Amorphous diffusion alloy and preparation method thereof

A diffusion alloy and amorphous technology, applied in the field of powder metallurgy, can solve the problems of tensile fatigue resistance, low wear resistance and heat resistance, high cost of precious metal addition, and low impact resistance, so as to improve impact resistance and maintain comprehensive mechanical properties. performance, the effect of increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

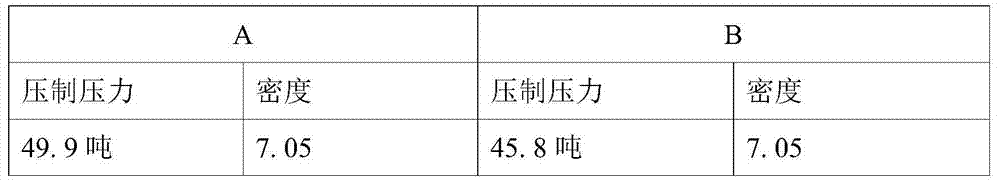

Examples

Embodiment 1

[0029] An amorphous diffusion alloy made from the following raw materials:

[0030] Nickel-coated titanium carbide 5%, boron carbide 2.5%, mixed rare earth 5%, titanium iron powder 5%, superfine high carbon ferrochrome powder 5%, silicon carbide whisker 4%, boron nitride 0.6%, lanthanum oxide 0.2% , oxygen cerium 0.2%, pickaxe 0.1%, copper powder 4%, high nitrogen ferrochrome 2%, cobalt powder 5%, manganese powder 4%, tungsten powder 4%, nano-titanium oxide 0.8%, superfine iron powder balance . The mixed rare earths are heavy rare earths. The ultra-fine high-carbon ferrochrome powder and the ultra-fine iron powder are powders of more than 500 mesh.

[0031] The preparation method of above-mentioned amorphous diffusion alloy comprises the following steps:

[0032] ① Ingredients

[0033] Take the raw material according to the above weight percentage;

[0034] ② scattered

[0035] Mix the raw materials weighed in step S1 by high-speed dry powder mixing for 20 minutes, high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com