Organic-inorganic antibacterial antifouling interior wall coating and preparation method thereof

A technology of inorganic antibacterial and interior wall coatings, applied in the field of coatings, can solve the problems of non-cracking and adhesion of inorganic coatings, and achieve super strong adhesion, not easy to pulverize, and environment-friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

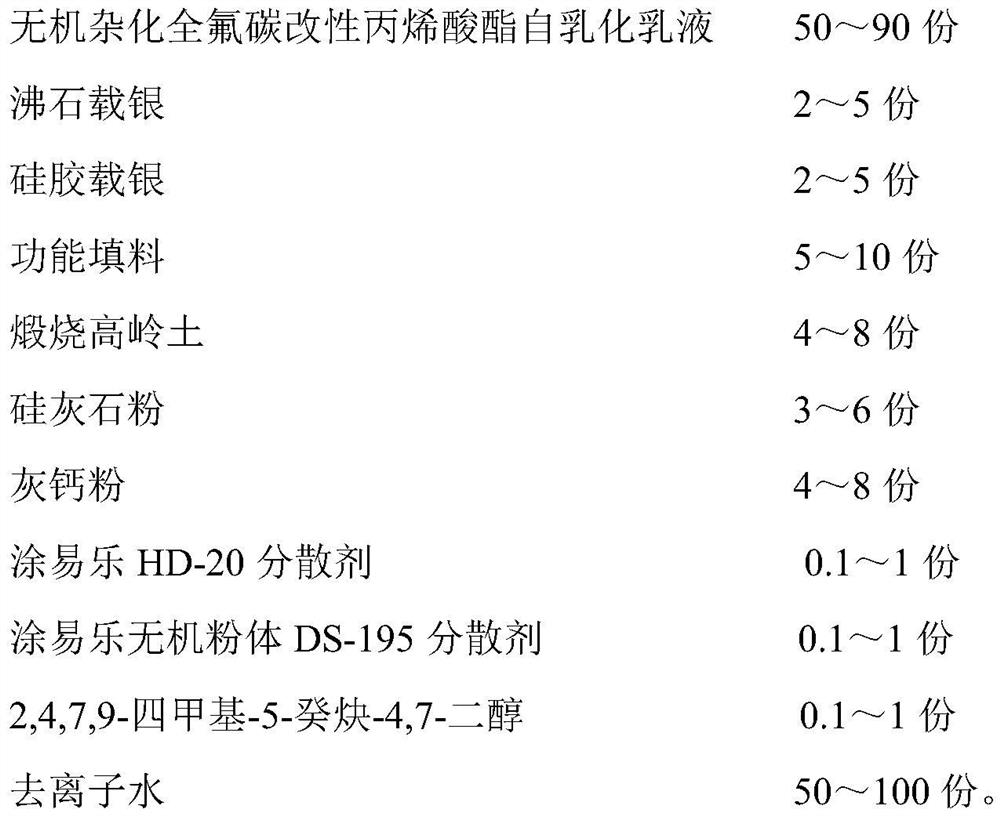

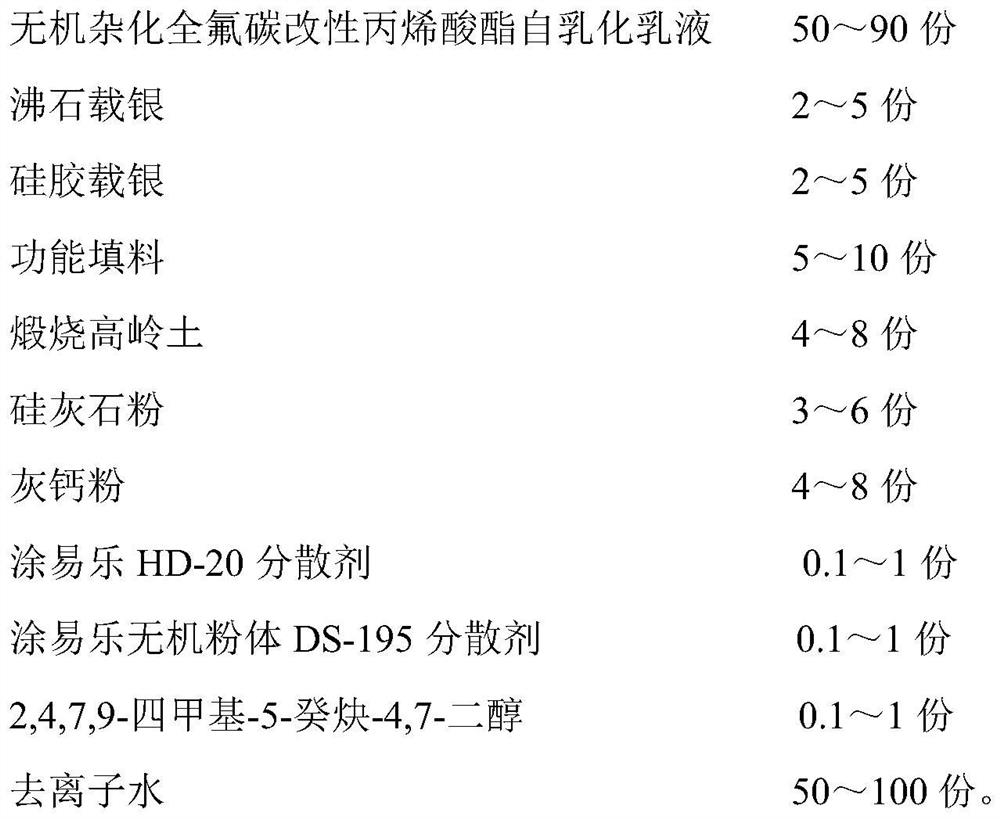

Method used

Image

Examples

Embodiment 1

[0040] Organic-inorganic antibacterial antifouling interior wall paint is prepared according to the following steps:

