A kind of preparation method of bulge sample of layered electromagnetic thin film functional material

A thin-film material and thin-film technology, which is applied in the field of preparation of layered electromagnetic thin film bulging samples, can solve the problems of small thickness of brittle pure films, difficult to apply directly, and difficult to directly apply bulging mechanical experimental test, etc. Simple, low-corrosion-condition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

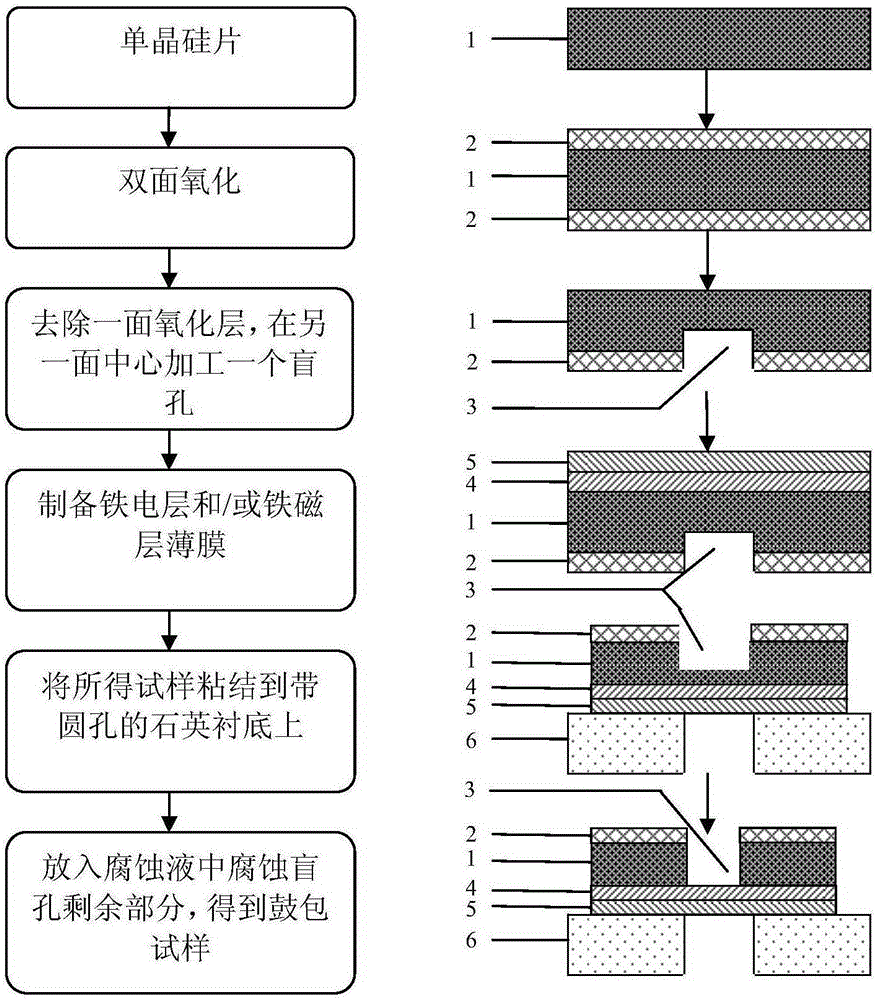

[0040] (1) Cut the 4-inch monocrystalline silicon wafer polished on one side into small square pieces, and then carry out high-temperature wet oxidation for 5 hours, and the oxidation temperature is 800°C. A layer of dense silicon dioxide 2 is formed on the upper and lower surfaces of the single crystal silicon wafer 1; the silicon dioxide 2 on a certain surface of the single crystal silicon wafer 1 is removed by grinding with metallographic sandpaper, and then cleaned with 40% hydrofluoric acid, Polished with 0.5 μm diamond micropowder. The silicon dioxide 2 on the other surface of the monocrystalline silicon wafer 1 remains.

