Environment-friendly degradation modified linear low density polyethylene foam material and preparation method thereof

A linear low-density, polyethylene foaming technology, applied in the field of polymer modification and processing, can solve problems such as poor compatibility, strength and toughness resilience defects, low melting point, etc., to achieve improved impact toughness, light strength, resistance Good flame and fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

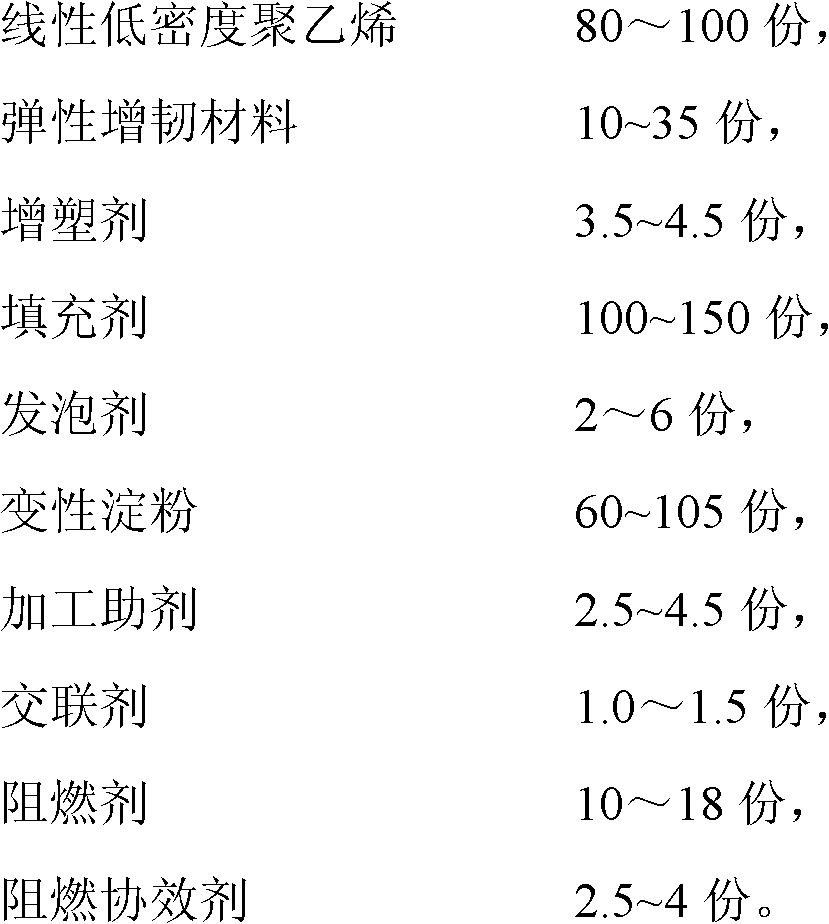

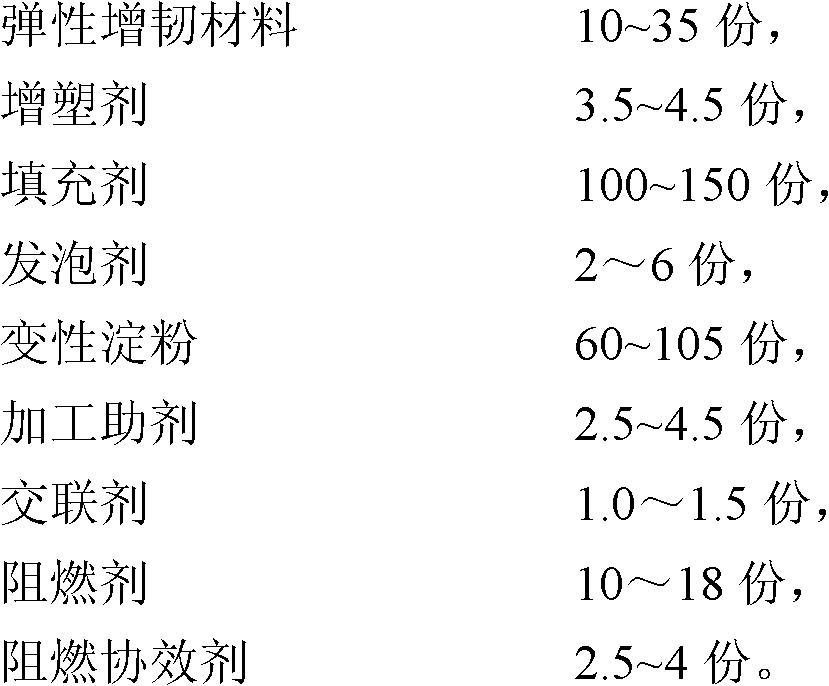

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of modified starch: Add 65 parts of 220-mesh tapioca starch into a high-speed mixer, add 2.5 parts of isopropyl triisostearyl titanate, and couple at a low speed. When the temperature of the material rises to 30°C Stop the coupling, add 14 parts of glycerin, continue mixing at low speed until the material temperature rises to 80°C, add 7.5 parts of carboxamide and 2.4 parts of polyethylene wax, mix at low speed until the material temperature is 90°C, then change to high speed mixing , when the material temperature reaches 100°C, stop mixing, and let it stand at room temperature of 20°C for 24 hours to obtain modified starch;

[0032] (2) 85 parts of linear low-density polyethylene, 20 parts of ethylene / vinyl acetate copolymer, 3.6 parts of dioctyl phthalate, 115 parts of talcum powder, 4.5 parts of azodicarbonamide, and 82 parts of modified starch , 3.2 parts of processing aids (a mixture of polyethylene wax and white oil in a weight ratio of 1:1), 1.2 p...

Embodiment 2

