Halogen-free flame retardant wood-plastic composite material and preparation method thereof

A technology of wood-plastic composite materials and plastics, which is applied in the field of halogen-free flame-retardant wood-plastic composite materials and its preparation, can solve the problems of large influence on material color, reduced flammability, and small smoke emission, and achieves good mechanical properties and high The effect of flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

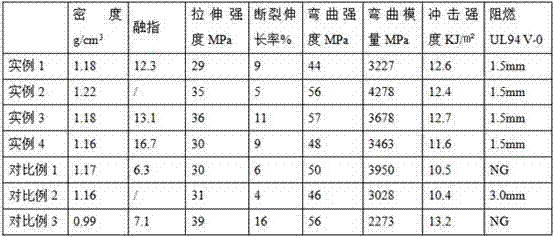

Examples

preparation example Construction

[0030] A preparation method of a halogen-free flame-retardant wood-plastic composite material, the steps are as follows:

[0031] a. Pre-drying the natural fibers;

[0032] b. Mix the dried natural fiber and coupling agent evenly and leave it for 3-10 minutes, then fully mix the mixture with flame retardant, plastic, compatibilizer, lubricant and antioxidant;

[0033] c. Extrusion plasticization, pelletizing, injection molding.

Embodiment 1

[0036] Raw materials for the preparation of halogen-free flame-retardant wood-plastic composites (percentage by weight, the same below): poplar wood powder 20%, homopolypropylene 31%, ammonium polyphosphate (model: PreniphorTM EPFR-APP222) 20%, aluminum hypophosphite 10% %, melamine 7%, maleic anhydride grafted polypropylene (graft rate: 0.9~1.1MA%) 6%, tetrakis(3,5-di-tert-butyl-4-hydroxy)pentaerythritol phenylpropionate 0.5%, 1.5% of ethylene bisstearamide, 3% of polyethylene wax, and 1% of vinyl triethoxysilane, according to the preparation method of the present invention, the halogen-free flame-retardant wood-plastic composite material of the present invention is obtained .

[0037] Specifically: first, dry the above-mentioned wood powder in an oven at 105°C for 4 hours, then add vinyltriethoxysilane to the above-mentioned dried wood powder and mix evenly, and then add ammonium polyphosphate and hypophosphorous acid after standing for 5 minutes. Compound flame retardant m...

Embodiment 2

[0039] The raw materials for the preparation of the halogen-free flame-retardant wood-plastic composite material according to the present invention include the following components and weight percentages: elm wood powder 40%, high-density polyethylene (HDPE) 21%, ammonium polyphosphate (model: PreniphorTM EPFR-APP222) 17%, melamine phosphate 5%, aluminum hydroxide 3%, maleic anhydride grafted polyethylene (graft rate: 1.2%) 4%, phosphite antioxidant TNPP 0.5%, ethylene Based on 1.5% of bis stearamide, 3% of polyethylene wax, and 1% of vinyl trimethoxysilane, according to the preparation method of the present invention, the halogen-free flame-retardant wood-plastic composite material of the present invention is obtained.

[0040]Specifically: first, dry the above-mentioned wood powder in an oven at 95°C for 6 hours, then add vinyltrimethoxysilane to the above-mentioned dried wood powder and mix evenly, and then add ammonium polyphosphate and melamine phosphate after standing for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grafting rate | aaaaa | aaaaa |

| Grafting rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com