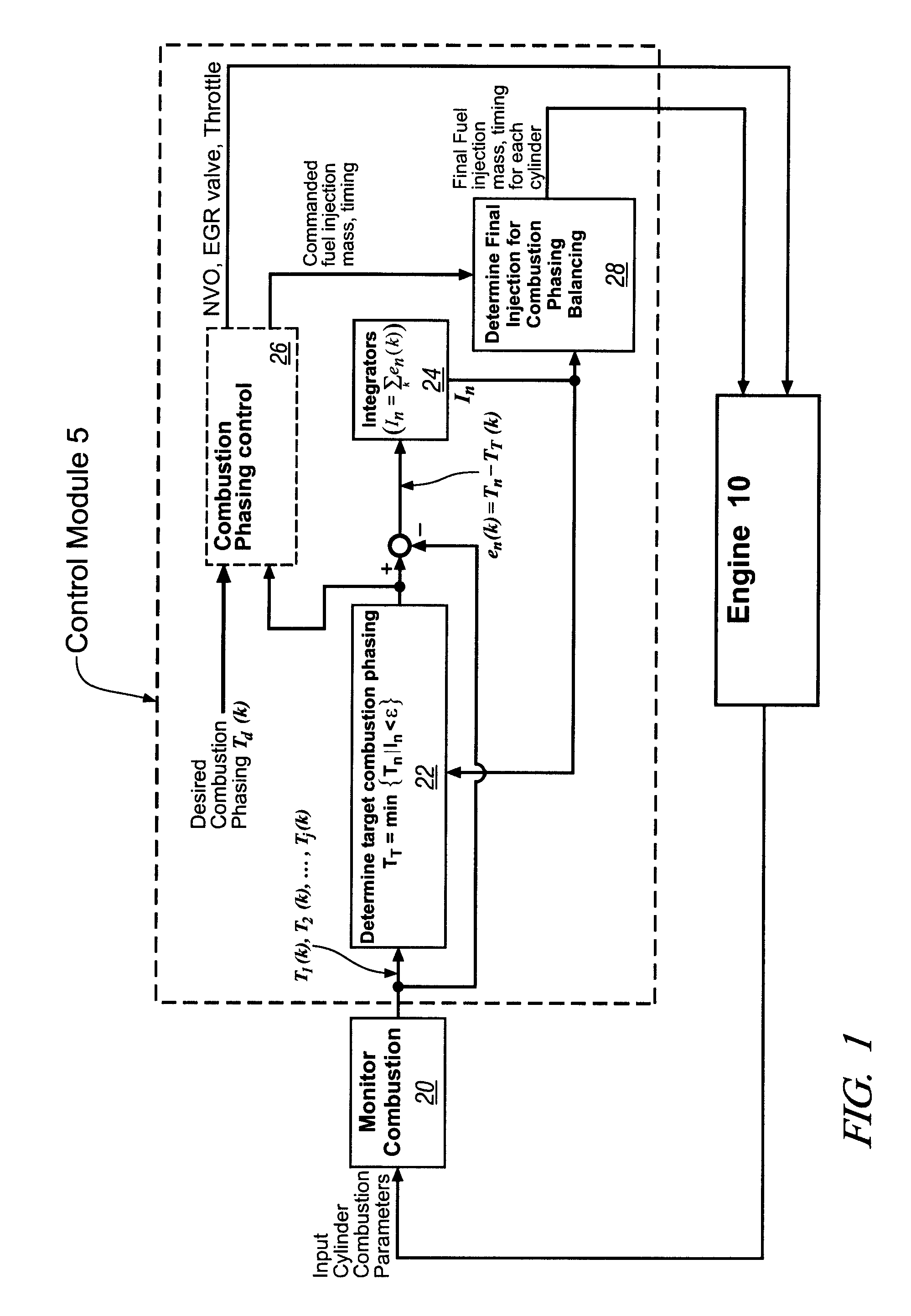

Method and apparatus to control combustion in a multi-cylinder homogeneous charge compression-ignition engine

ActiveUS7739999B2Electrical controlNon-fuel substance addition to fuelEngineeringInternal combustion engine

A method and apparatus are provided to control combustion in a multi-cylinder internal combustion engine operating in a controlled auto-ignition mode with minimum combustion phasing error using a least amount of fuel reforming. This comprises monitoring combustion in each cylinder, and determining a target combustion phasing. Fuel delivery to each cylinder is selectively controlled effective to achieve the target combustion phasing, and, effective to achieve the target combustion phasing further comprises controlling the fuel delivery effective to equilibrate combustion phasing of the cylinders.

Owner:GM GLOBAL TECH OPERATIONS LLC

Fuel adaptation in a homogeneous charge compression ignition engine

InactiveUS7337762B2Improve combustion stabilityImprove operationValve arrangementsElectrical controlEngineeringMechanical engineering

Owner:GM GLOBAL TECH OPERATIONS LLC

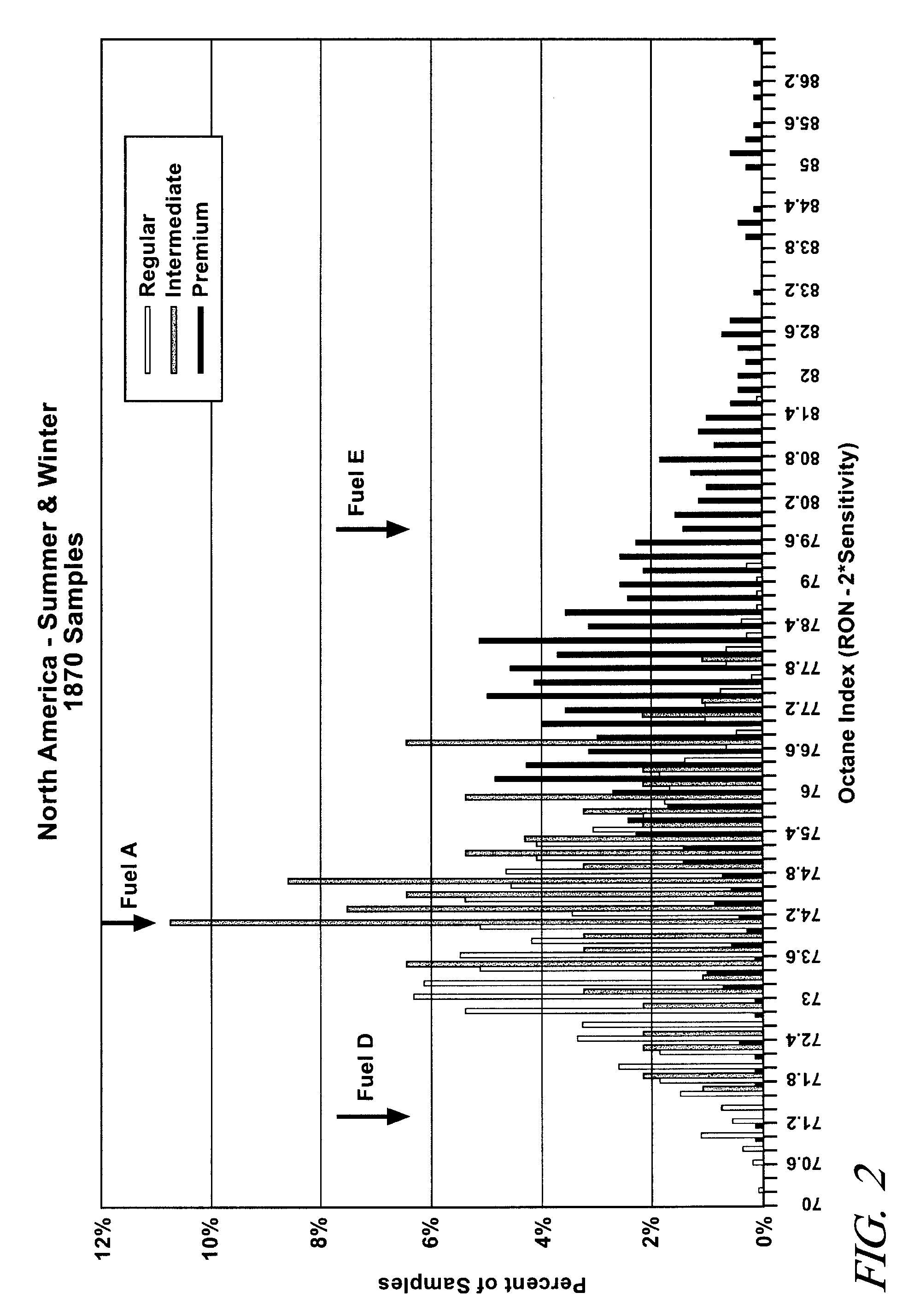

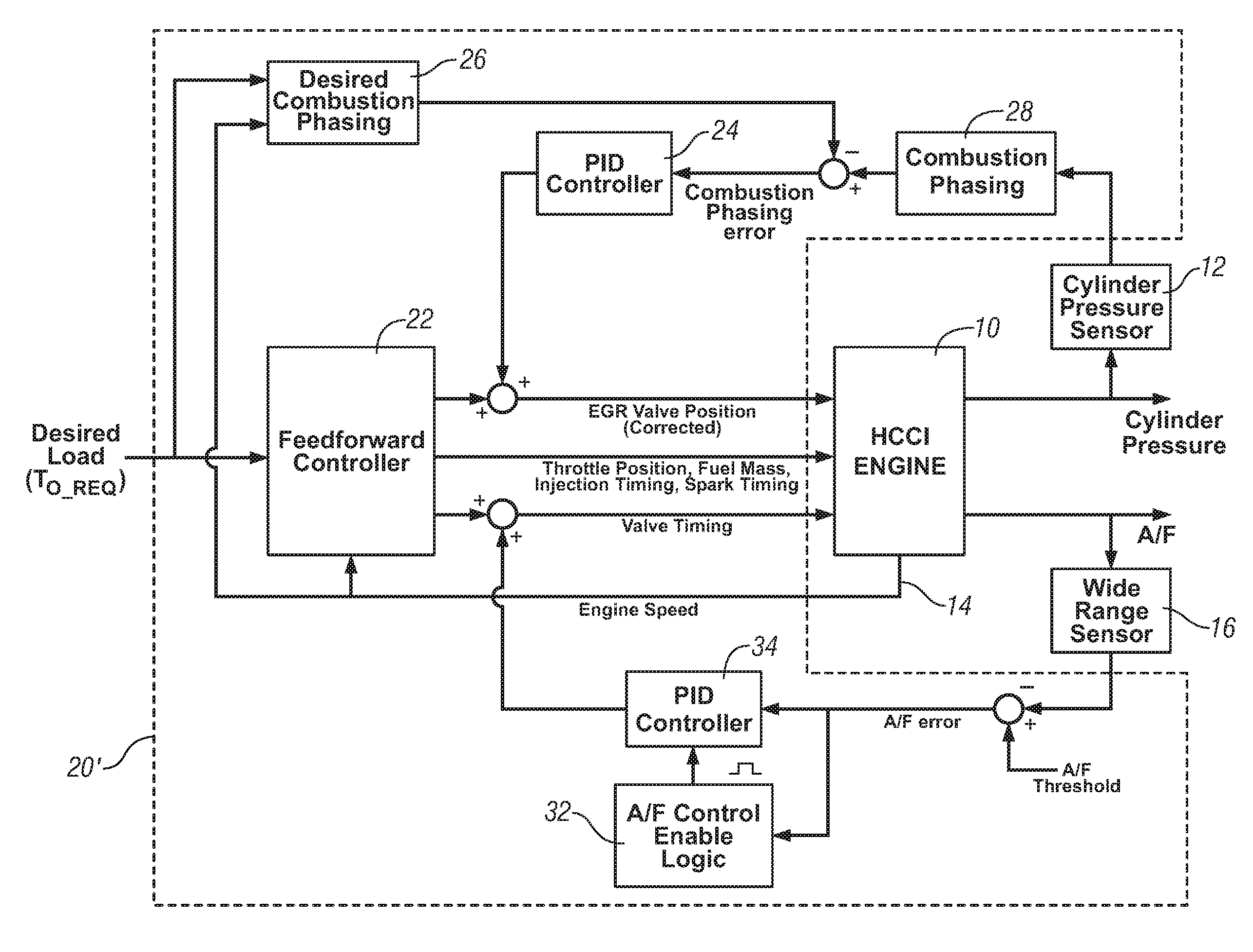

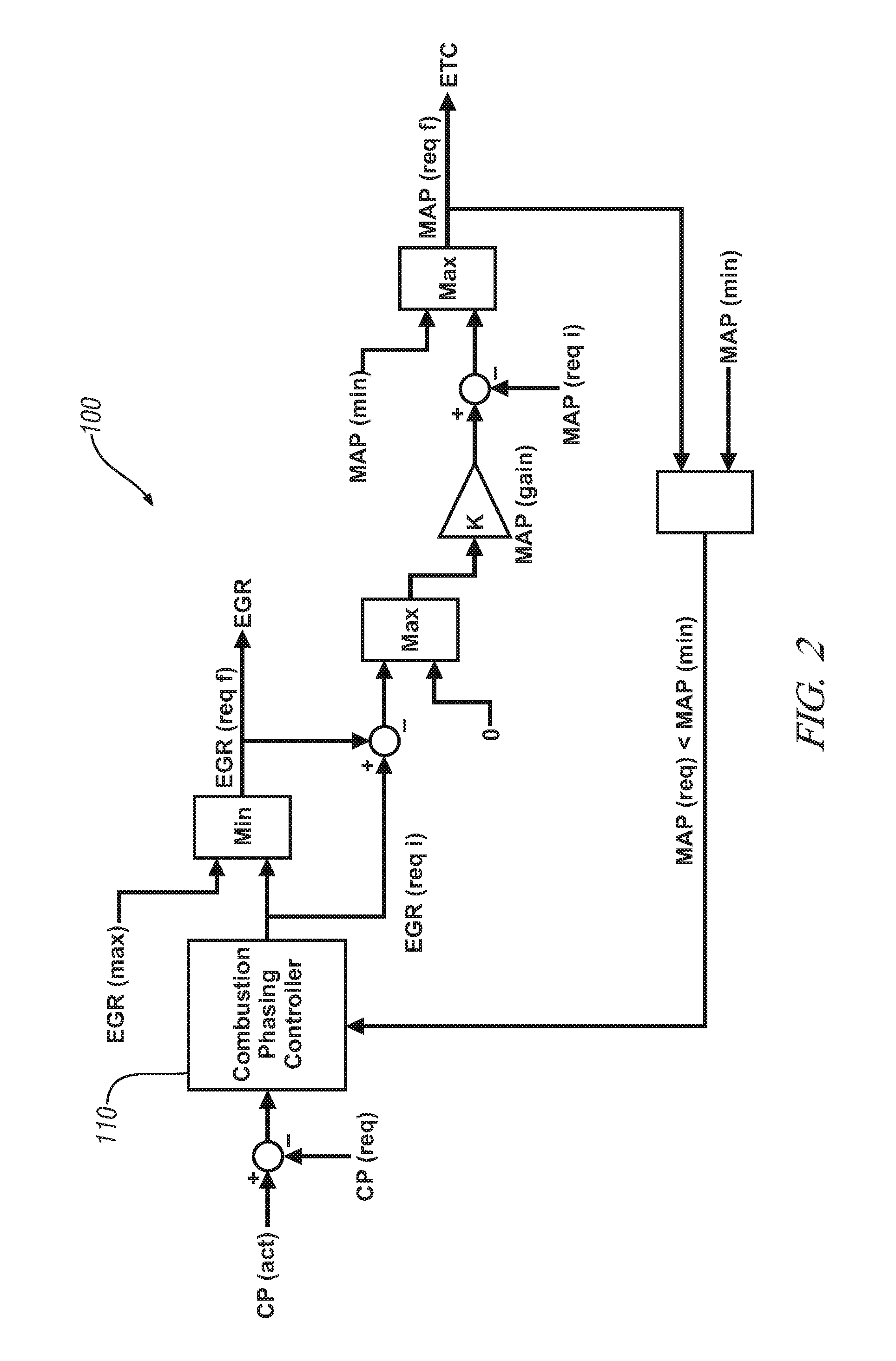

Method and apparatus for controlling a homogeneous charge compression ignition engine