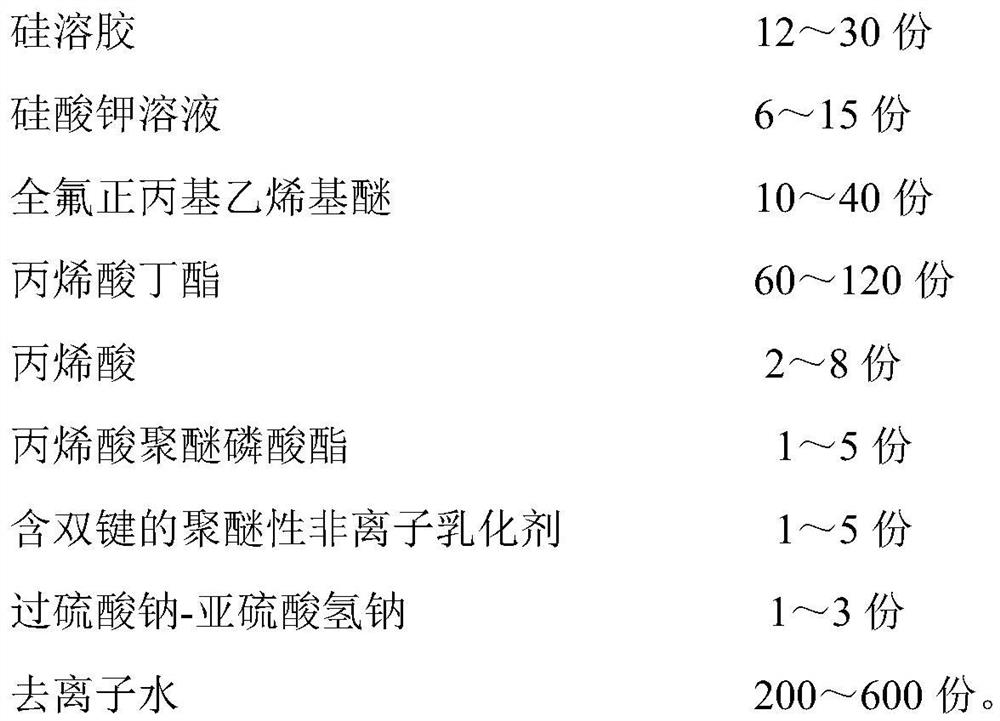

[0041] 1. Inorganic hybrid perfluorocarbon modified acrylate self-emulsifying emulsion, the number of parts by mass is 80 parts, and the preparation steps are as follows:

[0042] (1) Add 40 parts of perfluoro-n-propyl vinyl ether SF-000360, 80 parts of butyl acrylate, and 4 parts of acrylic acid into the reaction kettle, stir and mix to obtain a mixed monomer;

[0043] (2) Add 600 parts of deionized water, 3 parts of acrylic polyether phosphate APE-2005, 3 parts of polyether nonionic emulsifier ONIST AE-100 containing double bonds, and 3 parts of sodium persulfate-sodium bisulfite Into the reaction kettle, feed nitrogen, turn on the electric mixer to stir, pre-emulsify for 0.5 hours, and raise the temperature to 60°C to obtain a pre-emulsion;

[0044] (3) Keep the pre-emulsion at 60°C, add the mixed monomer obtained in step (1) dropwise to the pre-emulsion o...

Embodiment 2

[0060] Organic-inorganic antibacterial antifouling interior wall paint is prepared according to the following steps:

[0061] 1. Inorganic hybrid perfluorocarbon modified acrylate self-emulsifying emulsion, the number of parts by mass is 50 parts, and the preparation steps are as follows:

[0062] (1) Add 10 parts of perfluoro-n-propyl vinyl ether SF-000360, 60 parts of butyl acrylate, and 2 parts of acrylic acid into the reaction kettle, stir and mix to obtain a mixed monomer;

[0063] (2) Add 200 parts of deionized water, 1 part of acrylic polyether phosphate APE-2005, 1 part of polyether nonionic emulsifier ONIST AE-100 containing double bonds, and 1 part of sodium persulfate-sodium bisulfite Into the reaction kettle, feed nitrogen, turn on the electric mixer to stir, pre-emulsify for 0.5 hours, and raise the temperature to 40°C to obtain a pre-emulsion;

[0064] (3) Keep the pre-emulsion at 40°C, add the mixed monomer obtained in step (1) dropwise to the pre-emulsion obta...

Embodiment 3

[0080] Organic-inorganic antibacterial antifouling interior wall paint is prepared according to the following steps:

[0081] 1. Inorganic hybrid perfluorocarbon modified acrylate self-emulsifying emulsion, the number of parts by mass is 60 parts, and the preparation steps are as follows:

[0082] (1) Add 20 parts of perfluoro-n-propyl vinyl ether SF-000360, 60 parts of butyl acrylate, and 5 parts of acrylic acid into the reaction kettle, stir and mix to obtain a mixed monomer;

[0083] (2) Add 200 parts of deionized water, 1 part of acrylic polyether phosphate APE-2005, 2 parts of polyether nonionic emulsifier ONIST AE-100 containing double bonds, and 1 part of sodium persulfate-sodium bisulfite Into the reaction kettle, feed nitrogen, turn on the electric mixer to stir, pre-emulsify for 0.8 hours, and raise the temperature to 50°C to obtain a pre-emulsion;

[0084] (3) Keep the pre-emulsion at 50°C, add the mixed monomer obtained in step (1) dropwise to the pre-emulsion obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com