Ultrahigh-strength high-conductivity copper alloy and preparation method thereof

A high-conductivity, copper alloy technology, applied in the direction of metal/alloy conductors, etc., can solve the problems of unable to meet the needs of ultra-high strength, the conductivity is only 10%, and the preparation method is complicated, saving energy consumption, easy to burn Control and improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

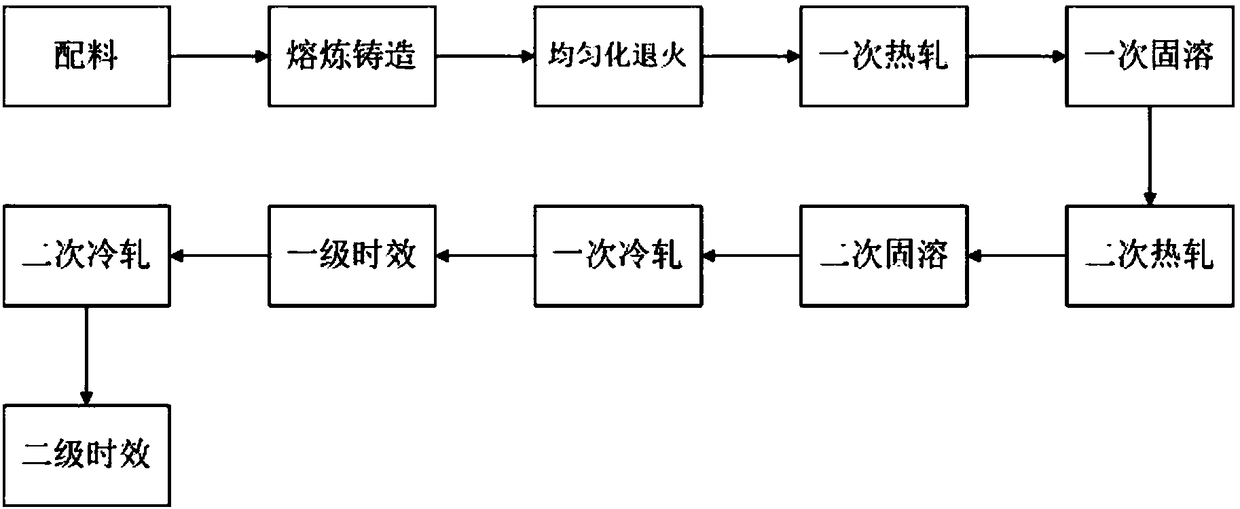

Method used

Image

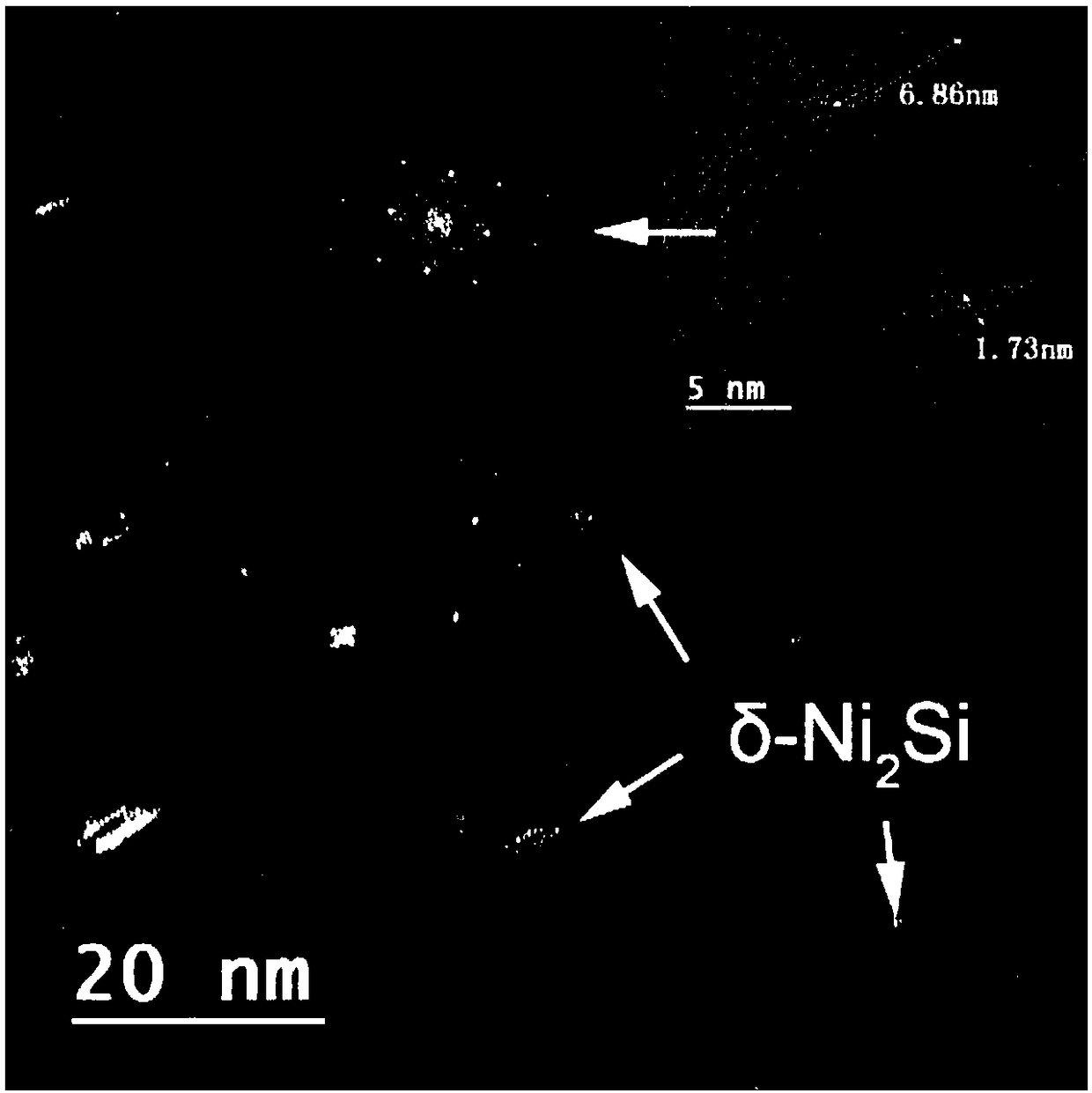

Examples

Embodiment 1

[0039] (1) According to the composition of the alloy, it is Ni5.0wt%, Co 1.5wt%, Si 1.2wt%, Mg 0.14wt%, Sr0.05wt%, Nb 0.05wt%, and the balance is Cu to carry out batching, and add covering agent ( The mass ratio of cryolite, industrial soda ash, fluorite and charcoal is 15%: 20%: 15%: 50%). After mixing evenly, put it into an induction melting furnace, and then smelt it in the atmosphere and at a temperature of 1300°C. Add the covering agent again when the metal starts to melt, and carry out mechanical stirring. After the smelting is completed and the slag is removed, a copper alloy melt with uniform and stable composition is obtained, and the alloy yield is 86%;

[0040] (2) The copper alloy melt is cast at a temperature of 1280°C, and then cooled in air;

[0041] (3) Under a nitrogen atmosphere, the temperature is controlled to be 920° C., and a homogenizing annealing treatment is performed for 4 hours to obtain a homogenized copper alloy ingot;

[0042] (4) hot-roll the ho...

Embodiment 2

