Iron oxide doped mixed crystal form titanium dioxide nano-net photocatalytic composite material

A technology of titanium dioxide and composite materials, which is applied in the field of photocatalytic materials, can solve the problems of rare raw materials, limited wide application, complicated preparation process, etc., and achieves the effects of stable properties, high photocatalytic reaction activity, and extended energy range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides a method for preparing iron oxide-doped titanium dioxide nano-network photocatalytic composite material in mixed crystal form, which includes the following steps:

[0042] (1) Titanium mesh pretreatment: put the pure titanium mesh in a beaker of propanol, methanol, and isopropanol in turn, place it in an ultrasonic cleaner for 10 minutes, and after taking it out, clean it with deionized water for 5 minutes and dry it for later use ; Then use mixed acid (HF: glacial acetic acid = 1:8) to ultrasonically clean to remove the surface oxide film; then wash with deionized water and ethanol for 2-5 minutes, dry, and seal.

[0043] (2) take the metal Pt sheet as the cathode, and the titanium mesh with the smooth surface obtained in the step (1) as the anode, the distance between the two electrodes is 7cm, and the NH containing 0.5wt% 4 F, 3% vol of H 2 Anodic oxidation is carried out in the electrolyte of ethylene glycol solution of O. The whole oxidati...

Embodiment 2

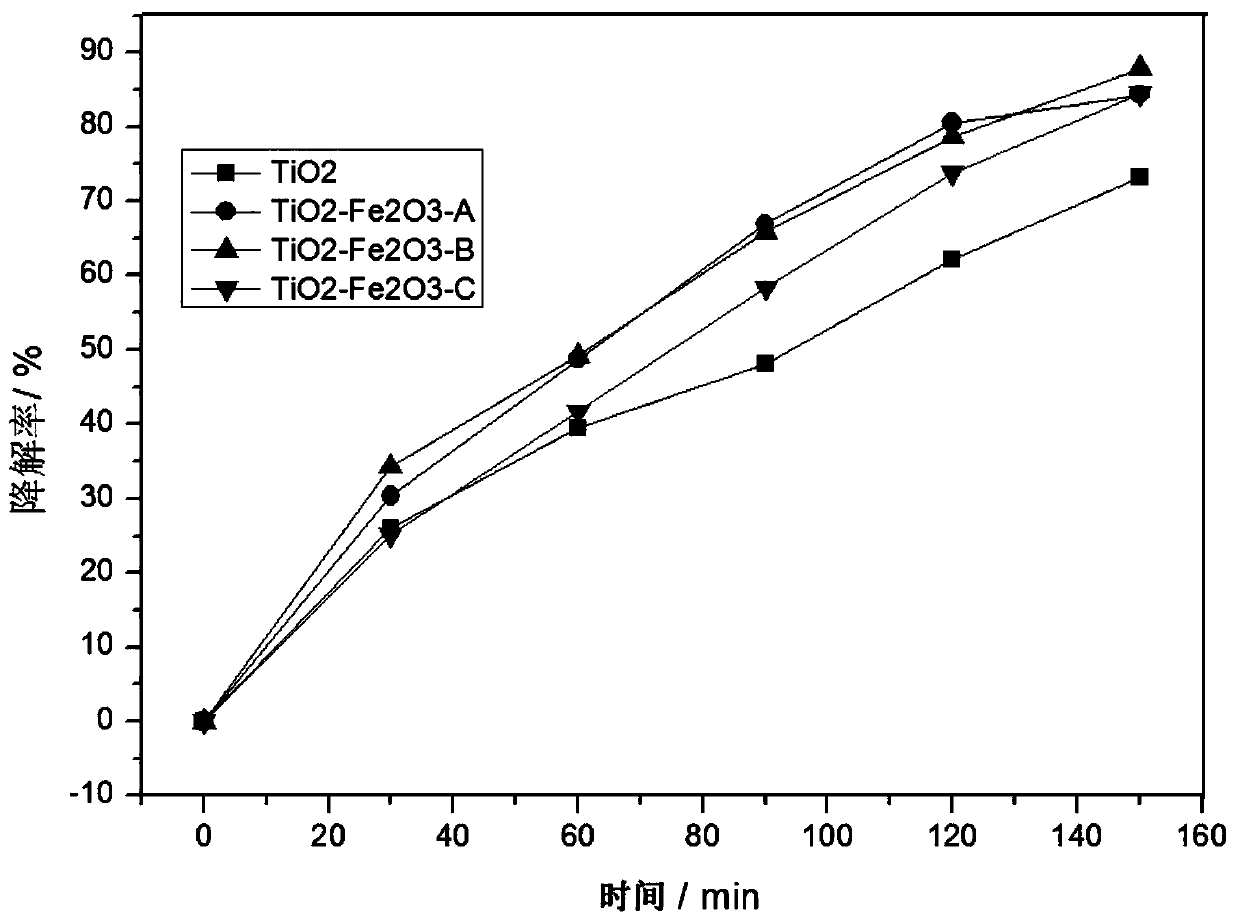

[0055] Embodiment 2 different concentration experiments

[0056] Prepare iron oxide doped TiO according to Example 1 2 Nano-mesh arrays, using ferric chloride ethanol solutions with mass concentrations of 0.1%, 0.63%, and 1%, respectively, and the prepared samples were named TiO 2 -Fe 2 o 3 -A,TiO 2 -Fe 2 o 3 -B,TiO 2 -Fe 2 o 3 -C; using 50mL methylene blue solution with a concentration of 12mg / L as the target degradation product, the titanium mesh substrate TiO modified with different concentrations of iron oxide 2 The nanomesh array was placed in it, and its photocatalytic activity was tested (the photocatalytic experimental device is the CEL-APR100H reactor of Beijing Zhongjiao Jinyuan Technology Co., Ltd., and the light source is a 500W xenon lamp), and the supernatant was taken out every 30 minutes at room temperature Measure its absorbance in a UV-Vis spectrophotometer, and calculate its concentration according to the F factor, the results are as follows figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com