A kind of ozone catalytic oxidation catalyst and its preparation method and application

An ozone catalytic oxidation and catalyst technology, which is applied in catalyst activation/preparation, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., to increase added value, save tower equipment investment, and significantly economical effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

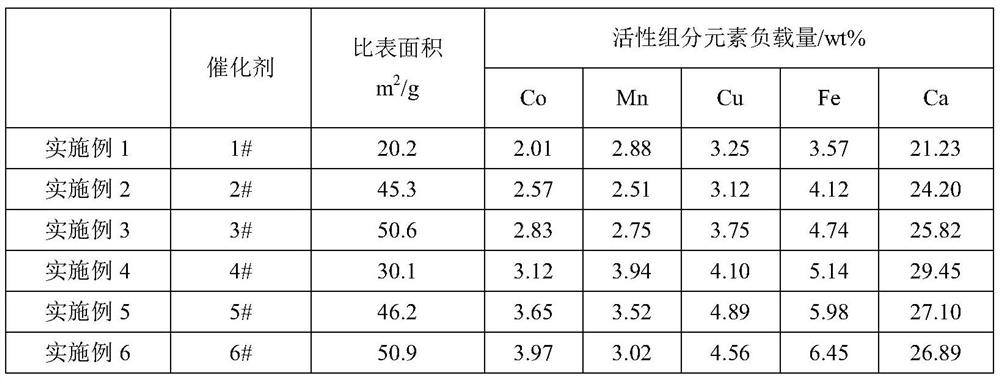

Embodiment 1

[0050] The present embodiment is used to illustrate the preparation method of the ozone catalytic oxidation catalyst of the present invention and the ozone catalytic oxidation catalyst prepared by the method, and the present embodiment adopts the following method to prepare the catalyst:

[0051] (1) Grind the collected fly ash into fine powder, pass through an 80-mesh sieve, take 200 g of the fine powder and place it in a muffle furnace, roast at 600 ° C for 4 hours, wash and dry with water, and add a concentration of 5wt% nitric acid 6 g of the solution was extruded, and then calcined at 500 °C for 3 h to obtain a pretreated carrier;

[0052] (2), take 8.2 mL of cobalt nitrate aqueous solution containing 0.5 g / mL cobalt, 11.8 mL manganese nitrate aqueous solution containing 0.5 g / mL manganese, 13.6 mL copper nitrate aqueous solution containing 0.5 g / mL copper, and 0.5 g / mL iron containing 14.4mL of ferric nitrate aqueous solution and 212.3mL of calcium nitrate aqueous soluti...

Embodiment 2

[0054] The present embodiment is used to illustrate the preparation method of the ozone catalytic oxidation catalyst of the present invention and the ozone catalytic oxidation catalyst prepared by the method, and the present embodiment adopts the following method to prepare the catalyst:

[0055] (1) Grind the collected fly ash into fine powder, pass through a 200-mesh sieve, take 200 g of the fine powder and place it in a muffle furnace, roast it at 700 ° C for 5 hours, wash and dry it, and add a concentration of 5wt% nitric acid The solution was 8g, extruded, and then calcined at 550°C for 4h to obtain a pretreated carrier;

[0056] (2), using ultraviolet modified lamp radiation treatment above-mentioned pretreatment carrier, ultraviolet modified lamp power 250W, dominant wavelength 365nm, irradiation time 6h, obtain the carrier of ultraviolet radiation modification;

[0057] (3), take 10.4 mL of cobalt nitrate aqueous solution containing 0.5 g / mL cobalt, 10.2 mL manganese n...

Embodiment 3

[0059] The present embodiment is used to illustrate the preparation method of the ozone catalytic oxidation catalyst of the present invention and the ozone catalytic oxidation catalyst prepared by the method, and the present embodiment adopts the following method to prepare the catalyst:

[0060] (1) Grind the collected fly ash into fine powder, pass through a 200-mesh sieve, take 200 g of the fine powder and place it in a muffle furnace, roast it at 700 ° C for 5 hours, wash and dry it, and add a concentration of 5wt% nitric acid 10 g of the solution was extruded, and then calcined at 500 °C for 3 h to obtain a pretreated carrier;

[0061] (2), using ultraviolet modified lamp radiation treatment above-mentioned pretreatment carrier, ultraviolet modified lamp power 500W, dominant wavelength 365nm, irradiation time 12h, obtain the carrier of ultraviolet radiation modification;

[0062] (3), take 11.6 mL of cobalt nitrate aqueous solution containing 0.5 g / mL cobalt, 11.6 mL mang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com