Water soluble microsphere preparation method and application thereof

A water-soluble, microsphere technology, applied in the field of materials, can solve the problems of high non-specific adsorption, high toxicity, inactivation of biologically active macromolecules, etc., and achieve good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A preparation method of water-soluble microspheres, comprising the steps of:

[0043] (1) Preparation of coarse emulsion: dissolving oil-soluble nanoparticles in an organic solvent to obtain an oil phase, dissolving water-soluble biomacromolecules containing mercapto groups or disulfide bonds into water to obtain a water phase, and pre-mixing the oil-water two-phase, A crude emulsion is obtained.

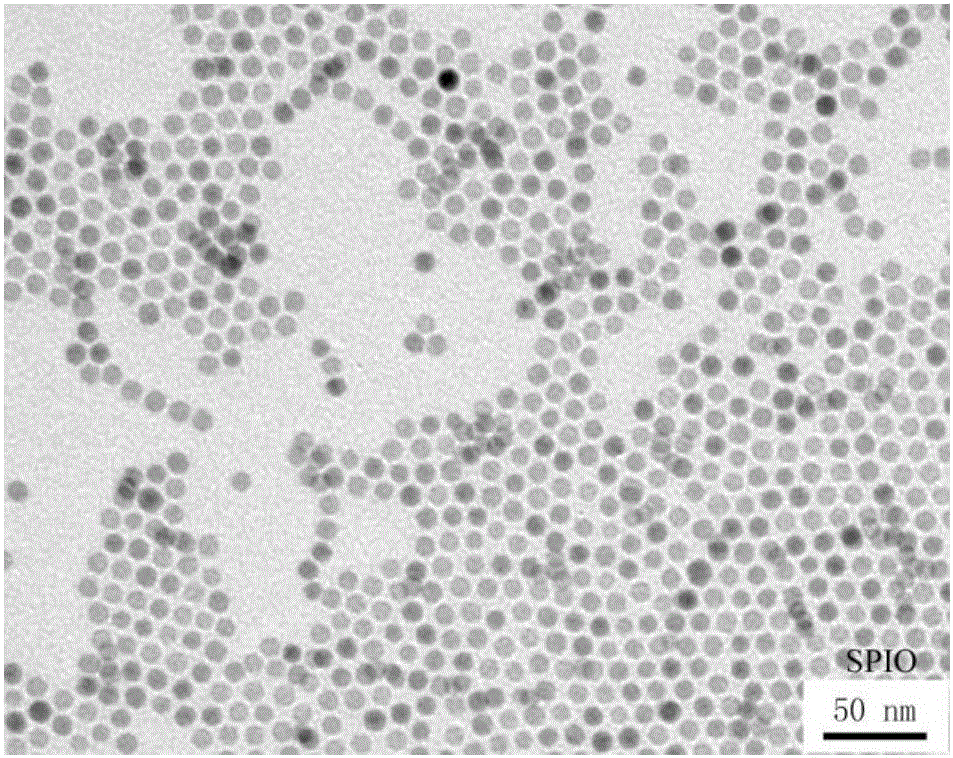

[0044] Wherein, the nanoparticles can be oil-soluble superparamagnetic nanoparticles, such as ferric oxide nanoparticles, ferric oxide nanoparticles or other doped iron oxide nanoparticles; the organic solvent is chloroform, dichloromethane, formic acid Ethyl ester, ethyl acetate, n-hexane, cyclohexane, or their mixtures, while containing absolute ethanol as a co-emulsifier; biomacromolecules contain immunoglobulin, albumin, hemoglobin, casein, collagen, Mixing of one or more kinds of enzymes, such as serum, ascites, milk and other biological fluids; the method of premixing ...

