Composite material for separating CH4 gas and preparation method thereof

A composite material and gas technology, applied in separation methods, gas fuel, gas treatment, etc., can solve the problems of cumbersome preparation methods, long preparation time, increased wear rate, etc., to solve the problem of reduced separation efficiency, increased gas adsorption capacity, and increased The effect of hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

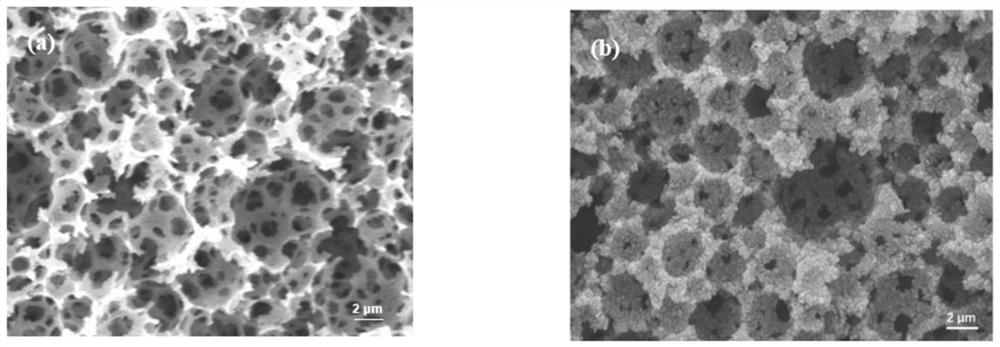

Image

Examples

Embodiment 1

[0028](1) Preparation of PGT. With acrylate as the main component, W / O emulsion was first synthesized. Oil phase (continuous phase) composition: TBMA 2.3g, GMA 0.7g, TMPTA 2g, emulsifier (PEG-PPG-PEG 5800) 0.5g, oxidant (benzoyl peroxide) 0.2g, toluene 6ml. Aqueous phase (dispersed phase) composition: deionized water 16ml. Stir the oil phase at a speed of 5000r / min for 5min, and at the same time add the water phase dropwise to the continuously stirring oil phase, and add 7 drops of reducing agent N,N-dimethylaniline during the process to prepare a uniform W / O lotion. At a speed of 230r / min, pour the prepared W / O emulsion into an aqueous solution containing 3wt.% polyethylene glycol (100ml, 70°C), and add 1ml of reducing agent tetramethylethylenediamine to form a redox Initiation system, quickly initiates the polymerization reaction of monomer and crosslinking agent, and obtains spherical polymer carrier (PGT).

[0029] (2) Preparation of precursor solution. AlCl 3 ·6H 2...

Embodiment 2

[0032] (1) Preparation of PGT. With acrylate as the main component, W / O emulsion was first synthesized. Oil phase (continuous phase) composition: TBMA 2.3g, GMA 0.7g, TMPTA 2g, emulsifier (PEG-PPG-PEG 5800) 0.5g, oxidant (benzoyl peroxide) 0.2g, toluene 6ml. Composition of the aqueous phase (dispersed phase): 16 ml of deionized water and 0.3 g of ammonium persulfate. Stir the oil phase at a speed of 5000r / min for 5min, and at the same time add the water phase dropwise to the continuously stirring oil phase, and add 7 drops of reducing agent N,N-dimethylaniline during the process to prepare a uniform W / O lotion. At a speed of 230r / min, pour the prepared W / O emulsion into an aqueous solution containing 3wt.% polyethylene glycol (100ml, 70°C), and add 1ml of reducing agent tetramethylethylenediamine to form a redox Initiation system, quickly initiates the polymerization reaction of monomer and crosslinking agent, and obtains spherical polymer carrier (PGT).

[0033] (2) Prepa...

Embodiment 3

[0036] (1) Preparation of PAM. With acrylamide as the main component, the O / W emulsion was first synthesized. Water phase (continuous phase) composition: AM3.2g, MBAM0.8g, F1270.4g, deionized water10g, initiator ammonium persulfate0.06g. Composition of the oil phase (dispersed phase): 18.44 g of toluene and 6.86 g of cyclohexane. The composition of the third phase: 30ml of toluene, 120ml of cyclohexane, 30ml of carbon tetrachloride, and 0.3g of EC. The water phase components were ultrasonically dissolved in deionized water, stirred at a high speed of 8000r / min for 5min, and the oil phase was added dropwise to the continuously stirred water phase to prepare a uniform O / W emulsion. At a speed of 320r / min, pour the prepared O / W emulsion into the third-phase solution (65°C) containing ethyl cellulose, and add 1ml of reducing agent TMEDA to form a redox initiating system to rapidly initiate monomer Polymerization reaction with cross-linking agent to obtain spherical polymer carr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com