Aluminum oxide base polishing solution for sapphire substrate polishing and preparation method thereof

A technology of alumina and polishing liquid, applied in polishing compositions containing abrasives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

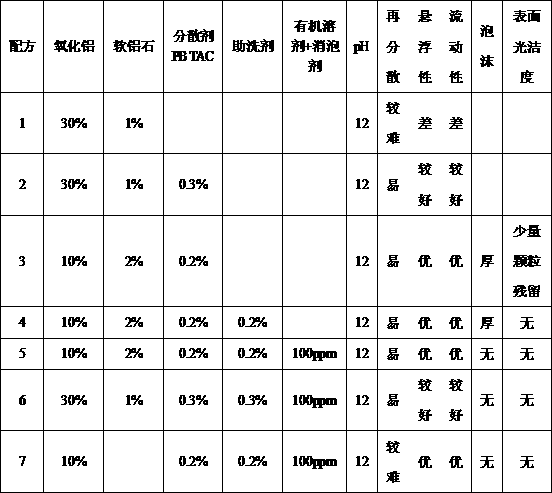

Examples

Embodiment 1

[0022] 1) Add 300g of 3μm ɑ-type alumina powder and 10g of boehmite powder into 650ml of deionized water at a constant speed, disperse at high speed at 1000rpm for 20 minutes to form a uniform slurry, and add triethanolamine to adjust the pH value to 10.5, and then adjust the pH value to 11.5 with potassium hydroxide; 2) Use 0.5mm yttrium-stabilized zirconia ball milling beads, and enter the sand mill at a flow rate of 5kg / min for ball milling until the average particle size is 0.1-0.5μm; 3) Continue to adjust the pH to 12 with potassium hydroxide; 4) Finally, filter and fill the slurry with a 500-mesh filter bag.

Embodiment 2

[0024] 1) Add 300g of 3μm ɑ-type alumina powder and 10g of boehmite powder into 650ml of deionized water at a constant speed and disperse at high speed at 1000rpm for 20 minutes to form a uniform slurry, slowly add 3g of dispersant organic Phosphoric acid PBTCA, continue to stir for 20 minutes, add triethanolamine to adjust the pH value to 10.5, and then use potassium hydroxide to adjust the pH value to 11.5; 2) Use 0.5mm yttrium-stabilized zirconia ball milling beads, and enter the sand mill at a flow rate of 5kg / min for ball milling , until the average particle size is 0.1-0.5um; 3) Continue to adjust the pH to 12 with potassium hydroxide; 4) Finally, filter and fill the slurry with a 500-mesh filter bag.

Embodiment 3

[0026] 1) Add 100g of 3μm ɑ-type alumina powder and 20g of boehmite powder into 850ml of deionized water at a constant speed and disperse at high speed at 1000rpm for 20 minutes to form a uniform slurry, slowly add 2g of dispersant organic Phosphoric acid PBTCA, continue to stir for 20 minutes, add triethanolamine to adjust the pH value to 10.5, and then use potassium hydroxide to adjust the pH value to 11.5; 2) Use 0.5mm yttrium-stabilized zirconia ball milling beads, and enter the sand mill at a flow rate of 5kg / min for ball milling , until the average particle size is 0.1-0.5 μm; 3) Continue to adjust the pH to 12 with potassium hydroxide; 4) Finally, filter and fill the slurry with a 500-mesh filter bag.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com