Formula and preparation process of heat-conducting aluminum base copper-clad plate with high heat resistance and high insulation

An aluminum-based copper clad laminate, high-insulation technology, applied in the direction of adhesive types, chemical instruments and methods, non-polymer adhesive additives, etc., can solve the problems of poor insulation, complex processing technology, low heat resistance, etc. Achieve high heat resistance, low glue viscosity and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

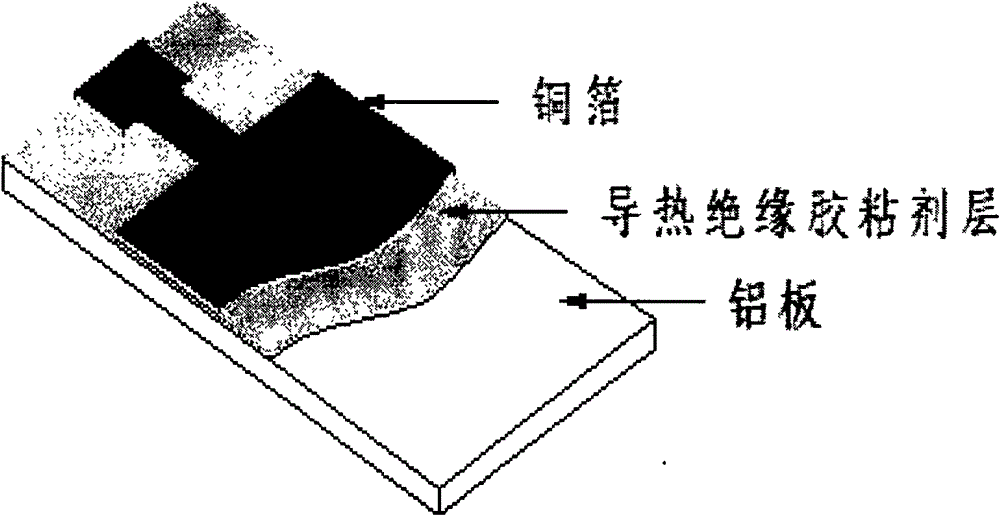

[0037] The present invention is described in further detail with specific embodiment now in conjunction with accompanying drawing:

[0038] The raw material prescription used in the present invention and preparation technology thereof are:

[0039] A. Raw material composition:

[0040]

[0041] B. Raw material composition:

[0042] Dicyandiamide 83%

[0043] KH-560 silane coupling agent 17%

[0044] C. Raw material composition:

[0045]

[0046]

[0047] (a) Prepared by mixing the ingredients of A: mixed glue A.

[0048] (b) Prepared by mixing B raw materials: curing agent and auxiliary agent B.

[0049] (c) Prepared by mixing the raw materials of C: high-insulation and heat-conducting powder C.

[0050] According to the ratio of mixed raw materials in A, weigh each raw material component respectively, the total amount is 30 kg, and put them into a stainless steel reactor with jacketed heating and stirring equipment. Turn on the stirring equipment, turn on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com