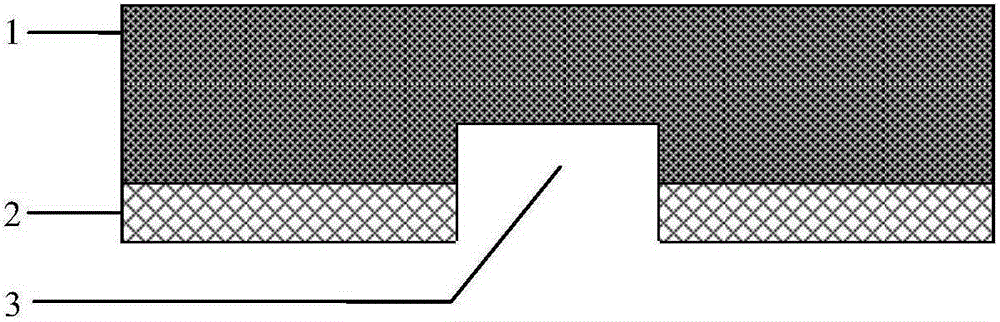

[0041] (2) Use a micro-drilling machine with a diamond drill bit to gently and repeatedly grind and drill the center of the surface of the remaining silicon dioxide layer 2 to form a blind hole 3 with a diameter of 2 mm and a depth of 100 μm to 200 μm. The diameter and depth of the blind holes 3 can be changed as required, and can also be designed as...

Embodiment 2

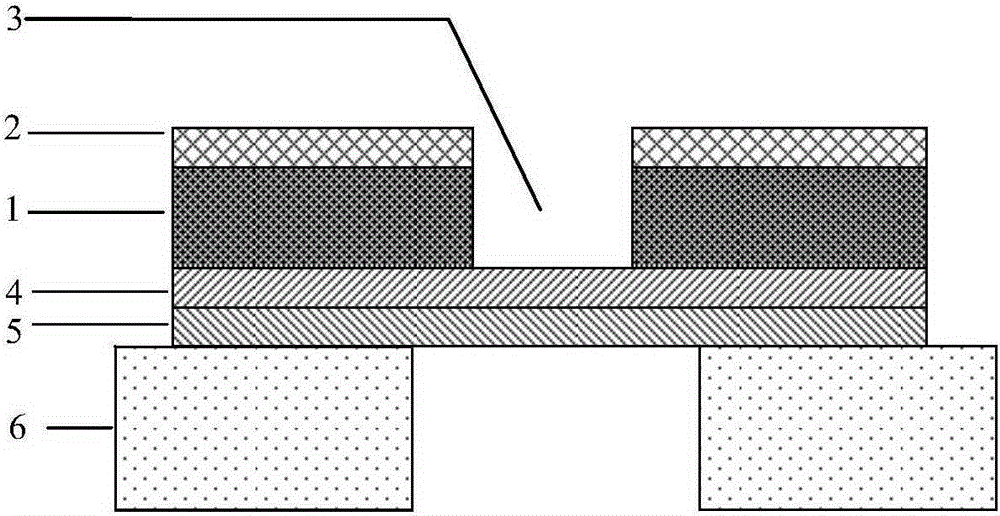

[0047] In this embodiment, the preparation method of the layered electromagnetic thin film bulge sample is basically the same as that in Example 1, except that in step (3) the sol-gel method is used in step (2) to obtain the single Bismuth sodium titanate ferroelectric thin film was prepared on the polished side of the crystalline silicon wafer. The number of homogenization times was 8, the heat treatment temperature was 420°C, and the annealing temperature was 700°C. The final film thickness obtained is 360nm, and the morphology of the obtained bismuth sodium titanate ferroelectric film is as follows: Figure 4 Shown, this is that steps (1), (2), (4), (5) and (6) in the embodiment are the same as in Example 1, and are prepared as image 3 Shown is a bulged specimen of layered electromagnetic material.

Embodiment 3

[0049] In the present embodiment, the preparation method of the layered electromagnetic thin film bulging sample is basically the same as that in Example 1, except that in step (4), heat-resistant and corrosion-resistant epoxy resin is used to seal the sample in step (4). ) to prepare the resulting sample; select 25% potassium hydroxide solution in step (5) and step (6), and the corrosion temperature is 40°C. All the other steps (1), (2), (3) and (4) are identical with embodiment 1, prepare as image 3 Shown is a bulged specimen of layered electromagnetic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com