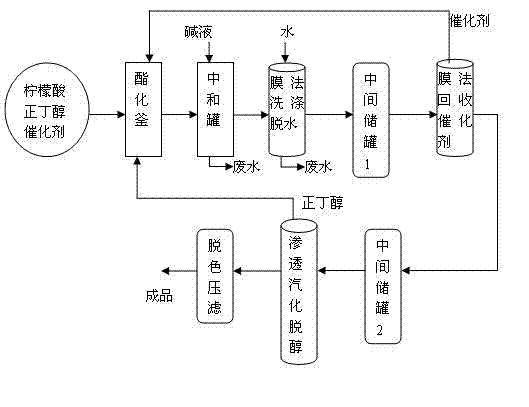

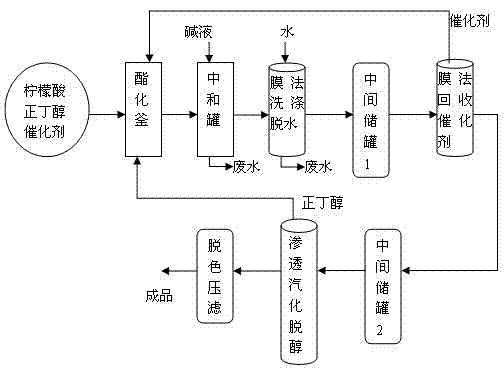

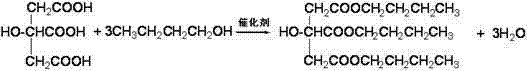

Continuous production process for tributyl citrate

A technology of tributyl citrate and production process, which is applied in the field of chemical engineering, can solve the problems of discontinuous process, reduced production efficiency, large amount of waste water, etc., and achieves the effects of meeting environmental protection requirements, speeding up reaction speed, and small amount of waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Esterification process

[0038] Put citric acid and n-butanol into the reactor according to the molar ratio of 1:4.5, add 1.5% (mass percentage of citric acid) solid superacid catalyst 50 nm, close the feeding port, open the jacket heating steam valve, and control the steam <0.6 MPa (gauge pressure). Pay attention to the water outlet, strictly control the pressure in the kettle (gauge pressure) < 0.015 MPa, so as not to cause material flushing, control the maximum temperature of the reaction to less than 120°C, and take a sample for testing after 2 hours of reaction, and then take a sample every half an hour. When the acid value of the solution reaches less than 0.02 mg KOH / g, it can be considered that the esterification is completed, the jacket heating steam valve is closed, the reflux valve is closed, and the stirring is stopped. Open the reactor condenser to cool down.

[0039] 2. Membrane neutralization and water washing process

[0040] After the reaction is ...

Embodiment 2

[0046] 1. Esterification process

[0047] Put citric acid and n-butanol into the reaction kettle according to the molar ratio of 1:4, add 1% (mass percentage of citric acid) molecular sieve catalyst 10 nm, close the feeding port, open the jacket heating steam valve, and control the steam < 0.6 MPa (gauge pressure). Pay attention to the water outlet, strictly control the pressure in the kettle (gauge pressure) < 0.015 MPa, so as not to cause material flushing, control the maximum temperature of the reaction to less than 100 ° C, react for 3 hours, take samples for testing, and then take samples every half an hour, when the crude ester liquid When the acid value reaches less than 0.02mgKOH / g, it can be considered that the esterification is completed, the jacket heating steam valve is closed, the reflux valve is closed, and the stirring is stopped. Open the reactor condenser to cool down.

[0048] 2. Membrane neutralization and water washing process

[0049] After the reaction...

Embodiment 3

[0055] 1. Esterification process

[0056] Put citric acid and n-butanol into the reactor according to the molar ratio of 1:6, add 3% (mass percentage of citric acid) heteropolyacid catalyst 100 nm, close the feeding port, open the jacket heating steam valve, and control the steam <0.6 MPa (gauge pressure). Pay attention to the water outlet, strictly control the pressure in the kettle (gauge pressure) < 0.015 MPa, so as not to cause material flushing, control the maximum temperature of the reaction to less than 140 ° C, react for 4 hours, take samples for testing, and then take samples every half an hour, when the crude ester liquid When the acid value reaches less than 0.02mgKOH / g, it can be considered that the esterification is completed, the jacket heating steam valve is closed, the reflux valve is closed, and the stirring is stopped. Open the reactor condenser to cool down.

[0057] 2. Membrane neutralization and water washing process

[0058] After the reaction is compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com