PVC cable sheath material and preparation method thereof

A technology of cable sheath material and PVC resin, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of environmental and human health damage, achieve short biodegradation cycle, good mechanical processing performance, and easy The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

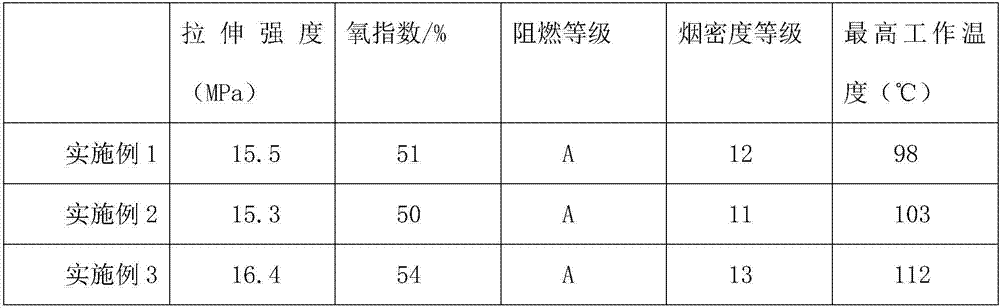

Examples

Embodiment 1

[0023] A PVC cable sheathing material is made of the following raw materials in parts by weight:

[0024] 50 parts of PVC resin, 5 parts of natural rubber, 5 parts of butadiene rubber, 5 parts of polyethylene, 1 part of fumed silica, 1 part of glass fiber, 2 parts of graphene, 1.5 parts of impact modifier, 5 parts of nano titanium dioxide powder 1 part, heat stabilizer 1 part, plasticizer 4 parts, accelerator 4 parts, barium oxide 2 parts, coupling agent 3 parts, calcium oxide 4 parts, perlite 5 parts, lubricant 5 parts, diammonium phosphate 3 parts , 3 parts of zinc borate.

[0025] The plasticizer is citrate.

[0026] The accelerator is vulcanization accelerator M.

[0027] The preparation method of described a kind of PVC cable sheath material, comprises the steps:

[0028] (1) PVC resin, natural rubber, butadiene rubber, polyethylene, fumed white carbon black, glass fiber, graphene, nanometer titanium dioxide powder, perlite and lubricant are put into agitator and stirr...

Embodiment 2

[0031] A PVC cable sheathing material is made of the following raw materials in parts by weight:

[0032] 60 parts of PVC resin, 10 parts of natural rubber, 10 parts of butadiene rubber, 10 parts of polyethylene, 4 parts of fumed silica, 2 parts of glass fiber, 5 parts of graphene, 3 parts of impact modifier, 10 parts of nano titanium dioxide powder 4 parts, heat stabilizer 4 parts, plasticizer 8 parts, accelerator 6 parts, barium oxide 5 parts, coupling agent 5 parts, calcium oxide 8 parts, perlite 15 parts, lubricant 10 parts, diammonium phosphate 6 parts , 6 parts of zinc borate.

[0033] The plasticizer is citrate.

[0034] The accelerator is vulcanization accelerator M.

[0035] The preparation method of described a kind of PVC cable sheath material, comprises the steps:

[0036] (1) PVC resin, natural rubber, butadiene rubber, polyethylene, fumed white carbon black, glass fiber, graphene, nanometer titanium dioxide powder, perlite and lubricant are put into agitator a...

Embodiment 3

[0039] A PVC cable sheathing material is made of the following raw materials in parts by weight:

[0040] 55 parts of PVC resin, 8 parts of natural rubber, 8 parts of butadiene rubber, 8 parts of polyethylene, 3 parts of fumed silica, 1.5 parts of glass fiber, 3.5 parts of graphene, 2 parts of impact modifier, 7 parts of nano titanium dioxide powder 2.5 parts of heat stabilizer, 6 parts of plasticizer, 5 parts of accelerator, 3.5 parts of barium oxide, 4 parts of coupling agent, 6 parts of calcium oxide, 10 parts of perlite, 8 parts of lubricant, 4.5 parts of diammonium phosphate , 4.5 parts of zinc borate.

[0041] The plasticizer is citrate.

[0042] The accelerator is vulcanization accelerator M.

[0043] The preparation method of described a kind of PVC cable sheath material, comprises the steps:

[0044] (1) PVC resin, natural rubber, butadiene rubber, polyethylene, fumed white carbon black, glass fiber, graphene, nanometer titanium dioxide powder, perlite and lubrican...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com