Preparation method of adiponitrile

A technology for adiponitrile and pentene nitrile, which is applied in the field of preparation and separation of chemical products, can solve the problems of complicated separation and recovery process of homogeneous catalyst, increased production cost of adiponitrile, extremely sensitive catalyst to water, etc. It is easy to recover and recycle, reduce the consumption of phosphorus ligands, and save the effect of removing water from raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

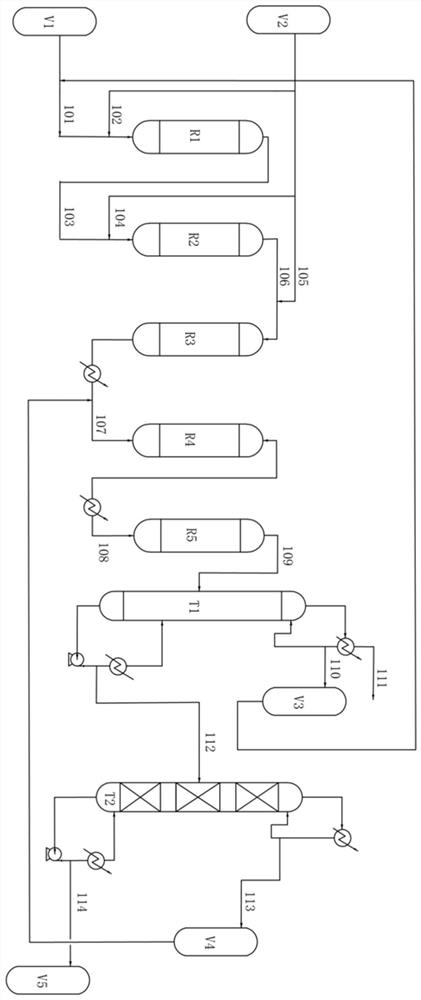

Image

Examples

preparation example Construction

[0051] The invention provides a kind of preparation method of adiponitrile, comprising:

[0052] Step 1: hydrocyanic acid and butadiene carry out the first hydrogen cyanation reaction in the presence of porous polymer-nickel catalyst, forming 3-pentenenitrile (3PN), 2-methyl-3-butenenitrile ( 2M3BN) and the first stream of butadiene, the molar ratio of the total amount of hydrocyanic acid and the amount of butadiene in the first hydrocyanation reaction is 0.75-1.0;

[0053] Step 2: The first stream obtained in step 1 is subjected to an isomerization reaction in the presence of a porous polymer-nickel catalyst to obtain a compound comprising 2-pentenenitrile (2PN), 3-pentenenitrile (3PN) and 4-pentenenitrile Mononitrile of acetonitrile (4PN), unreacted 2-methyl-3-butenenitrile (2M3BN) and a second stream of butadiene; a second stream comprising 3-pentenenitrile (3PN) is then obtained by a work-up step the material flow;

[0054] Step 3: The second hydrocyanation reaction is c...

Embodiment 1

[0176] (1) Preparation of porous polymer A

[0177]

[0178] Dissolve monomer 2-a (23.3g, 60mmol) and monomer 3-a (40.2g, 60mmol) in 800mL tetrahydrofuran (the difference between the solubility parameters of the solvent and the mixed monomer is 2.35MPa 1 / 2 ), add 1.0g of azobisisobutyronitrile (AIBN), and carry out prepolymerization with stirring at 50°C for 4 hours to obtain a prepolymer; then add 133mL of n-heptane (so that the solubility parameter of the mixed solvent and The difference is 0.3MPa 1 / 2 ), heated up to 85°C and continued to react for 4 hours to make the prepolymer swell and fully solidify. After the reaction was completed, the temperature was lowered to normal temperature, filtered, washed with 3-pentenenitrile, and vacuum-dried to obtain porous polymer A (58.4 g).

[0179] Adopt BET test method to test, the specific surface area of gained porous polymer A is 1840m 2 / g; pore volume is 1.50cm 3 / g. Micromeritics ASAP 2020 automatic physical adsorptio...

Embodiment 2

[0183] (1) Preparation of porous polymer B

[0184]

[0185] Dissolve monomer 2-a (23.3g, 60mmol) and monomer 3-b (45.3g, 60mmol) in 1000mL chloroform (the difference between the solubility parameters of the solvent and the mixed monomer is 2.28MPa 1 / 2 ), add 1.0g of azobisisobutyronitrile (AIBN), and carry out prepolymerization with stirring at 50°C for 4 hours to obtain a prepolymer; then add 200mL of isobutyl acetate (so that the solubility parameters of the mixed solvent and the prepolymer The difference is 0.39MPa 1 / 2 ), followed by obtaining porous polymer B (63.1 g) in the same manner as in Example 1.

[0186] The test was carried out in the same manner as in Example 1, and the performance parameters of the porous polymer B are shown in Table 2-1.

[0187] (2) Preparation of porous polymer-nickel catalyst B

[0188] Under nitrogen atmosphere, porous polymer B (57.1 g, the amount of P is 150 mmol) and bis-(1,5-cyclooctadiene)nickel (8.3 g, 30 mmol) were added to 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com