[0054] (1) According to the alloy composition, it is Ni 5.4wt%, Co 1.3wt%, Si 1.0wt%, Mg 0.15wt%, Sr0.05wt%, Nb 0.05wt%, and the balance is Cu to carry out batching, and add covering agent ( The mass ratio of cryolite, industrial soda ash, fluorite and charcoal is 15%: 20%: 15%: 50%). After mixing evenly, put it into the induction melting furnace, and then melt it in the atmosphere and the temperature of 1320°C. Add the covering agent again when the metal starts to melt, and carry out mechanical stirring. After the smelting is completed and the slag is removed, a copper alloy melt with uniform and stable composition is obtained, and the alloy yield is 88%;

[0055] (2) The copper alloy melt is cast at a temperature of 1280°C, and then cooled in air;

[0056] (3) Under a nitrogen atmosphere and a temperature of 980° C., perform a homogenizing annealing treatment for 2 hours to obtain a homogenized copper alloy ingot;

[0057] (4) hot-roll the homogenized copper alloy ingot on ...

Embodiment 3

[0069] (1) According to the composition of the alloy: Ni 4.8wt%, Co 1.0wt%, Si 1.0wt%, Mg 0.15wt%, Sr0.05wt%, Nb 0.05 and the balance is Cu for batching, and add a covering agent, mix well Put it into an induction melting furnace, then smelt it in the atmosphere and at a temperature of 1300°C, and add the covering agent again when the metal starts to melt (the mass ratio of cryolite, industrial soda ash, fluorite and charcoal is 10%: 15%: 15%:60%), and carry out mechanical stirring, after smelting is completed and slag removal, obtain the copper alloy melt with uniform and stable composition, the alloy yield is 85%;

[0070] (2) The copper alloy melt is cast at a temperature of 1280°C, and then cooled in air;

[0071] (3) Under a nitrogen atmosphere and a temperature of 950° C., perform a homogenizing annealing treatment for 6 hours to obtain a homogenized copper alloy ingot;

[0072](4) The homogenized copper alloy ingot is hot-rolled on an ordinary two-roll rolling mill, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com