[0036] (1) Preparation of modified starch: Add 70 parts of 200-mesh cornstarch into a high-speed mixer, add 4 parts of tris(dioctyl pyrophosphate oxy) titanate, couple at a low speed, and when the temperature of the material rises to Stop coupling at 30°C, add 15 parts of glycerol, continue mixing at a low speed until the temperature of the material rises to 80°C, add 10 parts of carbonamide and 2 parts of polyethylene wax, mix at a low speed until the temperature of the material is 90°C, change to Mix at high speed, stop mixing when the material temperature reaches 100°C, and let stand at room temperature of 20°C for 24 hours to obtain modified starch;

[0037] (2) 80 parts of linear low density polyethylene, 25 parts of ethylene / ethyl acrylate copolymer, 3.8 parts of dinonyl phthalate, 100 parts of talcum powder, 3.6 parts of azobisisobutyronitrile, modified starch 76 parts, 2.5 parts of processing aids (a mixture of polyethylene wax and white oil in a weight ratio of 1:1), ...

Embodiment 3

[0041] (1) Preparation of modified starch: Add 60 parts of 250-mesh potato starch into a high-speed mixer, add 2 parts of isopropyl triisostearyl titanate, and couple at a low speed. When the temperature of the material rises to 30°C Stop the coupling, add 12 parts of glycerol, continue mixing at low speed until the material temperature rises to 80°C, add 7 parts of carbonamide and 3 parts of polyethylene wax, mix at low speed until the material temperature is 90°C, change to high speed mixing , when the material temperature reaches 100°C, stop mixing, and let it stand at room temperature of 20°C for 24 hours to obtain modified starch;

[0042] (2) 95 parts of linear low-density polyethylene, 10 parts of ethylene / vinyl acetate copolymer, 3.5 parts of dibutyl phthalate, 150 parts of calcium carbonate, 2 parts of azodicarbonamide, and 60 parts of modified starch , 3.8 parts of processing aids (a mixture of polyethylene wax and white oil in a weight ratio of 1:1), 1.5 parts of di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com