Method for producing flexible printed wiring board, and flexible printed wiring board

A flexible printing and manufacturing method technology, applied in the direction of printed circuit manufacturing, printed circuit, printed circuit components, etc., can solve problems such as wiring short circuit, pattern compression, poor contact of IC chip connection, etc., and achieve the effect of high-precision connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

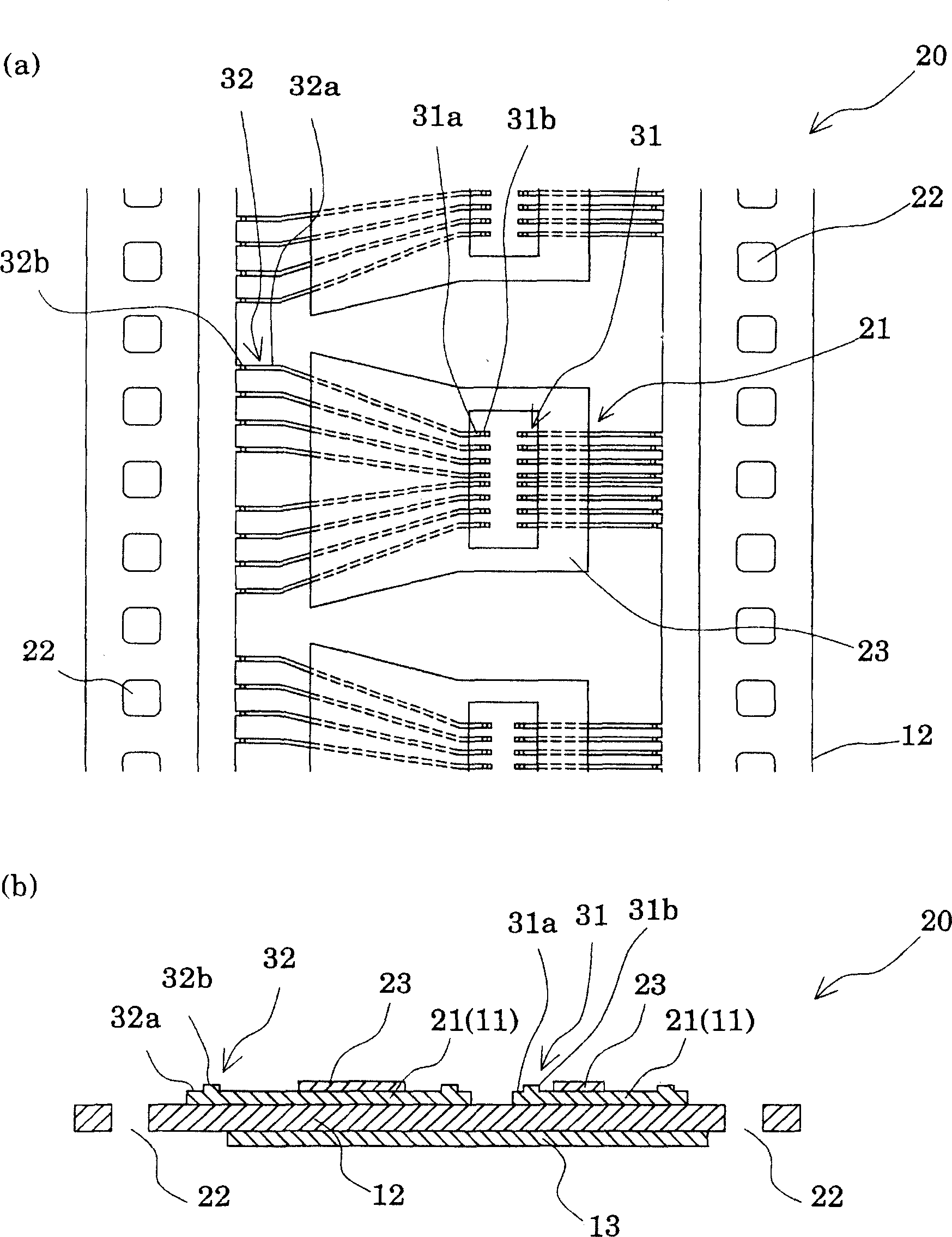

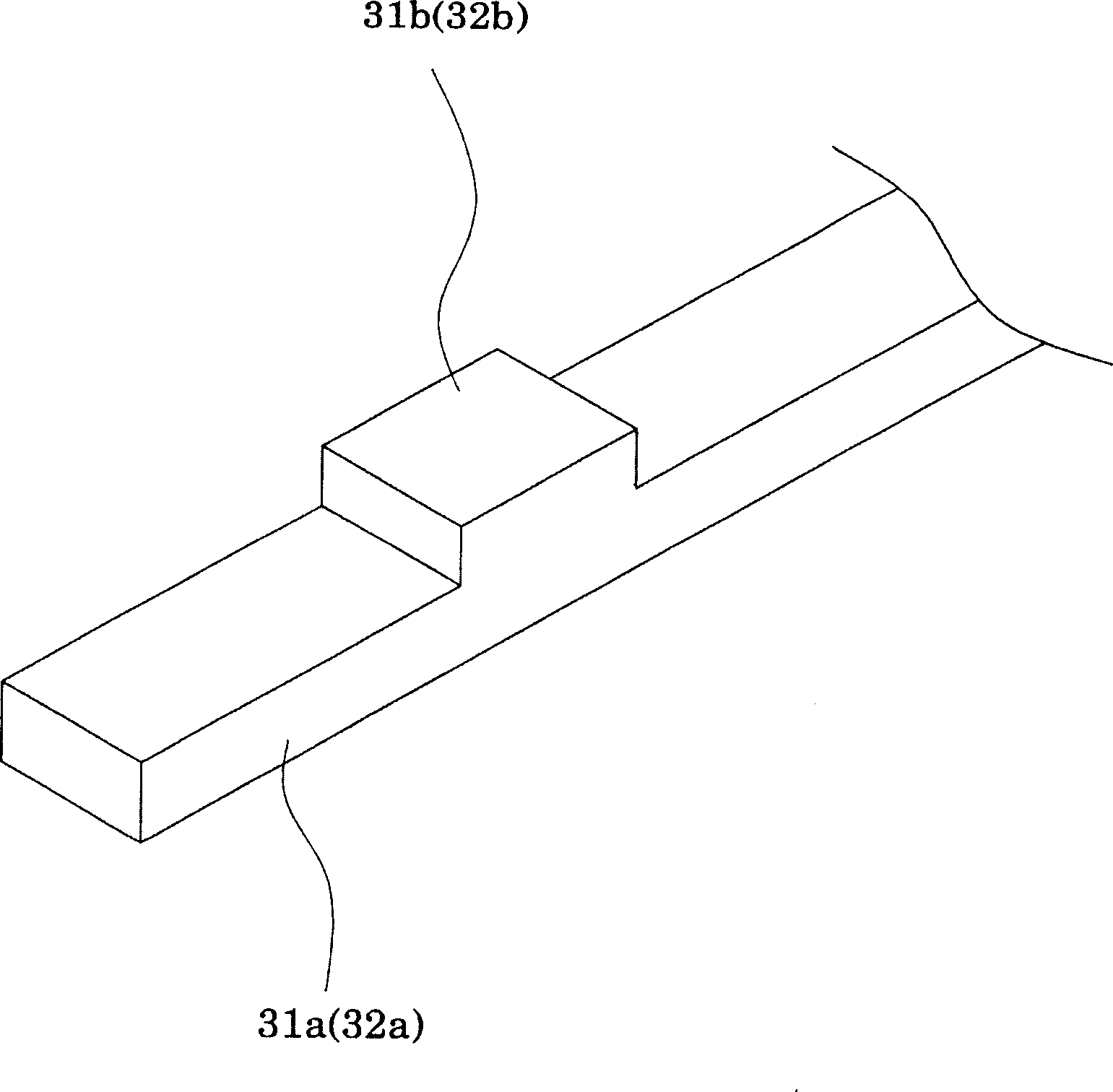

Examples

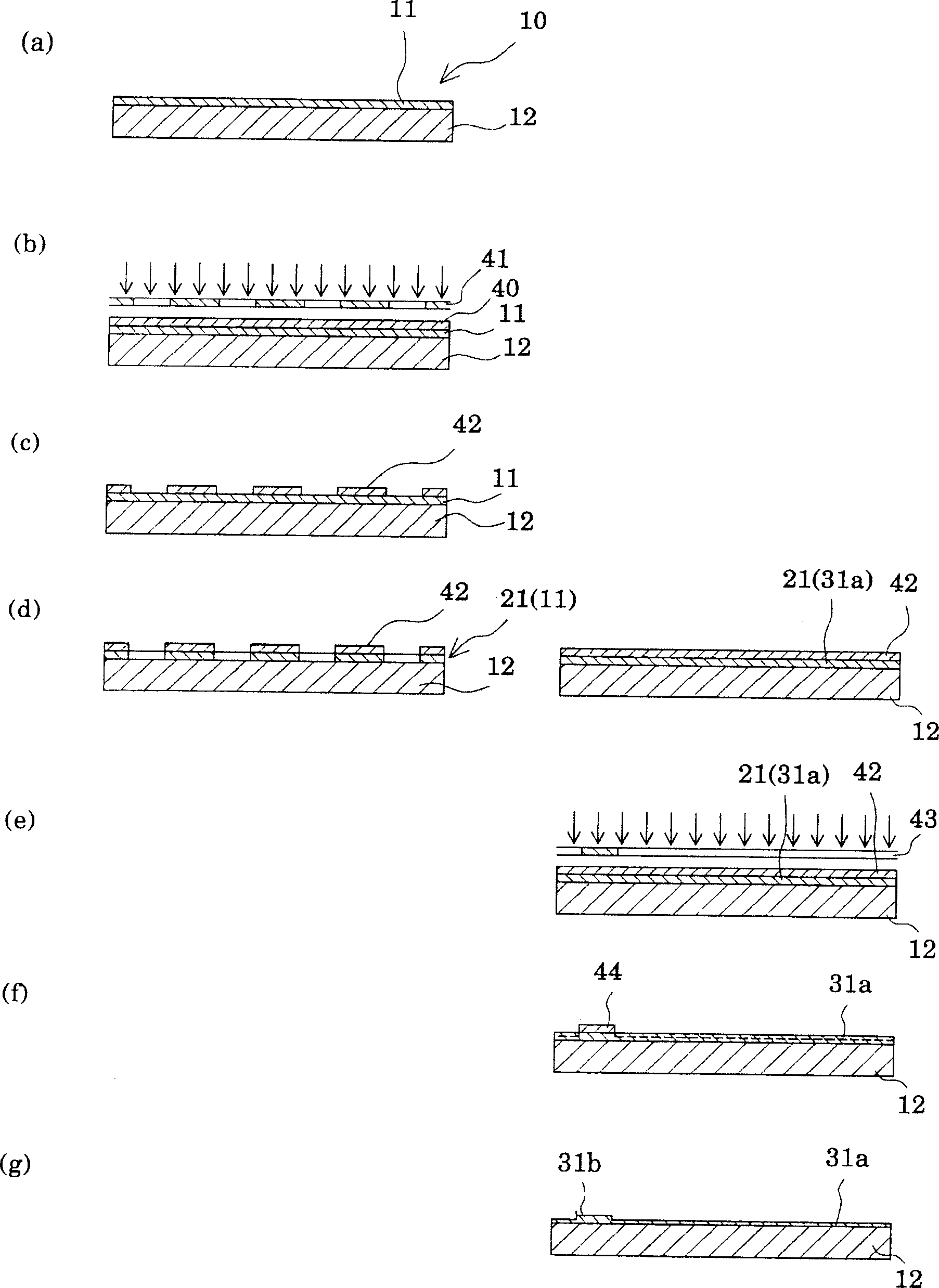

Embodiment 1

[0081] To the copper foil side of a laminated film (Espanex M, manufactured by Nippon Steel Chemical Co., Ltd.) formed by laminating a copper foil with a thickness of 12 μm on a polyimide film with a thickness of 40 μm, a thickness of 30 cps with a viscosity Roll-coat positive