Embodiment 1

[0055] A method for preparing water-soluble magnetic microspheres wrapped by biomacromolecules, comprising the following steps:

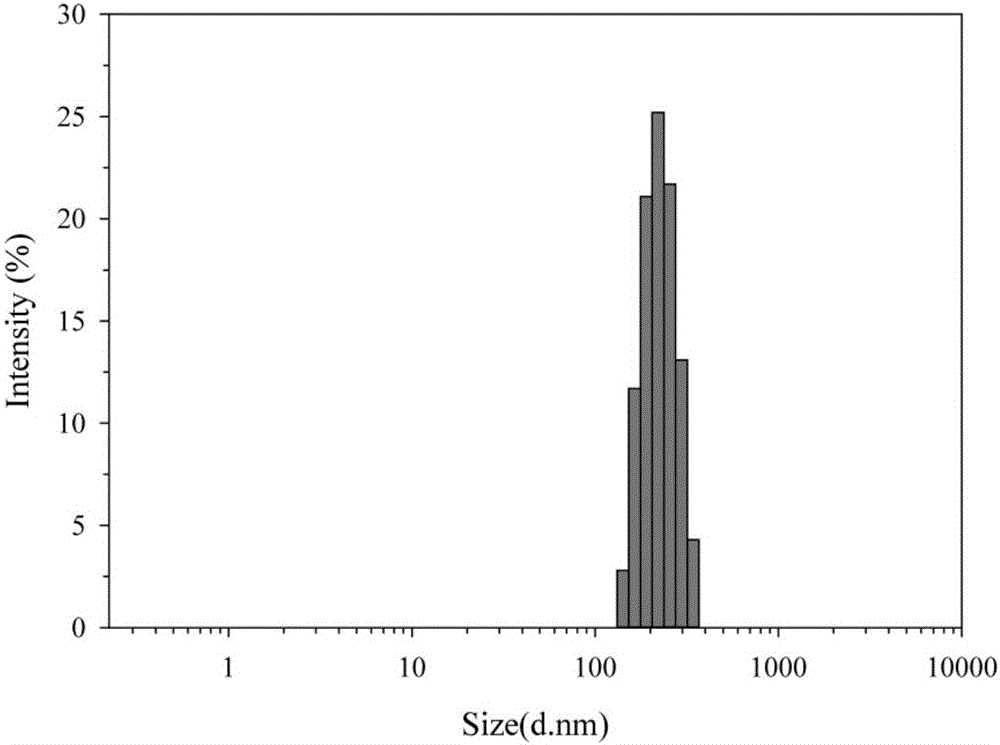

[0056] (1) Preparation of coarse emulsion: 0.6 mL of chloroform dissolved with 140 mg / mL of superparamagnetic iron oxide nanoparticles, 0.06 mL of absolute ethanol, and 30 mL of an aqueous solution of 4.4 g / L bovine serum albumin were mixed evenly, and superparamagnetic The mass ratio of iron oxide to bovine serum albumin is 1:1.57, and the volume ratio of oil-water two-phase is 1:44.

[0057] (2) Cavitation cross-linking reaction: use a high-shear dispersing emulsifier (FLUKO FA25, Shanghai Fluke Fluid Machinery Manufacturing Co., Ltd.) to process the coarse emulsion prepared in step (1) through 10000 rpm high-shear for 30s, and then In a high-pressure homogenizer (JNBIOJN-02HC, Guangzhou Juneng Biotechnology Co., Ltd.), a uniform microemulsion was formed after 600 bar high-pressure homogenization once.

[0058] (3) Separation and purification: Fi...

Embodiment 2-14

[0062] A method for preparing water-soluble magnetic microspheres wrapped by biomacromolecules, preparing water-soluble magnetic microspheres wrapped by biomacromolecules according to the experimental conditions of Examples 2-14 in Table 1, comprising the following steps:

[0063] (1) Preparation of coarse emulsion: 0.6-4.1 mL of chloroform dissolved with 16.7-180 mg / mL superparamagnetic iron oxide nanoparticles, 0.06-0.41 mL of absolute ethanol, and an aqueous solution of 0.5-250 g / L bovine serum albumin Mix 30mL, the mass ratio of superparamagnetic iron oxide to bovine serum albumin is 1:1.25-20, and the volume ratio of oil-water two-phase is 1:5-200.

[0064] (2) Cavitation cross-linking reaction: use a high-shear dispersing emulsifier (FLUKO FA25, Shanghai Fluke Fluid Machinery Manufacturing Co., Ltd.) to process the coarse emulsion obtained in step (1) through 10000-16000 revolutions per minute high-shear 30-90s, and then in a high-pressure homogenizer (JNBIO JN-02HC, Gua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com