Wear resistant self-lubricating polyformaldehyde and preparation method thereof

A polyoxymethylene and self-lubricating technology, applied in the field of polymer material processing, can solve the problems of low surface free energy and poor compatibility of PTFE, and achieve excellent wear resistance, self-lubrication and mechanical properties, good molecular compatibility, good The effect of toughening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

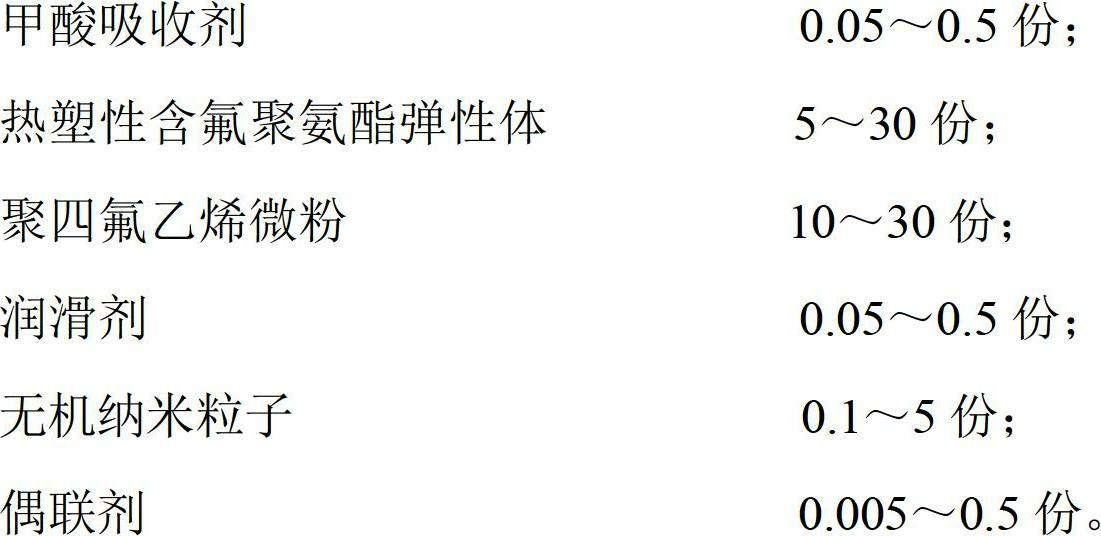

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 prepares wear-resistant self-lubricating polyoxymethylene

[0029] Mix 10Kg of POM resin with 30g of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, 20g of melamine, 20g of magnesium hydroxide, 2Kg of polytetrafluoroethylene micropowder, thermoplastic fluorine Add 1.5Kg of polyester elastomer, 100g of calcium carbonate treated with a coupling agent, and 10g of glycerol monostearate into a high-speed mixer for mixing, then melt and knead with a vented twin-screw extruder, and extrude to granulate, namely Obtain wear-resistant self-lubricating polyoxymethylene, wherein, the screw speed: 50 rpm; the temperature of each section of the barrel: 140 ~ 200 ℃. The product has a tensile strength of 45MPa and a notched impact strength of 10KJ / m 2 .

Embodiment 2

[0030] Embodiment 2 prepares wear-resistant self-lubricating polyoxymethylene

[0031] Mix 10Kg of POM resin with N,N'-bis-[3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl]hexamethylenediamine 20g, dicyandiamide 10g, magnesium oxide 10g, polytetramethylene Add 3Kg of vinyl fluoride micropowder, 3Kg of thermoplastic fluorine-containing polyester elastomer, 200g of silicon dioxide treated by coupling agent, and 20g of bisstearamide into a high-speed mixer, and then melt and knead with a vented twin-screw extruder. Extrude and granulate to obtain wear-resistant self-lubricating polyoxymethylene, the screw speed is 150 rpm; the temperature of each section of the barrel is 160-220°C. The product has a tensile strength of 33MPa and a notched impact strength of 20KJ / m 2 .

Embodiment 3

[0032] Embodiment 3 prepares wear-resistant self-lubricating polyoxymethylene

[0033] Mix 10Kg of POM resin with 10g of β-(4-hydroxy-3,5-di-tert-butylphenyl) octadecyl propionate, 70g of urea, 7g of calcium silicate, 1Kg of polytetrafluoroethylene micropowder, thermoplastic fluorine-containing polystyrene Add 2.5Kg of ester elastomer, 400g of talc powder treated with coupling agent, and 30g of pentaerythritol tristearate into a high-speed mixer for mixing, then melt and knead with a vented twin-screw extruder, extrude and granulate, and obtain Wear-resistant self-lubricating polyoxymethylene, screw speed, 100 rpm; temperature of each section of the barrel, 170-210 °C. The product has a tensile strength of 35MPa and a notched impact strength of 15KJ / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com