A method for additive manufacturing of large-scale dispersion-strengthened copper components

A technology for dispersion-strengthened copper and additive manufacturing, which is applied in the field of additive manufacturing of dispersion-strengthened copper components and the preparation of dispersion-strengthened copper. , the inability to prepare dispersion-strengthened copper components, etc., to achieve the effect of being conducive to automation, facilitating powder deposition, and improving shaping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

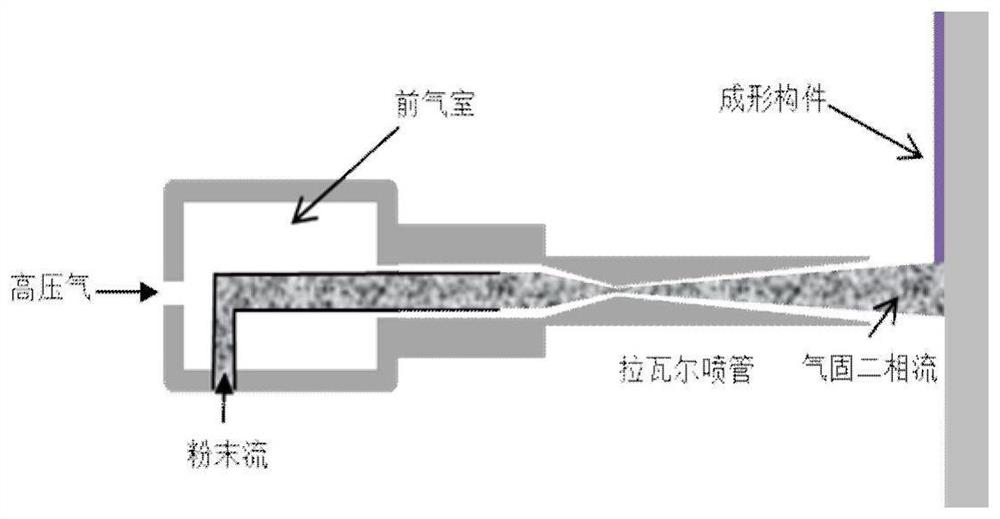

[0037] see figure 1 , an additive manufacturing method for a dispersion-strengthened copper component, comprising the following steps:

[0038] 1) Degrease, dry and polish the surface of the plate-shaped aluminum alloy substrate with a size of 15000mm*100mm*50mm. Because aluminum alloy has good thermal conductivity and heat dissipation performance, it can ensure the uniform internal temperature of dispersion-strengthened copper components in the process of additive manufacturing, and it is convenient to control the temperature within a certain range to reduce the occurrence of problems such as deformation and cracking caused by temperature concentration.

[0039]2) Heat treatment of the dispersion-strengthened copper powder for cold spraying at a heat treatment temperature of 600° C. and a heat treatment time of 3 hours. In step 2), the mass percentage of alumina in the dispersion-strengthened copper powder for medium cold spraying is 1.2%. Appropriate heat treatment conditi...

Embodiment 2

[0053] An additive manufacturing method for a dispersion-strengthened copper component, comprising the following steps:

[0054] 1) Degrease, dry and grind the surface of the plate-shaped aluminum alloy substrate with a size of 2000mm*100mm*60mm.

[0055] 2) Heat treatment of the dispersion-strengthened copper powder for cold spraying, the heat treatment temperature is 200°C, and the heat treatment time is 0.5 hours. Step 2) The mass percentage ratio of alumina in the dispersion-strengthened copper powder for medium cold spraying is 0.3%.

[0056] The dispersion-strengthened copper powder in step 2) is prepared by internal oxidation, and can also be prepared by mechanical alloying method. The internal oxidation preparation and mechanical alloying method can all adopt the existing technology. The heat treatment in step 2) adopts hydrogen reduction heat treatment, which can also be replaced by vacuum heat treatment, argon protective atmosphere heat treatment, and nitrogen prot...

Embodiment 3

[0064] An additive manufacturing method for a dispersion-strengthened copper component, comprising the following steps:

[0065] 1) Degrease, dry and grind the surface of the plate-shaped aluminum alloy substrate with a size of 20000mm*100mm*60mm.

[0066] 2) Heat treatment of the dispersion-strengthened copper powder for cold spraying at a heat treatment temperature of 400° C. and a heat treatment time of 1 hour. In step 2), the mass percentage of alumina in the dispersion-strengthened copper powder for medium cold spraying is 5%.

[0067] The dispersion-strengthened copper powder in step 2) is prepared by internal oxidation, and can also be prepared by mechanical alloying method. The internal oxidation preparation and mechanical alloying method can all adopt the existing technology. The heat treatment in step 2) adopts hydrogen reduction heat treatment, which can also be replaced by vacuum heat treatment, argon protective atmosphere heat treatment, and nitrogen protective ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com