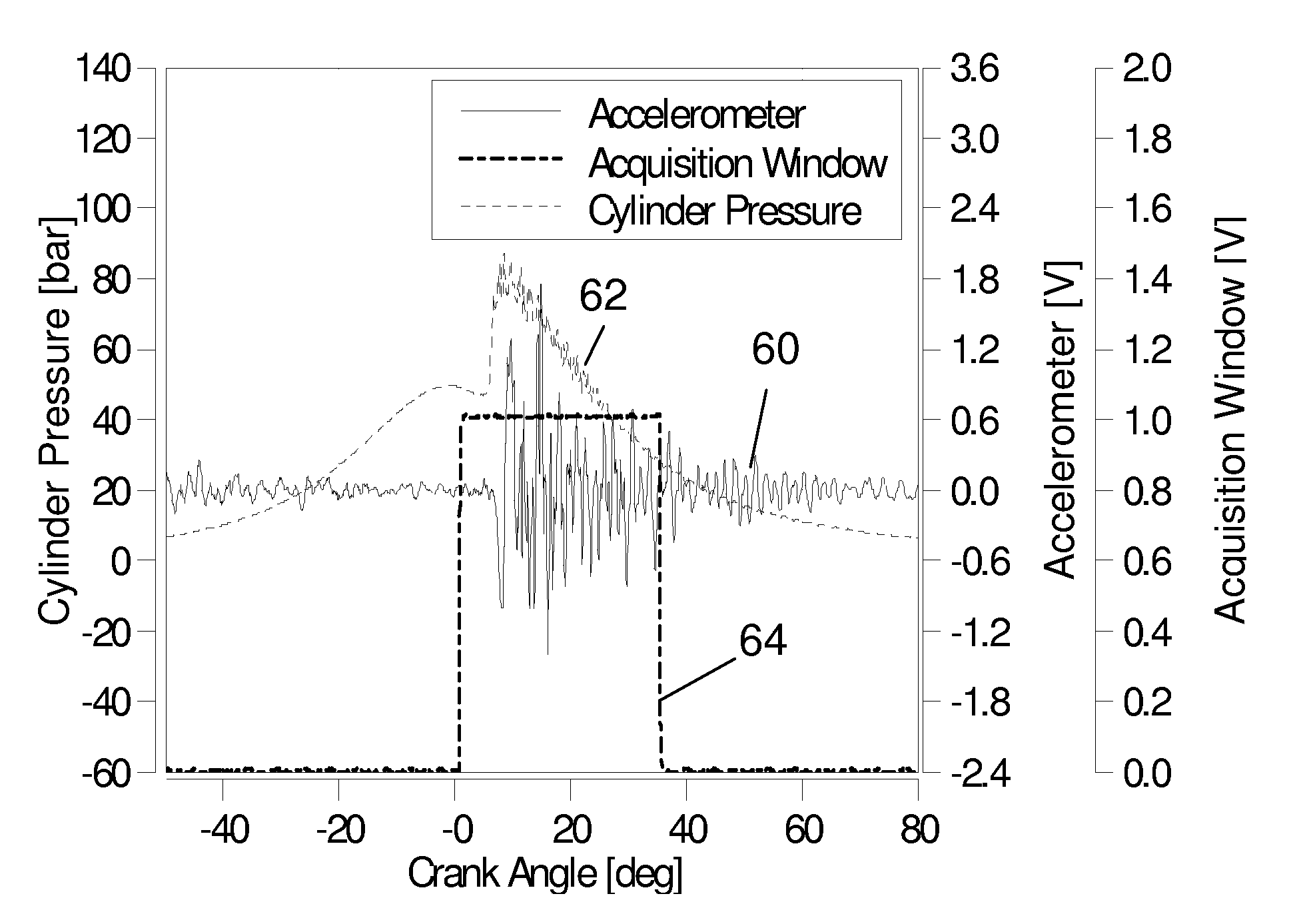

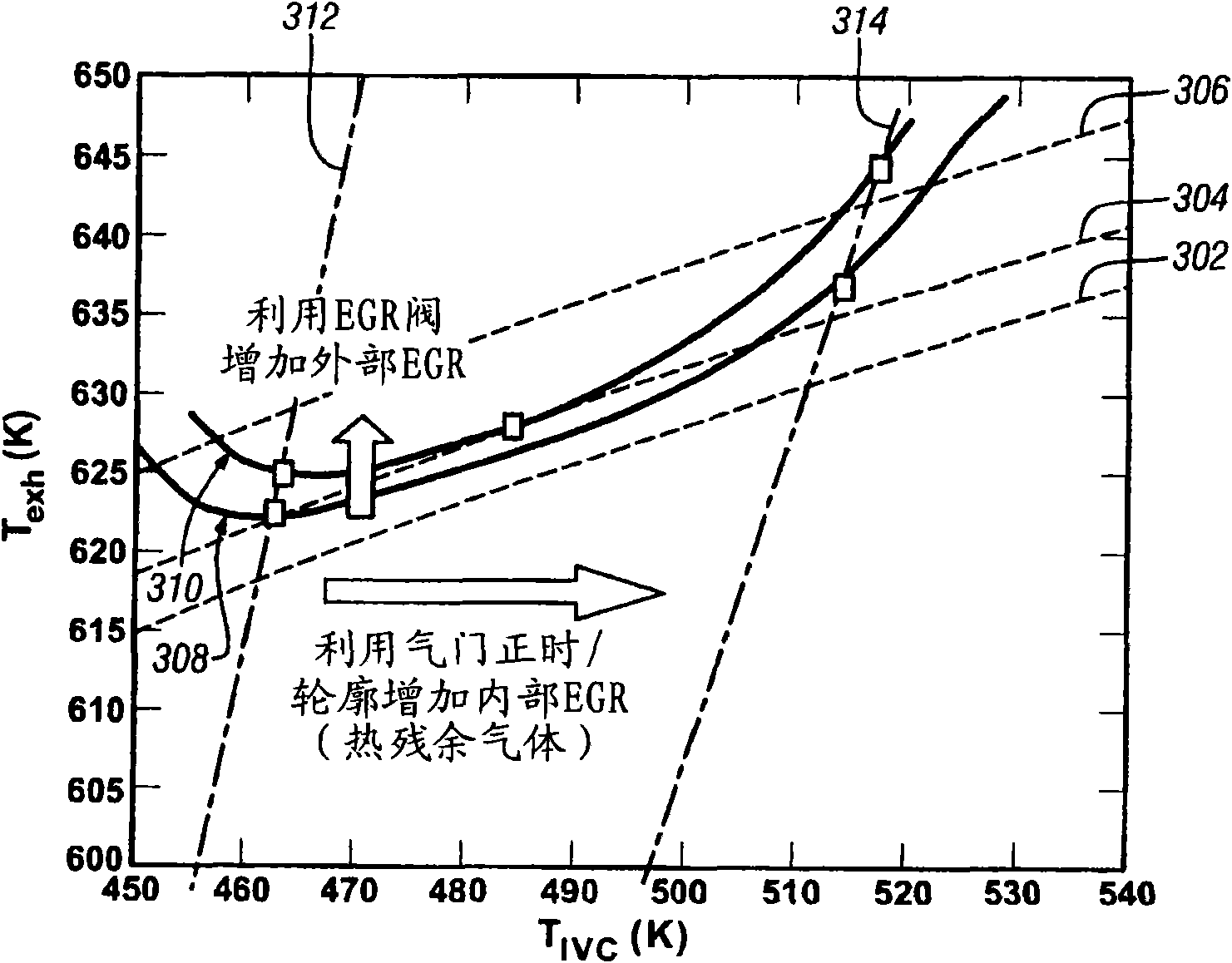

The invention comprises a method for controlling operation of a homogeneous charge combustion ignition engine operating in an auto-ignition mode. The method comprises determining a desired combustion phasing; and, controlling a mass flowrate of externally recirculated exhaust gas based upon an actual combustion phasing. A closed-loop control scheme is executed to control the mass flowrate of externally recirculated exhaust gas based upon a difference between the actual and the desired combustion phasing.

Owner:GM GLOBAL TECH OPERATIONS LLC

Combustion control based on a signal from an engine vibration sensor

InactiveUS7810469B2Robust controlLow costInternal-combustion engine testingElectrical controlCombustionEnergy based

Feedback control of an internal combustion engine is performed based on a signal from a vibration sensor and a crankshaft angle sensor. An energy factor can be computed based on these sensor signals. A vector of energy factor can be computed as a function of crank angle degree over a particular window of engine rotation of interest. Based on the energy factor vector, combustion phasing can be estimated.

