Polycrystalline black silicon texturization treatment fluid, polysilicon chip texturization method applying treatment fluid, and polycrystalline black silicon texturization product

A polycrystalline silicon wafer and treatment liquid technology, applied in the directions of post-processing, post-processing details, polycrystalline material growth, etc., can solve the problems of the surface area and uniformity need to be improved, the texturing reaction process is not easy to control, the minority carrier compound is serious, etc. The effect of enhanced light effect, low cost and high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

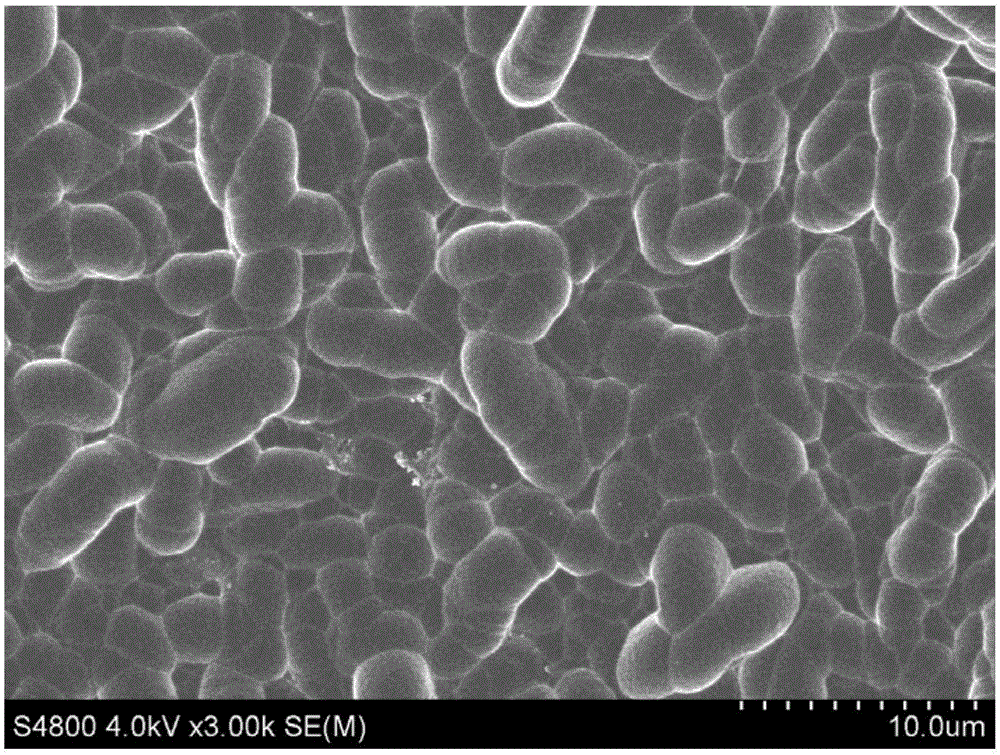

[0075] Mix 50wt% hydrofluoric acid solution, 65wt% nitric acid solution and water at a volume ratio of 1:6:10 to obtain hydrofluoric acid nitric acid texturing solution. The polysilicon wafer cut by mortar is placed in hydrofluoric acid nitric acid texturizing solution for texturing treatment. The time of the texturing treatment is 100 seconds, and the temperature of the texturing treatment is 12°C. Then rinse with deionized water for 2 minutes. figure 1 It is the scanning electron micrograph of the textured silicon wafer textured product.

