A kind of reworking method of acid textured polycrystalline battery

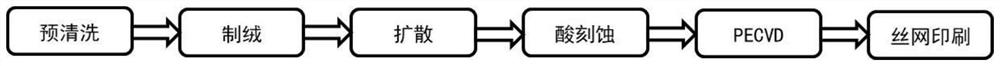

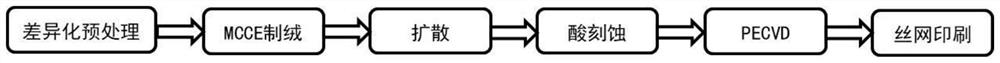

A technology of acid texturing and batteries, which is applied in the direction of polycrystalline material growth, chemical instruments and methods, sustainable manufacturing/processing, etc. It can solve the problems of appearance and color difference, achieve uniform suede, reduce state differences, and reduce the proportion of color difference films Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] For the reworked wafers produced in the texturing process, put them in a diffusion furnace for annealing treatment, set the temperature at 450°C, set the time for 20 minutes, and set the maximum nitrogen flow rate at 1000mL / min. Through this pretreatment, the residues on the surface of the silicon wafers after the first texturing process are removed. Organic matter, and then match the MCCE texturing process.

Embodiment 2

[0034] For the reworked sheet produced in the diffusion process, the phosphosilicate glass on the surface of the reworked sheet can be removed by HF solution, and the MCCE texturing is carried out after pretreatment, the HF volume concentration is 5%, and the reaction time is 150s.

Embodiment 3

[0036] For the reworked sheet produced in the PECVD process, the SiNx on the surface of the reworked sheet can be removed by HF / HCl mixed acid solution, and the MCCE texturing is performed after pretreatment, the volume concentration of HF is 2%, the volume concentration of HCl is 3%, and the reaction time is 300s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com