Owner:FORD GLOBAL TECH LLC

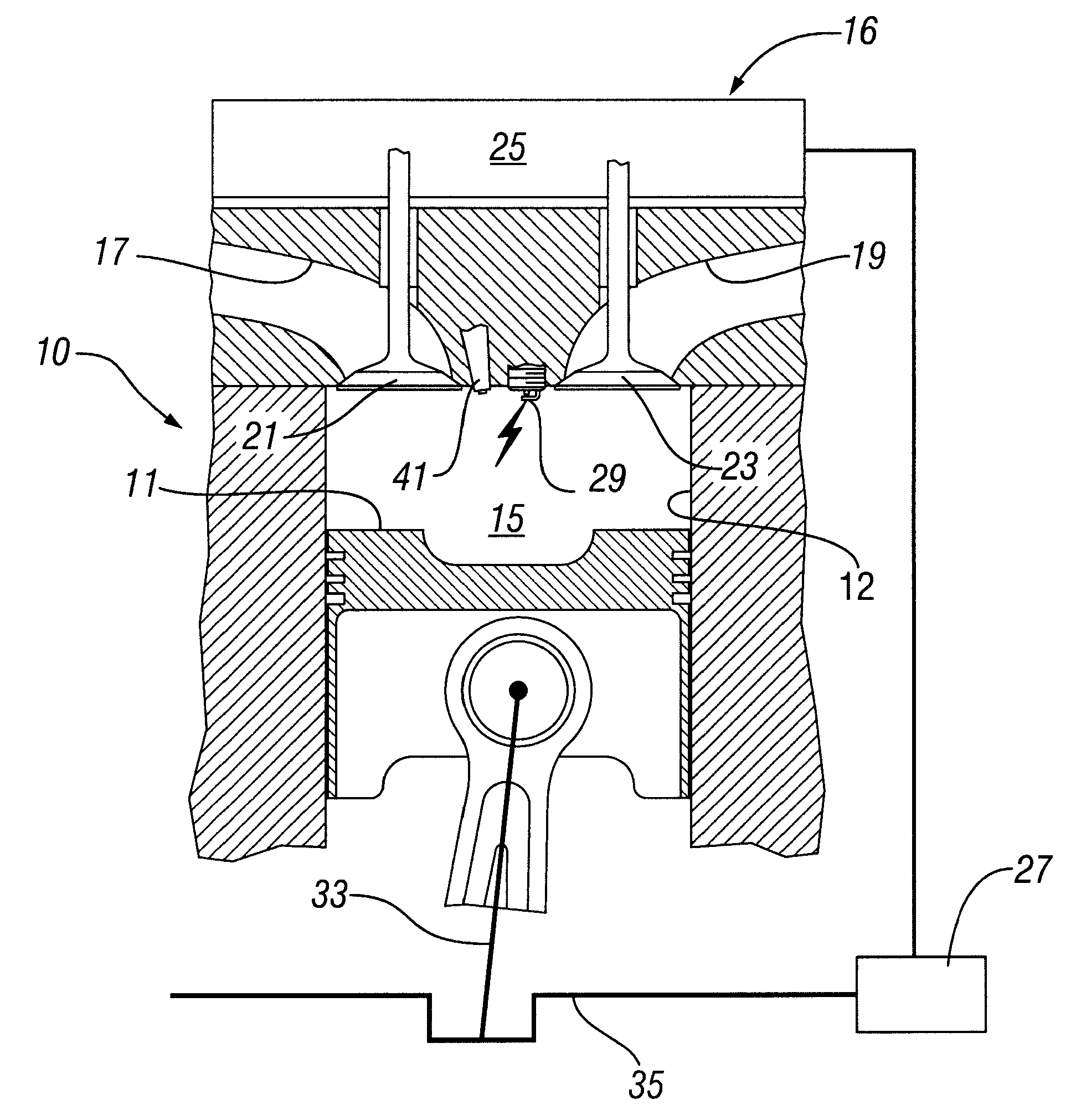

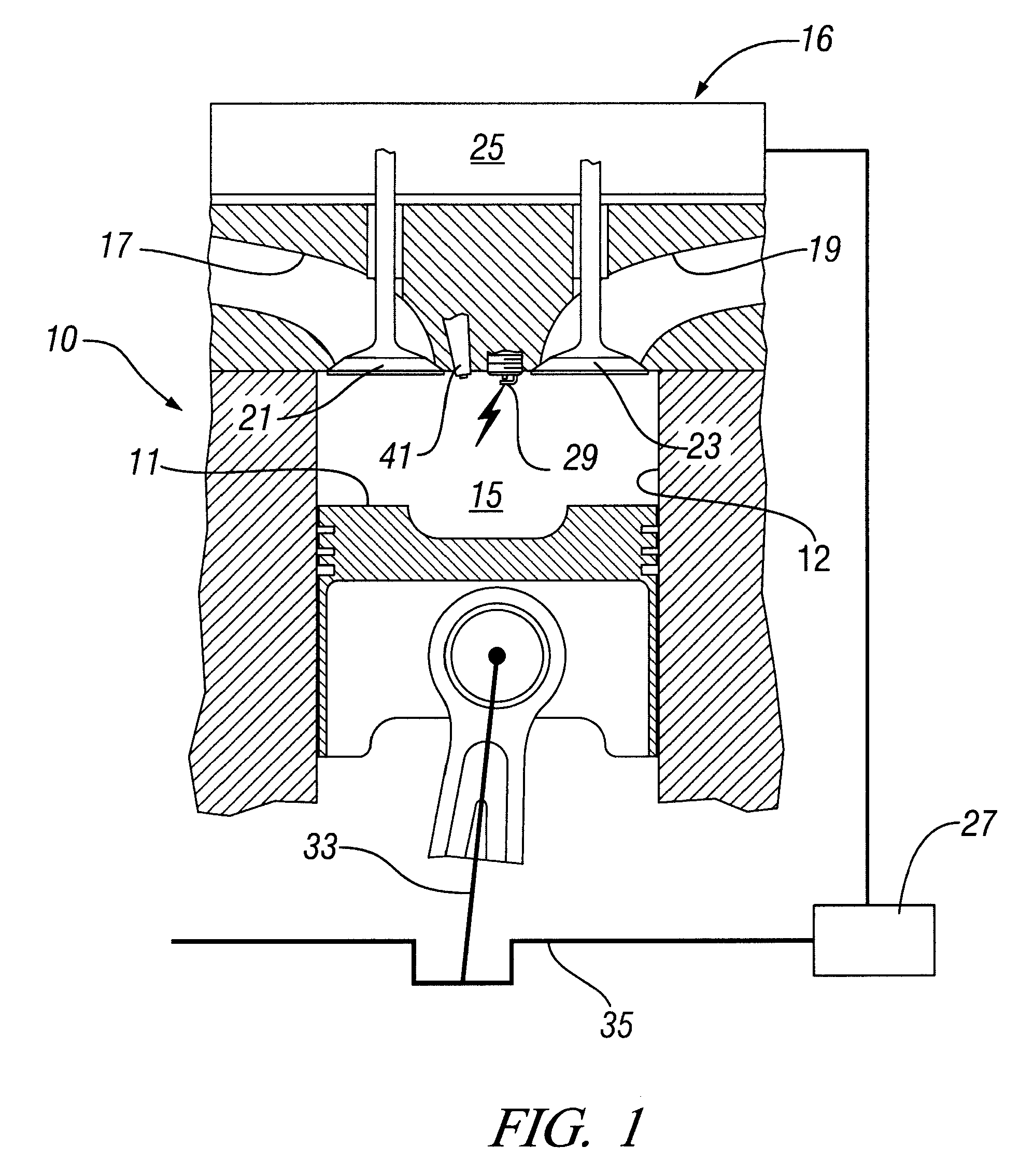

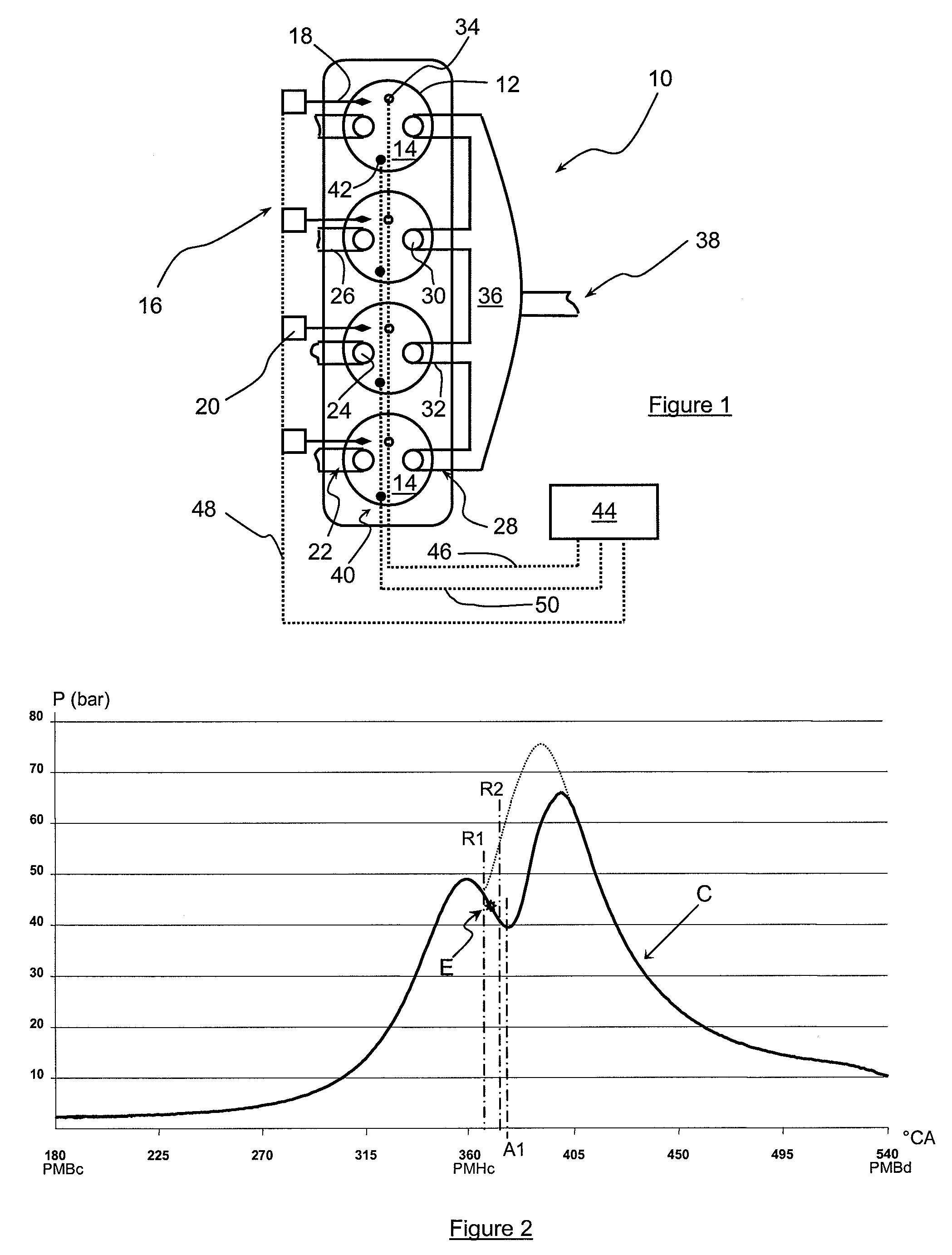

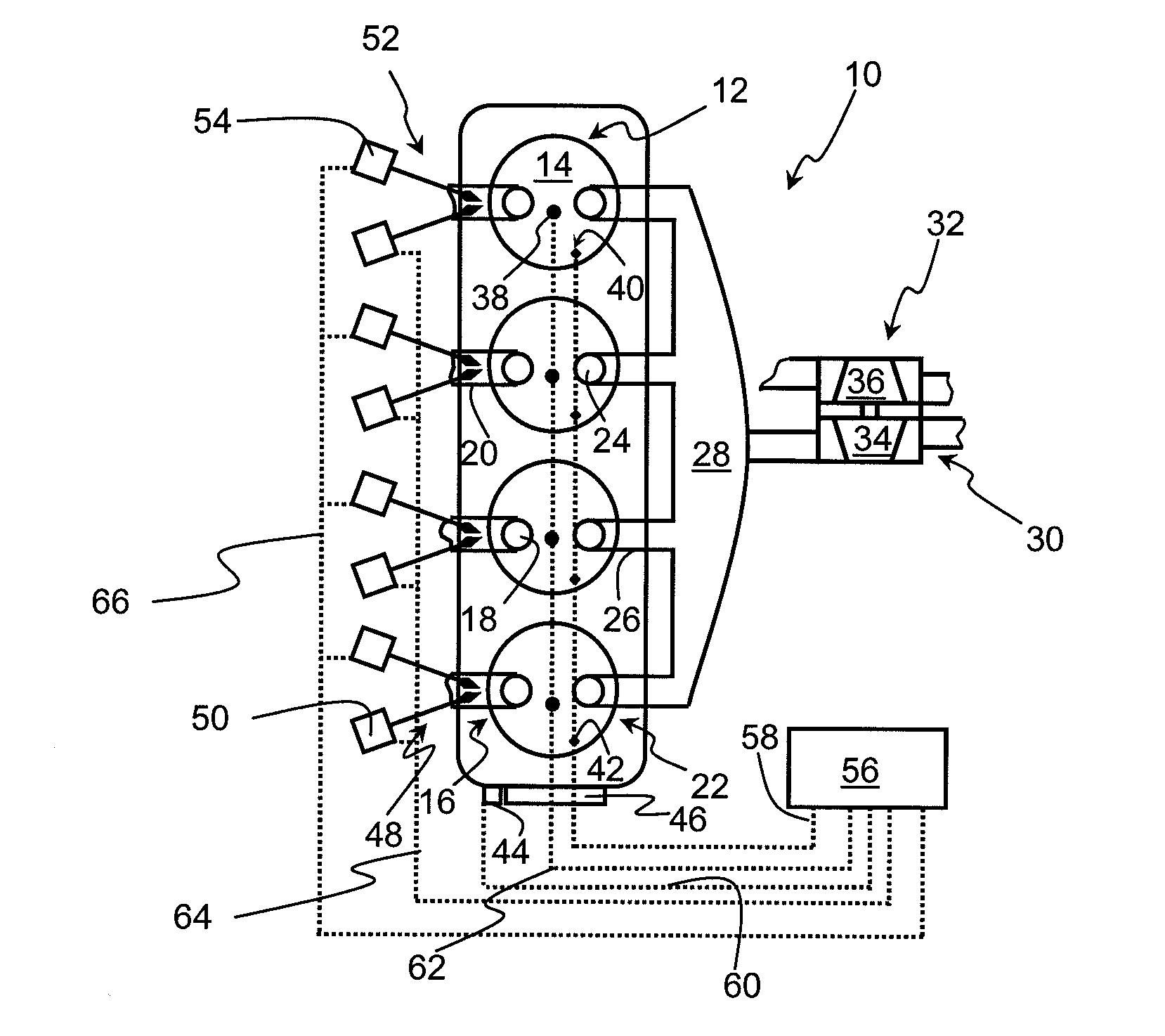

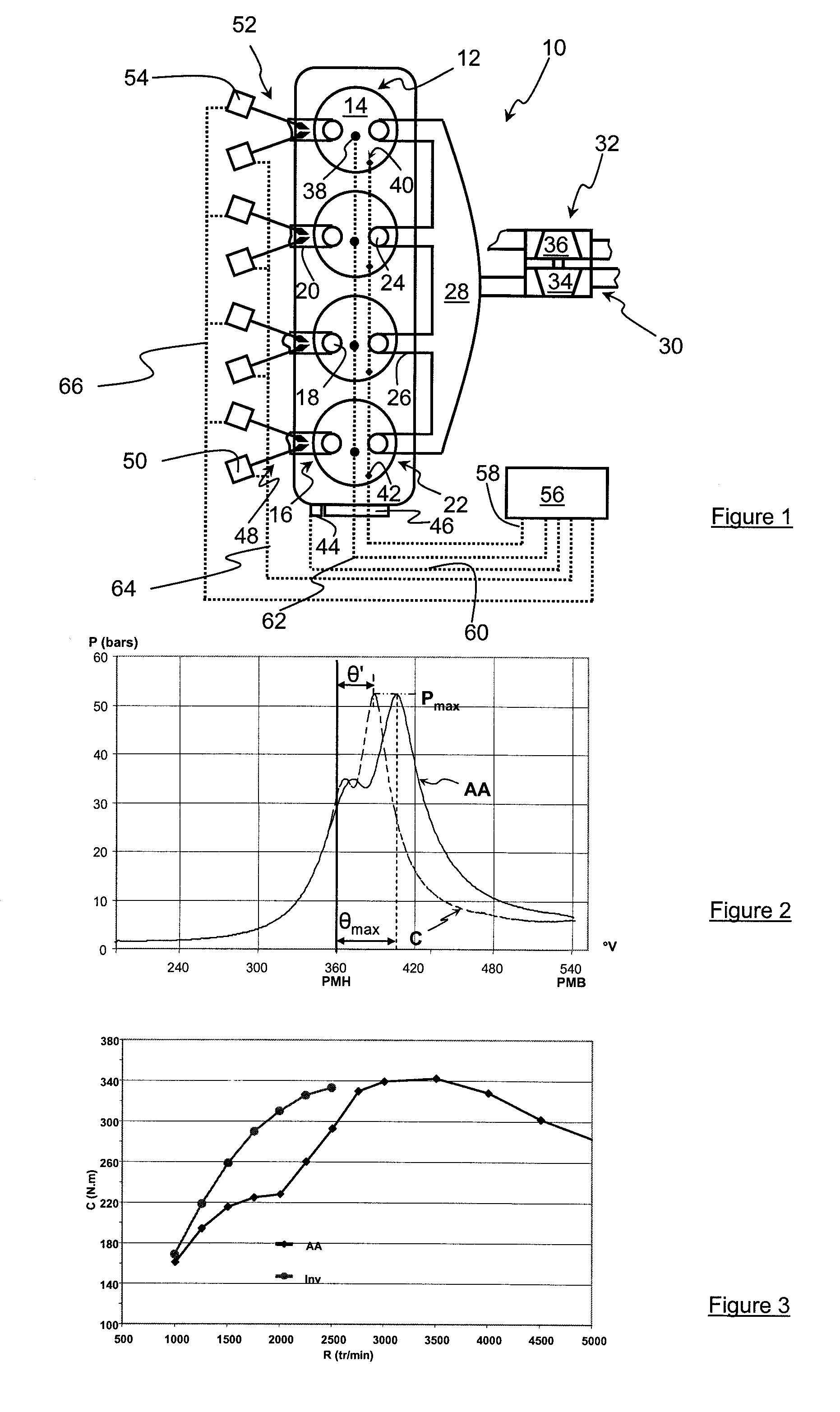

Method of controlling the combustion phase of an internal-combustion engine, notably a gasoline type direct-injection supercharged engine

