PEG (polyethylene glycol) in-situ covalent grafted alginate microcapsule as well as preparation and application thereof

A technology of alginate gel and alginate, which is applied in the direction of microcapsules, capsule delivery, medical preparations of non-active ingredients, etc., and can solve problems such as poor stability, inability to form PEG brush-like structures, and small exclusion volume , to achieve the effect of improving stability, good biocompatibility, and reducing entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

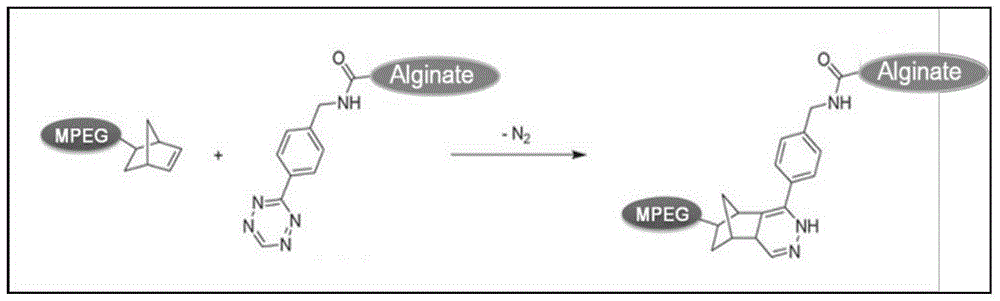

[0045] 1) Prepare the solution of azide modified alginate: use 4-aminomethyl-benzonitrile hydrochloride as raw material to synthesize 3-(4-aminomethylphenyl)-1,2,4,5- Tetrazine, molecular weight 187g / mol, sodium alginate molecular weight 350kDa, the terminal amino group of 3-(4-aminomethylphenyl)-1,2,4,5-tetrazine is combined with sodium alginate carboxyl group by amidation method The valence bond sum, the modification rate of sodium alginate is 9%, and the sodium alginate modified with azide is dissolved in physiological saline at a concentration of 15g / L.

[0046] 2) Preparation of chitosan solution: chitosan has a molecular weight of 65kDa, a degree of deacetylation of 90%, and is dissolved in a pH 6.5 sodium acetate / acetic acid buffer at a concentration of 5g / L.

[0047] 3) Preparation of PEG-modified olefin solution: PEG-NH 2 The degree of polymerization is 44, the molecular weight is 2kDa, and the PEG-NH 2 The terminal amino group is covalently bonded with the terminal carbox...

Embodiment 2

[0063] 1) Prepare the solution of azide modified alginate: sodium alginate has a molecular weight of 200kDa, and the terminal amino group of 3-(4-aminomethylphenyl)-1,2,4,5-tetrazine is combined with the amidation method The sodium alginate carboxyl group is covalently bonded, the sodium alginate modification rate is 15%, and the sodium alginate modified with azide is dissolved in physiological saline at a concentration of 25 g / L.

[0064] 2) Preparation of polyarginine solution: L-polyarginine has a molecular weight of 20 kDa and is dissolved in physiological saline with a concentration of 4 g / L and a concentration of 10 g / L.

[0065] 3) Preparation of PEG-modified olefin solution: PEG-NH 2 The molecular weight is 500Da, and PEG-NH is 2 The terminal amino group is covalently bonded with the terminal carboxyl group of 5-norbornene-2-carboxylic acid to obtain the olefin modified PEG, which is dissolved in physiological saline at a concentration of 25 g / L.

[0066] 4) Immerse the azide...

Embodiment 3

[0070] 1) Prepare a solution of azide modified alginate: Sodium alginate has a molecular weight of 500kDa, and the terminal amino group of 3-(4-aminomethylphenyl)-1,2,4,5-tetrazine is combined with the amidation method. Sodium alginate carboxyl groups are covalently bonded, and the modification rate of sodium alginate is 30%. Sodium alginate modified with azide is dissolved in physiological saline at a concentration of 10g / L.

[0071] 2) Preparation of α-polylysine solution: α-polylysine has a molecular weight of 20 kDa and is dissolved in physiological saline at a concentration of 5 g / L.

[0072] 3) Preparation of PEG-modified olefin solution: PEG-NH 2 The molecular weight is 10kDa, and the PEG-NH is 2 The terminal amino group is covalently bonded with the terminal carboxyl group of 5-norbornene-2-carboxylic acid to obtain the olefin modified PEG, which is dissolved in physiological saline at a concentration of 5 g / L.

[0073] 4) Immerse the azide-modified calcium alginate gel micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com