Processing method of local laser blackening for coating metalwork

A processing method and technology for metal parts, applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., to achieve the effect of suppressing the influence of stray light, accurate laser control, and clear black border

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A processing method for partial laser blackening of a coated cover plate, the processing process is carried out according to the following steps:

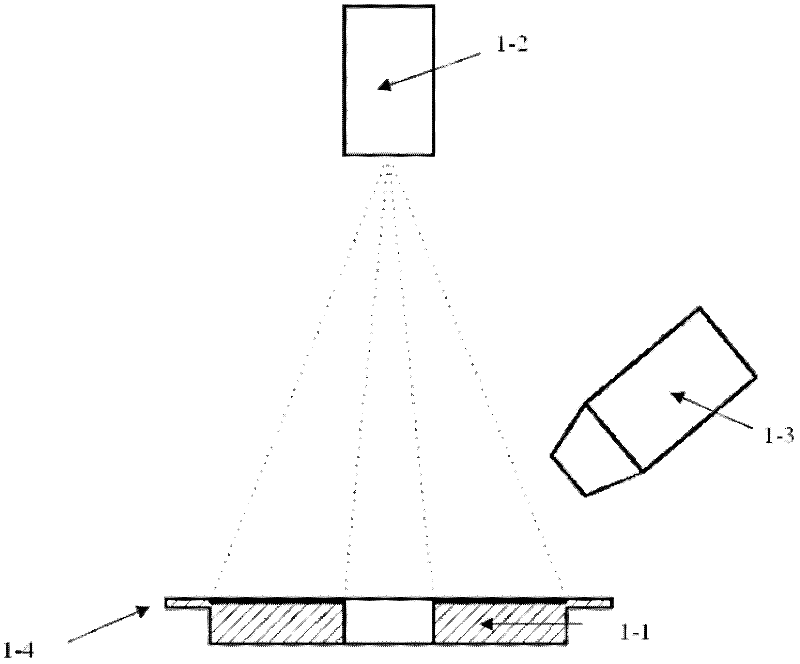

[0021] (1) The base material is made of iron-based Kovar alloy, and the cover plate 1-1 with a length and width of 15 mm, a thickness of 1.5 mm and a central opening 2-1 is machined first, such as figure 1 , figure 2 , and then finish the welding edge 1-4 to 0.2mm;

[0022] (2) Gold-plate the cover plate as a whole, and the thickness of the gold-plated layer is about 0.8 μm;

[0023] (3) Fix the cover plate on the laser processing workbench, and align the area to be blackened 2-2 with the laser; use CAD software to draw the shape of the area to be blackened, and select a laser with a wavelength of 1064nm and a spot diameter of 0.05mm Infrared laser, and set other laser parameters, scan twice, the first parameters are: laser energy is 5.2W, scanning line spacing is 0.05mm, defocus is 3mm, laser scanning speed is 600mm / s, l...

Embodiment 2

[0028] The processing steps of this example are roughly the same as those of the previous example, the difference is that the base material is made of stainless steel plate, polished after nickel plating, and a blackening treatment is adopted. The parameters in the blackening process are: laser energy is 5W, scanning line spacing is 0.05 mm, the defocus amount is 5mm, the laser scanning speed is 20mm / s, the laser frequency is 40000Hz, and the pulse width is 15μs.

[0029] Figure 4 It is the comparison of the reflectance of the coated steel plate with and without blackening treatment at different wavelengths.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com