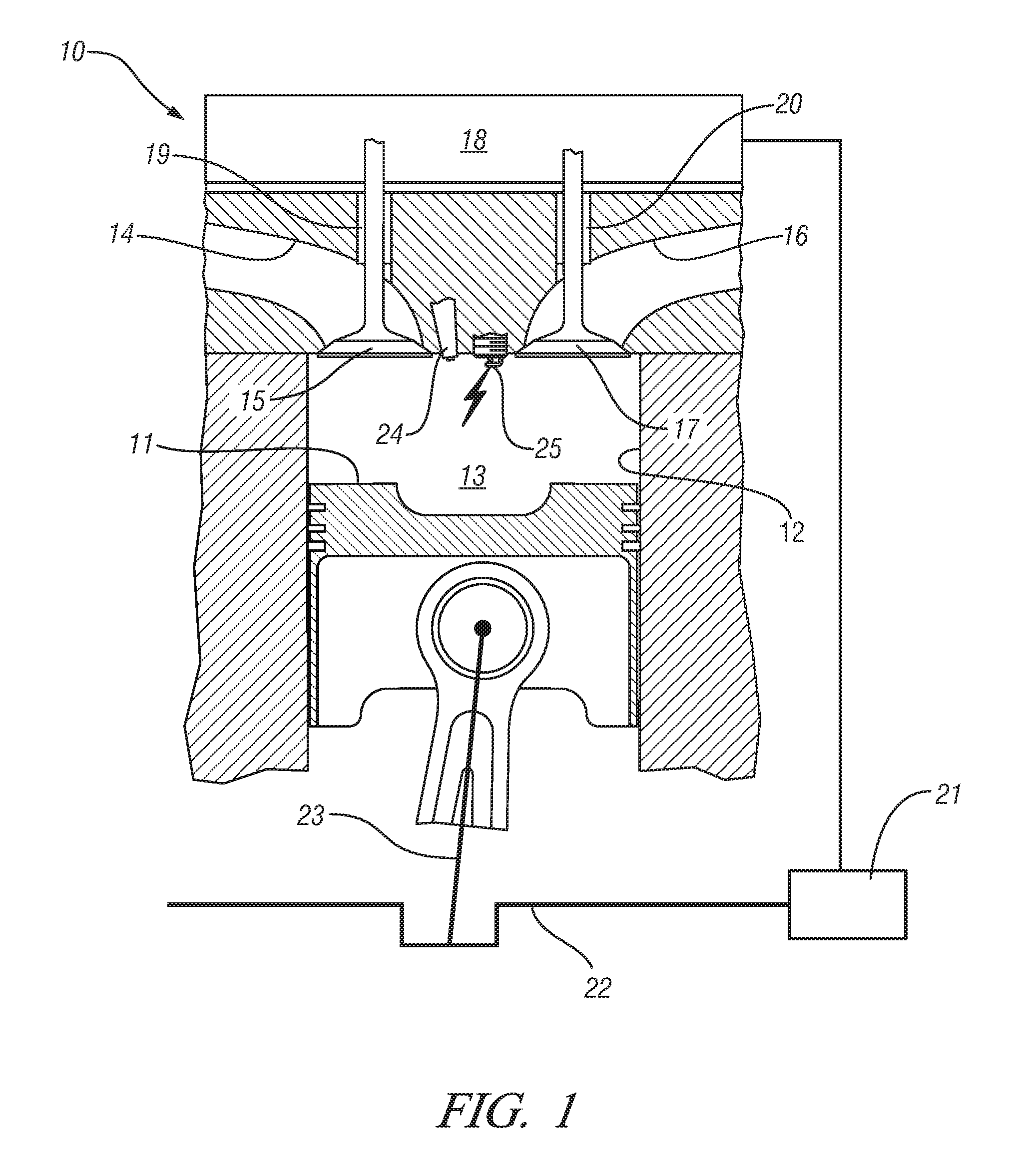

InactiveUS7461633B2Reduce pressureElectrical controlInternal combustion piston enginesCombustion chamberGasoline

Method of controlling the combustion of an internal-combustion engine, in particular a direct-injection supercharged engine, notably of gasoline type, wherein the engine comprises at least one cylinder (12) with a combustion chamber (14) within which a compression stage takes place, followed by a stage of combustion of a fuel mixture by a spark-ignition means (34), characterized in that it consists in measuring a quantity related to at least one parameter representative of the state of the fuel mixture during said stages; in determining a value that depends on the amplitude of the measured quantity; in comparing the determined value with at least one threshold value representative of the quantity related to said parameter representative of the conventional state of the fuel mixture during said stages; in detecting the start of an abnormal combustion when the determined value exceeds said threshold value and when the ignition means is not actuated; in controlling the course of the abnormal combustion detected in the combustion chamber.

Owner:INST FR DU PETROLE

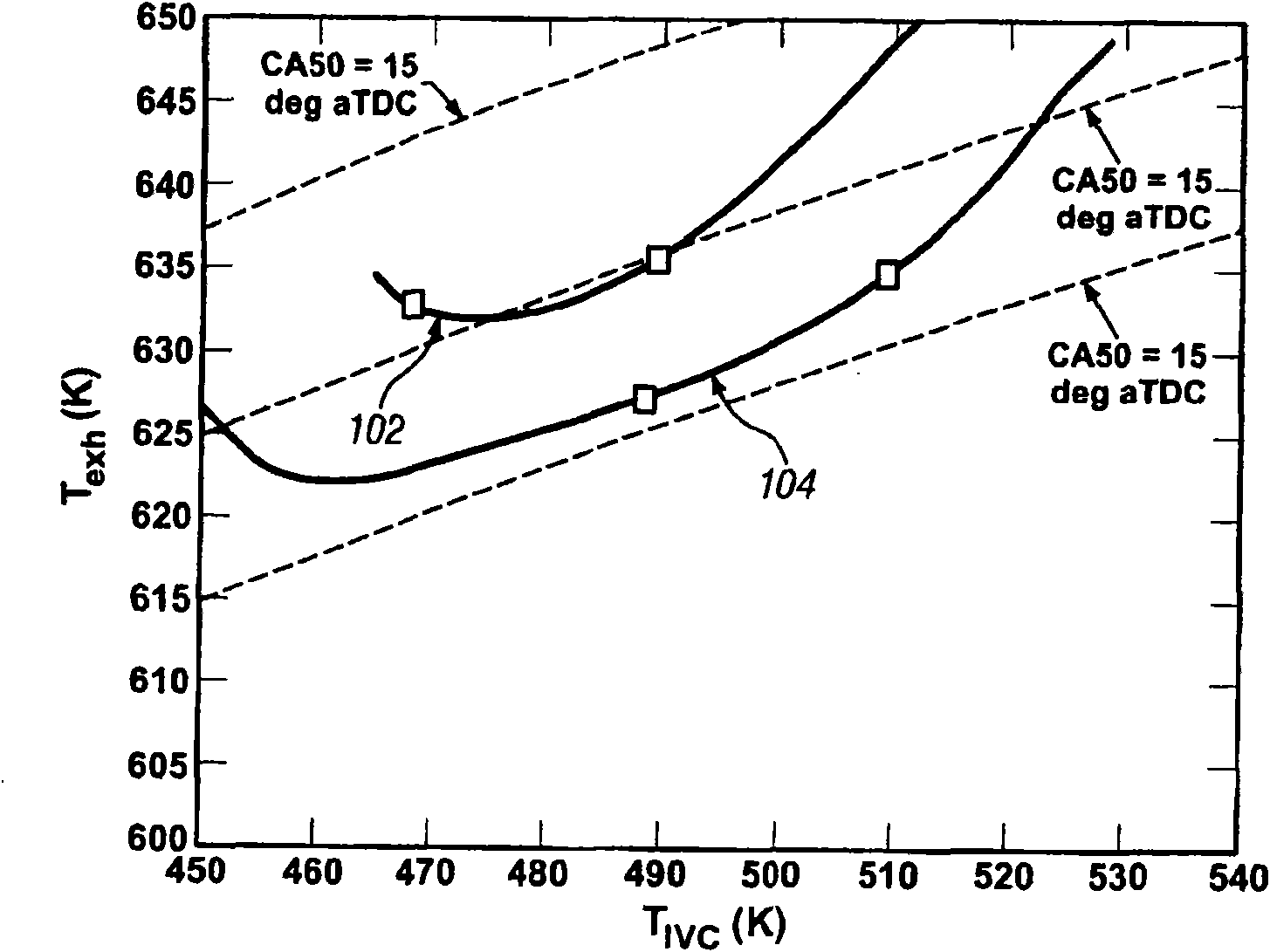

Homogeneous charge compression ignition engine operation

InactiveUS20070250256A1Robust operating set-pointsGuaranteed uptimeAnalogue computers for vehiclesElectrical controlData setEquilibrium constant

