Method for preparing catalyst for coke-oven gas methanation

A coke oven gas and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, gas fuels, etc., can solve problems such as high-performance use of coke oven gas, complicated preparation process, and environmental pollution. Good stability and anti-knot performance, reasonable material ratio, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

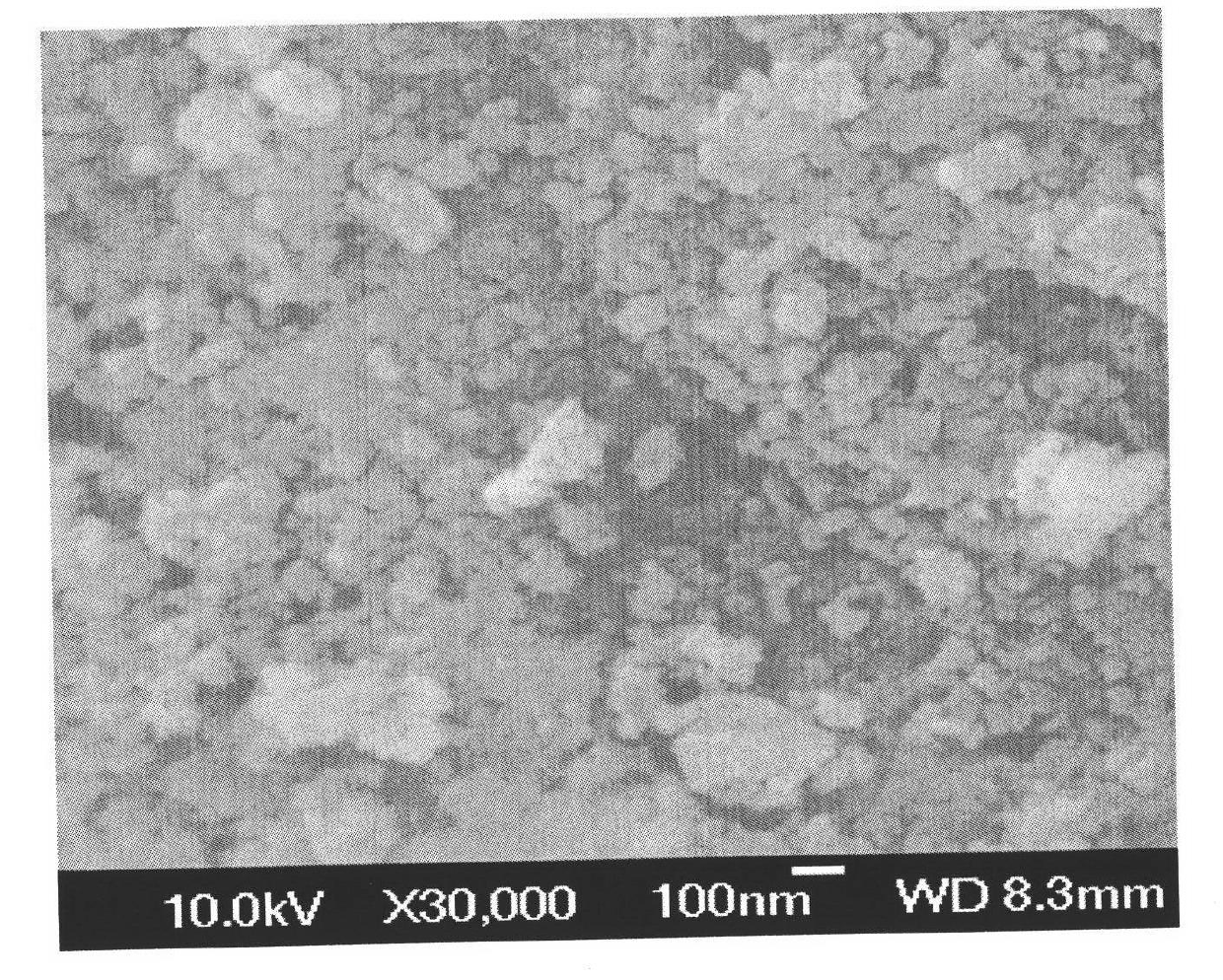

Image

Examples

Embodiment 1

[0063] To prepare a catalyst for methanation of coke oven gas, the proportion of its chemical substances can be as follows:

[0064]

[0065] The preparation method is the same as the technical solution;

[0066] The mass ratio of each component of the prepared catalyst is: γ-Al 2 o 3 Content 60%, NiO content 19%, CeO 2 Content 6%, SiC content 15%.

Embodiment 2

[0068] The performance measurement of the prepared catalyst for coke oven gas methanation, the method is as follows:

[0069] Analyzer: Shanghai Haixin Chromatography Co., Ltd. GC-950 gas chromatograph, thermal conductivity cell detector, chromatographic column is carbon molecular sieve TDX-01, carrier gas Ar, mainly analyzes H in reformed gas 2 , N 2 , O 2 , CO, CO 2 and CH 4 ; Capillary column is Agilent PLOT Al 2 o 3 , the inner diameter of the column is 0.35mm, and the column length is 50m. 2 and above higher hydrocarbons;

[0070] Composition of raw coke oven gas: H 2 57.46%, CO 6.90%, CO 2 2.99%, CH 4 Accounting for 25.80%, C 2 h 6 2.42%, N 2 3.95%, O 2 0.48%;

[0071] At a temperature of 400°C, the catalyst was reduced for 4 hours by raising the pressure to 0.5MPa with hydrogen, and the reduction space velocity was 2000h -1 ;After the reduction, disconnect the hydrogen, feed the coke oven gas and supplement 4% carbon dioxide relative to the coke oven gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com