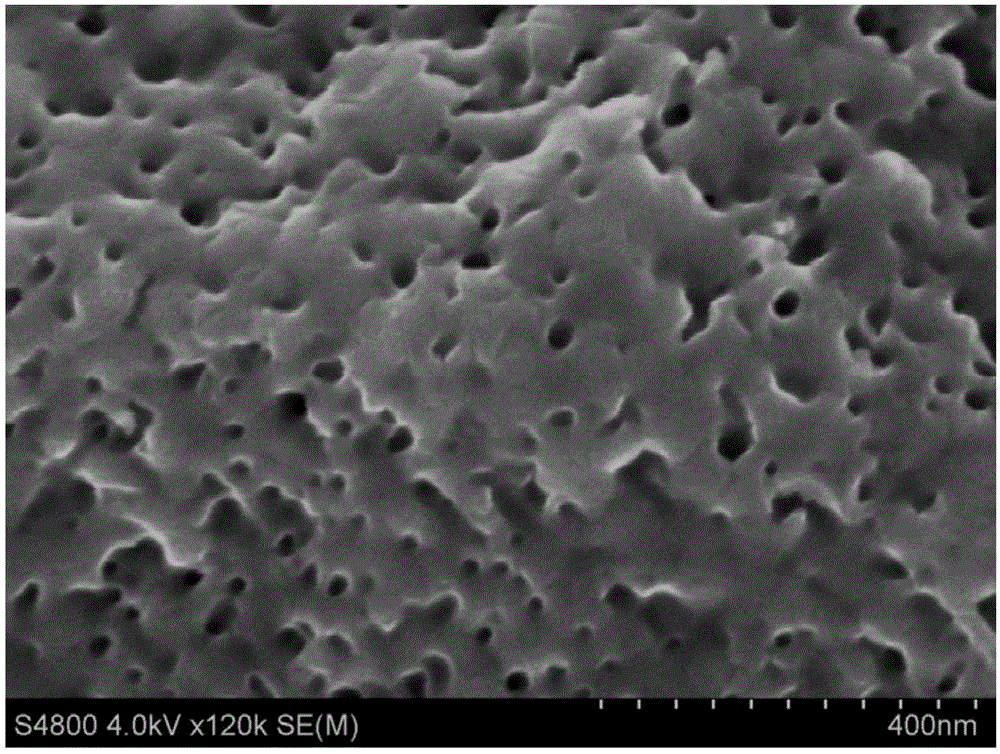

[0076] Putting the textured silicon chip into the polycrystalline black silicon texturing solution for black silicon treatment, so as to form a uniform porous structure on the surface of the silicon chip. The polycrystalline black silicon texturing treatment solution includes 50wt% hydrofluoric acid solution, 30wt% hydrogen peroxide solution and silver nitrate. Wherein, the volume ratio of the hydrofluoric acid solution and the hydrogen...

Embodiment 2

[0079] Mix 40wt% hydrofluoric acid solution, 68wt% nitric acid solution and water at a volume ratio of 3:8:10 to obtain hydrofluoric acid nitric acid texturing solution. The polysilicon wafer cut by mortar is placed in hydrofluoric acid nitric acid texturizing solution for texturing treatment. The time of the texturing treatment is 150 seconds, and the temperature of the texturing treatment is 10°C. Then rinse with deionized water for 2 minutes.

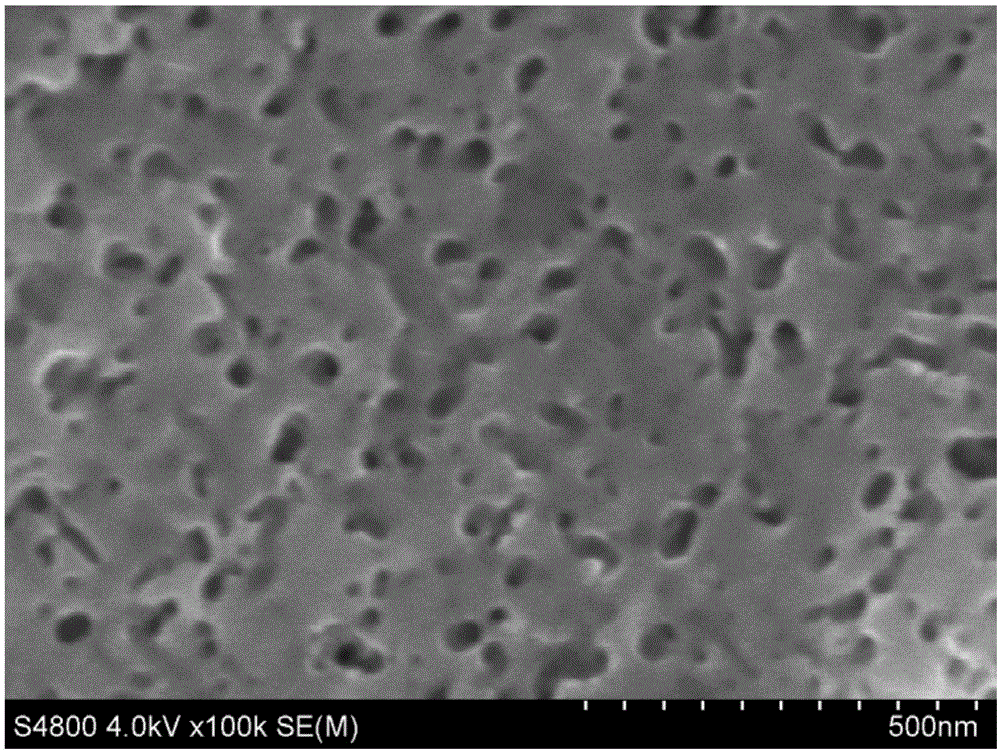

[0080] Putting the textured silicon chip into the polycrystalline black silicon texturing solution for black silicon treatment, so as to form a uniform porous structure on the surface of the silicon chip. The polycrystalline black silicon texturing treatment liquid includes 40wt% hydrofluoric acid solution, 30wt% hydrogen peroxide solution and copper nitrate. Wherein, the volume ratio of the hydrofluoric acid solution and the hydrogen peroxide solution is 5:30, and the molar concentration of copper nitrate in the polycrystalline bl...

Embodiment 3

[0083] Mix 40wt% hydrofluoric acid solution and 30wt% hydrogen peroxide solution at a volume ratio of 3:20, and add silver nitrate to obtain a texturing pretreatment solution. The concentration of silver nitrate in the texturing pretreatment liquid is 100 μmol / L, the reaction time is 65 seconds, and the reaction temperature is 20° C.

[0084] The diamond-wire-cut polysilicon wafer is placed in a texturing pretreatment solution for pretreatment, the pretreatment temperature is 25° C., and the pretreatment time is 1 minute. Then rinse with deionized water for 2 minutes.

[0085] Mix 40wt% hydrofluoric acid solution, 68wt% nitric acid solution and water at a volume ratio of 5:8:15 to obtain hydrofluoric acid nitric acid texturing solution. The polysilicon wafer cut by mortar is placed in hydrofluoric acid nitric acid texturizing solution for texturing treatment. The time of the texturing treatment is 120 seconds, and the temperature of the texturing treatment is 6°C. Then rins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com