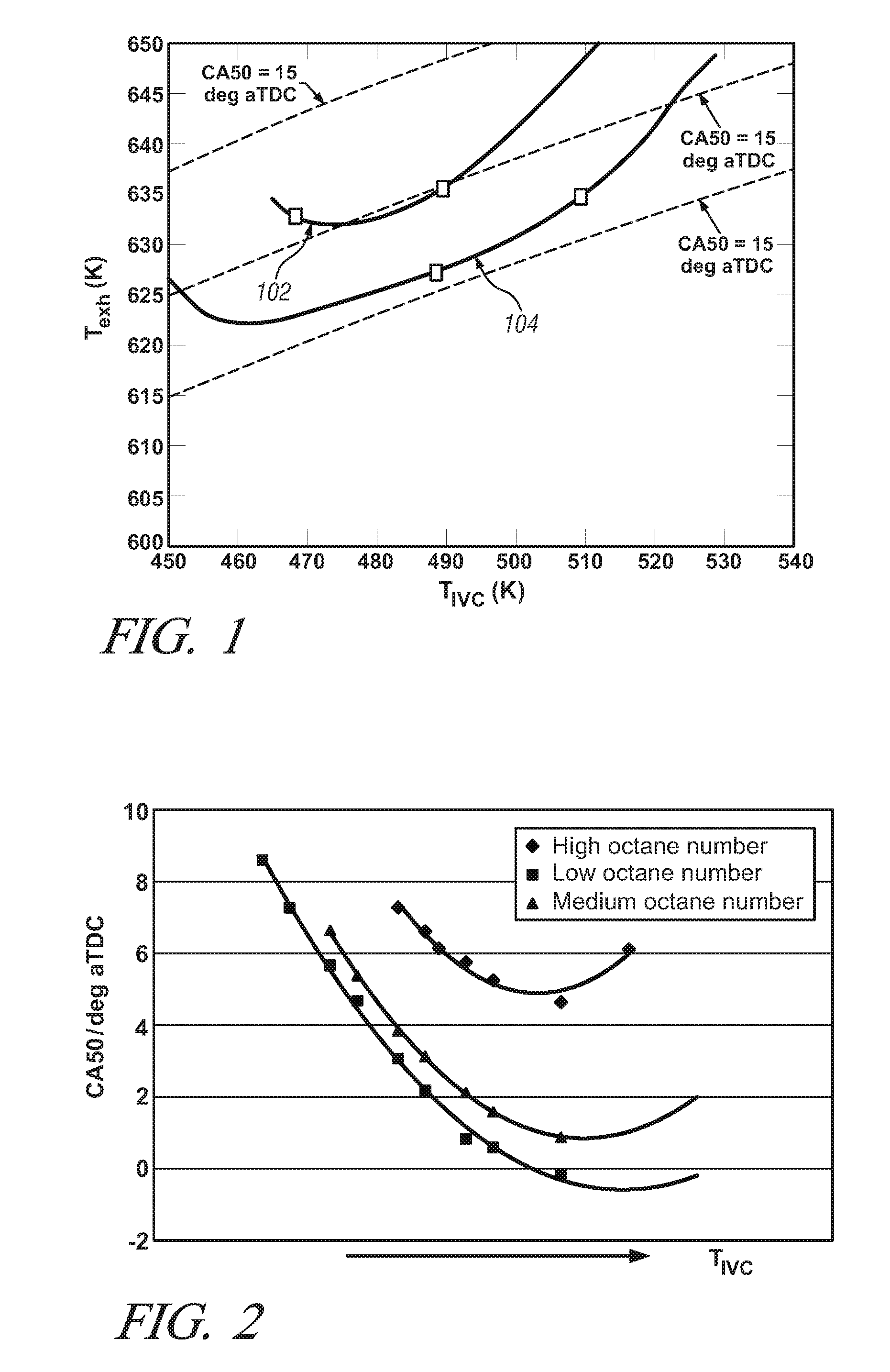

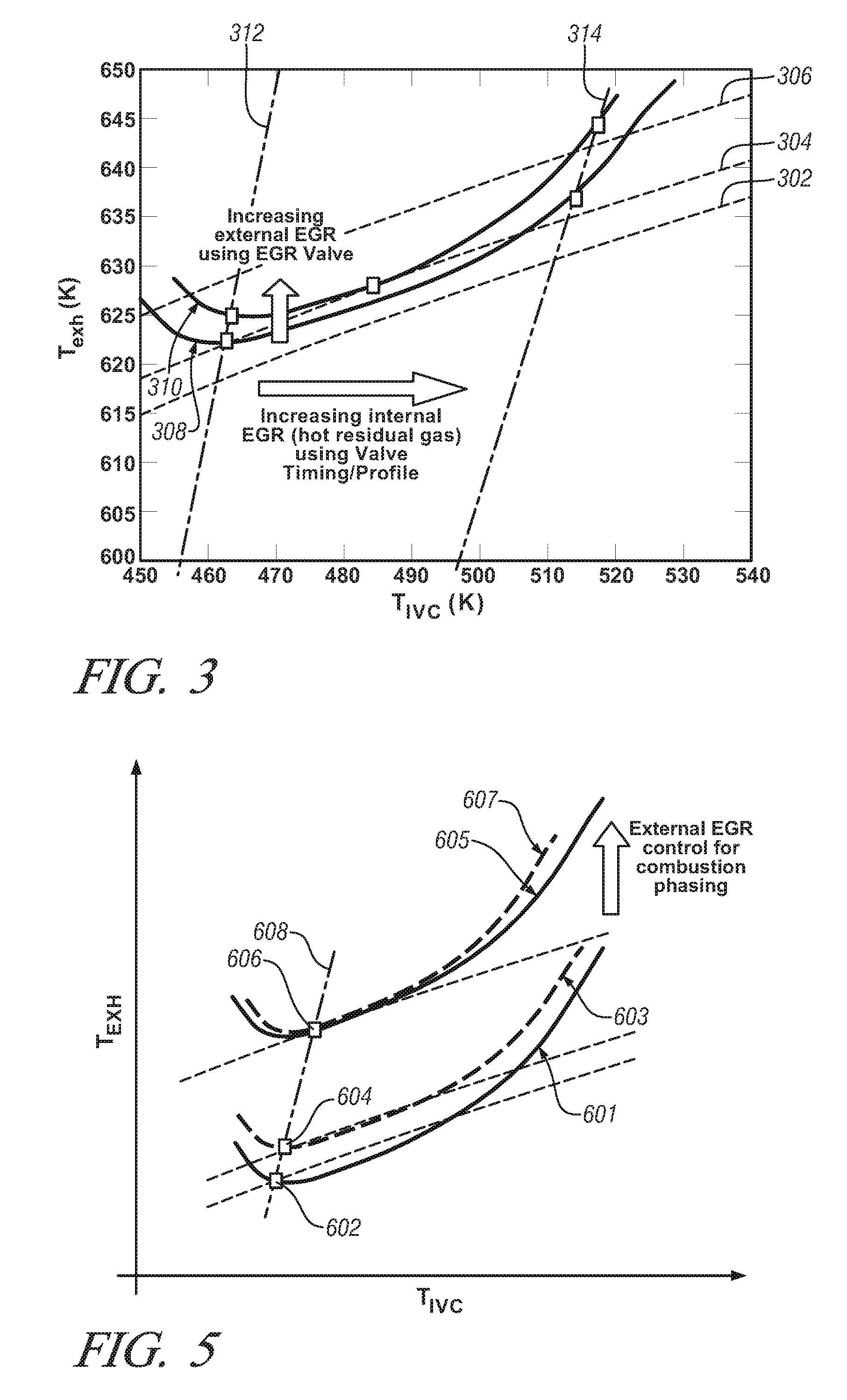

An HCCI engine is operated by controlling a plurality of engine operating parameters in accordance with a calibration data set representing equilibrium set-points of engine operation characterized by combustion phasing that is relatively least sensitive to cylinder charge temperature deviations.

Owner:GM GLOBAL TECH OPERATIONS LLC

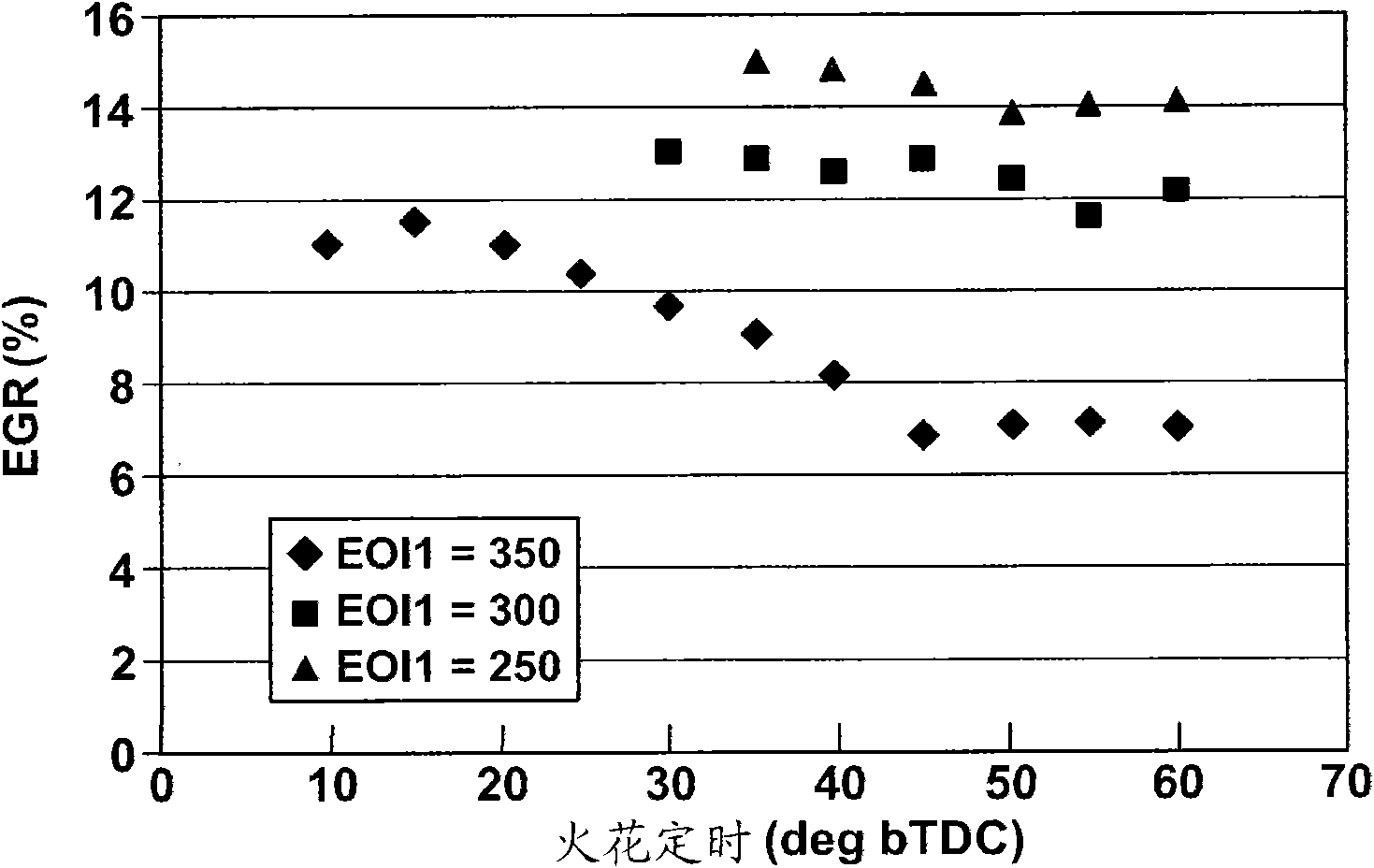

Egr control in hcci engines

InactiveUS20110146637A1Electrical controlNon-fuel substance addition to fuelExternal combustion engineEngineering

An internal combustion engine operates in an unthrottled condition during HCCI operation while preferred combustion phasing is determined. An EGR mass flow rate is commanded to correspond with the preferred combustion phasing. The EGR valve is controlled to achieve commanded EGR mass flow rate. Position of the throttle valve is controlled to achieve commanded EGR mass flow rate when the commanded EGR mass flow rate exceeds control authority of the EGR valve.

Owner:GM GLOBAL TECH OPERATIONS LLC

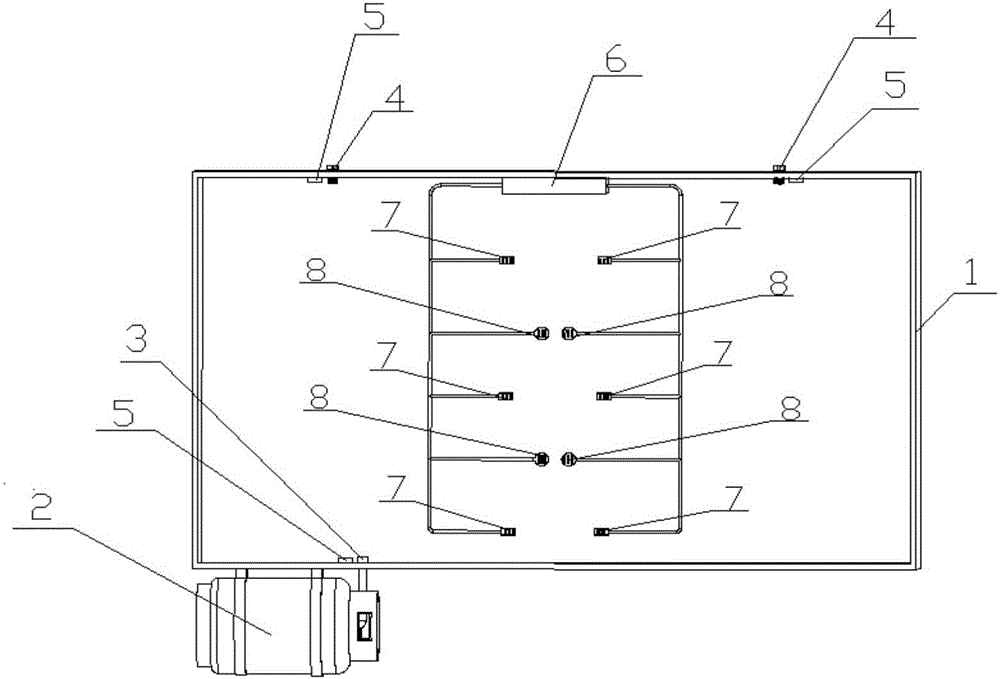

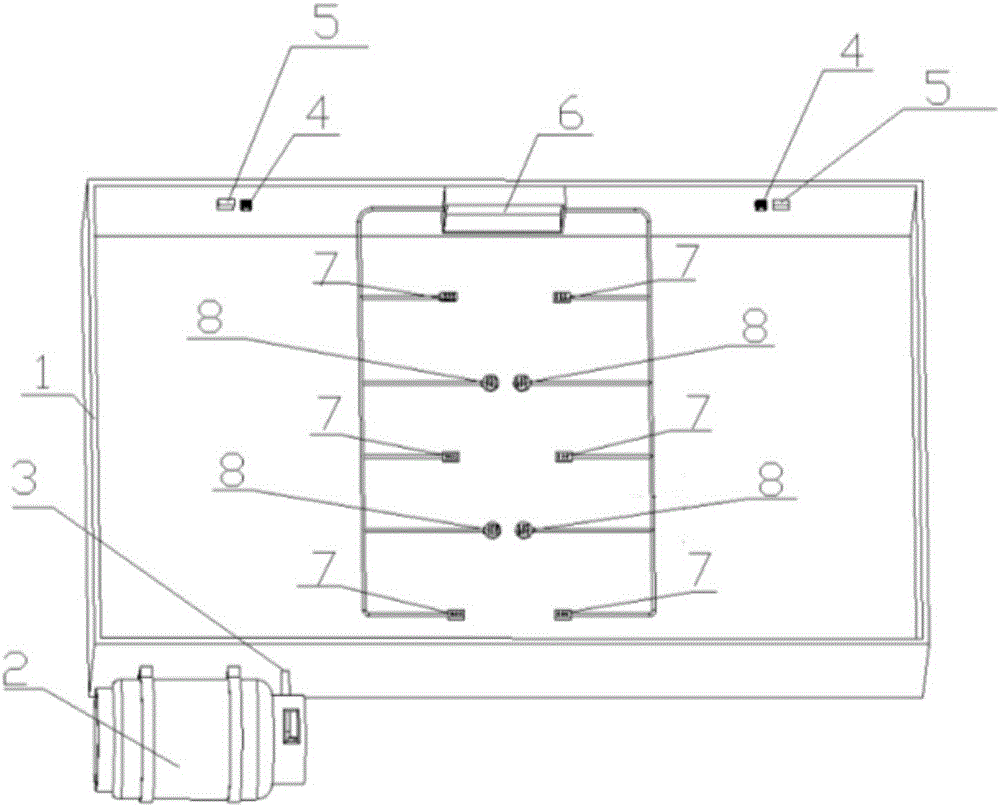

Initiative flame retarding device of battery pack of battery electric vehicle

InactiveCN106098989AAvoid burnsProtection securityFire rescueCell component detailsExhaust valveAutomotive battery

The invention discloses an initiative flame retarding device of a battery pack of a battery electric vehicle and belongs to the field of parts of electric vehicles. A flame retarding gas bottle is mounted in front of a battery pack shell body; the flame retarding gas bottle is connected with a gas inlet valve through a gas guide pipe; the gas inlet valve is communicated with the inner part of the battery pack shell body; an exhausting valve is located at the position, close to the top end, on the back surface of the battery pack shell body and is directly communicated with the inner part of the battery pack shell body; a temperature sensor and a smoke sensor, which are connected with a battery management system (BMS), can monitor whether the temperature of a battery in the battery pack is changed or not and whether smoke is generated or not in real time; the BMS can rapidly respond once if an abnormal signal is monitored; when the gas inlet valve and the exhausting valve are opened at the same time, carbon dioxide gas enters the battery pack; and meanwhile, combustion-supporting gas in the battery pack shell body is exhausted out of the pack in time so that the flame retarding aim is realized. The initiative flame retarding device has a very good flame retarding effect on the electric vehicle which is about to have thermal runaway or an initial combustion phase, and thus the safety of the battery pack and the whole vehicle is protected.

Owner:JIANGSU UNIV

Method, an arrangement, and a computer readable storage device for controlling homogeneous charge compression ignition combustion

ActiveUS7089912B2Increasing negative valve overlapNegative valve overlap is increasedValve arrangementsElectrical controlExhaust valveInlet valve

The invention relates to a method for operating an internal combustion engine operable in compression ignition mode, said engine comprising a fuel supply means, a piston in each cylinder causing ignition during compression ignition mode, at least one inlet and one exhaust valve, a control unit that controls the valve timing and fuel quantity, and at least one sensor for measuring an engine operation parameter. The following steps are performed when switching from spark ignition to compression ignition mode: controlling the exhaust and intake valves to perform a negative valve overlap to retain exhaust residual gas, determining a current combustion phasing timing, and correcting the combustion phasing by increasing the retained exhaust residual gas fraction by stepwise control of a combustion related parameter. The invention further relates to an arrangement and a computer readable device for controlling the combustion process.

