All-solid-state battery and preparation method thereof

An all-solid-state battery and solid-state electrolyte technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, non-aqueous electrolyte batteries, etc. Electrochemical performance, improved interfacial compatibility, good viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of interface layer precursor solution: in a glove box filled with argon, 1 g of polyethylene carbonate (PEC) and lithium salt LiTFSI (mole fraction 60 mol%) were dissolved in 4 mL of acetonitrile, stirred and dissolved to obtain a clear interface layer precursor solution;

[0029] (2) To assemble the battery, 150mg Li 10 GeP 2 S 12 The ceramic sheet pressed into a sheet is used as the electrolyte sheet. After the electrolyte sheet and the two electrodes are assembled, they are soaked in the above interface layer precursor solution, and the solvent is dried in a glove box at 85°C to form an interface layer in situ.

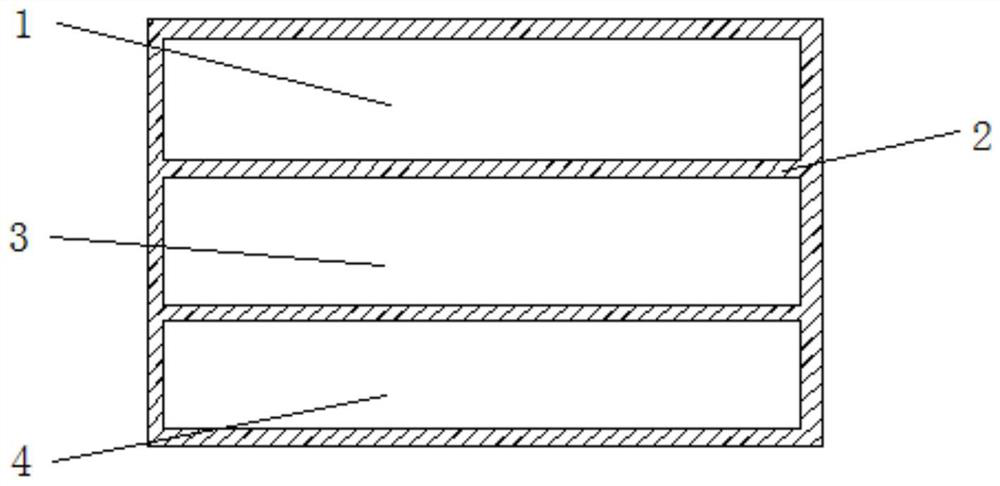

[0030] The all-solid-state lithium symmetric battery prepared in this example includes a sandwich structure consisting of a positive electrode 4, an inorganic solid electrolyte 3, and a negative electrode 1, and an interface layer 2 is provided at the interlayer interface of the sandwich structure, and the interface layer 2 is a continuous ...

Embodiment 2

[0032] (1) Preparation of interfacial layer precursor solution: in a glove box filled with argon, 1 g of polyethylene carbonate (PEC) and lithium salt LiTFSI (mole fraction 80 mol%) were dissolved in 4 mL of acetonitrile, stirred and dissolved to obtain a clear interface layer precursor solution;

[0033] (2) To assemble the battery, 150mg Li 10 GeP 2 S 12 The ceramic sheet pressed into a sheet is used as the electrolyte sheet. After the electrolyte sheet and the two electrodes are assembled, they are soaked in the above interface layer precursor solution, and the solvent is dried in a glove box at 85°C to form an interface layer in situ.

Embodiment 3

[0035] (1) Preparation of interface layer precursor solution: in a glove box filled with argon, 1 g of polyethylene carbonate (PEC) and lithium salt LiTFSI (mole fraction 100 mol%) were dissolved in 4 mL of acetonitrile, stirred and dissolved to obtain a clear interface layer precursor solution;

[0036] (2) To assemble the battery, 150mg Li 10 GeP 2 S 12 The ceramic sheet pressed into a sheet is used as the electrolyte sheet. After the electrolyte sheet and the two electrodes are assembled, they are soaked in the above interface layer precursor solution, and the solvent is dried in a glove box at 85°C to form an interface layer in situ.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap