Epoxy adhesion for lithium battery flexible package and lithium battery flexible package material

An epoxy adhesive and flexible packaging technology, applied in the direction of adhesive types, non-polymer adhesive additives, packaging, etc., can solve the problems of separation of the inner layer and aluminum foil, low adhesion, and many layers, etc. , to achieve the effect of good heat sealing, high peel strength and high interlayer adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

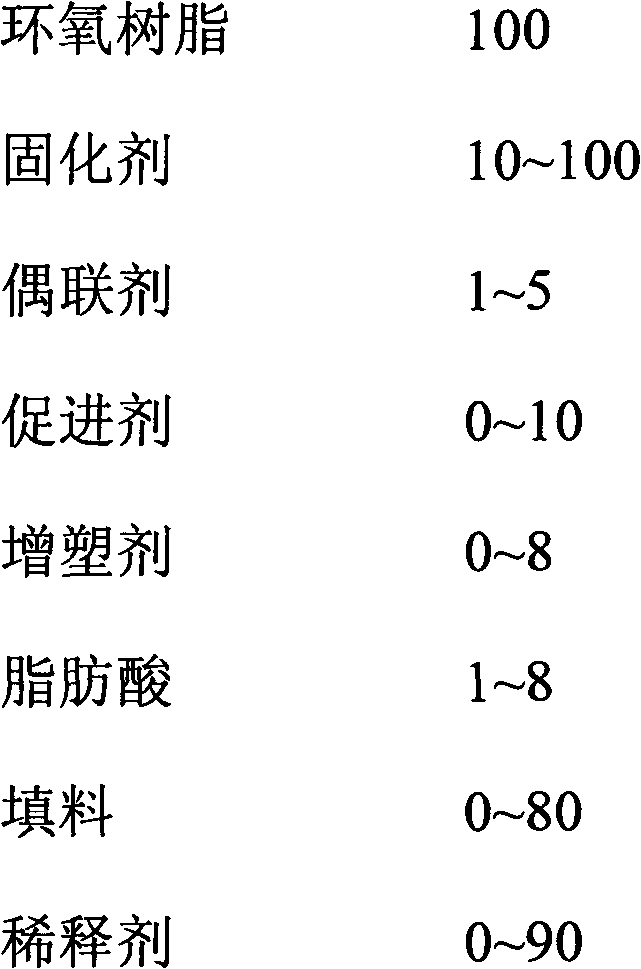

[0036] Embodiment 1: The epoxy adhesive for lithium battery flexible packaging comprises: the bisphenol A type epoxy resin E-44 of 100 mass parts, the methyltetrahydrophthalic anhydride of 90 mass parts, the vinyl tetrahydrophthalic anhydride of 5 mass parts Triethoxysilane, 3 parts by mass of 2,4,6-tris(dimethylaminomethyl)phenol, 5 parts by mass of stearic acid, 50 parts by mass, titanium dioxide with a particle size of 1.5um, 20 parts by mass of ethyl acetate.

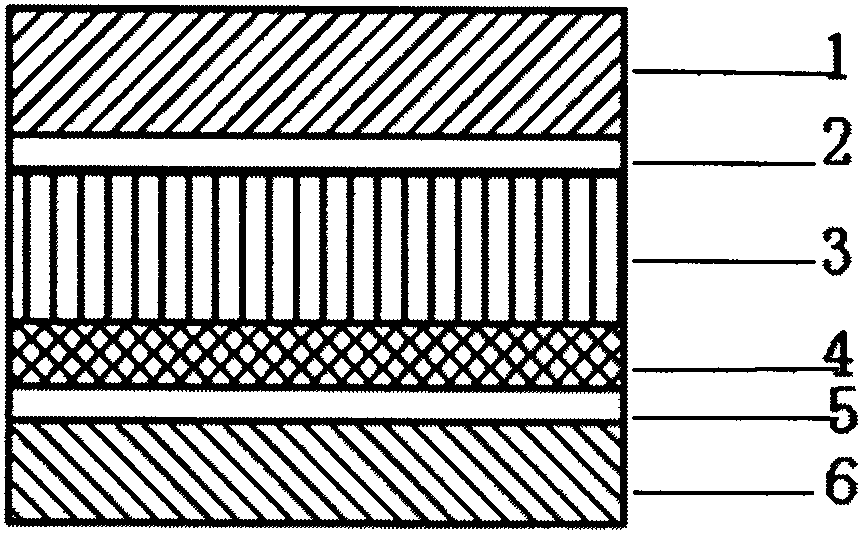

[0037] As shown in the figure, the lithium battery flexible packaging material adopts a six-layer aluminum-plastic composite film structure, which is the base layer 1, the outer adhesive layer 2, the aluminum foil layer 3, the conversion film layer 4, and the inner adhesive layer from top to bottom. Layer 5 and Heat Seal Layer 6.

[0038] The base layer 1 is made of nylon 6 with a thickness of 25um, the outer adhesive layer 2 is a two-component solvent-based polyurethane adhesive (UK3640 and UK6800, Henkel, Germany...

Embodiment 2

[0041] Embodiment 2: The epoxy adhesive for lithium battery flexible packaging comprises: the bisphenol A type epoxy resin E-44 of 100 mass parts, the methyl hexahydrophthalic anhydride of 90 mass parts, the vinyl of 4 mass parts Triethoxysilane, 3 parts by mass of 2,4,6-tris(dimethylaminomethyl)phenol, 5 parts by mass of oleic acid, and 20 parts by mass of glycidyl methacrylate.

[0042] As shown in the figure, the lithium battery flexible packaging material adopts a six-layer aluminum-plastic composite film structure, which is the base layer 1, the outer adhesive layer 2, the aluminum foil layer 3, the conversion film layer 4, and the inner adhesive layer from top to bottom. Layer 5 and Heat Seal Layer 6.

[0043] The base layer 1 is made of nylon 6 with a thickness of 25um, the outer adhesive layer 2 is a two-component solvent-based polyurethane adhesive (UK3640 and UK6800, Henkel, Germany) with a thickness of 5um, and the thickness of the aluminum foil layer 3 is 40um sof...

Embodiment 3

[0046] Embodiment 3: Epoxy adhesives for flexible packaging of lithium batteries include: 100 parts by mass of bisphenol A epoxy resin E-44, 10 parts by mass of hexahydropyridine, 3 parts by mass of glycidyloxypropyltrimethoxy Silane, 3 parts by mass of phthalate, 4 parts by mass of stearic acid, 50 parts by mass of titanium dioxide with a particle size of 1.5um, and 30 parts by mass of acetone.

[0047] As shown in the figure, the lithium battery flexible packaging material adopts a six-layer aluminum-plastic composite film structure, which is the base layer 1, the outer adhesive layer 2, the aluminum foil layer 3, the conversion film layer 4, and the inner adhesive layer from top to bottom. Layer 5 and Heat Seal Layer 6.

[0048] The base layer 1 is made of nylon 66 with a thickness of 25um, the outer adhesive layer 2 is a two-component solvent-based polyurethane adhesive (UK3640 and UK6800, Henkel, Germany) with a thickness of 8um, and the thickness of the aluminum foil lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Initial peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com