High atmospheric pressure synthetic method for flaky La(Fe, Si)13-based hydride block with efficient room temperature magnetic refrigeration performance

A synthesis method and hydride technology, which can be applied to various metal hydrides, etc., can solve the problems of unusable samples, reducing the magnetic entropy change per unit volume, and reducing the value of the magnetic entropy change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

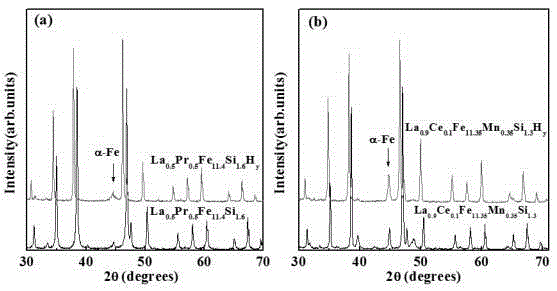

[0027] will have cubic NaZn 13 structure of La 0.5 PR 0.5 Fe 11.4 Si 1.6After the master alloy is crushed into particles with a diameter of 1-2 mm, it is placed in an autoclave to absorb hydrogen for 5 hours at a hydrogen absorption temperature of 500°C and a hydrogen pressure of 50 MPa. Maintain the hydrogen pressure of 50 MPa and cool to room temperature to obtain saturated hydrogen-absorbing hydride particles. The hydride particles were ground into a powder with a particle size of less than 50 μm, and then pressed under a pressure of 6 MPa into a sheet-like block with a diameter of 10 mm and a thickness of 0.8 mm. The pressed sheet samples were placed in a high-pressure heat treatment device for sintering treatment, the sintering time was 24 hours, the sintering temperature was 600°C, and the hydrogen pressure was 50MPa. After the sintering, it was cooled to room temperature under a hydrogen atmosphere, and the hydrogen pressure was maintained at 50 MPa during the cool...

Embodiment 2

[0029] will have cubic NaZn 13 structure of La 0.9 Ce 0.1 Fe 11.35 mn 0.35 Si 1.3 After the master alloy is pulverized into particles with a diameter of 1-2 mm, hydrogen is absorbed in a high-pressure heat treatment device for 5 hours at a hydrogen absorption temperature of 500°C and a hydrogen pressure of 50 MPa. Maintain the hydrogen pressure of 50 MPa and cool to room temperature to obtain saturated hydrogen-absorbing hydride particles. The hydride particles were ground into a powder with a particle size of less than 50 μm, and then pressed under a pressure of 6 MPa into a sheet-like block with a diameter of 10 mm and a thickness of 0.8 mm. The pressed sheet samples were placed in a high-pressure heat treatment device for sintering treatment, the sintering time was 48 hours, the sintering temperature was 500°C, and the hydrogen pressure was 50MPa. After the sintering, it was cooled to room temperature under a hydrogen atmosphere, and the hydrogen pressure was maintain...

Embodiment 3

[0032] will have cubic NaZn 13 structure of La 0.5 PR 0.5 Fe 11.4 Si 1.6 After the master alloy is crushed into particles with a diameter of 1-2 mm, it is placed in an autoclaving device to absorb hydrogen for 3 hours, the hydrogen absorption temperature is 400°C, and the hydrogen pressure is 60MPa. Maintain the hydrogen pressure of 60 MPa and cool to room temperature to obtain saturated hydrogen-absorbing hydride particles. The hydride particles were ground into a powder with a particle size of less than 50 μm, and then pressed under a pressure of 8 MPa into a sheet-like block with a diameter of 20 mm and a thickness of 0.6 mm. The pressed sheet-like samples were placed in a high-pressure heat treatment device for sintering. The sintering time was 24 hours, the sintering temperature was 650° C., and the hydrogen atmosphere pressure was 60 MPa. After the sintering, it was cooled to room temperature under a hydrogen atmosphere, and the hydrogen pressure was maintained at 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic hysteresis | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com