Owner:FORD GLOBAL TECH LLC

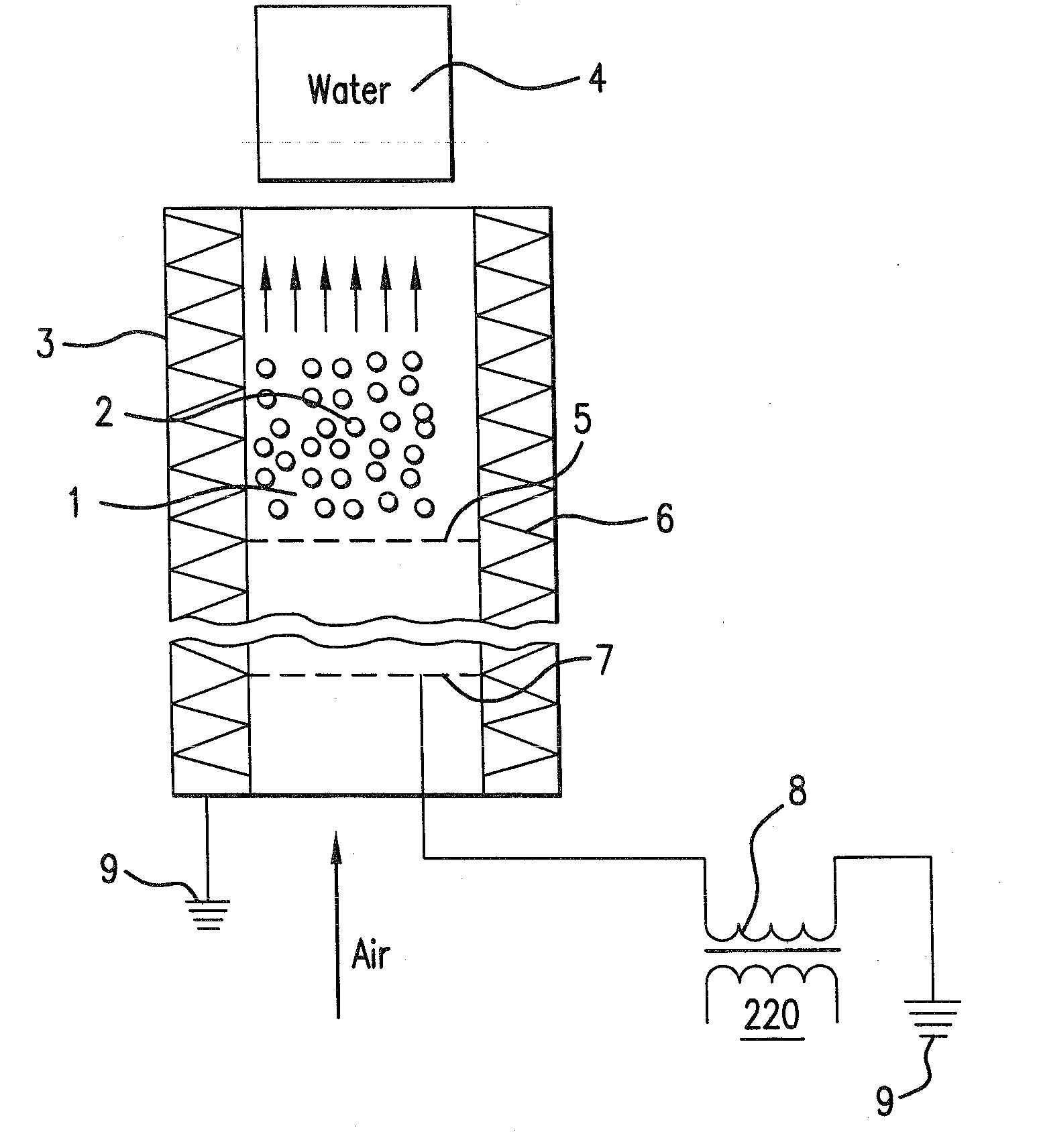

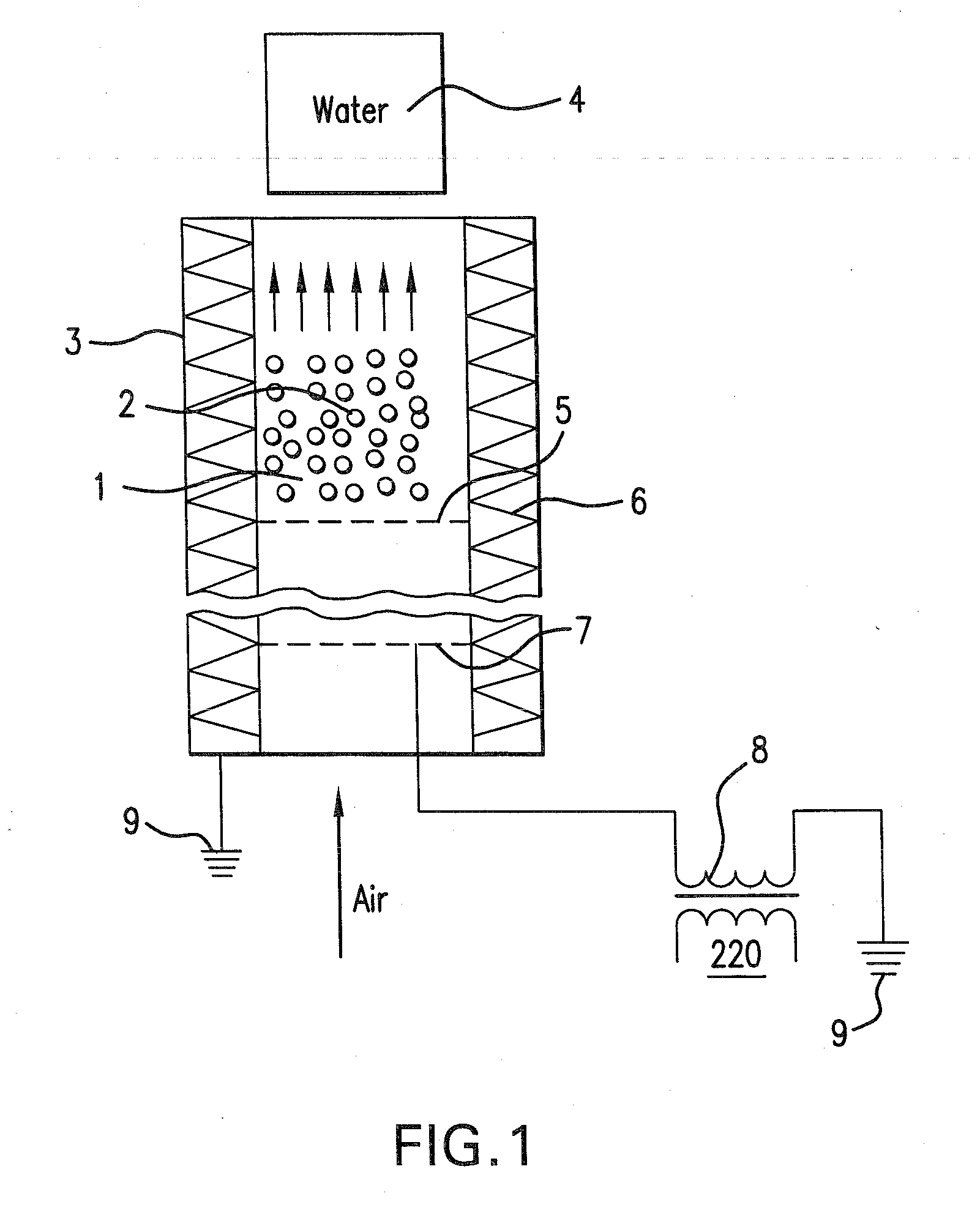

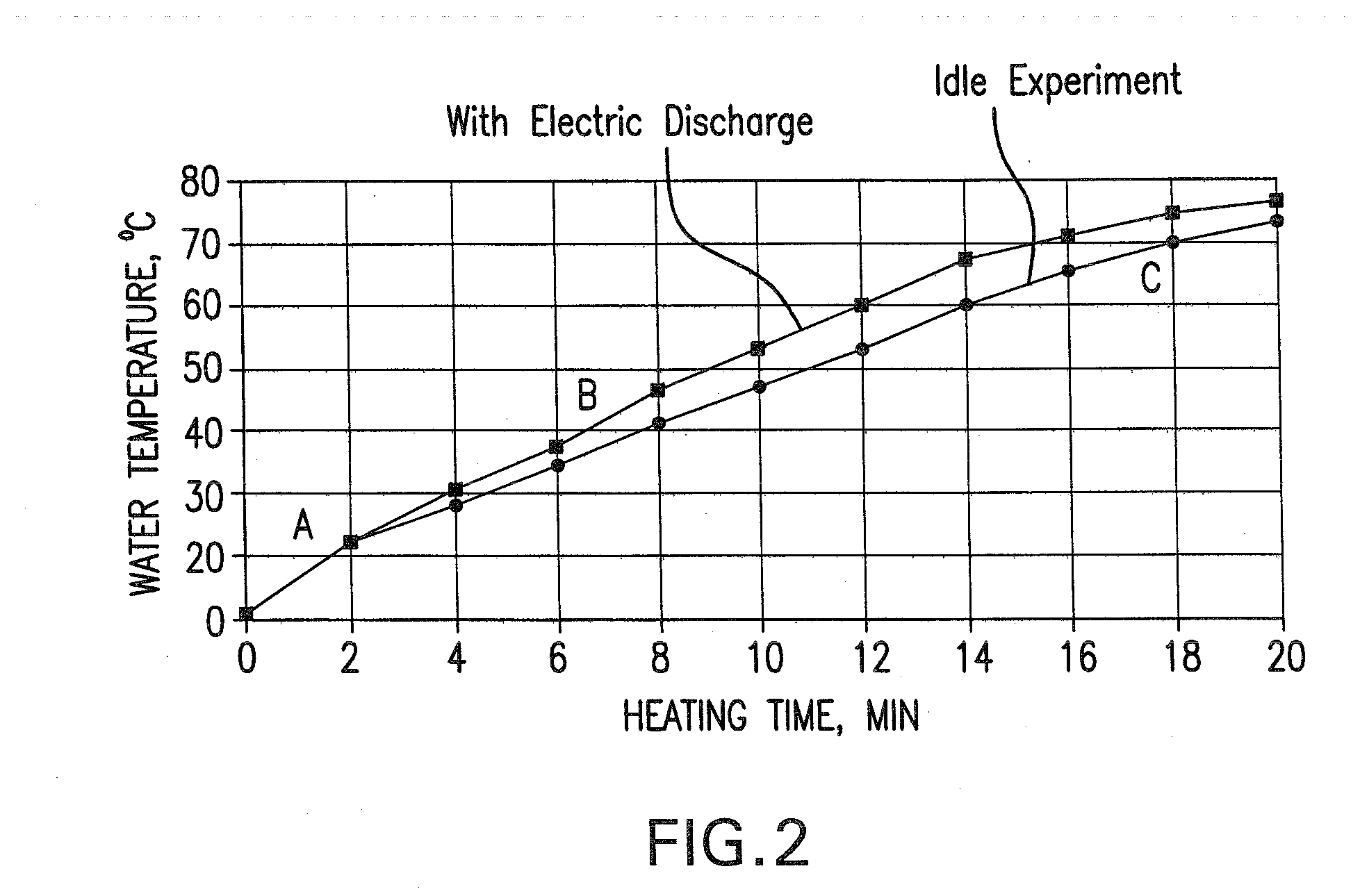

Method of solid fuel combustion intensification

InactiveUS20080044781A1Increase oxidation rateDegree of improvementIncandescent ignitionCatalytic ignitersOxygenEnergy expenditure

The substance of the invention consists in the combustion of the fuel-air mixture in the electric field by means of the catalyst located in the combustion zone and to which high voltage is applied, which results in reduction of activation energies of all endothermic combustion phases due to the formation of oxygen atoms, carbon radicals and oxygen-containing radicals.Technical result: introduction of the catalyst in the combustion zone minimizes energy expenditure for creation of the low-temperature plasma, allows to increase the temperature in the combustion zone, to reduce activation energy of all endothermic processes taking place at the initial phase of combustion and to reduce carbon content in the ash and to achieve considerable fuel economy.

Owner:LIMITED LIABILITY RES AND PRODION COMPANY UKRTRANSKOM +1

Method and apparatus to control combustion in a multi-cylinder homogeneous charge compression-ignition engine

ActiveUS20070113821A1Efficient implementationElectrical controlInternal combustion piston enginesInternal combustion engineFuel delivery

A method and apparatus are provided to control combustion in a multi-cylinder internal combustion engine operating in a controlled auto-ignition mode with minimum combustion phasing error using a least amount of fuel reforming. This comprises monitoring combustion in each cylinder, and determining a target combustion phasing. Fuel delivery to each cylinder is selectively controlled effective to achieve the target combustion phasing, and, effective to achieve the target combustion phasing further comprises controlling the fuel delivery effective to equilibrate combustion phasing of the cylinders.

