Method for molding coaxial dielectric filter green body

A technology of dielectric filter and molding method, which is applied in the field of green body molding, can solve problems such as unstable performance, poor operability, and low flexibility, and achieve the effect of process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

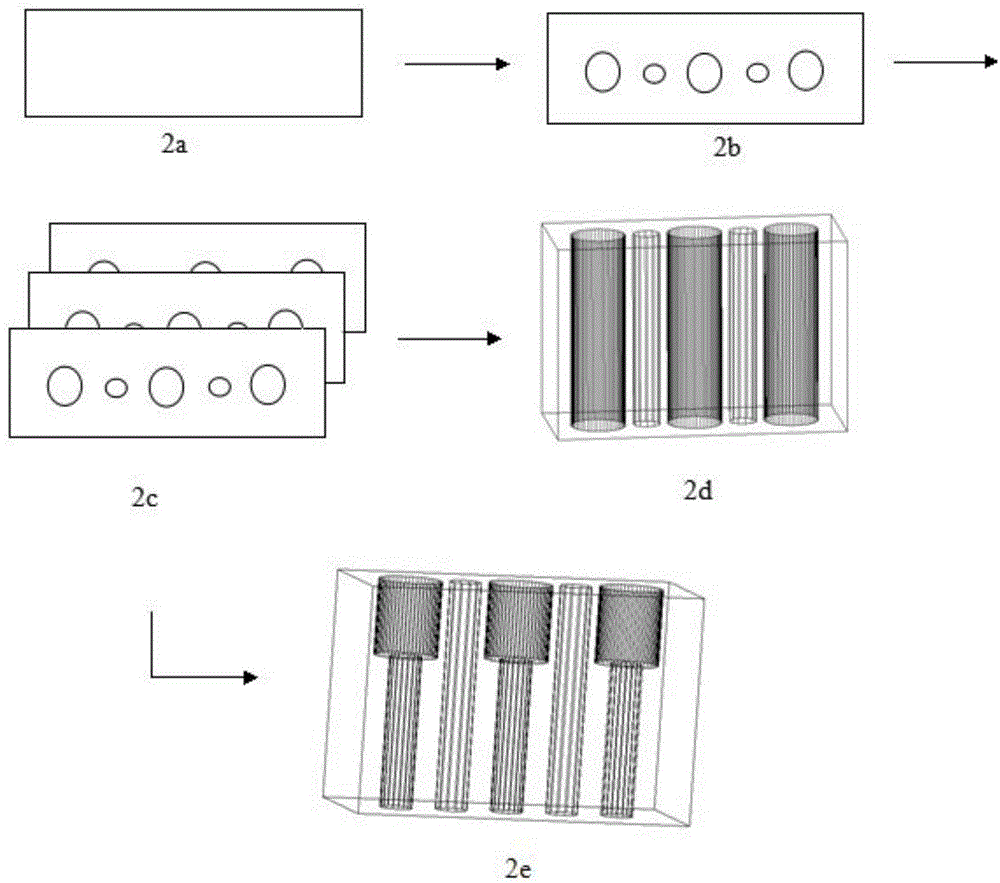

[0020] The present invention provides an effective preparation method for a ceramic device body with a complex structure, the preparation method comprising:

[0021] (1) Design the target component structure and size, consider the 20% to 30% shrinkage of the material after sintering and debinding, and convert the target component size into the green body size.

[0022] (2) Mix the prepared microwave dielectric ceramic powder (A) with a group of organic matter (B) by ball milling to prepare a slurry with high solid phase content and moderate viscosity, defoaming and casting to prepare a slurry with a thickness of 0.5 ~1.5mm ceramic base diaphragm;

[0023] Among them, the microwave dielectric ceramic powder A is required to meet the mechanical and electrical performance requirements of the device, and the BCZN system is preferred, that is, Ba(Co 1-x Zn x ) 1/3 Nb 2/3 o 3 System ceramics, where x=0.2~0.4, the powder is pretreated by ball milling, pre-calcination, and sievin...

Embodiment 1

[0050] Step 1: Design a 3rd-order SIR filter body model, the working frequency is 2.4GHz, the total length of the resonant cavity after conversion is 1=6mm, the length of the stepped hole is 1r1:1r2=3:1, the normal plane size of the resonance direction w=13mm, h=6mm , resonant hole r1=1.5mm, r2=1mm, coupling hole r3=1mm

[0051] Step 2: Prepare the slurry, the slurry contains Ba(Co 0.6 Zn 0.4 ) 1/3 Nb 2/3 o 3 System ceramic powder material 100g and additive 100g, wherein the additive consists of binder polyvinyl butyral 8g, plasticizer polyethylene glycol-4002.5ml and polyethylene glycol-20004.6g, dispersant triolein 8ml, solvent ethanol 16ml, methyl ethyl ketone 64ml, defoaming agent n-butanol 6ml ethylene glycol 7ml, additive octanol 0.5ml cyclohexanone 1ml, use QM-BP planetary ball mill for 2 ball mills, and add in the first ball mill Powder, solvent ethanol 12ml butanone 48ml and dispersant, add the remaining reagents in the second ball mill, vacuum degassing for 10 m...

Embodiment 2

[0065] Step 1: Design a 3rd-order SIR filter body model, the working frequency is 2.4GHz, the total length of the resonant cavity after conversion is 1=6mm, the length of the stepped hole is 1r1:1r2=3:1, the normal plane size of the resonance direction w=13mm, h=6mm , resonant hole r1=1.5mm, r2=1mm, coupling hole r3=1mm

[0066] Step 2: Prepare the slurry, the slurry contains Ba(Co 0.8 Zn 0.2 ) 1/3 Nb 2/3 o 3 System ceramic powder material 130g and additive 70g, binder polyvinyl butyral 2.8g, plasticizer polyethylene glycol-4000.4ml and polyethylene glycol-20002.5g, dispersant triolein 7ml , solvent ethanol 9ml and methyl ethyl ketone 53ml, defoaming agent n-butanol 4.5ml ethylene glycol 3.5ml, additive octanol 0.8ml cyclohexanone 0.8ml, use QM-BP planetary ball mill for 2 ball mills, the first time Add powder, solvent ethanol 20ml, butanone 30ml and dispersant to the ball mill, add the remaining reagents to the second ball mill, vacuum defoam for 18 minutes, pour the slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com