Back washing type micropore filtering device

A microporous filtration and backwashing technology, which is applied to fixed filter element filters, filtration separation, membrane filters, etc., can solve the problems of increased enterprise costs, frequent replacement of filter screens, etc., to increase application times and reduce cleaning time , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

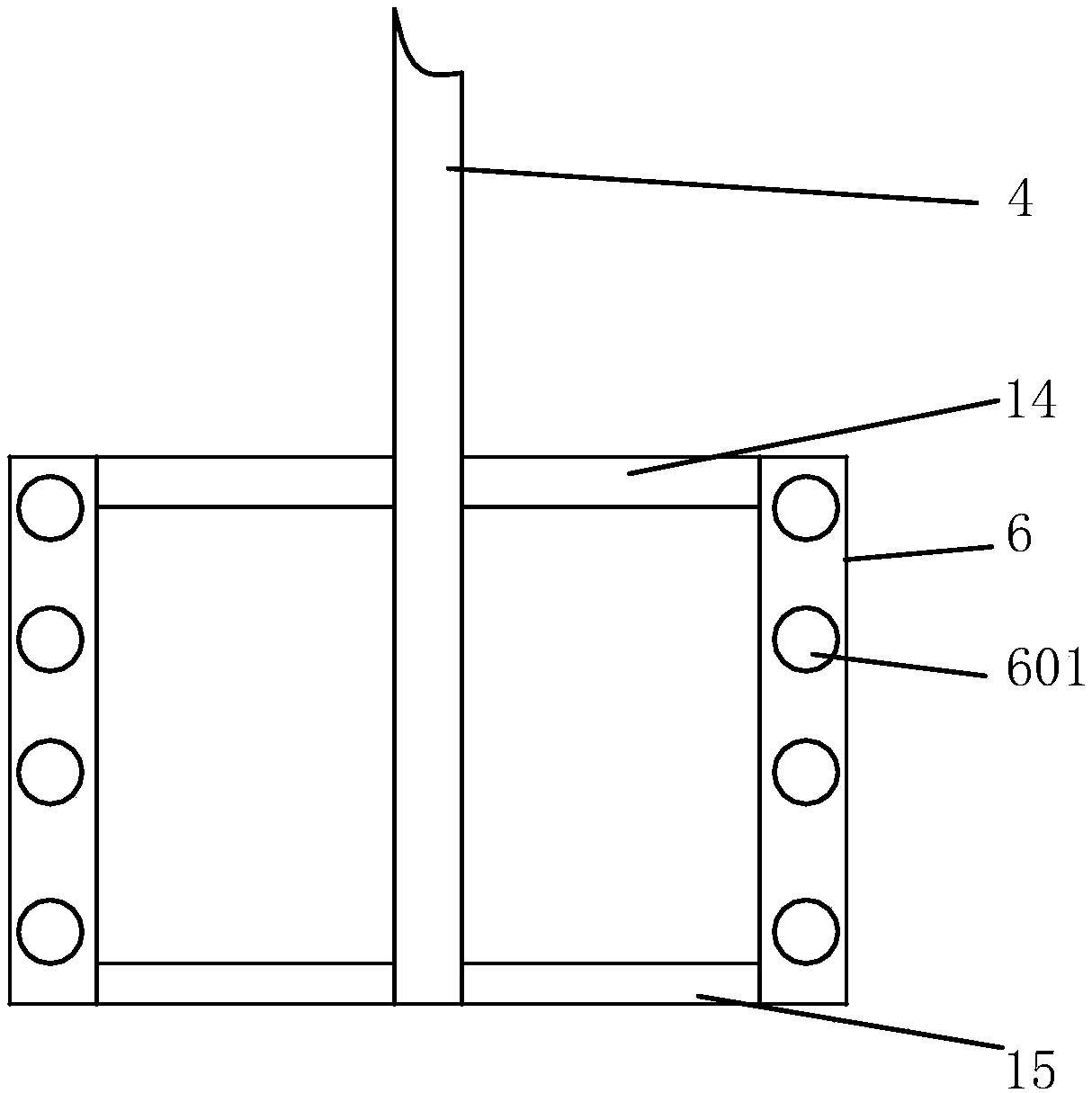

[0020] Such as figure 1 , figure 2 , image 3 As shown, a backwashing microporous filter device includes a housing 5 and a discharge port 18 arranged at the bottom of the housing 5 and a feed inlet 13 arranged on the left side of the top opening of the housing 5, and the opening of the housing 5 The top bolt is connected to the top cover 17, the top of the top cover 17 is installed with a bracket 2 by welding, the top of the bracket 2 is fixedly connected to the deceleration motor 1, and the output end of the deceleration motor 1 is rotationally connected to one end of the rotating shaft 4 through the coupling 3, The other end of the rotating shaft 4 extends into the housing 5 through the top cover 17, and the bottom of the other end of the rotating shaft 4 is sequentially welded to the first connecting rod 14 and the second connecting rod 15 from top to bottom. Both ends of the first connecting rod 14 are The two ends of the second connecting rod 15 are vertically connecte...

Embodiment 2

[0023] Such as figure 2 , image 3 , Figure 4 , Figure 5 As shown, a backwashing microporous filter device includes a housing 5 and a discharge port 18 arranged at the bottom of the housing 5 and a feed inlet 13 arranged on the left side of the top opening of the housing 5, and the opening of the housing 5 The top bolt is connected to the top cover 17, the top of the top cover 17 is installed with a bracket 2 by welding, the top of the bracket 2 is fixedly connected to the deceleration motor 1, and the output end of the deceleration motor 1 is rotationally connected to one end of the rotating shaft 4 through the coupling 3, The other end of the rotating shaft 4 extends into the housing 5 through the top cover 17, and the bottom of the other end of the rotating shaft 4 is sequentially welded to the first connecting rod 14 and the second connecting rod 15 from top to bottom. Both ends of the first connecting rod 14 are The two ends of the second connecting rod 15 are verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com