Owner:GM GLOBAL TECH OPERATIONS LLC

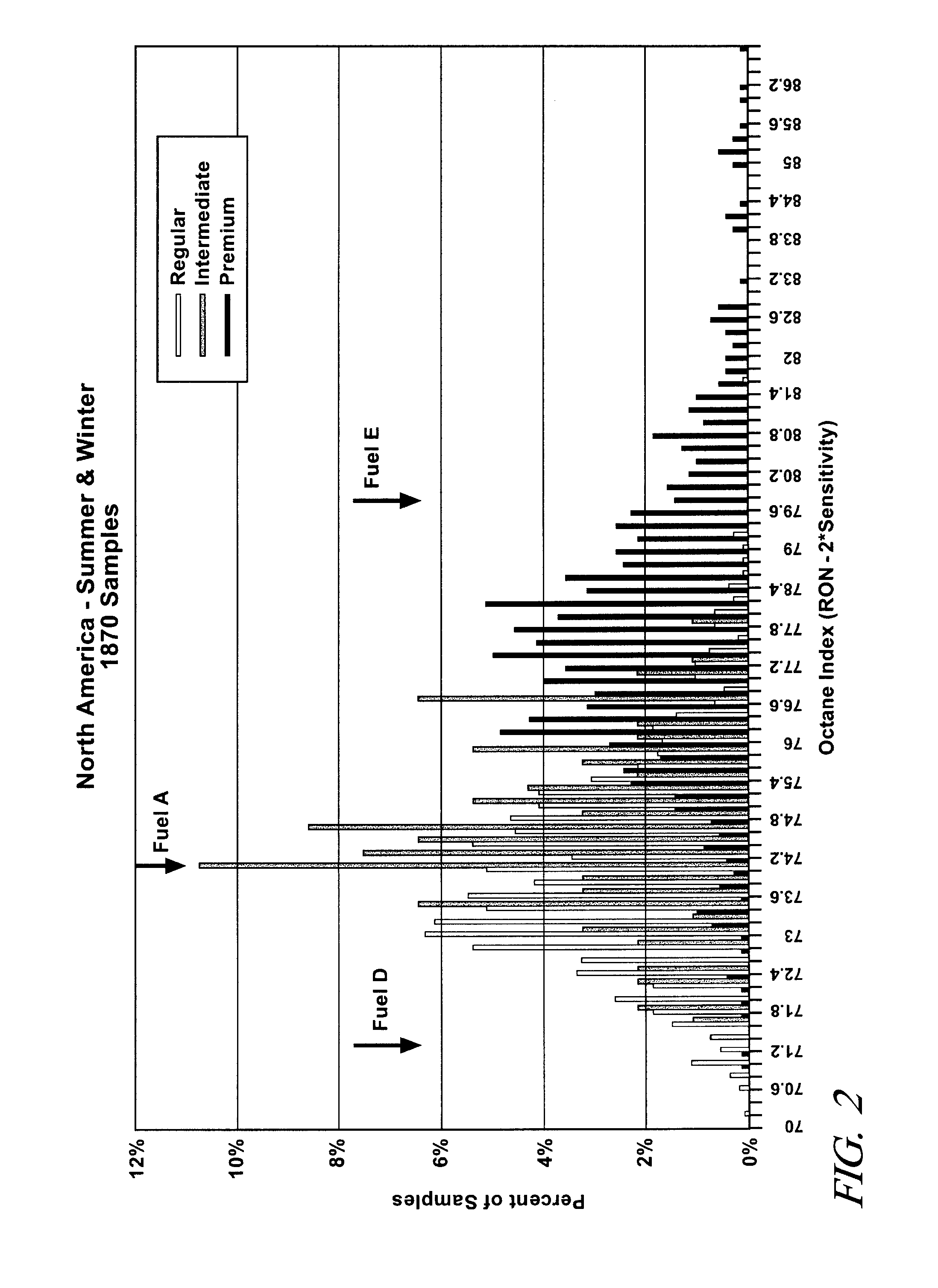

Method of controlling the combustion phase of a fuel mixture of a spark-ingnition supercharged internal-combustion engine, notably of gasoline type

InactiveUS20120016567A1Reduce crank angleBoost octaneElectrical controlInternal combustion piston enginesCombustion chamberLow speed

The present invention relates to a method of controlling the combustion phase of a fuel mixture of a spark-ignition supercharged internal-combustion engine comprising at least one cylinder (12) with a combustion chamber (14), at least one fuel supply means (48, 52) and spark ignition means (38).According to the invention, the method consists, for high loads and low speeds of said engine, in determining, during the combustion of the fuel mixture, the value of crank angle (θ′) where the maximum cylinder pressure (Pmax) occurs in the combustion chamber ; in comparing the value thus determined with a maximum angle threshold value (θmax) representative of an abnormal combustion in said chamber ; in detecting the start of an abnormal combustion when the determined value reaches said threshold value and when the ignition means are not actuated ; and in feeding an amount of another fuel into the fuel mixture in order to modify the energy index of this mixture so as to reduce the crank angle where the maximum cylinder pressure occurs.

Owner:INST FR DU PETROLE

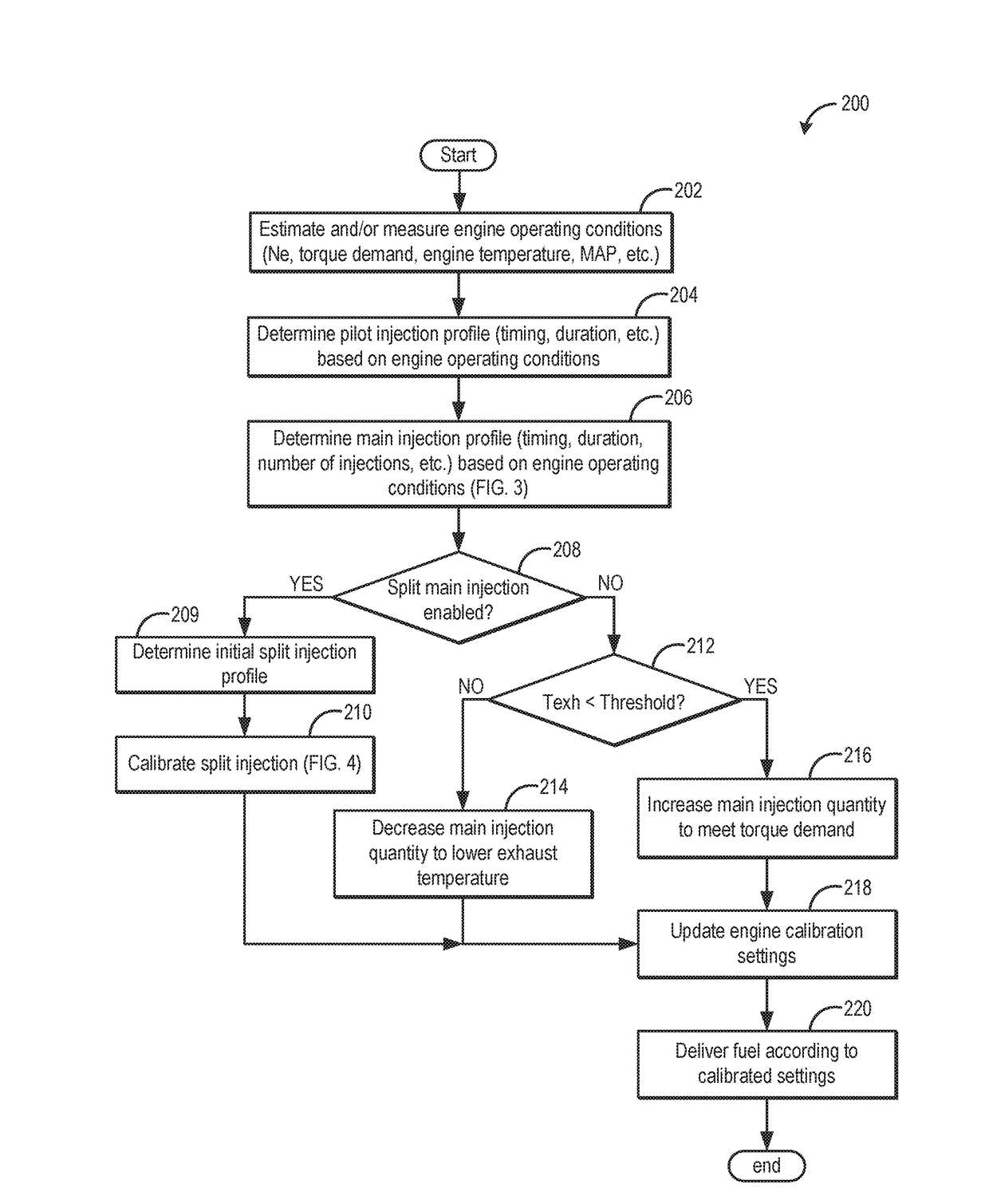

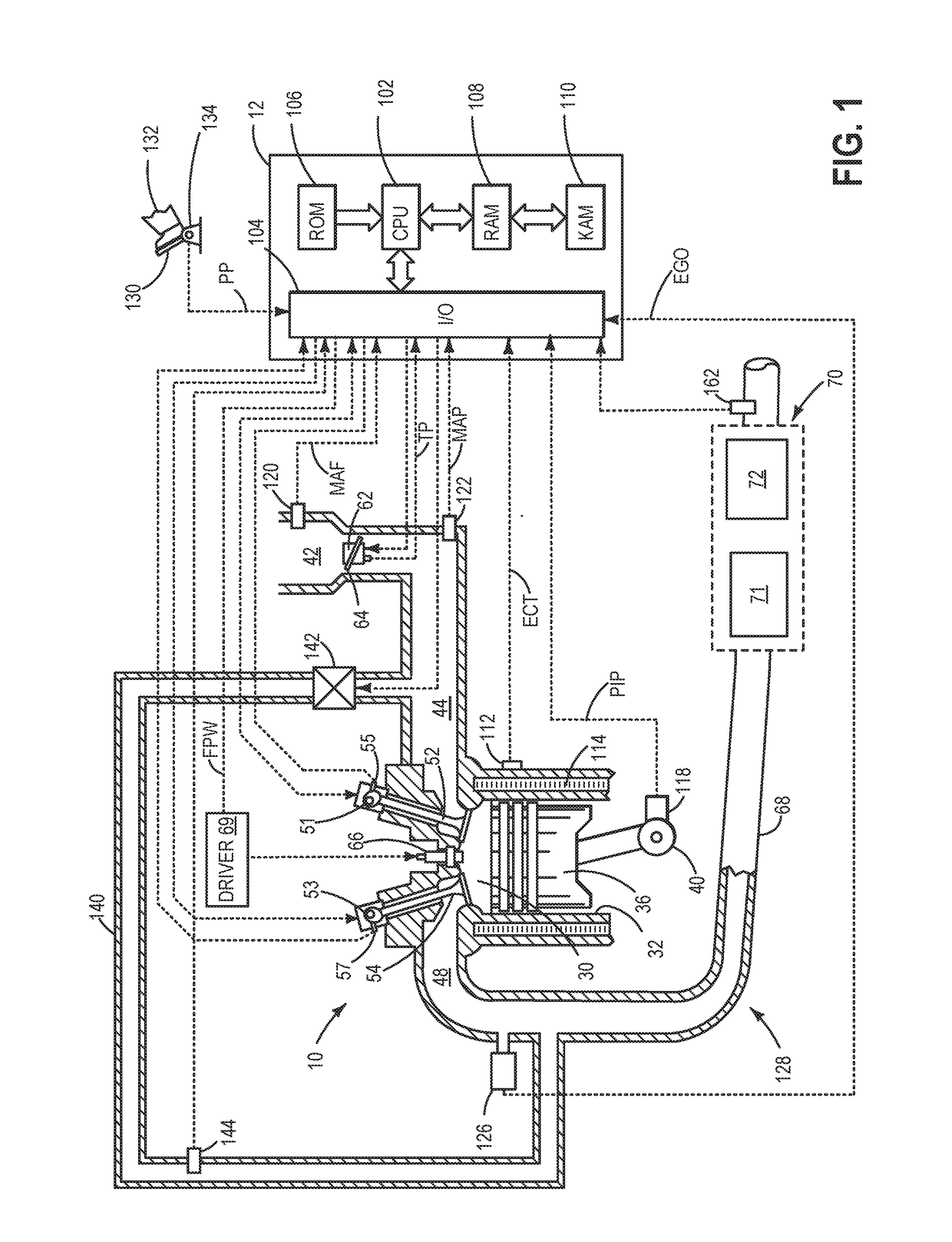

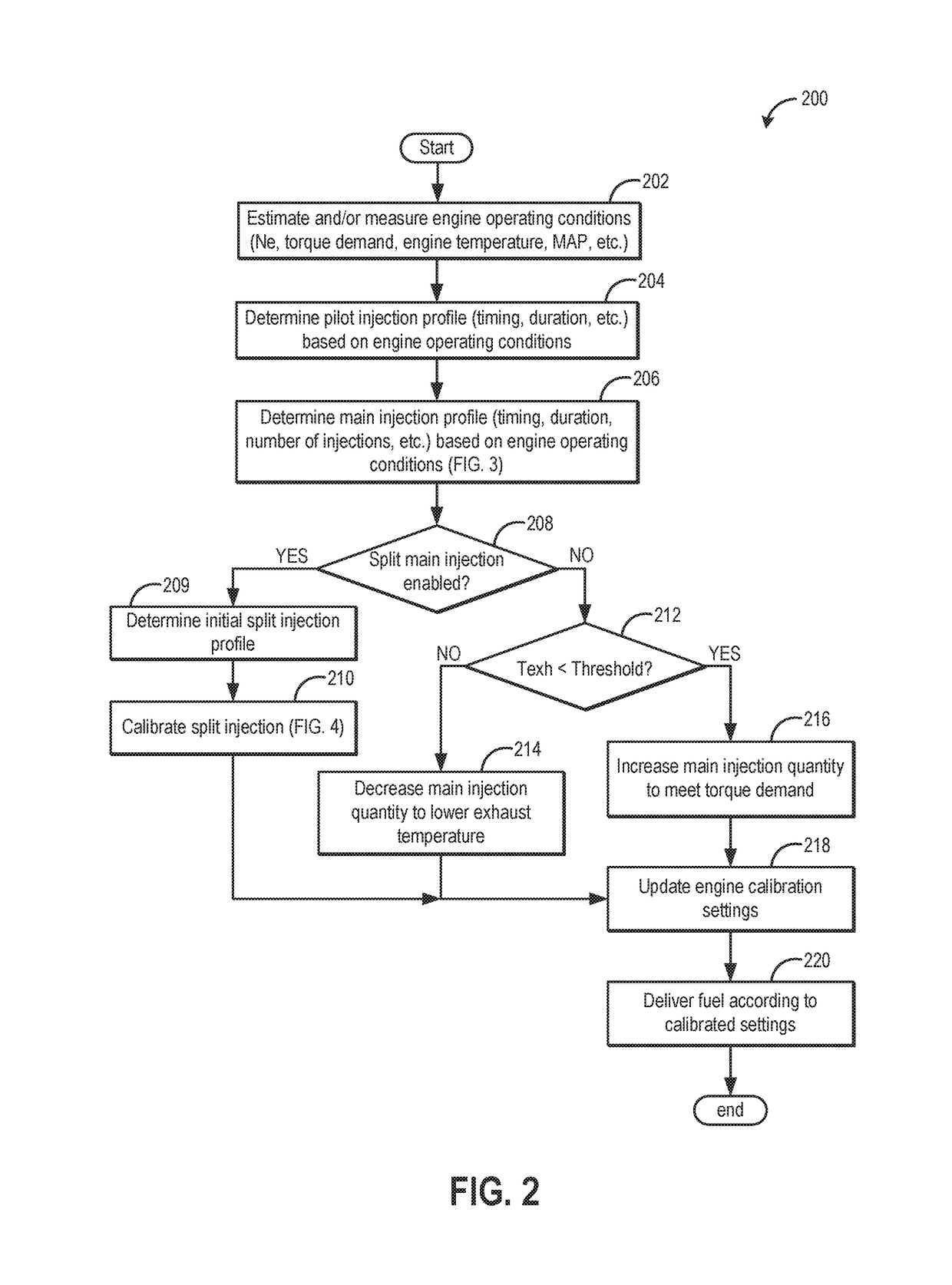

Method of fuel injection control

ActiveUS20170191442A1Improve engine efficiencyHigh torqueElectrical controlInternal combustion piston enginesFuel injectionCylinder pressure

Methods and systems are provided for improving engine performance at high load conditions with reduced combustion phasing while maintaining in-cylinder peak pressures within limits. Following a pilot fuel injection, a main fuel injection is split into multiple smaller injections, the smaller injections spread around a timing of the main fuel injection so that peak cylinder pressures for each injection are within cylinder pressure limits. In this way, more enthalpy is created for expediting warming of exhaust catalysts.