type liquid photoresist FR200 (manufactured by Rohm & Haas Co.) on the entire surface in a 4-5 μm manner, and after drying, form a prescribed wiring circuit pattern (in this example, as an external lead , including 720 linear wirings with a width of 35 μm arranged side by side at a pitch of 50 μm), a glass photomask for ultraviolet light (320mJ / cm 2 ) is exposed to light.

[0082] Then, a photoresist pattern is formed by developing, and the solution of divalent copper chloride+hydrochloric acid+hydrogen peroxide is sprayed at 1.2kg / cm 2continuous etching. After etching, it is pickled with hydrochloric acid and then washed with water to obtain a wiring pattern including external leads. At this time, th...

Embodiment 2

[0087] In this embodiment, nodules in the shape of nodules or needles are formed on the bumps to improve connectivity with the LCD substrate or the like.

[0088] In this embodiment, a laminated film (Espanex M, manufactured by Nippon Steel Chemical Co., Ltd.) formed by laminating copper foil with a thickness of 15 μm on a polyimide film with a thickness of 40 μm is used, and the implementation is the same as in Example 1. The steps up to the etching step to form bumps are the same as those in Embodiment 1, and therefore description thereof will be omitted.

[0089] After the etching step is completed, a solder resist coating solution is printed onto the outer leads and portions other than the inner leads.

[0090] Then, in a plating bath prepared by adding 50 ppm of β-naphthoquinone to a copper sulfate solution (Cu: 8gr / L, sulfuric acid: 100gr / L), Dk = 3A / dm at 30°C 2 Plating for 15 seconds at 1A / dm 2 In the usual precipitation state, copper plating is performed to fix the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com