Harrow disc strip steel and production method and harrow disc heat treatment method

A heat treatment method and production method technology, which are applied to the heat treatment of rake blanks and the field of special hot-rolled strip steel for rake blades, can solve the problems of low impact toughness, poor toughness and plasticity of steel plates, and difficulty in replacement of rake blades, and achieve formability. Good wear resistance and toughness and plasticity, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with embodiment.

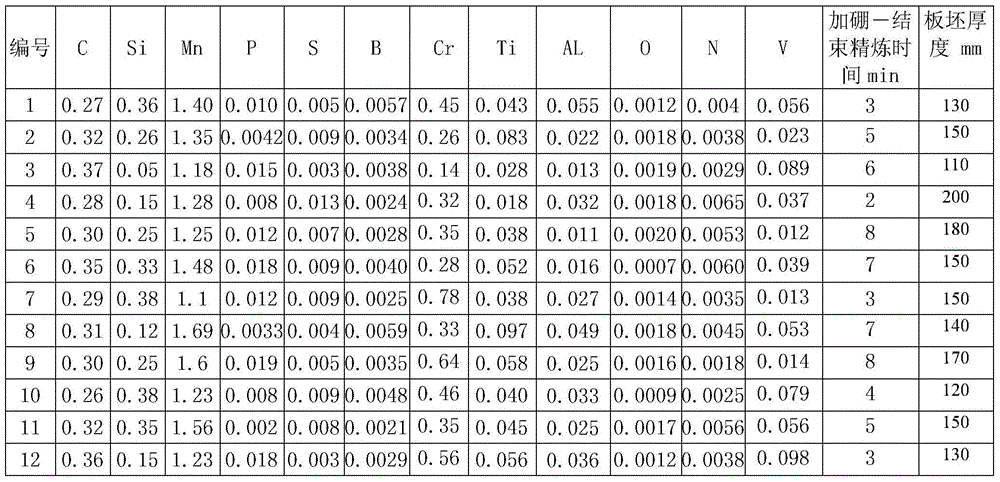

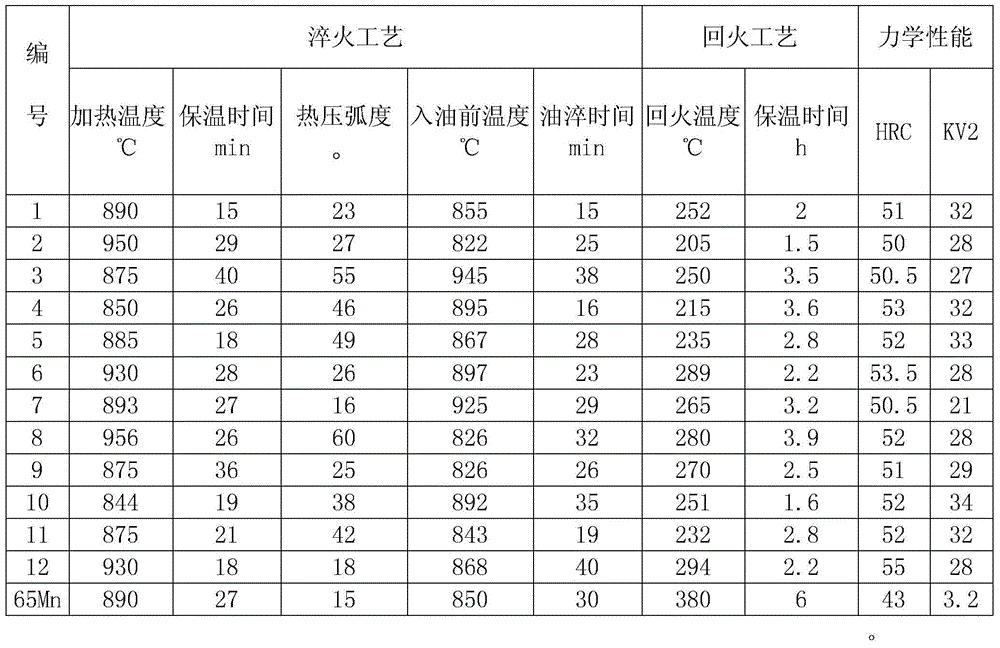

[0043] Table 1 shows the chemical composition wt% and process parameters of steel strips used for rakes in Examples 1-12.

[0044] Table 1 Embodiment 1~12 steel strip chemical composition wt% and process parameters

[0045]

[0046] The production method of strip steel for harrow slices includes converter smelting, electric furnace refining, slab continuous casting and rolling, ultra-rapid cooling, coiling and slow cooling processes.

[0047] In the refining process, first add deoxidizer to deoxidize, then add Ti and V microalloying nitrogen fixation, control O≤0.002%, N≤0.007%, add boron alloying in the later stage of refining, finish refining within 5-8 minutes after adding boron, and control steel Medium boron content.

[0048] After continuous casting, the slab does not go off the assembly line, but directly enters the heating furnace for heating.

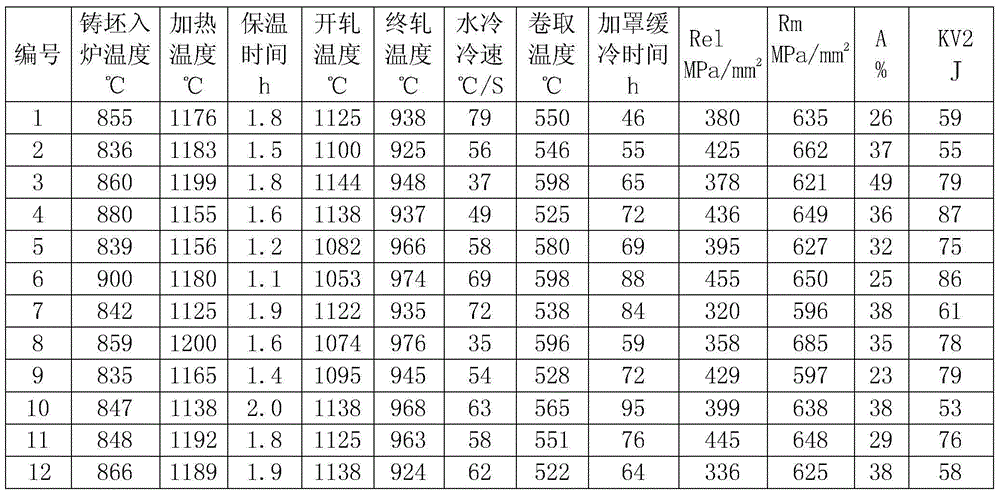

[0049] Table 2 is the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com