Owner:FORD GLOBAL TECH LLC

Method and apparatus for controlling a homogeneous charge compression ignition engine

Owner:GM GLOBAL TECH OPERATIONS LLC

Fuel system diagnostics by analyzing cylinder pressure signal

InactiveCN102066728AElectrical controlInternal combustion piston enginesCombustion chamberInternal combustion engine

A method for diagnosing combustion within a direct-injection, internal combustion engine including a plurality of combustion chambers and operative lean of stoichiometry includes monitoring combustion in the combustion chambers and estimating mass fraction burn therein. Mass fraction burn of sequential ones of the plurality of combustion chambers are compared and combustion phasing differences between sequential ones of the plurality of combustion chambers based on said mass fraction burn comparisons are identified.

Owner:GM GLOBAL TECH OPERATIONS LLC

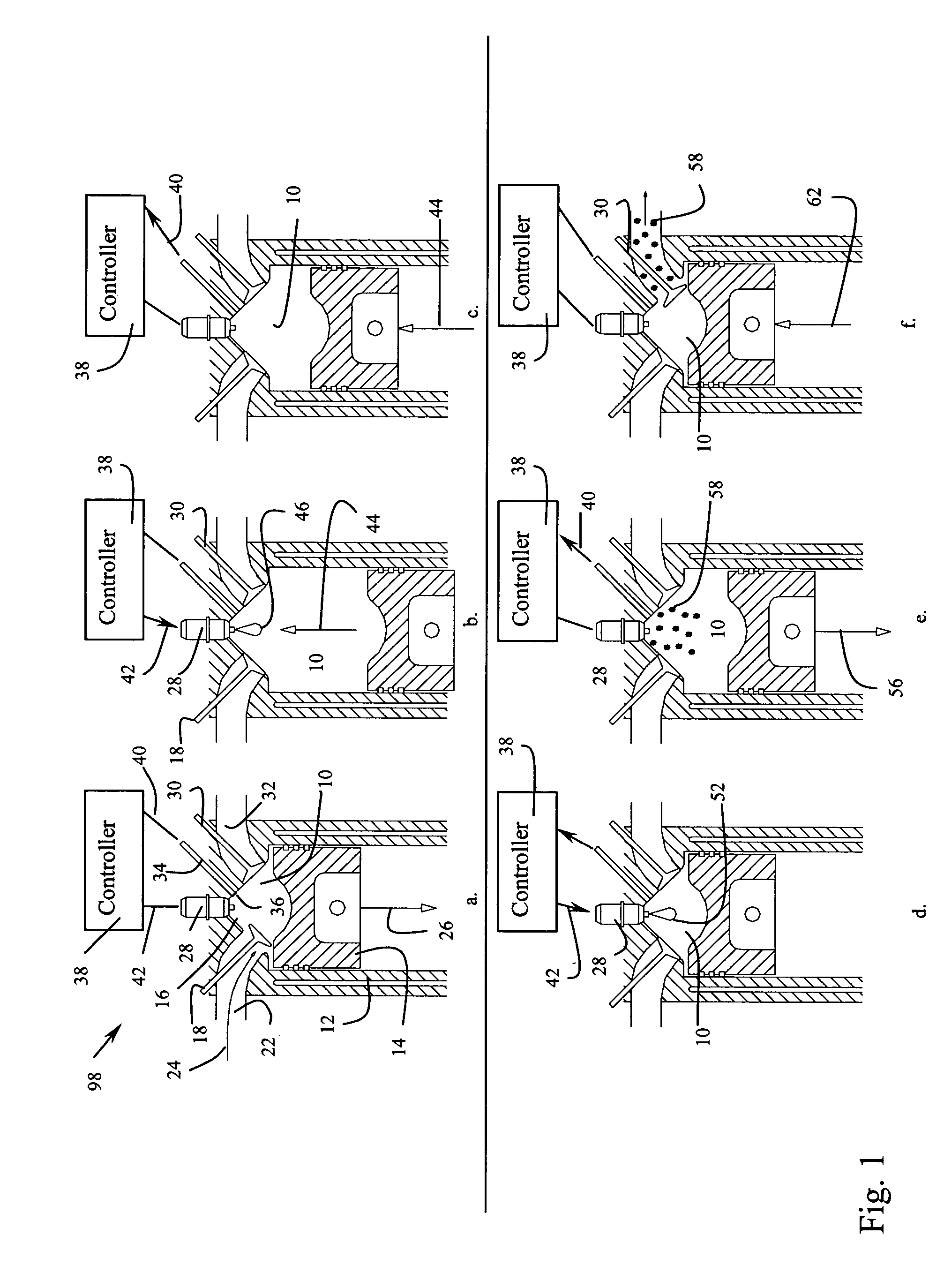

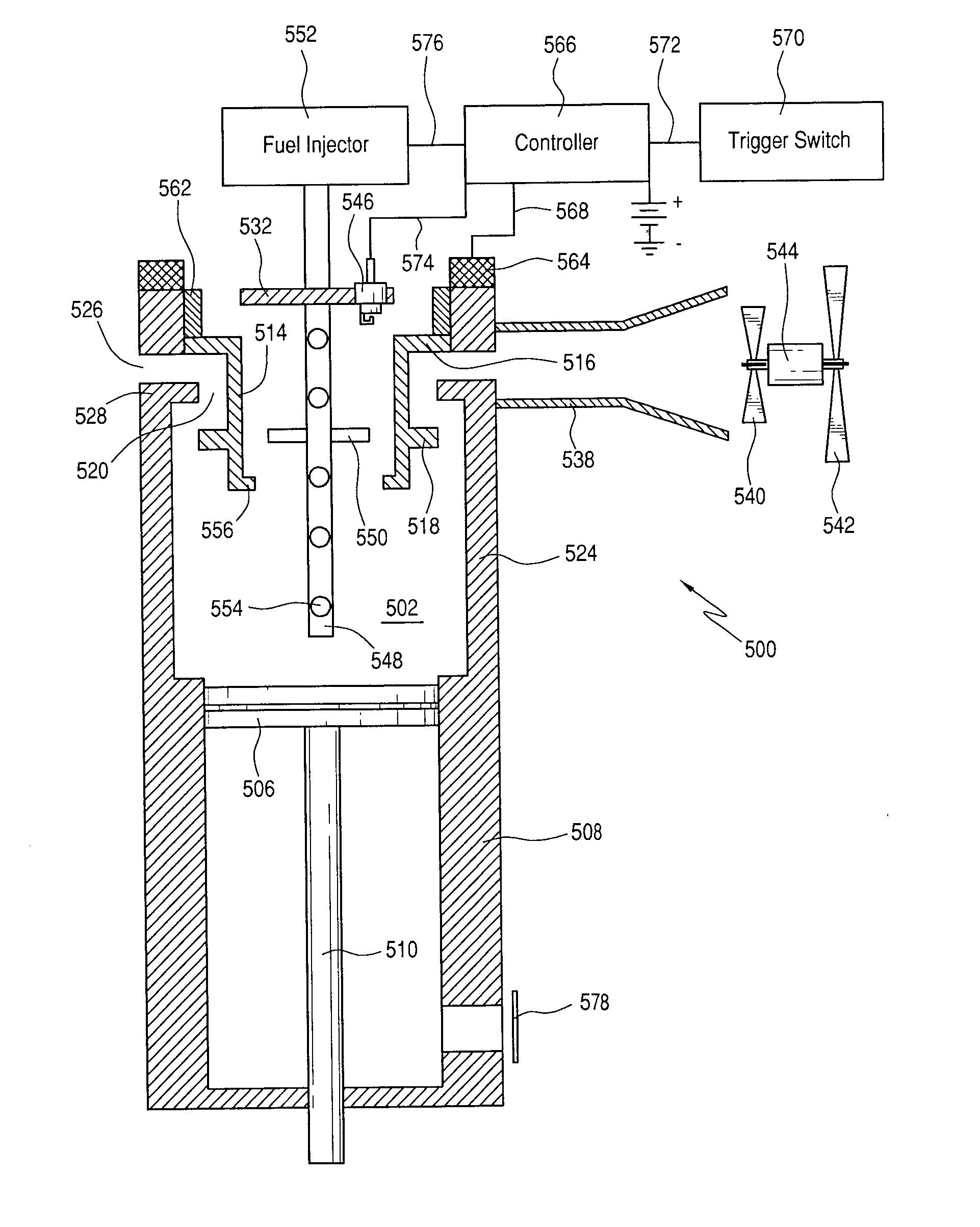

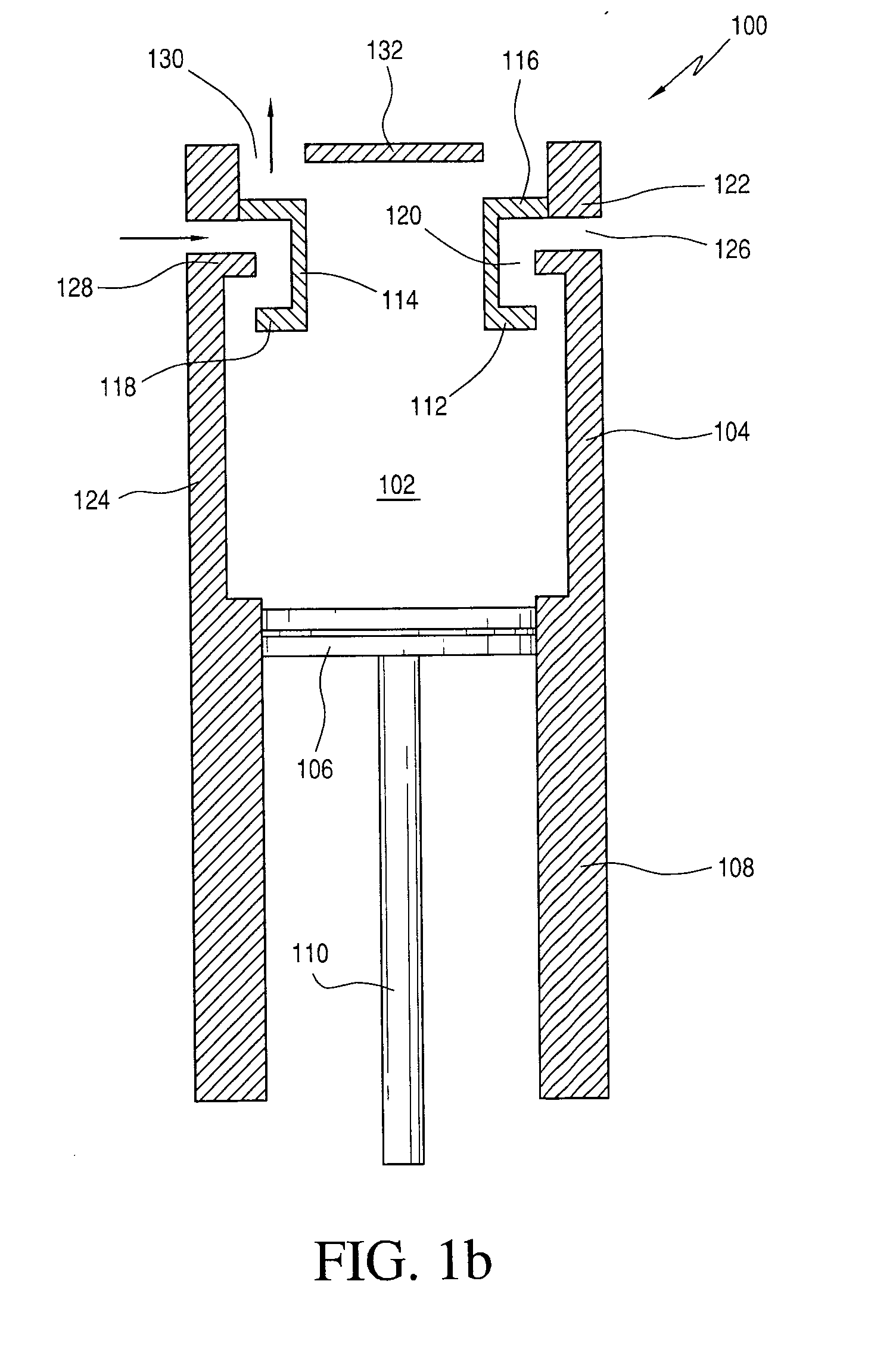

Single component intake/exhaust valve member, fuel distribution system, and cooling system for combustion-powered fastener-driving tool

ActiveUS20110005502A1Function increaseMaximize mixing of airCombustion enginesLift valveCombustion chamberExhaust valve

A new and improved combustion-powered fastener-driving tool utilizes a new and improved single component in-take / exhaust valve member which integrally defines both the intake and exhaust valves thereon. The intake / exhaust valve member is axially movable within the combustion chamber, and operatively cooperates with wall structure of the combustion chamber. When the intake / exhaust valve member is disposed, for example, at a first upper position, both the intake and exhaust ports defined within the wall structure of the combustion chamber are closed so as to permit the ignition and combustion phases of the tool-firing cycle to proceed, whereas, conversely, when the intake / exhaust valve member is disposed, for example, at a second lower position, both the intake and exhaust ports within the combustion chamber are open so as to permit incoming air to scavenge combustion exhaust products and to subsequently mix with injected fuel in preparation for the commencement of another tool-firing cycle.

Owner:ILLINOIS TOOL WORKS INC

Methodology for extending the high load limit of hcci operation by adjusting injection timing and spark timing

A method for operating an internal combustion engine including extended operation in a homogeneous charge compression ignition mode at high loads includes operating the engine in the homogeneous charge compression ignition mode including spark-assisted ignition, monitoring an engine load, monitoring an engine speed, determining the engine to be in a high ringing range based upon the engine load and the engine speed, and when the engine load is in the high ringing range, operating the engine in a reduced ringing mode. The reduced ringing mode includes modulating a fuel injection timing according to a calibrated maximum combustion chamber cooling fuel injection timing, determining a preferred combustion phasing value, and modulating a spark timing based upon the modulated fuel injection timing and the preferred combustion phasing value.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com