Method for fine-hair maring using monocrystalline silicon slice

A monocrystalline silicon wafer and texturing technology, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve the problems of large cone structure size, small short-circuit current, and difficult control, and achieve a cone structure The effects of fine size, improved photoelectric conversion rate, and reduced wafer thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

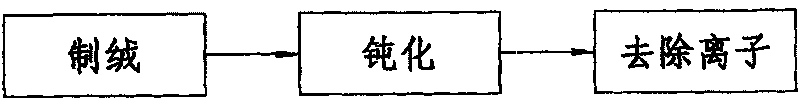

[0021] refer to figure 1 , a method for texturing monocrystalline silicon wafers of the present invention includes corrosion texturing, passivation, and ion removal, wherein: the corrosion texturing is as follows: the single crystal silicon wafers to be texturized after cleaning are placed in a container There are 0.8% by weight of analytically pure sodium hydroxide NaOH, 5.3% of electronic grade isopropanol C 3 h 3 O, 1.4% analytically pure sodium silicate Na 2 SiO 3 9H 2 O, 92.5% pure water H 2 In the texturing tank of the texturing liquid composed of O, under the conditions of 88°C±2°C liquid temperature, one atmospheric pressure, and 0.15MPa nitrogen microbubble stirring, the texturing is etched for 25 to 35 minutes, and formed on the surface of the monocrystalline silicon wafer. The operation process of the textured surface of the microcone structure; the passivation is that the monocrystalline silicon chip after the corrosion making of the texture is placed in a con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com